Abstract

Occupational health agencies, researchers and policy makers have recognized the need for evidence on the effectiveness of interventions designed to reduce or prevent workplace injuries and illnesses. While many workplaces comply with legal or obligatory requirements and implement recommended interventions, few publications exist documenting the effectiveness of these actions. Additionally, some workplaces have discovered through their own processes, novel ways to reduce the risk of injury. Peer-reviewed information on the effectiveness of the many strategies and approaches currently in use could help correct weaknesses, or further encourage their adoption and expansion. The evaluation of intervention effectiveness would certainly contribute to improved worker health and safety. This need is particularly relevant regarding noise exposure in the workplace and hearing loss prevention interventions. In a 2006 review of the U.S. National Institute for Occupational Safety and Health (NIOSH) Hearing Loss Research Program, the independent National Academies of Sciences recommended that NIOSH place greater emphasis on identifying the effectiveness of hearing loss prevention measures on the basis of outcomes that are as closely related as possible to reducing noise exposure and work related hearing loss (http://www.nap.edu/openbook.php?record_id=11721). NIOSH used two different approaches to address that recommendation: the first one was to conduct research, including broad systematic reviews on the effectiveness of interventions to prevent occupational noise-induced hearing loss. The second was to create an award program, the Safe-In-Sound Excellence in Hearing Loss Prevention Award™, to identify and honor excellent real-world examples of noise control and other hearing loss prevention practices and innovations.

Keywords: Evidence-based practice, noise control, Buy Quiet, intervention effectiveness, hearing conservation

INTRODUCTION

The auditory risks associated with hazardous noise exposure in the workplace and the need for public health policy, early intervention and preventive programs addressing such risks have been well recognized for decades [1-3]. In several countries industry has also been required to comply with governmental regulatory requirements to control hazardous noise exposures and implement hearing conservation programs [4]. Yet, despite these regulations, evidence shows that hearing conservation programs need to be continuously improved and innovative strategies developed, evaluated, and disseminated [5-7].

Unfortunately, evidence supporting intervention effectiveness can be misinterpreted to be merely the account of a “success story” based on a single example, instead of high quality evidence involving formalized testing through cross-sectional or (better yet) prospective experimental design. While the term “best practice” has become commonplace, for practices to be accepted as best, they must truly be supported by evidence of effectiveness and require a stronger quality and quantity of evidence than a single case study in a specific environment with a specific group of affected workers. In 2010, the US Centers for Disease Control and Prevention (CDC) has issued guidance to address the criteria for, and development of, public health best practice entitled CDC Best Practices Workgroup Definitions, Criteria, and Associated Terms (Version 1.0: September 15, 2010), which provides additional guidance. (http://is.gd/BestPracticesDefinitions). This topic was also covered in the U.S. National Institute for Occupational Safety and Health (NIOSH) 2001 “Guide to Evaluating the Effectiveness of Strategies for Preventing Work Injuries: How to Show Whether a Safety Intervention Really Works” (http://www.cdc.gov/niosh/docs/2001-119/).

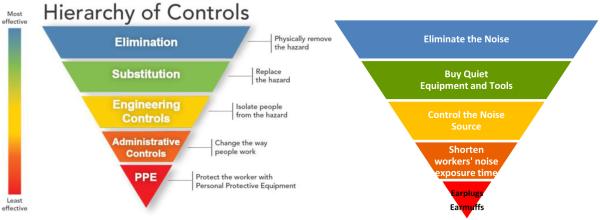

As it pertains to occupational health, NIOSH has encouraged the use of a hierarchy of controls (Figure 1) that prioritizes controlling the source of exposures (primary prevention), as this approach is potentially more effective and protective than those involving personal protective equipment such as earplugs and/or earmuffs (http://www.cdc.gov/niosh/engcontrols/). Following the hierarchy normally leads to the implementation of inherently safer systems, ones where the risk of illness or injury has been substantially reduced. However, regarding noise, published reports on interventions to control the hazard at the source refer primarily to experimental conditions tested in laboratory settings with no mention of field evaluations involving the effect of these conditions on workers’ noise exposure [8-11].

Figure 1.

Hierarchy of controls specific to hearing loss prevention (adapted from http://www.cdc.gov/niosh/topics/noisecontrol/).

