Abstract

Aim and Objectives:

The aim of this study is to evaluate the frictional forces generated by five different orthodontic brackets when used in combination with stainless steel (SS), titanium molybdenum alloy (TMA), and nickel-titanium (NiTi) archwires in dry conditions at physiological temperature.

Materials and Methods:

Five different types of maxillary upper right side self-ligating brackets (SLBs) (Damon 3MX, Smart Clip and Carriere LX) and conventional SS brackets (Mini 2000, Optimum Series and Victory Series) with a slot size 0.022 inch were coupled with 0.016” NiTi and 0.019 × 0.025” SS/titanium molybdenum alloy (TMA) archwires. Tests were carried out for each group of the bracket-wire combination at physiological temperature and in the dry state. Frictional forces were measured by Instron universal testing machine.

Results:

SLB showed lower fictional values in comparison with elastic ligatures. Frictional force increased proportionally to the wire size; TMA and NiTi archwires presented higher frictional resistance than SS archwires.

Conclusion:

SS brackets tied with conventional ligatures produced high and low friction when ligated with SLBs with passive clip.

Keywords: Archwire, conventional ligation, friction, low-friction biomechanics, self-ligating bracket

INTRODUCTION

As orthodontists moved away from multi-loop stainless steel (SS) archwires to high-tech nickel-titanium (NiTi) archwires to start leveling and aligning, obviously it's a good time to think about what kind of bracket can couple with those archwires better.[1] Khambay et al. evaluated different methods of ligations regarding frictional resistance, including self-ligation, elastomeric modules, and stainless steel ligature wires.[2] Conventional ligation systems have a number of drawbacks such as failure to provide and maintain full archwire engagement, and high friction.[3] Elastomeric ties force decays very fast, and it has a potential impediment to oral hygiene, whereas wire ligation is very slow.

Self-ligating bracket (SLB) provides consistent archwire engagement throughout orthodontic treatment, elimination of the need for frequent visits for the replacement of ligatures and is more comfortable, and easier to clean.[4] However, SLB do have several disadvantages such as full expression of bracket torque is difficult to achieve,[5] clinical management is more problematic than with conventional brackets due to frequent failure of brackets, brackets are bulkier and more expensive. Thus, this study was to evaluate the static and kinetic friction of SLBs with different archwires and to compare the static and dynamic friction value of conventional brackets with SLBs using different archwires. During sliding mechanics, one needs to understand the interplay of friction between brackets and arch wires and to apply an appropriate force for obtaining an optimal biologic tissue response with efficient and desired tooth movement which is the ultimate goal in clinical orthodontics.[2,5] Of all factors, wire material, the cross-section of wire used, type of ligation and use of SLBs are the four most important factors which can be influenced by an orthodontist. The availability of a wide array of brackets, wires and ligatures have provided the clinician a multitude of combination for use during various stages of orthodontic treatment.

Recently, innovative ligatures manufactured with a special polyurethane mix by injection molding (Slide, Leone S.p.A., Firenze, Italy) were introduced. The nonconventional elastomeric ligature is used on conventional brackets to produce low levels of frictional resistance treatment mechanics with the preadjusted appliance. These modules have an excellent esthetic appearance and low friction, which make these modules very beneficial to the adult patients. The importance of the ligature in creating friction at the binding unit is emphasized indirectly by therapeutic approaches that avoid the use of any form of ligature like SLBs.[6]

This study was to evaluate various parameters that can be influenced by the clinician during different stages of orthodontic treatment in maintaining the low friction value using recently introduced wires and brackets. The aim of this study is to evaluate the resistance to movement of various arch wires through three types of conventional SS brackets using slide and silver mini module.

MATERIALS AND METHODS

Brackets: The following brackets were used for the study:

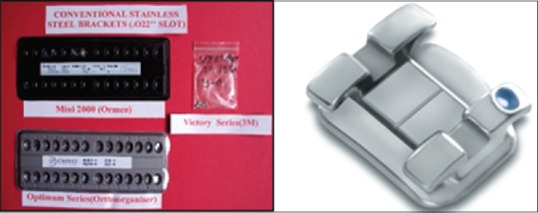

0.022″ × 0.028″ SS conventional bracket, i.e., Mini 2000, Victory Series, Optimum Series [Figure 1]

0.022″ × 0.0275″ SS passive SLB, i.e., Damon 3MX, Carriere LX, Smart Clip [Figure 2].

Figure 1.

Conventional stainless steel brackets

Figure 2.

