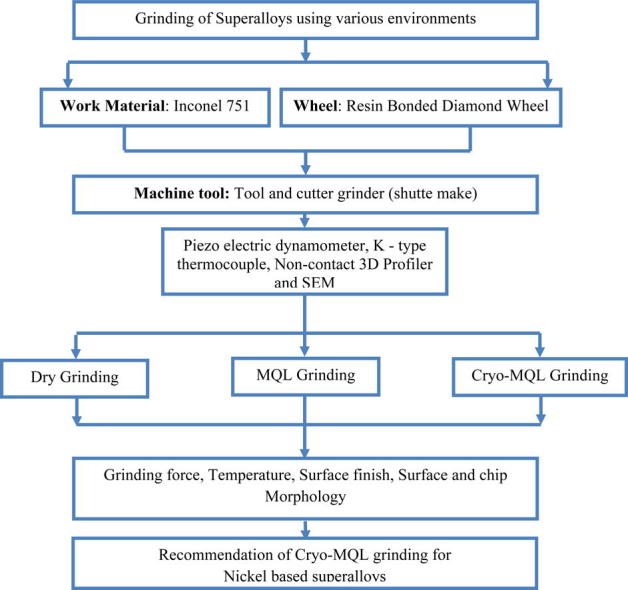

Graphical abstract

Keywords: Cryogenic minimum quantity lubrication, Grinding, Force components, Surface finish, Specific energy, Chip morphology

Abstract

The application of emulsion for combined heat extraction and lubrication requires continuous monitoring of the quality of emulsion to sustain a desired grinding environment; this is applicable to other grinding fluids as well. Thus to sustain a controlled grinding environment, it is necessary to adopt an effectively lubricated wheel-work interface. The current study was undertaken to assess experimentally the effects of different grinding environments such as dry, minimum quantity lubrication (MQL) and Cryo-MQL on performance, such as grinding force, temperature, surface roughness and chip morphology on Inconel 751, a higher heat resistance material posing thermal problems and wheel loading. The results show that grinding with the combination of both liquid nitrogen (LN2) and MQL lowers temperature, cutting forces, and surface roughness as compared with MQL and dry grinding. Specific cutting energy is widely used as an inverse measure of process efficiency in machining. It is found from the results that specific cutting energy of Cryo-MQL assisted grinding is 50–65% lower than conventional dry grinding. The grindability of Inconel 751 superalloy can be enhanced with Cryo-MQL condition.

Introduction

Nickel based superalloys exhibit very high hot hardness and also maintain its mechanical, chemical, creep resistant, and corrosion properties at elevated temperature. Inconel 751 a nickel-chromium alloy is used for high-temperature application such as IC engine exhaust valves. This alloy that is normally precipitation hardened exhibits similar physical, mechanical, and corrosion properties comparable to Inconel 750 [1]. However, some properties such as low thermal diffusivity, work hardening, and high strength at higher temperature normally lead these superalloys to difficult-to-machine material. Grinding of these alloys normally leads to thermal damage of the work surface due to higher heat generation at the grinding zone and possible loading of the grinding wheel [2]. The surface of the workpiece will be affected more by the combined action of mechanical forces and temperature. Grinding temperature comprises abrasion and sliding heat. Proper usage of lubricant at an appropriate pressure and mass flow rate can minimize the grinding force and sliding heat. This can be achieved by an effective access of lubricant to wheel-work interface, facilitating film lubricating environment [3]. Dry and wet grinding methods have their own impacts such as thermal softening and quench cracks, so an alternative method is minimum quantity lubrication (MQL) where atomized air-cutting oil mixture is introduced into the machining zone [4]. There is more advantage of using MQL over wet grinding, such as reduced oil consumption rate, eco-friendly, less space and cost [5]. Minimum flow rate and higher pressure facilitate better grinding action while grinding superalloys with diamond wheel and also MQL facilitates significant reduction in the cutting forces, temperature, roughness, and the absence of grinding burn marks [6]. Brinksmeier et al. have applied MQL in grinding. Hardened steel (16MnCr5) and tempered steel (42CrMo4V) were used as workpiece materials. They found that MQL facilitates better result than flood and dry environments in terms of reducing machinability cost by minimizing machine power and coolant consumption [7]. Unlike conventional cutting fluids, liquid nitrogen has its own inherent environmental benefits such as non-toxic, clean and safe fluid that evaporates quickly in atmosphere without any expensive disposal [8]. Grinding of steel under cryogenic condition yields better results mainly due to substantial reduction in cutting temperature in the grinding zone, when compared with wet and dry grinding [9]. Pu et al. have investigated the surface integrity of AZ31B Mg alloy by cryogenic assisted turning process; they found reduction up to 20% in surface roughness compared to dry machining [10]. Cryogenic milling of hardened AISI H13 tool steel shows lower cutting force, temperature and morphology of chips formed during this process shows minimum serrations, when compared with wet and dry machining [11]. Cryogenic cooling provides increased tool life through reduction in tool wear by drastically reducing the cutting zone temperature, while machining titanium alloy [12]. Rapid heat extraction with cryogenic environment leaves a frozen layer of material at the surface, with compressive residual stress; also machining at low temperature could have resulted in dominant mechanical force and compressive residual stress [13].

