Abstract

The effects of gaseous ozone exposure on the bacterial counts and oxidative properties were evaluated in duck and chicken breast fillets, which were stored under a continuous flux of gaseous ozone (10×10−6 kg O3/m3/h) at 4±1℃ for 4 d. The ozone generator was set to on for 15 min and off for 105 min, and this cyclic timer was set during storage. Ozone effectively reduced the growth of coliform, aerobic and anaerobic bacteria in both chicken and duck breast. However, lipid oxidation occurred faster in duck breast than chicken breast with higher degree of discoloration, TBARS value, and antioxidant enzyme (glutathione peroxidase and catalase) activity decline rates. It is concluded that ozone effectively controlled the growth of bacteria in both chicken and duck breast with less effects on oxidative deterioration in chicken breast.

Keywords: bacterial counts, chicken, duck, lipid oxidation, ozone

Introduction

Poultry meat is known for its low fat content but high nutritional value and is relatively cheaper due to low cost of production compared to beef or pork (Chouliara et al., 2007). According to FAO (2006), poultry meat consumption accounts for approximately 31% of global meat consumption. However, poultry meats are highly perishable due to bacterial contamination (Hong et al., 2007), and in the worst case scenario, the contamination can cause food poisoning. Various processing techniques as well as treatments during storage have been developed to extend the shelf-life of poultry meat and meat products (Hwang and Beuchat, 1995; Kim and Day, 2007).

Ozone is commercially used for the deodorization of industrial waste and the disinfection of drinking water. However, the use of ozone for food stuff has increased after its designation as Generally Recognized as Safe (GRAS) by the Food and Drug Administration (FDA) in 1997 (Kim et al., 1999). Ozone is used in a wide variety of agricultural products, such as vegetables, fruits and fish with broad-spectrum antimicrobial activity and is regarded as a potential bactericidal agent (Greene et al., 2012). Botzenhart et al. (1993) have shown that ozone is a more effective sanitizer than chlorine dioxide. The possible action of ozone for bacterial elimination is that ozone can disrupt the cell membrane and cell wall constituents of bacteria, leading to cell lysis and damage proteins and DNA (Komanapalli and Lau, 1996). The disruption or lysis of cell walls by ozone is a faster bacterial inactivation mechanism than inactivation by disinfectants, which require time to permeate the cell membrane (Pascual et al., 2007). Yang and Chen (1979) found that broiler cuts soaked in water-containing ozone prior to refrigerated storage, had longer shelf-life.

Lipid oxidation is one of the primary factors that reduce the quality of meat and meat products such as discoloration, and the compound generated by lipid oxidation may affect human health. Lipid oxidation occurs through the presence of both endogenous and exogenous pro-oxidants. Environmental conditions also promote the occurrence of lipid oxidation. In fresh meat, the endogenous pro-oxidants, such as reactive oxygen species (ROS) contained in muscle, are the common initiators of lipid oxidation (Chan and Decker, 1994). However, for meat products or fresh meat subjected to processing, the susceptibility to lipid oxidation is greater. Spices or additives, physical processes (including grinding, chopping and mixing), cooking and storage increase the chance of lipid oxidation (Ladikos and Lougovois, 1990). Ozone causes oxidative conditions to which the cells respond by stimulating the expression of antioxidant enzymes such as catalase, glutathione peroxidase (GPx) and superoxide dismutase (SOD) (Lee et al., 2003).

Previous study was focus on the bactericidal effect of gaseous ozone exposure on chicken breast inoculated with Salmonella enterica serovar Typhimurium (Muhlisin et al., 2015). Study on the effect of ozone exposure on poultry meat from different species was limited. Thus, present study reported the effect of gaseous ozone exposure during refrigerated storage on bacterial counts and oxidative properties in chicken and duck breast meat including meat antioxidant enzyme activity.

