SUMMARY

Rock dusting is used to prevent secondary explosions in coal mines, but inhalation of rock dusts can be hazardous if the crystalline silica (e.g., quartz) content in the respirable fraction is high. The objective of this study is to assess the quartz content and physical characteristics of four selected rock dusts, consisting of limestone or marble in both treated (such as treatment with stearic acid or stearates) and untreated forms. Four selected rock dusts (an untreated and treated limestone and an untreated and treated marble) were aerosolized in an aerosol chamber. Respirable size-selective sampling was conducted along with particle size-segregated sampling using a Micro-Orifice Uniform Deposit Impactor. Fourier Transform Infrared spectroscopy and scanning electron microscopy with energy-dispersive X-ray (SEM-EDX) analyses were used to determine quartz mass and particle morphology, respectively. Quartz percentage in the respirable dust fraction of untreated and treated forms of the limestone dust was significantly higher than in bulk samples, but since the bulk percentage was low the enrichment factor would not have resulted in any major change to conclusions regarding the contribution of respirable rock dust to the overall airborne quartz concentration. The quartz percentage in the marble dust (untreated and treated) was very low and the respirable fractions showed no enrichment. The spectra from SEM-EDX analysis for all materials were predominantly from calcium carbonate, clay, and gypsum particles. No free quartz particles were observed. The four rock dusts used in this study are representative of those presented for use in rock dusting, but the conclusions may not be applicable to all available materials.

Keywords: rock dust, quartz

INTRODUCTION

Accumulations of combustible dust in underground coal mines create the risk of large-scale explosions that have resulted in multiple deaths and traumatic injuries.(1) Mine explosions have caused 65 fatalities and 18 injuries in U.S. underground coal mines over the past 10 years.(2) The explosion hazard can be effectively controlled by application of inert rock dust, such as limestone or dolomite, to render inert the combustible coal dust generated during the mining and transport of coal.(3) The Office of Mine Safety and Health Research (OMSHR), a division of the National Institute for Occupational Safety and Health (NIOSH), has investigated the effect of rock dusting on the prevention and suppression of coal dust explosions.(4-6) OMSHR investigators found that an 80% total incombustible content (TIC) of rock dust mixed with coal dusts was needed to prevent dust explosions in intake airways when methane is absent.(7) This recommendation has been included in the Code of Federal Regulations (CFR), so that 30 CFR Part 75.403 states that the incombustible content of the combined coal dust, rock dust, and other dust shall be not less than 80 percent.(8) The rock dust must meet the definition in 30 CFR 75.2, which states that it shall be comprised of pulverized limestone, dolomite, [etc.]; “the particles of which when wetted and dried will not cohere to form a cake which will not be dispersed into separate particles by a light blast of air; and which does not contain more than 5 percent combustible matter or more than a total of 4 percent free and combined silica (SiO2), or, where the Secretary finds that such silica concentrations are not available, which does not contain more than 5 percent of free and combined silica”.(9)

A recent nationwide surveillance study found quartz content in bulk rock dust samples was < 2% (97.3% of 444 grab samples).(10) The study also determined that most of the grab samples (87.7%) contained more than 20% respirable size particles (< 10 um) as measured by laser diffraction. The study did not report the quartz content of the respirable size fraction, and thus it remains unclear whether the respirable fraction is enriched relative to the bulk. NIOSH is concerned that the quartz content of the respirable size fraction may vary according to mineralogy and friability of the pulverized rock that comprises the final dust product. It is possible that even if the overall quartz content is low, the content in the respirable fraction may be large enough to pose a potential health risk.

In 2011, the Mine Safety and Health Administration (MSHA) issued a Program Information Bulletin warning mine operators and rock dust manufacturers that an investigation of rock dusts had revealed two concerns with the supply of rock dust to US mines, one being an excessive fine particle content and the other being the tendency of all rock dusts studied to form a cake when wetted and dried, such that they could not be easily dispersed by a light blast of air.(11) Fine particles that are easily dispersed also more readily form cakes, but the use of anticaking additives (such as hydrophobic agents) reduces the tendency of rock dust to cake from moisture and enhance its dispersibility even in high moisture environments.(12)

At present, the composition and physical characteristics of untreated and treated rock dusts remain incompletely understood with regard to human health. The objective of the current work was to assess the quartz content and characterize some physical aspects of commonly used rock dust types (limestone and marble) including anticaking treated forms of the same dusts (such as treatment with stearic acid or stearates). The study reported here used simultaneous respirable size-selective and particle size segregated sampling to focus on the quartz content of the rock dust in the respirable size range. This type of study provides basic information on quartz content and particle morphology and can be applied to the selection of untreated and treated rock dust for use in underground coal mines.