In this study, a combined mixture of liquid nitrogen and cutting oil was sprayed onto the work surface during grinding of Inconel 751. Its influence in terms of cutting temperature, surface roughness, cutting forces and chip morphology was investigated in relation to dry and MQL conditions.

Experimental

The surface grinding experiments on Inconel 751 superalloy were carried on a Tool and cutter grinder (Schuette make) grinding machine with a resin bonded diamond wheel. Grinding wheel specification and machining parameters for various grinding environments such as dry, MQL and Cryo-MQL are tabulated in Table 1. The experimental setup with all measuring sensors for Cryo-MQL grinding is shown in Fig. 1.

Table 1.

Experimental conditions.

| Parameters | Conditions |

|---|---|

| Grinding machine | Tool and cutter grinder (Schuette make) |

| Grinding mode | Surface grinding (Down grinding) |

| Grinding wheel | D126 C75 (resin bonded Diamond wheel of 150 mm diameter; 13 mm width; grit size 126) |

| Wheel velocity (Vs) | 518, 1413 and 2826 m/min |

| Work feed rate (Vw) | 0.4, 0.6 and 0.9 m/min |

| Depths of cut (a) | 10, 20 and 30 μm |

| Grinding environment | Dry, MQL, Cryo-MQL |

| MQL oil flow rate (Q) | 60 mL/h |

| Air pressure (P) | 6 bar |

| Standoff distance | 80 mm |

| Spray angle | 10–20° |

| MQL oil | Cimtech D14 MQL oil with viscosity = 5 cSt, and ρ = 1080 kg/m3 |

| Liquid nitrogen | P = 1 bar, Q = 0.5 l/min |

Fig. 1.

Experimental setup of Cryo-MQL system.

Down grinding was carried out to contain the possible wheel loading and thereby the sliding heat during grinding. No coolant was used during the grinding experiments (Dry Grinding). In the MQL environment, the air pressure and mass flow rate can be effectively atomized through an air atomizer (special nozzle) to produce micro droplets of oil, lead into the grinding zone. In the Cryo-MQL system, MQL nozzle jetting into the grinding zone from one side of the rotating grinding wheel and pressurized liquid nitrogen was passed from other side of the wheel. This will also ensure effective access of lubricant droplet to the grinding zone without much problem such as freezing/turbulence environment. The experimental design involves in the selection of suitable levels for the grinding parameters for all grinding environments i.e. cutting speed, feed, depth of cut. The parameters each at three levels would result in 33 – 27 combinations and full factorial experiment was conducted. To ensure repeatability all the experiments were repeated thrice and the average was taken. A K-type (Chromel/Alumel) thermocouple was used to measure the interface temperature. A three component piezoelectric dynamometer was used to monitor both grinding force components and its peak values are recorded after every 10th pass. The surface roughness of the ground samples were measured using a non-contact 3-D profiler which is based on an advanced optical interferometry.

