Abstract

Bioinspired design is an emerging field that takes inspiration from nature to develop high-performance materials and devices. The sea urchin mouthpiece, known as the Aristotle's lantern, is a compelling source of bioinspiration with an intricate network of musculature and calcareous teeth that can scrape, cut, chew food and bore holes into rocky substrates. We describe the bioinspiration process as including animal observation, specimen characterization, device fabrication and mechanism bioexploration. The last step of bioexploration allows for a deeper understanding of the initial biology. The design architecture of the Aristotle's lantern is analyzed with micro-computed tomography and individual teeth are examined with scanning electron microscopy to identify the microstructure. Bioinspired designs are fabricated with a 3D printer, assembled and tested to determine the most efficient lantern opening and closing mechanism. Teeth from the bioinspired lantern design are bioexplored via finite element analysis to explain from a mechanical perspective why keeled tooth structures evolved in the modern sea urchins we observed. This circular approach allows for new conclusions to be drawn from biology and nature.

Keywords: Bioengineering, Issue 110, Bioinspiration, sea urchin, micro-computed tomography, 3D printing, Aristotle's lantern

Introduction

The fields of biology, biological materials science, biomaterials, bioengineering and biochemistry employ the premiere scientific techniques and minds in an attempt to provide a deeper understanding of the incredible natural world. This research has explained many of the most amazing biological structures and organisms; from the intrinsic toughness of human bone1,2 to the large beak of the toucan3. However, much of this knowledge is difficult to employ in a manner that can provide a benefit to society. As a result, the tangential field of bioinspiration employs the lessons learned from nature to modern materials in order to solve common problems. Examples include superhydrophobic surfaces inspired by lotus leaves4-6, adhesive surfaces inspired by the feet of geckos and insects7,8, tough ceramics inspired by the nacre of abalone9-11 and biopsy harvesters inspired by the mouthpiece of the sea urchin, also known as the Aristotle's lantern12,13.

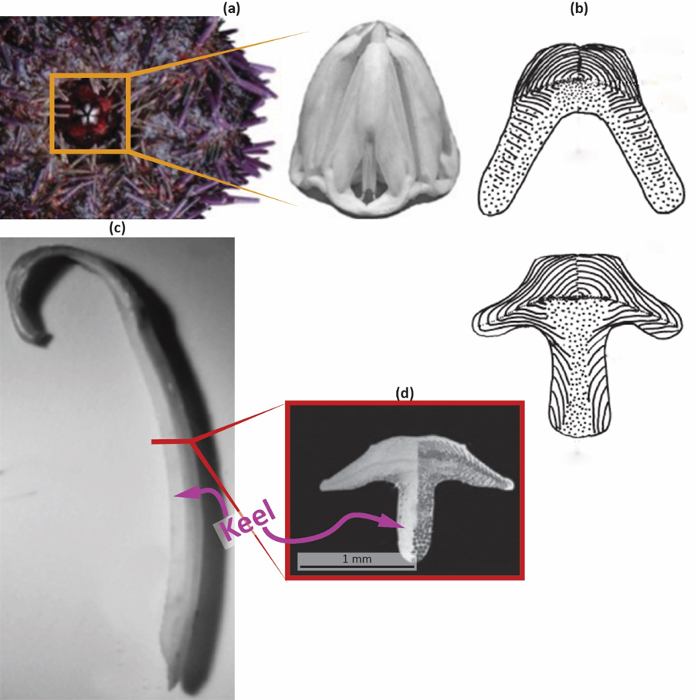

Sea urchins are invertebrate animals covered with spines whose habitat most commonly consists of the rocky beds on the ocean floor. The body (called a test) in the largest urchin species can be more than 18 cm in diameter; test size in pink sea urchins (Strongylocentrotus fragilis) examined in this study can grow to 10 cm diameter. The Aristotle's lantern is composed of five predominately calcium carbonate teeth supported by pyramid structures composed of mineralized tissue and arranged into a dome-like formation that enclose all but the distal grinding tips of the teeth (Figure 1A).

The muscle structure of the jaws is capable of efficient chewing and scraping even against hard ocean rocks and corals. When the jaws open, the teeth protrude outwards and when the jaws close, the teeth retract inwards in a single smooth motion. Comparison between primitive (above) and modern (below) sea urchin tooth cross-sections (Figure 1B) indicates that a keeled tooth evolved to strengthen the tooth when grinding against hard substrates. Each individual tooth has a slightly convex curvature and a T-shaped morphology in the transverse plane (normal to the growth direction) due to the longitudinally attached keel (Figure 1C, D).

