Abstract

With the development of models to predict fire growth and spread in buildings, there has been a concomitant evolution in the measurement and analysis of experimental data in real-scale fires. This report presents the types of analyses that can be used to examine large-scale room fire test data to prepare the data for comparison with zone-based fire models. Five sets of experimental data which can be used to test the limits of a typical two-zone fire model are detailed. A standard set of nomenclature describing the geometry of the building and the quantities measured in each experiment is presented. Availability of ancillary data (such as smaller-scale test results) is included. These descriptions, along with the data (available in computer-readable form) should allow comparisons between the experiment and model predictions. The base of experimental data ranges in complexity from one room tests with individual furniture items to a series of tests conducted in a multiple story hotel equipped with a zoned smoke control system.

Keywords: accuracy assessment, data analysis, experiments, fire models, fire tests, instruments

1. Introduction and Background

Analytical models for predicting fire behavior have been evolving within the fire research community for some years. Individuals have tried to describe in mathematical language the various phenomena which have been observed in fire growth and spread. These separate representations often describe only a small part of a fire experience. When combined, they create a complex computer code intended to give an estimate of expected behavior based upon given input parameters. These analytical models have progressed to the point of providing predictions of fire behavior. However, it is important to be able to state with confidence how close are the actual conditions to those predicted by the model.

The Building and Fire Research Laboratory (BFRL) has a program to develop a generic methodology for the evaluation and accuracy assessment of fire models. Our goal is to define a mechanism by which the model predictions can be assessed so that a model user can test the limits of the model predictions. A key aspect of this process is the availability of a sufficient quantity of experimental data with which to compare the performance of any given model. This report presents such a set of experimental data gathered from several sources which can be used to test the limits of a typical two-zone fire model. All of these data are available in computer readable form from the authors. The format of the data has been previously documented [1].

The remainder of this section provides a brief historical perspective of room fire testing leading up to tests specifically designed for comparison with predictive computer models.

Section 2 describes the process for assessing the accuracy of a predictive computer model. This report details one aspect of this process.

Sections 3 and 4 present the types of analyses that can be used to examine large-scale room fire test data to prepare the data for comparison with zone-based fire models. Although not every technique was used for all data sets presented in this report, section 3 can be used for guidance in the design of future experiments. In addition, a rough guideline used to judge the quality of the data in each data set is described.

In sections 5 to 9, five sets of experimental data are detailed. A standard set of nomenclature describing the geometry of the building and the quantities measured in each experiment is presented. Availability of ancillary data (such as smaller-scale test results) is included. These descriptions, along with the data should allow comparisons between the experiment and model predictions.

1.1 Early Developments in Room Fire Testing

Before the mid-1970s there was not much need to make experimental studies of the details of room fires. Room fire experiments were typically conducted as an adjunct to studying fire endurance [2,3]. For these experiments, it was necessary to track the average room temperature. This temperature was viewed as the prerequisite for determining the fire exposure of the room structure. Neither the heat release rate nor other aspects of the room fire, such as gas production rates, were of major interest. While as early as 1950, some investigators, conducting full-scale house burns, tried to study the gas production rates to determine how soon untenable environments might exist [4]. There was little incentive to pursue the topic quantitatively. Incentives came with the development of mathematical theories of room fires. Post flashover room fire theories were being developed throughout the 1950s, 1960s, and 1970s. The more detailed understanding necessary for the pre-flashover portion of room fires was becoming achievable by around 1975.

During the 1970s, however, empirical room fire tests were regularly being conducted at many fire research and testing facilities throughout the world. Instrumentation typically included a multiplicity of thermocouples; several probes where gas samples were extracted; smoke meters, typically located at several heights along an open burn room doorway; heat flux meters located in the walls of the burn room; and, possibly, a load platform. The load platform might register the weight of a single burning item, but was of little use when fully-furnished rooms were tested.

Despite the basic role of heat release rate in the room fire, there was no technique available to measure it. Since neither the burning item’s mass loss rate nor the air and gas flows could, in most instances, be determined, the measurements of gas and smoke concentrations at isolated measuring stations were not of much use in tracking species evolution rates.

Even before the era of heat-release-rate focused studies could begin, there were at least three series of notably thorough room fire experiments. Two were conducted at Factory Mutual Research Corporation (FMRC), while a third one was at NBS (former name of NIST). The first series at FMRC [5–7] served as a basis for the Harvard Computer Fire Code. Three replicate full-scale bedroom fire tests, in which the fire grew from a small ignition in the middle of a polyurethane mattress to flashover, were studied in enough detail to define the fire as a series of loosely coupled events. As the components of the fire became better understood, a model of the entire fire growth process as a series of quantitative calculations was developed [8]. To make these tests most useful for a scientific study of fire, several hundred measurements of temperature, radiation level, gas composition, gas velocity, and weight loss were made. The mechanism of fire spread from the initial burning mattress to other room furnishings, estimates of the flow of the gases through room openings, and estimates of the energy balance of the system were all quantified. A second series of tests at FMRC [9] used a simpler test configuration—single slabs of polyurethane foam in the room, instead of fully-furnished bedrooms. A similarly fundamental series of experiments was also conducted at NBS by Quintiere and McCaffrey [10], who examined wood and polyurethane foam cribs burning in well-instrumented rooms. The largest distinction between these tests and earlier test series was the carefully defined purpose to understand the underlying principles of fire growth to be able to predict the progress of a fire in a generic building.

1.2 Measurement of Heat Release Rate in Room Fires

The first attempt to develop a technique for measuring rate of heat release in room fires was in 1978, by Fitzgerald, at Monsanto Chemical [11]. He constructed a small room (2.7 m cube) instrumented with a large number of thermocouples, located in the gas space, on the walls, and in the exhaust duct (fig. 1). The room had a forced air supply of 0.19 m3/s, from a small 0.15 m square supply duct (later raised to 0.26 m3/s [12]), with another duct used to exhaust the combustion products. The room was also equipped with a load cell and a port for extracting gas samples. Fitzgerald realized that a simple measurement of temperatures in the exhaust duct would not be enough to determine the heat release rate. Instead, he developed a purely statistical method—a correlation was sought between contributions from the various temperature measurements to the heat release rate. The stated capacity was 140 kW, which would not now be considered to be full-scale. This system has been sporadically in use at the Southwest Research Institute in San Antonio, Texas. The approach, however, has not been pursued by any other laboratories due to its empirical nature, its limited heat handling capacity, and to concerns about errors due to varying radiative fractions.

Figure 1.

The Monsanto room calorimeter.

A sensible-enthalpy calorimeter, such as the Monsanto one, was not judged by the profession to be adequate for the needs. Instead, it was necessary to await the development of two measurement techniques: a robust instrument for measuring the flow rates of air and gas in a soot-laden environment; and a heat release measurement which did not depend on direct measurement of heat flow in inevitably loss-prone systems. The first was developed by Heskestad at FMRC in 1974. Conventional velocity measurement devices are normally precluded from use in fire applications due to several problems. These include clogging of small orifices (an issue with pitot/static probes) and the inability to calibrate properly for high temperature use (hot wire or disc anemometers). The new “bidirectional velocity probe” (fig. 2) solved these problems of measuring air flow rates in rooms, in corridors, and in smoke extraction systems.

Figure 2.

Bi-directional velocity probe.

By far, the most important development which was needed, however, was the principle of oxygen consumption. As early as 1917, Thornton [14] showed that for many organic fuels, a reasonably constant net amount of heat is released per unit of oxygen consumed for complete combustion. The principles have been covered in detail by Huggett [15] and Parker [16]. The application of this principle to room fires revolutionized the field. Before that, the focus was on point measurements. It is adequate to use measurements of temperatures and other quantities at individual locations in a room as a means of verifying a model if a near-ideal model is already available. Such point measurements, however, were of limited use in developing and extending the models. With the availability of oxygen consumption-based rate of heat release measurements, for the first time quantitative descriptions of fire output could be made.