Results and discussion

Grinding force

Relative parametric influence on tangential (Fx) and normal components (Fz) of grinding force with different grinding environments is illustrated in Fig. 2a–d respectively. As the cutting velocity increases there is a reduction in both tangential and normal forces and also a rise in depth of cut induces increased/enhanced cutting force. This is mainly due to the increase in the undeformed chip thickness at higher feed and depth. So there is a rise in both of the force components. The grinding mode changes from ploughing to steady state over 518–1413 m/min range of wheel velocity, which is clearly indicated by a reduction in grinding force with higher velocity. It is also seen that the grinding force increases with increasing depth of cut and this may be due to enhanced chip section and also possible wheel loading. As the depth of cut increases the magnitude of the both grinding forces increases. In dry grinding, the work material experiences heating due to abrasion as well as abrasive sliding over the workpiece. Hence the need for lubricant is to minimize the sliding heat. It can be anticipated that unlike dry grinding, with MQL the workpiece will experience least heating due to reduction in sliding heat. However grinding with cryogenic environment is vastly different; the workpiece will not experience much heat of grinding since it will be carried away. The observed reduction in grinding force is attributed to better abrasion (the absence of plowing). The observed change in the trend with higher cutting velocity can be attributed to bond-dynamics, i.e. the deformation of the bond at higher wheel speed (Centrifugal force) can result in increased sliding, as seen with the observed raising trend of force components. It is also seen that dry grinding results in higher force, while Cryo-MQL grinding with the least force. Dry grinding recorded more grinding force due to possible thermal softening of wheel bond and also degrading of diamond abrasives at higher temperature, leading to more rubbing and ploughing. Under MQL environment the interface (wheel-work) experiences boundary lubrication, which enhances better abrasive action. This is mainly due to the high pressure (6 bar) lubrication of MQL which enhances the grindability by reducing the wheel loading and sliding friction. The energy formation of material drops down (Rehbinder effect) as the film forming tendency in MQL increases and this will also reduce the grinding force by increasing the elastic–plastic deformation under the abrasive edge [14]. Cryo-MQL recorded least force owing to better cooling effect of LN2, minimizing the possible evaporation of cutting oil, and enhances the strength of lubrication film in the grinding zone. This can minimize the cutting force. It is seen that the force components tends to increase beyond 1413 m/min of grinding velocity. The increasing temperature associated with higher wheel speed can influence bond stiffness due to centrifugal force.

Fig. 2.

Comparison of grinding force at different cooling environments.

Temperature

Typical monitored parametric influence on grinding temperature with different cooling conditions is illustrated in Fig. 3. Grinding temperature consists of components due to abrasion and sliding. Grinding temperature increases with increase in both depth of cut and cutting velocity. This is mainly due to the increase in undeformed chip thickness of Inconel during grinding. As the cutting velocity increases, there is a reduction in the undeformed chip thickness (finer chips) leads to higher material deformation energy. The friction between the work and the grit increases due to ploughing and sliding. Therefore, the grinding temperature increases [16]. In dry grinding the temperature shows a significant rise with higher cutting velocity for 10 and 30 μm depth of cut, and this may be due to wheel loading. The Inconel chips have the property to adhere to wheel surface at higher temperature, and this may cause higher wheel loading leading to higher temperature. With increasing depth of grinding, a different trend of variation in grinding temperature can be seen. The temperature tends to drop down up to 1413 m/min of grinding speed, after which a rise can be seen. This is an indication of sliding associated grinding, attributable to occurrence of wheel loading; this is supplemented by the increasing trend of Fz (normal). This may be due to possible thermal softening of workpiece at temperatures associated with higher speed (leads to wheel loading) and also possible softening of the wheel bond causing increased rubbing/heating [2]. MQL grinding can cause an effective penetration of droplet into the pressure belt facilitating enhanced wetting of the work-wheel interface. This results in the observed reduction in temperature. Cooling and lubrication action of MQL facilitate a reduction in both cutting energy and grinding force and also convective heat transfer of the oil droplets carries away the major part of heat from the grinding zone. During Cryo-MQL grinding, smaller grinding temperature is seen when compared with dry and MQL grinding. This is because when liquid nitrogen was supplied to the grinding zone, it evaporates quickly to absorb the heat, thereby maintaining the strength of lubrication film in the grinding zone, thus improving the lubrication effect of oil droplet, thereby reducing the grinding temperature. The reduction in temperature can enhance the grindability of abrasive diamond, exhibiting lower order grinding force. The grinding temperature for Cryo-MQL cooling was less by 82–89% over dry grinding and 66–81% over MQL grinding.

