ABSTRACT

Group II nonproteolytic Clostridium botulinum (gIICb) strains are an important concern for the safety of minimally processed ready-to-eat foods, because they can grow and produce botulinum neurotoxin during refrigerated storage. The principles of control of gIICb by conventional food processing and preservation methods have been well investigated and translated into guidelines for the food industry; in contrast, the effectiveness of emerging processing and preservation techniques has been poorly documented. The reason is that experimental studies with C. botulinum are cumbersome because of biosafety and biosecurity concerns. In the present work, we report the construction of two nontoxigenic derivatives of the type E gIICb strain NCTC 11219. In the first strain, the botulinum toxin gene (bont/E) was insertionally inactivated with a retargeted intron using the ClosTron system. In the second strain, bont/E was exchanged for an erythromycin resistance gene using a new gene replacement strategy that makes use of pyrE as a bidirectional selection marker. Growth under optimal and stressed conditions, sporulation efficiency, and spore heat resistance of the mutants were unaltered, except for small differences in spore heat resistance at 70°C and in growth at 2.3% NaCl. The mutants described in this work provide a safe alternative for basic research as well as for food challenge and process validation studies with gIICb. In addition, this work expands the clostridial genetic toolbox with a new gene replacement method that can be applied to replace any gene in gIICb and other clostridia.

IMPORTANCE The nontoxigenic mutants described in this work provide a safe alternative for basic research as well as for food challenge and process validation studies with psychrotrophic Clostridium botulinum. In addition, this work expands the clostridial genetic toolbox with a new gene replacement method that can be applied to replace any gene in clostridia.

INTRODUCTION

Botulism, caused by the botulinum neurotoxin (BoNT) produced by Clostridium botulinum, is a rare but severe paralytic illness in humans and animals. Botulinum toxins are 150-kDa proteins with zinc endopeptidase activity, consisting of two subunits, a 100-kDa heavy chain and a 50-kDa light chain. The heavy chain is responsible for binding and translocation of the light chain into the cytosol of neuronal cells, whereas the light chain cleaves SNARE proteins that are involved in the docking of acetylcholine-containing vesicles and fusion to the presynaptic membrane. When the SNARE proteins are cleaved, neurotransmitter release is inhibited, leading to the paralysis of the corresponding muscle (1, 2).

C. botulinum is a strictly anaerobic bacterium that thrives in decaying organic matter in soils and sediments of ponds, lakes, and oceans. It also forms dormant endospores that are highly resilient to hostile conditions and therefore can be found widespread in the environment. These spores may contaminate foods via raw materials or other sources, possibly leading to food-borne botulism when they are not eliminated by processing and when their outgrowth is not controlled (3, 4, 5, 6, 7). C. botulinum is divided into four distinct groups (I to IV) based on phylogenetic and physiological characteristics, of which only group I and II typically are associated with human botulism. Group I C. botulinum consists of proteolytic mesophilic strains producing toxin types A, B, and/or F. These strains form heat-resistant spores and are the main target for the so-called botulinum cook, the process used in canning of low-acid foods (121°C for 3 min or equivalent). Group II C. botulinum (gIICb) comprises nonproteolytic strains producing toxin types B, E, or F, which are saccharolytic and psychrotrophic (with minimum growth temperatures of 3°C) and whose spores are less heat resistant than those of group I (8). In the food industry, gIICb is a major concern for the safety of minimally processed, chilled ready-to-eat foods with an extended shelf life (REPFEDs), because spores surviving the mild processing treatments subsequently may germinate, grow, and produce toxin during refrigerated storage (6, 7, 9, 10, 11). The combination of the heat resistance of its spores and the ability to grow under refrigeration conditions makes this pathogen the main target pathogen that must be controlled in these foods. Guidelines for the control of this hazard in the food industry were developed more than 2 decades ago, requiring either a 6-decimal (6-D) reduction of the spores by heat treatment (90°C for 10 min or equivalent) or the control of outgrowth by limitation of the refrigerated storage time to <10 days, inclusion of ≥3.5% NaCl and ≥100 ppm nitrite, acidifying to pH ≤5.0, or an appropriate combination of these or additional hurdles (11, 12). However, the increasing consumer demand for fresh-tasting, healthy ready-to-eat foods that have been minimally processed and contain less salt and no artificial preservatives yet have a long shelf-life represents a challenge for the food industry in view of these botulinum safety guidelines (10, 11, 12). Furthermore, novel food processing and preservation technologies (e.g., high-pressure or pulsed electric field treatment and natural preservatives) have found their way to commercial food production, but data regarding their efficiency in controlling gIICb is scarce or lacking (13, 14, 15, 16, 17). This is in sharp contrast to the attention given in this context to other pathogens, like Listeria monocytogenes, Salmonella, and enterohemorrhagic Escherichia coli. The main reason for this paucity of data is that C. botulinum studies are subject to important biosafety and bioterrorism restrictions and because their culture requires strict anoxic conditions. One possible approach to circumvent these difficulties is the use of nonpathogenic surrogate organisms. For example, C. sporogenes has been widely used as a surrogate for proteolytic C. botulinum in studies on thermal processing of low-acid shelf-stable foods (18). However, a suitable validated surrogate for gIICb has been lacking to date. Recently, Parker et al. (19) studied previously isolated natural nontoxigenic Clostridium species that could be used as surrogates for gIICb. Two out of the three strains analyzed showed equal or faster growth than toxigenic gIICb under most (but not all) stress conditions (low temperature, reduced pH, and water activity [aw]), making them potentially useful for challenge studies with refrigerated foods, at least under some conditions. However, the spores of the three strains had lower heat resistance than some gIICb strains and could not be used for the validation of heating processes. Furthermore, it could not be excluded that the strains still carried bont or other toxin genes, and the (phylo)genetic relatedness of the strains to gIICb was not documented. This makes the behavior of the strains under other than the tested environmental conditions unpredictable (e.g., sensitivity to nitrite and other preservatives, sensitivity to organic acids, etc.).

As an alternative approach to develop safe strains for challenge studies and process validation, in the present work we attempted to construct nontoxic derivatives from a toxic gIICb strain by making a targeted knockout of the bont gene. The resulting derivative strains are expected to differ from their parent only in toxin production and thus to be a highly reliable alternative for challenge studies. Although the inactivation of specific genes in clostridial species has proven to be a rather difficult, slow, and inefficient task for a long time, the genetic toolbox for knockout mutagenesis has been expanding in the last few years. The ClosTron system, which makes use of a mobile intron that can be retargeted to a sequence of interest, has proven to be particularly efficient for insertional mutagenesis in a range of clostridial species (20), but only a few studies have used ClosTron mutagenesis in gIICb thus far (21, 22). Interestingly, ClosTron has been used to knock out the bont gene in both gICb and gIICb (21, 23), but the properties of the gIICb knockout strain in view of its possible usefulness for challenge or process validation studies in foods were not further investigated. Importantly, a disadvantage of ClosTron mutagenesis is that reversion to the toxigenic state by the excision of the intron from the bont gene cannot be excluded. For this reason, we additionally developed a method for bont deletion that makes use of pyrE, a gene encoding the enzyme orotate phosphoribosyltransferase, which is required for de novo uracil biosynthesis. This gene has been used before in various clostridia (C. sporogenes, C. difficile, and C. acetobutylicum) as a positive/negative selection marker. PyrE is essential for growth in the absence of uracil, while cells lacking PyrE become resistant to 5-fluoroorotic acid (5-FOA), a substrate analogue in de novo uracil biosynthesis that is converted to a toxic product. Therefore, cells encoding pyrE can be selected on uracil-free medium or counterselected in the presence of 5-FOA (24, 25, 26). We used this bidirectional selection to delete bont/E and replace it with an erythromycin resistance cassette. This study reports a targeted gene deletion in gIICb. The gene replacement strategy is novel in that it allows a single-step selection of gene replacement by double homologous recombination and loss of the plasmid on which the donor DNA is supplied.