Self-ligation brackets

Archwires: Three types of orthodontic wires were tested:

0.016″ NiTi (Ortho Organiser)

0.019″ × 0.025″ β-titanium (Ormco)

0.019″ × 0.025″ SS (Ormco).

Ligatures: Conventional elastomeric ligature (CEL) (Leone) [Figure 3].

Figure 3.

Nonconventional elastomerics and silver mini module

A five bracket assembly was used comprising of brackets for central incisor, lateral incisor, canine, first premolar, and second premolar bonded with a cyanoacrylate adhesive to steel.

Bars of dimensions: An experimental model (7 cm × 3.5 cm × 1 cm) reproducing the right buccal segment consisting of five SS preadjusted edgewise brackets for second premolar, first premolar, canines, lateral incisor, and central incisor was fabricated to study both kinetic and static attritions.[7]

All the brackets were ligated with the help of this Jig (0.021 × 0.028” SS wire) using 0.010” SS ligature wire and cured using a light cure adhesive (Enlight Ormco).

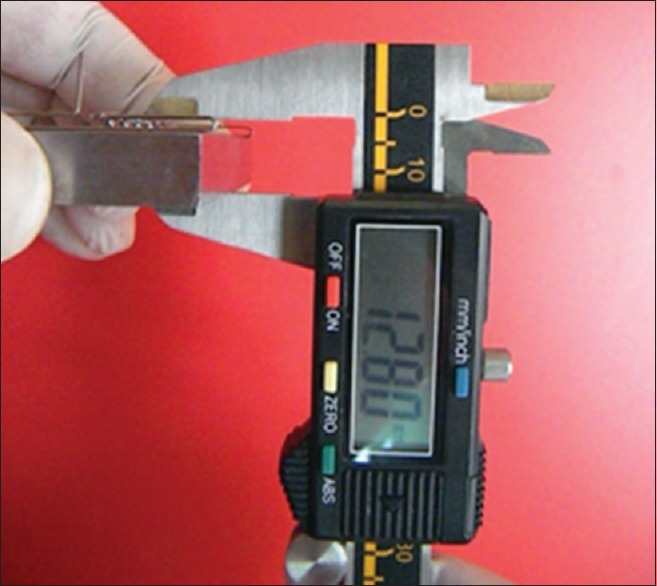

Vertical height for all bracket slots was made similar using a digital caliper. This was performed using an alignment fixture, which ensured that the all the brackets were placed parallel to centrally placed bracket of each block at 8.5 mm distance, and the bracket slot was right-angled to the surface of each block [Figure 4]. Each steel bar had a line scribed parallel to its long axis. This was to aid in aligning the pull of the wire through the bracket so that friction was not induced by adverse tipping or torsion moments. Brackets were supported on a 0.021 × 0.028-inch SS wire while the adhesive hardened, which enabled the bracket slot to be aligned along the length of the steel bar and parallel to it. This allowed the bracket to move along the wire as an axial tensile force was applied by the universal testing machine (UTM).

Figure 4.

Vertical measurements with Vernier caliper

The bracket-archwire assembly was vertically mounted on UTM, and load cell was calibrated at 100 kN. This device allowed the bracket to move along the wire as an axial tensile force was applied by the load cell with a crosshead. Each of the bracket-wire ligation combinations was tested three times. This in vitro comparative study was carried on a total of 18 samples consisting of three SLBs and three conventional brackets with three different wires alloy and different cross-sections. All the models were evaluated for static and kinetic friction which was measured on UTM (Model LR-100K, Lloyd, UK) [Figure 5].

Figure 5.