Fig. 3.

Comparison of grinding temperature at different cooling environments.

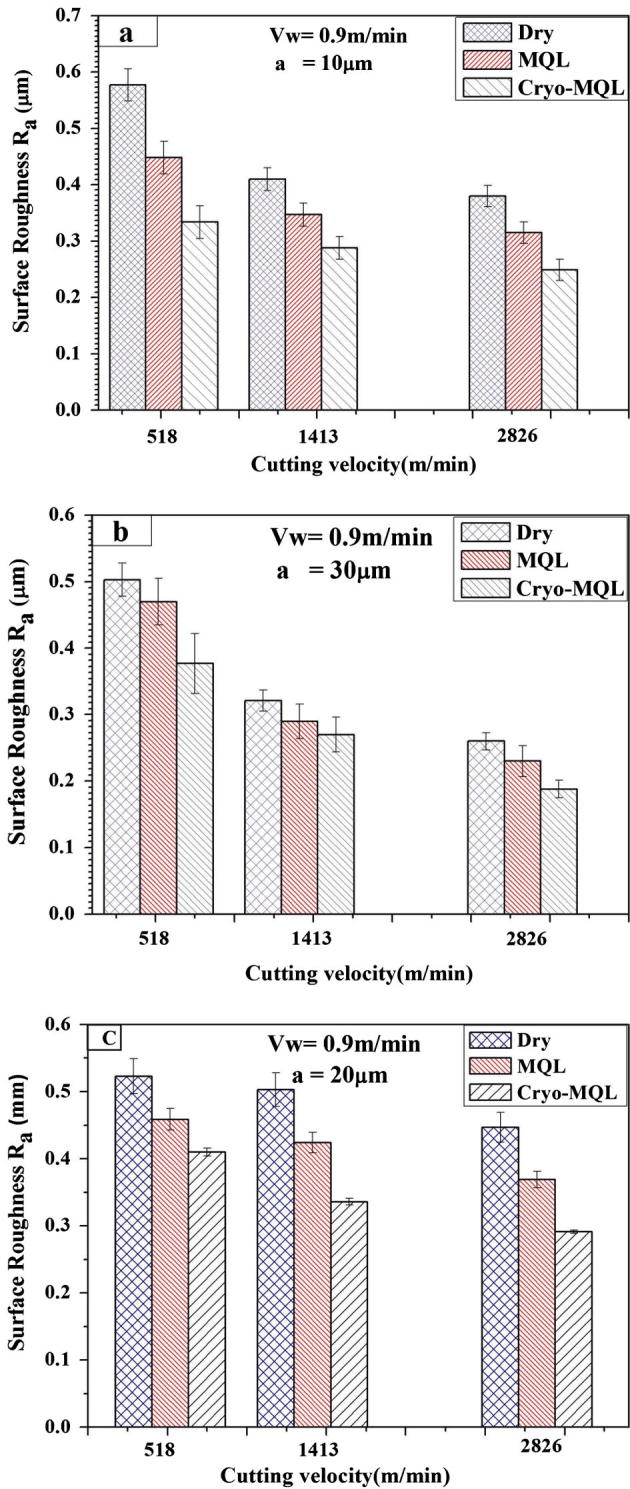

Surface roughness

Typical monitored parametric influence on roughness of ground Inconel 751 surface with different cooling environments is illustrated in Fig. 4. Under all grinding conditions, the surface roughness drops down with grinding (wheel) velocity. With increasing wheel speed and associated rise in temperature, the resultant bond dynamic is such that more wheel-work interface compatibility occurs, leading to better texture formation. With increasing depth of grinding, surface roughness drops down with higher feed rate. The associated rise in temperature can facilitate bond softening, dulling of abrasive and wheel loading. In dry grinding, the trend change and occurrence of a marginal variation of roughness with increasing speed can be mostly attributed to wheel loading. The observed change in the trend of variation around 1413 m/min can be attributed also to increased bond flexibility (bond dynamics) promoting intensive sliding and a glazed texture with surface roughness varying marginally. Better surface obtained under MQL environment is mainly due to the effective cooling and lubrication of abrasives grits at the wheel-work interface [15]. The fine surface obtained with Cryo-MQL technique is owing to more cooling and effective lubrication of LN2 and MQL oil at the grinding zone by maintaining the thickness of the oil film, in addition to sustaining the grindability of the abrasive diamond. The surface roughness for Cryo-MQL cooling was less by 15–28% over dry grinding and 7–20% over MQL grinding. MQL grinding produces better surface than dry grinding; the effective removal of heat from the grinding zone can minimize the probable wheel loading, leading to better work-grit interaction and fine surface texture. The 3-D optical images of surface roughness under different cooling environments are shown in Fig. 5. With MQL and Cryo-MQL environment the surface texture presents a lay pattern with asperity folding. Under lubricated condition, according to Rehbinder effect the surface energy drops down thereby facilitating possible elastic–plastic deformation of the asperities.

Fig. 4.

Comparison of surface roughness at different cooling environments.

Fig. 5.

3D optical images of surface roughness under different cooling environments.

Specific grinding energy and undeformed chip thickness

Specific energy (u) is one of important grindability indices. It is evaluated using process parameters and tangential grinding force measured in the experiment, as follows:

| (1) |