1.3 Standard Room Fire Tests

During the late 1970s and early 1980s several laboratories agreed to develop a standardized method for measuring heat release rates in rooms, based on oxygen consumption. Unlike the Monsanto test, the concern here was in measuring the burning rate of combustible room linings (i.e., wall, ceiling, or floor coverings), and not furniture or other free-standing combustibles. The original development was at the University of California by Fisher and Williamson [17]. Later, extensive development also was done at the laboratories of the Weyerhaeuser Co., and at NBS [18]. The method, in its simplest form, consisted primarily of adding oxygen consumption measurements into the exhaust system attached to a room very similar to that originally used by Castino and coworkers at Underwriters Laboratories [19]. However, they did not measure heat release rates at all. The room was 2.4 × 3.7 × 2.4 m high, with a single doorway opening in one wall, 0.76 × 2.03 m high (fig. 3). The original studies at the University of California led to ASTM issuing in 1977 a Standard Guide for Room Fire Experiments [20]. The Guide did not contain prescriptive details on room size, ignition source, etc., but was simply a guide to good practice in designing room fire tests. ASTM then developed an actual prescriptive test method for room fire tests and published it as a “Proposed method” in 1982 [21]. The 1982 document mandated the above-mentioned room size and also a standard ignition source, which was a gas burner, placed in a rear corner of the room, giving an output of 176 kW. Since the development work at the University of California uncovered problems with a natural convection exhaust system, the actual test specification entailed a requirement to “establish an initial volumetric flow rate of 0.47 m3/s through the duct if a forced ventilation system is used, and increase the volume flow rate through the duct to 2.36 m3/s when the oxygen content falls below 14 percent.” This specification required a complex exhaust arrangement, and it is not clear that there were many laboratories prepared to meet it. The proposed method was thus withdrawn by ASTM. However, variants of this method continue to be used by several laboratories [22].

Figure 3.

The original (1982) ASTM proposed room fire test.

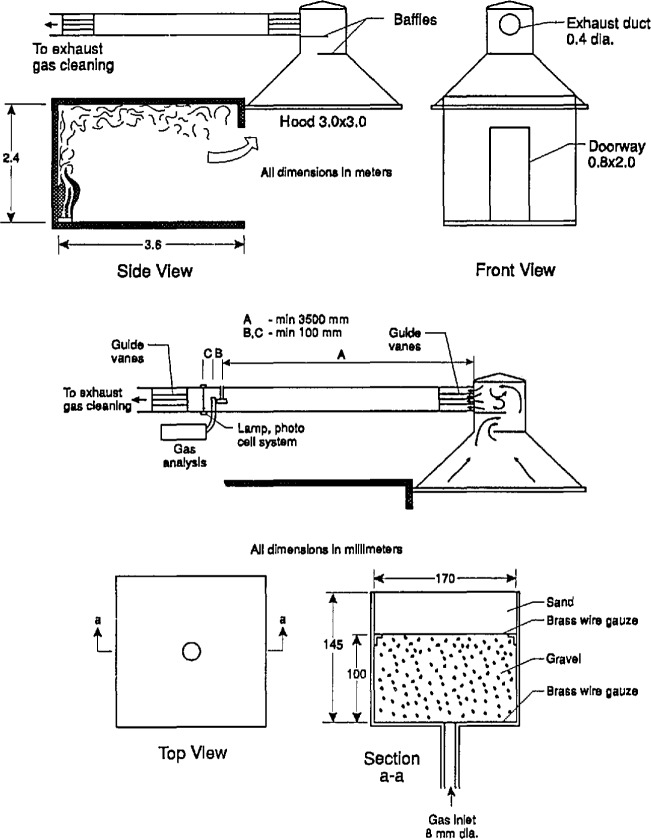

Following ASTMs disengagement, development of a standard room fire test was accelerated in the Nordic countries, operating under the auspices of the NORDTEST organization. Development was principally pursued in Sweden, at the Statens Provningsanstalt by Sundström [23]. The NORDTEST method [24,25], as eventually published in 1986, uses a room of essentially the ASTM dimensions, 2.4 × 3.6 × 2.4 m high, with an 0.8 × 2.0 m doorway opening (fig. 4). The exhaust system flow capability was raised to 4.0 kg/s, with the capability to go down to 0.5 kg/s to increase the resolution during the early part of the test.

Figure 4.

The NORDTEST room fire test.

A special concern in the Nordic countries has been the effect of the igniting burner. A parallel project at the Valtion Teknillinen Tutkimuskeskus (VTT) in Espoo, Finland by Ahonen and coworkers [26] developed data on three burner sizes and three burner outputs. The three burners had top surface sizes of 170 × 170 mm, 305 × 305 mm, and 500 × 500 mm. The energy release rates were 40, 160, and 300 kW, respectively. VTTs reported results were on chipboard room linings. They found no significant differences at all among the burner sizes. The burner output did, of course, make a difference; however, the difference between 40 and 160 kW was much larger than between 160 and 300 kW. The VTT conclusion was that either the 160 or the 300 kW level was acceptable. The NORDTEST method itself has taken an ignition source to be at the 100 kW level. If no ignition is achieved in 10 minutes, the heat output is then raised to 300 kW.

ISO (International Organization for Standardization) has adopted the NORDTEST room fire test and is finalizing the standard [27].

1.4 Room Fire Tests for Modeling Comparisons

Several systematic test series have been undertaken specifically to provide data for comparison with model predictions. In other cases, tests in which fire properties have been systematically varied (for various reasons) have been modeled using current computer fire simulations. In the first category are the study of Alpert et al. [28] for a single room connected to a short, open corridor, and that of Cooper et al. [29] or Peacock et al. [30] for gas burner fires in a room-corridor-room configuration. The second category is large, but the works of Quintiere and McCaffrey [10], and Hes-kestad and Hill [31] are particularly detailed.

Cooper et al. [29] report on an experimental study of the dynamics of smoke Filling in realistic, full-scale, multi-room fire scenarios. A major goal of the study was to generate an experimental data base for use in the verification of mathematical fire simulation models. The test space involved 2 or 3 rooms, connected by open doorways. During the study, the areas were partitioned to yield four different configurations. One of the rooms was a burn room containing a methane burner which produced either a constant energy release rate of 25, 100, or 225 kW or a time-varying heat release rate which increased linearly with time from zero at ignition to 300 kW in 600 s. An artificial smoke source near the ceiling of the burn room provided a means for visualizing the descent of the hot layer and the dynamics of the smoke filling process in the various spaces. The development of the hot stratified layers in the various spaces was monitored by vertical arrays of thermocouples and photometers. A layer interface was identified and its position as a function of time was determined. An analysis and discussion of the results including layer interface position, temperature, and doorway pressure differentials is presented. These data were later used by Rockett et al. [32,33] for comparison to a modern predictive fire model.

Quintiere and McCaffrey [10] describe a series of experiments designed to provide a measure of the behavior of cellular plastics in burning conditions related to real life. They experimentally determined the effects of fire size, fuel type, and natural ventilation conditions on the resulting room fire variables, such as temperature, radiant heat flux to room surfaces, burning rate, and air flow rate. This was accomplished by burning up to four cribs made of sugar pine or of a rigid polyurethane foam to provide a range of fire sizes intended to simulate fires representative of small furnishings to chairs of moderate size. Although few replicates were included in the test series, fuel type and quantity, and the room door opening width were varied. The data from these experiments were analyzed in terms of quantities averaged over the peak burning period to yield the conditions for flashover in terms of fuel type, fuel amount, and doorway width. The data collected were to serve as a basis for assessing the accuracy of a mathematical model of fire growth from burning cribs.

Heskestad and Hill [31] performed a series of 60 fire tests in a room/corridor configuration to establish accuracy assessment data for theoretical fire models of multi-room fire situations with particular emphasis on health care facilities. With steady state and growing fires from 56 kW to 2 MW, measurements of gas temperatures, ceiling temperatures, smoke optical densities, concentrations of CO, CO2, and O2, gas velocities, and pressure differentials were made. Various combinations of fire size, door opening size, window opening size, and ventilation were studied. In order to increase the number of combinations, only a few replicates of several of the individual test configurations were performed.

2. Assessing the Accuracy of Room Fire Models

In essence, every experiment is an attempt to verify a model. In the simplest case, the model is a hypothesis which is based on some observed phenomenon—or even a single observation — and raises the question “why?” The hypothesis then needs to be tested to determine whether the observation is repeatable and to help define the boundaries of the validity of the hypothesis. In as simple a case as presented here, a yes or no answer may suffice to test the agreement between the model and experiment. For more complex models, the question is not does the model agree with experiment, but rather how close does the model come to the experiment over time. A quantification of the degree of agreement between a model and perhaps many experiments is the subject of the model accuracy assessment process. Quantification is made complicated by the transient nature of fires. Not only must a model be accurate at any point in time, but also have verisimilitude with the rate of change.

2.1 Documentation of the Model

For an analytical model designed for predicting fire behavior, the process of accuracy assessment is similar to the single observation case above, but perhaps more extensive because of the complexity of the model. The first step in the process is thorough documentation of the model so other modelers can use it and so its testing can be properly designed. The basic structure of the model, including the limitations, boundary conditions, and fundamental assumptions must be clearly described. Additionally, the functional form of the input parameters must be well-defined to allow any experiments carried out in the accuracy assessment process to be properly simulated (what are the inputs; what are the appropriate units for each). The same applies to the model outputs. In this way, the format of the experimental input and output can be defined to match that of the model.

