Abstract

The Ponseti method is a widely accepted and highly successful conservative treatment of pediatric clubfoot involving weekly manipulations and cast applications. Qualitative assessments have indicated the potential success of the technique with cast materials other than standard plaster of Paris. However, guidelines for clubfoot correction based on the mechanical response of these materials have yet to be investigated. The current study sought to characterize and compare the ability of three standard cast materials to maintain the Ponseti corrected foot position by evaluating cast creep response. A dynamic cast testing device, built to model clubfoot correction, was wrapped in plaster-of-Paris, semi-rigid fiberglass, and rigid fiberglass. Three-dimensional motion responses to two joint stiffnesses were recorded. Rotational creep displacement and linearity of the limb-cast composite were analyzed. Minimal change in position over time was found for all materials. Among cast materials, the rotational creep displacement was significantly different (p < 0.0001). The most creep displacement occurred in the plaster-of-Paris (2.0 degrees), then the semi-rigid fiberglass (1.0 degrees), and then the rigid fiberglass (0.4 degrees). Torque magnitude did not affect creep displacement response. Analysis of normalized rotation showed quasi—linear viscoelastic behavior. This study provided a mechanical evaluation of cast material performance as used for clubfoot correction. Creep displacement dependence on cast material and insensitivity to torque were discovered. This information may provide a quantitative and mechanical basis for future innovations for clubfoot care.

Keywords: Biomechanics, creep, cast materials, clubfoot, Ponseti method

1. Introduction

Idiopathic clubfoot is a congenital deformity of the lower extremity, with a prevalence of one to six in 1000 births.1-3 The Ponseti method is a mainstay conservative treatment technique that is widely accepted and practiced today.1, 3-6 It relies on manipulation and casting of the foot performed weekly for on average of 5 weeks, depending on deformity severity. Clubfoot correction by use of the Ponseti method has been shown to be successful to progressively correct the foot.3, 7-12

The historical standard for clubfoot immobilization has been plaster of Paris (POP).1, 6, 9, 13 It has been praised for its moldability and patient comfort for serial casting purposes. However, it can be heavy, takes a long time to dry completely, and requires soaking for several hours or a cast saw to remove it, risking skin injury. Material selection could affect not only the comfort level of the patient, but also treatment outcomes and duration.13 Alternative cast materials used in conjunction with the Ponseti method have been considered.8, 13-15 Coss and Hennrikus15 found that parents preferred semi-rigid fiberglass (SRF) over POP due to its ease of removal, durability, and performance.

Over the last few decades, studies have been conducted to determine the mechanical properties and advantages of different cast materials, as well as to identify the advantages of using one material over another.14, 16-24Several metrics have been investigated to define material properties, including stiffness, ultimate strength, and yield strength, based on tests applying short durations of compression, tension, and bending. However, these tests were based on models that do not adequately represent the clinical application. Corrective casts used with the Ponseti method are applied across a joint and are subjected to complex load for up to 7 days. These previous models do not account for the permanent cast deformation that occurs under prolonged, low-level loading conditions, or creep. In a recent study performed by our group, differences in performance were seen between SRF and rigid fiberglass (RF) casts that were monitored on a custom-made clubfoot correction model.25 POP has yet to be examined in this manner, and models addressing the linearity of the viscoelastic behavior of these cast materials have not been investigated. Further insight regarding the biomechanics of Ponseti cast correction will require continued modeling efforts.14 A better understanding of the cast creep behavior may influence the duration and efficacy of clubfoot treatment.

The purpose of this study was to assess the ability of three common cast materials to hold the foot in position. The objectives addressed in this study were (1) to quantify creep of POP during Ponseti correction under two different corrective joint load conditions, (2) to assess the viscoelastic linearity of the limb-cast composite, and (3) to compare the results of the POP behavior test to those of synthetic cast materials. Cast creep was evaluated through application of an experimental foot model with articulation acting in the transverse plane. Low and high torques were applied through the transverse plane to the model during the setting process and beyond as measured using three-dimensional (3D) motion capture technology. Cast creep was monitored by tracking the motion of the internal “foot” structure of the model.