where b is the width of working zone of the grinding wheel, i.e., 13 mm in this investigation. Specific energy can be related to the maximum undeformed chip thickness (grit-depth) hm taken by an individual cutting point (abrasive grits). Assume that the active cutting points per unit area C are uniformly distributed on the wheel surface and hm can be expressed as in Eq. (2).

| (2) |

Here θ is the semi-included angle for the undeformed chip cross section which is assumed to be triangular. For calculating hm, θ was taken as 60° and ds is wheel diameter (150 mm) [16]. The cutting point density for each wheel, is obtained by counting ‘active grains’ on the wheel surface using an optical microscope and C = 15 mm−2 for the 126 grit wheel.

From Fig 6 it is seen that the specific grinding energy of Inconel 751 superalloy varies from 200 to 2000 J/mm3 for dry condition. Such a wide variation in specific grinding energy reflected on the severity of process due to thermal influence, owing to heat resistant Inconel and bond dynamics making Inconel 751, a difficult to grinding metal. With smaller undeformed chip thickness, the specific energy is higher and it is mainly due to high sliding and ploughing action of abrasive grits. As the undeformed chip thickness increases, the specific energy decreases. It is seen that there is a visible reduction in specific grinding energy up to undeformed chip thickness of around 0.8 μm above in which only a marginal variation in energy can be seen. Inconel can be ground with a minimum constrain such as wheel loading at consequent sliding grinding, with a specific energy of around 400 J/mm3. It is found that the specific grinding energy of Inconel 751 under MQL condition ranges between 160 and 1142 J/mm3. It is slightly lower than dry grinding. This implies that the grindability of Inconel 751 superalloy is much better under MQL condition. As in the case of dry grinding, a threshold value of 0.80 μm for undeformed chip thickness can be seen, below which grinding is done with higher specific energy; however, grinding with MQL is carried out with reduced order of specific energy. Under Cryo-MQL condition the specific energy ranges between 100 and 700 J/mm3. It is 50–65% lower than dry grinding and MQL. This implies that the grindability of Inconel 751 superalloy can be enhanced with Cryo-MQL condition. The illustration of specific grinding energy indicates that it is preferable to grinding Inconel with conditions associated with the critical grinding energy of around 250 J/mm3 i.e., grinding with reduced undeformed thickness condition and relatively minimum specific grinding energy.

Fig. 6.