2.2 Sensitivity Analysis

The sensitivity analysis of a model is a quantitative study of how changes in the model parameters affect the results generated by the model. The parameters through which the model is studied consist of those variables which are external to the program, (i.e., input variables), those variables which are internal to the program, (i.e., encoded in the program), and the assumptions, logic, structure, and computational procedures of the model. For this discussion, the model will be considered to be defined by its assumptions, logic, structure, and computational procedures and its sensitivity will be measured in terms of its external and internal variables. The key questions of interest to be investigated by the analyst are: 1) what are the dominant variables? 2) what is the possible range of the result for a given input that may arise from uncertainties within the model? and 3) for a given range of an input variable, what is the expected range for the result?

Sensitivity analysis of a model is not a simple task. Fire models typically have numerous input parameters and generate numerous output responses which extend over the simulation time. So multiple output variables must each be examined over numerous points in time. To examine such a model, many (likely to be more than 100) computer runs of the model must be made and analyzed. Thus, if the model is expensive to run or if time is limited, a full analysis is not feasible and the set of variables selected for study must be reduced. When the set of variables to be investigated must be reduced, a “pre-analysis” for the important variables can be performed or the important variables can be selected by experienced practitioners.

Classical sensitivity analysis examines the partial derivatives of the underlying equations behind a model with respect to its variables in some local region of interest. A complex model may be sensitive to changes in a variable in one region while insensitive in another region. In addition, it is most likely to be unfeasible to determine the intervals for each variable for which a complex model is sensitive. This suggests that stating a single value as a measure of sensitivity is not always sufficient and, consequently, some measure of its variability should be determined to make a global statement of how sensitive a model is to a variable.

Several methods for estimating the sensitivity of a model to its variables are available, each with its advantages and disadvantages. The choice of method is often dependent upon the resources available and the model being analyzed. It is beyond the scope of this paper to go into the details of any of these.

2.3 The Experimental Phase

Once an assessment has been made of the relative importance of the model parameters, a selection process is carried out to determine which parameters will be studied in the experimental phase of the accuracy assessment process. Typically, with a fixed budget for model testing, tradeoffs are made in the selection of the number and range of variables to be studied, replication of the experiments, and complexity of the experiments to be performed. Elements of a well-designed experimental program, discussed below, address these trade-offs so the model assessment can be carried out with the available resources.

The number of possible tests, while not being infinite, is large. It is unreasonable to expect all possible tests to be conducted. The need exists to use reason and some form of experimental design strategy to optimize the range of results while minimizing the number of tests. While this is not the forum for a detailed discussion of experimental design, some elaboration is required. Traditionally, a latin-square arrangement or full factorial experimental design is employed to determine the effect of variations in input conditions on output results [35]. This, as expected, results in the number of tests increasing with the number of input variables and variations. However, there exists a reduced factorial experimental plan [36] called fractional replication. The basic concept behind fractional replication is to choose a subgroup of experiments from all possible combinations such that the chosen experiments are representative, amenable to analysis, and provide the maximum amount of information about the model from the number of observations available.

The choice of data to be collected during the experimental phase depends upon the model under evaluation. A description of the input and output data of the model directs the selection of the measurements to be made. The evaluator or test engineer must constrain the range of test conditions to those which apply to the fire model. The test design then includes a varied and representative set of conditions (i.e., enclosure configuration, fuel loading, fuel type, ignition mechanism) from this range.

The evaluator develops the instrumentation design by starting with the model output data and determining suitable algorithms for generating comparable data output from the large-scale tests. This defines the instrumentation requirements, and experience is used to define instrument placement. Unfortunately, any experimental design will include only a fraction of the range of conditions for all the input variables of a complex fire model. The choice of test conditions and instrumentation will, to a large extent, determine the quality and completeness of the accuracy assessment of the chosen model.

2.4 Review and Analysis of the Model and Experimental Data

Large-scale tests are performed according to the experimental plan designed by the evaluator. The individual data instrumentation, of which there may be one to two hundred, have to be carefully installed, calibrated, and documented (what they measure and where they are located). Since it is rare to find an individual raw data observation that can be compared to the model output, single data elements are combined to provide derived data which can be compared to the model. Using data collection techniques appropriate to the testing needs, the individual data points are collected and typically processed by computer to provide the desired outputs.

Expected and unexpected uncertainties will define the level of replication necessary for each set of test conditions [37]. There are many sources that can contribute to expected variation in large-scale fire tests, such as variations in the materials or assemblies to be tested, environmental conditions, instruments or apparatus, and calibration techniques used in the measuring process. Because of the nonuniformity of building materials normally encountered and the variability associated with fire exposures and combustion reactions, excellent repeatability is not expected. The development of an experimental plan is, to a large extent, the search for the major factors influencing the outcome of the measurements and the setting of tolerances for their variations [38]. Within the constraints of a fixed budget, replication is usually limited to less than that statistically desired to minimize the unexpected variations. The larger variations that result must be accepted and thus affect the level of confidence in the resulting model accuracy assessment.

As part of the data analysis of the large-scale tests, potential error sources must be quantitatively determined. There are recognized uncertainties in the instrumentation used for each data element as well as random and systematic “noise” in the data acquisition process. The unevenness of burning of a material or the turbulent nature of fluid motion in most fire situations also introduce “noise” into the data analysis process and erratic burning does so among replicate tests. Each step in the data reduction process contributes to the accumulated uncertainties.

Data analysis itself requires the development of a series of algorithms that combine individual data elements to produce the desired output parameter [39]. As can be seen from this short discussion, data analysis of the large-scale tests requires a significant effort before comparisons between the model and the large-scale tests are possible. The size of the data reduction program can be as large and complex as the model being evaluated.

3. Analyses Used for the Data

For most large-scale room fire tests, instrumentation is characterized by a multiplicity of thermocouples; several probes where gas samples are extracted; smoke meters, typically located at several heights along doorways or in rooms; heat flux meters located in the walls of the burn room; and, possibly, a load platform. Although certainly useful for evaluation the burning behavior of the specific materials studied, variables representing key physical phenomena are required for comparison with predictive room fire models. Some typical variables of interest from large-scale tests are:

| • heat release rate (of fire, through vents, etc.) | (W) |

| • interface height | (m) |

| • layer temperatures | (°C |

| • wall temperatures (inside and out) | (°C) |

| • gas concentrations | (ppm or %) |

| • species yields | (kg/kg) |

| • pressure in room | (Pa) |

| • mass flow rate | (kg/s) |

| • radiation to the floor | (W/m2) |

| • mass loss | (kg) |

| • mass loss rate | (kg/s) |

| • heat of combustion | (J/kg) |

To obtain these variables, a significant amount of analysis of a large-scale fire test is required. This data analysis requires the development of a series of algorithms that combine individual data elements to produce the desired output parameter. Breese and Peacock [1] have prepared a specially designed computer program for the reduction of full-scale fire test data. In addition to easing the burden of repetitive and similar calculations, the program provides a standard set of algorithms for the analysis of fire test data based upon published research results and a standard form for detailing the calculations to be performed and for examining the results of the calculations. The program combines automated instrument calibrations with more complex, fire-specific calculations such as

smoke and gas analysis,

layer temperature and interface position,

mass loss and flows, and

rate of heat release.

A description of these algorithms applicable to the analysis of large-scale fire test data is presented below along with an example of each of the algorithms. Although not every one of the techniques was applied to every test (individual measurements available for analysis varied from test to test), many of the techniques were applied to most of the data sets. Details of those applied to an individual data set are available in the sections describing the data sets in sections 5 to 9.

3.1 Smoke and Gas Analysis

In the recent past, optical smoke measurements in room fires have been made in several ways:

vertical or horizontal beams within the room [40],

vertical or horizontal beams in the doorway [41],

vertical or horizontal beams in the corridor [42], and

a diagonal, 45° beam across the doorway plume [43].

The actual measurement is typically made with a collimated light source and directly opposed photometer receiver. This provides a measure of the percentage of the light output by the source that reaches the photometer, and is typically expressed as an extinction coefficient, k, as follows:

| (1) |

Bukowski [44] has published a recommended practice for a widely-used design of photometer using an incandescent lamp source. Newer designs [45] are available, however, based on a laser source and are therefore, free of certain measurement errors [46].