2. Materials and Methods

2.1.Device design

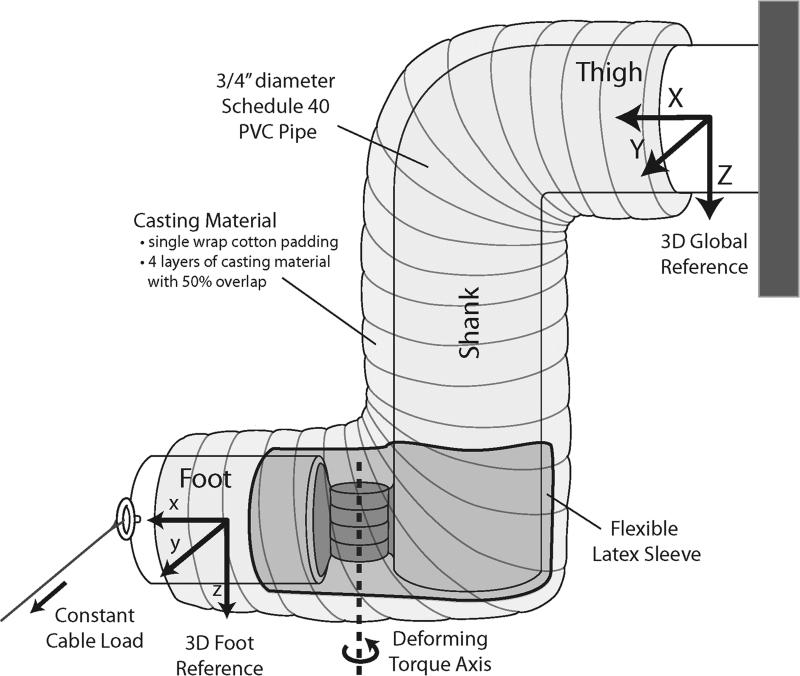

A dynamic cast testing device (DCTD), previously described in Cohen et al.25, was built to model pediatric clubfoot correction with long leg casting (Figure 1). Anatomic segments were constructed from 1-in diameter polyvinyl chloride (PVC) piping. A stainless steel hinge was cemented into the foot and the shank segments. This hinge represented a single axis of correction about which the cast creep behavior was evaluated. Two joint stiffness conditions were simulated by a constant torque (0.44 and 0.75 Nm) applied through a weighted cable. These values equated to the minimum and maximum corrective torques required by two experienced orthopaedic surgeons (HA and PS, Shriners Hospitals for Children, Chicago, IL) to sufficiently abduct the foot of a Ponseti teaching model (MD Orthopaedics; Wayland, IA) to neutral position.

Figure 1.

Dynamic Cast Testing Device (DCTD).

2.2.Protocol

The protocol follows similar instructions to those in Cohen et al.25 POP (BSN Medical, Charlotte, NC) was applied to the DCTD by one investigator (T.L.C.), according to the vendor instructions. The DCTD was held in neutral alignment during the cast setup until the end of the 4-min setting time. A single layer of cast padding (3M™, Parsippany, NJ) was wrapped around the device with 50% overlap. Four layers of POP were also wound around the device, with 50% overlap and along the same length as the padding. Molding and contouring were performed by the same investigator (T.L.C.) to ensure proper fit and adhesion. Time was marked at the initiation of casting to monitor the setting time and data acquisition intervals.

The positions of two triads of 7-mm diameter infrared light-emitting diode (IRED) markers, placed at each end of the device (Figure 1), were monitored by Optotrak 3D motion capture system cameras (0.01-mm resolution; 0.1-mm 3D accuracy) (Northern Digital Inc., Ontario, Canada) during testing. Five trials were completed for each torque for a total of 10 trials. Each trial used one roll of individually wrapped cast material. Acquisition of marker position began 4 min after the start of cast application. Three 10-min intervals were recorded at a sampling frequency of 1 Hz. Interval 1 was recorded between 4 and 14 min. Interval 2 was recorded between 18 and 28 min. Interval 3 was recorded between 60 and 70 min.

The coordinate systems of the foot and the shank-thigh segments were oriented with the z-axis pointed inferiorly, paralleled with the hinge axis, the y-axis pointed laterally, and the x-axis pointed anteriorly (Figure 1).

2.3.Analytical methods

The motion data from each POP trial were analyzed with a custom written program in MATLAB (MathWorks, Natick, MA) and segmental translational and rotational displacements were computed. The Euler angle sequence, Z-Y-X, was used to describe the relative rotation of the distal (foot) segment with respect to the proximal (shank- thigh) segment. The z-axis was assumed to align with the axis of the hinge, or axis of correction. Rotational creep displacement about the z-axis, Δθ(t), was calculated as:

| (1) |

where θ(t)is the angle at time t, θo is the angle at time to, and t is the time interval in seconds started at to. Creep displacement values at the end of each trial and at the end each interval were compared. Curve fitting was performed on the POP time series data, as well as on the SRF and RF data from Cohen et al.25 using a nonlinear least squares formulation. Predicted values were calculated from the best-fit model at times of 20 min, 72 h, 5 days, and 7 days. These times were selected, as they represent the manufacturers’ specified times to weight bearing for the synthetic cast materials and POP, and the clinical treatment durations, respectively.

To further explore the behavior of the limb-cast composite, stress and time dependencies of the creep were assessed by using the quasi-linear viscoelasticity model (QLV), proposed by Fung.26, 27

| (2) |

where ε(t, σ) is the creep strain at time t under stress σ, εe (σ) is the instantaneous elastic response and J̄(t) is the reduced creep compliance function representing the time-dependent strain response normalized by the strain at the time of the step input of stress.

From torsional deformation theory, shear strain (γ) is proportional to the radius (r) and length (L) of a circular rod, as in equation (3):

| (3) |

where θ is the rotation angle. Assuming equal radii and lengths across trials, it is possible to relate shear strain across groups in the form of rotation. Substituting equation (3) into equation (2), the relationship between creep strain and creep compliance becomes:

| (4) |

where θ(t, σ) is the creep shear strain represented by the rotation at time t under stress condition σ, and θe(σ) is the elastic response at σ. The rotation data from each trial was normalized with the instantaneous elastic strain response to calculate the reduced creep function. Curve fitting was performed on the reduced creep function from trials of all three cast materials using nonlinear least squares formulation.

Statistical analyses were performed in R (www.R-project.org) using linear models. Distributions of the creep displacement, creep compliance, and parameter data were tested using the Shapiro-Wilk test. Cast material and torque were the factors explored via one- and two-way analysis of variance (ANOVA) models and Tukey Honest Significance Difference test. A Kruskal-Wallis one-way ANOVA was performed on data that was not normally distributed. Significance was defined as p < 0.05.

