Abstract

In 1966, Pohl and Hawk [Science 152, 647–649 (1966)] published the first demonstration of dielectrophoresis of living and dead yeast cells; their paper described how the different ways in which the cells responded to an applied nonuniform electric field could form the basis of a cell separation method. Fifty years later, the field of dielectrophoretic (DEP) cell separation has expanded, with myriad demonstrations of its ability to sort cells on the basis of differences in electrical properties without the need for chemical labelling. As DEP separation enters its second half-century, new approaches are being found to move the technique from laboratory prototypes to functional commercial devices; to gain widespread acceptance beyond the DEP community, it will be necessary to develop ways of separating cells with throughputs, purities, and cell recovery comparable to gold-standard techniques in life sciences, such as fluorescence- and magnetically activated cell sorting. In this paper, the history of DEP separation is charted, from a description of the work leading up to the first paper, to the current dual approaches of electrode-based and electrodeless DEP separation, and the path to future acceptance outside the DEP mainstream is considered.

INTRODUCTION

Modern biomedicine depends on the process of separating and isolating subpopulations of cells from a heterogeneous group. Be it for the identification of white blood cells for counting, or the isolation of circulating tumour cells, or the identification of stem cells of potential therapeutic use from an undifferentiated cell mass, the ability to select a single cell type and collect it is a key tool in the modern cell biologist's armoury. At present, three methods of cell separation dominate. The simplest uses differences in density to fraction cells, most commonly nucleated white blood cells from anucleated red blood cells. The remaining two methods use more complex approaches; fluorescence activated cell sorting (FACS) uses fluorescent labels which bind to molecules within the cells of interest. Cells are then fired in droplets small enough to contain a single cell; each droplet is interrogated with a laser, and those droplets containing the fluorescent agent are subject to an electric field which guides them to a receptacle, where they are collected. Those not containing the agent continue to a waste outlet. A third separation technique is magnetism-activated cell sorting (MACS). Here, magnetic beads are covered in antibodies raised to an antigen present only on the cells of interest within the heterogeneous population. Cells and beads are mixed; the cells of interest bind to the beads, and are retrieved by applying a magnetic field. However, all three methods have drawbacks. Whilst inexpensive, density methods lack specificity—there are few instances where cells differ in density to a significant amount. Both FACS and MACS rely on the use of expensive antibodies, and in the case of FACS, expensive equipment to perform the separation. Specificity is high, and throughput is typically 20–30 000 cells per second, with maximum cell numbers typically reaching low multiples of 107. However, cell losses are significant—typically over half the cells input to the system will be lost. There is hence a need for an alternative method of separation—one which, like the density method, relies on the intrinsic properties of the cell rather than the use of expensive labels which can limit the usefulness of cells, or can affect their function. Furthermore, such a method would ideally be able to discriminate between cell populations that the other methods cannot—for example, separating them on the basis of ion concentration in the cytoplasm, or the capacitance of the membrane. One such method is dielectrophoresis (DEP).

DEP1 is the name given to the phenomenon of induced motion in a suspended particle due to its interaction with an applied nonuniform electric field. The motion occurs along the direction of increasing field gradient, but may point towards the point of highest electric field (termed positive DEP), or may be a repulsion from the highest field point (termed negative DEP). Where the particle experiences positive or negative DEP depends on whether it is more or less polarisable than the suspending medium at a given frequency of energising electric field. Where a mix of particles is present, a range of frequencies may exist where one population experiences positive DEP, whilst another experiences negative DEP, causing them to locate in different places—one at the electrodes, the other removed from them. Hence, the populations are separated by DEP. The phenomenon was first applied to suspensions of inorganic particles, but in 1966 was used to demonstrate that biological cells could be manipulated—and furthermore, that populations of live and dead cells could be separated.2

This year marks the 50th anniversary of the publication of that groundbreaking paper. During the intervening period, DEP separation has undergone a transformation. In the last full year of publication (2015), as many papers were produced on DEP separation as were published in the first 34 years from the publication of the first paper. Moreover, in the last few years DEP has finally made the transition to commercialisation; there are now products becoming available to researchers that use DEP separation at their core, so that the use of DEP separation is no longer limited to those who understand how to build their own separator device.

To commemorate this auspicious anniversary, this paper reviews the progress of DEP for cell separation technology from the very first demonstration of biological DEP, to the new generation of technologies and point towards the likely future applications of DEP separator technology. Note that it is not intended to be a comprehensive review of the literature, of which many fine examples exist in the literature (e.g., Refs. 3–6); instead, it aims to place these reviews in their historical context.