MATERIALS AND METHODS

Bacterial strains and growth conditions.

Cultures of C. botulinum type E NCTC 11219 (obtained from National Collection of Type Cultures, Public Health England) were routinely grown at 30°C in Trypticase peptone glucose yeast extract broth (TPGY; 50 g/liter Trypticase [BD], 5 g/liter bacteriological peptone [Oxoid], 20 g/liter yeast extract [Oxoid], 4 g/liter glucose, 1 g/liter sodium thioglycolate) and plated on reinforced clostridial medium (RCM [VWR]; 37 g/liter RCM with 15 g/liter agar), TPGY agar (TPGY broth with 15 g/liter agar), or tryptone yeast extract thioglycolate agar (TYG; 30 g/liter tryptone [Lab M], 20 g/liter yeast extract, 1 g/liter sodium thioglycolate, 15 g/liter agar). Trypticase glucose yeast broth (Bio-Rad) supplemented with 0.1% trypsin (Life Technologies) was used to grow cultures for the mouse bioassays. Uracil-deficient medium was made by replacing yeast extract in TPGY agar with 20 g/liter acid-hydrolyzed casein (Lab M) (27). Clostridial vegetative cultures were manipulated and incubated in a Whitley DG250 anaerobic workstation (initial gas mixture comprised of 80% N2, 10% CO2, and 10% H2) using overnight prereduced media. E. coli strains were grown in lysogeny broth (LB; 10 g/liter tryptone, 5 g/liter yeast extract, 5 g/liter NaCl) or on LB agar (LB with 15 g/liter agar) at 37°C. E. coli DH5α was used for cloning and maintenance of plasmids, while E. coli CA434 (HB101 containing plasmid R702 [28]) was used as a conjugation donor. Media were supplemented with the following antibiotics (Applichem): thiamphenicol (Tm; 15 μg/ml in agar, 7.5 μg/ml in broth) and erythromycin (Em; 2.5 μg/ml) for C. botulinum, as well as cycloserine (Cy; 250 μg/ml) and chloramphenicol (Cm; 25 μg/ml in agar, 12.5 μg/ml in broth) for E. coli. 5-Fluoroorotic acid (5-FOA; 500 μg/ml [Manchester Organics]) was used for the screening of uracil auxotrophs.

Sporulation and purification of spore crops.

Spore crops were prepared using a two-phase sporulation medium as described before, with minor adjustments (29). First, a single colony was inoculated in 1 ml TPGY broth at 30°C. After 24 h of growth, this culture was added to a two-phase medium consisting of 4 ml distilled deoxygenated water over solid sporulation medium (3 g cooked meat medium [Oxoid], 0.03 g glucose, 0.45 g agar in 30 ml water). Spores were harvested from the liquid phase after 6 days of incubation at 30°C by centrifugation (3,400 × g, 4°C, 15 min). The resulting pellet was washed four times with 0.85% sterile saline by centrifugation, concentrated 5-fold, and stored in saline at 1 to 4°C outside the anaerobic workstation.

Construction of plasmids.

The ClosTron technology was used for the generation of an insertion mutant. This system is based on retargeting a bacterial group II intron to insert in a gene of interest (20, 30). Possible target sites in the bont/E gene of C. botulinum NCTC 11219 were identified using an intron design tool on the ClosTron website (www.clostron.com), and one site was chosen based on a high score according to the algorithm as well as proximity to the N terminus of the toxin. The plasmid pMTL007C-E2:Cbo:bontE-211a, containing the intron flanked by the specific targeting sequences (GGTCATAATAACTACTATCTCCATTTTTTA<intron>CTAATTATTTACAAA), was obtained from DNA 2.0 Inc. (Menlo Park, California, USA).

The second knockout strategy consisted of an allelic exchange of bont/E with ermB, an Em resistance gene. A novel three-step strategy was designed, with each step requiring a specific plasmid construct. Oligonucleotide primers used in these constructions are listed in Table 1 and were obtained from Integrated DNA Technologies (Heverlee, Belgium). Constructs were routinely transferred to E. coli DH5α by electroporation and verified by sequencing before further use. The first plasmid construct was used to generate a pyrE deletion (locus tag SR42_16845) in strain NTCT 11219. To this end, flanking loci of pyrE were cloned in pMTL84151 (31) to yield pMTL84151_pyr5′pyr3′. More specifically, the 5′ fragment (1,086 bp) was amplified from genomic DNA (gDNA) of NCTC 11219 with primers pyrE_5′F/pyrE_5′R, and the 3′ fragment (1,164 bp) was amplified with primers pyrE_3′F/pyrE_3′R. Amplicons were restricted with KpnI/BamHI and BamHI/XhoI, respectively, ligated end to end in pMTL84151 opened with KpnI and XhoI, and electroporated to E. coli DH5α. Second, the plasmid pMTL84151_Δbont, used to replace bont/E with ermB, was constructed as illustrated in Fig. 1. Flanking loci (5′ locus, 1,080 bp; 3′ locus, 1,261 bp) of bont/E first were cloned in pMTL84151 using primers bontE_5′F/bontE_5′R and bontE_3′F/bontE_3′R for amplification. These loci include the first two codons of bont/E in the 5′ fragment and the last 16 codons in the 3′ fragment. After restriction of the PCR products with KpnI/BamHI and BamHI/XhoI, respectively, the 5′ and 3′ fragments were ligated end to end in pMTL84151 opened with KpnI and XhoI. Subsequently, ermB (amplified from pMTL82254 with pMTL82254ermB_F/pMTL82254ermB_R and restricted at both ends with BamHI) was inserted in the BamHI site of this plasmid, resulting in pMTL84151_5′bont_ermB_3′bont. In addition, wild-type (WT) pyrE of NCTC 11219 (675 bp) was amplified from start to stop codons with primers pyrE11219_F/pyrE11219_R, restricted with NdeI/SacI, and placed after promoter pfdx in pMTL83353 opened with the same enzymes. pfdx was used to drive pyrE expression, because pyrE is located at the end of an operon in NCTC 11219 and could not be amplified simply with its native promoter. Here, the fragment containing pfdx and pyrE was amplified with pMTL83353_F/pyrE11219_R, digested with SbfI and SacI, and cloned in pMTL84151_5′bont_erm_3′bont restricted with the same enzymes. This resulted in the plasmid pMTL84151_Δbont. A third plasmid was designated pMTL84151_WTpyr and was used for restoring the pyrE deletion back to wild-type status. This was created by cloning a pyrE amplicon with its 5′ and 3′ flanking regions (2,956 bp) generated with primers pyrE_5′F/pyrE_3′R and restricted with KpnI and XhoI into pMTL84151 cleaved with the same enzymes. A promoter is absent from this construct; thus, pyrE is not expressed on the plasmid.

