Abstract

This research describes a new technological process for sesame oil extraction. The process deals with the effect of ohmic heating on enhancement of oil recovery and quality of cleaned and graded sesame seed. The effect of ohmic heating parameters namely electric field strength (EFS), end point temperature (EPT) and holding time (HT) on oil extraction process were investigated. Three levels of electric field strength (600, 750 and 900 V/m), end point temperature (65, 75 and 85 °C) and holding time (5, 10 and 15 min.) were taken as independent variables using full factorial design. Percentage oil recovered from sesame seed through mechanical extracted oil by application of ohmic heating varies from 39.98 to 43.15 %. The maximum oil recovery 43.15 % was obtained when the sample was heated and maintained at 85 °C using EFS of 900 V/m for a holding time of 10 min as against 34.14 % in control sample. The free fatty acid (FFA) of the extracted oil was within the acceptable limit (1.52 to 2.26 % oleic acid) of 0.5 to 3 % as prescribed respectively by Prevention of Food Adulteration (PFA) and Bureau of Indian Standards (BIS). The peroxide value of extracted oil was also found within the acceptable limit (0.78 to 1.01 meq/kg). The optimum value for maximum oil recovery, minimum residual oil content, free fatty acid (FFA) and peroxide value were 41.24 %, 8.61 %, 1.74 % oleic acid and 0.86 meq/kg, respectively at 722.52 V/m EFS at EPT 65 °C for 5 min. holding time which was obtained by response surface methodology.

Keywords: Sesame seeds, Ohmic heating, Oil recovery, Free fatty acids, Peroxide value

Introduction

The major sesame producing countries India, Sudan, China and Burma contribute about 60 % of the total world production (El Khier et al. 2008). Sesame seeds are rich in fat (44–58 %), protein (18–25 %), carbohydrates (7–13 %), and fiber (Borchani et al. 2010; Gandhi 2009; Hansen 2011; Nzikou et al. 2009). The seeds also contained significant amount of important minerals with the Potassium concentration being the highest, followed by Phosphorus, Magnesium, Calcium and Sodium (Loumouamou et al. 2010).

Ohmic heating utilizes the inherent electrical resistance of food material to generate heat; hence it is the promising method for food processing. (Wang et al. 2007). Because of the promise of ohmic heating in improving mass transfer effects and enhance diffusion by electroporation, some workers have investigated ohmic heating for various application (Kemp and Fryer 2007; Wang and Sastry 2002; Parascopic et al. 2006). Rao et al. (2004) reported that the application of ohmic heating as a pre–treatment prior to oil extraction resulted in higher oil recovery from rice bran.

However, most of the applications are still at small scale and are yet to be commercially exploited. Therefore, the ecofriendly innovative technologies leading to higher oil yield coupled with lower processing cost is the need of the hour.

Therefore the present investigation was undertaken to study the effect of ohmic heating parameters on oil recovery and to optimize the process parameters of ohmic heating for maximum oil recovery.

Materials and methods

The sesame seed (var. RT-44) procured from local market was cleaned and graded using CIAE cleaner cum grader. The initial moisture content of raw sesame seeds was determined by single stage hot air oven method (Rangnna, 2000). The oil content in raw sesame seeds was determined as per AACC (2003) using Soxhlet apparatus (Model No. BST/SXW-6, Bionics Scientific Technologies Pvt. Ltd., New Delhi, India).

Experimental design

Electric field strength (EFS), end point temperature (EPT) and holding time (HT) were taken as independent variables, whereas temperature, current during ohmic heating, residual oil content in cake, free fatty acid in oil, peroxide value and color of oil were considered as dependent variables. Three levels of electric field strength (600, 750 and 900 V/m), end point temperature (65, 75 and 85 °C) and holding time (5, 10 and 15 min.) taken as independent variables using full factorial design. Pare et al. (2009) conducted the similar study for the extraction of soybean oil and used the same EFS with holding time of 0, 5 and 10 min at end point temperature of 70, 80 and 90 °C respectively.