1966–1991: ORIGIN OF THE DISCIPLINE

As a field of research, DEP separation began slowly. The phenomenon we now refer to as dielectrophoresis had been observed previously; Hatschek and Thorne described something similar in 1923,7 whilst a 1924 patent described the use of a phenomenon which was effectively DEP.8 Herbert Pohl had originally devised DEP for the manipulation of materials as a form of processing chemicals, such as suspended particles from polymer solutions. It was not applied to biological cells until 1966, when Pohl and Hawk performed the first experiments on the electrical characterisation, and subsequent separation, of live and dead yeast cells.9 The apparatus used was simple; comprising a signal generator and a pair of electrodes, one a needle, the other a plate to form a “point and plane” arrangement. They observed that when a 2.55 MHz, 30 Vrms signal was applied to the electrodes, those live cells were attracted to the electrodes whilst the dead cells remained in solution. Nowadays, we would anticipate that the dead cells were actively repelled from the electrodes, though in such electrode arrangements this behaviour is difficult to observe, let alone quantify.

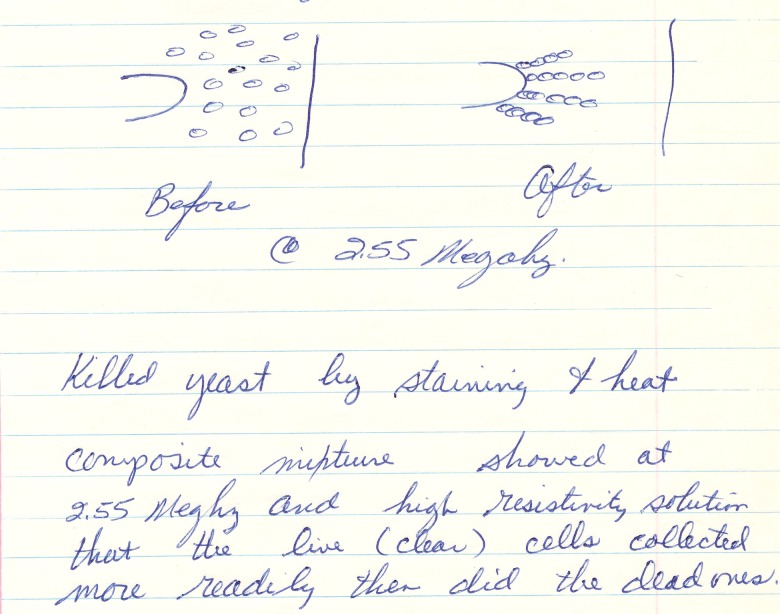

Dr. Ira Hawk, now retired from an academic post at Cameron University, recently related his recollections of his Master's project with Prof. Pohl, which provided the science that later became the Science paper. He still possesses his experimental records of the work, including the image in Figure 1 showing his experimental observation when undertaking the first DEP experiment on living cells, and the Master's thesis outlining the first experimental results (supplementary material).

FIG. 1.

Excerpt from Ira Hawk's laboratory notebook, showing the first report of a demonstration of DEP collection of yeast cells. Courtesy Ira Hawk.

“I was a young and naive graduate student when I began work with Dr. Pohl. I had completed a couple of semesters of course work and had passed the preliminary exam for the master's degree when I interviewed with Dr. Pohl about his research. Although I had an offer to research under another professor, I found Dr. Pohl's research interests more appealing. He was quite charismatic and interesting to visit with. Dr. Pohl did not have external funding at the time, so I had to take a teaching assistantship for living expenses. I enjoyed the research, but did not have as much time for it as I would have liked.”

“Besides working with yeast cells we did studies on dog platelets that were provided by the Veterinary School at OSU. They had a colony of hemophiliac dogs. The cells from normal, transmitter and hemophiliac dogs reacted differently when placed under a non-uniform electric field. We thought we really had some dramatic results, but since they provided us with only one sample from a normal dog–when getting more normal dog platelets found the results were inconclusive.”

“Did Dr. Pohl get involved in the experiment? Dr. Pohl was an idea man and he guided me in doing the experiment, but he never took a single data point on the experiment. The electrodes were fabricated in house at OSU, but can not recall if the machine shop did the work or not. The cell that we used to test Dr. Pohl's theory–I designed with Dr. Pohl's guidance.”

“I did come back one summer after leaving OSU to work on a cell to try to continuously separate living and dead cells by passing them through a divergent electric field, but no matter how small the field the flow moved from laminar to non-laminar. The bottom line is: I had no idea the paper by Pohl and I would have much of an impact.”

Pohl was keen to continue the work which he and Ira Hawk had pioneered, and penned an outline proposal for follow-up research (supplementary material). However, due to family commitments, Hawk had committed to a career in teaching, though would later return to research and complete a Ph.D. in atomic physics.