Our objective in this paper is to describe two of the approaches NIOSH took to examine the effectiveness of interventions to control noise exposure in the workplace and prevent hearing loss. The first approach was to conduct research, including systematic reviews focused on such interventions, and the second involved encouraging occupational health and safety practice through the creation of an incentive program that makes it attractive for industry personnel to volunteer their success stories by nominating their hearing loss prevention strategies for an award. Each initiative is reviewed in further detail below.

EVALUATION OF THE EFFECTIVENESS OF HEARING CONSERVATION PROGRAM (HCP) COMPONENTS

NIOSH conducted an evaluation of the effectiveness of hearing conservation program (HCP) components by using historical data and a novel metric for calculating historical cumulative exposures [12]. Audiometric and work-history databases were used in this retrospective cohort study, combined with historical noise monitoring data to develop a time-dependent exposure matrix for each plant. Historical changes in production and HCP implementation were collected through structured audits of company records, supplemented with employee interviews and focus groups. This information was used to develop time-dependent quality assessments for various HCP components. Female workers tended to have less noise-induced hearing loss (NIHL) at given exposure levels than males. Duration of noise exposure stratified by intensity (in dBA) was found to be a better predictor of NIHL than the standard equivalent continuous noise level (Leq) based upon a 3-dBA exchange. The reported enforced use of hearing protection devices was shown to significantly reduce NIHL. The data did not have sufficient within-plant variation to determine the effectiveness of noise monitoring or worker training [12].

SYSTEMATIC REVIEWS ON THE EFFECTIVENESS OF INTERVENTIONS TO PREVENT NOISE-INDUCED HEARING LOSS

The term “systematic” review implies a well-defined, rigorous approach which requires a clearly defined question, identification of relevant studies, assessment of study quality, and synthesis of evidence through an explicit methodology designed to minimize bias [13]. Modern systematic reviews make use of evaluation tools to appraise the quality of included studies and assess the strength of inferences drawn from them [14]. Quality is assessed across multiple domains, including risk of bias (study limitations from an internal validity perspective), precision (sample size, effect size), consistency (direction and magnitude of effect), and generalizability [15, 16].

NIOSH holds a seat on the advisory and editorial boards of the Cochrane Work. This group is one of the many entities that make up the Cochrane Collaboration. The Cochrane Collaboration produces high quality systematic reviews about the effectiveness of health interventions. The Cochrane Collaboration is a not-for-profit organization with collaborators from over 120 countries working to produce credible, accessible health information that is free from commercial sponsorship and other conflicts of interest. Cochrane systematic reviews try to help with the decision-making process by synthesizing the results of multiple studies. Cochrane systematic reviews seek answers to the most basic question: “does this intervention work?” In recent years a couple of Cochrane reviews examined 1) interventions to promote the use of hearing protectors [17] and 2) other interventions to control noise and promote hearing loss prevention [8].

Systematic review on interventions to promote the use of hearing protection

The most common attempt to reduce noise happens through the distribution of hearing protectors, despite the general acceptance that noise reduction strategies in the workplace is the preferable intervention for the prevention of noise-induced hearing loss. The effectiveness of interventions to promote the use of hearing protectors has been examined in a 2012 Cochrane Review [17]. Studies were included in this review if they had a randomized design, if they included an intervention to promote the wearing of hearing protection (compared to another intervention or no intervention), among noise exposed (> 80 dBA) persons, and if the outcome measured was the amount of wear time use of hearing protection or a proxy measure thereof. Interventions including computer-based interventions tailored to the risk of an individual worker, a video providing general hearing loss prevention information, a four-year school-based hearing loss prevention program, and ‘mixed’ interventions (classroom instruction, distribution of hearing protective devices or HPDs, mailings, noise level assessments and audiometric testing) were compared. A computer-based intervention tailored to the risk of an individual worker, was not found to be more effective than a video providing general information among workers. A four-year school-based hearing loss prevention program found that the intervention group was twice as likely to wear some kind of hearing protection as the control group that received a baseline hearing test and two additional tests at years two and three. Two meta-analyses were performed for the comparisons tailored strategy (the use of communication or other types of interventions that are specific to an individual or a group and aim to change behavior) versus non-tailored strategy and tailored strategy versus a commercial video on the use of hearing protection to look at mean percentage use of HPDs. An improvement in the mean use of HPDs was reported for the tailored group. A meta-analysis of the comparison mixed interventions versus control showed improvement in self-reported use of HPDs when shooting firearms (for more details see El Dib et al. [17]).