Ohmic heating of sesame seeds

A laboratory model ohmic heating system developed at Department of Processing & Food Engineering, College of Technology & Engineering, MPUAT, Udaipur was used for conducting experiment trials. The moisture content of raw sesame seed was increased up to 35 % by adding the required amount of water (tap water) as decided through the preliminary experiment. A sample of 3.5 kg sesame seed was placed in ohmic heater. EFS of 600, 750 and 900 V/m were applied with the help of AC variate fixed on control panel and heat the samples until its geometric centre temperature reached the desired temperature of 65, 75, and 85 °C. A PT-100 temperature sensor was placed into geometric centre of the sample to monitor temperature during heating. Current and temperature were recorded after every minute during ohmic heating. The required electric field strength was maintained with the help of control panel. Once the sample is placed into ohmic heater then sample was attaining desired temperature (i.e. EPT), then switch off the assembly and the sample is hold for the required time (Holding time). If the temperature gets reduced at the same time then again switch on the assembly. The sample took almost 15–18 mins to reach desired EPT. The ohmically treated samples were shade dried to reduce the moisture content up to 10–12 % which is required for mechanical extraction of oil (Shukla et al. 1992). The resulted samples were not in slurry form.

Oil extraction

The mechanical oil expeller (Model No. NE2, make Vergara Machineries, India) was used to extract the oil from untreated and ohmically treated sesame seeds.

Residual oil content of the cake

The residual oil content was determined by using soxhlet apparatus (Model No. BST/SXW–6, Bionics Scientific Technologies pvt. Ltd., New Delhi, India) (AACC 2003).

Quality evaluation

Colour of the extracted oil was measured using a Hunter Lab Colorimeter (Model CFLX/DIFF, CFLX-45, Hunter Associates Laboratory, Virginia, USA). The free fatty acid (% oleic acid) present in the extracted oil was determined by using titration method (AOAC 1984). The peroxide value was determined by standard method (AOAC 1970).

Optimization of process parameters

The optimization of process parameters for maximum oil recovery with minimum FFA and peroxide value was carried out using numerical optimization technique with the help of Design Expert 8.0.6 statistical software by Response surface methodology (RSM). RSM is a statistical procedure frequently used for optimization studies and enables efficient exploration of a process or system (Madamba 2002; Myers et al. 2009). Full second order model was fitted in various responses and independent variables using multiple regression analysis.

Results and discussions

The initial moisture content of sesame seed was found to be 5.32 % and the total oil content of was found to be 46.31 %.

Effect of variables on per cent oil extraction

Percentage of oil recovered from sesame seed through mechanical extracted oil by application of ohmic heating varies from 39.98 to 43.15 % (Table 1, 2, and 3). The maximum oil recovery (43.15 %) was obtained for the omhically treated seed sample at 85 °C using electric field strength of 900 V/m for a holding time of 10 min. It may be seen that the oil recovery was highest at interactions of EFS and EPT. The increases in yield at high electric field strength may be due to the combined effect of electroporation and thermal softening of the tissues as reported by Parascopic et al. 2006. Increase in holding time of omhic treatment caused significant increase in the amount of oil extracted with slight decrease in the amount of moisture. The results are in agreement with the findings of Parrado et al. (2003), Lakkakula et al. (2004) and Tyagi et al. (2012). Some recent studied have been conducted on the extraction of sesame oil. Akinoso et al. (2006) reported the oil yield of sesame seed after roasting of seeds at 70, 90, 110 and 130 °C for 5, 10, 15 and 20 min roasting duration was found to be 12.85 to 51.86 %. Latif and Anwar (2010) reported that there was 12.3 % increase in the yield of sesame oil as compared to the control after the treatment with enzyme. Carvalho et al. (2012) also conducted the study on sesame oil extraction by supercritical fluid extraction and soxhlet extraction. He reported the best result (26.47 %) by supercritical technique when CO2 and ethanol were used and during soxhlet extraction, the maximum yield (58.93 %) was achieved when using ethanol as a treatment.

Table 1.

Effect of electric field strength (600 V/m) on oil recovery and quality parameters of sesame seed oil

| Parameters | Control value | Temperature (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 65 | 75 | 85 | ||||||||

| Holding Time (min) | Holding Time (min) | Holding Time (min) | ||||||||

| 5 | 10 | 15 | 5 | 10 | 15 | 5 | 10 | 15 | ||

| Oil extracted (%) | 34.14 | 40.18 | 39.98 | 40.12 | 40.97 | 40.48 | 41.24 | 40.89 | 41.48 | 41.24 |

| Oil recovery over control (%) | – | 8.19 | 7.68 | 5.95 | 10.32 | 8.99 | 11.05 | 10.11 | 11.7 | 11.05 |