Through the next 20 years, DEP separation slowly began to gain momentum, though even in the 1970s, the authors reported publications being rejected due to the presence of “Dielectrophoresis” in the title! Prior to the publication of his epic monograph Dielectrophoresis in 1978,9 Herbert Pohl was the primary driver for research, working with students, researchers such as Kaler,10 later a leader in the field in his own right, and other academics such as Ronald “Ron” Pethig (who would later act as Ph.D. adviser to many in the DEP field including Peter Gascoyne, Hywel Morgan, and Michael Hughes). Their work together led to the inclusion of a chapter in Pethig's own monograph.11 However, by the end of the 1980s, DEP separation had produced no more than 30 research papers, often on new types of cells for separation such as cell chloroplasts12 and bacteria.13 The electrodes were usually machined or otherwise fabricated by the placement of pins and rods, placed within chambers containing pins or plates, or within conducting cylinders to create field non-uniformity along the length of the tube. Such an arrangement would allow positive dielectrophoresis to trap one population of cells on the inner rod, whilst the other is repelled from the rod by negative dielectrophoresis. Cells forming a sheath around the rod would be propelled along by the flow passing through the cylinder, ultimately being collected in a glass tube at the end of the rod. Such an arrangement was used for several different cell separations, though no published figures exist for separation efficiencies, of cell throughput. Ultimately, it was this arrangement of electrodes that was the limiting factor in DEP separation; whilst the design was entirely amenable to continuous flow-through separation, the electric field gradient was low due to the lack of sharp features on the inner rod.

THE MICROFABRICATION EXPLOSION

The period leading up to the end of the 1980s had seen a number of developments in dielectrophoretic characterisation technology. Electrorotation14 had seen the development of dielectric theory developing a better understanding of the dielectrophoretic behaviour of cells, and micropatterned electrodes had been developed by Ron Pethig's group, initially using printed circuit board technology to pattern complex electrodes with sharply defined features which they used as part of an optical system to measure DEP collection.15 However, this production method produced rather low resolution, and higher-precision methods were sought. The first experiments with photolithographic fabrication methods developed by Mr. John Tame at Bangor; when asked to develop these electrodes, he was at first bemused, suggesting that electronic devices immersed in water tend to short-circuit! However, the group persevered and soon produced the first microelectrode pattern specifically designed to create areas of high and low field nonuniformity, the interdigitated, castellated electrode. Other leading groups in the field—such as those of Masa Washizu and Gunter Fuhr, followed shortly afterwards with papers describing microfabricated electrodes for insulator-based DEP and travelling-wave DEP, which will be described later.

These approaches featured the use of microfabrication—the production of micron-scale features on electrodes produced from metal (typically gold) films deposited onto glass slides. Using techniques borrowed from the semiconductor fabrication sector, microfabrication offered many advantages. First, it meant that voltages used could be made smaller; the DEP force has units V2 m−3, and so making electrodes smaller created much high field uniformities and larger forces without the need for high voltages. Second, it allowed the production of electrodes of any arbitrary shape, provided that shape was two-dimensional; masks used for electrode production could be made with features as small as a few microns. This was then developed to allow more complex fabrication methods, such as permitting the insertion of bus bars or more complex arrangements to provide power to the electrodes, so that much more complex arrangements of signal generation could be used—for example, the use of many more phases of signal than the previously used two—or that complex channel arrangements could be implemented to send cells into different passages from the device. Finally, the fact that the cells need to be constrained into flowing close to the electrode edges meant that the cells were always in the same focal plane, and so the separation process could be observed, and potentially orchestrated, using a microscope. These developments, coupled with the increase in available computing power for image analysis, paved the way for an explosion of new DEP separation technologies; it would herald new and diverse ways of separating and analysing cells that would tie in with the new paradigm in research, that of the Laboratory on a Chip.16