METHODS

Test Materials

The rock dusts used in these experiments were an untreated and treated limestone (treatment with proprietary hydrophobic stearate coating is representative of other similar treatments), and an untreated marble and a treated product consisting of a blend of that marble (at 87.5%) with another, surface-modified marble product. These are referred to as untreated limestone (UL), treated limestone (TL), untreated marble (UM), and treated marble (TM), respectively. Dust source and treatment are proprietary.

Generation of Rock Dust and Respirable-Size-Selective Sampling

The selected rock dusts were aerosolized by a fluidized bed aerosol generator (Model 3400, TSI Inc., Shoreview, MN, USA). The generated aerosols were introduced into an aerosol chamber with a special aerosol nozzle that allows the airflow to enter the chamber in a radial direction. The testing setup is similar to one that has been described previously.(13, 14) Six high-flow rate respirable size-selective samplers, FSP10 cyclones (GSA Messgerätebau GmbH, Ratingen, Germany), which operated at 11.2 L min−1, loaded with polyvinyl chloride filters (PVC, 5-μm pore size, 37 mm; GLA5000, SKC Inc., Eighty Four, PA, USA) were placed in the aerosol chamber, and rock dusts were collected in three repetitions. Prior to sample collection, the PVC filters were equilibrated for a minimum of 72 hours in a weighing room at constant relative humidity (50% ± 2) and temperature (26 °C ± 2). Filters were pre-weighed with a micro balance (XP6U, Mettler-Toledo, Columbus, OH, USA; readability, 0.1 μg).(15) The filters were passed through an electrostatic bar (Mettler-Toledo) before weighing to dissipate static charge. A single measurement for each filter was made after allowing exactly 180 seconds for balance stabilization. The flow rates through the samplers were calibrated with a mass flow meter (Model 4040, TSI Inc.). The flow rates were calibrated before and after each sampling session to confirm that they did not change significantly (all remained within ±5%). The filters were equilibrated in the weighing room for a minimum of 72 hours before post-weighing. The respirable dust mass concentration was determined on the basis of obtained mass, pre and post flow rate, and sampling time.

Particle Size Distribution

Particle size-segregated samples were obtained with a Micro-Orifice Uniform Deposit Impactor (MOUDI™ Model 110, MSP Corp., Minneapolis, MN, USA). The MOUDI consists of an inlet stage (with a 50% cut-off aerodynamic diameter [d50] of 18 μm) and additional impaction stages (with d50 of 10.0, 5.6, 3.2, 1.8, 1.00, 0.56, 0.32, 0.18, 0.10, and 0.056 μm). Gravimetric analyses of the PVC filters loaded at each stage of the MOUDI, was as described for cyclone filters above. The size distributions represent the dust mass concentration per unit width of size channel at different aerodynamic diameters. The MOUDI data were obtained with the equation

| (1) |

where

mi = the mass of the dust collected on the filter of stage i of the MOUDI;

QM = the sampling flow rate of the MOUDI (nominal flow rate is 30 L min−1);

TM = the total sampling time of the MOUDI for one test; and

Δlog(dp)= the width of the size channel for the MOUDI.

It is assumed that the inlet stage has an upper size limit of 100 μm and the final filter stage has a lower size limit of 0.01 μm. The particle size distribution of each rock dust was averaged using three replicate measurements.