Smoke measurements have been reported in a multitude of ways. Many reporting variables suffer from the drawback that the values depend as much on geometric or flow details of the apparatus, as they are on properties of the combustible being burned. Thus, it was important to arrive at a set of variables from which the apparatus influence is removed. There are two such variables. The first is the total smoke production for the duration of the test, P (m2). This variable can be visualized as the area of obscuration that would be caused by the smoke produced in the experiment. The second normalizes the production by the specimen mass loss during burning to form the yield of smoke per kg of specimen mass lost (m2/kg) [47]. The latter has come to be called the specific extinction area, σf. None of the measurement geometries mentioned above, however, are at all useful in characterizing these variables. Such information can be obtained by providing a photometer in the exhaust collection system [48], as, for instance, is done with the ISO/NORDTEST standard (fig. 4). Although such smoke data are sparse, encouraging progress is being made [49].

The specific extinction area is the true measure of the smoke-producing tendency of a material which can be described on a per-mass basis, for instance, wall covering materials. If a fully-furnished room is being tested, or some other configuration is examined where mass loss records are not available, then the smoke production serves to characterize the results.

The total smoke production is computed as

| (2) |

where is the actual volume flow at the smoke measuring location.

The average specific extinction area is then computed as

| (3) |

One of primary applications of the yield is in comparing results on the same material conducted in different test apparatus or geometries. Since the effects of specimen size, flow, etc., have been normalized out in this expression, the variable permits actual material properties to be compared.

In some cases, it is also of interest to derive the instantaneous, time-varying expression for σf. Its definition is analogous the one given in eq (3).

Gas measurements in the 1970s were typically made by installing probes for CO, CO2, etc., analyzers in several places in the room or in the doorway. Data from such measurements had the same limitations as point measurements of temperature: only the behavior at one point was characterized, and no measurement of total fire output was available. Once measurement systems, such as the ISO/NORDTEST room fire test have been adopted which collect all of the combustion products in an exhaust hood, it became a simple manner to instrument that exhaust system for combustion gases.

Old data for gas measurements are typically reported as ppm’s of a particular gas. Similar as to smoke, such measurements depend strongly on the test environment and are not very useful for describing the fuel itself. The appropriate units are very similar to those for smoke. The production of a particular gas is simply the total kg of that gas which flowed through the exhaust duct for the duration of the entire test. The yield of a particular gas (kg/kg) is the production divided by the total specimen mass lost. As for smoke, there may be scale effects applicable to a particular gas; the yield of a given gas might be expected to be similar for various apparatus and experiments where the specimen was burned under similar combustion conditions [50].

3.2 Layer Interface and Temperature

Cooper et al. [29] have presented a method for defining the height of the interface between the relatively hot upper layer and cooler lower layer induced by a fire. Since the calculation depends upon a continuous temperature profile, and a limited number of point-wise measurements are practical, linear interpolation is used to determine temperatures between measured points. The equivalent two zone layer height is the height where the measured air temperature is equal to the temperature TN and is determined by comparison of TN with the measured temperature profile:

| (4) |

Once the location of the interface has been determined, it is a simple matter to determine an average temperature of the hot and cold layers within the rooms as:

| (5) |

With a discrete vertical profile of temperatures at a given location, the integral can be evaluated numerically. The average layer temperature (either of the lower layer or the upper layer), Tavg, is thus simply an average over the height of the layer from the lower bound, z1, to the upper bound, zu, for either the upper or lower layers. Figure 5 shows the results of such a calculation of layer height and layer temperature for a set of eight replicate experiments [51]. Although systematic errors are apparent in the data (two distinct subsets of the data are apparent which may relate to seasonal temperature variations over the testing period) and the limitations inherent in two-zone fire models are equally applicable to these layer height and temperature calculations, the reproducibility of the calculation is good. For a series of large-scale test measurements in a multiple room facility, the uncertainty between 95 percent confidence limits averaged under 16 percent [51].

Figure 5.

An example of layer interface position and layer temperature calculated from temperature profiles measured during several tests along with estimated repeatability of the measurement [51].

While the in-room smoke measurement schemes are not useful in quantifying the smoke production or yield, they can be used to deduce the location of the interface in a buoyantly stratified compartment [52]. In this method, if a two zone model is assumed (a smoke-filled upper zone and a clear lower zone), the use of a paired vertical (floor to ceiling) smoke meter and horizontal (near the ceiling) smoke meter can be used to determine the smoke layer thickness. If the smoke layer is homogeneous, kv/Lv = kh/Lh, then the height of the smoke layer Lv can be given as a simple ratio,

| (6) |

where the subscripts v and h refer to the vertical and horizontal measurements.

Figure 6 presents a comparison of the smoke layer height calculated from smoke measurements and from temperature measurements for one series of tests [51]. Within experimental uncertainty, the two methods may be equivalent. However, small systematic differences exist. First, the smoke measurement estimates are typically higher than the temperature based calculations. This is consistent with the observations of others, notably Zukoski and Kubota [53], who measured temperature profiles in detail in a scale “room” measuring 0.58 m square with a doorway in one wall measuring 0.43 × 0.18 m. A smoke tracer was used to allow visual observation of the smoke layer thickness along with the temperature profile measurements. They concluded that, since the lower boundary layer is not steady and there are distinct gravity waves along the boundary, the smoke measurements produce a less steep boundary than would be measured from instantaneous profiles at a given instant of time. For tests where the interface height reaches the floor, the temperature based method falters since it is based upon interpolation between adjacent measurement points. Without extensive instrumentation near the floor, a bottom limit at the level of the lowest thermocouple is evident in the temperature-based calculations. However, with the typically higher uncertainty of the smoke-based measurements, the significance of any perceived difference between the two different techniques must be questioned.

Figure 6.

A comparison of hot/cold layer interface position estimated from temperature profiles and from smoke obscuration in one test series (an average of 9 individual tests) [51].

3.3 Mass Flows

Computation of mass flows through openings can be accomplished through a knowledge of the velocity profile in the opening [54,55]:

| (7) |

The velocity profile can be determined in a number of ways. In some experiments, the bi-directional velocity probes described earlier can be used to directly measure velocity in a room doorway. This is usually done by locating 6 to 12 such probes vertically along the centerline of the doorway. Mass flow rates can be computed by eq (7) and can give adequate results for steady-state fires, especially if the opening is much taller than its breadth [56]. Use of such a straightforward technique in non-steady state fires, and especially when the opening is broader than tall, has been shown to give nonsensical results [57]. Lee [56] exploits this method to calculate the mass flow using the pressure drop across the doorway to calculate the velocity. Since the pressure drop across an opening passes through zero as the flow changes direction at the height of the neutral plane, measurement of the pressure profile in a doorway is particularly difficult. Estimation of the pressure in the extreme lower resolution of the instrumentation (as the pressure drop approaches zero) yields an inherently noisy measurement. As such, these measurements are used only as an alternate to the temperature method, to provide an assessment of the consistency of the data collected. As an alternative measurement technique combined with dramatically higher instrumentation costs (several orders of magnitude higher than the temperature measurements), a less detailed profile of measurement points can be used for the pressure profile.

Steckler, Quintiere, and Rinkinen [58] use an integral function of the temperature profile within the opening to calculate the mass flow. Casting their equations in a form that can be used directly to calculate the velocity profile for use in eq (7) yields:

| (8) |

The temperature profile may also be used with a single pressure measurement to determine the neutral plane height, hN, required in eq (8). The neutral plane is obtained by solving for hN in eq (9) [56]:

| (9) |

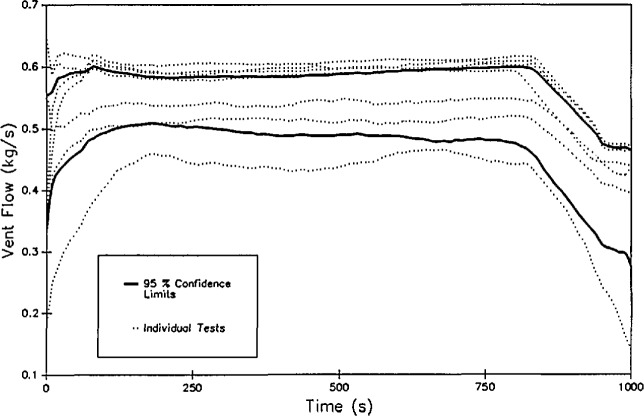

Figure 7 shows the results of such a mass flow calculation for a set of eight replicate experiments. For the same set of experiments, the reproducibility of the mass flow calculation is lower than the layer height and temperature calculations, averaging 35 percent [51]. The reasons for this are at least two-fold. The technique used, as described by Steckler et al. [58] was developed for a single room exhausting into an infinite reservoir of ambient air. An extension of the technique for flow between rooms is available [59]. Since the technique depends upon the temperature gradient across the opening as a function of height, the choice of temperature conditions “outside” the opening may be important. Finally, the technique utilizes temperature changes from the neutral plane to the edges of the opening to calculate the flow. Because the smaller temperature change from the neutral plane is in the lower, cooler region, a small variation in temperature should cause more uncertainty in mass flow than in the upper, hotter region where the temperature gradient is larger.