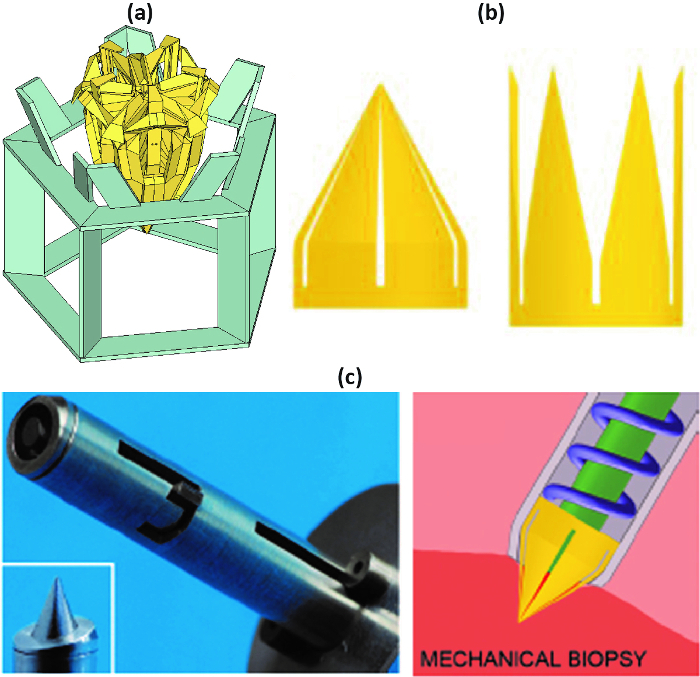

Bioinspiration begins with observation of interesting natural phenomena, such as the efficient chewing motion of the Aristotle's lantern in sea urchins. This natural structure initially captivated Aristotle because it reminded him of a horn lantern with the panes of horn left out. More than two millennia later, Scarpa was fascinated by the complexity of the Aristotle's lantern that he and later Trogu mimicked the natural chewing motion using only paper and rubber bands (Figure 2A)15,16. Similarly, Jelinek was bioinspired by the chewing motion of the Aristotle's lantern and developed a better biopsy harvester that could safely isolate tumorous tissue without spreading cancerous cells (Figure 2B, C)12,13. In this case, bioinspired design was utilized to make a biomedical device that fit a specific need for a desired application.

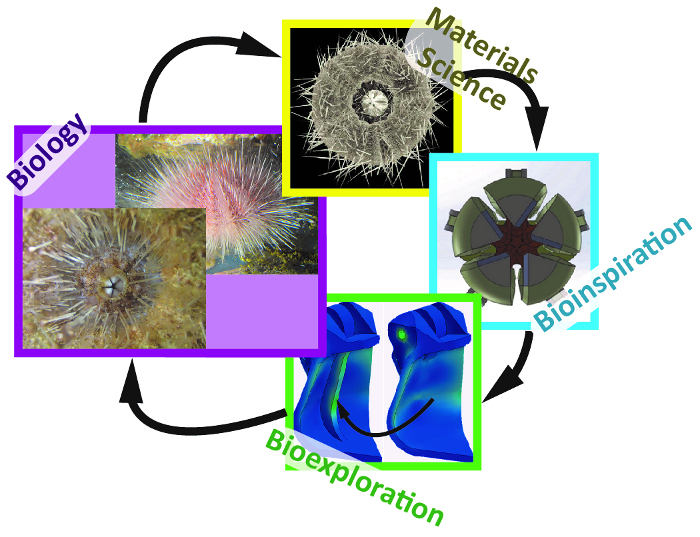

The design protocol described here applies to a sediment sampler bioinspired by sea urchins. Through biological materials science, the natural structure of the Aristotle's lantern is characterized. Bioinspired design identifies potential applications where the natural mechanisms can be enhanced through the use of modern materials and fabrication techniques. The final design is re-examined through the prism of bioexploration to understand how the natural tooth structure evolved(Figure 3). The last bioexploration step, proposed by Porter17,18, uses engineering analysis methods to explore and explain biological phenomena. All the important steps of the bioinspiration process are presented as an example for harnessing technology, pre-approved by nature, which can be used for solving modern problems. Our protocol, motivated by previous bioinspiration procedures presented for specific applications by Arzt7, is targeted for biologists, engineers and anyone else who is inspired by nature.

Protocol

1. Biological Materials Science

Wear personal protective equipment (i.e., gloves, safety glasses and lab coat) and follow all applicable safety procedures for using dissecting tools.

Rinse off the forceps and scalpel with distilled water to use for dissection.

- Thaw a frozen pink sea urchin at RT for 1 hr. Place a thawed specimen in a glass dish with sufficient space to be able to maneuver the urchin and cutting tools. Turn the urchin upside down so that the teeth tips face up.

- Cut away the connective tissue around the perimeter of the Aristotle's lantern with the scalpel and carefully lift out the lantern. Rinse the lantern off with running distilled water. Discard unused urchin parts in a proper waste disposal container.

- Turn the Aristotle's lantern over again so the tips of the teeth face down. Locate the plumula end of each tooth (opposite to the tip) facing up and use the forceps to carefully slide out individual teeth from the lantern.

- Prepare epoxy to pot the teeth. Weigh 5 g of resin and add 1.15 g of hardener (e.g., 100 parts resin to 23 parts hardener by weight) in a shallow disposable plastic tray. Mix contents together slowly without forming bubbles. Note: Do not leave leftover mixed epoxy in a container with insufficient exposure to the atmosphere. The curing process is exothermic and can ignite nearby flammables. Keep any leftover mixed epoxy in a well-ventilated fume hood away from flammable items.