Fourier Transform Infrared (FTIR) Analysis for Quartz Quantification

Quartz was measured according to the NIOSH Manual of Analytical Methods (NMAM) 7603 (Quartz in Coal Mine Dust, by IR [redeposition]).(16) Briefly, the filter with dust catch was treated with hydrochloric acid such that any carbonates in the dust would be dissolved. The acid solution was rinsed from the filter with 2-propanol leaving the remainder of the catch in place. The filters with remaining dust catch were air dried and transferred to loosely covered crucibles (Model 5013, Avogadro's Lab Supply Inc., Miller Place, NY, USA) and ashed in a muffle furnace (Model F6010, Barnstead/ThermoLyne, Dubuque, IA, USA) for 2 hours at 600°C. The residue from the ashed filters was then gently re-suspended with 10 mL of 2-propanol and sonication for 5 minutes. The re-suspended ashed residues were re-deposited on a PVC filter. Although NMAM 7603 requires the residue to be redeposited onto a 10 mm diameter area of a vinyl/acrylic copolymer (DM-450) filter, these filters are currently unobtainable, and in the present study the re-suspended ashed sample was redeposited on a 5-μm pore size PVC filter. Information regarding the performance of the replacement PVC filters for respirable quartz measurement by infrared spectroscopy has been described previously.(17) The quartz mass was quantified by FTIR (Nicolet 6700, Thermo Fisher Scientific, Waltham, MA, USA with the Omnic software package Version 8.1.11), reading peak height at 800 cm−1 (with baseline between 820 and 670 cm−1). In the previous study noted above we demonstrated that the recovery in spiked samples of respirable α-quartz suspension in isopropyl alcohol ranged from 109-118% (coefficient of variation 1.8-4.5%). (17)

Bulk Sample Analysis

Three different net masses (5, 10, and 15 mg) of each rock dust were weighed on a micro balance (AG245, readability 0.01 mg, Mettler-Toledo) without size-selective sampling (as-received; unknown particle size distribution), and the quartz mass of each sample was then determined as described above. Note that bulk sample analysis using calibration standards of respirable-size quartz can lead to differences in results between infra-red and x-ray methods, due to their different particle size-dependent responses.(18)

Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) Analysis

Particle morphology analysis was conducted with a combination of scanning electron microscopy (SEM, S-4800-2, Hitachi High Technologies America Inc.) under computer control and energy-dispersive x-ray spectroscopy (EDX) analysis (EDX, PGT Inc., Princeton, NJ, USA). Three cowls (BestChek® cassettes, SKC Inc.) loaded with polycarbonate filters for SEM/EDX were placed in the aerosol chamber, and dusts were collected with simultaneous respirable size-selective sampling. Transmission electron micrographs of rock dust particles in respirable size fraction were obtained on a JEOL TEM 1220 (JEOL USA, Peabody, MA, USA) at a working voltage of 80 kV. TEM images were photographed by placing a drop of diluted sample on a formvar-coated copper grid to dry. Several TEM images were analyzed to identify at least 5-10 individual particles per image to estimate approximate dimensions.

RESULTS AND DISCUSSION

Respirable Dust and Quartz Mass Concentrations

A total of 72 individual samples of respirable dust were collected (4 different rock dusts × 6 size-selective samplings × 3 repetitions). One sample was lost during handling. The respirable dust mass concentrations and quartz concentrations (values shown in parentheses here) determined with the FSP10 cyclone ranged from 1.72 to 4.70 mg m−3 (8.80 to 49.0 μg m−3) for UL; 11.3 to 17.9 mg m−3 (78.6 to 118 μg m−3) for TL; 4.17 to 7.97 mg m−3 (2.86 to 3.64 μg m−3) for UM; and13.2 to 23.9 mg m−3 (0.29 to 31.8 μg m−3) for TM. Quartz was detected in only 2 of 18 respirable dust samples of UM because of its low bulk quartz content.