Materials and Methods

Sample preparation

Skinless chicken and duck breast fillets were obtained from a local market on the day of experiment. A 20.0±1.0 g sample was placed on a sterilized petri dish (Ø60 mm × 15 mm; SPL Life Sciences, Korea) in two different chambers (L × W × H = 25 × 20 × 20 cm). The first chamber contained a normal air composition, and the second chamber was equipped with an ozone generator (MA-2, NOAH environmental clean, Korea). It generates electric tension to produce a continuous flux of ozone (10×10−6 kg O3/m3/h) and negative ions. The ozone generator was set to on for 15 min and off for 105 min (on/off = 1:7) using an automatic timer plug (Theben 0260.0, Germany) and this setting was run during the 3-d storage period. The chamber was cleaned with 70% ethanol to eliminate potential contaminants during storage. The chambers were placed in a refrigerator at a temperature of 4±1℃. Daily experiments were conducted to measure the bacterial counts and oxidative properties. The bacterial counts included total plate counts of coliform, aerobic and anaerobic bacteria bacteria. The oxidative properties measurements included instrumental color, TBARS and antioxidant enzyme activity.

Bacterial count measurements

Approximately 1 g of sample was put in a sterile bag (Nasco Whirl-Pak, USA) and was homogenized with 9 mL sterilized 0.1% peptone water for 2 min using a stomacher (Lab blender 400 Seward Laboratory, UK). Decimal dilutions were prepared using 0.1% sterilized peptone water. Coliform was enumerated using VRBA (violet red bile agar, Difco, USA), and total bacteria was enumerated using plate count agar (PCA; Difco, USA). For coliform and aerobic bacteria enumeration, the plates were incubated aerobically at 37℃ for 24-48 h. For total anaerobic bacteria count determination, the plates was incubated anaerobically at 37℃ for 24-48 h. Microbial population was counted using a colony counter (C-C03, Chang Shin Scientific, Korea) and expressed as Log CFU/g.

Instrumental color

The surface color of the samples was measured instrumentally using a chromameter (CR-400, Konica Minolta Sensing Inc., Japan) on each day of storage. The light source of illuminant C (2° observer) was calibrated with a white plate (Y=93.6, X=0.3134, y=0.3194). The instrumental surface color of the CIE L* (lightness), a* (redness) and b* (yellowness) of the sample was measured in triplicates for each sample. Chroma (C* = (a*2 + b*2)0.5) and hue-angle (h° = arctan (b*/a*)) were calculated using a data processor (DP-400, Konica Minolta Sensing Inc., Japan). Three measurements of each sample were performed on the surface immediately after the samples were taken out of the chamber.

Chemicals

HPLC-grade chloroform was purchased from Daejung Chemical and Metals Co. Ltd. (Korea). Distilled water (DW) was purified with a glass still (Mega-PureTM System MP-11A, Corning Inc., USA). All other reagents were purchased from Sigma-Aldrich Co., LLC. (USA).

Lipid oxidation

Each 0.5 g of sample was mixed with three drops of antioxidant solution, 3 mL of TBA solution and 17 mL of 25% (w/v) trichloroacetic acid (TCA), followed by incubation in a water bath at 100℃ for 30 min. The mixture was cooled, and 5 mL volume was removed and centrifuged at 2,400 g for 30 min. The absorbance of the supernatant was measured at 532 nm using a spectrophotometer (UVmini-1240, Shimadzu, Japan). The results were expressed as mg of malonaldehyde (MA) per kg of sample (Sinnhuber and Yu, 1977).

Determination of antioxidant enzyme activity

Protein extraction

A 5-g sample was homogenized with 25 mL of 50 mM phosphate buffer (pH 7.0) using a homogenizer (Ultra- Turrax T25 basic, IkaWerke GmbH & Co., Germany) for 15 s at 13,500 rpm. Centrifugation was performed at 1,000 g for 15 min at 2℃. The supernatant was filtered through a Whatman filter paper No. 1.

Catalase (CAT)

CAT activity was measured using a method described by Aebi (1984). First, 100 μL of filtered supernatant was mixed with 2.9 mL of 30 mM H2O2 within a crystal cuvette (light path: 1 cm). The decrease in absorbance at 240 nm was recorded every 10 s for 2 min. The catalase activity was calculated as follows:

The number 3.45 represents the decomposition of 3.45 μmol of hydrogen peroxide in a 3.0 mL reaction mixture to produce a decrease in absorbance at 240 nm from 0.45 to 0.40 absorbance units. T-min corresponds to the time in minutes required for absorbance at 240 nm to decrease from 0.45 to 0.40 absorbance units, and 0.1 mL represents the volume of the meat extract. The catalase activity was expressed as units/g sample. CAT activity was expressed as U/g sample.