3. Results

Translational and rotational kinematic data were computed for all trials and used to determine creep. The resultant translational displacement between the segments was less than 0.05 mm for each of the cast materials under either torque. Rotational creep displacement about the axis of the hinge (z-axis) of the POP trials corresponds with forefoot adduction (Figure 2).

Figure 2.

Representation of rotational creep displacement of POP under low and high torque conditions. Interval 1: 4 – 14 min; Interval 2: 18 – 28 min; Interval 3: 60 – 70 min.

The average rotational creep displacement was calculated for the total trial and per interval (Table 1). Comparing all three cast materials, the greatest amount of creep displacement was experienced by the POP. Within the first 10 min of the hour long creep trial, all three cast materials underwent at least 65% of the total creep experienced. A two-way ANOVA found material type to significantly affect the total and interval creep displacement, while the effect of torque was negligible (Table 2).

Table 1.

Mean ± standard deviation rotational creep displacement in each interval and total creep about the axis of correction (z) of three cast materials under two torque conditions during simulated clubfoot correction. POP: plaster of Paris; SRF: semi-rigid fiberglass; RF: rigid fiberglass. Interval 1: 4 – 14 min; Interval 2: 18 -28 min; Interval 3: 60 – 70 min.

| Cast Material | Plaster of Paris |

Semi-rigid Fiberglass |

Rigid Fiberglass |

|||

|---|---|---|---|---|---|---|

| Torque | Low | High | Low | High | Low | High |

| Interval 1 (deg) | 1.7 ± 0.4 | 1.6 ± 0.4 | 0.6 ± 0.2 | 0.6 ± 0.2 | 0.2 ± 0.1 | 0.4 ± 0.2 |

| Interval 2 (deg) | 0.1 ± 0.03 | 0.1 ± 0.01 | 0.07 ± 0.02 | 0.08 ± 0.02 | 0.03 ± 0.02 | 0.3 ± 0.02 |

| Interval 3 (deg) | 0.01 ± 0.001 | 0.02 ± 0.01 | 0.02 ± 0.008 | 0.02 ± 0.01 | 0.008 ± 0.008 | 0.007 ± 0.007 |

| Total (deg) | 2.1 ± 0.4 | 2.0 ± 0.4 | 0.9 ± 0.3 | 0.8 ± 0.3 | 0.3 ± 0.2 | 0.5 ± 0.2 |

Table 2.

Table of Statistics.

| Material | Torque | Interaction | |

|---|---|---|---|

| P – value | P - value | P – value | |

| Total | < 0.0001* | 0.85 | 0.4 |

| POP – SRF | < 0.0001* | ||

| POP – RF | < 0.0001* | ||

| SRF – RF | 0.01* | ||

| Interval 1 | < 0.0001* | 0.87 | 0.3 |

| POP – SRF | < 0.0001* | ||

| POP – RF | <0.0001* | ||

| SRF – RF | 0.13 | ||

| Interval 2 | < 0.0001* | 0.55 | 0.86 |

| POP – SRF | < 0.0001* | ||

| POP – RF | < 0.0001* | ||

| SRF – RF | < 0.0001* | ||

| Interval 3 | 0.0005* | 0.88 | 0.58 |

| POP – SRF | 0.16 | ||

| POP – RF | 0.036* | ||

| SRF – RF | 0.0003* | ||

P – values are from the 2-way ANOVA and Tukey tests performed on the overall creep model for the total trial and the creep seen during each interval. POP: plaster of Paris; SRF: semi-rigid fiberglass; RF: rigid fiberglass. Interval 1: 4 – 14 min; Interval 2: 18 – 28 min; Interval 3: 60 – 70 min.

p < 0.05.

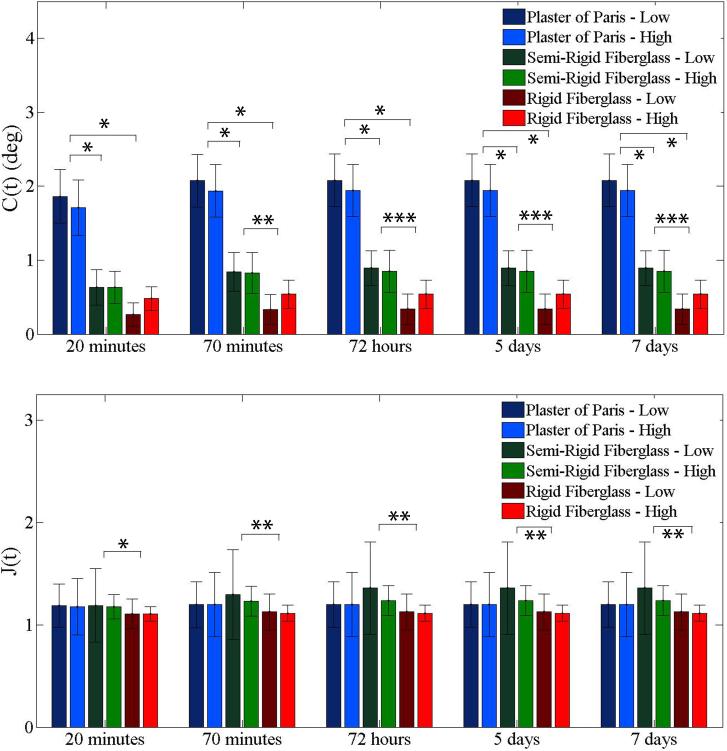

Mathematical models of the creep displacement behavior of each cast material are presented in Figure 3. The responses of the cast materials were best described using a decaying exponential equation