TABLE 1.

PCR oligonucleotides used for cloning and construct verification

| Category and primer name | Sequencec (5′–3′) | Coordinate of 3′ end |

|---|---|---|

| ClosTron | ||

| bontE_F | CCAGGCGGTTGTCAAGAATTTTAT | 2298420a |

| bontE_R | TCAAATAAATCAGGCTCTGCTCCC | 2298057a |

| RAM_F | ACGCGTTATATTGATAAAAATAATAATAGTGGG | |

| RAM_R | ACGCGTGCGACTCATAGAATTATTTCCTCCCG | |

| pCD6_F | GTTGGGAGTAGTTGTGC | |

| pCD6_R | ATGGTATCTCATTATTGGC | |

| ClosTron_R | GTTTCAGACACTTTCCTCTATCGAG | |

| Y-linker primer | TTTCTGCTCGAATTCAAGCTTCTAACGATGTACGGGGACACATG | |

| ΔpyrE | ||

| pyrE_5′F | AACGGTACCCCACTACGTTCTCTCTTAGAGG | 246521b |

| pyrE_5′R | AACGGATCCTGAGTTTAAGGTTTTTAGTTGG | 247564b |

| pyrE_3′F | CATGGATCCTCCTCCCAAATTTCATAATGT | 248312b |

| pyrE_3′R | CATCTCGAGTGTTTTATGCTGTGGTCCTG | 249436b |

| pyrE_5′Fb | CCAACTTTATCAAAAGCTCAG | 246369b |

| pyrE_3′Rb | CTAATACAGGAAAGCATGGC | 249503b |

| pMTL84151_mcsF | AGGAAACAGCTATGACCG | |

| pMTL84151_mcsR | GACGTTGTAAAACGACGG | |

| ΔbontE | ||

| pyrE11219_F | AGGCATATGGAAGCATATAAAAAAGAG | 248264b |

| pyrE11219_R | CTTGAGCTCCTACTTAGCACCATATTC | 247627b |

| bontE_5′F | TAAGGTACCGTTATTGGAGATACATCCGG | 2299564a |

| bontE_5′R | TAAGGATCCTGGCATATACAGCATCTCC | 2298522a |

| bontE_3′F | TAAGGATCCAGAGATCATACAAACAGCAATGG | 2294800a |

| bontE_3′R | TAACTCGAGCTATTCGAGAGAGCATTGGTCG | 2293583a |

| upbontE_F | GAACTACTTATAAAAGAACAAACCTCACC | 2299627a |

| downbontE_R | GAATGGATATCTTAGGATAATCATTCCAC | 2293466a |

| pMTL83353_F | GAGCCTGCAGGATAAAAAAATTGTAG | |

| pMTL82254ermB_F | GTTGGATCCGAAGCAAACTTAAGAGTGTG | |

| pMTL82254ermB_R | TACGGATCCACATTCCCTTTAGTAACGTG |

The primer coordinates for NCTC 11219 are based on accession number JXMR01000001.

The primer coordinates for NCTC 11219 are based on accession number JXMR01000004.

Restriction sites are underlined: KpnI (GGTACC), BamHI (GGATCC), XhoI (CTCGAG), NdeI (CATATG), SacI (GAGCTC), and SbfI (CCTGCAGG).

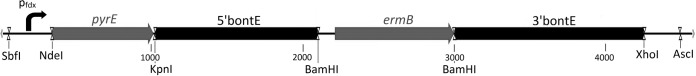

FIG 1.

Scheme showing the different fragments cloned between SbfI and AscI restriction sites of shuttle vector pMTL84151 (Tmr) to create pMTL84151_Δbont (Tmr Emr), which was used for replacing the bont/E gene with an ermB marker. The pfdx promoter (bent arrow) was derived from pMTL83353 and drives the expression of pyrE, which was amplified from gDNA of NCTC 11219. The 5′ and 3′ fragments of bont/E also were amplified from NCTC 11219 gDNA and flank ermB derived from pMTL82254.

Mating.

Each of the four plasmid constructs described above was introduced into E. coli CA434 by electroporation and selecting Cmr transformants. For plasmid transfer to C. botulinum NCTC 11219, 1 ml of an overnight LB culture of E. coli donor containing the appropriate plasmid was centrifuged. The pellet was washed with PBS (phosphate-buffered saline; 8 g/liter NaCl, 0.2 g/liter KCl, 1.44 g/liter Na2HPO4, 0.24 g/liter KH2PO4, pH adjusted with HCl to 7.4) and taken to the anaerobic workstation. The pellet next was resuspended in 200 μl of NCTC 11219 recipient grown for 24 h in TPGY broth, after which the mixture was spread on a cellulose acetate filter (pore size, 0.45 μm) on nonselective TYG agar. After 24 h of incubation at 30°C, the cells were washed off the filter with 1 ml PBS, and 200 μl was plated on selective RCM plates (Tm for resistance encoded by the plasmid, Cy against E. coli donor). Colonies appearing within 3 days were restreaked to purity on the same selective medium.

Isolation and verification of bont/E ClosTron insertion mutant.

To confirm the transfer of the ClosTron plasmid pMTL007C-E2:Cbo:bontE-211a to NCTC 11219, Tmr colonies were purified after mating and analyzed by PCR using primers RAM_F/RAM_R. Subsequently, transconjugants were streaked on RCM supplemented with Em, and well-developed colonies appearing within 3 days were restreaked on the same medium for purification. PCR and sequence analysis with primers bontE_F/bontE_R were performed to verify successful intron insertion in bont/E. Individual colonies from a verified clone then were screened for Tm sensitivity, indicating the loss of the ClosTron plasmid, which was confirmed here by PCR using primers pCD6_F/pCD6_R.

To investigate whether only one insertion event took place, the Y-linker PCR described by Kwon and Ricke (32) was used. In this method, gDNA of the ClosTron mutant is restricted to completion with NlaIII and ligated to a Y-shaped linker, generated by mixing two oligonucleotides that are complementary only at one end. The complementary parts of these oligonucleotides form the stalk of the linker, which has a 3′ CATG overhang that stocks to the NlaIII chromosomal DNA ends. The noncomplementary parts of the oligonucleotides form the Y-linker arms. PCR then is conducted on the ligation mixture with a ClosTron-specific primer (ClosTron_R) and a Y-linker primer with a sequence identical, not complementary, to the sequence of one of the arms. The Y-linker primer can anneal and a PCR product is formed only when the ClosTron_R primer extends DNA synthesis during the first PCR cycle into the Y-linker arm. Consequently, the two primers selectively amplify all fragments in the genome containing the ClosTron insert.

Isolation and verification of bont/E deletion mutant.