Glutathione peroxidase (GPx)

The GSH-Px activity measurement was performed according to the enzymatic protocol by Flohé and Günzler (1984) with slight modification. A total of 100 μL of filtered supernatant was mixed with 0.5 mL of phosphate buffer-0.001 M EDTA-0.1 M NaN3, 100 μL of the assay mixture containing 5 units/mL glutathione reductase in 50 mM phosphate buffer, 100 μL of 10 mM L-glutathione reduced, 100 μL of 1.5 mM NADPH in NaHCO3, and 100 μL of 1.5 mM H2O2 within a 10-mm precision cell (104-QS, Hellma Analytics, Germany) and incubated for 5 min at room temperature. GSH-Px activity was measured by recording the decrease in absorbance of the incubated mixture at 340 nm over 2 min. GSH-Px activity was expressed as U/g sample. One unit represents the amount of meat extract needed to alter 1 μmol of NADPH with a mM extinction coefficient of 6.3 at 340 nm.

Statistical analysis

All values are reported as mean±standard deviation for each treatment group. Analysis of variance (ANOVA) was performed using the general linear model (GLM) procedure of SPSS, version 19.0 (SPSS 2010), followed by Duncan’s multiple range test to compare the mean of oxidative properties. The difference in bacterial counts between the ozone treatment and control groups was determined using a paired sample t-test with a confidence interval of 95% (p<0.05).

Results and Discussion

Bacterial growth

Total aerobic, anaerobic and coliform are presented in Table 1. Ozone significantly reduced the aerobic bacterial counts in chicken breast from 1 d of storage and in duck breast from 3 d of storage (p<0.05). Ozone decreased the anaerobic bacteria counts from 2 d of storage in both duck and chicken breast. The inhibition rate of aerobic and anaerobic bacteria by ozone treatment was found higher in chicken than duck breast meat on day 3 because the population of aerobic and anaerobic bacteria in non-treated chicken breast meat was higher 1 Log CFU than those in duck breast meat. Total coliform was significantly lower from 2 d of storage in sample exposed to ozone (p<0.05). Moreover, on day 4 of storage, coliform was not detected in both duck and chicken breast exposed to ozone. These data clearly show that ozone was more effective to diminish the population of coliform in duck and chicken breast until day 4 of storage and indicate that exposing ozone at 10×10−6 kg O3/m3/h could disinfect harmful pathogen such as Escherichia coli. This result agrees with a previous study showing that 12×10−6 kg O3/m3/h of ozone treatment reduced the CFU by 0.65 Log CFU/g in a circular beef sample cut from a carcass at 5℃ on day 1 after the samples were inoculated with 50 μL of 108 CFU/mL of E. coli O157:H7 (Cardenas et al., 2011).

Table 1. Bacteria counts (Log CFU/g) of duck and chicken breast exposed with gaseous ozone during refrigerated storage.

| Total Bacteria | Treatment | Storage (d) |

||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Aerobic | Duck+Ozone | 2.72±0.02bD | 2.96±0.04bC | 3.13±0.04bB | 2.52±0.27cD | 5.79±0.04cA |

| Duck | 2.72±0.02bD | 3.18±0.21bC | 3.44±0.45bC | 4.11±0.06bB | 6.54±0.09aA | |

| Chicken+Ozone | 3.09±0.19aB | 2.14±0.13cD | 2.55±0.07cC | 2.96±0.25cB | 6.24±0.07bA | |

| Chicken | 3.09±0.19aD | 3.40±0.47aD | 5.01±0.11aC | 5.35±0.13aB | 6.60±0.00aA | |

| Anaerobic | Duck+Ozone | 2.89±0.07C | 3.11±0.13bB | 3.00±0.12cB | 3.46±0.18cA | 3.58±0.32cA |

| Duck | 2.89±0.07C | 4.19±0.16aB | 3.80±0.34bB | 3.95±0.17bB | 6.47±0.01aA | |

| Chicken+Ozone | 2.73±0.06B | 2.29±0.13cC | 2.57±0.38dB | 2.18±0.19dC | 6.10±0.10bA | |

| Chicken | 2.73±0.06C | 2.86±0.36bC | 4.67±0.32aB | 4.63±0.24aB | 6.46±0.02aA | |

| Coliform | Duck+Ozone | 1.39±0.12b | 1.54±0.09c | 1.59±0.16c | 1.39±0.12d | Not determined |

| Duck | 1.39±0.12bE | 2.24±0.18aD | 3.00±0.02aC | 3.28±0.04bB | 3.54±0.01A | |

| Chicken+Ozone | 1.93±0.04a | 1.98±0.03b | 1.39±0.12d | 1.74±0.06c | Not determined | |

| Chicken | 1.93±0.04aD | 2.16±0.17abD | 2.79±0.30bC | 3.35±0.04aB | 3.65±0.07A | |

Mean values±standard deviation.

a-dMeans in the same column followed by different superscript letters in lower-case are significantly different (p<0.05).