| (5) |

where C(t) is the rotational creep displacement response, t is the time (in seconds), and A1, b1, C1, d1 and E1 are parameters. Parameter values were significantly different between cast materials, however, not across torque (Table 3). From these models, the average amount of creep displacements was calculated for each material at 20 min, 70 min, 72 h, 5 days, and 7 days (Figure 4(a)). These predicted values were significantly different between cast materials. The percent of the 7-day creep displacement at 70 min is 99% for the POP under both torques, 94% and 98% for the SRF under low and high torque, respectively, and 99% for the RF under both torques.

Figure 3.

Representative rotational creep displacement vs. time curves, C(t) = A1e−b1t + C1e−d1t + E1 of POP, SRF, and RF under (a) low torque (b) high torque. Figure created by author. Source of SRF and RF data from Cohen et al.25

Table 3.

Parameters and R2 values of creep displacement model, C(t) = A1e−b1t + C1e−d1t + E1.

| Material | Torque | A1 | b1 | C1 | d1 | E1 | R2 |

|---|---|---|---|---|---|---|---|

| POP | Low | −0.959 | 0.0113 | −0.6233 | 0.001469 | 2.018 | 0.9954 |

| −1.094 | 0.03366 | −0.9318 | 0.001532 | 2.225 | 0.9978 | ||

| −1.03 | 0.01186 | −0.6737 | 0.001265 | 1.804 | 0.9983 | ||

| −0.7796 | 0.01357 | −0.8761 | 0.001177 | 1.736 | 0.9993 | ||

| −1.608 | 0.009426 | −0.8679 | 0.001406 | 2.613 | 0.9991 | ||

| High | −0.8816 | 0.009919 | −0.7119 | 0.001138 | 1.691 | 0.9990 | |

| −1.338 | 0.01267 | −0.8969 | 0.001629 | 2.383 | 0.9968 | ||

| −1.191 | 0.01154 | −0.7552 | 0.001162 | 2.057 | 0.9991 | ||

| −1.097 | 0.01169 | −0.8478 | 0.001336 | 2.094 | 0.9986 | ||

| −0.6427 | 0.01138 | −0.7964 | 0.001145 | 1.494 | 0.9997 | ||

| SRF | Low | −0.5742 | 0.01165 | −0.458 | 0.000648 | 1.161 | 0.9980 |

| −0.4523 | 0.009642 | −0.5942 | 0.000724 | 1.107 | 0.9980 | ||

| −0.2903 | 0.009605 | −0.5252 | 0.000769 | 0.8401 | 0.9994 | ||

| −0.1967 | 0.01183 | −0.3908 | 0.000317 | 0.6032 | 0.9988 | ||

| −0.29 | 0.01177 | −0.4204 | 0.000695 | 0.7449 | 0.9989 | ||

| High | −0.4843 | 0.01012 | −0.6256 | 0.000772 | 1.18 | 0.9992 | |

| −0.2945 | 0.01139 | −0.4448 | 0.000762 | 0.7773 | 0.9988 | ||

| −0.4725 | 0.009771 | −0.5495 | 0.000763 | 1.086 | 0.9986 | ||

| −0.1799 | 0.01026 | −0.2916 | 0.000781 | 0.4907 | 0.9987 | ||

| −0.2835 | 0.01161 | −0.3896 | 0.000904 | 0.7095 | 0.9988 | ||

| RF | Low | −0.2071 | 0.01728 | −0.4178 | 0.000867 | 0.6406 | 0.9992 |

| −0.2101 | 0.0154 | −0.2005 | 0.001198 | 0.4385 | 0.9971 | ||

| −0.1076 | 0.02352 | −0.07158 | 0.001189 | 0.1836 | 0.9878 | ||

| −0.1313 | 0.02053 | −0.1636 | 0.001141 | 0.3065 | 0.9940 | ||

| 0.01371 | 0.04286 | −0.1268 | 0.000956 | 0.1252 | 0.9965 | ||

| High | −0.2753 | 0.01673 | −0.2901 | 0.001285 | 0.5927 | 0.9982 | |

| −0.4026 | 0.01759 | −0.3352 | 0.001288 | 0.8036 | 0.9977 | ||

| −0.2207 | 0.02355 | −0.1267 | 0.00135 | 0.3591 | 0.9955 | ||

| −0.2068 | 0.02314 | −0.1203 | 0.001367 | 0.3515 | 0.9942 | ||

| −0.261 | 0.02465 | −0.3151 | 0.002165 | 0.5948 | 0.9979 | ||

| p - values | |||||||

| Tukey Test | POP - SRF | < 0.0001* | − | < 0.0001* | − | < 0.0001* | |

| POP - RF | < 0.0001* | − | < 0.0001* | − | < 0.0001* | ||

| SRF - RF | 0.21 | − | 0.0001* | − | 0.0056* | ||

| Kruskal - Wallis | POP - SRF | − | 0.56 | − | < 0.0001* | − | |

| POP - RF | − | 0.012* | − | 0.88 | − | ||

| SRF - RF | − | 0.001* | − | < 0.0001* | − | ||

P – values are from Tukey tests of normally distributed parameters and Kruskal-Wallis tests of non-normally distributed parameters across cast materials.

p < 0.05.