| Residual oil content (%) | 14.34 | 10.24 | 10.52 | 11.47 | 9.03 | 9.79 | 8.62 | 9.16 | 8.24 | 8.61 |

| Moisture content of oil | 0.25 | 0.19 | 0.26 | 0.22 | 0.18 | 0.19 | 0.23 | 0.25 | 0.2 | 0.17 |

| Moisture content of oil cake | 2.32 | 2.22 | 2.88 | 3.15 | 3.09 | 3.24 | 2.05 | 2.51 | 2.98 | 2.93 |

| FFA (% oleic acid) | 1.24 | 1.86 | 1.75 | 1.92 | 1.69 | 1.75 | 1.69 | 1.58 | 1.64 | 1.58 |

| Peroxide value (meq/kg) | 0.86 | 0.9 | 0.85 | 0.8 | 0.83 | 0.94 | 0.91 | 0.95 | 0.87 | 0.91 |

| L color value | 46.47 | 44.41 | 44.29 | 44.56 | 44.53 | 45.1 | 44.73 | 44.92 | 44.62 | 45.37 |

Table 2.

Effect of electric field strength (750 V/m) on oil recovery and quality parameters of sesame seed oil

| Parameters | Control value | Temperature (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 65 | 75 | 85 | ||||||||

| Holding time (min) | Holding time (min) | Holding time (min) | ||||||||

| 5 | 10 | 15 | 5 | 10 | 15 | 5 | 10 | 15 | ||

| Oil extracted (%) | 34.14 | 41.53 | 42.39 | 42.2 | 41.82 | 42.07 | 41.48 | 41.61 | 41.69 | 41.85 |

| Oil recovery over control (%) | – | 11.81 | 14.15 | 13.62 | 12.59 | 13.29 | 11.69 | 12.04 | 12.25 | 12.69 |

| Residual oil content (%) | 14.34 | 8.17 | 6.84 | 7.11 | 7.72 | 7.31 | 7.98 | 8.45 | 7.92 | 7.66 |

| Moisture content of oil | 0.25 | 0.17 | 0.16 | 0.24 | 0.18 | 0.2 | 0.24 | 0.23 | 0.23 | 0.25 |

| Moisture content of oil cake | 2.32 | 2.44 | 2.45 | 2.53 | 3.11 | 3.22 | 2.67 | 2.44 | 2.57 | 2.55 |

| FFA (% oleic acid) | 1.24 | 1.69 | 1.8 | 1.52 | 1.58 | 1.67 | 1.79 | 2.14 | 2.26 | 2.14 |

| Peroxide value (meq/kg) | 0.86 | 0.78 | 0.81 | 0.91 | 0.95 | 0.99 | 0.85 | 1.01 | 0.97 | 1.01 |

| L color value | 46.47 | 44.33 | 44.12 | 44.92 | 45.41 | 45.86 | 45.89 | 44.71 | 45.18 | 44.85 |

Table 3.

Effect of electric field strength (900 V/m) on oil recovery and quality parameters of sesame seed oil

| Parameters | Control value | Temperature (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 65 | 75 | 85 | ||||||||

| Holding time (min) | Holding time (min) | Holding time (min) | ||||||||

| 5 | 10 | 15 | 5 | 10 | 15 | 5 | 10 | 15 | ||

| Oil extracted (%) | 34.14 | 42.48 | 42.05 | 42.46 | 43 | 42.85 | 42.67 | 42.85 | 43.15 | 43.06 |

| Oil recovery over control (%) | – | 14.37 | 13.23 | 14.33 | 15.78 | 15.37 | 14.89 | 15.37 | 16.19 | 15.95 |

| Residual oil content (%) | 14.34 | 6.66 | 7.34 | 6.69 | 5.8 | 6.06 | 6.34 | 6.07 | 5.55 | 5.7 |

| Moisture content of oil | 0.25 | 0.26 | 0.25 | 0.24 | 0.22 | 0.19 | 0.18 | 0.18 | 0.19 | 0.19 |

| Moisture content of oil cake | 2.32 | 2.24 | 2.34 | 2.66 | 2.43 | 2.25 | 2.55 | 3.08 | 2.22 | 2.23 |

| FFA (% oleic acid) | 1.24 | 1.8 | 1.91 | 1.97 | 2.2 | 1.64 | 1.92 | 1.69 | 1.69 | 2.12 |

| Peroxide value (meq/kg) | 0.86 | 0.89 | 0.93 | 0.96 | 0.81 | 0.97 | 0.99 | 0.97 | 0.84 | 0.89 |

| L color value | 46.47 | 44.86 | 44.91 | 45.49 | 45.29 | 45.85 | 45.53 | 45.06 | 45.06 | 45.58 |