- Lubricate a 2.5 dram plastic tube (22 mm inner diameter, 39 mm length) using petroleum jelly applied with a finger and wipe off any excess with a tissue. Fill up the tube halfway with mixed epoxy.

- Use the forceps to pick up a tooth and carefully submerge it in the epoxy with the curved concave side facing up. Let the epoxy cure at RT for 24 hr. Note: Prevent the tooth tip from drifting to touch the plastic tube wall as the epoxy cures since this will make polishing the tip more difficult.

- Place the plastic tube with cured epoxy in a vise. Tighten the vise slowly until a fissure is made in the plastic tube. Peel away residual plastic from the epoxy surface.

- Use a sectioning saw to cut the epoxy around the tooth down to a smaller block (1 cm3).

- Prepare a clean area for polishing and set up a flat work station with a hard plastic board. Fill a squirt bottle with distilled water.

- Start with the lowest grit sandpaper available (e.g., 120) and squeeze a small amount of water from the wash bottle onto the sandpaper. Using light pressure, rub the sample in one back and forth direction (e.g., left-right) for 5 min.

- Wash off the surface of the sample over a sink and wipe off with a particle-free tissue. Remove any leftover sandpaper grit with compressed air for 15 sec.

- Use progressively higher grit sandpaper (e.g., 600 and 2,400) to repeat protocol steps 1.6.1 and 1.6.2. Using light pressure, rub the sample in a back and forth direction perpendicular to the previous polish step (e.g., up-down, left-right). Note: Use a light microscope at 20X magnification to see perpendicular scratch marks intersect with each grit level (e.g., 120, 600, 2,400). Move to the next higher grit sandpaper when scratch marks from the previous grit level disappear.

- Prepare a squirt bottle with 3-µm diamond polishing suspension in a 1:1 distilled water solution. Use a polish cloth for diamond suspensions to repeat protocol steps 1.6.1 and 1.6.2.

- Prepare a squirt bottle with 0.5-µm alumina polishing suspension in a 1:1 distilled water solution. Use a microcloth polishing surface to repeat protocol steps 1.6.1 and 1.6.2. Note: Fine scratch marks from protocol steps 1.6.4 and 1.6.5 will not be visible at 20X magnification. For these protocol steps, polish for 5 min in a back and forth motion to remove all previous scratches.

- Clean the polished surface with distilled water and use particle-free tissue with compressed air to carefully dry. Wrap with particle-free tissue to maintain mirror polished finish. Note: Dry all polishing surfaces face down on large particle-free tissues. Store in a plastic sleeve to avoid dust particles settling on the surface between polishing times.

- Characterize the sea urchin tooth microstructure using scanning electron microscopy (SEM). Use a sputter coater to sputter iridium with a deposition current of 85 mA for 10 sec onto the polished tooth surface for a coating thickness of ~20 nm.

- Obtain micrograph images at 250X - 4,000X magnification using a SEM. Note: Use 5 kV in the scanning electron (SE) mode and 15 kV in the back-scattered electron (BSE) mode. Use BSE mode to identify calcite fibers interspersed with Mg-enriched polycrystalline matrix.

- Perform micro-computed tomography (µ-CT) scans of a whole pink sea urchin and a freshly dissected Aristotle's lantern. Position each thawed sample inside the closed chamber container with a moistened tissue to provide a humidified environment while scanning.

- Scan the whole urchin and the Aristotle's lantern by µ-CT with an isotropic voxel size of 36.00 µm and 9.06 µm, respectively. Apply an electrical potential of 100 kVp and 70 kVp with current of 100 mA and 141 mA, for the whole urchin and the Aristotle's lantern, respectively, using a 1.0 mm aluminum filter for both.

- Apply a beam hardening correction algorithm during image reconstruction to account for beam hardening artifacts that result from the µ-CT x-ray source emitting x-rays of multiple energies using manufacturer's protocol.

- Use imaging software to refine image segmentation and acquire a triangle mesh model for the Aristotle's lantern structure.

- Load and preview Aristotle's lantern image data from the µ-CT scan. Match the voxel size (9.06 µm) to the values from the micro-CT scan.

- Use a volume rendering function to visualize the Aristotle's lantern in 3D space. Adjust the 2D orthogonal slice with the Bounding Box module and adjust the threshold value/color with the Volume Rendering module.

- Make mask segments for the region of interest (e.g., sea urchin tooth) using the segmentation editor. Select XY, YZ, and XZ planes and the 3D isometric view. Use the magic wand (black arrow) to distinguish between simple structures (tooth vs. pyramid) in the Aristotle's lantern.

- Reconstruct the model surface from the extracted mask segments. Select the Surface Generation module and apply. Deselect the Volume Rendering Settings to have the visible top surface disappear. Add the Surface View module to display the surface result.

- Simplify the model surface by reducing the number of faces to < 18,000.