Figure 4.

(a) Mean and standard deviation of predicted values of rotational creep displacement, C(t), of POP, SRF, and RF, under low and high min, 70 min, 72 h, 5 days, and 7 days. * p < 0.0001, ** p = 0.01, *** p = 0.006. (b) Median and interquartile range of predicted values of reduced creep compliance, J(t), of POP, SRF, and RF, under low and high torque conditions at 20 min, 70 min, 72 h, 5 days, and 7 days. * p = 0.04, ** p = 0.01.

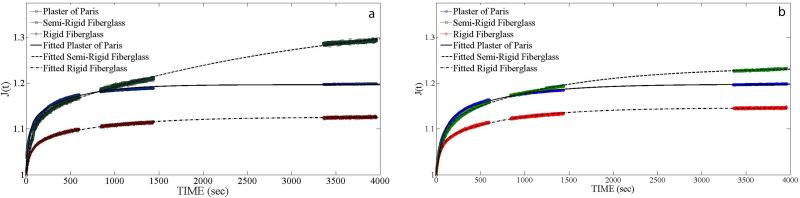

Trials curves of the creep function J(t), shown in Figure 5, were fit with a five parameter exponential equation:

| (6) |

where J(t) is the reduced creep function, t is equal to time (in seconds), and A2, b2, C2, d2 and E2 are parameters. Significant differences were not found across torque; however, all parameters except A2 showed differences between the synthetic casts (Table 4). For values of J(t), differences between cast materials are not seen during the trial length; however extended out, significant differences are seen between the synthetic materials (Figure 4(b)).

Figure 5.

Representative reduced creep compliance vs. time curves, J(t) = A2e−b2t + C2e−d2t + E2 of POP, SRF, and RF under (a) low torque (b) high torque.(a) low torque and (b) high torque.

Table 4.

Parameters and R2 values of Reduced Creep Function, J(t) = A2e−b2t + C2e−d2t + E2.

| Material | Torque | A2 | b2 | C2 | d2 | E2 | R2 |

|---|---|---|---|---|---|---|---|

| POP | Low | −0.1122 | 0.03014 | −0.08489 | 0.002098 | 1.196 | .9948 |

| −0.2651 | 0.0448 | −0.1925 | 0.001584 | 1.448 | .9987 | ||

| −0.04441 | 0.01404 | −0.02898 | 0.001341 | 1.073 | .9988 | ||

| −0.05534 | 0.01597 | −0.0591 | 0.001211 | 1.114 | .9994 | ||

| −0.1814 | 0.0111 | −0.1048 | 0.001522 | 1.287 | .9992 | ||

| High | −0.04861 | 0.01193 | −0.03925 | 0.001208 | 1.088 | .9990 | |

| −0.4475 | 0.0159 | −0.3122 | 0.001772 | 1.758 | .9982 | ||

| −0.04179 | 0.01345 | −0.02627 | 0.001228 | 1.068 | .9991 | ||

| −0.1117 | 0.01468 | −0.08551 | 0.001427 | 1.197 | .9987 | ||

| −0.1265 | 0.01303 | −0.1516 | 0.001174 | 1.278 | .9996 | ||

| SRF | Low | −0.3039 | 0.0162 | −0.2184 | 0.000745 | 1.525 | .9975 |

| −0.3573 | 0.01224 | −0.4521 | 0.00078 | 1.811 | .9984 | ||

| −0.05489 | 0.01114 | −0.0962 | 0.000793 | 1.151 | .9995 | ||

| −0.126 | 0.01324 | −0.2317 | 0.000333 | 1.358 | .9990 | ||

| −0.05661 | 0.01412 | −0.07666 | 0.000725 | 1.133 | .9990 | ||

| High | −0.1054 | 0.01272 | −0.129 | 0.00082 | 1.235 | .9990 | |

| −0.08494 | 0.01397 | −0.1207 | 0.000795 | 1.205 | .9989 | ||

| −0.2128 | 0.01233 | −0.2384 | 0.000822 | 1.452 | .9987 | ||

| −0.05965 | 0.01228 | −0.09249 | 0.000811 | 1.152 | .9990 | ||

| −0.1306 | 0.01428 | −0.1695 | 0.000942 | 1.3 | .9990 | ||

| RF | Low | −0.1367 | 0.01956 | −0.2581 | 0.000877 | 1.393 | .9994 |

| −0.0667 | 0.01886 | −0.05934 | 0.001245 | 1.126 | .9982 | ||

| −0.1079 | 0.02541 | −0.06857 | 0.001204 | 1.174 | .9951 | ||

| −0.00261 | 0.003875 | −0.04319 | 0.000894 | 1.045 | .9941 | ||

| −0.02629 | 0.02348 | −0.03035 | 0.001158 | 1.056 | .9981 | ||

| High | −0.07369 | 0.01954 | −0.07295 | 0.001316 | 1.146 | .9989 | |

| −0.05222 | 0.02089 | −0.04296 | 0.001328 | 1.095 | .9986 | ||

| −0.05302 | 0.02585 | −0.02898 | 0.001375 | 1.081 | .9983 | ||

| −0.1624 | 0.02785 | −0.08719 | 0.001424 | 1.247 | .9975 | ||

| −0.05347 | 0.02802 | −0.06088 | 0.0022 | 1.113 | .9990 | ||

| p - values | |||||||

| Kruskal - Wallis | POP - SRF | 0.55 | 0.23 | 0.06 | 0.0002* | 0.17 | |

| POP - RF | 0.26 | 0.10 | 0.47 | 0.20 | 0.23 | ||

| SRF - RF | 0.06 | 0.002* | 0.002* | 0.0003* | 0.01* | ||

P – values are from non-parametric Kruskal-Wallis tests across cast materials. POP: plaster of Paris; SRF: semi-rigid fiberglass; RF: rigid fiberglass.

p < 0.05.