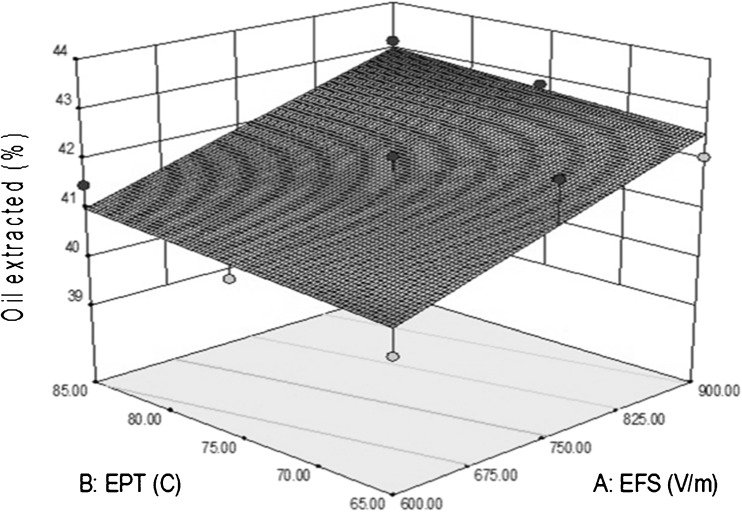

The combined effect of two variables on per cent oil extracted can be visualized from Figs. 1, 2, and 3 generated by using Design Expert as a function of two variables while keeping third variable at its central value.

Fig. 1.

The contour and response surface showing the effect of end point temp. (EPT) and electric field strength (EFS) on oil recovery

Fig. 2.

The contour and response surface showing the effect of holding time (HT) and end point temperature (EPT) on oil recovery

Fig. 3.

The contour and response surface showing the effect of electric field strength (EFS) and holding time (HT) on oil recovery

Effect of ohmic heating parameters on residual oil content of cake

The residual oil content in cake ranged from 5.55 to 11.47 % (Tables 1, 2, and 3). The minimum residual (5.77 %), as expected corresponded to conditions of maximum oil recovery that is EFS of 900 V/m, EPT 85 °C and holding time of 10 min. The results justify the usefulness of ohmic heating treatment as residual oil in the cake of sesame seed has been reported to be 18–22 % (Yen et al. 1986) when extracted with expeller. It was found that the effect of EFS and EPT had a significant effect on residual oil content in cake, whereas HT is less significant parameter than the EPT. The variation in residual oil content with interaction effect of ohmic heating parameters is shown in Fig. 4.

Fig. 4.

The contour and response surface showing the effect of end point temp. (EPT) and electric field strength (EFS) on residual oil content

Effect of ohmic treatment on FFA of extracted oil

The value of FFA was observed in the range of 1.52 to 2.26 as against 1.24 in case of control sample (Tables 1, 2, and 3). ANOVA of FFA (Table 4) shows that the effect of EFS, EPT and HT is highly significant. The increase in FFA value with increase in temperature may be due to hydrolysis during extraction. Similar results were reported by Nagre et al. (2011); Akinhanmi and Akintokun (2008); Nielsen (1994).

Table 4.

Analysis of Variance (ANOVA)

| Oil extracted from ohmically heated seeds | |||||||

|---|---|---|---|---|---|---|---|

| Source of variance | DF | SS | MS | Fcal | SE(m) | CD (1 %) | CV |

| Electric field strength | 2 | 427.279 | 231.639 | 493.284** | 0.127 | 0.478 | 5.31 |

| End point temperature | 2 | 35.642 | 17.821 | 41.148** | 0.127 | 0.478 | |

| Holding time | 2 | 0.906 | 0.453 | 1.046NS | 0.127 | ||

| Error | 54 | 23.3872 | |||||

| Residual oil content in cake | |||||||

| Electric field strength | 2 | 145.421 | 72.710 | 458.277** | 0.077 | 0.290 | 5.10 |

| End point temperature | 2 | 11.256 | 5.628 | 35.470** | 0.077 | 0.290 | |

| Holding time | 2 | 0.5084 | 0.254 | 1.602NS | 0.077 | 0.290 | |

| Error | 54 | 8.5686 | |||||

| L* color value | |||||||

| Electric field strength | 2 | 4.3601 | 2.18 | 14.720** | 0.074 | 0.280 | 0.85 |