The fabrication methods developed in the 1980s would, by the early 1990s, provide the basis of several papers which would found separate schools of DEP separation. The first of these key papers was, in 1991, the first paper on the use of traveling electrical waves to generate lateral dielectrophoretic forces.17 Traveling-wave dielectrophoresis (TWD) was actually a lateral form of electrorotation—an effect caused by an out-of-phase relationship between the induced dipole and the applied field. Cells suspended above TWD electrodes would be induced to move along the electrodes, at right-angles to the electrode orientation, and the velocity and direction of movement are related to the electrical properties of the cells. Demonstrations were performed of the separation of live and dead cells18 with the two populations heading to opposite ends of the array; similarly, blood cell populations were separated by fractionation, with subpopulation of cells moving along the array at different speeds.19 The use of TWD as a general motive force led to the development of putative “biofactories on a chip,” highly complicated devices where railway tracks of electrodes would peel away from one another, sending populations in different directions.20 Ultimately, the use of TWD as a separation technology waned through the early 2000s as the limitations associated with the technology became apparent. Chief among these was the power requirements to overcome losses in the large number of electrodes required to move cells; the large scale electrode arrays would struggle to move cells along the required distances. Cells moved at relatively slow speeds of perhaps a few tens of microns per second, with no clear mechanism of retrieving them from the electrode array after separation. Though some new work still appears every few years, for the moment, TWD has become a technological dead-end, perhaps awaiting a reappraisal of the way in which it could be implemented. The first of our 1992 papers has similarly been displaced; Adjari and Prost21 used electrodes shaped like ratchets to “rectify” Brownian motion. Nanoparticles would be attracted to the top of the ratchet and then released; those diffusing in one direction would be attracted back to the start point on reapplication of the field, but those diffusing in the other direction would be attracted to the next point along the ratchet, causing net motion. The speed of average displacement would depend on the size of particles, with smaller particles diffusing further and hence moving faster. Ultimately, the technology had limited application, but the principles underpinning it would later be used to understand fluid pumping by asymmetric electrodes.

The third of our papers, and without doubt the most significant, appeared in 1992. In a collaborative effort between Peter Gascoyne and Fred Becker at the MD Anderson Cancer Center, and Ron Pethig and two Ph.D. students working at Bangor, presented the first separation of cancer cells using the new interdigitated castellated electrode array described earlier.22 The paper set a template for what would become the conventional approach to DEP separation on microelectrodes; a cell solution is pumped across an electrode array, and separation takes place at interdigitated electrodes; cells experiencing positive dielectrophoresis are trapped at the electrode edges, whilst those experiencing negative dielectrophoresis are repelled from the electrodes and can pass through the chamber. This first demonstration did not include the pumping mechanism, but did feature what would become something of a benchmark assay for dielectrophoresis research for years to come; that of the separation of cancerous cells from normal cells. The first demonstration of separation using such an arrangement, but with a pump being used to drive mixed populations of live and dead yeast cells across the electrodes, was published two years later by Markx and Pethig.23 This work gave performance figures for the first time, indicating separation efficiencies in excel of 90%, with cells inserted into the device at a high concentration; the device separated 14 million cells suspended in 1 ml of solution. No figures were quoted for cell losses. However, this approach truly reached its stride in 1996, when two key works were produced with this approach. One demonstration, from Peter Gascoyne's group at MD Anderson Cancer Center, showed the technique could separate cancer cells spiked into human blood, potentially marking it out as a prognostic technique for the detection of circulating tumor cells;24 the second, by the Pethig lab at Bangor, where CD34+ hematopoietic stem cells were separated from bone marrow.25 By this point—30 years after the first demonstration of DEP separation—what could be regarded as the key separation targets in DEP had already been demonstrated; cancer cells from blood,24 stem cells,25,26 bacteria of different strains27,28 and live and dead cells.2

One final implementation of DEP separation has endured from this period. The use of dielectrophoresis as a motive force in field flow fractionation was first mooted by Davis and Giddings in 198629 but was not implemented until parallel work by the Pethig30 and Gascoyne31 groups in 1997. Field-flow fractionation (FFF) uses a liquid flow containing cells of interest, across which a force field is applied. This moves cells to different heights in the flow chamber, depending on a characteristic which interacts with the force field and which discriminates between the different populations of cells. The flow of solution is engineered such that the liquid flows at different rates according to position, usually due to viscous drag retarding the flow at the chamber edge; hence, different cells, at different heights, move at different speeds and can be fractionated. In the case of DEP-FFF, typically negative dielectrophoresis is used to repel the cells from the bottom of the chamber; cells are introduced at the bottom of the chamber (either by a laminar flow at this level, or by using positive DEP to attract them there) and then repelled to a height proportional to the magnitude of the DEP force experienced by each cell. These cells can then be removed, such as by using an outlet port on the chip surface to remove cells travelling close to the electrodes. As with interdigitated separation, DEP-FFF has remained an important method in contemporary DEP.