4. Discussion

The current work presents the evaluation of creep response of POP and two synthetic cast materials using a novel experimental setup to simulate conservative clubfoot correction under a constant torque.25 The study resulted in small amounts of creep for all cast materials, with a maximum of only 2 degrees. The findings indicated that the most creep occurs in the POP, then the SRF, and then the RF, regardless of the torque level. In addition, the materials proved to be quasi-linear viscoelastic. Outcomes of this experiment include the creep dependence on cast material and independence on torque. Clinically, this could indicate that severity of deformity may not affect the performance of the cast material.

The current study shows the behavior of the material under low loads while it is curing (hardening), however, many earlier studies examining mechanical properties of these cast materials looked at the material properties after the recommended curing time for weight bearing and at higher loads.16, 21, 23, 24 As a result, their conclusions were of the ultimate and yield behaviors of the materials, and may differ from the findings of this investigation. Several of these studies have found POP to be stiffer, yet less strong, than synthetic cast materials. In Mihalko et al.,24 two regions of linear elasticity were seen, the first attributed to the hard plaster and the second attributed to the elastic gauze. In this study, creep rate was highest in the beginning of the trial, and then plateaued within the last time interval, indicating that the behavior of the gauze was seen initially, and the stiffness of the plaster became more dominant over time. This could indicate that a portion of the creep displacement seen is related to the material setting properties. Schmidt et al.18 and Berman and Parks19 analyzed optimal mechanical properties of POP and synthetic casts, respectively, with respect to time and water content. Schmidt et al. found that 72 h of drying and 21% water content produced the optimal mechanical properties of POP, while Berman et al. found that synthetic cast material had reached 75% of its 5-day strength within an hour of drying. In this study, it is predicted with an exponential model that at 72 h, creep displacement response of the POP plateaus and by the end of the trial, at least 70% of the creep displacement response is reached by the synthetic casts.

The results of this study differ slightly from the pressure-volume study conducted by Deshpande,22 as that study showed the SRF to be most compliant. However, the findings do correspond with those of both Deshpande22 and Davids et al.,17 in that RF was the most rigid of all the cast materials tested and that all the cast materials exhibited viscoelastic behavior. Results in these studies were determined by gauging the pressure change when infusing measured volumes of fluid into bladders that are surrounded by cast material. The current study modeled a different clinical application. These discrepancies can be attributed to not only dryness of the material, but also the complex combination of motion, padding, and/or multilayering effect that were based on the standard clinical procedure (Ponseti method) that was applied.

Studies examining the use of different orthopaedic casting materials have resulted in unclear conclusions as to which material is best for clubfoot treatment based on patient satisfaction and efficacy.13, 14 Zmurko et al.14 found that although his tests showed that SRF was best used with nonrigid immobilization, one of the authors found it to be sufficiently rigid in the correction of clubfoot and metatarsus adductus. Pittner et al.13 found that in clinical trials, the clubfeet corrected with either POP or SRF both resulted in a 95% overall correction rate with the addition of percutaneous tendoachilles lengthening. Feet treated with SRF casts had statistically significant lower Dimeglio-Bensahel scores at the completion of nonoperative manipulation; however, patient satisfaction in terms of convenience, cast weight, and cast durability was higher for this material. In a study comparing parent satisfaction with POP and SRF used during serial casting, Coss et al.15 found that parents preferred the SRF based on its ease of removal, durability, and performance.15 In their study though, the authors did not correlate each cast material in regard to their efficacy. Similarly, Brewster et al.,8 using SRF, and Ng et al.,28 using fiberglass material, published their favorable clinical results.

In the current study, an internal torque, applicable to joint stiffness, supplied the driving force on the cast after the recommended setting time, which is clinically relevant to the conservative clubfoot treatment procedure. The forces being applied to the cast during treatment were significantly lower than those seen during yield, as defined by the definition of the creep phenomena. At the initial application of the cast material, the force on the cast is at its greatest. Over time, the force imposed by the clubfoot would decrease due to stress relaxation of the soft tissue in the foot and ankle. In addition, after 20 min, creep values surpassed 88%, 70%, and 77% of the predicted 7-day creep experienced by the POP, SRF, and RF, respectively. Therefore, the decaying exponential function is a realistic model of the creep displacement curve. The results of the statistics on the parameters of this function indicated that the response was different between cast materials. Further analysis into the parameters showed that parameters b and d affect the rate of change in displacement, especially seen in the initial slope during interval 1.

Just as with the creep displacement curves, the reduced creep function was fitted with an exponential function. The materials were able to be modeled as quasi-linear viscoelastic, meaning that the ratio of creep to elastic response is the same under different loads. The reduced creep function J(t) was found to be different between SRF and RF, which could support the differences found in the displacement data. Parameter d2 of the SRF proved to be different from that of the other casts, which may explain the difference in curvature. Furthermore, when reviewing J(t) at different time points, it was seen that within the trial time frame, the values for the three materials did not differ significantly. However, over time, the values diverged.