- Edit individual triangle mesh on the model surface as needed. Save the model as a stereolithography (STL) file for exporting to use with computer-assisted design (CAD) modeling software.

2. Bioinspired Design

Use the Aristotle's lantern from the micro-CT scan as a reference to make a bioinspired design with CAD modeling software. Note: The bioinspired design has five curved teeth with height 6 cm and diameter 8 cm for the closed lantern. It is scaled up ~5x from the size of the natural Aristotle's lantern.

- Save the STL file parts to a flash drive and upload the files to a fused deposition modeling (FDM) 3D printer.

- Load acrylonitrile butadiene styrene (ABS) plastic and support plastic material cartridges into the appropriate slots of the 3D printer.

- Insert the modeling base on the Z platform and align tabs with slots on the metal tray.

- Open each of the STL file parts and follow the display screen steps to print all the lantern parts at the same time. Note: Lantern parts must fit within the building envelope (25 x 25 x 30 cm3) for the 3D printer. All five teeth are arranged on the modeling base and printed simultaneously with the tooth tip facing up. The build rate is 16 cm3 per hour and the total build time is approximately 8 hr.

- Release the modeling base from the tabs when all file parts are printed and slide the base out of the 3D printer along the tray guides.

- Use a metal spatula to pry all parts off the base and a metal file to wear down any extra plastic attached to the parts.

- Place the printed parts into a heated base bath until the support plastic material dissolves.

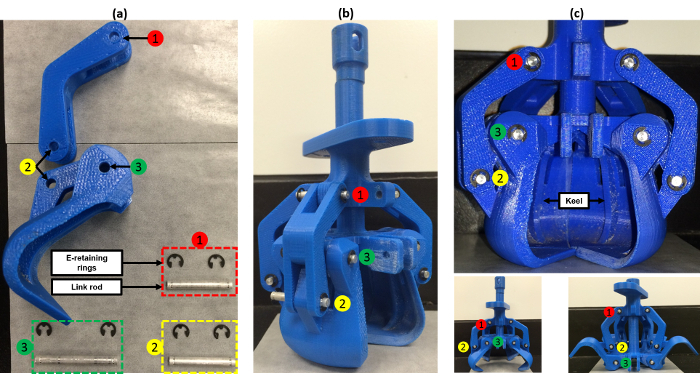

Fasten each tooth to a joint arm with a link rod and two E-retaining rings on either side. Note: Refer to Figure 6 for assembly of the bioinspired Aristotle's lantern.

3. Bioexploration

- Use the CAD file for the bioinspired tooth to do a finite element modeling (FEM) stress analysis test.

- Open the file (xx.sldprt) to do further engineering analysis. Above the "Office Products" tab, select the "SolidWorks Simulation" button.

- Above the "Simulation" tab, select the "Study Advisor" button and then the drop-down option "New Study".

- Select the type of simulation test to be run by choosing "Static".

- On the Static Test list, right-click on "Fixtures" and select "Fixed Geometry".

- Click on the inner faces to add fixtures to the mounting holes where pins will go.

- On the Static Test list, right-click on "External Loads" and select "Force".

- Click on the tooth grinding tip faces to apply 45 N force to the edges.

- On the Static Test list, right-click on "External Loads" and select "Gravity".

- Indicate "Top Plane" for the gravity force applied normal to the plane.

- On the Static Test list, right-click on "Mesh" and select "Create Mesh".

- Move the scale bar for "Mesh Density" all the way to the right for "Fine".

- On the Static Test list, right-click on "Static" and select "Run" to run the test. Note: The colored scale bar for areas of highest stress and the "Yield Strength".

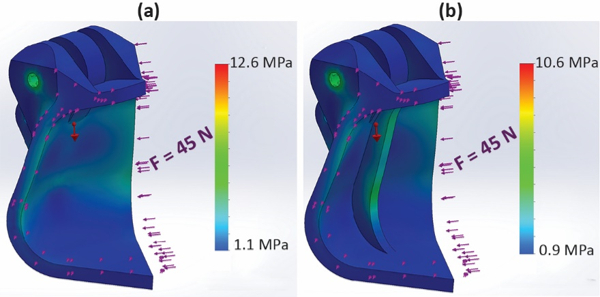

Compare stress analysis test results for the bioinspired tooth with and without the keel.