After conjugation of pMTL84151-pyr5′pyr3′ to NCTC 11219, transconjugants were streaked on RCM supplemented with 5-FOA to select for PyrE-deficient mutants generated by double homologous recombination between the plasmid-based pyrE-flanking fragments and the corresponding chromosomal sequences. Deletion was confirmed by PCR and sequence analysis with primers pyrE_5′Fb/pyrE_3′Rb, which anneal outside the homologous fragments involved in recombination. Further, a clone from which the plasmid was cured was isolated by screening for Tm sensitivity. The NCTC 11219 ΔpyrE mutant next was mated with E. coli CA434 containing pMTL84151_Δbont. Transconjugants were streaked on RCM supplemented with Em and 5-FOA to select for clones in which double homologous recombination as well as the loss of the plasmid had occurred. Plasmid loss was confirmed by the Tm sensitivity of the clones. PCR and sequence analysis with primers upbontE_F/downbontE_R, annealing outside the homologous fragments, were performed to confirm that bont/E was deleted and replaced by ermB. Finally, the wild-type pyrE gene was restored by first conjugating pMTL84151-WTpyr to the NCTC 11219 ΔpyrE ΔbontE::ermB mutant and subsequently propagating one transconjugant in liquid TPGY medium for about 60 generations and then plating on uracil-deficient medium. Only clones in which the chromosomal pyrE gene is restored by allelic exchange with the plasmid-based promoterless pyrE grow well on these plates. One such clone, confirmed by PCR and sequence analysis to be identical to the wild type in the pyrE locus and from which the plasmid was cured as explained before, was isolated and designated the NCTC 11219 ΔbontE::ermB mutant.

Mouse bioassays.

Mouse bioassays were performed for the detection of active botulinum toxin in clostridial cultures. The assays were performed with NCTC 11219 bontE211a::CT and NCTC 11219 ΔpyrE ΔbontE::ermB bont/E knockout strains and with the corresponding positive-control strains NCTC 11219 wild type and NCTC 11219 ΔpyrE mutant, respectively. Supernatants from 5-day cultures of the strains in Trypticase glucose yeast broth supplemented with trypsin at 30°C were used for toxin testing. A seroneutralization test using anti-E antitoxin, which specifically neutralizes the toxic effects of BoNT/E, was included. Neutralized (i.e., mixed with antitoxin) and untreated filtered supernatants were injected intraperitoneally in mice for evaluating the toxicity. Two animals were used per sample. Mice were observed at regular intervals for a period of 4 days for signs of botulism (ruffling of the fur, hypotonic abdomen, wasp-waist, difficulty in breathing, weakness of limbs, and total paralysis) or death. Typical paralysis and/or death of the mice with prevention of these effects by the administration of antitoxin was established a positive test for BoNT/E.

Phenotypical analysis of wild-type NCTC 11219 and NCTC 11219 bont/E mutants. (i) Unstressed growth.

Wild-type C. botulinum NCTC 11219 and bontE211a::CT and ΔbontE::ermB mutants were inoculated from single colonies in 1 ml TPGY broth in triplicate and incubated for 24 h at 30°C. The stationary-phase cultures were diluted 5 × 103-fold in 50 ml TPGY (equal to time zero) and incubated at 30°C. Cell numbers were determined by plate counting on TPGY agar every 2 h during 16 h and again 8 h later.

(ii) Stressed growth.

Overnight cultures of the wild type and mutants were streaked 6-fold on RCM plates with different pHs (5.7, 5.5, 5.2, and 4.9; adjusted with HCl and measured before and after autoclaving) or NaCl content (1.9%, 2.1%, 2.3%, and 2.5%; taking into account that 0.5% NaCl is already present in RCM). The plates were incubated at 30°C in an anaerobic workstation, and colony formation was observed macroscopically for several days. Growth at lower temperatures was analyzed in 6-fold by streaking single colonies that were pregrown at 12°C on RCM plates and incubating in AnaeroGen bags (Oxoid) at 8°C and 12°C. Colony formation was observed daily.

(iii) Heat resistance of spores.

Spore crops were made in triplicate from different colonies per strain and used within 2 weeks for this experiment. The initial spore count was determined by plate counting on TPGY after a heat treatment to inactivate remaining vegetative cells (65°C, 10 min), but samples that were not preheated were used for the heat inactivation experiment. Heat treatments were conducted in a heating block at 70°C, 73°C, 90°C, and 93°C. At different time points, samples were taken and cooled immediately to stop inactivation, diluted in 0.85% NaCl, plated on TPGY, and incubated at 30°C for colony counting. For the treatments at 90°C and 93°C, lysozyme (10 μg/ml; Carl Roth GmbH) was added to the plating medium.

Statistical analysis.

To statistically assess the equivalence of unstressed growth, spore yield, and spore heat resistance between the wild type and the two bont/E mutants, the two-tailed unpaired Student's t test was used with a significance level of 0.05. Since growth at low temperature was analyzed in a time-to-colony-formation experiment, a logistic regression model was fitted using the day, temperature, and strain as predictor variables. The proposed model was highly significant (P value of <0.001 by the whole-model likelihood ratio test; generalized R2 of 0.9063) and showed no lack of fit (P value of ∼1 by the lack-of-fit likelihood ratio test), indicating it was suitable for testing the individual parameters.

RESULTS AND DISCUSSION

C. botulinum NCTC 11219 is a group II type E strain isolated in 1979 from salmon after an outbreak of human botulism (33), of which we previously reported the genome sequence of four contigs (GenBank accession no. JXMR01000001 to JXMR01000004) (34). Here, we used this strain for the construction of atoxigenic mutants. The ClosTron system was used for the insertional inactivation of the bont/E gene, whereas a new approach based on double homologous recombination using the selection markers pyrE and ermB was designed to create a bont/E deletion.

Construction of C. botulinum NCTC 11219 bontE211a::CT insertion mutant.

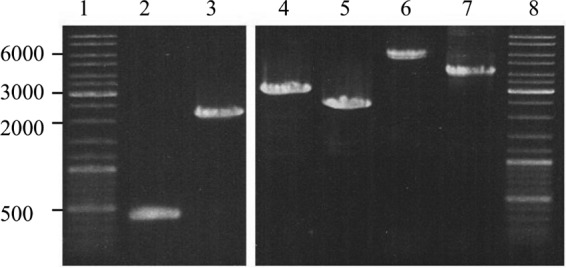

Plasmid pMTL007C-E2:Cbo:bontE-211a, containing an intron retargeted to insert into bont/E, was transferred by conjugation to NCTC 11219. Since the intron contains a retrotransposition-activated marker (RAM) based on the ermB gene, the successful insertion of the intron in the genome is selectable by the expression of Em resistance. Emr clones were picked up and analyzed by PCR and sequence analysis. The intron was correctly located in one clone at position 211 in the bont/E open reading frame with an antisense orientation of ermB relative to bont/E (Fig. 2 and 3, lanes 2 and 3). Further analyzing this clone by Y-linker PCR and sequencing of the PCR product confirmed that only a single intron was present in the genome. The efficiency of the different steps in the ClosTron mutagenesis procedure was rather low. For the conjugation of the ClosTron plasmid to NCTC 11219, several attempts were needed to obtain only two transconjugants. Similarly, several clones of transconjugants had to be restreaked to obtain 15 Emr colonies, and only one of these had the correct intron insertion. This confirms earlier statements in the literature that C. botulinum is less genetically tractable than most other clostridia (21, 35).

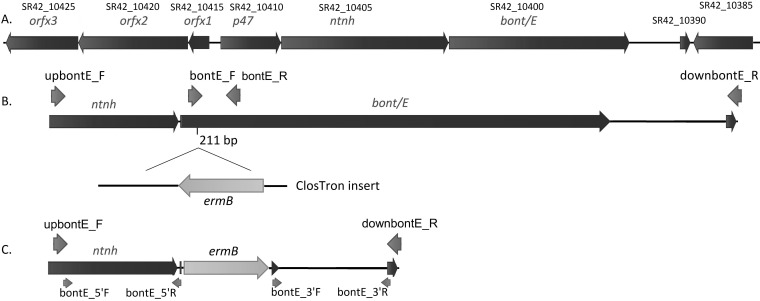

FIG 2.