Some limitations are present in this examination. This study models rigid bodies that are connected by a single, revolute hinge joint. While the ankle-subtalar complex is not a simple revolute joint, the model does best represent the second, most prominent phase of clubfoot correction by addressing the transverse plane adduction. In addition, the cast materials’ responses to the simulated joint stiffness may be a function of the number of layers used in the construction of the cast. The effect of the number of layers of cast material was not addressed in this study; however, this protocol was consistent with clinical standards and the Ponseti protocol. It was assumed in this study that the radii and lengths were the same across trials and materials; however, only the number of layers of material was monitored. If these measurements were inconsistent, they would have to be factored into the shear strain equation. Error may also be attributed to bending in the PVC tubing of the model, as it was the motion of the tubing that was tracked. However, experimental bending tests and theoretical analysis indicated that the amount of angular deflection would be less than 1% of the total creep experienced by any of the cast materials. The effectiveness of the cast material also depends on the surgeoǹs skill at molding. The moldability of the cast material and its significance on the ability to apply the cast material and its influence on the efficacy of clubfoot treatment is not addressed in this model. To date, there have been no studies that specifically address moldability.

The three cast materials selected for this study are all used clinically. Clinical selection includes a number of considerations, including availability of the material, cost effectiveness, patient comfort, and physician preference. POP is currently the material of choice in developing countries due to cost and availability advantages. Further understanding of the mechanics of cast behavior, as defined in this study, may improve future strategies for clubfoot care and correction.

5. Conclusion

This study provided a mechanical evaluation of cast material performance as used for conservative clubfoot correction. Results from this study illustrate the amount of creep experienced by the three different casting materials, POP, SRF, and RF during a simulated clubfoot casting. Creep displacement dependence on cast material and insensitivity to torque were discovered. Further insight into the viscoelasticity of each material indicated quasi-linear behavior. Reducing the amount of cast creep may result in a more efficient correction and a shortened clubfoot treatment time. This information may provide a quantitative and mechanical basis for future innovations for clubfoot care.

Future plans include clubfoot soft tissue specimen testing for characterization, as well as applying this information to a finite element model of the ligament in a pediatric idiopathic clubfoot to assess more complex interactions.

Acknowledgements

The authors thank Dr. Steven Abramowitch for his knowledgeable insight and assistance.

Funding

Funding for this study has been provided by the National Institute on Disability and Rehabilitation Research (NIDRR), U.S. Department of Education [grant numbers H133G060252, H133E100007], as well as from the Clinical and Translational Science Award (CTSA) program of the National Center for Research Resources (NCRR) and the National Center for Advancing Translational Science (NCATS) [grant number UL1RR031973]. The contents do not necessarily represent the policy of the Department of Education, and you should not assume endorsement by the Federal Government.

Footnotes

Conflict of Interest

The authors declare that there are no financial interests to disclose.

References

- 1.Dobbs MB, Gurnett CA. Update on clubfoot: etiology and treatment. Clin Orthop Relat Res. 2009;467:1146–1153. doi: 10.1007/s11999-009-0734-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Terrazas-Lafargue G, Morcuende JA. Effect of cast removal timing in the correction of idiopathic clubfoot by the Ponseti method. Iowa Orthop J. 2007;27:24–27. [PMC free article] [PubMed] [Google Scholar]

- 3.Morcuende JA. Congenital idiopathic clubfoot: prevention of late deformity and disability by conservative treatment with the Ponseti technique. Pediatr Ann. 2006;35:128–30. 32–36. doi: 10.3928/0090-4481-20060201-13. [DOI] [PubMed] [Google Scholar]

- 4.Roye BD, Hyman J, Roye DP., Jr. Congenital Idiopathic Talipes Equinovarus. Pediatr Rev. 2004;25:124–130. doi: 10.1542/pir.25-4-124. [DOI] [PubMed] [Google Scholar]

- 5.Richards BS, Faulks S, Rathjen KE, et al. A comparison of two nonoperative methods of idiopathic clubfoot correction: the Ponseti method and the French functional (physiotherapy) method. J Bone Joint Surg Am. 2008;90:2313–2321. doi: 10.2106/JBJS.G.01621. [DOI] [PubMed] [Google Scholar]

- 6.Ponseti, Campos J. Observations on pathogenesis and treatment of congenital clubfoot. Clin Orthop Relat Res. 1972;84:50–60. doi: 10.1097/00003086-197205000-00011. [DOI] [PubMed] [Google Scholar]

- 7.Abdelgawad AA, Lehman WB, van Bosse HJP. Treatment of idiopathic clubfoot using the Ponseti method: minimum 2-year follow-up. J Pediatr Orthop B. 2007;16:98–105. doi: 10.1097/BPB.0b013e32801048bb. [DOI] [PubMed] [Google Scholar]

- 8.Brewster MBS, Gupta M, Pattison GTR, et al. Ponseti casting: A New Soft Option. J Bone Joint Surg Br. 2008;90-B:1512–1515. doi: 10.1302/0301-620X.90B11.20629. [DOI] [PubMed] [Google Scholar]