Systematic review on interventions to prevent occupational noise-induced hearing loss

A Cochrane Review with a broader scope also examined the effectiveness of various interventions to prevent occupational noise-induced hearing loss [8]. It evaluated a set of interventions or specific components of hearing loss prevention programs. Interventions consisting of one or more of the following elements were included:

Engineering controls: reducing or eliminating the source of the noise, changing materials, processes or workplace layout;

Administrative controls: changing work practices, management policies or worker behavior;

Personal noise protection devices;

Hearing surveillance: monitoring the hearing levels of exposed workers. Clinical interventions such as the use of anti-oxidants, magnesium or other compounds were excluded.

Regrettably, the review found no field studies that evaluated the effect of engineering controls for decreasing noise levels, except for one study that indirectly measured the effect of legislation on the decrease of noise levels in the US mining industry [8]. Evidence of long-term evaluation studies of the individual components of a Hearing Loss Prevention Program (HLPP) showed that the use of hearing protection devices in well-implemented HLPP was associated with less hearing loss. The studies that evaluated earmuffs versus earplugs also showed that, in high noise levels, earmuffs probably perform better than earplugs and vice versa for low noise levels. Success was not demonstrated for other elements of HLPPs such as worker training, audiometry alone or noise exposure monitoring. More individual information on daily noise exposure as part of a HLPP showed favorable but non-significant effects both for hearing loss and for daily noise-exposure levels. When noise-exposed workers are compared to non-exposed workers in long-term follow-up there was very low quality evidence that participation in a typical HLPP does not reduce the risk of hearing loss to below a level at least equivalent to that of workers who are exposed to 85 dBA. The mean hearing loss for an 85 dBA exposure would be about 4.2 dB which is still within the 95% confidence interval reported in the review [1, 18, 19]. In addition, two other studies that could not be combined in the meta-analysis still found considerable risks of hearing loss in spite of participants being covered by a HLPP. While better use of available data for retrospective cohort studies is needed, the current results reinforce the argument that technical measures to control exposure should be the focus of hearing loss prevention interventions at work. Publications are needed reporting the reduction in personal noise doses received by workers following noise control efforts. Better implementation and reinforcement of the law could be effective in better implementing technical measures for reducing noise levels [8].

INCENTIVE PROGRAMS

In the environmental and occupational health arenas, recognition of benchmarks, awards, and incentive schemes are receiving increasing attention for their role in promoting excellence and adoption of preventive interventions [20-27]. In Taiwan, after 10 years of the creation of a voluntary compliance program for occupational health, dramatic reductions in occupational injuries and illness were observed in the worksites granted certification. In comparison with all industries, the certified sites had a 49% lower frequency of injury rate during the past 3 years. The severity rate reduction was 80% during the same period [28]. Some of the Australian occupational health and safety jurisdictions have award or incentive schemes for general occupational safety and health [29-30]. Some provide incentives for interventions that include the control of noise or chemical exposures [30-33] or other initiatives to improve occupational health [34], while another program recognizes efforts for the control of environmental noise [35].

Safe-in-Sound Excellence in Hearing Loss Prevention Award™

In 2007, the National Institute for Occupational Safety and Health (NIOSH) partnered with the National Hearing Conservation Association (NHCA) to create the Safe-in-Sound Award™ for Excellence and Innovation in Hearing Loss Prevention (www.safeinsound.us). The objectives of this award program are to recognize effective and innovative initiatives, and to share leading edge information to a broader community. The Safe-in-Sound Award™ implements a rigorous systematic applicant review process to capture and evaluate the successes and lessons learned from examples of excellence in hearing loss prevention programs. Since 2009, awards are presented annually at the NHCA annual conference by the NIOSH director or his or her representative. Current and past award winners can be reviewed at http://www.safeinsound.us/winners.html. Safe-in-Sound Award™ winner values and characteristics were summarized previously [36].

Despite the challenges of confidentiality, trade secrets and legal constraints that may inhibit the publication of noise control efforts even within the Safe-in-Sound Award program, the award process has resulted in the acquisition of high quality field data related to noise exposure monitoring and successful noise control outcomes. These interventions led to the elimination of the need for a HLPP or in the reduction of number of workers enrolled in the program due to reduced noise exposures. In an effort to more widely disseminate the practicality, feasibility, and significant individual worker impacts of noise control in the workplace, a few strategies and examples of outcomes have been selected to share in this Special Issue.