Particle Size Distribution of Rock Dusts

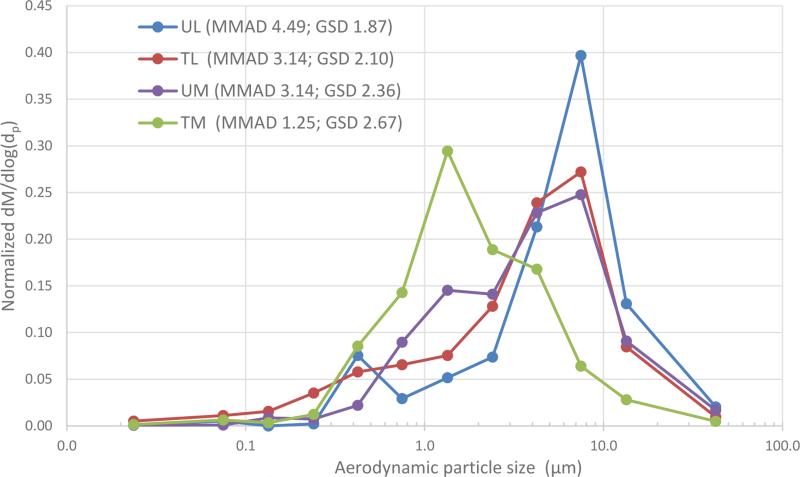

Normalized mass-weighted size distributions of the aerosolized rock dusts, determined by MOUDI cascade impactor, are shown in FIGURE 1. In general, the MOUDI data showed reasonably good repeatability. The particle size distribution was similar for three of the types of rock dust whereas TM particles had a smaller mass median aerodynamic diameter (MMAD, 1.25 μm). This difference in MMAD between UM and TM is not likely the result of the addition of the surface-modified marble even if it were very much finer than the untreated marble because a bimodal distribution is not observed. The change is more likely the result of a further grinding step or further size classification involved in the preparation of TM.

FIGURE 1.

Average normalized particle size distribution (n=3) of airborne rock dusts (UL: untreated limestone, TL: treated limestone, UM: untreated marble, and TM: treated marble) measured in an aerosol chamber, with average mass median aerodynamic diameter (MMAD) and geometric standard deviation (GSD).

The MMAD, GSD, airborne total dust concentration, quartz concentration, and quartz content (%) from each test using the MOUDI are shown in TABLE I. All particle size distributions showed a lognormal distribution, with the MMAD between 1.17 μm (TM #3) and 5.26 μm (UL #3) and the GSD less than 2.78 (TM #1; as shown in TABLE I). All the size distributions show that a large fraction of the airborne rock dust was respirable (smaller than 10 μm). Note that the normalized particle size distribution determined with laboratory samples might differ from actual mining industry situations because the low velocity at the exit of the fluidized bed generator prevents the output of particles with aerodynamic diameters greater than 50 μm.(19)

TABLE I.

Mass median aerodynamic diameter, geometric standard deviation, and airborne total dust concentration, airborne total quartz, and quartz content from the MOUDI in samples of four different rock dusts.

| Rock dust type | MMAD | GSD | Airborne total dust (mg m−3) | Airborne total quartz (μg m−3) | Quartz content (%) |