Figure 7.

An example of mass flow calculated from temperature profiles measured during several tests along with estimated repeatability of the measurement [51].

Figure 8 shows a comparison of the mass flow through a typical doorway calculated from pressure measurements, from temperature measurements, and from velocity measurements made in the doorway for a large-scale room fire test [60]. Comparing the mass flow calculations, it is apparent that the temperature based calculations result in a slightly lower calculated mass flow into a room and correspondingly higher mass flow out of a room than for the pressure-based calculations. This is consistent with the difference in calculated neutral plane height for the two methods. As previously discussed, measurement of flows using commercially available pressure transducers is difficult due to the extremely low pressures involved. Compounding the problem for the measurement of the neutral plane height is the desire to know where the flow changes direction. Thus, the most important measurement points are those with the smallest magnitude, just on either side of the neutral plane. Since the neutral plane calculation from pressure measurements searches for the point of zero pressure from the floor up, the calculated point of zero pressure is consistently low.

Figure 8.

A comparison of calculated mass flow based upon temperature, pressure, and velocity profiles measured during a large-scale fire test [60].

The potential for multiple neutral planes within an opening further complicates the measurement of flow with pressure-based measurements. Jones and Bodart [61] have described an improved fluid transport model with up to three neutral planes within a single opening to incorporate in predictive models (see fig. 9). With potentially different layer boundaries in the two rooms connected to the opening, cross flows are possible between the layers, leading to flow reversals depending upon the relative positions of the two layer boundaries.

Figure 9.

Flow possibilities in a single vent connected to two rooms with different layer boundaries in the rooms [61].

Temperature based measurements have far less dependency on the low flow region of the opening, relying on only one pressure measurement near the bottom (or top) of the opening where the pressure gradient is highest. Thus, for the determination of neutral plane height, the temperature based measurement technique seems preferable.

3.4 Rate of Heat Release

The large-scale measurement which has benefited the most from the emergence of science in large-scale fire testing is the measurement of the rate of heat released by a fire. With few exceptions [62,63], this is calculated by the use of the oxygen consumption principle. If all the exhaust from a room fire test is collected, measurement of temperature, velocity, and oxygen, carbon dioxide, carbon monoxide, and water vapor concentrations in the exhaust collection hood can be used to estimate the rate of energy production of the fire. With these measurements, the total rate of heat release from the room can be determined from [16]:

| (10) |

where

| (11) |

| (12) |

| (13) |

| (14) |

Simplifications are available, with some loss of precision, if concentrations of some of the gas species are not measured [64].

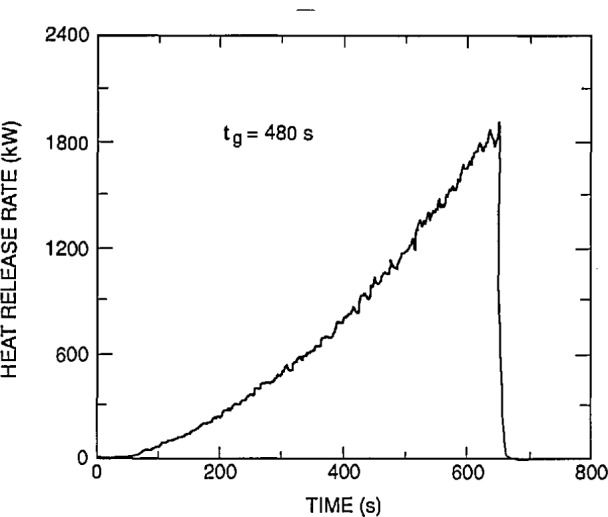

Figure 10 shows an example of calculated heat release rate from several large scale fire tests [65]. Measurement errors in rate of heat release measurements can be higher than in other measurements, especially for smaller fires. In one study [51], coefficients of variation ranged from 4 to 52 percent. With an oxygen depletion for a 100 kW fire of only 0.26 percent, the calculation of heat release rate suffers the same fate as the calculation of mass flows with pressure probes described above, with much of the uncertainty in the heat release calculations attributable to noise in the underlying measurements.

Figure 10.

An example of heat release rate calculated from oxygen consumption calorimetry in several large scale fire tests [65].

This technique has been used extensively in both small- and large-scale testing [25,57,66,67]. Babrauskas [57], for instance, has demonstrated the validity of the measurements in a study of upholstered furniture fires. He provides comparisons between replicate tests in the open and enclosed in a room. He notes precision to within 15 percent for fires of 2.5 MW and consistent comparisons of heat release rate expected from mass loss measurements to those measured by oxygen consumption calorimetry.

4. Criteria Used to Judge the Quality of the Data

In order to take better advantage of the extensive library of large-scale test data presented in this report, a method of qualifying the data for fast identification was devised. This identification included the type of test that was performed (e.g., furniture calorimeter, multiple room, etc.), the major types of materials tested, the kinds of data available (e.g., gas concentrations, mass flow rates, heat release rate, etc.), and a rating of the quality of the data. This information is presented at the beginning of each section describing the data (secs. 5 to 9).

Since the rating of the data will necessarily be somewhat subjective, a simple type of rating system, one with not-too-fine distinctions, should be employed. The ratings used in this report are the following:

− data not available or not valid or of questionable validity;

±data exist but may not be appropriate for comparison to other tests (check test conditions and quality of data); and

+ data should be appropriate for comparisons.

Availability of small-scale and/or individual burning item data is identified, since these are desirable for development of model input data.

5. Single Room with Furniture

This data set describes a series of room fire tests using upholstered furniture items in a room of fixed size but with varying opening sizes and shapes. For the four tests conducted, good agreement was seen in all periods of the room fires, including post-flashover, noting that only fuel-controlled room fires were considered. It was selected for its well characterized and realistic fuel sources in a simple single-room geometry. In addition, the wide variation in opening size should provide challenges for current zone fire models.

5.1 Available Data in the Test Series

Following the subjective ratings discussed in section 4, the following set of ratings were apparent from the examination of the test data:

| heat release rate (of fire, through vents, etc.) | + |

| interface height | + |

| layer temperatures | + |

| wall temperatures (inside and out) | − |

| gas concentrations | + |

| species yields | ± |

| pressure in room | − |

| mass flow rate | ± |

| radiation to the floor | + |

| mass loss | + |

| mass loss rate | + |

| heat of combustion | ± |

In general, the data included in the data set is consistent with the experimental conditions and expected results. Heat release rate, mass loss rate, and species yields are available for all the tests. This should allow straightforward application of most fire models.

5.2 General Description of the Test Series

This data set describes a series of room fire tests using upholstered furniture items for comparison with their free burning behavior, previously determined in a furniture calorimeter. Furniture is most often a hazard, not when burned in the open, but rather inside a room [57]. Room fire data lack generality and often cannot be extrapolated to rooms other than the test room; open burning rates have more useful generality. This work was undertaken in a room of fixed size but with varying opening sizes and shapes, in which furniture specimens identical to those previously tested in the furniture calorimeter would be burned. For the four tests conducted, good agreement was seen in all periods of the room fires, including post-flashover, noting that only fuel-controlled room fires were considered.

The conclusions from this study can be summarized as follows:

The validity of open burning measurements for determining pre-flashover burning rates has been shown for typical upholstered furniture specimens.

Post-flashover burning of these upholstered items was also seen not to be significantly different from the open-burning rate, for fires which are fuel limited. Fires with ventilation control, by definition, show a lower heat release rate within the room.

The typical test arrangement of velocity probes spaced along the centerline of the window opening was found to lead to serious errors in computed mass and heat flows. Data taken in the exhaust system collecting the fire products did provide for satisfactory heat release measurements. A method is still lacking which could adequately separate the outside plume combustion heat from that released within the room itself.

Various relationships for predicting flashover were examined considering the present data. The relationship proposed by Thomas was identified as the most useful, taking into account wall area and properties; however, this relationship may not apply to fires with a very slow build-up rate or for wall materials substantially different from gypsum wallboard.

This program was carried out at the National Institute of Standards and Technology in Gaithersburg, MD in which four experiments were conducted in a single room enclosure; ventilation to the room was provided by window openings of varying sizes. The room was equipped with an instrumented exhaust collection system outside the window opening. The exhaust system could handle fires up to about 7 MW size.