A-EMeans in the same row followed by different superscript letters in upper-case are significantly different (p<0.05).

Lipid oxidation

TBARS value (Table 2) is a strong objective predictor of the perception of rancidity. The TBARS value of the duck breast was higher than that of the broiler chicken throughout storage time. Starting from 2 d of storage, the TBARS value in duck breast meat exposed to ozone was significantly higher compared with duck without ozone exposure and chicken breast (p<0.05). However, the ozone effect on the TBARS of chicken breast was only observed on day 4 of storage.

Table 2. TBARS values (mg MA/kg) of duck and chicken breast exposed with gaseous ozone during refrigerated storage.

| Treatment | Storage (d) |

||||

|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | |

| Duck+Ozone | 0.50±0.08E | 1.09±0.25aD | 2.63±0.22aC | 3.16±0.16aB | 3.40±0.18aA |

| Duck | 0.50±0.08E | 1.23±0.03aD | 1.35±0.19bC | 1.61±0.32bB | 2.11±0.20bA |

| Chicken+Ozone | 0.32±0.12D | 0.35±0.08bD | 0.66±0.07cC | 0.82±0.12cB | 1.63±0.28cA |

| Chicken | 0.32±0.12D | 0.34±0.09bD | 0.52±0.07cC | 0.81±0.10cB | 1.46±0.18dA |

Mean values±standard deviation.

a-dMeans in the same column followed by different letters in superscript lower-case are significantly different (p<0.05).

A-EMeans in the same row followed by different letters in superscript upper-case are significantly different (p<0.05).

Ozone promotes lipid oxidation in chicken and duck breast meat. The action of ozone on oxidants causes irreversible damage to the fatty acids in the cell membrane and the cellular protein through oxidation (Sekhon et al., 2010). Ozone (O3) is categorized as a radical derivative reactive oxygen species (ROS) that is mainly responsible for the initiation of the oxidation reaction of foods, particularly in lipids, where it destroys essential fatty acids (Choe and Min, 2005). Moreover, ozone gas is unstable and decays naturally into diatomic oxygen (Finch and Fairbairn, 1991). During continuous exposure, the oxygen generated by ozone degradation might increase. Previous studies have reported the effect of oxygen on the promotion of the lipid oxidation in meat (Li et al., 2012; Vitale et al., 2014).

Antioxidant enzyme activity

The effects of the ozone treatment on the CAT and GPx activities are presented in Table 3. The initial CAT activity of the duck breast meat was higher that than of chicken breast (p<0.05). As the storage time increased, the CAT activity of all sample groups decreased. The ozone exposure reduced the CAT activity in duck from 3 d of storage (p<0.05). However, the ozone exposure did not statistically affect the CAT activity in chicken breast. The CAT activity in chicken breast exposed to ozone tended to be lower than that in the non-ozone counterpart. The relatively stable CAT activity of beef muscles under aerobic conditions was also reported by Renerre et al. (1996). Pradhan et al. (2000) found stable CAT activity in ground beef during 6 d of aerobically refrigerated storage. Whiteside and Hassan (1988) reported CAT inactivation caused by exposure to ozone gas. They also noted that the inactivation of CAT by ozone depended on the time exposure and pH level. Lee et al. (2003) suggested that the inactivation of CAT by ozone was primarily due to damage in protein moieties, which subsequently led to heme release.