Representative Results

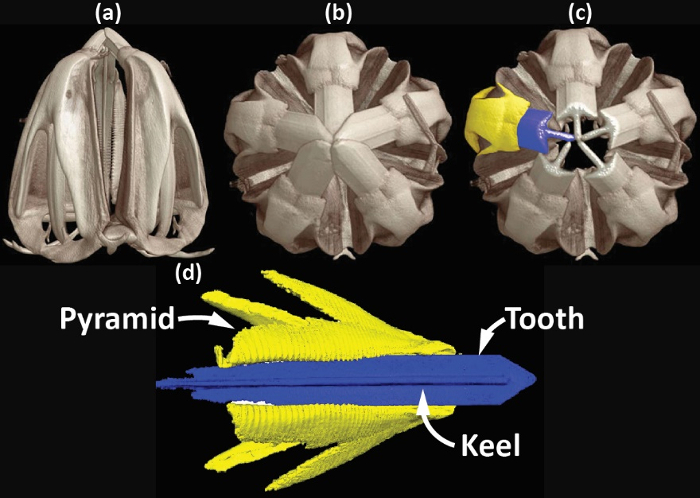

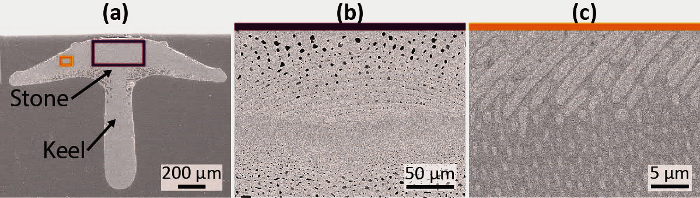

Bioinspired design of the Aristotle's lantern sampling device depends heavily upon the quality of the characterization methods used. Non-invasive techniques like µ-CT are helpful for analyzing the whole lantern and individual teeth to apply application specific enhancements for the bioinspired design (Figure 4). Meanwhile, the tooth microstructure can be explored via secondary electron and back-scattered electron micrographs of the polished cross-section of an individual tooth (Figure 5). The darker gray region is the harder stone part of the tooth grinding tip and consists of up to 40 mol % magnesium atoms that replace the calcium atoms.

Analysis of the tooth microstructure with BSE-SEM (Figure 5) confirmed the structural importance of the Mg-enriched stone part in the tooth grinding tip. Plate and fiber primary elements (calcite monocrystals, lighter gray in Figure 5C) are connected together by a matrix of secondary elements (calcite and magnesium carbonate polycrystals, darker gray in Figure 5C), that make up the hardest stone region of the tooth grinding tip.

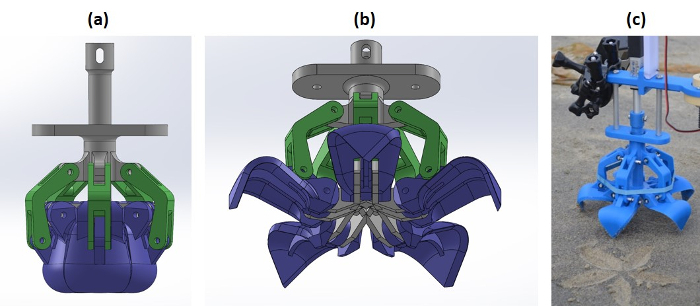

The bioinspired lantern was designed with CAD software, 3D printed and assembled (Figure 6) for collection of sand at the beach (Figure 7). Stress analysis tests were used to calculate the von Mises stress of two tooth designs, one without the keel (Figure 8A) and the other with the keel (Figure 8B). A solid mesh composed of tetrahedrons was employed over the geometry of the tooth. The force value chosen (45 N) matched measurements from tests at the beach to penetrate 1 cm deep into hard sand with lantern teeth perpendicular to the surface.

The mass of the keeled tooth design (12.72 g) was compared with that of the non-keeled tooth design (12.26 g) to find a ~4% increase for the added keel. For 45 N applied force, the maximum stress experienced by the keeled tooth design (10.6 MPa) versus the non-keeled tooth design (12.6 MPa) was ~16% less for the keeled tooth (Figures 7A, B). The mass increase is small compared with the decrease in stress that the keel provides. The decrease in stress demonstrates the effectiveness of this bioinspired design for concentration of stress within the keeled region.

Figure 1. Sea urchin Aristotle's lantern and tooth morphology. (A) Close-up of the ventral view of a sea urchin (left) and the Aristotle's lantern (right)13. (B) Cross-sections of the grooved tooth of a primitive cidaroid urchin (top) and the keeled tooth of a modern camarodont urchin (bottom)14. (C) An isolated tooth seen from its side with the tip (bottom) and indicated keel (left side)20. (D) SEM image of a polished tooth cross-section with the indicated keel (bottom)20. Images adapted from indicated references for (A), (B), (C) and (D). Please click here to view a larger version of this figure.

Figure 1. Sea urchin Aristotle's lantern and tooth morphology. (A) Close-up of the ventral view of a sea urchin (left) and the Aristotle's lantern (right)13. (B) Cross-sections of the grooved tooth of a primitive cidaroid urchin (top) and the keeled tooth of a modern camarodont urchin (bottom)14. (C) An isolated tooth seen from its side with the tip (bottom) and indicated keel (left side)20. (D) SEM image of a polished tooth cross-section with the indicated keel (bottom)20. Images adapted from indicated references for (A), (B), (C) and (D). Please click here to view a larger version of this figure.

Figure 2. Bioinspired designs based on the Aristotle's lantern. (A) Isometric view of a drawing for a bionic model of the Aristotle's lantern, which has 3D printed plastic parts connected by rubber bands (not shown) for the attached musculature16. (B, C) The Aristotle's lantern served as a biological inspiration for a biopsy harvester13. Please click here to view a larger version of this figure.