| End point temperature | 2 | 6635 | 3.317 | 22.403** | 0.074 | 0.280 | |

| Holding time | 2 | 1.946 | 0.973 | 6.571** | 0.074 | 0.280 | |

| Error | 54 | 7.997 | |||||

| FFA (% oleic acid) | |||||||

| Electric field strength | 2 | 0.407 | 0.2035 | 70.458** | 0.010 | 0.039 | 2.96 |

| End point temperature | 2 | 0.1465 | 0.07325 | 25.359** | 0.010 | 0.039 | |

| Holding time | 2 | 0.0556 | 0.0278 | 9.636** | 0.010 | 0.039 | |

| Error | 54 | 0.1559 | |||||

| Peroxide value of extracted oil | |||||||

| Electric field strength | 2 | 0.0209 | 0.0104 | 3.924* | 0.010 | 0.038 | 5.69 |

| End point temperature | 2 | 0.0647 | 0.0323 | 12.135** | 0.010 | 0.038 | |

| Holding time | 2 | 0.00273 | 0.00136 | 0.513NS | 0.010 | 0.038 | |

| Error | 54 | 0.144 | |||||

*, ** Significant at 5 and 1 %, respectively, NS Non significant, CV critical value, SS sum of squares, DF degree of freedom, MS mean of squares

Effect of ohmic treatment on L* value (color lightness)

The L color value of oil samples was found in the range of 44.12 to 45.89 as against 46.47 of control sample. The results are in confirmation with the findings of previous research workers (Torres and Maestri 2006; Ozdemir and Golukcu 2007). ANOVA for color value (L) of oil samples showed that the effect of EFS, EPT & HT was highly significant (Table 4).

Effect of ohmic treatment on peroxide value of extracted oil

Peroxide values measure the content of hydroperoxides and are used as indicators of lipid oxidation (Gray 1978). The peroxide value of ohmically treated oil samples ranged from 0.81 to 1.01 meq/kg. Ogbonna and Ukaan (2013) reported the PV value of fresh sesame oil varies from 1.01 to 7.61 meq/kg. The ANOVA of peroxide value (Table 4) clearly shows that EFS and EPT have significant effect and holding time have non-significant effect.

Optimization of process parameters

The desired goals for each factors and response are shown in Table 5. The optimized the process parameter for ohmic heating by numerical optimization which find a point that maximizes the desirability function; equal importance ‘3’ was given to the process parameters and 4 responses. The optimum value for maximum oil recovery, minimum residual oil content, free fatty acid (FFA) and peroxide value were 41.24 %, 8.61 %, 1.74 and 0.86, respectively at 722.52 V/m EFS at EPT 65°C for 5 min. holding time. Akinoso et al. (2006) optimized the process parameters for the extraction of sesame oil and reported optimum moisture content, roasting duration and roasting temperature were 4.6 % wet basis (wb), 13.0 min. and 124.2 ºC. These combinations gave 50.4 % oil yield, 1.1 % free fatty acid, 0.1 % oil impurity.

Table 5.

Process variables and response for ohmic heating

| Attributes | Goals | Lower limit | Upper limit | Importance |

|---|---|---|---|---|

| EFS (V/m) | Minimize | 600 | 900 | 3 |

| EPT (°C) | Minimize | 65 | 85 | 3 |

| HT (min) | Minimize | 5 | 15 | 3 |

| Oil recovery (%) | Maximize | 39.98 | 43.15 | 3 |

| Residual oil content (%) | Minimize | 5.55 | 11.47 | 3 |

| FFA (% oleic acid) | Minimize | 1.52 | 2.26 | 3 |

| Peroxide value | Minimize | 0.78 | 1.01 | 3 |

Conclusion

During ohmic heating of sesame seeds, the current first increased with time to a certain level and then stabilized and once again increased. The temperature distribution within the ohmic heating system was relatively uniform. Percentage oil recovered from sesame seed through mechanical extracted oil by application of ohmic heating varies from 39.98 to 43.15 %. The maximum oil recovery 43.15 % was obtained when the sample was heated and maintained at 85 °C using EFS of 900 V/m for a holding time of 10 min as against 34.14 % in control sample. The FFA values obtained in this study are below the maximum permissible limit (3 %) at all combinations of treatment. It was therefore concluded that ohmic heating treatment of sesame slightly increased the FFA in oil.