Table 3. Antioxidant enzymes activity of duck and chicken breast exposed with gaseous ozone during refrigerated storage.

| Item | Treatment | Storage (day) |

||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| Catalase activity (U/g) | Duck+Ozone | 93.35±6.1aA | 87.40±5.1aB | 73.61±1.3aC | 65.36±8.1bD | 58.82±5.6bE |

| Duck | 93.35±6.1aA | 89.56±7.5aA | 78.19±8.3aB | 75.82 ±1.3aB | 68.15±10.3aC | |

| Chicken+Ozone | 55.89±8.7bA | 46.70±4.7bB | 44.12±5.3bBC | 40.17±1.3cC | 30.38±5.6cD | |

| Chicken | 55.89±8.7bA | 49.19±3.4bB | 48.31±5.6bB | 42.19±4.3cC | 30.96±5.1cC | |

| Glutathione peroxidase activity (U/g) | Duck+Ozone | 0.28±0.06aA | 0.21±0.06bAB | 0.19±0.01aB | 0.16±0.01aBC | 0.12±0.07bC |

| Duck | 0.28±0.06aA | 0.27±0.09aA | 0.23±0.05aAB | 0.20±0.05aB | 0.18±0.03aB | |

| Chicken+Ozone | 0.26±0.10aA | 0.21±0.05bA | 0.21±0.06aA | 0.18±0.06aA | 0.13±0.02bB | |

| Chicken | 0.26±0.10aA | 0.25±0.09abA | 0.22±0.01aAB | 0.20±0.04aB | 0.15±0.06abB | |

Mean values±standard deviation.

a-dMeans in the same column followed by different superscript letters in lower-case are significantly different (p<0.05).

A-EMeans in the same row followed by different superscript letters in upper-case are significantly different (p<0.05).

GPx decreased as the storage time increased in all samples. The GPx activity of both duck and chicken breast exposed to ozone tended to be lower than in the sample without ozone exposure. A significant effect of ozone on GPx activity was only detected on days 1 and 4 of storage, during which GPx was lower. These results indicate that GPx was more resistant to ozone than CAT. This result is in accordance with that of Lee et al. (2003). CAT and GPx, together with SOD, are known to act to prevent the accumulation of lipid oxidation products (Utama et al., 2016). Because the activity of CAT and GPx was reduced by ozone, these enzymes lost their antioxidant abilities, which resulted in increased lipid oxidation rates.

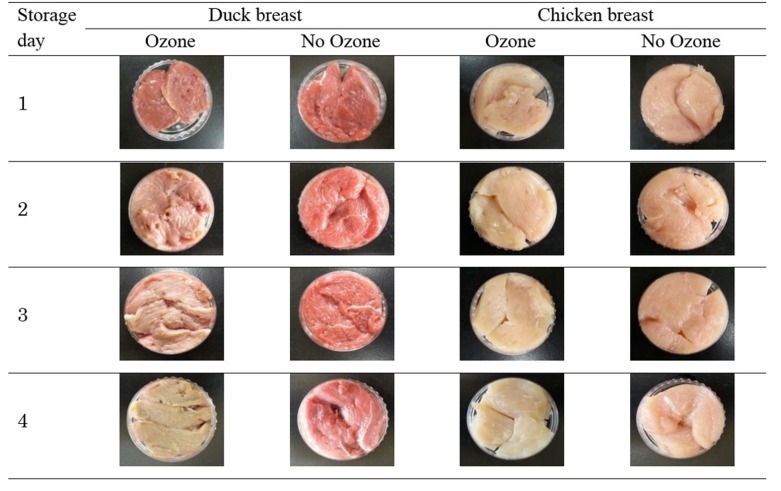

Instrumental surface color

The changes in surface color of chicken and duck breast exposed to gaseous ozone are shown in Table 4 and Fig. 1. Ozone exposure significantly reduced the redness of duck and chicken breast during storage. This color appearance was instrumentally proved by CIE a* value data measured with a color difference meter. The CIE a* value of duck meat was significantly higher than that of chicken. The redness was significantly reduced by ozone exposure (p<0.05) throughout the storage days and higher decline rate was recorded in duck breast. Ozone accelerated the increasing degree of CIE L*, b* and h° value on the surface of duck and chicken breast during storage. However, the chroma values were affected by ozone exposure in the same manner as the CIE a* values, creating pale and brown characteristics.