|---|---|---|---|---|---|

| UL#1 | 3.16 | 2.16 | 4.77 | 55.9 | 1.17 |

| UL #2 | 5.06 | 1.83 | 13.9 | 119 | 0.86 |

| UL #3 | 5.26 | 1.63 | 14.62 | 166 | 1.15 |

| TL #1 | 3.52 | 1.90 | 28.34 | 290 | 1.02 |

| TL #2 | 2.90 | 2.26 | 25.16 | 310 | 1.22 |

| TL #3 | 2.99 | 2.13 | 21.57 | 210 | 0.97 |

| UM #1 | 3.01 | 2.64 | 11.42 | ||

| UM #2 | 2.30 | 2.49 | 11.43 | - | - |

| UM #3 | 4.10 | 1.96 | 15.41 | ||

| TM #1 | 1.25 | 2.78 | 10.63 | 3.81 | 0.04 |

| TM #2 | 1.34 | 2.63 | 18.08 | 3.36 | 0.02 |

| TM #3 | 1.17 | 2.60 | 13.74 | 8.02 | 0.06 |

Quartz Contents in the Bulk and Airborne Samples

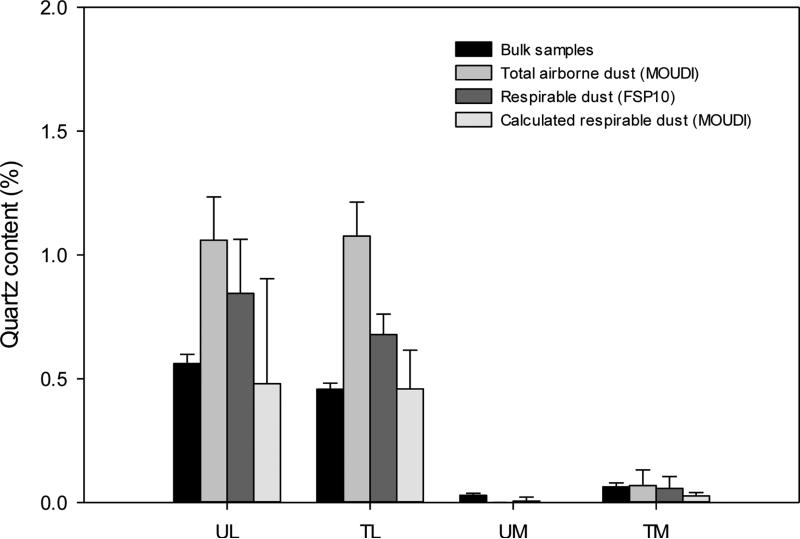

FIGURE 2 shows the average and standard deviation of quartz content (%) in bulk samples, the airborne total dust from the MOUDI, respirable dust from the FSP10, and the calculated respirable fraction from MOUDI of UL, TL, UM, and TM rock dusts. Quartz percentage contents for each category were calculated as follows:

FIGURE 2.

Average and standard deviation of silica content (%) in bulk samples, total airborne dust from the MOUDI, respirable dust from the FSP10, and calculated respirable dust fraction from MOUDI in untreated limestone (UL), treated limestone (TL), untreated marble (UM), and treated marble (TM) rock dusts. No quartz mass was detected in most of the respirable dust samples (n=16) of UM and in most of the MOUDI stages, and the respirable quartz calculations cannot be made. The number of bulk samples was 3 (5, 10, and 15 mg of each type of rock dust).

Quartz content in bulk samples:

Quartz content in airborne total dust from MOUDI: .

Quartz content in respirable dust:

Calculated respirable quartz content according to the published sampling efficiency of the FSP10(13) from size distribution found by the MOUDI: (i is stage of MOUDI; respirable fraction of FSP10 cyclone as previously reported).

The percentage of quartz in airborne total dust from the MOUDI is significantly (p < 0.05) enriched in UL and TL compared to the percentage of quartz in the nonaerosolized bulk samples, but the difference is smaller for only the respirable fractions. The percentage of quartz in UL and TL airborne samples collected by the FSP10 respirable samplers is significantly (p < 0.05) greater than that in the respective bulk materials, with an increase around 40-50%. The percentage of quartz in the respirable fraction from the FSP10 is greater than the percentage of quartz in the respirable fraction calculated from the MOUDI. This may be an artefact of dividing the quartz into smaller amounts of sample on the MOUDI stages. The percentage of quartz in both bulk and respirable UM and TM is extremely low and there is no significant enrichment in the respirable fraction over the bulk.