Real-world Examples of Effective Interventions in Noise Control and Hearing Loss Prevention

Noise control has emerged as a cost-effective primary preventive strategy implemented by several of the award recipients. Successes have also been demonstrated by using “Buy-Quiet” and “Quiet-by-Design” initiatives. These are programs guiding purchasers to compare the noise emission levels of different models of equipment, and whenever possible, select the quieter model. Some examples are summarized next.

A. Manufacturing Industry

3M facilities in Alexandria, MN (2016 recipient) and Hutchinson, MN (2012 recipient)

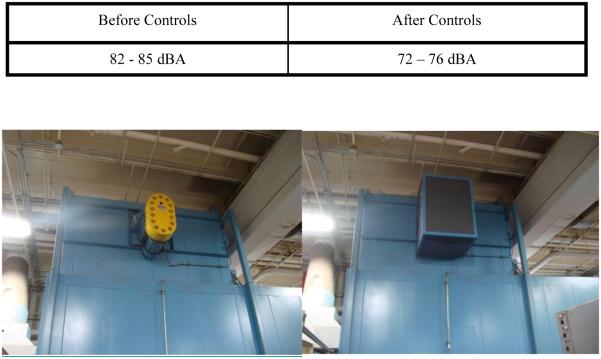

3M has 180 plant locations worldwide which produce over 50,000 products. Two of these plants received the award on two different occasions: the Hutchinson Plant, which manufactures a range of pressure sensitive adhesive tapes, micro abrasives, and coated and uncoated plastic films; and the Alexandria MN plant which produces a variety of these industrial abrasives products. Both facilities were recognized for their strongly integrated approach to worker hearing health including statistically driven noise exposure assessments, implementation of a Buy-Quiet program, and noise control for existing equipment. Their interventions started by identifying the areas with the highest risk as a starting point for assessment, control and ultimately the reduction of noise sources. Of the original 203 employees from the 3M Alexandria Hearing Conservation Program, 199 did not need to remain enrolled due to the reduction in noise levels to below 85 dBA time-weighted average (TWA) across 24 different areas of the facility. The plant also reported a noticeable culture shift in the way employees and engineers approached noise related issues. Employees continue to use hearing protection in off-the-job functions, and are diligent in bringing concerns of excessive noise to the Environmental Health and Safety department. Engineering has also shown change, as they now require any new equipment being brought into the facility to be engineered below 78-79 dBA. Regarding cost, they were able to remove 11 of the 24 areas from hearing conservation program at zero cost (by improving the noise assessment, involving in-house personnel in the interventions, and by using existing materials). Many of the controls implemented in these areas were simple changes to existing processes, and included but were not limited to reconditioning brakes, reduction of air pressures, installation of vibration dampening pads, and planned equipment relocations. The cost of noise control to provide sufficient noise exposure reductions for removal of employees from the HLPP for the other 13 areas was approximately $250,000, well below the original budget of $500,000. See Figure 2:

Figure 2.

Noise control: Drum slitting and disc converting

Controls Implemented: Acoustical enclosures installed around blower motors

Direct Costs: $600

In addition, the 3M Hutchinson Plant was recognized for comprehensive implementation of hearing protection fit-testing of all plant personnel, availability of both general and specialty hearing protection devices for off-the-job noise exposures (e.g. hunting and target shooting), high quality audiometric testing with professional supervision and evidence of strong support from corporate management, plant management and individual workers. This 3M program was tailored for individualized training and development of a culture of personal responsibility to maintain noise controls, identify noise hazards and properly fit and utilize hearing protectors throughout the facility.

United Technologies Corporation (2015 Recipient)

United Technologies Corporation (UTC) is a global company with over 210,000 employees from 46 states and 186 countries. UTC was recognized for including in its current sustainability goals “to reduce employee exposure to noise and chemicals to levels so safe that wearing personal protective equipment is no longer mandatory….” and for the subsequent multi-level strategies used to support the diverse companies within the corporation to fulfill that goal. Their approach includes corporation-wide interventions such as: reduction of sound levels below an 85-dBA limit for 8-hour noise exposures; adoption of inclusive criteria in their comprehensive hearing loss prevention program; completion of multiple noise-control studies throughout each business unit to identify all noise sources affecting worker exposure; documentation of cost and noise reduction results; and the adoption of Buy-Quiet policies and practices. Employees at all levels of the corporation are engaged in the initiatives and each individually contributes to these noteworthy accomplishments.