Table 4. Surface color of duck and chicken breast exposed with gaseous ozone during refrigerated storage.

| Item | Treatment | Storage (d) |

||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| CIE L* | Duck+Ozone | 45.18±0.85bC | 45.28±1.38bC | 48.04±1.44bC | 51.70±2.82bA | 50.31±1.87cA |

| Duck | 45.18±0.85bC | 45.52±1.58bC | 46.85±2.44bB | 46.97±2.64cB | 51.60±2.78cA | |

| Chicken+Ozone | 55.6±0.51aC | 55.93±3.13aC | 57.48±2.64aB | 59.49±3.46aB | 65.10±1.28aA | |

| Chicken | 55.6±0.51aBC | 58.10±2.68aAC | 54.92±1.95a | 57.91±2.03aAB | 56.13±3.23bB | |

| CIE a* | Duck+Ozone | 15.87±0.56aA | 12.77±0.75bB | 9.74±1.16bC | 7.60±2.82bD | 4.58±0.89bE |

| Duck | 15.87±0.56aA | 15.56±2.12aA | 15.98±1.79aA | 14.82±1.92aA | 12.40±1.95aB | |

| Chicken+Ozone | 2.5±0.64bA | 1.73±0.94cAB | 0.05±0.04dC | 1.17±0.66cB | 0.33±0.20cC | |

| Chicken | 2.5±0.64bA | 1.79±0.73cBC | 1.62±0.44cBC | 1.47±0.78cC | 2.16±0.46cB | |

| CIE b* | Duck+Ozone | 8.84±1.20aB | 8.44±3.80aB | 9.22±0.85aA | 8.97±1.69aAB | 10.87±0.77aA |

| Duck | 8.84±1.20aA | 8.76±1.45aA | 9.08±0.74aA | 8.50±1.34aA | 6.25±1.29bB | |

| Chicken+Ozone | 2.0±0.67bD | 5.60±0.94bB | 6.74±0.58bA | 4.65±0.86bC | 5.13±1.10bcB | |

| Chicken | 2.0±0.67bC | 5.83±0.73bA | 4.98±1.18cB | 6.47±1.10bA | 4.23±0.67cB | |

| C* | Duck+Ozone | 17.12±0.87aA | 15.31±0.75bB | 13.45±0.98bC | 11.86±1.53bD | 11.82±0.84bD |

| Duck | 17.12±0.87aA | 17.87±2.47aA | 18.40±1.77aA | 17.08±2.33aA | 13.90±2.26aB | |

| Chicken+Ozone | 6.52±1.02bA | 5.95±1.19cA | 6.76±0.59cA | 4.84±0.76cB | 5.15±1.10cAB | |

| Chicken | 6.52±1.02bA | 6.15±0.97cAB | 5.25±1.17dB | 6.67±1.15cA | 4.77±0.73cB | |

| h° | Duck+Ozone | 29.65±1.32bD | 33.50±1.47bC | 43.51±4.40cB | 49.69±8.37bB | 67.20±4.00aA |

| Duck | 29.65±1.32bA | 29.31±2.38bA | 29.72±2.55dA | 29.77±0.98cAcA | 26.63±2.56dB | |

| Chicken+Ozone | 72.85±2.54aB | 72.23±11.06aB | 89.75±3.70aA | 74.98±8.85aB | 86.24±2.33aA | |

| Chicken | 72.85±2.54aB | 72.42±8.31aB | 71.61±5.36bB | 77.40±5.84aA | 62.99±4.19bC | |

Mean values±standard deviation.

a-dMeans in the same column followed by different letters in superscript lower-case are significantly different (p<0.05).

A-DMeans in the same row followed by different letters in superscript upper-case are significantly different (p<0.05).

Fig. 1. Changes in surface color of duck and chicken breast meat exposed to gaseous ozone during refrigerated storage.

Our results are in line with those of Cardenas et al. (2011), who found lower a* values of beef exposed continuously to ozone for 24 h. An ozone-induced decrease of a* during the storage of ground beef was also reported by Stivarius et al. (2002). The decrease in a* was due to the oxidation of myoglobin and oxymyoglobin to metmyoglobin through the ozone exposure. Ozone and other reactive oxygen species are strong oxidants that initiate lipid and myoglobin oxidation (Bekhit et al., 2013). The oxidation of myoglobin produces metmyoglobin, which causes the discoloration of meat that is characterized by lower redness (Mancini and Hunt, 2005).

Conclusions

Gaseous ozone exposure at 10×10−6 kg O3/m3/h effectively inhibited the growth of coliform and total aerobic and anaerobic bacteria in chicken and duck breast meat during refrigerated storage. As the TBARS values of chicken breast meat were still in acceptable amount until day 3, chicken breast meat could be preserved by gaseous ozone exposure at 10×10−6 kg O3/m3/h until no longer than 3 d of storage. In contrast, preserving duck breast meat by ozone exposure is not recommended as undesirable brown color appears and TBARS values increase rapidly.