5.3 Test Facility

An experimental room with a window opening in one wall was constructed inside the large-scale fire test facility as shown in figure 11. The dimensions of the room and the window openings for the various tests is given in table 1. The soffit depth of the window opening was the same in all cases (fig. 12). For tests 1 and 2, the opening height (and therefore the ventilation parameter ) only was varied. For test 6, the same was retained but the shape of the opening was changed, compared to test 2. Test 5 resembled test 6, except that the armchair was used. Thus, for specimen type, ventilation factor, and opening aspect ratio, a pair of tests each was provided where these variables were singly varied, the other two being held constant.

Figure 11.

Plan view of experimental room for single room tests with furniture.

Table 1.

Room and vent sizes for one room tests with furniture

| Locationa | Room | Vent | Dimensions (m)b |

|---|---|---|---|

| Room 1 (burn room) | ✓ | 2.26 × 3.94 × 2.31 | |

| Doorway or window, room 1 to ambient | ✓ | 2.0 × 1.13 × 0.31 (test 1) | |

| 2.0 × 1.50 × 0.31 (test 2) | |||

| 1.29 × 2.00 × 0.31 (test 5) | |||

| 1.29 × 2.00 × 0.31 (test 6) |

Notation used for rooms and vents were changed from the original report to be consistent throughout this report.

For rooms, dimensions are width × depth × height. For vents, dimensions are width × height × soffit depth.

Figure 12.

Elevation view of experimental room for single room tests with furniture.

The walls and ceiling materials in the room were 16 mm thick Type X gypsum wallboard, furred out on steel studs and joists. Floor construction was normal weight concrete.

The location of the instrumentation used in these experiments is shown in table 2 and figure 11. Two arrays of thermocouples, each consisting of 15 vertically spaced thermocouples, were installed in the room. The top and bottom thermocouples were at the ceiling and on the floor, respectively. In addition, a load cell for mass loss and a Gardon heat flux meter for measuring radiation to the floor were installed on the centerline of the room. Figure 11 also shows the location where a gas burner was used to check the calibration of the exhaust system; the gas burner was removed before testing furniture specimens.

Table 2.

Location of instrumentation for one room tests with furniture

| Room locationa | Measurement typeb | Positionc |

|---|---|---|

| Room 1 (burn room) | Gas temperature arrays in two positions | 0.17, 0.33, 0.50, 0.66, 0.83, 0.99, 1.16, 1.32,1,49, 1.65, 1.82, 1.98, and 2.15 m |

| Surface temperature in two positions | On floor and ceiling | |

| Heat flux | On floor | |

| Specimen mass loss | ||

| Doorway, room 1 to ambient (burn room doorway) | Gas temperature array | See footnote d |

| Gas concentration, CO, CO2, and O2 | 1.66 and 1.72 m | |

| Gas velocity array (bi-directional velocity probes) | See footnote d | |

| Exhaust hood | Gas temperature array | Nine positions evenly spaeed |

| Gas velocity array | Nine position evenly spaced | |

| Gas concentration, CO, CO2, and O2 | At centerline of hood | |

| Smoke obscuration | At eenterline of hood |

Notation used for rooms and vents were changed from the original report to be consistent throughout this report. For reference, names used in the original report are shown in parentheses.

Notation used for instrumentation was changed from the original report to be consistent throughout this report. For reference, names used in the original report are shown in parentheses.

Distances are measured from floor.

15 locations spaeed evenly from bottom to top of ventc.

For test 1: 0.93, 1.00, 1.08, 1.15, 1.22, 1.29, 1.36, 1.43, 1.50, 1.57, 1.64, 1.72, 1.79, 1.86, and 1.93 m.

For test 2: 0.58, 0.67, 0.77, 0.86, 0.96, 1.05, 1.14, 1.24, 1.33, 1.43, 1.52, 1.61, 1.71, 1.80, and 1.90 m.

For tests 5 and 6: 0.13, 0.25, 0.38, 0.50, 0.63, 0.75, 0.88,1.00, 1.13, 1.25, 1.38, 1.50, 1.63, 1.75, and 1.88 m.

Fifteen closely spaced velocity probes, with companion thermocouples, were located evenly spaced along the vertical centerline to facilitate accurate measurements of mass and heat flow through the opening. Two gas sampling probes were also located along the upper part of the opening center-line.

The exhaust system had an array of velocity probes and thermocouples, together with O2, CO2, and CO measurements to permit heat release to be determined according to the principle of oxygen consumption [13].

5.4 Experimental Conditions

Four of the six tests are listed in table 3. The test furniture included a 28.3 kg armchair (F21) and a similar 40.0 kg love seat (F31). Both were of conventional wood frame construction and used polyurethane foam padding, made to minimum California State flammability requirements, and polyolefin fabric. A single piece of test furniture and the igniting wastebasket were the only combustibles in the test room.

Table 3.

Tests conducted for one room test with furniture

| Test | Chair | Soffit depth (m) | Opening width (m) | Opening height (m) | |

|---|---|---|---|---|---|

| 1 | love seat | 0.31 | 2.0 | 1.13 | 2.43 |

| 2 | love seat | 0.31 | 2.0 | 1.50 | 3.65 |

| 5 | armchair | 0.31 | 1.29 | 2.00 | 3.65 |

| 6 | love seat | 0.31 | 1.29 | 2.00 | 3.65 |

The tests in the furniture calorimeter [68,69] made use of a gas burner simulating a wastebasket fire as the ignition source. Because of practical difficulties in installing that burner in the test room, actual wastebasket ignition was used. This involved a small polyethylene wastebasket filled with 12 polyethylene-coated paper milk cartons. Six cartons were placed upright in the wastebasket, while six were torn into six pieces and dropped inside, The total weight of a wastebasket was 285 g, while the 12 cartons together weighed 390 g, for a total weight of 675 g. The gross heat of combustion was measured to be 46.32 kJ/g for the wastebasket and 20.26 kJ/g for the cartons, representing 21.10 MJ in all. Using an estimated correction, this gives a heat content of 19.7 MJ, based on the net heat of combustion. To characterize this ignition source, it seems appropriate to consider a constant mass loss rate (equivalent to 52.5 kW) for the first 200 s and negligible thereafter.

The test room was conditioned before testing by gas burner fires where the paper facing was burned off the gypsum wallboard and the surface moisture driven off. The room was allowed to cool overnight and between tests.

Initial calibrations with gas burner flows showed adequate agreement, to within 10 to 15 percent, of window inflows and outflows, after an initial transient period of about 30 s. Similarly, during the final, smoldering stages of the furniture fires, a reasonable mass balance was obtained. During peak burning periods in the upholstered furniture tests, such agreement, however, was not obtained.

5.5 Examples of Data from the Test Series

Three examples of the data contained in this data set are shown below:

Concentrations of O2, CO2, and CO in the upper gas layer in the doorway of the room (fig. 13).

Rate of heat release from the four room burns in the test series (fig. 14.).

Rate of mass loss of the burning furniture items for the four room burns in the test series (fig. 15).

In all three of these figures, the consistency of the data set can be seen. In figure 13, the effect of the opening can be seen along with the effect noted above for the heat release rate. For test 1, the O2 concentration drops lower (with a concomitant rise in the CO2 and CO concentrations) than test 3 or test 6 (the three tests with the same furniture item). However, the three peaks are similar in duration with the fourth peak for test 5 lagging slightly behind. In figure 14, three near replicate curves are seen with a fourth curve of lower peak heat release rate. This is consistent with the two different furniture items burned during the tests. In the original work, Babrauskas [57] suggests an uncertainty of ± 330 kW in these heat release rate measurements. Thus, the three love seat tests (tests 1, 2, and 6) can be considered identical. Not surprisingly, the mass loss rate curves shown in figure 15 shows similar results.

Figure 13.

Gas concentrations measured during single room tests with furniture.

Figure 14.

Heat release rate during single room tests with furniture.

Figure 15.

Mass loss rate measured during single room tests with furniture.

6. Single Room with Furniture and Wall Burning

Like the first set, this data set describes a series of single room fire tests using furniture as the fuel source. It expands upon that data set by adding the phenomenon of wall burning in some of the tests. It was chosen for examination because it provides an opportunity 1) to compare burning in the open and in a compartment using the same fuel package, and 2) to compare the effects of non-combustible wall linings versus combustible wall linings in the room [60].

6.1 Available Data in the Test Series

Following the subjective ratings discussed in section 4, the following set of ratings were apparent from the examination of the test data:

| heat release rate (of fire, through vents, etc.) | + |

| interface height | + |

| layer temperatures | + |

| wall temperatures (inside and out) | − |

| gas concentrations | + |

| species yields | ± |

| pressure in room | + |

| mass flow rate | + |

| radiation to the floor | ± |

| mass loss | − |

| mass loss rate | − |

| heat of combustion | − |

A few notes on the ratings are appropriate. Test 5 in the test series seems to be of questionable quality. It is the only test where the mass flow through the doorway does not exhibit a reasonable mass balance, and although a replicate, radically different than test 2. Thus, its quality must be questioned. Although no mass loss rates were obtained during the tests, the burning materials should allow estimation by the method presented by Babrauskas et. al. [70].