The last 20 years or so of dielectrophoretic separation has been characterised by a diversity of approach. As fabrication technologies have advanced—with complex multilayer photolithographic designs taking advantage of advances in semiconductor manufacture such as gradient masks, laser ablation and so on—so geometries have been able to become more complex. Despite this, planar electrode separators have most commonly persisted with the template laid down in the early 1990s; electrodes are generally microfabricated on planar surfaces (usually glass) on which a conducting film (typically gold with an interlayer to promote adherence to the glass) is patterned. This is then enclosed in a channel—often PDMS or glass—and then covered with a lid, possibly containing a second electrode array. Advances over earlier work then come from changes to the pattern in the gold, or in alterations in fluidics; this is usually performed to improve capture rates for rare cells or to improve the diversity of output by providing multiple outlets for different cells. However, most commonly, the developments in the field by this approach have been more about finding new potential separation targets, and adopting new strategies to separate and refine more interesting cell types. Where advances have come, they have often been on the form of hybrid technologies, offering a “twist” on previous concepts; often using negative DEP as a barrier to guide cells. For example, Vahey and Voldman32 used a conductivity gradient across a channel, which cells travelled across; whilst the field caused negative DEP the cell remained in the trap, but once conditions changed such that the force was no longer able to restrain the cell it was caught in the flow, allowing separation and analysis on the basis of the force. The primary divide in DEP separation strategies could be divided approximately in two, being “batch” vs. “continuous” separation. The former—where positive DEP is used to trap one cell type whilst the other is repelled and collected, requiring a second step to recover the first cells—is undoubtedly simpler, but is regarded to have limitations on throughput and the total number of cells which can be trapped. Continuous separation is more complex since it requires balancing of microfluidic flows; from a single input, particles must be directed to one of multiple outputs according to their response to dielectrophoresis. Since trapping of cells is to be avoided, many such devices use negative DEP as the primary motive force for separation, placing the cells at appropriate points in the channel for subsequent collection. An early example of this is the work by Doh and Cho where DEP was used to sort cells into three outputs.33 However, whilst 2D DEP devices have produced some highly novel separations based on subtle cellular differences, they have thus far failed to obtain throughputs comparable to existing, non-DEP cell separation technologies such as FCAS and MACS. To overcome this, electrode designs have re-incorporated ideas from the 1970s, with the reintroduction of electrodes extending into the 3rd dimension.

THREE-DIMENSIONAL ELECTRODES

As stated earlier, the primary challenge preventing the wider adoption of DEP is that expectations of throughput, purity, and cell loss have been laid down by existing separation methods used widely in the life sciences, such as FACS and MACS. The problem with planar approaches is that constraining the flow to a distance above the electrodes that enables interaction with the field means that the rate of flow through the device is slow, the fluid velocity profile is affected by surface drag, and the pressures required can create difficulties in interfacing DEP modules with other components such as sensors. To overcome this, researchers have been investigating new methods of separating cells using a much higher chamber, increasing flow velocity and throughput. This has been accomplished in two ways; the first uses electrodes in a similar manner to the microfabricated approaches, but uses novel ways of extending these in a vertical direction. The second removes electrodes from the separation area entirely, and uses insulating posts to warp an otherwise uniform electric field, or novel fluidics to remove the electrodes from the separation space. These two complementary techniques are sufficiently different that it is worth considering their development in parallel. However, in both cases, the same challenges have aimed to be overcome; to develop a separator system with high throughput, high purity, and low cell loss.

The second approach is commonly referred to as “electrodeless.” The original principle was demonstrated by Masao Washizu in 1990, who developed the original concept in the late 1980s; that rather than using an electrode array to generate field non-uniformities, insulating obstructions and shaped pathways were constructed in resin, and used to manipulate cells in channels by energising electrodes distant to the insulator.34 Another approach was demonstrated in 2003,35 which showed that using glass beads as insulators could be used to increase the separation efficiency of live and dead yeast. However, it was another paper in 2003 that laid a template for much of the research since. The electrodeless approach was effectively “rebooted” as a high-throughput separation method, pioneered by Eric Cummings of Sandia National Labs in 200336 and nicknamed insulating dielectrophoresis, or iDEP. Rather than using energised electrodes to generate a non-uniform electric field, Cummings and co-workers used a relatively long chamber with electrodes at either end, and a series of insulating posts in between. Using a highly conductive medium (as opposed to the low-conductivity medium favoured by electrode-based approaches), particles were inserted at one end of the chamber and a large (kV-scale) voltage applied. This then used capillary electrophoresis to transport the particles along the chamber, whilst the insulating posts warped the electric field along the chamber to cause areas of high and low electric field strength, and hence dielectrophoresis. The particles then interact with these field non-homogeneities, collecting or being repelled from them; in a difference from the typical arrangement in electrode-based devices, negative dielectrophoresis is commonly used to trap particles in the device, where a highly repulsive field between the electrodes creates a barrier between the posts which cells experiencing negative DEP are unable to cross. Cells which experience a weaker repulsive or attractive force (which can be overcome by the flow) pass through the device and can be collected, and the setup has been used for bacteria37 and mammalian cells,38 though separations are commonly of the “live/dead” variety, and bacteria feature widely. Partially, this may be due to the very high voltages (and concomitant Joule heating) associated with substantial voltages, though recent designs39 have been published to reduce this. Another approach to removing electrodes in 3D electrodes have also emerged, such as that illustrated by Henslee et al.,40 who moved the electrodes out of the fluid path entirely by energising channels containing “fluid electrodes,” which were capacitively coupled into the main channel.