Figure 2. Bioinspired designs based on the Aristotle's lantern. (A) Isometric view of a drawing for a bionic model of the Aristotle's lantern, which has 3D printed plastic parts connected by rubber bands (not shown) for the attached musculature16. (B, C) The Aristotle's lantern served as a biological inspiration for a biopsy harvester13. Please click here to view a larger version of this figure.

Figure 3. Four steps of the bioinspiration process. (clockwise from left) The bioinspiration process begins with learning from nature through observation of the pink sea urchin and the Aristotle's lantern. (top) Analysis of the sea urchin and the Aristotle's lantern structure from µ-CT scans (left). (right) Collected results are used to generate a bioinspired design prototype. (bottom) Engineering analysis methods were applied to explore biological phenomena and the bioinspired design17,18. Please click here to view a larger version of this figure.

Figure 3. Four steps of the bioinspiration process. (clockwise from left) The bioinspiration process begins with learning from nature through observation of the pink sea urchin and the Aristotle's lantern. (top) Analysis of the sea urchin and the Aristotle's lantern structure from µ-CT scans (left). (right) Collected results are used to generate a bioinspired design prototype. (bottom) Engineering analysis methods were applied to explore biological phenomena and the bioinspired design17,18. Please click here to view a larger version of this figure.

Figure 4. Micro-computed tomography analysis of the Aristotle's lantern structure. (A) Side view of the pyramid structures that help to support the teeth. (B) Sea urchin teeth stack on top of each other and exhibit five-fold symmetry. (C) Distal tip portions are removed to show the longitudinally attached keel structures for all five teeth. (D) An individual tooth and keel (blue) with corresponding pyramid (yellow) are shown and also indicated in (C). Please click here to view a larger version of this figure.

Figure 4. Micro-computed tomography analysis of the Aristotle's lantern structure. (A) Side view of the pyramid structures that help to support the teeth. (B) Sea urchin teeth stack on top of each other and exhibit five-fold symmetry. (C) Distal tip portions are removed to show the longitudinally attached keel structures for all five teeth. (D) An individual tooth and keel (blue) with corresponding pyramid (yellow) are shown and also indicated in (C). Please click here to view a larger version of this figure.

Figure 5. Scanning electron microscopy (SEM) analysis of the sea urchin tooth microstructure. (A) SEM micrograph of a polished tooth cross-section with the faint stone stripe region and keel (bottom) indicated. (B, C) Backscattered electron SEM micrographs of the purple and orange boxes from (A) show curved plate and round fiber calcite primary elements situated above a denser Mg-enriched polycrystalline matrix (darker gray). Please click here to view a larger version of this figure.

Figure 5. Scanning electron microscopy (SEM) analysis of the sea urchin tooth microstructure. (A) SEM micrograph of a polished tooth cross-section with the faint stone stripe region and keel (bottom) indicated. (B, C) Backscattered electron SEM micrographs of the purple and orange boxes from (A) show curved plate and round fiber calcite primary elements situated above a denser Mg-enriched polycrystalline matrix (darker gray). Please click here to view a larger version of this figure.

Figure 6. Assembled 3D printed bioinspired Aristotle's lantern parts. (A) E-retaining rings and link rods are used to fasten the 3D printed tooth parts at three joint positions. (B) Assembled bioinspired Aristotle's lantern with one tooth removed. (C) View of the keel for individual teeth and the changing joint positions when the lantern is partially (left) and fully open (right). Please click here to view a larger version of this figure.

Figure 6. Assembled 3D printed bioinspired Aristotle's lantern parts. (A) E-retaining rings and link rods are used to fasten the 3D printed tooth parts at three joint positions. (B) Assembled bioinspired Aristotle's lantern with one tooth removed. (C) View of the keel for individual teeth and the changing joint positions when the lantern is partially (left) and fully open (right). Please click here to view a larger version of this figure.

Figure 7. Bioinspired Aristotle's lantern design and usage at the beach. (A, B) Computer aided design images of the bioinspired Aristotle's lantern while closed and fully open, respectively. (C) The 3D printed bioinspired Aristotle's lantern collected different types of sand on the beach. Please click here to view a larger version of this figure.

Figure 7. Bioinspired Aristotle's lantern design and usage at the beach. (A, B) Computer aided design images of the bioinspired Aristotle's lantern while closed and fully open, respectively. (C) The 3D printed bioinspired Aristotle's lantern collected different types of sand on the beach. Please click here to view a larger version of this figure.

Figure 8. Bioinspired sea urchin tooth stress analysis test. (A, B) Finite element analysis shows the non-keeled (A) versus keeled (B) tooth when force is applied at the tooth edges. The keeled tooth design experienced ~16% less stress due to addition of the keel. Please click here to view a larger version of this figure.

Figure 8. Bioinspired sea urchin tooth stress analysis test. (A, B) Finite element analysis shows the non-keeled (A) versus keeled (B) tooth when force is applied at the tooth edges. The keeled tooth design experienced ~16% less stress due to addition of the keel. Please click here to view a larger version of this figure.