6.2 General Description of the Test Series

This data set was chosen for examination because it provides an opportunity 1) to compare burning in the open and in a compartment using the same fuel package, and 2) to compare the effects of non-combustible wall linings versus combustible wall linings in the room [60]. In the former case, the early stages of the fire between the open burns and the room burns are similar; however, it is possible to show how the burning regime changes when influenced by the confines of the room and when the ventilation effects take over. In the latter case, the room wall linings were well-characterized and data are available for estimating heat transfer through the walls. Peak heat release rates as high as 7 MW were measured in these tests.

The relevant conclusions from this study can be summarized as follows:

Room flashover could occur as early as 233 s with a peak heat release rate of over 2 MW; wood paneling in the room increased the peak heat release to 7 MW.

The presence or degree of combustibility of a wall behind the bed did not have a significant effect on the free burn rate nor on the smoke and carbon monoxide generation from the furnishing fires. Differences due to the wall were within the experimental scatter found between repeat runs of each test.

Prior to the ignition of the exposed combustible ceiling surface (paper), the effect of the room on the rate of burning of the furnishings did not appear to be significant. However, subsequent to ceiling surface ignition, noticeable enhancement in the burning rate of furnishings was indicated in all open door room burn tests with one exception.

Much higher concentrations of carbon monoxide occurred inside the room for a well-ventilated fire than those for a closed room fire. Higher carbon monoxide levels occurred at the 1.5 m height than at the 0.30 m height in the room.

Mass flow out of the doorway, calculated using three computational techniques, showed good agreement with each other.

6.3 Test Facility

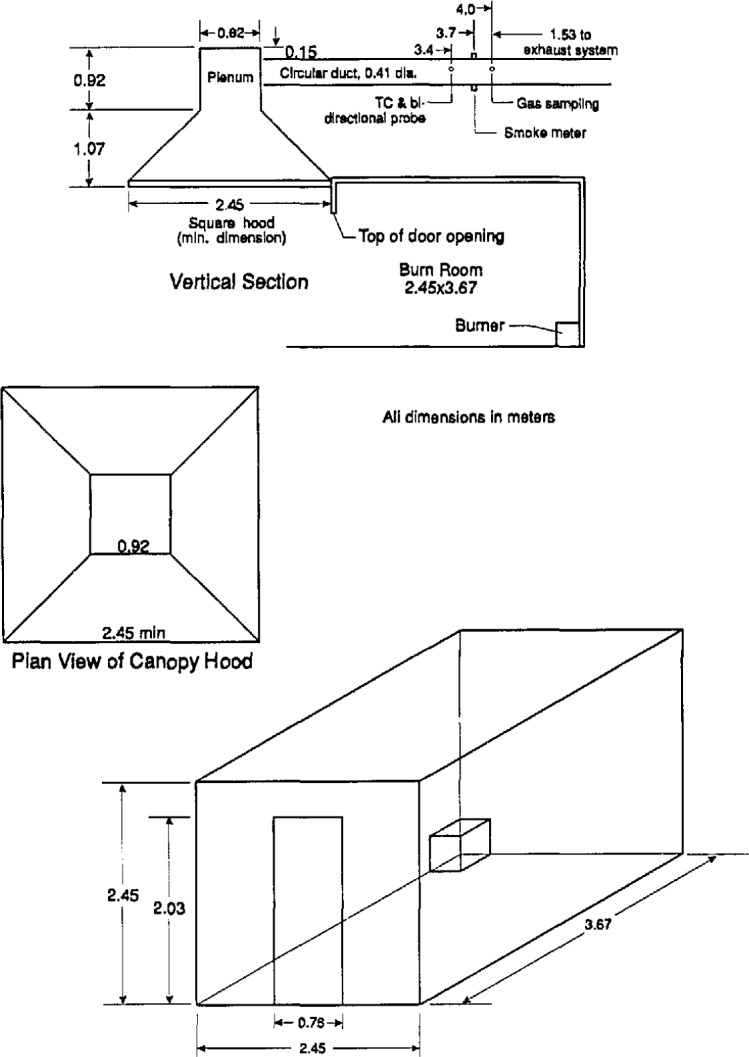

A furnishing arrangement typical of those in the U.S. Park Service (Dept. of the Interior) lodging facilities was evaluated for its burning characteristics and the times for sprinkler activation. Six open fire tests, i.e., unconfined fires in a large open space, and six room fire tests of one bedroom furnishing arrangement were performed. The test room and exhaust hood arrangement is shown in figure 16. The dimensions of the room and doorway are given in table 4. As can be seen, the 2.44 × 3.66 × 2.44 m high test room was located adjacent to the 3.7 × 4.9 m exhaust collector hood which had an exhaust flow capacity of 3 m3/s. In the open burns, the furnishing arrangement was located directly under the hood with the headboard positioned 0.76 m away from the exterior front wall of the room. Two of the open burns had a 2.44 × 2.44 m free standing wall 25.4 mm behind the headboard and in front of the room. This wall was constructed from 12.7 mm gypsum board mounted on 51 × 102 mm steel studs 0.41 m apart. Two other open burns had 6.4 mm plywood lining the same free standing wall. For the room tests, the headboard was located 40 mm away from the back wall. The back and two side walls were 12.7 mm thick gypsum board mounted over 51 × 102 mm steel studs 0.41 m apart. The ceiling was fabricated from 15.9 mm thick fire resistant gypsum board over a sub-layer of 25 mm thick calcium silicate board and was attached to the underside of several steel joists spanning the side walls. The front wall, with a 0.76 × 2.03 m high doorway, was constructed from a single layer of calcium silicate board. Three of the room tests had 6.4 mm plywood over the gypsum board on the two side walls and back wall. In one of the gypsum board lined room tests (test 6), a 0.76 m wide × 2.03 m high and 9.55 mm thick door made from transparent poly(methylmethacrylate) was used for manually closing off the room upon activation of the smoke detector.

Figure 16.

Test room exhaust hood arrangement and instrumentation for single room tests with wall burning.

Table 4.

Room and vent sizes for one room tests with furniture and wall burning

| Locationa | Room | Vent | Dimensions (m)b |

|---|---|---|---|

| Room 1 (burn room) | ✓ | 2.44 × 3.66 × 2.44 | |

| Doorway, room 1 to ambient | ✓ | 0.76 × 2.03 × 0.31 |

Notation used for rooms and vents were changed from the original report to be consistent throughout this report. For reference, names used in the original report are shown in parentheses.

For rooms, dimensions are width × depth × height. For vents, dimensions are width × height × soffit depth.

Measurements were made in the room and doorway to characterize the fire environment and to allow calculation of the mass flow from the room. These measurements included the air temperature and pressure gradients in the room and air temperature and velocity gradients along the doorway centerline. Total incident heat flux to a horizontal target on the floor was monitored along with the thermal radiance to a vertical surface measured at a height of 0.64 m in the room, next to the left wall, facing the wastebasket. In addition, CO and CO2 concentrations were recorded at the 0.30 and 1.5 m heights in the room for test R6. Measurements were also taken in the room to help evaluate sprinkler head and smoke detector responses to the fire environment. Temperatures, velocities, and O2 and CO2 concentrations in the exhaust gases in the stack were monitored to determine the mass flow through the stack and the total rate of heat production by the fire.

An average temperature taken across the inlet of the exhaust collection hood was used together with the mass flow in the stack to estimate hs, the total flux of heat from the fire test room ( minus the heat loss to the room boundaries). The estimated value for the quantity hs is actually equal to hs minus the heat loss to the surroundings between the room doorway and the inlet to the exhaust collection system. Smoke and CO also were monitored in the stack to help quantify the products of combustion from the room fires.