Specific grinding energy related to undeformed chip thickness.

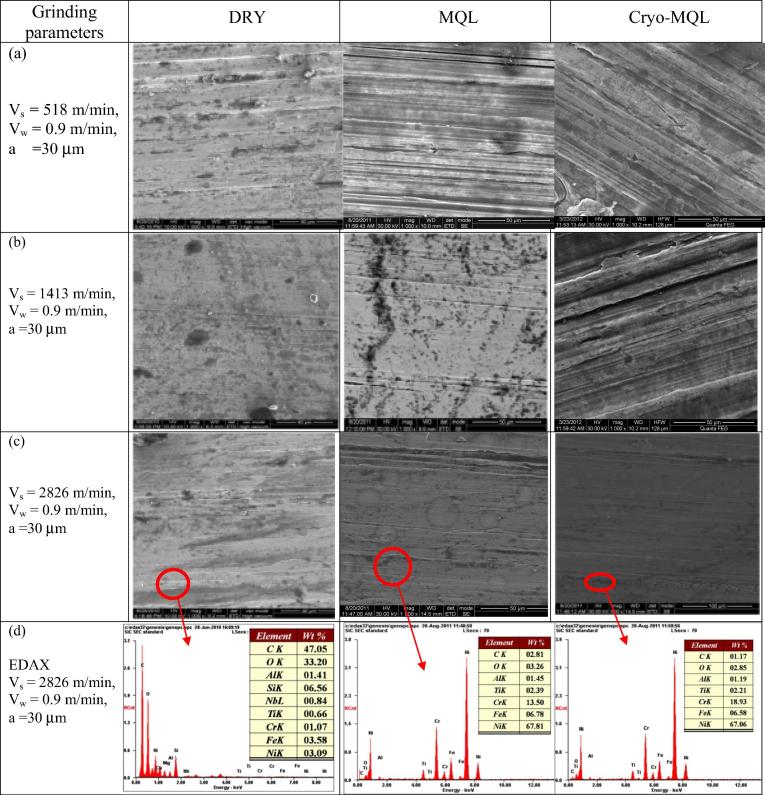

Surface morphology

With dry condition, the grinding has been carried out with the relatively higher order force component, temperature and rougher texture. Fig. 7 shows a glazed (smeared) texture with asperity folding (material flow) and localized material pullout. Formation of micro lay pattern with localized pullout, attributable to sliding dominant grinding, can be seen. In dry grinding the sheared chip particles adhered to the abrasive grains of the wheel and are redeposited over the surface of the workpiece. The ground surface also shows the presence of transfer loading of particle from the wheel. The energy dispersive profile EDAX of a zone of ground surface indicates pickup of carbon. Normally grinding with loaded wheel results, in transfer of particle to worn surface. The texture presents transferred particles, with dominant C and O2 contents (EDAX – data Fig.7d). This may be attributed to possible graphitization of diamond. The surface also shows a glazed texture, with marks of surface burn and transfer particles; this is associated with increased ratio of Fz/Fx, indicative of grinding with higher order temperature. Under this condition, the wheel-bond would become more flexible leading to rubbing dominant, (partial) grinding.

Fig. 7.

Surface Morphology of Inconel 751 under dry MQL and Cryo-MQL cooling conditions (Magnification: 1000×).

A matt texture fairly uniform surface lay and crest flattening can be seen with MQL grinding. The texture of ground Inconel with MQL lubrication presents a relatively smoother texture. Fig.7c presents surface texture of Inconel grounded with higher speed under MQL environment. Relatively smoother texture can be seen, unlike the case of crest flattened texture with 518 m/min velocity. Grinding with higher speed (2826 m/min), results in smooth texture without any visible crest flattening. The softening of the bond and increased wheel-work (surface) compatibility promotes sliding dominant grinding [17]. EDAX profile of ground surface also supplemented the observation of grinding with reduced temperature, with MQL grinding (Fig.7d) better film formation has results in less carbon pickups. With Cryo-MQL grinding, it shows a finer surface, owing to effective lubrication with LN2, which reduces the evaporation of cutting oil, ensuring the maintenance of strength of lubrication film in the grinding zone [9]. This results in the reduction in grinding temperature resulting in better surface with mild crest flattening of the asperities. The energy formation of material drops down (Rehbinder effect) as the film forming tendency in MQL increases and this will facilitate the elastic–plastic deformation under the abrasive edge with associated reduction in workpiece roughness. EDAX profile of ground surface under Cryo-MQL (7d) condition supplemented the strength of lubrication film with very less carbon pickup than MQL.