Acknowledgments

This study was supported by a 2014 research grant from Kangwon National University (No. 120140200).

References

- 1.Aebi H. Catalase in vitro. Methods Enzymol. 1984;105:121–126. doi: 10.1016/s0076-6879(84)05016-3. [DOI] [PubMed] [Google Scholar]

- 2.Bekhit A. E. D. A., Hopkins D. L., Fahri F. T., Ponnampalam E. N. Oxidative processes in muscle systems and fresh meat: Sources, markers, and remedies. Compr. Rev. Food Sci. Food Saf. 2013;12:565–597. doi: 10.1111/1541-4337.12027. [DOI] [PubMed] [Google Scholar]

- 3.Botzenhart K., Tarcson G. M., Ostruschka M. Inactivation of bacteria and coliphages by ozone and chlorine dioxide in a continuous flow reactor. Water Sci. Tech. 1993;27:363–370. [Google Scholar]

- 4.Cardenas F. C., Andres S., GiannuzI L., Zaritzky N. Antimicrobial action and effects on beef quality attributes of a gaseous ozone treatment at refrigeration temperatures. Food Control. 2011;22:1442–1447. doi: 10.1016/j.foodcont.2011.03.006. [DOI] [Google Scholar]

- 5.Chan K. M., Decker E. A. Endogenous skeletal muscle antioxidants. Crit. Rev. Food Sci. Nutr. 1994;34:403–426. doi: 10.1080/10408399409527669. [DOI] [PubMed] [Google Scholar]

- 6.Choe E., Min D. B. Chemistry and reactions of reactive oxygen species in food. J. Food Sci. 2005;70:142–159. doi: 10.1111/j.1365-2621.2005.tb07087.x. [DOI] [PubMed] [Google Scholar]

- 7.Chouliara E., Karatapanis A., Savvaidis I. N., Kontominas M. G. Combined effect of oregano essential oil and modied atmosphere packaging on shelf-life extension of fresh chicken breast meat, stored at 4℃. Food Microbiol. 2007;24:607–617. doi: 10.1016/j.fm.2006.12.005. [DOI] [PubMed] [Google Scholar]

- 8.FAO. Databases: food balance sheets. 2006 Available from: http://www.fao.org/ag/againfo/themes/en/meat/background.html . Accessed Feb. 21, 2014.

- 9.Finch G. R., Fairbairn N. Comparative inactivation of poliovirus type 3 and MS2 coliphage in demand free phosphate buffer by using ozone. Appl. Environ. Microbiol. 1991;57:3121–3126. doi: 10.1128/aem.57.11.3121-3126.1991. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Flohé L., Günzler W. A. Assays of glutathione peroxidase. Methods Enzymol. 1984;105:114–120. doi: 10.1016/s0076-6879(84)05015-1. [DOI] [PubMed] [Google Scholar]

- 11.Greene A. K., Guzel-Seydim Z. B., Seydim A. C. Chemical and physical properties of ozone In: O’Donnell C., Tiwari B. K., Cullen P. J., Rice R. G., editors. Ozone in food processing. Wiley-Blackwell Publishing Co.; Ames, IA: 2012. pp. 19–32. [Google Scholar]

- 12.Hong Y. H., Ku G. J., Kim M. K., Song K. B. Inactivation of Listeria monocytogenes and Campylobacter jejuni in chicken by aqueous chlorine dioxide treatment. J. Food Sci. Nutr. 2007;12:279–283. [Google Scholar]

- 13.Hwang C. A., Beuchat L. R. Efcacy of a lactic acid, sodium benzoate wash solution in reducing bacterial contamination of raw chicken. Int. J. Food Microbiol. 1995;27:91–98. doi: 10.1016/0168-1605(94)00150-5. [DOI] [PubMed] [Google Scholar]

- 14.Kim D., Day D. F. A biocidal combination capable of sanitizing raw chicken skin. Food Control. 2007;18:1272–1276. doi: 10.1016/j.foodcont.2006.08.004. [DOI] [Google Scholar]

- 15.Komanapalli I. R., Lau B. H. S. Ozone-induced damage of Escherichia coli K-12. Appl. Microbiol. Biotechnol. 1996;46:610–614. doi: 10.1007/s002530050869. [DOI] [PubMed] [Google Scholar]