(A) Schematic representation of bont/E with its upstream and downstream genes in C. botulinum NCTC 11219. Locus tags for all genes are shown. (B) Position of the ClosTron insert after the 211th base of the bont/E open reading frame in the NCTC 11219 bontE211a::CT mutant, with ermB positioned antisense to bont/E. Also shown are primers bontE_F/bontE_R, annealing up- and downstream of the ClosTron target site, and primers upbontE_F/downbontE_R, annealing outside the loci used in double homologous recombination to delete bont/E. (C) NCTC 11219 ΔbontE::ermB mutant with bont/E deleted and replaced by ermB, confirmed by PCR using primers upbontE_F/downbontE_R. The positions of the cloning primers bontE_5′F/bontE_5′R and bontE_3′F/bontE_3′R, used for construction of pMTL84151_Δbont, also are indicated.

FIG 3.

PCR analysis of different strain constructs. Lanes 1 and 8, molecular weight marker (GeneRuler from Life Technologies); lane 2, NCTC 11219 with bont/E fragment amplified with primers bontE_F/bontE_R (expected size, 410 bp); lane 3, NCTC 11219 bontE211a::CT mutant with bont/E fragment with ClosTron insertion amplified with primers bontE_F/bontE_R (expected size, 2,008 bp); lane 4, NCTC 11219 with pyrE region amplified with primers pyrE_5Fb/pyrE_3Rb (expected size, 3,174 bp); lane 5, NCTC 11219 ΔpyrE mutant with pyrE region amplified with primers pyrE_5Fb/pyrE_3Rb (expected size, 2,474 bp); lane 6, NCTC 11219 ΔpyrE mutant with bont/E region amplified with primers upbontE_F/downbontE_R (expected size, 6,218 bp); lane 7, NCTC 11219 ΔbontE::ermB mutant with bont/E region amplified with primers upbontE_F/downbontE_R (expected size, 3,449 bp).

Construction of C. botulinum NCTC 11219 ΔbontE::ermB deletion mutant.

A deletion strategy to knock out bont/E was developed by combining different genetic tools that have not yet been used in gIICb, despite their success in other clostridia. Since effective suicide plasmids have not yet been described for C. botulinum, and given the reported low frequency of DNA transfer into gIICb, we chose to make use of pseudosuicide plasmids for conjugation (30, 36). These plasmids autonomously replicate but are segregationally unstable, providing the advantage of being lost more rapidly in the absence of selection after successful conjugation. A set of modular shuttle vectors, the pMTL80000 series, carrying four different Gram-positive replicons was constructed by Heap et al. (31) for use in the clostridia. We selected pMTL84151 with the pCD6 replicon from this set, since this plasmid has the lowest stability in groups I and II C. botulinum (31 and unpublished results). Another key element in the knockout strategy was the use of the pyrE gene as a bidirectional selection marker. First, pyrE was deleted from NCTC 11219, resulting in a 5-FOA-resistant and uracil auxotrophic strain (Fig. 3, lanes 4 and 5). The obtained ΔpyrE mutant then was used as the background to delete bont/E and replace it with an ermB marker. This was achieved by first conjugating pMTL84151_Δbont (Fig. 1) to the ΔpyrE mutant and selecting for Tm resistance and then streaking a transconjugant on medium containing both Em and 5-FOA. Since the plasmid expresses pyrE in trans, 5-FOA selects for its loss. Further, clones that lost the plasmid can remain resistant to Em only when the ermB gene was exchanged with the bont/E gene by double homologous recombination. Although this procedure selects for two events simultaneously, the frequency was sufficient to allow the isolation of several colonies from a single streak. Obviously, the efficiency benefits from the low segregational stability of the plasmid. The loss of the plasmid was confirmed by the loss of Tm resistance, and PCR and sequence analysis confirmed the replacement of bont/E by ermB (Fig. 2 and 3, lanes 6 and 7).

Finally, the pyrE deletion strain was restored to wild-type status by inserting pyrE and its flanking regions back into the chromosome by double homologous recombination with pMTL84151_WTpyr. To this end, the plasmid first was conjugated to the NCTC 11219 ΔpyrE ΔbontE::ermB mutant. The Tmr transconjugants remained resistant to 5-FOA, which confirmed that pyrE was not expressed on pMTL84151_WTpyr. Since pyrE was cloned without its promoter (which is further upstream of the pyr operon) on this plasmid, there is no leaky expression from plasmid promoters. In line with this observation, the transconjugants did not grow when they were plated on uracil-deficient medium, except for some rare colonies which showed normal growth when restreaked on the same medium. From these, subclones having lost the plasmid with a Tms phenotype were isolated. These were confirmed to have a wild-type chromosomal pyrE allele and were designated the NCTC 11219 ΔbontE::ermB strain.

Mouse bioassays.

The presence of BoNT/E in culture supernatants of the NCTC 11219 wild type and the ΔpyrE strain was confirmed, whereas no active toxin was detected for the bont/E insertion and deletion mutants. All mice injected with supernatant of wild-type and ΔpyrE strains died within a day, while mice injected with supernatants of the mutants or supernatants from the bont/E wild-type strains mixed with antitoxin E survived until the end of observation at 4 days. Thus, the loss of toxicity in both mutants was confirmed. In addition, the seroneutralization test using anti-E antitoxin confirmed that only one neurotoxin is produced by NCTC 11219, as was already predicted from the genome sequence (34).

Phenotypic analysis of wild-type NCTC 11219 and NCTC 11219 bont/E mutants.

Nontoxic mutants of gIICb have the potential to greatly facilitate basic research and food challenge studies with this organism, provided that their properties related to growth, sporulation, survival, and inactivation are not modified due to the knockout of the bont/E gene. Here, we compared the growth, sporulation, and spore heat resistance of both constructed bont/E mutants and the wild-type NCTC 11219 strain.

(i) Unstressed growth.

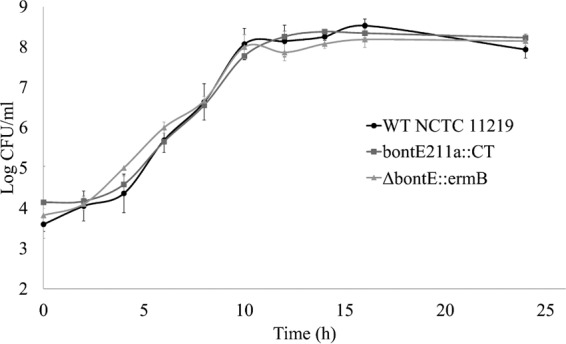

The growth curves of the mutants and the wild type at 30°C were very similar (Fig. 4). The DMFit software was used to determine the maximum growth rate, μmax, and the upper asymptote, yend. The lag phase could not be evaluated because there were not enough points available to measure this accurately. No significant differences existed between μmax and yend of the wild-type, ClosTron, and ΔbontE mutant strains. The values were 0.7 ± 0.2, 0.5 ± 0.1, and 0.4 ± 0.0 (log CFU/ml)/h for μmax and 7.8 ± 0.3, 8.0 ± 0.0, and 8.0 ± 0.1 log CFU/ml for yend, respectively.