Chip morphology

Normally with chip removal process, the chips production can be a good indicator of the status of process/tool-work interface. The chip morphology can be lamellar/segmental, blocky, elongated and extruded depending on the process-status. Chip for dry condition was collected during regular intervals of the grinding trails. Typical macro graph of chips pertaining the grinding condition of Vs = 518 m/min, S = 0.9 m/min, a = 30 μm is presented in Fig.8a. The chip is of flow-type with the characteristic lamella-type structure with extrusion-like configuration. Typical short curled, segmental chip can be seen, indicates good grinding (dominant abrasive cutting). Typical morphology of chip collected during grinding of Inconel with Vw = 1413 m/min, S = 0.9 m/min and a = 30 μm is shown. Mostly elongated blocky segments can be seen. This is indication of dry grinding with higher temperature (Fig. 3). Typical morphology of chip collected during grinding with higher order conditions of (Vw = 2826 m/min, S = 0.9 m/min, a = 30 μm) is shown in Fig.8c. Mostly segmental/blocky chips with solidified segments can be seen. Also due to high temperature the cutting chip tends to close tending to form spherical morphology. This can be inferred that under dry conditions, with higher grinding conditions, the resin bond becomes more flexible facilitating rubbing/sliding dominant grinding, associated with better texture and squeezed chip forming. Typical macro graph of chips produced during the MQL grinding with lower order cutting condition is Vs = 518 m/min, S = 0.9 m/min, a = 30 μm shown in Fig.8a. Relatively short coiled/mild elongated chips can be seen; unlike the case of dry grinding, the absence of chip straining can be seen. MQL Grinding with 1413 m/min cutting speed, relatively broader and elongated chips with reduced chip strain can been seen and with 2826 m/min cutting velocity has results in chips consisting of fine powdery and upset lumps are shown in Fig.8b and c. Typical macro graph of chips collected during Cryo-MQL grinding with various cutting velocities is illustrated in Fig. 8a–c respectively. Unlike the case of extruded curl chips with low speed of grinding, mostly blocky chips can be seen for higher speed. This is due to appreciable reduction in grinding zone temperature and rapid cooling/heat extraction results in thin laminates/blocky chips.

Fig. 8.

Chip Morphology of Inconel 751 under dry MQL and Cryo-MQL cooling conditions (magnification: 200×).

Conclusions

From this study the significance of both MQL and Cryo-MQL on the grinding performance is highlighted and the following conclusions are drawn.

Dry grinding of Inconel with resin bonded diamond wheel indicates the mode of grinding changes from ploughing to steady state over 518–1413 m/min range of cutting velocity with the variation of grinding force components. Grindability of Inconel has been enhanced by MQL and Cryo-MQL environment and MQL conditions provide better grinding performance than dry environment. This is because of enhanced lubrication in the wheel-work interface which facilitates better grindability. Cryo-MQL grinding condition facilitates considerable reduction in grinding forces, temperature and roughness, compared to dry and MQL grinding. Surface roughness was reduced by 28% compared to dry and 20% over MQL conditions. Under Cryo-MQL and MQL conditions there is hardly any material side flow over the ground surface unlike dry grinding condition is attributed to thermal damage. The chip of flow-type with the characteristic lamella-type structure was seen during dry grinding, thin flaked and elongated chips were be seen with MQL grinding and blocky chips were seen with Cryo-MQL grinding and it is found from the results that specific cutting energy of Cryo-MQL assisted grinding is 50–65% lower than conventional dry grinding. This implies that the grindability of Inconel 751 superalloy can be enhanced with Cryo-MQL condition.