In electrode-based designs, the primary approach has been to extend the electrodes found in 2D DEP geometries but extend them upwards, so that DEP separation occurs with similar forces applied across the entire channel cross-section, rather than interactions being strong at the bottom (near the electrodes) and weak at the top of the channel. This in turn allows for much higher throughput, provided the electrodes are not positioned such that they impede flow. This can be done virtually, by using electrodes above and below the channel to create a volume effect,41 or physically; 3D electrodes in this manner have been created by the use of electroplating to “grow” electrodes across the channel,42 or by carbonization of complex pillar shapes formed from the photoresist SU-8.43 A third approach used vertical traveling-wave dielectrophoresis electrodes, effectively producing a novel field effect for FFF.44 An third approach to 3D electrode structures requiring no microfabrication at all was demonstrated by Fatoyinbo et al.45 and expanded on by Azhar Razak,46 where electrodes were formed from a laminate of conducting and insulating sheets through which holes are drilled—forming many channels, each with electrodes “striped” down the inside. The advantage of these “DEP-Wells” is that many wells can be drilled in parallel, increasing the throughput significantly.

THE FUTURE: MATURITY AND COMMERCIALISATION?

As technology matures to the point where it is useful, robust, and repeatable, it is inevitable that it should find its way to market. Dielectrophoresis has taken a long path to commericalisation; after 50 years only five products presently exploit the phenomenon, having come to market in the last 10 years. Of these, three devices perform some form of characterisation using DEP; the Shimadzu IC100 uses DEP to attract nanoparticles to surfaces for sizing, the Panasonic Bacterial Counter uses DEP to attract bacteria to electrodes, assessing their number by changes in impedance; and the DEPtech 3DEP performs full-frequency DEP analysis for extraction of cellular electrical properties. However, at present, there are two commercially available DEP-related separation technologies available, and only one truly uses DEP as a separation criterion. The Silicon Biosystems DEParray uses DEP “field cages” to trap and manipulate single cells from a population, allowing specific cells to be sorted to an output, but requires additional methods of analysis such as fluorescence or image analysis to identify those cells of interest. Only the ApoStream platform from ApoCell in Texas currently performs full DEP cell separation, using the response to an electrical field as a separation criterion; based on principles developed in the 1990s and described above, the ApoStream uses a combination of DEP and field-flow fractionation to separate circulating tumor cells from a mixture and presents an interesting combination of 2D and 3D approaches, where a cell-containing sheath flow passes over an electrode array, and negative DEP is used to push unwanted cells into a faster flow above. The wanted cells remain in the laminar flow and are collected. A second technology, based on the 3D “DEP-Well” technology, is currently being prepared for market by DEPtech and is likely to enter the market in 2017. This device differs in philosophy from the ApoStream, delivering enrichment rather than “one cell in a million” precision, but at much lower cost.

The shift towards commercial intent can also be seen in the approaches to patenting. A search of the European Patent Office database shows 92 patents with priority dates in 2014, containing the word “dielectrophoresis” about a quarter of the number of papers appearing in the same year on the Thomson-ISI database. Whilst this may be due to changes in University funding causing researchers to seek alternative sources, the large proportion from corporate sponsors suggest that dielectrophoresis—and in particular, dielectrophoretic separation, regarded by any as its most useful embodiment—is finally at a turning-point regarding its entry to the commercial domain, and widespread acceptance and use.

CONCLUSION

In the mid-1960s, a grad student in Oklahoma performed the first experiments to prove a principle that drives a significant body of research to this day. Dielectrophoresis has many advantages over other cell separation methods, and development of the technique and its applications has produced over 2000 journal papers; references to papers on dielectrophoretic separation are cited over 5000 time annually. That the technique has not yet made the transition to benchtops in every cell biology lab is perhaps due to the Academic cycle of producing research that impresses our peers, but not in taking these ideas through the long and often tedious path to commercialisation. However, recent changes—the first dielectrophoresis-based product, and extensive patent activity—may point to a change in direction that may yet see DEP as a standard tool for specialists in other disciplines, rather than just our own.

SUPPLEMENTARY MATERIAL

See supplementary material for Masters dissertation from 1966, recording the first experiments with dielectrophoresis and yeast. Courtesy Ira Hawk and a one-page research proposal outline from Dr. Hawk's archive, written by Herbert Pohl. Courtesy Ira Hawk.

ACKNOWLEDGMENTS

The author wishes to thank Dr. Ira Hawk and Professor Ron Pethig for their valuable insights, input and recollections.