Vulcan Materials Company (2013 recipient)

Vulcan Materials Company (VMC) is a major producer of construction aggregates; primarily crushed stone, sand and gravel. VMC was recognized for their commitment and implementation of a quality data-driven HLPP that extends beyond simple regulatory compliance. VMC’s effort is especially noteworthy when one considers the diverse and ever-changing and challenging work environments that are characteristic of this industry. VMC provides extensive noise measurement and control training and re-training for select employees to function as industrial hygiene support staff. VMC has embraced innovative and cost-effective noise measurement and control strategies. Examples are illustrated in Figure 4.

Figure 4.

Examples of the different types of noise control developed by the Vulcan Materials Company: a) climate-controlled work booth; b) climate-controlled enclosed cab; and c) cameras used to reduce the need for employees to position themselves in noisy areas while conducting visual inspections of equipment operation, as seen in the Safe-in-Sound presentation; see http://www.safeinsound.us/swf/VM/index.html.

VMC’s is also leading the advancements in noise monitoring strategies for mobile workers by integrating sophisticated technologies such as GPS, and video into their noise measurement protocols. These novel approaches could benefit other industries in the future and contribute to the goal of eliminating occupational noise-induced hearing loss; see http://www.safeinsound.us/swf/VM/index.html.

Other examples of successful noise control projects from the manufacturing industry were provided by the 2013 recipient Johns Manville, 2011 recipient Shaw Industries Group, Fibers Division, Plant WM, GA and 2009 recipient Domtar Paper Company, Kingsport Mill, TN. Their accomplishments are also detailed at http://www.safeinsound.us/archive.html.

B. Construction Industry

Bechtel National Inc., BSII, Waste Treatment & Immobilization Plant Project (Richland, WA). (2012 recipient)

The Hanford Waste Treatment and Immobilization Plant (WTP) is the world’s largest radioactive waste treatment plant. It is being designed, constructed, and commissioned by Bechtel National, Inc. They have developed innovative strategies to address industry specific challenges in the areas of noise monitoring, noise risk evaluation and noise risk communication. They have adopted the NIOSH-recommended exposure limit of 85 dBA with the 3 dB exchange rate, promoted the active involvement of the workforce in their efforts, and encouraged the adoption of their strategies by other Bechtel sites. All noise sources (tools, stationery equipment and mobile equipment) were compiled into an Inventory of Noise Sources with noise levels and distances from the sources that would constitute a Hearing Protection-Required area. The NIOSH Power Tool database (http://wwwn.cdc.gov/niosh-sound-vibration/) was also used to complete their inventory. Engineering controls were put in place for stationery equipment and workshops, while portable noise absorbing curtains were made available for workers as needed. Details of their award-winning strategies can be seen at http://www.safeinsound.us/swf/Bechtel/index.html.

In summary, the Safe-in-Sound Award™ serves to highlight the real world accomplishments of awardees and remind a larger public audience of the importance of these efforts. Several of the winning approaches are readily adaptable to diverse industries. A large cross-section of workers could benefit if similar noise control efforts are implemented. The Award application itself may be a catalyst for stimulating a program evaluation from a new perspective of… “what are we doing right” and “what might we be missing.”

Until now, the award has been presented exclusively to large organizations, which is not unexpected, given the greater availability of resources. However, the rationale behind this initiative is that by disseminating evidence-based strategies Safe-in-Sound™ will enable other groups to effectively advance hearing loss prevention practice. It is encouraging to note that many of characteristics and strategies adopted by the award recipients are easily transferable to other industries, organizations and worksites. Many surprisingly simple and easy to implement noise control approaches have been identified. Noise control has emerged as a cost-effective primary preventive strategy implemented by several of the award recipients. While some key elements and strategies are not new ideas, they are unique in how extensively they are implemented and valued, and how integrated they are at different organizational levels. Perhaps the real value of this award program is to change the perception that noise control is not feasible, practical or desirable.

Winning organizations/employers reported that the Safe-in-Sound Award™ provided leverage and opportunities to expand the reach of their current approaches; pilot programs have been adopted by other entities or in other geographical regions (http://www.safeinsound.us/impact.html). Winners indicated having received greater administrative/managerial support with additional resources allocated to their hearing loss prevention efforts. New strategies are spreading corporate-wide and professional/government organizations are discussing new policies, guidelines and/or procedures.