Conflict of Interest

The authors have declared no conflict of interest.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Footnotes

Peer review under responsibility of Cairo University.

References

- 1.Mishra B., Sinha A.K., Moore J.J. Effect of single aging on microstructure and impact property of INCONEL X-750. Metall Trans A. 1985;16:821–829. [Google Scholar]

- 2.Wenfeng D., Jiuhua X., Zhenzhen C., Honghua S., Yucan F. Grindability and surface integrity of cast nickel-based superalloy in creep feed grinding with brazed CBN abrasive wheels. Chinese J Aeronaut. 2010;23:501–510. [Google Scholar]

- 3.Zhong Z., Ramesh K., Yeo S.H. Grinding of nickel-based super-alloys and advanced ceramics. Mater Manuf Process. 2001;16:195–207. [Google Scholar]

- 4.da Silva L.R., Bianchi E.C., Fusse R.Y., Catai R.E., Frana T.V., Aguiar P.R. Analysis of surface integrity for minimum quantity lubricant-MQL in grinding. Int J Mach Tools Manuf. 2007;47:412–418. [Google Scholar]

- 5.Tai B.L., Dasch J.M., Shih A.J. Evaluation and comparison of lubricant properties in minimum quantity lubrication machining. Mach Sci Technol. 2011;15:376–391. [Google Scholar]

- 6.Balan A.S.S., Vijayaraghavan L., Krishnamurthy R. Minimum quantity lubricated grinding of Inconel 751 alloy. Mater Manuf Process. 2013;28:430–435. [Google Scholar]

- 7.Brinksmeier E., Heinzel C., Wittmann M. Friction, cooling and lubrication in grinding. CIRP Ann – Manuf Technol. 1999;48:581–598. [Google Scholar]

- 8.Bermingham M.J., Palanisamy S., Kent D., Dargusch M.S. A comparison of cryogenic and high pressure emulsion cooling technologies on tool life and chip morphology in Ti-6Al-4V cutting. J Mater Process Technol. 2012;212:752–765. [Google Scholar]

- 9.Paul S., Chattopadhyay A.B. Effects of cryogenic cooling by liquid nitrogen jet on forces, temperature and surface residual stresses in grinding steels. Cryogenics (Guildf) 1995;35:515–523. [Google Scholar]

- 10.Pu Z., Outeiro J.C., Batista A.C., Dillon O.W., Puleo D.A., Jawahir I.S. Enhanced surface integrity of AZ31B Mg alloy by cryogenic machining towards improved functional performance of machined components. Int J Mach Tools Manuf. 2012;56:17–27. [Google Scholar]

- 11.Ravi S., Pradeep Kumar M. Experimental investigations on cryogenic cooling by liquid nitrogen in the end milling of hardened steel. Cryogenics (Guildf) 2011;51:509–515. [Google Scholar]

- 12.Venugopal K.A., Paul S., Chattopadhyay A.B. Tool wear in cryogenic turning of Ti-6Al-4V alloy. Cryogenics (Guildf) 2007;47:12–18. [Google Scholar]

- 13.Pusavec F., Hamdi H., Kopac J., Jawahir I.S. Surface integrity in cryogenic machining of nickel based alloy—Inconel 718. J Mater Process Technol. 2011;211:773–783. [Google Scholar]

- 14.El-Shall H., Somasundaran P. Physico-chemical aspects of grinding: a review of use of additives. Powder Technol. 1984;38:275–293. [Google Scholar]

- 15.Tawakoli T., Hadad M.J., Sadeghi M.H., Daneshi A., Stockert S., Rasifard A. An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication-MQL grinding. Int J Mach Tools Manuf. 2009;49:924–932. [Google Scholar]

- 16.Malkin S. Soc of Manuf Eng; Dearborn, MI: 1989. Grinding technology, theory and applications of machining with abrasives. [Google Scholar]

- 17.Balan A.S.S., Vijayaraghavan L., Krishnamurthy R. Experimental investigation on the influence of oil mist parameters on minimum quantity lubricated grinding of Inconel 751. Int J Precis Technol. 2014;4:96–109. [Google Scholar]