Universal testing machine

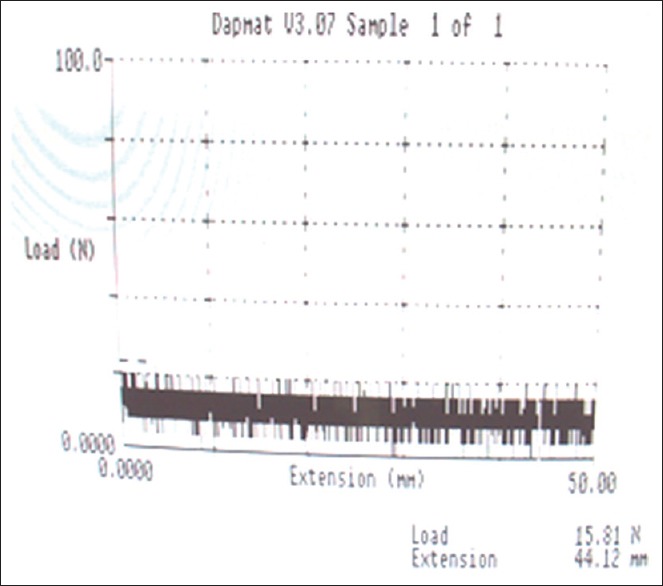

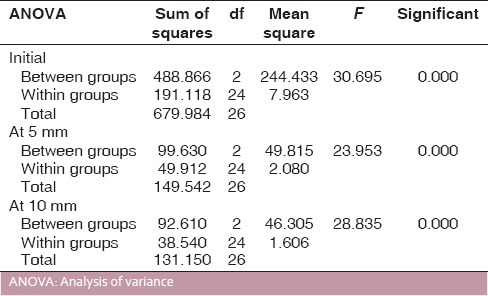

The maximum force needed to move the bracket along the wire (static friction) at zero and the mean frictional force registered at 0 mm, at 5 mm, and at 10 mm of movement (kinetic friction) with the computerized graph [Figure 6]. This was in accordance with the specifications for material testing with universal testing machine (UTM). All measurements were performed under dry conditions at room temperature of 20±2°C. All the data were subjected for statistical analysis. Analysis of variance was used to evaluate the effect of bracket type on frictional resistance in between groups and within groups [Table 1]. When subjected to a Kruskal–Wallis (Mann–Whitney test) statistical analysis of six bracket-wires types and ligation techniques were derived. For every bracket type, wire alloy and ligation technique, friction was plotted for each wire size and post hoc test was applied. The mean, standard deviation and P- value were calculated for all the inter-wire groups. The level of significance was set at P < 0.05.

Figure 6.

Recorded value of computer software

Table 1.

Analysis of variance results of brackets versus ligation for all three wires

RESULTS

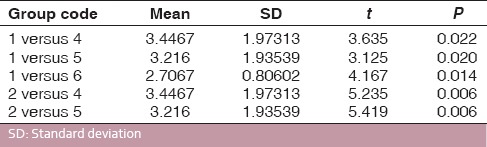

The conventional elastomeric ligature produced high friction when compared with self-ligating brackets [Tables 2 and 3]. When compared to the materials type titanium molybdenum alloy (TMA) produced the highest friction among all materials and NiTi produced the lowest friction [Table 3]. When all wires are compared individually to each bracket then in Carriere LX both static and kinetic frictional force was highest for TMA, which was equal to SS and lowest for NiTi. When all wires are compared individually to each bracket then in Damon 3MX static frictional force was highest for SS wire and lowest for NiTi wire followed by TMA [Table 2]. While kinetic force was highest for SS and lowest for NiTi followed by TMA. When all wires are compared individually to each bracket then in Damon 3MX static frictional force was highest for SS and lowest for NiTi followed by TMA. While kinetic frictional force was highest for SS and lowest for TMA followed by NiTi. Friction was greater in conventionaly ligated brackets when compared with self ligating brackets [Table 4].

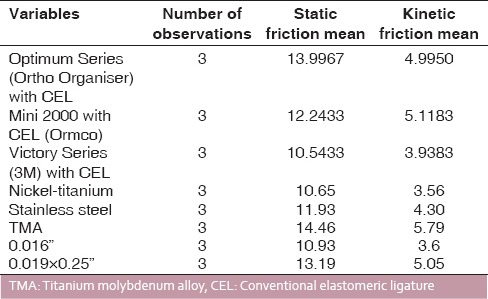

Table 2.

Descriptive evaluations of static and kinetic of stainless steel brackets with conventional elastomeric ligature

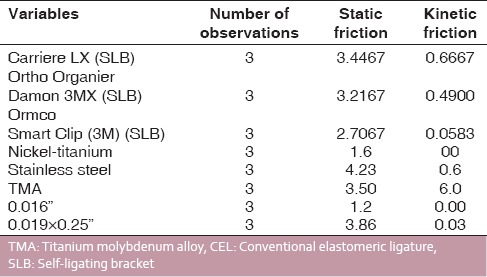

Table 3.

Descriptive evaluations of static and kinetic friction of self-ligating bracket

Table 4.