Discussion

Sea urchins use the Aristotle's lantern (Figure 1A) for a variety of functions (feeding, boring, pivoting, etc.). The fossil record indicates that the lantern has evolved in shape and function from the most primitive cidaroid type to the camarodont type of modern sea urchins14. Cidaroid lanterns have longitudinally grooved teeth (Figure 1B, top) and non-separated muscle attachment to its pyramid structure. This limits their up and down movement and robs them of the greater scraping power generated by lateral movement, which is observed in the more modern camarodont lanterns (Figure 1B, bottom). Biologists have speculated that the keeled tooth (Figure 1C, D) evolved in camarodonts to reinforce the tooth under the strong tensile forces generated by scraping hard substrates18,20,23.

The bioinspired design protocol in this work combined biology, biological materials science, bioinspired design and bioexploration (Figure 3) to develop a bioinspired device with a specific function for sampling sediment. The µ-CT scan of the Aristotle's lantern (Figure 4) was imported as an STL file for reference only since the final sampler design did not mimic the complex muscle attachment in the natural structure. Instead the bioinspired design employed a simpler opening and closing mechanism with parts that could be manufactured easily by a 3D printer for assembly into the Aristotle's lantern sampler. Overall, we used a circular approach for bioinspired design since the bioexploration step allowed for new conclusions to be drawn from the natural biology. Potential modifications of the bioinspired design can address different applications besides sampling sediment. A limitation of this protocol is that it is focused on one specific application of the bioinspired process for a device based on the Aristotle's lantern. However, the protocol outlined here can be applied to the analysis, development and ultimate fabrication of other bioinspired designs based upon biological samples.

The primary application for this assembled bioinspired Aristotle's lantern sampler (Figure 6) was for collecting loose and compacted sand (Figure 7). Looking ahead, NASA has a plan to bring back Martian samples to Earth using a sample-return rover after a succession of missions over many years29. A sample-return rover outfitted with a bioinspired Aristotle's lantern sampler may be beneficial to future missions. A smaller sampler that resembles the size of a natural Aristotle's lantern may also be useful for other applications. The anisotropy of hardness in natural urchin teeth, while interesting in its own right, was not incorporated in this bioinspired design.

Bioexploration of keeled versus non-keeled teeth confirmed the important structural purpose of the keel in natural sea urchins (Figure 8). The bioexploration result provides data that helps explain why modern sea urchins evolved keel structures. We acknowledge that Porter17,18 was the first to propose the bioexploration step applied in this work, which was essential for using engineering analysis methods to quantify the mechanical advantage of the keel structure in the sea urchin tooth. Future bioinspired design that connects natural observation, biological materials science, bioinspired design and bioexploration can be beneficial for incorporating a deeper rooted familiarity with natural design principles.

Disclosures

We have nothing to disclose.

Acknowledgments

This work is supported by Multi-University Research Initiative through the Air Force Office of Scientific Research of the United States (AFOSR-FA9550-15-1-0009) (M. B. F., S. E. N., J.-Y. J., J. M). Collection of pink sea urchins was supported by the University of California Ship Funds and the US National Marine Fisheries Service (K.N.S., J.R.A.T). The authors acknowledge the following people: Prof. Jerry Tustaniwskyj for helpful suggestions during development of the bioinspired Aristotle's lantern sampler, Prof. Marc A. Meyers (UCSD, Dept. of Mechanical and Aerospace Engineering, Materials Science and Engineering Program), Prof. Robert L. Sah and Esther Cory (UCSD, Dept. of Bioengineering), and Dr. Maya deVries (Marine Biology Research Division, Scripps Institution of Oceanography). We also thank undergraduate students Sze Hei Siu, Jerry Ng and Ivan Torres for polishing urchin teeth cross-sections.

References

- Nalla RK, Kruzic JJ, Ritchie RO. On the origin of the toughness of mineralized tissue: Microcracking or crack bridging? Bone. 2004;34(5):790–798. doi: 10.1016/j.bone.2004.02.001. [DOI] [PubMed] [Google Scholar]

- Ritchie RO, Buehler MJ, Hansma P. Plasticity and toughness in bone. Physics Today. 2009;62(6):41–47. [Google Scholar]

- Seki Y, Schneider MS, Meyers MA. Structure and mechanical behavior of a toucan beak. Acta Mater. 2005;53(20):5281–5296. [Google Scholar]

- Feng L, et al. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002;14(24):1857–1860. [Google Scholar]

- Sun TL, Feng L, Gao XF, Jiang L. Bioinspired surfaces with special wettability. Acc. Chem. Res. 2005;38(8):644–652. doi: 10.1021/ar040224c. [DOI] [PubMed] [Google Scholar]

- Feng XJ, Jiang L. Design and creation of superwetting/antiwetting surfaces. Adv. Mater. 2006;18(23):3063–3078. [Google Scholar]

- Arzt E. Biological and artificial attachment devices: Lessons for materials scientists from flies and geckos. Mat. Sci. Eng. C. 2006;26(8):1245–1250. [Google Scholar]