References

- 1. Pohl H. A., J. Appl. Phys. 22, 869–871 (1951). 10.1063/1.1700065 [DOI] [Google Scholar]

- 2. Pohl H. A. and Hawk I., Science 152, 647–649 (1966). 10.1126/science.152.3722.647-a [DOI] [PubMed] [Google Scholar]

- 3. Dash S. and Mohanty S., Electrophoresis 35, 2656–2672 (2014). 10.1002/elps.201400084 [DOI] [PubMed] [Google Scholar]

- 4. Chen L., Zheng X. L., Yang J., Luo H. Y., Jiang F., and Liao Y. J., Chin. J. Anal. Chem. 43, 300–309 (2015). 10.1016/S1872-2040(15)60808-8 [DOI] [Google Scholar]

- 5. Shields C. W., Reyes C. D., and Lopez G. P., Lab Chip 15, 1230–1249 (2015). 10.1039/C4LC01246A [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6. Pethig R., Biomicrofluidics 4, 022811 (2010). 10.1063/1.3456626 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7. Hatschek E. and Thorne P. C. L., “ Metal sols in non-dissociating liquids. I. - Nickel in toluene and benzene,” Proc. R. Soc. A 103, 276 (1923). 10.1098/rspa.1923.0056 [DOI] [Google Scholar]

- 8. Hatfield H. S., “ Means and process of separating substances one from another,” U.S. patent 1498911A (1924).

- 9. Pohl H. A., Dielectrophoresis: the Behavior of Neutral Matter in Nonuniform Electric Fields ( Cambridge University Press, Cambridge, 1978). [Google Scholar]

- 10. Pohl H. A. and Kaler K., Cell Biophys. 1, 15–28 (1979). 10.1007/BF02785053 [DOI] [PubMed] [Google Scholar]

- 11. Pethig R., Dielectric and Electronic Properties of Biological Materials ( Wiley, Chichester, 1979). [Google Scholar]

- 12. Ting I. P., Beasley C. A., and Pohl H. A., Biochim. Biophys. Acta 234, 324–329 (1971). 10.1016/0005-2728(71)90198-8 [DOI] [PubMed] [Google Scholar]

- 13. Dimitrov D. S., Tsoneva J., Stoicheva N., and Zhelev D., J. Biol. Phys. 12, 26–30 (1984). 10.1007/BF01857654 [DOI] [Google Scholar]

- 14. Arnold W. M. and Zimmermann U., Z. Naturforsch. 37, 908–915 (1982). [Google Scholar]

- 15. Price J. A. R., Burt J. P. H., and Pethig R., Inst. Phys. Conf. Ser. 85, 75–79 (1987). [Google Scholar]

- 16. Manz A., Graber N., and Widmer H. M., Sens. Actuators, B 1, 244–248 (1990). 10.1016/0925-4005(90)80209-I [DOI] [Google Scholar]

- 17. Fuhr G., Hagedorn R., Muller T., Benecke W., Wagner B., and Gimsa J., Stud. Biophys. 140, 79–102 (1991). [Google Scholar]

- 18. Huang Y., Wang X. B., Tame J. A., and Pethig R., J. Phys. D: Appl. Phys. 26, 1528–1535 (1993). 10.1088/0022-3727/26/9/030 [DOI] [Google Scholar]

- 19. Green N. G., Hughes M. P., Monaghan W., and Morgan H., Microelectron. Eng. 35, 421–424 (1997). 10.1016/S0167-9317(96)00122-0 [DOI] [Google Scholar]

- 20. Pethig R., Burt J. P. H., Parton A., Rizvi N., Talary M. S., and Tame J. A., J. Micromech. Microeng. 8, 57–63 (1998). 10.1088/0960-1317/8/2/004 [DOI] [Google Scholar]

- 21. Rousselet J., Salome L., Adjari A., and Prost J., Nature 370, 446–447 (1994). 10.1038/370446a0 [DOI] [PubMed] [Google Scholar]

- 22. Gascoyne P. R. C., Huang Y., Pethig R., Vykoukal J., and Becker F. F., Meas. Sci. Technol. 3, 439–445 (1992). 10.1088/0957-0233/3/5/001 [DOI] [Google Scholar]

- 23. Markx G. H. and Pethig R., Biotechnol. Bioeng. 45, 337–343 (1995). 10.1002/bit.260450408 [DOI] [PubMed] [Google Scholar]

- 24. Becker F. F., Wang X. B., Huang Y., Pethig R., Vykoukal J., and Gascoyne P. R. C., Proc. Nat. Acad. Sci. U.S.A. 92, 860–864 (1995). 10.1073/pnas.92.3.860 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25. Talary M. S., Mills K. I., Hoy T., Burnett A. K., and Pethig R., Med. Biol. Eng. Comput. 33, 235–237 (1995). 10.1007/BF02523050 [DOI] [PubMed] [Google Scholar]

- 26. Stephens M., Talary M. S., Pethig R., Burnett A. K., and Mills K. I., Bone Marrow Transplant. 18, 777–782 (1996). [PubMed] [Google Scholar]

- 27. Markx G. H., Huang Y., Zhou X. F., and Pethig R., Microbiology 140, 585–591 (1994). 10.1099/00221287-140-3-585 [DOI] [Google Scholar]

- 28. Marks G. H., Dyda P. A., and Pethig R., J. Biotechnol. 51, 175–180 (1996). 10.1016/0168-1656(96)01617-3 [DOI] [PubMed] [Google Scholar]

- 29. Davis J. M. and Giddings J. C., Sep. Sci. Technol. 21, 969–989 (1986). 10.1080/01496398608058390 [DOI] [Google Scholar]

- 30. Markx G. H., Rousselet J., and Pethig R., J. Liq. Chromatogr. Relat. Technol. 20, 2857–2872 (1997). 10.1080/10826079708005597 [DOI] [Google Scholar]

- 31. Huang Y., Wang X. B., Becker F. F., and Gascoyne P. R. C., Biophys. J. 73, 1118–1129 (1997). 10.1016/S0006-3495(97)78144-X [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32. Vahey M. D. and Voldman J., Anal. Chem. 80, 3135–3143 (2008). 10.1021/ac7020568 [DOI] [PubMed] [Google Scholar]

- 33. Doh I. and Cho Y. H., Sens. Actuators, A 121, 59–65 (2005). 10.1016/j.sna.2005.01.030 [DOI] [Google Scholar]

- 34. Washizu M., J. Electrost. 25, 109–123 (1990). 10.1016/0304-3886(90)90040-3 [DOI] [Google Scholar]

- 35. Suehiro J., Zhou G. B., Imamura M., and Hara M., IEEE Trans. Ind. Appl. 39, 1514–1521 (2003). 10.1109/TIA.2003.816535 [DOI] [Google Scholar]

- 36. Cummings E. B. and Singh A. K., Anal. Chem. 75, 4724–4731 (2003). 10.1021/ac0340612 [DOI] [PubMed] [Google Scholar]

- 37. Lapizco-Encinas B. H., Simmons B. A., Cummings E. B., and Fintschenko Y., Anal. Chem. 76, 1571–1579 (2004). 10.1021/ac034804j [DOI] [PubMed] [Google Scholar]

- 38. Jen C. P. and Chen T. W., Biomed. Microdevices 11, 597–607 (2009). 10.1007/s10544-008-9269-1 [DOI] [PubMed] [Google Scholar]

- 39. Braff W. A., Pignier A., and Buie C. R., Lab Chip 12, 1327–1331 (2012). 10.1039/c2lc21212a [DOI] [PubMed] [Google Scholar]

- 40. Henslee E. A., Sano M. B., Rojas A. D., Schmelz E. M., and Davalos R. V., Electrophoresis 32, 2523–2529 (2011). 10.1002/elps.201100081 [DOI] [PubMed] [Google Scholar]

- 41. Li Y. and Kaler K. V. I. S., Anal. Chim. Acta 507, 151–161 (2004). 10.1016/j.aca.2003.08.071 [DOI] [Google Scholar]

- 42. Wang L., Flanagan L. A., Jeon N. L., Monuki E., and Lee A. P., Lab Chip 7, 1114–1120 (2007). 10.1039/b705386j [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43. Martinez-Duarte R., Renaud P., and Madou M. J., Electrophoresis 32, 2385–2392 (2011). 10.1002/elps.201100059 [DOI] [PubMed] [Google Scholar]

- 44. Cheng I. F., Froude V. E., Zhu Y. X., Chang H. C., and Chang H. C., Lab Chip 9, 3193–3201 (2009). 10.1039/b910587e [DOI] [PubMed] [Google Scholar]

- 45. Fatoyinbo H. O., Kamchis D., Whattingham R., Ogin S. L., and Hughes M. P., IEEE Trans. Biomed. Eng. 52, 1347–1349 (2005). 10.1109/TBME.2005.847553 [DOI] [PubMed] [Google Scholar]

- 46. Abdul Razak M. A., Hoettges K. F., Hoettges K. F., Fatoyinbo H. O., Labeed F. H., and Hughes M. P., Biomicrofluidics 7, 64110 (2013). 10.1063/1.4842395 [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

See supplementary material for Masters dissertation from 1966, recording the first experiments with dielectrophoresis and yeast. Courtesy Ira Hawk and a one-page research proposal outline from Dr. Hawk's archive, written by Herbert Pohl. Courtesy Ira Hawk.