Location of all instrumentation in the room fires is indicated in table 5 and figure 16. Temperatures in the room and doorway were measured with chromel-alumel thermocouples made with 0.05 mm wire. Because these thermocouples were difficult to prepare and were vulnerable to breakage under normal fire test operations, more robust thermocouples fabricated from 0.51 mm chromel-alumel wires also were employed at these same locations. The larger thermocouples were more susceptible to radiation error and were used primarily as backup measurements. Pressures in the room were measured with probes mounted in one corner of the burn room, flush with the interior surface of the front wall, along the height of the room. Bi-directional velocity probes [71] were employed for measuring the air velocity in the doorway and to note the occurrence of any flow reversal along the doorway. Heat flux was monitored with water-cooled total heat flux meters of the Gardon type. Crumpled newspaper on the floor also was used to indicate if and when the irradiance was sufficient to ignite such light combustible materials in the lower half of the room. Non-dispersive infrared analyzers were used to record the concentrations of CO and CO2 in the room and in the stack and oxygen concentration was measured with a paramagnetic type instrument. Stack velocities were measured with pitot-static probes and stack temperatures were monitored with chromel-alumel thermocouples fabricated from 0.51 mm wire. The optical density of the smoke was determined by attenuation of a light beam in the stack. Neutral optical density filters were used to calibrate the light sensor over the range of optical densities from 0.04 to 3.0. At the inlet of the exhaust hood, the average temperature was monitored with a grid of 25 chromel-alumel thermocouples arranged in parallel; each thermocouple was made from 0.51 mm diameter wire.

Table 5.

Location of instrumentation for one room tests with furniture and wall burning

| Room locationa | Measurement typeb | Positionc |

|---|---|---|

| Room 1 (burn room) | Gas temperature arrays (0.51 mm and 0.05 mm thermocouple trees) | Two sets of each 0.20, 0.41, 0.61, 0.81, 1.02, 1.22, 1.42, 1.63, 1.83, 2.03, and 2.24 m |

| Gas temperature | Center of room, 2.34 m | |

| Surface temperature (thermocouple near brass disks) | On three walls, 2.31 m | |

| Gas concentration, CO and CO2 | 0.30 and 1.52 m | |

| Heat flux | On floor and 0.64 m | |

| Doorway, room 1 to ambient (burn room doorway) | Gas temperature arrays (0.51 mm and 0.05 mm thermocouple trees) | Each set 0.10, 0.20, 0.51, 0.81, 1.12, and 1.73 m |

| Differential pressure array (pressure probes) | 0.20, 0.41, 0.61, 0.81, 1.02, 1.22, 1.42, 1.63, 1.83, 2.03, and 2.24 m | |

| Gas velocity array (bi-directional velocity probes) | 0.30, 0.91, 1.22, 1.52, and 1.83 m | |

| Exhaust hood | Gas temperature array | Nine positions evenly spaced |

| Gas velocity array | Nine position evenly spaced | |

| Gas concentration, CO, CO2, and O2 | At centerline of hood | |

| Smoke obscuration | At centerline of hood |

Notation used for rooms and vents were changed from the original report to be consistent throughout this report. For reference, names used in the original report are shown in parentheses.

Notation used for instrumentation was changed from the original report to be consistent throughout this report. For reference, names used in the original report are shown in parentheses.

Distances are measured from floor.

A sprinkler head with an activation temperature of 71 °C and two different size brass disks, used to simulate faster response sprinkler heads, were used in tests 2 to 6. The smaller disk had a diameter of 9.8 mm, was 0.8 mm thick, and weighed 0.5 g; the larger disk had a diameter of 21.6 mm, was 2.4 mm thick, and weighed 7.3 g. Each disk had a 0.51 mm chromel-alumel thermocouple soldered on its surface. Test R1 did not have a sprinkler or brass disk. The sprinkler in test R3 had a discharge rate of 1.4 L/s (22 gal/min), corresponding to an operating water pressure of 103,400 Pa (15 psi). The other room tests used a dry sprinkler where the pipe was pressured with air to 34,500 Pa (5 psi). In addition, two types of ionization smoke detectors were used in test 6.

6.4 Experimental Conditions

These tests are outlined in tables 6 and 7. The standard set of furnishings shown in figure 17 was used for these tests and was based on an inspection of some selected U.S. Park Service lodging facilities at Yosemite National Park in California and at Shenandoah National Park in Virginia. The room furnishings consisted of a 1.37 m wide × 1.91 m long × 0.53 m high double bed, a 2.39 × 0.89 m high headboard, and 0.51 m wide × 0.41 m deep × 0.63 m high night table. Both headboard and night table were fabricated from 12.7 mm thick plywood. The bedding was comprised of two pillows, two pillow cases, two sheets, and one blanket. The pillows had a polypropylene fabric with a polyester filling. The pillow cases and sheets were polyester-cotton. The blanket was acrylic material. The bedding was left in a “slept in” condition which was duplicated to the degree possible in each test. The spring mattress had the same upholstery and padding on the top as on the bottom. The upholstery was a polyester quilted cover. Padding consisted of 6.4 mm polyurethane foam over a fire-retarded cotton felt layer with sub-layers of a cotton felt and a synthetic cellulosic fiber pad. The box spring had a covering of polyester fabric over a layer of cotton felt and a sub-layer of cellulosic fiber pad. Underneath the padding was a wood frame with a steel wire grid on top and a cellulosic cloth cover on the bottom. The combustible weight of each item is given in table 8. The total combustible fire load for this arrangement was 6.0 kg/m2 of floor area. With three walls of the room lined with 6.4 mm plywood, the room fire load came to 14.8 kg/m2 of floor area.

Table 6.

Room fire tests

| Test | Furnishings | Wall materiala | Sprinkler | Test durations | Ambient room conditions

|

|

|---|---|---|---|---|---|---|

| Temperature °C | Relative humidity % | |||||

| R1 | Std. set | 12.7 mm gypsum board | None | 1800 | 23 | 50 |

| R4 | Dry | 1800 | 23 | 56 | ||

| R6 | Dry | 1800 | 23 | 45 | ||

| R2 | 6.4 mm A/D plywood over 12.7 mm gypsum board | Dry | 525 | 23 | 50 | |

| R3 | Wet | 470 | 22 | 52 | ||

| R5 | Dry | 1800 | 24 | 48 | ||

Ceiling material was 15.9 mm fire-resistant gypsum board.

Table 7.

Open burn tests

| Test | Furnishings | Wall behind headboard | Test durations | Ambient room conditions

|

|

|---|---|---|---|---|---|

| Temperature °C | Relative humidity % | ||||

| O4 | Std. set | No wall | 1800 | 22 | 32 |

| O6 | 1800 | 21 | 38 | ||

| O1 | 12.7 mm gypsum board | 1800 | 22 | 50 | |

| O3 | 1800 | 21 | 40 | ||

| O2 | 6.4 mm A/D plywood over gypsum board | 1800 | 22 | 50 | |

| O5 | 1800 | 21 | 38 | ||

Figure 17.

Fire test room arrangement for single room tests with furniture.

Table 8.

Fuel loading in fire tests

| Fuel item | Combustible weight, kg

|

|

|---|---|---|

| Open burns | Room burns | |

| Mattress and box springa | 24.7 | 24.7 |

| Headboard | 14.4 | 14.4 |

| Night table | 10.6 | 10.6 |

| Bedding | 3.2 | 3.2 |

| Filled wastebasket | 0.75 | 0.75 |

| Total combustible furnishings | 53.7 | 53.7 |

| Plywoodb | 19.5 | 77.9 |

Mattress and box spring weight excluding that of the inner springs.

Only used for open burn tests 2 and 5 and for room tests 2, 3, and 5.

In all of the tests, the fire was started with match flame ignition of a 0.34 kg (240 × 140 × 240 mm high) wastebasket, filled with 0.41 kg of trash, positioned adjacent to the night table and against the bed. The type and distribution of the contents is shown in table 9.

Table 9.

Wastebasket ignition source

| Wastebasket—polyethylene wastebasket weight: 0.34 kg |

|---|

| Trash contents, in order of stacking |

| 1 polyethylene liner |

| 16 sheets of newspaper |

| 1 paper cup, 3 oz, crumpled |

| 2 sheets of writing paper |

| 3 paper tissues, crumpled |

| 1 cigarette pack, crumpled |

| 1 milk carton, 8 oz |

| 2 paper cups, crumpled |

| 1 cigarette pack, crumpled |

| 1 sheet of writing paper, crumpled |

| 2 paper tissues, crumpled

|

| Total weight of contents: 0.41 kg |

Duplicate experiments were performed under free-burning conditions (in the open) using three different scenarios: 1) no wall behind the bed, 2) a gypsum wall behind the bed, and 3) a plywood wall behind the bed. In all cases, the same furnishing arrangement and ignition scenario was used.

Three replicate room burns using the same furnishing arrangement and ignition scenario as in the open burns were performed in the room lined with gypsum board and three replicate room burns were carried out in the room lined with plywood. In the latter tests, one fire was extinguished early (167 s) due to sprinkler activation, a second was extinguished after 525 s, and, in the third test, the door to the room was closed after 22 s and reopened after 960 s.

6.5 Examples of Data from the Test Series

Three examples of the data contained in this data set are shown below: