Abstract

Purpose:

This paper summarizes the development of a high-power distributed x-ray source, or “multisource,” designed for inverse-geometry computed tomography (CT) applications [see B. De Man et al., “Multisource inverse-geometry CT. Part I. System concept and development,” Med. Phys. 43, 4607–4616 (2016)]. The paper presents the evolution of the source architecture, component design (anode, emitter, beam optics, control electronics, high voltage insulator), and experimental validation.

Methods:

Dispenser cathode emitters were chosen as electron sources. A modular design was adopted, with eight electron emitters (two rows of four emitters) per module, wherein tungsten targets were brazed onto copper anode blocks—one anode block per module. A specialized ceramic connector provided high voltage standoff capability and cooling oil flow to the anode. A matrix topology and low-noise electronic controls provided switching of the emitters.

Results:

Four modules (32 x-ray sources in two rows of 16) have been successfully integrated into a single vacuum vessel and operated on an inverse-geometry computed tomography system. Dispenser cathodes provided high beam current (>1000 mA) in pulse mode, and the electrostatic lenses focused the current beam to a small optical focal spot size (0.5 × 1.4 mm). Controlled emitter grid voltage allowed the beam current to be varied for each source, providing the ability to modulate beam current across the fan of the x-ray beam, denoted as a virtual bowtie filter. The custom designed controls achieved x-ray source switching in <1 μs. The cathode-grounded source was operated successfully up to 120 kV.

Conclusions:

A high-power, distributed x-ray source for inverse-geometry CT applications was successfully designed, fabricated, and operated. Future embodiments may increase the number of spots and utilize fast read out detectors to increase the x-ray flux magnitude further, while still staying within the stationary target inherent thermal limitations.

Keywords: distributed x-ray source, dispenser cathode, oil-cooled anode, inverse-geometry CT, multisource CT

1. INTRODUCTION

Distributed x-ray sources are required for several novel tomographic imaging architectures, such as stationary computed tomography (CT),1 inverse-geometry CT, and x-ray tomosynthesis.

We have previously shown that CT systems using distributed (“multi”) sources can extend axial coverage while mitigating cone-beam artifacts and reduce the dose compared to conventional CT systems.24 Figure 1 shows the x-ray distributed source demonstrated here for inverse-geometry CT.

FIG. 1.

32-spot x-ray multisource subsystem for inverse-geometry CT without cover and with four distributed source modules, each including eight x-ray focal spots (left hand side). The right hand side photo has the vacuum vessel of the multisource made “transparent” via software, to get a rendition of the module distribution from a different angle.

Novel system architectures utilizing distributed x-ray source technology were considered in the early days of CT system development. In 1978, the Mayo Clinic in Rochester, MN began investigations using the world’s first 3D volume CT scanner with high temporal resolution.2,3 The dynamic spatial reconstructor (DSR) employed 14 discrete x-ray tubes in a semicircular array and operated at frame rates as high as 60 Hz in order to reduce motion artifacts from dynamic organs, such as the heart. This “brute force” approach was eclipsed by Imatron, which in 1983 began clinical trials of their electron beam computed tomography (EBCT) scanner.4 In EBCT, the x-ray source is a single electron gun that focuses and steers the electron beam to a set of stationary semicircular target rings partially surrounding the patient table. Sweeping the electron beam produces a moving fan beam of x-rays that are collected by an opposing detector and reconstructed into images. EBCT has been clinically demonstrated with a temporal resolution of 50 ms.4 In 1998, Cardiac Mariners received FDA clearance for its inverse-geometry fluoroscopic x-ray system.5 This inverse-geometry x-ray system positions a 2D, spatially distributed x-ray source close to the patient and acquires data using a small, relatively distant detector array to produce nearly scatter-free images and lower patient skin dose. The source consists of an electron gun whose beam is indexed across a 2D array of points on a circular transmission x-ray target.6,7 The electron beam dwells for about 1 μs at each location, much like a cathode ray tube (CRT) operates. This system was later used for inverse-geometry computed tomography (IGCT) experiments.8 More recently, research conducted by a team at the University of North Carolina—Chapel Hill using cold-cathode carbon nanotubes (CNTs) as field emitters, has demonstrated distributed x-ray source concepts for several applications.9–11 In some embodiments, a discrete array of emitters utilize high electric field pulses to trigger electron emission. Such pulses are applied to each emitter following a particular sequence. The resulting electron beams are accelerated to an opposing target array and x-rays are emitted from the desired array of locations. The result is a rapidly switching distributed x-ray source whose sequence of emission locations can be controlled to produce a variety of spatially and temporally varying x-ray beams. A detailed review on distributed x-ray source history, state of the art, applications, component design and trends (emitters, electron guns, electronics, anodes), as well as a future vision on where these systems may find applicability was recently published.12

The performance benchmark for evaluating every distributed x-ray source is a rotating-anode single-spot x-ray tube, which provides instantaneous power of around 100 kW and is the standard for medical imaging (especially CT and interventional imaging). Some CT tubes are able to deflect the spot over a small distance. These tubes are too large and expensive for a multisource application. A stationary, oil-cooled anode architecture is more scalable and less expensive; however, since the anode does not rotate under the electron beam, it can only withstand comparable power for dwell times of <40μs. Unlike the rotating-anode source, the dwell time is equal to the x-ray detector frame rate. Detector technology evaluation is not part of this research, but is equally important for the multisource system. Rapid switching and focusing of the electron beam at the appropriate time requires sophisticated control electronics. High-voltage stability and anode cooling are shared challenges for all x-ray tube configurations. Lastly, the electron emission properties for a multisource tube cathode must enable up to ∼10 A/cm2 current density to be comparable to rotating-anode designs, be reliable, and have low cost. One could use larger area electron emitters with lower emission densities, but the beam focusing would be more challenging. Each of these challenges will be discussed in Secs. 2–10. Previous conference publications covered intermediate steps in the development of our x-ray multisource subsystem and associated components.13–15

2. DISTRIBUTED SOURCE ARCHITECTURE

2.A. Initially built distributed source concept

The principal goals for the multisource architecture are to maximize the number of x-ray sources, the power delivered from each source, and overall system reliability. Subordinate goals are to minimize source cost, volume, and weight. Simultaneous optimization of all of these goals would produce the best x-ray source for the IGCT system.24

A grounded cathode design was chosen to avoid having to operate the electron beam switching circuits at high potential relative to ground—unlike traditional x-ray tubes, which either operate anode grounded or with the anode and cathode each at half of the total voltage.

An initially built concept utilized a segmented anode with tungsten bars brazed onto copper blocks (Fig. 2). The calculated natural frequency of this design was 188 Hz, above that of the IGCT gantry. Separate anode blocks also allowed the modular cathodes and electrical insulators (Fig. 2), mounted directly to a base plate. Stainless steel tubing conducts cooling oil to each anode block.

FIG. 2.

Fabricated module used in our initially built concept source architecture: (left) frontal view of anode and (right) side view of module. Reproduced with permission from Frutschy et al., “x-ray multisource for medical imaging,” Proc. SPIE 7258, 725822 (2009). Copyright 2009 SPIE - The International Society for Optics and Photonics.

Three rows of four focal spots were used per module (Fig. 2), with rows spaced at 100 mm and spots in each row at 25 mm. This design provides large longitudinal coverage, meeting the 16 cm value required to perform most cardiac CT scans, while limiting the cone angles and minimizing cone-beam artifacts. To maximize x-ray photons per watt of anode heating, an electron beam incidence angle of 20° was selected. However, the projected manufacturing cost for this anode was about twice that of our final embodiment (see Fig. 3, with one insulator and eight spots per module compared to two insulators and twelve spots here).

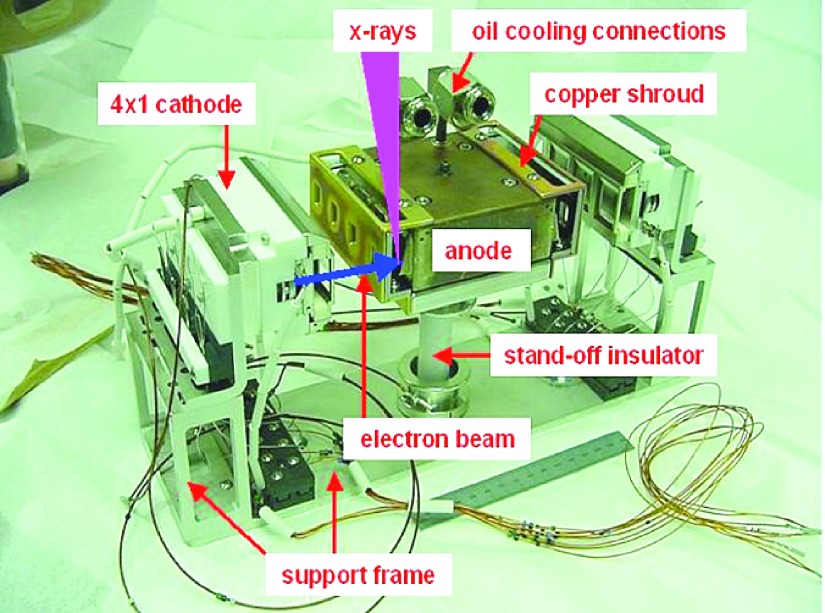

FIG. 3.

Fabricated module with eight spots used in the final concept for our distributed source architecture with a copper anode block suspended on a single standoff insulator and two opposing cathode arrays, each with four emitters (4 × 1 arrays). Reproduced with permission from Frutschy et al., “High power distributed x-ray source,” Proc. SPIE 7622, 76221H (2010). Copyright 2010 SPIE - The International Society for Optics and Photonics.

2.B. Final embodiment of the distributed source architecture

The final concept simplified the anode module to have two rows, each with four focal spots, using the traditional configuration where the electron beam is approximately perpendicular to the target surface (Fig. 3). The row spacing is 100 mm and spot spacing 25 mm within each row. The source comprises four modules to provide 32 spots. The manufacturing cost is much lower for this configuration compared to the earlier concepts. The electrical insulator supporting the anode block within the module (Fig. 3) is oriented radially and so it experiences mostly compressive force on a rotating gantry. Insulator average compressive failure was measured at 20 000 lbf (89 kN). Our companion paper summarizes the rationale for utilizing at least two longitudinally offset rows of focal spots for CT imaging.

3. ELECTRON EMITTER APPROACH

Vacuum tube applications use a variety of electron emitter technologies including thermionic emitters and cold-cathode field emitters. Most medical x-ray tubes use thermionic emitters as coiled tungsten filaments, which operate at about 2600 °C. Advantages of these emitters include low cost, long lifetime, robust emission properties, and reliability. Such tubes are permanently sealed, requiring no pumping to maintain a vacuum of ∼10−5 Torr. The principal failure mechanism for tungsten emitters is evaporation. Since distributed x-ray sources comprise a large number of cathodes in a compact vacuum chamber, thermal management of hot tungsten emitters would be very challenging.

Cold-cathode emitters may one day replace thermionic emitters in x-ray sources12 and vacuum-based microwave amplifiers. Various research groups have demonstrated encouraging results using CNT emitters in x-ray source configurations.9–11 Spindt cold emitters have also been demonstrated in x-ray sources.16 Research groups have been exploring other materials (Ref. 12 includes a comprehensive list of materials and research groups with published work). However, so far only Spindt and CNT cathodes have been successfully used in x-ray medical imaging research prototypes (no CT application so far). The advantages of these emitters include compactness and elimination of the power required to heat thermionic emitters, flexibility in emission area patterning, ability to have multiple emitters in the same vacuum chamber with minimal electron gun thermal management, and easier electron beam gating (especially in the triode configuration). A typical thermionic emitter requires a small negative bias to quench electron emission, while field emitters can be rapidly switched off by reducing the surface potential to zero. For example, Spindt emitters in a recently demonstrated distributed x-ray source were controlled by voltages on the order of 100 V.16 Before cold cathode-based electron emitters become a viable commercial alternative for x-ray CT applications, one must overcome some existing challenges: electron emission density below CT required levels, low lifetime, sensitivity to ion backbombardment, and potential performance degradation at typical tube vacuum levels.

While cold-cathode electron emitters would provide benefits for distributed sources, based on the risks described above, this initial multisource demonstration used dispenser cathode emitters (DCEs)—a mature technology currently being used in various vacuum tube applications (e.g., microwave amplifiers). In a DCE, a tungsten matrix is impregnated with various materials to reduce the work function and lower the required operating temperature to provide sufficient electron flow. DCEs combine some of the strengths of pure tungsten cathodes (proven technology, demonstrated long lifetime, and high electron emission characteristics) and cold-cathode electron emitters (operation at much lower temperature than pure tungsten emitters, and manageable thermal load at the electron gun for distributed x-ray sources). Typical dispenser cathodes operate at around 1100 °C, compared to 2600 °C for pure tungsten emitters.

Commercially available dispenser cathodes manufactured by Semicon Associates (Lexington, KY) were used here. The devices were cylinders with a diameter of 3.5 mm (Fig. 4), integrated into stainless steel enclosures for assembly in an electron gun. Figure 4 (right) shows a picture of four DCE enclosures being assembled in the 4 × 1 cathode array (each module shown in Fig. 3 would include two 4 × 1 cathode arrays, for a total of eight spots).

FIG. 4.

Left: 3.5 mm diameter dispenser cathode emitters (DCEs) used for demonstrating the distributed source concept. Right: four stainless steel enclosures incorporating DCEs being integrated in the distributed source electron gun (part of the 4 × 1 cathode array shown here). The white base was made from Macor (high temperature ceramic).

DCEs typically require higher vacuum levels than pure tungsten emitters for the same lifetime (10−7 vs 10−5 Torr, respectively). The use of DCEs for our application prompted the need for active pumping (described later). Each dispenser cathode requires ∼10 W (7.5 V @ 1.3 A) to reach 1100 °C temperature and ensure optimal emission (about 10–12 A/cm2) when operated in pulsed mode.

Figure 5 shows an example of the measured emission current of DCEs selected for this multisource demonstration. Up to 1200 mA was measured at low grid voltage (∼450 V) in pulse mode (6 μs pulses—single pulse measurement here).

FIG. 5.

Measured emission curve for the dispenser cathodes used in the multispot source obtained in pulse mode (6 μs pulses).

4. ANODE DESIGN

The principal function of the anode is to convert some of the kinetic energy of the incoming electrons into x-rays, when the electrons impinge onto a high-Z (mostly tungsten) target. X-rays are generated from changes in the electron momentum as they interact with the nuclei in the target. Approximately 99% of the energy in the incoming electron beam is converted into heat close to the surface of the target. Anode design challenges include keeping the target surface below its melting temperature and limiting cracking due to the rapid localized thermal expansion and contraction. Fatigue life is significantly extended by using an alloy of tungsten and rhenium for the target top layer. The remainder of the target consists of TZM alloy made up of molybdenum, zirconium, titanium, and other materials. Target thickness is 7 mm, with a top layer of 1 mm thick W-Re alloy.

This multisource anode consists of a series of segmented units (Figs. 1, 3, and 6), each with two rows of targets on either sides of a 100 mm wide copper block, which has internal passages to circulate cooling oil. The target slabs are machined to an angle of 12.5° relative to the transaxial imaging plane, which is typical for standard x-ray tubes with rotating anodes. Each target (four focal spots per row) is furnace brazed onto each block surface using a 0.5 mm foil of Incusil-15 (Bag-29) from Wesgo Metals,17 providing a low thermal resistance path from the target top surface to the cooling oil (Fig. 6). Final braze layer thickness in assembled anode is 0.45 –0.75 mm.

FIG. 6.

(a) Picture of a part of the anode subassembly showing the copper anode block, a slightly tilted target surface, tungsten shields, and copper shroud. (b) Optical microscope image of cross section of the multisource anode, showing good connectivity between the copper block, the braze material, and the target (TZM layer). Reproduced with permission from Frutschy et al., “High power distributed x-ray source,” Proc. SPIE 7622, 76221H (2010). Copyright 2010 SPIE - The International Society for Optics and Photonics.

To facilitate electron beam compression and focusing, a flat copper face plate/shroud is attached in front of each target segment, eliminating electric field gradients near the target segment. The electron beams pass through passages in each shroud before striking the targets. The shrouds also support 2 mm thick tungsten shielding plates which attenuate unwanted, off-axis x-rays.

The power capability of the anode was estimated as follows. The maximum peak power is a function of focal spot size, target angle, dwell time, and repeat time. Values used for this analysis were 120 kVp, focal spot energy absorption of 60% (40% backscattered in the anode block and the vacuum envelope), maximum surface temperature of 2600 °C, optical focal spot size (at the exit window of the tube) of 1 × 1 mm, target angle of 12.5°, convective heat transfer coefficient of 1000 W/m2 K to the oil, total scan time of 5 s, and an interscan delay of 10 min. A finite element model used in previous investigations14 was employed here. The focal spot temperature is the sum of impact temperature (incremental temperature rise while under the beam) and target bulk temperature (steady state temperature). The allowable maximum current for the distributed source is shown in Table I—considering an experimental protocol that with no “x-ray off time”; if a source emits x-rays, next source will emit x-rays as soon as the first source is turned off, while going through all sources once, before starting back from the first source. The 2600 °C is a practical limit utilized in x-ray tube target design when the electron beam hits a tungsten surface; this limit should be well below the melting temperature of the surface material, but high enough to enable large electron beam densities safely, while providing acceptable target life in the field.

TABLE I.

Calculated maximum beam current for a multisource configuration, as a function of dwell time and number of focal spots during a 5 s scan, with one x-ray source always turned on at a given moment of time (protocol considers going through all sources, before returning to any given source).

| Beam current/spot (mA) | Number of focal spots | ||||||

|---|---|---|---|---|---|---|---|

| Dwell time (μs) | 4 | 20 | 30 | 40 | 50 | 100 | 200 |

| 10 | 67 | 246 | 316 | 369 | 411 | 530 | 620 |

| 20 | 64 | 216 | 269 | 307 | 335 | 410 | 461 |

| 50 | 60 | 175 | 208 | 229 | 245 | 282 | 306 |

| 100 | 56 | 143 | 165 | 178 | 188 | 209 | 222 |

| 200 | 51 | 115 | 128 | 136 | 141 | 153 | 160 |

Table I quantifies the beam current increase with shorter dwell times and a greater number of spots. For 200 spots and 10 μs dwell time, the average tube power is approximately 75 kW over the 5 s scan.

Stainless steel tubing brazed onto each copper block (Fig. 3) circulates cooling oil and carries the beam current; Swage-Lock™ fittings form vacuum-tight seals between modules.

A ceramic insulator supports the anode subassembly (Fig. 3). Aligning the insulator radially with the anode’s center of mass minimizes bending stress and insulator volume required to withstand inertial loading from gantry rotation. Stainless steel shields at the end of each insulator provide reliable metal-to-ceramic fastening and also shield the vacuum-ceramic–metal triple point, which enables higher voltage isolation capability.

5. ELECTRON GUN DESIGN

The electron gun generates and focuses an electron beam onto an anode surface. A beam current of several 100s mA is the multisource goal. Beam area compression in the gun is desirable to reduce emitter current density and increase emitter life.

Three essential gun functions are electron extraction, beam focusing, and emitter protection. An effective extraction design has been developed15 using a molybdenum mesh grid with wire diameter and center spacing of 25 and 280 μm, respectively (Fig. 7), positioned 250 μm above close to the emitting surface. Its optical transparency is 80%.

FIG. 7.

(a) Mesh grid used for electron beam extraction in the multisource electron gun, (b) topology of the electron beam optics including electron emitter (dispenser cathode), ECE, and FP. The electron beam is emitted by the cathode and hits the target after passing through the focusing elements.

The electric field provided by the grid for extraction of electrons from the emitting surface was simulated. The approximate average field at the emitter surface is F = k∗V/d, where V is the applied grid voltage, d is the gap between the grid and emitter, and k for this mesh grid is around 0.85.

A compact and simple “matrix” triggering scheme was designed to reduce the number of feed-through control signals, with electron emitters grouped into rows and grids grouped into columns. The emitters in each row are electrically connected but each row is electrically independent. Grids in each column are electrically connected and each column is independent. Each emitter is addressed by its row and column numbers. The number of control channels is only N + M for N*M emitters. A 10 × 10 array of 100 emitters requires only 20 control channels in matrix configuration, compared to 100 lines when no matrix is implemented. When the emitters are in the OFF condition, all grids are kept at −500 V and all emitters at 1000 V. The emitter in row 1 corresponding to the grid in column 2 can be activated by setting row 1 to 0 V and column 2 to the bias voltage corresponding to the desired emission current (VON). All other emitters are off: those underneath column 2 grids are at (VON − 1000 V), and those in row 1 (except that underneath column 2) are at −500 V. All emitters/grid structures not in row 1 or column 2 are at the initial differential voltage of −1500 V (−500 V on grids, 1000 V on emitters). The maximum VON state voltage applied during testing was about 400 V.

Our final multisource embodiment in Fig. 1 includes two rows of 16 emitters each (two linear arrays of emitters using the same matrix type control).

The electron beam optics chosen for the multisource is shown in Fig. 7, with two focusing electrodes: an emittance compensation electrode (ECE) above the grid followed by a focusing plate (FP)—an electrostatic lens to focus the beam onto the target. The aperture size and thickness of the FP are designed for maximum beam compression. The electron beam is circular (3.5 mm diameter) at the emitter and elliptical when it reaches the anode. Opera 3D—an electromagnetic finite element analysis tool—was utilized for electron optics design and optimization. Beam compression (the area ratio between the electron emitting surface and the thermal focal spot) is predicted as ∼30 at 30 mA, ∼7 at ∼360 mA, and ∼3 at ∼1000 mA. Examples of ECE and FP voltages determined computationally and validated experimentally are presented in Sec. 9.

Figure 8 (top) is a rendering of the integrated gun assembly, which comprises four electron beams in a 4 × 1 cathode array. The ECE and FP are separate pieces of stainless steel, providing easy electrical connection.

FIG. 8.

Drawings and pictures of the electron gun 4 × 1 array (one array of four electron emitters). The mesh grids—all four grids for the four emitters—are integrated into a grid plate. ECE and FP are also indicated. Alumina insulators are separating the various metallic components here (grid plate, ECE, and FP). The four DCSs are heated to 1100 °C in the cathode 4 × 1 array during operation (each module has two 4 × 1 arrays, for a total of eight spots).

Electron gun design provides important capabilities including high beam current from dispenser cathodes (a mesh grid providing a high field for efficient electron extraction), high beam compression and focusing using only two electrostatic lenses, and low cost and complexity by employing a 2D matrix control scheme for the electron emitters. Beam optics design and experimental validation have been performed in two stages: the initial stage without Cu shroud (Fig. 7) and the final embodiment with Cu shroud (Fig. 6).

6. ELECTRON GUN ELECTRONICS AND CONTROL

The control electronics comprises a mother-board, daughter-boards, and a PC interface (Fig. 9).15 The mother-board connects power supplies to the DCEs for heating to the proper quiescent temperature and controls the voltages to all DCEs and mesh grids, while the daughter-boards generate the specific voltages to be locally applied to turn on or off a particular set of DCEs and mesh grids. The mother-board has an input voltage of 48 VDC and produces output voltages of −500 VDC to the grids and 1000 VDC to the DCEs when no emission is desired.

FIG. 9.

The left hand side image shows the complete control system completed with daughter boards (both grid and DCE) as well as the mother board cooling system and additional power supplies. The FPGA is housed under the cooling system so is not visible in this picture. The right hand side image includes an oscilloscope screen shot of a DCE pulse current and mesh grid voltage pulse in electron gun bench testing. Horizontal time scale is 1 μs/division.

A field-programmable gate array (FPGA) generates the signals to control the daughter-boards so that the desired voltages will be applied to the DCEs and mesh grids. The mother-board also hosts passive protection mechanisms preventing component failure from unwanted high-voltage discharges between the anode and cathode (an essential feature as such discharges are relatively common events). The protection is provided by a network of spark gaps, resistors, and inductors, which offer an alternative low-resistance path to ground for the energy released during discharges.

The emission current for each cathode is varied by accurately controlling the voltage on the associated mesh grid (DCE current vs mesh grid voltage is shown in Fig. 5). All focusing plates are at constant DC voltage. Every cathode can be independently controlled using the matrix controls scheme previously mentioned. The wireless controls allow the PC interface to be physically disconnected from the hardware electronics that is mounted on the multisource vacuum chamber—particularly useful when the source is on a rotating gantry.

Figure 9 shows the complete control system, as well as an oscilloscope screen shot of grid voltage and emitter current pulses. At 197 V, the DCE emits 463 mA, with a pulse rise time less than 500 ns. Figure 9 also shows that only 1.7 mA is lost to the ECE, when the anode is at 80 kV. No measurable current goes to FP in these conditions, and typical current loss in the mesh grid is on the order of 15%–20% of the emitted current. The very short rise time can provide very short x-ray pulses for motion freezing applications.

Figure 10 (top) exemplifies another capability of the multisource electronics: a “virtual bowtie” wherein the current from every emitter is tailored via application of specific grid voltages. System benefits of the virtual bowtie are described in a companion system article.24 The oscilloscope screen shot captures for clarity only the mesh grid voltages (∼380–470 V) for the 32 emitters. Each grid voltage pulse was 100 μs long, with 750 μs between x-ray pulses from each emitter. Full source sequences are every 5 ms—e.g., emitter 2 is triggered 750 μs after emitter 1; a sequence is completed after the emitter 32 is depowered, and after a 5 ms delay, the sequence continues from emitter 1.

FIG. 10.

Top: example of virtual bowtie implemented: vertical voltage scale is 200 V/division (oscilloscope screen shot). The varying grid voltages for the 32 emitters are visible, to trigger tailored currents from emitters. The horizontal scale is time (5 ms/division). Bottom: ten emitters from the total of thirty two are featured in this oscilloscope screen shot in virtual bow tie configuration. Each emitter has a different grid voltage and emitted current. Pulse width for each emitter is 100 μs; time scale is 1 ms. Voltage, black trace, is 200 V/division. Current, red trace, is 100 mA/division. The fourth emitter from the left emits 84 mA at 312 V on the grid, while the eighth emitter from the left emits 65 mA at 192 V on the grid (these values are visible in the oscilloscope screen shot)—these are two examples in the bowtie protocol above.

Figure 10 (bottom) presents for clarity only the voltages and currents of a set of 10 emitters, in the virtual bow tie format (emitted currents track varying extracting voltages for each emitter). Current traces, in red below, exhibit some ringing—an artifact of the measurement system on the gantry (note the lack of ringing in current trace from Fig. 9, a bench top, low-noise measurement system).

7. HIGH-VOLTAGE INSULATOR DESIGN

The anode design removes heat by flowing liquid coolant within special passages throughout the anode core. High-purity dielectric oil serves as a coolant and an electrical insulation medium. A metal/ceramic seal insulator was specially developed,18 in conjunction with a customized high-voltage connector, to accommodate feed-through connections that supply high voltage and cooling oil. Figure 11(a) shows an exploded view of the ceramic insulator design, (b) shows the schematic drawing of the connector, and (c) shows the high-voltage connector assembly.

FIG. 11.

Exploded view of the ceramic insulator design (a), the schematic drawing of the connector (b), and the high-voltage connector assembly (c). Schematic drawing (d), and picture of the high-voltage standoff insulator (e).

The metal/ceramic seal insulator used a “pancake” design for compactness. The high-voltage connector is essentially an interface for coupling cooling lines to the vacuum chamber, which slowly grades the electrical stress across the dielectric fluid as it traverses into the seal insulator. A plug/receptacle configuration provides connection to the high-voltage cable (Fig. 11). This assembly provides an oil flow of 4 gpm at 80 psi and withstands >150 kV. The oil flow provides a convective heat transfer coefficient of ∼1000 W/m2C on the back of the anode substrate.

The high voltage standoff insulators provide electrical isolation between the high voltage anode and the rest of the system—the anode block in every module is supported by one of these insulators [Figs. 3, 11(d), and 11(e)]. These insulators must be compact, minimize risk of electrical surface flashover, and operate under mechanical stress and x-ray and electron-beam radiation. Fully sintered alumina-based insulators were selected for their electrical and mechanical properties. Each insulator was seasoned to 140 kV and tested mechanically under compressive and shear forces individually, to ensure adequate safety factors under the high loading expected during IGCT gantry rotation. Satisfactory electrical insulation results were also achieved during later high-voltage testing of the module using these insulators.

8. SOURCE INTEGRATION

Each multisource component was cleaned, rinsed in an ultrasonic bath, and vacuum-baked. Each source module was also vacuum-baked for about 12 h after assembly, before being placed in the multisource vacuum chamber. The vacuum level in the multisource chamber reached 1.2 × 10−9 Torr with a turbo pump prior to testing (during x-ray testing pressure increased by more than two orders of magnitude). For gantry rotation, this turbo pump was removed, and pressure was maintained using ion and getter pumps. The vacuum chamber with mounted modules was heated to 200 °C using external electric heaters and infrared lamps to accelerate desorption of gases from vacuum components. The anode was seasoned by gradually increasing using reduced-energy, high-voltage pulses, successfully reaching >120 kV.

The internal size of the vacuum chamber enclosing the anode/cathode components is 54 × 45 × 26 cm. The ion pump has a pumping speed of 75 l/s and has no moving parts, which may be adversely impacted during gantry rotation. A getter pump (WP 1250/2, SAES, Milan, Italy) was integrated into the vacuum chamber for enhanced pumping. The vacuum was monitored during gantry rotation by wirelessly transmitting the measured ion pump current and comparing with previously generated calibration curves. Pressure increase reduces the emission current and life of DCEs and increases the likelihood of high-voltage electrical discharges in the x-ray distributed source. During gantry rotation with x-rays on, pressure was maintained at a level of 10−7 Torr (slightly higher for longer scans). In x-ray off mode, the pressure was on the order of 10−9 Torr. Vacuum quality in rotation may be increased by baking the entire source at 400 °C in a vacuum furnace and by adding more getters.

The first prototype of the IGCT system (containing eight cathodes) was operated on the rotating gantry at a speed of 1 revolution/s. The control electronics were attached to the vacuum chamber and rotated during data acquisition. Experiments with the final multisource embodiment (containing 32 cathodes) were conducted by rotating the phantom, and keeping the source (and gantry) stationary. For these experiments, all DCEs were maintained at ∼1100 °C (see examples of the electron gun in Fig. 8), so electron emission would be triggered in less than 1 μs by applying the desired extraction voltage between the electron emitter and the mesh grid. No oil cooling was used for these experiments.

While electron emitters in traditional x-ray sources may employ one or two tungsten filaments (providing small and large focal spots), our electron gun includes four thermionic DCEs, which operate at ∼1100 °C, creating a unique thermal challenge. Our electron gun module was designed to function properly when all DCEs are at 1100 °C; Fig. 12 shows measurements of steady state temperature of the grid plate and the macor base (see Fig. 8 for electron gun topology). At time zero the DCEs are brought to 1100 °C. With steady state temperature of the electron gun components at less than 400 °C, thermal stability of the electron gun is ensured.

FIG. 12.

Temperature measurements for the grid plate and the macor base when at time zero all four DCEs in an electron gun are turned ON, heated to 1100 °C.

9. EXPERIMENTAL RESULTS

Initial tests of the multisource subsystem utilized a source architecture incorporating eight dispenser cathode electron emitters. The output current capability of each DCE (Fig. 5) was greater than 1000 mA with pulse durations of several microseconds to tens of microseconds. Experiments were performed to identify the ECE and FP voltages that focus the electron beam within the desired specifications at various emitted currents. Focal spot measurements (using the line-pair gauge method and the pinhole method19) were completed using the electron gun. Figure 13 includes images of the focal spot during optimization experiments (460 mA emitted current, 80 kVp anode potential, 6 kV ECE potential, 200 V mesh grid potential, 0.49 magnification factor). For these images (from left to right), the focusing plate voltage was adjusted to be −0.5, −1.7, −2.2, −3.3, and −3.9 kV, respectively.

FIG. 13.

Images of the focal spot during optimization experiments (pinhole method). The white line here is 1.4 mm in length, added as a reference.

Approximately 60 mA (13%) of the 460 mA dispenser cathode current was intercepted by the mesh grid, while approximately 2 mA was intercepted by the ECE—no significant current was lost in the focusing plate. The optimal beam focusing occurs at −3.9 kV on the focusing plate (thermal focal spot of 0.36 × 6.9 mm, measured at 50% from maximum, FWHM, for width, and at 20% from the maximum for length). Optimization tests discussed here used pulse widths on the order of 5 μs, at a frequency of 350 Hz (only the mesh grid voltage was pulsed; voltages on the target, focusing electrodes, ECE, and focusing plate were held constant). Replicated experiments from emitter to emitter showed good focal spot reproducibility.

Table II itemizes the optical focal spot sizes achieved at 80 kVp. The parameters in this table are presented as an example only; the user could focus a beam current of 313 mA using other voltage selections on the ECE (typically on the order of few kV) and on the focusing plate. The optimum beam focusing at lower electron beam currents (∼100 mA or smaller) is generally obtained using positive voltages on the focusing plate, while at higher electron beam currents, the electron gun requires negative FP voltages.

TABLE II.

Measured optical focal spot size using the line-pair gauge method for different emitted currents and focusing voltages (anode potential held constant at 80 kVp).

| Emitted current (mA) | Grid voltage (V) | ECE voltage (kV) | FP voltage (kV) | Focal spot size (mm × mm) |

|---|---|---|---|---|

| 84 | 20 | 4 | 2.4 | 0.4 × 0.8 |

| 313 | 200 | 4 | −0.4 | 0.4 × 1.2 |

| 1000 | 450 | 6 | −2.2 | 0.5 × 1.4 |

While most beam focusing experiments have been performed at 80 kVp, a test was also performed at 120 kVp. A case study was performed at 360 mA emitted current, 123 V on the grid, −2 kV on the focusing plate, and 6 kV on the ECE (350 Hz, 5 μs pulses). The optical focal spot was 0.39 × 1.42 mm at 80 kV, 0.39 × 1.3 mm at 100 kVp, and 0.39 × 1.17 mm at 120 kVp. Essentially, going to higher kVp in this case maintains the focal spot width (parallel to the two rows of cathodes), but shrinks the focal spot length (perpendicular to the two rows of cathodes).

Finally, it should be mentioned that the experimental beam optics results generally match the simulated trends well.20

10. CONCLUSIONS

This paper describes the design, fabrication, assembly, and experimental testing of a unique x-ray multisource subsystem, with 32 dispenser cathode emitters arranged in two rows (25 mm spacing from spot to spot, and rows 100 mm apart), innovative electronics topologies, and control solutions including virtual bowtie, stationary target demonstrated up to 120 kVp and beam optics design and validated for CT specifications. We present here the evolution of our design concepts, challenges, and tradeoffs, and focus on describing in detail the final embodiment of the high-power distributed x-ray source for inverse-geometry CT. While other groups have demonstrated initial concepts of distributed x-ray sources in linear geometry and at relatively low current for mammography applications,21 the distributed x-ray source described here achieves emitted beam currents that are clinically relevant for rotating-gantry whole-body CT. The emitters used in this multisource have an emitting area of 10 mm2 and generated pulsed currents of more than 1000 mA. Furthermore, more than 80% of the emitted current in the multisource configuration reaches the target to provide the required x-ray flux relevant for the imaging tasks detailed in the companion system article.24

We have successfully utilized DCEs in our multisource prototype. Emission stability for these emitters at high current densities is a critical metric for potential implementation in future clinical systems. Dispenser cathodes are a mature technology, deployed in numerous vacuum tube based communication applications, with excellent lifetime when the vacuum conditions are appropriate (∼10−7 Torr total pressure, low levels of contaminants that are detrimental to DCEs, such as carbon monoxide, carbon dioxide, oxygen, and water vapor). Literature mentions that DCEs similar to the ones implemented in the multisource have a lifetime entitlement of thousands to tens of thousands of hours at current densities of few A/cm2;22 DCEs typically perform well at few A/cm2 in continuous mode and at low tens of A/cm2 in the pulse emission mode.23 The dispenser cathodes in the multisource have been heated at the operating temperature for few hundreds of hours, with excellent emission stability. These cathodes have emitted currents from tens of mA to more than 1000 mA (>10 A/cm2), at pulse widths from few microseconds to about 100 μs, frequencies of typically hundreds of Hz, and target voltages of 60–120 kV in the multisource. Select cathodes were tested for emission stability in a lifetime test after being utilized for low hundreds of hours in the multisource at the following parameters: 450 mA (∼4.5 A/cm2) emitted current, 1.5 kHz and 11 μs pulses, for a total of 11 × 106 pulses (parallel plate test—emitted current was collected on the grid plate). This limited lifetime test has showed excellent emission stability for DCEs even after being used in an x-ray tube environment for an extended period of time.

One limitation for this multisource concept relates to the maximum electron beam current delivered to the target at a certain pulse duration, as exemplified in Table I (higher beam current possible for smaller pulse durations due to limited cooling capability for the stationary target). Future x-ray detector architectures with higher detector read out speed would address some of these system limitations, by enabling the use of the multisource high currents, at short pulses (low tens of microseconds or shorter than 10 μs). Additionally, a larger number of spots—see Table I—may enable a future CT system to reach clinically relevant x-ray fluxes. Preliminary evaluations show that reducing the spot to spot spacing from 25 to 10 mm may be feasible with smaller diameter DCEs that would require less heating power but still deliver large pulse currents of high hundreds of mA.

ACKNOWLEDGMENTS

This work was supported in part by NIH NIBIB Grant Nos. R01 EB006837-01 and R01 EB006837-04S1 as well as by GE Healthcare and GE Global Research. The authors would like to acknowledge all scientists who contributed to the development of the multisource subsystem and are not coauthors on this paper, including Michael Idelchik, Vanita Mani, Dennis Jacobs, Frank Mueller, Gelu Comanescu, Kenneth Conway, Kirk Marquard, and Walter Smith.

CONFLICT OF INTEREST DISCLOSURE

The authors have no COI to report.

REFERENCES

- 1.De Man B. K. B., Basu S. K., Edic P. M., Senzig R. F., Ross W. R., Wu X., Wilson C. R., Vermilyea M. E., and Saragnese E. L., “Stationary computed tomography system and method,” U.S. patent 7,280,631 B2 (26 May, 2005).

- 2.http://www.mayo.edu/sppdg/About_SPPDG/History.html.

- 3.http://www.nature.com/ki/journal/v55/n2/full/4490600a.html.

- 4.Boyd D. P. and Lipton M. J., “Cardiac computed tomography,” Proc. IEEE 71, 298–308 (1983). 10.1109/PROC.1983.12588 [DOI] [Google Scholar]

- 5.Cardiac Mariners Receives Marketing Clearance From FDA; x-ray Imaging System Provides Scatter-Free Images at Lower Radiation Dose, 1 October 1998, BNET Business Network, http://findarticles.com/p/articles/mi_m0EIN/is_1998_Oct_1/ai_53048700.

- 6.Elliott D. D., Loeffler P. E., Baker D. E., and Skillicorn B., “Scanning beam x-ray source and assembly,” U.S. patent 6,198,802B1 (March 6, 2001).

- 7.Speidel M. A., Wilfley B. P., Star-Lack J. M., and Heanue J. A., “Scanning-beam digital x-ray (SBDX) technology for interventional and diagnostic cardiacangiography,” Med. Phys. 33(8), 2714–2727 (2006). 10.1118/1.2208736 [DOI] [PubMed] [Google Scholar]

- 8.Schmidt T. G., Fahrig R., Pelc N. J., and Solomon E. G., “An inverse geometry volumetric CT system with a large-area scanned source: A feasibility study,” Med. Phys. 31(9), 2623–2627 (2004). 10.1118/1.1786171 [DOI] [PubMed] [Google Scholar]

- 9.Sprenger F., Calderon X., Gidcumb E., Lu J., Qian X., Spronk D., Tucker A., Yang G., and Zhou O., “Stationary digitial breast tomosynthesis with distributed field emission x-ray tube,” Proc. SPIE 7961, 79615I (2011). 10.1117/12.878280 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Jing S., Shan J., Chtcheprov P., Tucker A. W., Lee Y. Z., Wang X., Foos D., Heath M. D., Lu J., and Zhou O., “Stationary chest tomosynthesis using a CNT x-ray source array,” Proc. SPIE 8668, 86680E (2013). 10.1117/12.2007993 [DOI] [Google Scholar]

- 11.Maltz J. S., Sprenger F., Fuerst J., Paidi A., Fadler F., and Bani-Hashemi A. R., “Fixed gantry tomosynthesis system for radiation therapy image guidance based on a multiple source x-ray tube with carbon nanotube cathodes,” Med. Phys. 36(5), 1624–1636 (2009). 10.1118/1.3110067 [DOI] [PubMed] [Google Scholar]

- 12.Bogdan Neculaes V., Edic P. M., Frontera M., Caiafa A., Wang G., and De Man B., “Multisource x-ray and CT: Lessons learned and future outlook,” IEEE Access 2, 1568–1585 (2014). 10.1109/ACCESS.2014.2363949 [DOI] [Google Scholar]

- 13.Frutschy K., De Man B., Edic P., Lounsberry B., Neculaes B., Zou Y., Inzinna L., Conway K., Zhang X., Cao Y., Gunturi S., Caiafa A., and Reynolds J., “X-ray multisource for medical imaging,” Proc. SPIE 7258, 725822 (2009). 10.1117/12.812043 [DOI] [Google Scholar]

- 14.Harding G., Strecker H., Olesinski S., and Frutschy K., “Radiation source considerations relevant to next-generation x-ray diffraction imaging for security screening applications,” Proc. SPIE 7450, 745007 (2009). 10.1117/12.827049 [DOI] [Google Scholar]

- 15.Frutschy K., Neculaes B., Inzinna L., Caiafa A., Reynolds J., Zou Y., Zhang X., Gunturi S., Cao Y., Waters B., Wagner D., De Man B., McDevitt D., Roffers R., Lounsberry B., and Pelc N. J., “High power distributed x-ray source,” Proc. SPIE 7622, 76221H (2010). 10.1117/12.843743 [DOI] [Google Scholar]

- 16.Schwoebel P. R., Boone J. M., and Shao J., “Studies of a prototype linear stationary x-ray source for tomosynthesis imaging,” Phys. Med. Biol. 59, 2393–2413 (2014). 10.1088/0031-9155/59/10/2393 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Gunturi S. S., T. C. Tiearney, Jr., Frutschy K. J., Zhong D., and Zhang X., “Method of joining materials, and articles made therewith,” U.S. patent application 20110135956 (9 June 2011).

- 18.Cao Y., Inzinna L., Roffers R., Tan D. Q., Vermilyea M., and Zou Y., “Apparatus for a compact HV insulator for x-ray and vacuum tube and method of assembling same,” U.S. patent 7,702,077 (20 April 2010).

- 19.Bushberg J. T., Seibert J. A., E. M. Leidholdt, Jr., and Boone J. M., The Essential Physics of Medical Imaging, 2nd ed. (Lippinncott Williams & Wilkins, Philadelphia, PA, 2002). [Google Scholar]

- 20.Bogdan Neculaes V., Zou Y., Zavodszky P., Inzinna L., Zhang X., Conway K., Frutschy K., Waters W., and De Man B., “Design and characterization of electron beam focusing for x-ray generation in novel medical imaging architecture,” Phys. Plasmas 21, 056702 (2014). 10.1063/1.4872033 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Qian X., Rajaram R., Calderon-Colon X., Yang G., Phan T., Lalush D. S., Lu J., and Zhou O., “Design and characterization of a spatially distributed multibeam field emission x-ray source for stationary digital breast tomosynthesis,” Med. Phys. 36(10), 4389–4399 (2009). 10.1118/1.3213520 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Falce R. L., “Dispenser cathodes: The current state of the technology,” in Electron Devices Meeting, 1983. [Google Scholar]

- 23.HeatWave Labs, http://www.cathode.com/.

- 24.De Man B., Uribe J., Baek J., Harrison D., Yin Z., Longtin R., Roy J., Waters B., Wilson C., Short J., Inzinna L., Reynolds J., Bogdan Neculaes V., Frutschy K., Senzig B., and Pelc N., “Multisource inverse-geometry CT. Part I. System concept and development,” Med. Phys. 43, 4607–4616 (2016). 10.1118/1.4954846 [DOI] [PMC free article] [PubMed] [Google Scholar]