- Geim AK, Dubonos SV, Grigorieva IV, Novoselov KS, Zhukov AA, Shapoval SY. Microfabricated adhesive mimicking gecko foot-hair. Nat. Mater. 2003;2(7):461–463. doi: 10.1038/nmat917. [DOI] [PubMed] [Google Scholar]

- Munch E, Launey ME, Alsem DH, Saiz E, Tomsia AP, Ritchie RO. Tough, bio-inspired hybrid materials. Science. 2008;322(5907):1516–1520. doi: 10.1126/science.1164865. [DOI] [PubMed] [Google Scholar]

- Launey ME, et al. Designing highly toughened hybrid composites through nature-inspired hierarchical complexity. Acta Mater. 2009;57(10):2919–2932. [Google Scholar]

- Launey ME, Munch E, Alsem DH, Saiz E, Tomsia AP, Ritchie RO. A novel biomimetic approach to the design of high-performance ceramic-metal composites. J. R. Soc. Interface. 2010;7(46):741–753. doi: 10.1098/rsif.2009.0331. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jelinek F, Smit G, Breedveld P. Bioinspired spring-loaded biopsy harvester-Experimental prototype design and feasibility tests. J. Med. Devices. 2014;8(1):015002. [Google Scholar]

- Jelinek F, Goderie J, van Rixel A, Stam D, Zenhorst J, Breedveld P. Bioinspired crown-cutter-The impact of tooth quantity and bevel type on tissue deformation, penetration forces, and tooth collapsibility. J. Med. Devices. 2014;8(4):041009. [Google Scholar]

- Reich M, Smith AB. Origins and biomechanical evolution of teeth in echnoids and their relatives. Palaeontology. 2009;52(5):1149–1168. [Google Scholar]

- Scarpa G. Modelli di Bionica, Capire la Natura Sttraverso i Modelli. Bologna, Italy: 1985. [Google Scholar]

- Trogu P. Bionics and Design: Pure and Applied Research. Living Machines 2014: 3rd International Conference on Biomimetics and Biohybrid Systems; Barcelona, Spain. 2014. [Google Scholar]

- Porter MM, Adriaens D, Hatton RL, Meyers MA, McKittrick JM. Bioexploration: How engineering designs help elucidate the evolution of seahorse tails. SICB Annual Meeting; 2015 Jan 3-7; West Palm Beach, FL: Society for Integrative and Comparative Biology; 2015. [Google Scholar]

- Porter MM. Bioinspired Design: Magnetic Freeze Casting. San Diego: University of California; 2014. [Google Scholar]

- De Ridder C, Lawrence JM. Echinoderm Nutrition. CRC Press; 1982. Food and feeding mechanisms: Echinoidea. [Google Scholar]

- Killian CE, et al. Self-sharpening mechanism of the sea urchin tooth. Adv. Funct. Mater. 2011;21(4):682–690. [Google Scholar]

- Kier PM. Evolutionary trends and their functional significance in the post-paleozoic echinoids. J. Paleo. 1974;48(3):1–95. [Google Scholar]

- Wang RZ, Addadi L, Weiner S. Design strategies of sea urchin teeth: structure, composition and micromechanical relations to function. Phil. Trans. R. Soc. B: Biol. Sci. 1997;352(1352):469–480. doi: 10.1098/rstb.1997.0034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma Y, et al. The grinding tip of the sea urchin tooth exhibits exquisite control over calcite crystal orientation and Mg distribution. Proc. Natl. Acad. Sci. U.S.A. 2009;106(15):6048–6053. doi: 10.1073/pnas.0810300106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Markel K, Gorny P, Abraham K. Microstructure of sea urchin teeth. Fortschritte der Zoologie. 1977;24(2-3):103–114. [Google Scholar]

- Andrietti F, MD Carnevali Candia, Wilkie IC, Lanzavecchia G, Melone G, Celentano FC. Mechanical analysis of the sea-urchin lantern: the overall system in Paracentrotus lividus. J. Zool., London. 1990;220:345–366. [Google Scholar]

- Ellers O, Telford M. Forces generated by the jaws of Clypeasteroids (Echinodermata: Echionoidea) J. Exp. Biol. 1991;155:585–603. [Google Scholar]

- Candia Carnevali MD, Wilkie IC, Lucca E, Andrietti F, Melone G. The Aristotle's lantern of the sea-urchin Stylocidaris affinis (Echinoida, Cidaridae): functional morphology of the musculo-skeletal system. Zoomorphology. 1993;113(3):173–189. [Google Scholar]

- Wilkie IC, Candia Carnevali MD, Andrietti F. Mechanical properties of sea-urchin lantern muscles: a comparative investigation of intact muscle groups in Paracentrotus lividus (Lam) and Stylocidaris affinis (Phil) (Echinodermata, Echinoidea) J. Comp. Physiol. B. 1998;168(3):204–212. [Google Scholar]

- Witze A. NASA plans Mars sample-return rover. Nature. 2014;509(7500):272. doi: 10.1038/509272a. [DOI] [PubMed] [Google Scholar]