Since the developmental phase of the Safe-in-Sound Award, we were confronted by the question of “How this award could be evaluated in the short and long term?” or “How can one tell whether it is making progress towards its goal?” As we discussed under Incentive Programs (above), currently, there are few examples in terms of research to guide the evaluation of health and safety award program effectiveness (20-22, 25). The Safe-in-Sound™ web site traffic gives us some short term indications of growing interest in the award program and in the profiles of the award winning strategies. Another objective measure of the interest generated by the award is provided by the quantity and quality of nominations to the award. Multiple quality nominations have been received since its creation. But perhaps, a more relevant marker of impact is the citations of project work by others. Such citations indicate that there was considerable uptake of the deliverables of this project. Examples include: Safe-in-Sound highlighted by NIOSH and former award recipients at Reducing Employee Noise Exposure in Manufacturing—Best Practices, Innovative Techniques, and the Workplace of the Future Workshop (a follow-up to the 2010 NAE Technology for a Quieter America (TQA) Report). It was organized by the Institute for Noise Control Engineering and NIOSH, and hosted by the National Academy of Engineering on February 19-20, 2014. A report is to be published by the NAE. Safe-in-Sound is highlighted in OSHA’s August 2013 OSHA Technical Manual (OTM), Section III: Chapter 5 – Noise (APPENDIX G—ALTERNATIVES FOR EVALUATING BENEFITS AND COSTS OF NOISE CONTROL). The chapter provides technical information and guidance to help Compliance Safety and Health Officers (CSHOs) evaluate noise hazards in the workplace. https://www.osha.gov/dts/osta/otm/new_noise/appendixg.pdf.

The Safe-in-Sound Award™ establishes credibility, especially for those award winners who stretch traditional boundaries with novel or unique approaches. Rather than the award serving to only recognize those that have reached a pinnacle of achievement, it actually motivates the award winners to continue to sustain the efforts and to also pursue additional program improvements and to reach higher goals. Personal commitments are renewed, re-dedicated and re-energized. In addition, the award has facilitated the extension of successful hearing loss prevention activities and strategies toward workers that are not traditionally considered in typical workplace HLPPs (e.g. musicians, hunters, military personnel). Input to the website and the award program can be sent to info@safeinsound.us or to the Twitter account @SafeinSoundUS. Perhaps these successes will encourage other noise researchers or groups to report on effective noise controls as measured in the field, consider applying for the award, and perhaps adopt the use of awards and other incentive systems to motivate effective hearing loss prevention actions.

CONCLUSION

Hearing Loss Prevention Programs or Hearing Conservation Programs in the workplace include a broad range of interventions, which can hinder the evaluation of the impact of such programs. Still, a few studies and systematic reviews can be found on the effect of specific components of a hearing loss prevention programs on the outcome “hearing loss”, despite the fact that there is some debate on how to best characterize noise-induced hearing loss. In contrast, it can be very obvious with regard to documenting a reduction in the outcome “noise exposure level”. Yet, no scientific studies documenting the evaluation of engineering controls for decreasing occupational noise exposures can be found to date. For this reason, the use of an incentive program in the form of an award was created in the US, and the results were summarized above.

If like us, you are searching for effectiveness in noise control and hearing loss prevention, a word of caution: if you ask experts for advice, ask for evidence that their recommendations are effective–AND- consider the quality of the evidence supporting their recommendations.

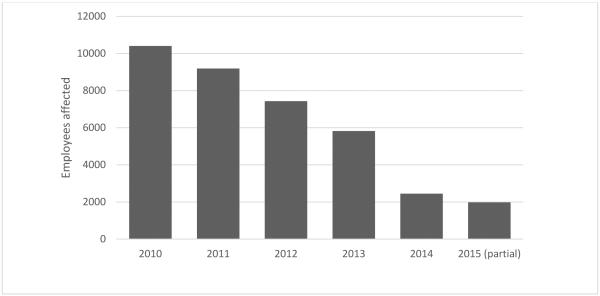

Figure 3.

Number of employees exposed to >85 dBA TWA as a result of the implementation of noise control projects across the United Technologies Corporation.