- 9.Laaveg SJ, Ponseti IV. Long-term results of treatment of congenital club foot. J Bone Joint Surg Am. 1980;62:23–31. [PubMed] [Google Scholar]

- 10.Zionts LE, Zhao G, Hitchcock K, et al. Has the rate of extensive surgery to treat idiopathic clubfoot declined in the United States? J Bone Joint Surg Am. 2010;92:882–889. doi: 10.2106/JBJS.I.00819. [DOI] [PubMed] [Google Scholar]

- 11.Herzenberg JE, Radler C, Bor N. Ponseti versus traditional methods of casting for idiopathic clubfoot. J Pediatr Orthop. 2002;22:517–521. [PubMed] [Google Scholar]

- 12.Radler C, Manner HM, Suda R, et al. Radiographic evaluation of idiopathic clubfeet undergoing Ponseti treatment. J Bone Joint Surg Am. 2007;89:1177–1183. doi: 10.2106/JBJS.F.00438. [DOI] [PubMed] [Google Scholar]

- 13.Pittner DE, Klingele KE, Beebe AC. Treatment of clubfoot with the Ponseti method: a comparison of casting materials. J Pediatr Orthop. 2008;28:250–253. doi: 10.1097/BPO.0b013e318164f8e7. [DOI] [PubMed] [Google Scholar]

- 14.Zmurko MG, Belkoff SM, Herzenberg JE. Mechanical evaluation of a soft cast material. Orthopedics. 1997;20:693–698. doi: 10.3928/0147-7447-19970801-08. [DOI] [PubMed] [Google Scholar]

- 15.Coss HS, Hennrikus WL. Parent satisfaction comparing two bandage materials used during serial casting in infants. Foot Ankle Int. 1996;17:483–486. doi: 10.1177/107110079601700809. [DOI] [PubMed] [Google Scholar]

- 16.Rowley DI, Pratt D, Powell ES, et al. The comparative properties of plaster of Paris and plaster of paris substitutes. Arch Orthop Trauma Surg. 1985;103:402–407. doi: 10.1007/BF00435449. [DOI] [PubMed] [Google Scholar]

- 17.Davids JR, Frick SL, Skewes E, et al. Skin Surface Pressure Beneath an Above-the- Knee Cast: Plaster Casts Compared with Fiberglass Casts. J Bone Joint Surg Am. 1997;79:565–569. doi: 10.2106/00004623-199704000-00013. [DOI] [PubMed] [Google Scholar]

- 18.Schmidt VE, Somerset JH, Porter RE. Mechanical properties of orthopedic plaster bandages. J Biomech. 1973;6:173–176. 5, 7–85. doi: 10.1016/0021-9290(73)90086-9. [DOI] [PubMed] [Google Scholar]

- 19.Berman AT, Parks BG. A comparison of the mechanical properties of fiberglass cast materials and their clinical relevance. J Orthop Trauma. 1990;4:85–92. doi: 10.1097/00005131-199003000-00015. [DOI] [PubMed] [Google Scholar]

- 20.Philbin TM, Gittins ME. Hybrid casts: a comparison of different casting materials. J Am Osteopath Assoc. 1999;99:311–312. doi: 10.7556/jaoa.1999.99.6.311. [DOI] [PubMed] [Google Scholar]

- 21.Callahan DJ, Carney DJ, Daddario N, et al. A comparative study of synthetic cast material strength. Orthopedics. 1986;9:679–681. doi: 10.3928/0147-7447-19860501-12. [DOI] [PubMed] [Google Scholar]

- 22.Deshpande SV. An experimental study of pressure-volume dynamics of casting materials. Injury. 2005;36:1067–1074. doi: 10.1016/j.injury.2005.02.003. [DOI] [PubMed] [Google Scholar]

- 23.Martin PJ, Weimann DH, Orr JF, et al. A comparative evaluation of modern fracture casting materials. Eng Med. 1988;17:63–70. doi: 10.1243/emed_jour_1988_017_019_02. [DOI] [PubMed] [Google Scholar]

- 24.Mihalko WM, Beaudoin AJ, Krause WR. Mechanical Properties and Material Characteristics of Orthopaedic Casting Material. J Orthop Trauma. 1989;3:57–63. doi: 10.1097/00005131-198903010-00011. [DOI] [PubMed] [Google Scholar]

- 25.Cohen TL, Altiok H, Tarima S, et al. Creep evaluation of (orthotic) cast materials during simulated clubfoot correction. Conf Proc IEEE Eng Med Biol Soc. 2012:3352–3355. doi: 10.1109/EMBC.2012.6346683. [DOI] [PubMed] [Google Scholar]

- 26.Fung YC. Biomechanics : mechanical properties of living tissues. 2nd ed Springer-Verlag; New York: 1993. pp. 41–48.pp. 50–52.pp. 277–287. [Google Scholar]

- 27.Oza AL, Vanderby R, Lakes RS. Creep and Relaxation in Ligament: Theory, Methods, and Experiment. In: Holzapfel GA, Ogden RW, editors. Mechanics of Biological Tissue. Springer; Berlin: 2006. pp. 379–397. [Google Scholar]

- 28.Ng BK, Lam TP, Cheng JC. Treatment of severe clubfoot with manipulation using synthetic cast material and a foam-casting platform: a preliminary report. J Pediatr Orthop B. 2010;19:164–170. doi: 10.1097/BPB.0b013e328333ab2e. [DOI] [PubMed] [Google Scholar]