FIG 4.

Growth in TPGY broth at 30°C of wild-type NCTC 11219, NCTC 11219 bontE211a::CT, and NCTC 11219 ΔbontE::ermB strains determined by plate counting on TPGY. Averages ± standard deviations are shown from three independent experiments.

(ii) Stressed growth.

A quantitative comparison of growth under acidic, NaCl, and low-temperature stress was performed by assessing the time to colony formation on RCM plates. On acidified RCM, results of both mutants and the wild type were identical in 6-fold streaking. Single colonies of 1 mm were visible after 24 h at pH 5.7 and after 30 h at pH 5.5, while pinpoint colonies appeared after 72 h at pH 5.2. No colonies were formed at pH 4.9 up to 5 days. Under NaCl stress, all three strains showed clear single colonies in 6-fold after 24 h at 1.9% and 2.1% NaCl. Unexpectedly, a small difference was observed at 2.3% NaCl between the ΔbontE::ermB strain and the wild type and ClosTron mutant. Strain ΔbontE::ermB formed clear 1-mm colonies after 24 h (6-fold), while those of the wild type and ClosTron mutant were pinpoint sized and reached 1 mm only after 48 h (6-fold streaking). No colonies appeared on 2.5% NaCl for any strain. The third stress condition tested was growth at low temperature. Single colonies grown at 12°C on RCM were restreaked 6-fold on RCM and then incubated at 12°C and 8°C, and the time to formation of colonies (1 mm) was registered. As opposed to the data for acid and NaCl stress, the time to colony formation at low temperature showed variability among the six replicates, as indicated in Table 2. A logistic regression model was fit on these data and showed that there was no significant effect of the strain (P value of 0.2388 by effect likelihood ratio test). Therefore, it can be concluded that there is no significant difference in growth at low temperature between the three strains.

TABLE 2.

Growth of NCTC 11219 WT, NCTC 11219 bontE211a::CT, and NCTC 11219 ΔbontE::ermB strains on RCM plates

| Strain | No. of plates showing single coloniesa at: |

||||

|---|---|---|---|---|---|

| 12°C |

8°C |

||||

| 3 days | 4 days | 7 days | 8 days | 9 days | |

| NCTC 11219 | 5/6 | 6/6 | 4/6 | 5/6 | 6/6 |

| bontE211a::CT | 4/6 | 6/6 | 4/6 | 6/6 | 6/6 |

| ΔbontE::ermB | 3/6 | 6/6 | 3/6 | 4/6 | 6/6 |

Single colonies were restreaked 6-fold, and the time to the formation of 1-mm colonies was noted.

(iii) Spore production.

Sporulation was performed in two-phase sporulation medium and observed regularly with phase-contrast microscopy. Spore formation started within 72 h for all strains. Spore counts were determined after 6 days by plate counting after the inactivation of the vegetative cells at 65°C for 10 min. No differences were observed in spore yield between wild-type, bontE211a::CT, and ΔbontE::ermB strains. Spore crops used for treatments at 90°C and 93°C had yields of 7.8 ± 0.1, 8.1 ± 0.3, and 7.9 ± 0.1 log CFU/ml, respectively. The spore crops used for heat treatments at 70°C and 73°C all had the same yield, 7.6 ± 0.1 log CFU/ml.

(iv) Spore heat resistance.

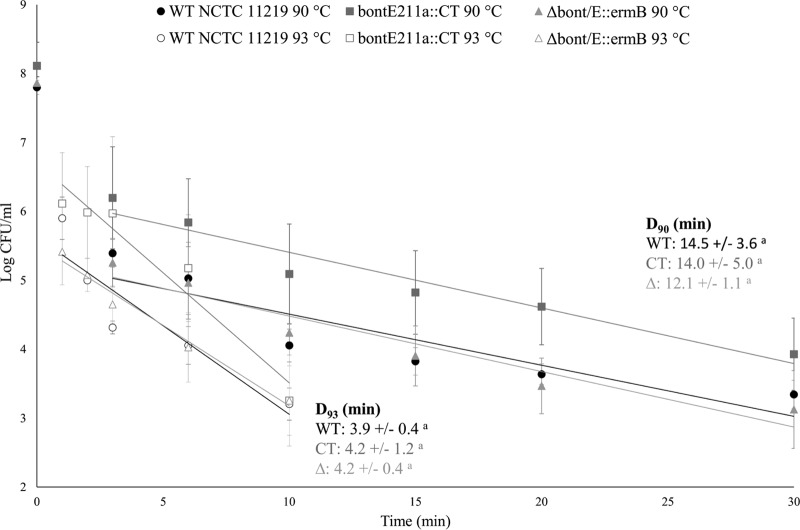

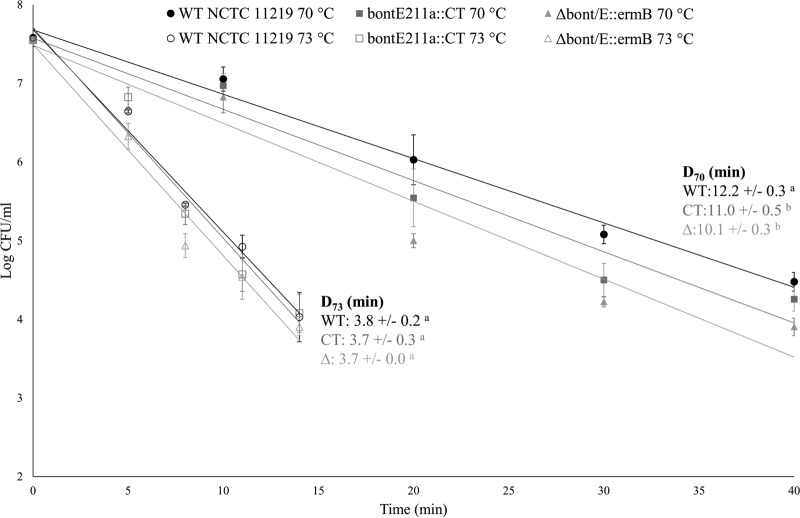

In the analysis of spore heat resistance, we incorporated lysozyme in the recovery medium because it is known to increase the number of survivors of gIICb spores (37, 38). This is because the cortex hydrolases, which are required for spore germination, are very heat sensitive but can be replaced with exogenous lysozyme. The inactivation curves at 90°C and 93°C showed a biphasic trend, with an initial rapid decrease of about 2 to 2.5 log, followed by a slower log-linear decrease (Fig. 5). This is in line with previous reports and has been attributed to the existence of a lysozyme-impermeable and -permeable fraction in the spore population (38, 39). The decimal reduction times (D values) were calculated only from the log-linear part, corresponding to the presumed lysozyme-permeable fraction. No differences were observed in the D90°C and D93°C between the three strains, suggesting that spore heat resistance is not affected by the inactivation of bont/E. In addition, we chose to report heat resistance without lysozyme in the recovery medium. This reduces the apparent heat resistance of the spores, and treatments were performed at 70°C and 73°C. Inactivation was log linear in this case (Fig. 6) and presumably correlates with the inactivation of the spore cortex hydrolases. The D70°C of the two mutants was slightly but significantly lower than that of the wild type, but no difference was found between the D70°C of both mutants mutually. In contrast, the D73°C was not different between the three strains. Together, these results indicate that spore heat resistance is unaffected in the mutants, except for a small difference at 70°C. Since this difference was observed in both the insertion and deletion mutants, it is unlikely to result from an accidental mutation unrelated to the knockout of the bont/E gene. One possible explanation is that the effect is due to a polar effect on one or more genes upstream or downstream of bont/E. However, given the gene context shown in Fig. 2, it is difficult to imagine how the same polar effect could exist in both mutants. Finally, it cannot be excluded that the difference is a direct consequence of the abolition of toxin production. For example, it has been demonstrated recently that there is a regulatory link between sporulation and toxin production in gIICb strain Beluga via the Spo0A gene product (40).