Statistical comparisons of static and kinetic friction of conventionally ligated and self-ligating brackets

DISCUSSION

In the present study, for SL SS brackets, the friction increased as the wire dimensions increased, i.e., lesser friction was observed with round wires than with rectangular wires in SLB [Table 3]. This is in accordance with the finding of Garner et al.[8] who founded that friction increased with increased wire size. Frank and Nikoli 1980 demonstrated that the round wires make point contact with the bracket slot; whereas rectangular wire makes line contact. Thus, they concluded that round wires generated less friction than rectangular wires [Table 2]. Within each bracket type, different archwire alloys, showed a significant difference and they are accordance with many reports.[6,8,9]

While evaluating against any SS conventional bracket, NiTi wire produced the lowest friction, beta-titanium wires produced higher friction. In the present study, couples comprising Mini 2000 bracket-wire, Mini 2000 bracket – TMA wire and Optimum Series – bracket with – TMA wires couples had a higher coefficient of friction. TMA archwire produced significantly greater levels of friction followed by SS and lowest for NiTi against all the six brackets. Higher frictional coefficient of beta-titanium had been attributed to different factors such as roughness, mechanical abrasion, or cold welding as reported by Henao.[5] In the present study, Optimum Series (Ortho Organiser) and (Ormco) brackets with conventional ligation produced higher friction with 0.016 NiTi wires. Finding from the present study are correlated to Suyama et al. who also recorded the greatest friction with 0.016 NiTi wires with conventional bracket when ligated with CEL.[10]

The result from the present study correlates with various studies, which show that SLBs produced lower friction with round wires as compared to rectangular wire and TMA wires had a markedly higher friction than SS wire.[3,11,12] The SLBs had lower friction than conventional SS bracket when ligated with the silver mini module.

Another observation in this study was a lower level of coefficients of friction in SLBs when compared to conventional SS brackets. This study correlates with many investigations.[3,7,8,9,11] The Damon 3MX and Carriere LX is different from conventional SS brackets, in which archwire covers slides vertically from the outer wall of archwire slot and convert the bracket into a rectangular tube. In the case of Smart Clip the wire is guided in the slot by active NiTi clip. The result in the present study showed that Smart Clip SLB produced lowest frictional force for all type of wire alloy, and among all types of a bracket used. There were conflicting literature reports regarding the friction force between self-ligating (Smart Clip) and conventional SS brackets that had the almost same time (1.2 mm/month) for space closure during sliding mechanics. In the present study, the SS bracket ligated with a slide had a lower level of friction value when compared to the SS bracket with CEL. Evaluating against any SS conventional bracket, NiTi wire produced the lowest friction, while beta-titanium wires produced higher friction. Our result with 0.019 × 0.025” archwire shows that when archwire/bracket alignment is carefully controlled, the friction generated at the model-wire bracket that interface is significantly affected by ligation method.

When considering the clinical implication of our results, it is important to remember that the effect of ligation on the total resistance to sliding decrease as bracket/archwire angulations increase. However, a low friction ligation method contributes to appliance efficiency and might have clinically important advantages over SLBs as in previous studies.[2,4,13]

The slide showed levels of friction that were significantly lower than those produced by CL during sliding mechanics for all type of wire tested. The amount of both static and kinetic friction was minimal for non-conventional elastomeric ligature. The ligation methods had significantly influence on friction. For every wire size, slide-ligated SS bracket had lesser friction than elastomeric ligated steel bracket. The friction increased with an increase in wire size when ligated nonconventionally.[1,3]

The use of 016” NiTi wire with SS brackets showed that frictional force was virtually absent for the NCEL. This data for the NCEL are in agreement with the previous results for passive SLBs.[4,5]

From a clinical perspective, the aim to keep the friction force as low as possible and ideally to eliminate them together. Sliding mechanics occurs predominately during space closure, and this needs to be carried out on the wire that was sufficient stiffness to prevent its distortion and subsequently tilting of the adjacent teeth into space. For this reason, space closure is normally undertaken on SS and probably on TMA arch wire.[14]

In the present study, the NCEL showed levels of friction were significantly lower than those produced by CEL during sliding mechanics with rectangular and round wires. The amount of static and kinetic frictional force exerted by the NCEL were minimal when compared to CEL. During mechanotherapy that involves sliding mechanics, friction at the bracket-wire interface may prevent the attainment of optimal force in the supporting tissues. Hence, orthodontist needs to know precisely the level of force required to overcome the friction and produce an optimal biological response for predictable tooth movement.[6,14]

In conventional SS brackets have a higher coefficient of friction when used along with TMA wires, these wires should be avoided while using sliding mechanics. It is also conformed to the previous study by Tidy et al., reported resilient wires produced more friction and should not be used for sliding along the brackets.[7] This study also demonstrated that SS SLBs generated significantly lower static and kinetic frictional forces. Admittedly, there is no such thing as the perfect brackets which satisfies all the criteria for ideal treatment, and it is devoid any disadvantages. Therefore, the final say is the clinicians to use the knowledge and strike a compromise and improvize his objectives and treatment plan based on his choices of material at hand, which in turn differ from one case to another. On the basis of the result of this study, the innovative elastomeric ligatures produce significantly lower levels of frictional forces than conventional elastomeric modules, so that new ligatures may represent a valid alternative to passive SLBs when a minimal amount of friction is desired.