Footnotes

DISCLAIMER

Mention of any company or product does not constitute endorsement by the Centers for Disease Control and Prevention (CDC), National Institute for Occupational Safety and Health (NIOSH). The findings and conclusions in this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

REFERENCES

- 1.International Standard Organisation . ISO 1999: Acoustics - Determination of occupational noise exposure and estimation of noise-induced hearing impairment. ISO; Geneva: 1990. [Google Scholar]

- 2.World Health Organization . Report of the First Informal Consultation on Future Programme Developments for the Prevention of Deafness and Hearing Impairment. World Health Organization; Geneva: 1997. [Google Scholar]

- 3.Nelson DI, Nelson RY, Concha-Barrientos M, Fingerhut M. The global burden of occupational noise-induced hearing loss. Am J Ind Med. 2005;48:446–58. doi: 10.1002/ajim.20223. [DOI] [PubMed] [Google Scholar]

- 4.Suter AH. Development of standards and regulations for occupational noise. In: Crocker MJ, editor. Handbook of Noise and Vibration Control. John Wiley and Sons; New York: 2007. pp. 377–82. [Google Scholar]

- 5.Fausti SA, Wilmington DJ, Helt PV, Helt WJ, Konrad-Martin D. Hearing health and care: The need for improved hearing loss prevention and hearing conservation practices. J. Rehab. Res. & Dev. 2005;42(S2):45–62. doi: 10.1682/jrrd.2005.02.0039. [DOI] [PubMed] [Google Scholar]

- 6.Daniell WE, Swan SS, McDaniel MM, Camp JE, Cohen MA, et al. Noise exposure and hearing loss prevention programmes after 20 years of regulations in the United States. Occup. Environ. Med. 2006;63:343–351. doi: 10.1136/oem.2005.024588. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Davies H, Marion S, Teschke K. The impact of hearing conservation programs on incidence of noise-induced hearing loss in Canadian workers. Am J Ind Med. 2008;51:923–31. doi: 10.1002/ajim.20634. doi: 10.1002/ajim.20634. [DOI] [PubMed] [Google Scholar]

- 8.Verbeek JH, Kateman E, Morata TC, Dreschler WA, Mischke C. Interventions to prevent occupational noise-induced hearing loss. Cochrane Database Syst. Rev. 2012 Oct 17;10:CD006396. doi: 10.1002/14651858.CD006396.pub3. [DOI] [PubMed] [Google Scholar]

- 9.Suter AH. The hearing conservation amendment: 25 years later. Noise & Health. 2009;11:2–7. doi: 10.4103/1463-1741.45306. [DOI] [PubMed] [Google Scholar]

- 10.Trabeau M, Neitzel R, Meischke H, Daniel WE, Seixas NS. A comparison of "Train-the-Trainer" and expert training modalities for hearing protection use in construction. Am. J. Ind. Med. 2008;51:130–7. doi: 10.1002/ajim.20499. [DOI] [PubMed] [Google Scholar]

- 11.Caporali Filho SA, Niezen C, Pérez F, de Visscher S. Economically feasible noise exposure reduction in an oral hygiene products manufacturing plant. Braz. Occup. Hyg. Assoc. J. 2007;6:12–18. [Google Scholar]

- 12.Heyer N, Morata TC, Pinkerton LE, Brueck SE, Stancescu D, Panaccio MP, Kim H, Sinclair JS, Waters MA, Estill CF, Franks JR. Use of historical data and a novel metric in the evaluation of the effectiveness of hearing conservation program components. Occup Environ Med. Jul. 2011;68:510–7. doi: 10.1136/oem.2009.053801. doi: 10.1136/oem.2009.053801. Epub 2010 Nov 7. [DOI] [PubMed] [Google Scholar]

- 13.Khan KS, Kunz R, Kleijnen J, Antes G. Five steps to conducting a systematic review. J R Soc Med. 2003;96:118–121. doi: 10.1258/jrsm.96.3.118. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Higgins JPT, Green S, editors. Cochrane Handbook for Systematic Reviews of Interventions Version 5.1.0 [updated March 2011] The Cochrane Collaboration; 2011. 2011. http://www.cochrane-handbook.org. Accessed 17 September 2015. [Google Scholar]

- 15.Agency for Healthcare Research and Quality (AHRQ) Evidence Report/Technology Assessment No. 47, Systems to Rate the Strength of Scientific Evidence. 2002 http://archive.ahrq.gov/clinic/epcsums/strengthsum.pdf Accessed 24 September 2015.