Footnotes

Research highlights

Effect of variables on per cent oil extraction

Percentage of oil recovered from sesame seed through mechanical extracted oil by application of ohmic heating varies from 39.98 to 43.15 %, the maximum oil recovery 43.15 % was obtained when the sample was heated and maintained at 85 °C using electric field strength of 900 V/m for a holding time of 10 min.

Effect on FFA and peroxide value of extracted oil

On an average it ranged from 1.52 to 2.26 as against 1.24 (% oleic acid) in case of control sample. The peroxide value of ohmically heated extracted oil ranged from 0.78 to 1.01 as against 0.86 meq/kg in control sample.

Optimization of process parameters

Ohmic heating parameter such as electric field strength (EFS), end point temperature (EPT) and holding time (HT) was selected on the basis of maximum oil recovery with low free fatty acid and peroxide value. The optimum value for maximum oil recovery, minimum residual oil content, free fatty acid (FFA) and peroxide value was 41.24 %, 8.61 %, 1.74 and 0.86, respectively at 722.52 V/m EFS at EPT 65 °C for 5 min holding time which was obtained by response surface methodology.

Contributor Information

Kirti Kumari, Phone: 01376-252101, Email: kumarikirti95@gmail.com.

V. D. Mudgal, Phone: 0294-2470210, Email: mudgalvd@yahoo.com

Gajanan Viswasrao, Phone: +91- 8764123665, Email: gajanan.viswasrao07@gmail.com.

Himani Srivastava, Phone: +91-9784129458, Email: himani037@gmail.com.

References

- AACC . Approved methods American associations of central chemists. 9. St. Pual: American Associations of Central Chemists; 2003. [Google Scholar]

- Akinhanmi TF, Akintokun PO. Chemical composition and physico-chemical properties of cashew nut (AnacardiumOccidentale) oil and cashew nut shell liquid. J Agric Food Environ Sci. 2008;2(1):5. [Google Scholar]

- Akinoso R, IgbekaJ, Olayanju T (2006) Process Optimization of Oil Expression from Sesame Seed (Sesamumindicum Linn.). Agricultural Engineering International: the CIGR Ejournal. Manuscript FP 06 011. Vol. 8

- AOAC (1970) Association of Official Analytical Chemists (1975). Official methods of analysis 11th ed. Washington, DC, pp. 927–928

- AOAC . In: Official methods of analysis. Associations of Official Analytical Chemists. 14. Horowitz W, editor. Washington, D.C: Associations of Official Analytical Chemists; 1984. [Google Scholar]

- Borchani C, Besbes S, Blecker CH, Attia H. Chemical characteristics and oxidative stability of sesame seed, sesame paste, and olive oils. J Agric Sci Tech. 2010;12:585–596. [Google Scholar]

- Carvalho RHR, Galvão E L, Barros JÂC, Conceição MM, Sousa EMBD (2012) Extraction, Fatty Acid Profile and Antioxidant Activity of Sesame Extract (SesamumIndicum L.). Brazilian Journal of Chemical Engineering. Vol. 29, No. 02, April – June. pp. 409–420

- El Khier MKS, Ishag KEA, Yagoub AEA. Chemical Composition and Oil Characteristics of Sesame Seed Cultivars Grown in Sudan. Res J Agric Biol Sci. 2008;4(6):761–766. [Google Scholar]

- Gandhi AP. Simplified process for the production of sesame seed (Sesamumindicum L) butter and its nutritional profile. Asian J Food Agro-Industry. 2009;2(01):24–27. [Google Scholar]

- Gray JI (1978) Measurement of lipid oxidation: a review. J Am Oil Chem Soc 59:117–118

- Hansen R (2011) Sesame Profile. http://www.agmrc.org/commodities products/grains oilseeds/sesame_profile .com. Accessed at 25 Feb. 2015

- Kemp MR, Fryer PJ. Enhancement of diffusion through foods using alternating electric fields. Innov Food Sci Emerg Technol. 2007;8:143–153. doi: 10.1016/j.ifset.2006.09.001. [DOI] [Google Scholar]

- Lakkakula N, Lima M, Walker T. Rice bran stabilization and rice bran oil extraction using ohmic heating. J BioresourTechnol. 2004;92:157–161. doi: 10.1016/j.biortech.2003.08.010. [DOI] [PubMed] [Google Scholar]