- 16.Ladikos D., Lougovois V. Lipid oxidation in muscle foods: A review. Food Chem. 1990;35:295–314. doi: 10.1016/0308-8146(90)90019-Z. [DOI] [Google Scholar]

- 17.Lee Y. K., Kim S. M., Han S. Ozone-induced inactivation of antioxidant enzymes. Biochimie. 2003;85:947–952. doi: 10.1016/j.biochi.2003.09.012. [DOI] [PubMed] [Google Scholar]

- 18.Li X., Lindahl G., Zamaratskaia G., Lundstrom K. Influence of vacuum skin packaging on color stability of beef longissimus lumborum compared with vacuum and high-oxygen modied atmosphere packaging. Meat Sci. 2012;92:604–609. doi: 10.1016/j.meatsci.2012.06.006. [DOI] [PubMed] [Google Scholar]

- 19.Mancini R. A., Hunt M. C. Current research in meat color: review. Meat Sci. 2005;71:100–121. doi: 10.1016/j.meatsci.2005.03.003. [DOI] [PubMed] [Google Scholar]

- 20.Muhlisin, Cho Y., Choi J. H., Hahn T. W., Lee S. K. Bacterial counts and oxidative properties of chicken breast inoculated with Salmonella Typhimurium exposed to gaseous ozone. J. Food Saf. 2015;35:137–144. doi: 10.1111/jfs.12161. [DOI] [Google Scholar]

- 21.Pascual A., Llorca I., Canut A. Use of ozone in food industries for reducing the environmental impact of cleaning and disinfection activities. Trends Food Sci. Technol. 2007;18:29–35. doi: 10.1016/j.tifs.2006.07.015. [DOI] [Google Scholar]

- 22.Pradhan A. A., Rhee K. S., Hernandez P. Stability of catalase and its potential role in lipid oxidation in meat. Meat Sci. 2000;54:385–390. doi: 10.1016/S0309-1740(99)00114-X. [DOI] [PubMed] [Google Scholar]

- 23.Sekhon R. K., Schilling M. W., Philips T. W., Aikins R. M. J., Hasan M. M., Nannapaneni R., Mikel W. B. Effects of carbon dioxide and ozone treatments on the volatile composition and sensory quality of dry-cured ham. J. Food Sci. 2010;75:452–458. doi: 10.1111/j.1750-3841.2010.01646.x. [DOI] [PubMed] [Google Scholar]

- 24.Sinnhuber R. O., Yu T. C. The 2-thiobarbituric acid reaction, an objective measure of the oxidative deterioration occurring in fat and oil. J. Oleo. Sci. 1977;26:259–267. [Google Scholar]

- 25.SPSS. Statistical package for social sciences for Windows(version 19.0) SPSS Inc.; Chicago, IL: 2010. [Google Scholar]

- 26.Stivarius M. R., Pohlman F. W., McElyea K. S., Apple J. K. Microbial, instrumental and sensory color and odor characteristics of ground beef produced from beef trimmings treated with ozone and chlorine dioxide. Meat Sci. 2002;60:299–305. doi: 10.1016/S0309-1740(01)00139-5. [DOI] [PubMed] [Google Scholar]

- 27.Utama D. T., Lee S. G., Baek K. H., Kim H., Cho C., Lee C., Lee S. K. Correlation between antioxidant enzyme activity, free iron content and lipid oxidation in four lines of Korean native chicken meat. Korean J. Food Sci. An. 2016;36:44–50. doi: 10.5851/kosfa.2016.36.1.44. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Vitale M., Perez-Juan M., Lloret E., Arnau J., Realini C. E. Effect of aging time in vacuum on tenderness, and color and lipid stability of beef from mature cows during display in high oxygen atmosphere package. Meat Sci. 2014;96:270–277. doi: 10.1016/j.meatsci.2013.07.027. [DOI] [PubMed] [Google Scholar]

- 29.Whiteside C., Hassan H. M. Role of oxyradicals in the inactivation of catalase by ozone. Free Radic. Biol. Med. 1988;5:305–312. doi: 10.1016/0891-5849(88)90101-3. [DOI] [PubMed] [Google Scholar]

- 30.Yang P. P. W., Chen T. C. Effects of ozone treatment on microflora of poultry meat. J. Food Process. Preserv. 1979;3:177–185. doi: 10.1111/j.1745-4549.1979.tb00579.x. [DOI] [Google Scholar]