FIG 5.

Heat inactivation of spores of wild-type NCTC 11219, NCTC 11219 bontE211a::CT, and NCTC 11219 ΔbontE::ermB strains at 90°C and 93°C. Averages ± standard deviations from three independent experiments are shown, as are average D values ± standard deviations at 90°C and 93°C derived from the linear part of the curve. A common superscript letter at the same temperature indicates that there is no significant difference.

FIG 6.

Heat inactivation of spores of wild-type NCTC 11219, NCTC 11219 bontE211a::CT, and NCTC 11219 ΔbontE::ermB strains at 70°C and 73°C. Averages ± standard deviations from three independent experiments are shown, as well as average D values ± standard deviations at 70°C and 73°C. A common superscript letter at the same temperature indicates that there is no significant difference. Since tailing occurred after 40 min at 70°C and after 15 min at 73°C, the corresponding data are not shown or used.

In conclusion, two strategies were employed in this study for obtaining a gIICb surrogate in which the bont/E gene is inactivated. Besides the well-known ClosTron system, which generates insertional knockouts, we additionally developed a new approach based on double homologous recombination for the replacement of bont/E with an ermB cassette. Growth under unstressed and stressed conditions, sporulation, and spore heat resistance of both mutants were compared to that of wild-type NCTC 11219 and were unaffected, except for two properties where small differences were noted. Heat resistance of the spores at 70°C was slightly lower for both mutants. In addition, the growth of the deletion mutant in 2.3% NaCl was faster than for the other strains. The reason for the changes currently is unclear, and it would be interesting to investigate whether they are related to the loss of toxin production or to random mutations that have occurred during strain construction. However, since the deviations in the mutants are small compared to the natural strain-to-strain variation within gIICb, the nontoxic strains will be useful to investigate the safety of novel food processing and preservation techniques and for food challenge studies. Furthermore, the method for gene deletion developed in this work is a novel tool to construct nontoxic derivatives of type B and F gIICb strains as well as to inactivate any other gene in gIICb and other clostridia.

ACKNOWLEDGMENTS

We thank N. P. Minton and J. T. Heap for generously providing the pMTL80000 kit and E. coli CA434.

Funding Statement

This work was funded by Research Foundation-Flanders (G.0C77.14N) and by KU Leuven Research Fund (METH/14/03). The funders had no role in study design, data collection and interpretation, or the decision to submit the work for publication.

REFERENCES

- 1.Turton K, Chaddock JA, Acharya KR. 2002. Botulinum and tetanus neurotoxins: structure, function and therapeutic utility. Trends Biochem Sci 27:552–558. doi: 10.1016/S0968-0004(02)02177-1. [DOI] [PubMed] [Google Scholar]

- 2.Dolly JO, Aoki KR. 2006. The structure and mode of action of different botulinum toxins. Eur J Neurol 13:1–9. doi: 10.1111/j.1468-1331.2006.01648.x. [DOI] [PubMed] [Google Scholar]

- 3.Johannsen A. 1965. Clostridium botulinum type E in foods and the environment generally. J Appl Bacteriol 28:90–94. [Google Scholar]

- 4.Bott TL, Johnson J Jr, Foster EM, Sugiyama H. 1968. Possible origin of the high incidence of Clostridium botulinum type E in an inland bay (Green Bay of Lake Michigan). J Appl Bacteriol 95:1542–1547. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Dodds KL. 1993. Clostridium botulinum in the environment, p 21–51. In Hauschild AHW, Dodds KL (ed), Clostridium botulinum: ecology and control in foods. Marcel Dekker, New York, NY. [Google Scholar]

- 6.Hielm S, Hyytiä E, Andersin AB, Korkeala H. 1998. A high prevalence of Clostridium botulinum type E in Finnish freshwater and Baltic Sea sediment samples. J Appl Microbiol 84:133–137. doi: 10.1046/j.1365-2672.1997.00331.x. [DOI] [PubMed] [Google Scholar]

- 7.Hyytiä E, Hielm S, Korkeala H. 1998. Prevalence of Clostridium botulinum type E in Finnish fish and fishery products. Epidemiol Infect 120:245–250. doi: 10.1017/S0950268898008693. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Carter AT, Peck MW. 2015. Genomes, neurotoxins and biology of Clostridium botulinum group I and group II. Res Microbiol 166:303–317. doi: 10.1016/j.resmic.2014.10.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Graham AF, Mason DR, Maxwell FJ, Peck MW. 1997. Effect of pH and NaCl on growth from spores of non-proteolytic Clostridium botulinum at chill temperature. Lett Appl Microbiol 24:95–100. doi: 10.1046/j.1472-765X.1997.00348.x. [DOI] [PubMed] [Google Scholar]

- 10.Lindström M, Kiviniemi K, Korkeala H. 2006. Hazard and control of group II (non-proteolytic) Clostridium botulinum in modern food processing. Int J Food Microbiol 108:92–104. doi: 10.1016/j.ijfoodmicro.2005.11.003. [DOI] [PubMed] [Google Scholar]

- 11.Peck MW. 2006. Clostridium botulinum and the safety of minimally heated, chilled foods: an emerging issue? J Appl Microbiol 101:556–570. doi: 10.1111/j.1365-2672.2006.02987.x. [DOI] [PubMed] [Google Scholar]

- 12.Peck MW, Stringer SC. 2005. The safety of pasteurised in-pack chilled meat products with respect to the foodborne botulism hazard. Meat Sci 70:461–475. doi: 10.1016/j.meatsci.2004.07.019. [DOI] [PubMed] [Google Scholar]

- 13.Lenz CA, Vogel RF. 2014. Effect of sporulation medium and its divalent cation content on the heat and high pressure resistance of Clostridium botulinum type E spores. Food Microbiol 44:156–167. doi: 10.1016/j.fm.2014.05.010. [DOI] [PubMed] [Google Scholar]

- 14.Reddy NR, Tetzloff RC, Solomon HM, Larkin JW. 2006. Inactivation of Clostridium botulinum nonproteolytic type B spores by high pressure processing at moderate to elevated high temperatures. Innov Food Sci Emerg Technolog 7:169–175. doi: 10.1016/j.ifset.2006.03.002. [DOI] [Google Scholar]

- 15.Margosch D, Ehrmann MA, Buckow R, Heinz V, Vogel RF, Gänzle MG. 2006. High-pressure-mediated survival of Clostridium botulinum and Bacillus amyloliquefaciens endospores at high temperatures. Appl Environ Microbiol 72:3476–3481. doi: 10.1128/AEM.72.5.3476-3481.2006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Gao YL, Ju XR. 2008. Exploiting the combined effects of high pressure and moderate heat with nisin on inactivation of Clostridium botulinum spores. J Microbiol Methods 72:20–28. doi: 10.1016/j.mimet.2007.11.003. [DOI] [PubMed] [Google Scholar]