- Latif S, Anwar F. Aqueous enzymatic sesame oil and protein extraction. Food Chem. 2010 [Google Scholar]

- Loumouamou B, Silou TH, Desobry S. Characterization of seeds and Oil of sesame (Sesamumindicum L.) and the kinetics of degradation of the oil during heating. Res J Appl Sci Eng Technol. 2010;2(3):227–232. [Google Scholar]

- Madamba PS. The response surface methodology: An application to optimize dehydration operations of selected agricultural crops. LWT—Food Sci Technol. 2002;35:584–592. [Google Scholar]

- Myers R, Montgomery D, Anderson-Cook C. Response surface methodology process and product optimization using designed experiments. 3. USA: Wiley; 2009. [Google Scholar]

- Nagre RD, Oduro I, Ellis WO. Comparative physico – chemical evaluation of Kombo kernel produced by three difference processes. Afr J Food Sci Technol. 2011;2(4):083–091. [Google Scholar]

- Nielsen SS. Introduction to the chemical analysis of foods. New York: Chapman and Hall; 1994. pp. 93–207. [Google Scholar]

- Nzikou JM, Mato SL, Bouanga-Kalou G, Ndangui CB, Pambou-Tobi NPG, Kimbonguila A, Silou T, Linder M, Desobry S. Chemical Composition on the Seeds and Oil of Sesame (Sesamumindicum L.) Grown in Congo-Brazzaville. Adv J Food Sci Technol. 2009;1(1):6–11. [Google Scholar]

- Ogbonna PE, Ukaan SI. Chemical composition and oil quality of seeds of sesame accessions grown in the Nsukka plains of South Eastern Nigeria. Afr J Agric Res. 2013;8(9):797–803. [Google Scholar]

- Ozdemir F, Golukcu M. Influence of different microwave seed roasting processes on the color value of Tehina (sesame paste) GIDA. 2007;32(3):129–135. [Google Scholar]

- Parascopic I, Lebovka NI, Ghnimi S, Vorobiev E. Ohmically heated enhanced expression of juice from apple and potato tissues. Biosyst Eng. 2006;93(2):199–201. doi: 10.1016/j.biosystemseng.2005.11.002. [DOI] [Google Scholar]

- Pare A, Nema A, Singh VK, Madhyan B (2009) Soy-oil Extraction Using Combined Pretreatment of Enzymatic Hydrolysis and Ohmic Heating. Unpublished Ph.D.thesis. J.N.K.VishwaVidyalaya, Jabalpur, India

- Parrado J, Miramontes E, Jover M, Marquez J, Mejias M, Collantes L. Prevention of bran protein and lipid oxidation elicited by a water soluble oryzanol enzymatic extract derived from rice bran. Eur J Nutr. 2003;42:307–314. doi: 10.1007/s00394-003-0424-4. [DOI] [PubMed] [Google Scholar]

- Rao LN, Lima M, Walker T. Rice bran stabilization and rice bran oil extraction using ohmic heating. Bioresour Technol. 2004;92(2):157–161. doi: 10.1016/j.biortech.2003.08.010. [DOI] [PubMed] [Google Scholar]

- Shukla P, Srivastava K, Ram K, Gupta . Oil seed processing technology. Technology mission on oilseed. Bhopal: CIAE; 1992. pp. 158–160. [Google Scholar]

- Torres MM, Maestri DM. Chemical composition of Arbequina virgin olive oil in relation to extraction and storage conditions. J Sci Food Agric. 2006;86(14):2311–2317. doi: 10.1002/jsfa.2614. [DOI] [Google Scholar]

- Tyagi K, Ansari MA, Ttagi S, Tyagi A (2012) Novel process for physically refining rice bran oil rough degumming. Adv Appl Sci Res 1435–1439

- Wang WC, Sastry SK. Effects of moderate electrothermal treatments on juice yield from cellular tissue. Innov Food Sci Emerg Technol. 2002;3(4):371–377. doi: 10.1016/S1466-8564(02)00054-1. [DOI] [Google Scholar]

- Wang LJ, Tatsumi D, Liu ZS, Chen XD, Li LT. Application of two- stage ohmic heating to tofu processing. Chem Eng Process. 2007;46(5):486–490. doi: 10.1016/j.cep.2006.06.017. [DOI] [Google Scholar]

- Yen GC, Shyu SL, Lin TC (1986) Food Sci. (Chinese), 13. pp.198