- 16.Institute of Medicine . IOM Standards for Systematic Reviews. The National Academies Press, Institute of Medicine; Washington, DC: 2011. http://www.iom.edu/Reports/2011/Finding-What-Works-in-Health-Care-Standards-for-Systematic-Reviews/Standards.aspx. Accessed 17 September 2015. [Google Scholar]

- 17.El Dib RP, Mathew JL, Martins RHG. Interventions to promote the wearing of hearing protection. Cochrane Database of Syst. Rev. 2012 doi: 10.1002/14651858.CD005234.pub5. doi:10.1002/14651858.CD005234.pub5. [DOI] [PubMed] [Google Scholar]

- 18.Hozo S, Djulbegovic B, Hozo I. Estimating the mean and variance from the median, range and the size of a sample. BMC Med. Res. Method. 2005;5:13–13. doi: 10.1186/1471-2288-5-13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Piaggio G, Elbourne DR, Altman DG, Pocock SJ, Evans SJW. Reporting of non-inferiority and equivalence randomised trials. JAMA. 2006;295:1152–1160. doi: 10.1001/jama.295.10.1152. [DOI] [PubMed] [Google Scholar]

- 20.Tait R, Walker D. Motivating the workforce the value of external health and safety awards. J Safety Research. 2000;31:243–251. [Google Scholar]

- 21.McAfee RB, Winn AR. The use of incentives/feedback to enhance work place safety: a critique of the literature. J Safety Res. 1989;20:7–19. [Google Scholar]

- 22.Hertz HS, Reimann CW, Bostwick MC. The Malcolm Baldrige National Quality Award concept: could it help stimulate or accelerate health care quality improvement? Qual Manag Health Care. 1994;2:63–72. [PubMed] [Google Scholar]

- 23.Noble J. The Codman competition: Rewarding excellence in performance measurement. Jt Comm J Qual Patient Saf. 2006;32:634–40. doi: 10.1016/s1553-7250(06)32082-x. [DOI] [PubMed] [Google Scholar]

- 24.Scott SD, Bertsche PK. OSHA's voluntary protection programs. The benefits to occupational health nurses and their companies. AAOHN J. 1991;39:219–24. [PubMed] [Google Scholar]

- 25.United States General Accounting Office Workplace Safety and Health 2004:10–34. http://www.gao.gov/new.items/d04378.pdf Accessed 10 September 2015.

- 26.Singapore Government. Workplace Safety and Health Council Workplace Safety and Health Awards. 2015 http://www.wshc.sg Accessed 06 November 2015.

- 27.Singapore Ministry of Manpower http://www.mom.gov.sg/workplace-safety-and-health/incentives-for-implementing-control-measures Accessed 06 November 2015.

- 28.Su TS, Tsai WY, Yu YC. An integrated approach for improving occupational health and safety management: the voluntary protection program in Taiwan. J Occup Health. 2005;47:270–6. doi: 10.1539/joh.47.270. [DOI] [PubMed] [Google Scholar]

- 29.WorkCover New South Wales WorkCover New South Wales Awards. New South Wales Government; http://www.safeworkawards.com.au. Accessed 6 November 2015. [Google Scholar]

- 30.Safe Work Australia . Work health and safety awards. Commonwealth of Australia; Canberra: http://www.safeworkaustralia.gov.au/sites/swa/media-events/awards/pages/awards Accessed 29 December 2015. [Google Scholar]

- 31.Institute of Noise Control Engineering INCE Honors and Awards. http://www.inceusa.org/about/awards.

- 32.Deutsches Institut für Gütesicherung und Kennzeichnung. Der Blaue Engel (The Blue Angel) https://www.blauer-engel.de/en Accessed 6 November 2015.

- 33.Worksafe Victoria . Worksafe Victoria Awards. Melbourne: http://worksafeawards.worksafe.vic.gov.au/ Accessed 6 November 2015. [Google Scholar]

- 34.European Agency for Safety and Health at Work. Awards https://osha.europa.eu/en/healthy-workplaces-campaigns/awards Accessed 6 November 2015.

- 35.Conseil National du Bruit, les Décibels d’Or. http://www.bruit.fr/concours-des-decibels-d-or-le-palmares-2014.html Accessed 6 November 2015.

- 36.Meinke DK, Morata TC. Awarding and promoting excellence in hearing loss prevention. Int. J. Audiol. 2012;51(S1):63–70. doi: 10.3109/14992027.2011.633569. [DOI] [PMC free article] [PubMed] [Google Scholar]