- 17.Bull MK, Olivier SA, van Diepenbeek RJ, Kormelink F, Chapman B. 2009. Synergistic inactivation of spores of proteolytic Clostridium botulinum strains by high pressure and heat is strain and product dependent. Appl Environ Microbiol 75:434–445. doi: 10.1128/AEM.01426-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Brown JL, Tran-Dinh N, Chapman B. 2012. Clostridium sporogenes PA 3679 and its uses in the derivation of thermal processing schedules for low-acid shelf-stable foods and as a research model for proteolytic Clostridium botulinum. J Food Prot 75:779–792. doi: 10.4315/0362-028X.JFP-11-391. [DOI] [PubMed] [Google Scholar]

- 19.Parker MD, Barrett PI, Shepherd J, Price LJ, Bull SD. 2015. Characterisation of non-toxigenic Clostridium spp. strains, to use as surrogates for non-proteolytic Clostridium botulinum in chilled food challenge testing. J Microbiol Methods 108:83–91. doi: 10.1016/j.mimet.2014.11.011. [DOI] [PubMed] [Google Scholar]

- 20.Heap JT, Kuehne SA, Ehsaan M, Cartman ST, Cooksley CM, Scott JC, Minton NP. 2010. The ClosTron: mutagenesis in Clostridium refined and streamlined. J Microbiol Methods 80:49–55. doi: 10.1016/j.mimet.2009.10.018. [DOI] [PubMed] [Google Scholar]

- 21.Marshall KM, Bradshaw M, Johnson EA. 2010. Conjugative botulinum neurotoxin-encoding plasmids in Clostridium botulinum. PLoS One 5:e11087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Mascher G, Derman Y, Kirk DG, Palonen E, Lindström M, Korkeala H. 2014. The CLO3403/CLO3404 two-component system of Clostridium botulinum E1 Beluga is important for cold shock response and growth at low temperatures. Appl Environ Microbiol 80:399–407. doi: 10.1128/AEM.03204-13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Bradshaw M, Marshall KM, Heap JT, Tepp WH, Minton NP, Johnson EA. 2010. Construction of a nontoxigenic Clostridium botulinum strain for food challenge studies. Appl Environ Microbiol 76:387–393. doi: 10.1128/AEM.02005-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Heap JT, Ehsaan M, Cooksley CM, Ng YK, Cartman ST, Winzer K, Minton NP. 2012. Integration of DNA into bacterial chromosomes from plasmids without a counterselection marker. Nucleic Acids Res 40:e59. doi: 10.1093/nar/gkr1321. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Ng YK, Ehsaan M, Philip S, Collery MM, Janoir C, Collignon A, Cartman ST, Minton NP. 2013. Expanding the repertoire of gene tools for precise manipulation of the Clostridium difficile genome: allelic exchange using pyrE alleles. PLoS One 8:e56051. doi: 10.1371/journal.pone.0056051. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Zhang Y, Grosse-Honebrink A, Minton NP. 2015. A universal mariner transposon system for forward genetic studies in the genus Clostridium. PLoS One 10:e0122411. doi: 10.1371/journal.pone.0122411. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Bitan-Banin G, Ortenberg R, Mevarech M. 2003. Development of a gene knockout system for the halophilic archaeon Haloferax volcanii by use of the pyrE gene. J Bacteriol 185:772–778. doi: 10.1128/JB.185.3.772-778.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Williams DR, Young DI, Young M. 1990. Conjugative plasmid transfer from Escherichia coli to Clostridium acetobutylicum. J Gen Microbiol 136:819–826. doi: 10.1099/00221287-136-5-819. [DOI] [PubMed] [Google Scholar]

- 29.Peck MW, Fairbairn DA, Lund BM. 1992. The effect of recovery medium on the estimated heat-inactivation of spores of non-proteolytic Clostridium botulinum. Lett Appl Microbiol 15:146–151. doi: 10.1111/j.1472-765X.1992.tb00749.x. [DOI] [PubMed] [Google Scholar]

- 30.Heap JT, Pennington OJ, Cartman ST, Carter GP, Minton NP. 2007. The ClosTron: a universal gene knock-out system for the genus Clostridium. J Microbiol Methods 70:452–464. doi: 10.1016/j.mimet.2007.05.021. [DOI] [PubMed] [Google Scholar]

- 31.Heap JT, Pennington OJ, Cartman ST, Minton NP. 2009. A modular system for Clostridium shuttle plasmids. J Microbiol Methods 78:79–85. doi: 10.1016/j.mimet.2009.05.004. [DOI] [PubMed] [Google Scholar]

- 32.Kwon YM, Ricke SC. 2000. Efficient amplification of multiple transposon-flanking sequences. J Microbiol Methods 41:195–199. doi: 10.1016/S0167-7012(00)00159-7. [DOI] [PubMed] [Google Scholar]

- 33.Ball AP, Hopkinson RB, Farrell ID, Hutchison JGP, Paul R, Watson RDS, Page AJF, Parker RGF, Edwards CW, Snow M, Scott DK, Leone-Ganado A, Hastings A, Ghosh AC, Gilbert RJ. 1979. Human botulism caused by Clostridium botulinum type E: the Birmingham outbreak. Q J Med 48:473–491. [PubMed] [Google Scholar]

- 34.Clauwers C, Briers Y, Lavigne R, Michiels CW. 2015. Two complete and one draft genome sequence of nonproteolytic Clostridium botulinum type E strains NCTC 8266, NCTC 8550 and NCTC 11219. Genome Announc 3:e00083-15. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Davis TO, Henderson I, Brehm JK, Minton NP. 2000. Development of a transformation and gene reporter system for group II, non-proteolytic Clostridium botulinum type B strains. J Mol Microbiol Biotechnol 2:59–69. [PubMed] [Google Scholar]

- 36.Cartman ST, Minton NP. 2010. A mariner-based transposon system for in vivo random mutagenesis of Clostridium difficile. Appl Environ Microbiol 76:1103–1109. doi: 10.1128/AEM.02525-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Alderton G, Chen JK, Ito KA. 1974. Effect of lysozyme on the recovery of heated Clostridium botulinum spores. Appl Environ Microbiol 27:613–615. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Peck MW, Fairbairn DA, Lund BM. 1993. Heat-resistance of spores of non-proteolytic Clostridium botulinum estimated on medium containing lysozyme. Lett Appl Microbiol 16:126–131. doi: 10.1111/j.1472-765X.1993.tb01376.x. [DOI] [Google Scholar]

- 39.Lindström M, Nevas M, Hielm S, Lähteenmäki L, Peck MW, Korkeala H. 2003. Thermal inactivation of nonproteolytic Clostridium botulinum type E spores in model fish media and in vacuum-packaged hot-smoked fish products. Appl Environ Microbiol 69:4029–4036. doi: 10.1128/AEM.69.7.4029-4036.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Mascher G, Derman Y, Mertaoja A, Virtala J, Toikka T, Korkeala H, Lindström M. 2015. Spo0A is important for sporulation and toxin production in Clostridium botulinum, p 29 Abstr 52nd Interagency Botulism Res Coord Comm Meet, Philadelphia, PA, 26 to 29 October 2014. [Google Scholar]