SUMMARY AND CONCLUSION

This study compared the frictional forces of nonconventional elastomeric and self-ligation brackets and SS brackets. The frictional value was recorded while sliding of different archwires in various bracket slots were recorded in as static friction for various brackets archwire combinations. Silver mini modules produced greater friction than slide ligature and self-ligation method with different archwires combinations. Damon 3MX self-ligation produced lesser friction than slide ligation with lower archwires and higher friction with higher arch wires. Slide ligation also showed lower friction with different archwires combinations. In present study, among all SLBs produced lowest frictional. When compared with 0.019 × 0.025” SS wire Smart Clip produced lowest friction.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Damon DH. The Damon low-friction bracket: A biologically compatible straight-wire system. J Clin Orthod. 1998;32:670–80. [PubMed] [Google Scholar]

- 2.Khambay B, Millett D, McHugh S. Evaluation of methods of archwire ligation on frictional resistance. Eur J Orthod. 2004;26:327–32. doi: 10.1093/ejo/26.3.327. [DOI] [PubMed] [Google Scholar]

- 3.Thorstenson GA, Kusy RP. Resistance to sliding of self-ligating brackets versus conventional stainless steel twin brackets with second-order angulation in the dry and wet (saliva) states. Am J Orthod Dentofacial Orthop. 2001;120:361–70. doi: 10.1067/mod.2001.116090. [DOI] [PubMed] [Google Scholar]

- 4.Henao SP, Kusy RP. Frictional evaluations of dental typodont models using four self-ligating designs and a conventional design. Angle Orthod. 2005;75:75–85. doi: 10.1043/0003-3219(2005)075<0075:FEODTM>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 5.Henao SP, Kusy RP. Evaluation of the frictional resistance of conventional and self-ligating bracket designs using standardized archwires and dental typodonts. Angle Orthod. 2004;74:202–11. doi: 10.1043/0003-3219(2004)074<0202:EOTFRO>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 6.Taylor NG, Ison K. Frictional resistance between orthodontic brackets and archwires in the buccal segments. Angle Orthod. 1996;66:215–22. doi: 10.1043/0003-3219(1996)066<0215:FRBOBA>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 7.Tidy DC. Frictional forces in fixed appliances. Am J Orthod Dentofacial Orthop. 1989;96:249–54. doi: 10.1016/0889-5406(89)90462-9. [DOI] [PubMed] [Google Scholar]

- 8.Garner LD, Allai WW, Moore BK. A comparison of frictional forces during simulated canine retraction of a continuous edgewise arch wire. Am J Orthod Dentofacial Orthop. 1986;90:199–203. doi: 10.1016/0889-5406(86)90066-1. [DOI] [PubMed] [Google Scholar]

- 9.Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 10.Suyama H, Higashi K, Nakata S, and Nakasima A. New edge wise bracket with rounded slot and variable ligation. J Clin Orthod. 1995;29:398–402. [PubMed] [Google Scholar]

- 11.Pizzoni L, Ravnholt G, Melsen B. Frictional forces related to self-ligating brackets. Eur J Orthod. 1998;20:283–91. doi: 10.1093/ejo/20.3.283. [DOI] [PubMed] [Google Scholar]

- 12.Rinchuse DJ, Miles PG. Self-ligating brackets: Present and future. Am J Orthod Dentofacial Orthop. 2007;132:216–22. doi: 10.1016/j.ajodo.2006.06.018. [DOI] [PubMed] [Google Scholar]

- 13.Shivapuja PK, Berger J. A comparative study of conventional ligation and self-ligation bracket systems. Am J Orthod Dentofacial Orthop. 1994;106:472–80. doi: 10.1016/S0889-5406(94)70069-9. [DOI] [PubMed] [Google Scholar]

- 14.O'Reilly D, Dowling PA, Lagerstrom L, Swartz ML. An ex-vivo investigation into the effect of bracket displacement on the resistance to sliding. Br J Orthod. 1999;26:219–27. doi: 10.1093/ortho/26.3.219. [DOI] [PubMed] [Google Scholar]