Particle Morphology

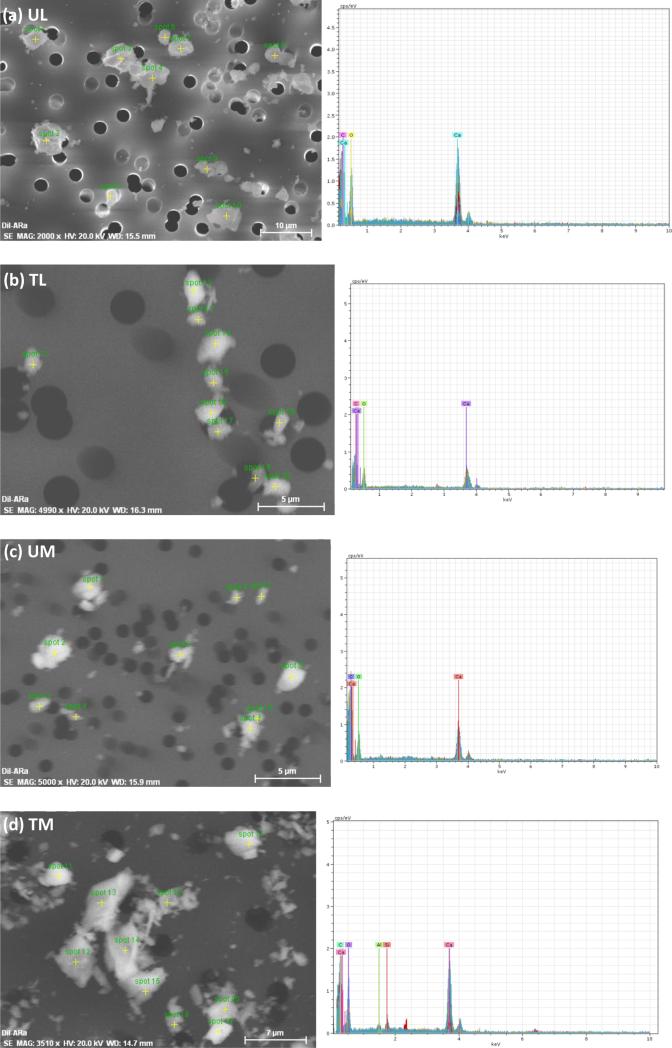

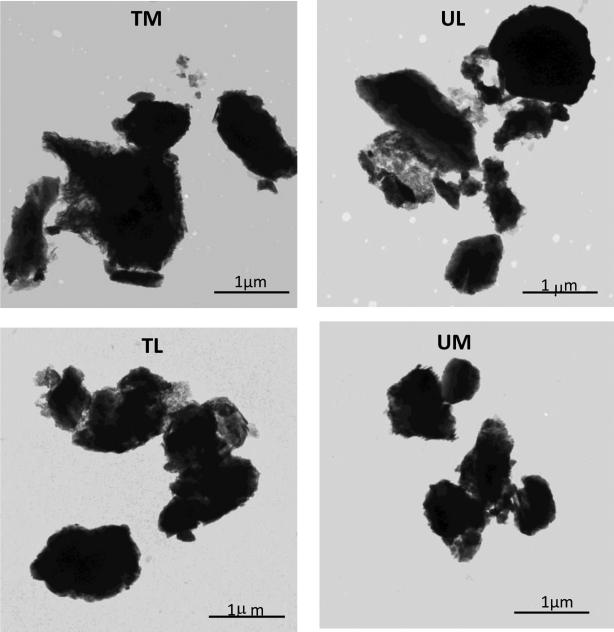

SEM images of each rock dust and energy-dispersive x-ray analysis results are presented in FIGURE 3, images (a) through (d). Images and x-ray spectra are typical of the four kinds of rock dust studied. By visual inspection, it is apparent that the particle sizes range from < 1 μm to 15 μm in most of these images. The dust spectra are predominantly from limestone or marble (calcium carbonate). There are some spectra from clay (aluminosilicate) particles (as shown in FIGURE 3 (d) for illustration) and gypsum (calcium sulfate) particles. No free quartz particles were observed because of the low quantity of quartz and the limited number of particles studied. Considerably more particles (thousands) would need to be examined to determine accurately the characteristics of a small percentage of particles.(20) In FIGURE 4, TEM analysis show that each rock dust in respirable size fraction contains irregularly-shaped particles, with size range from 0.2 to 3 μm. Size distributions for quantitative comparison would have required the measurement of many more particles as noted with SEM.

FIGURE 3.

An example of SEM image of each rock dust: (a) UL; (b) TL; (c) UM; (d) TM. Note a sufficient number of selected fields were imaged and interrogated such that at least 50 particles (10 particle counts per each figure as shown in each figure) were randomly selected and analyzed by the SEM.

FIGURE 4.

Representative TEM images of rock dusts.

CONCLUSIONS

All four types of dust contained a significant fraction of particles in the respirable size range. The respirable fraction of limestone dust, untreated and treated, had significantly higher percentage of quartz than the bulk material. This rock dust (both treated and untreated) has a low initial bulk quartz concentration so the elevation we found in the quartz content of the respirable fraction will not make a major change to the conclusion as to whether the presence of rock dust in the air will result in an exceedance of applicable exposure limit values for respirable crystalline silica. Provided general dust level requirements in mines are met the rock dust in itself would not cause an exceedance because less than 1.25% quartz in 2 mg m−3 respirable dust is less than 25 μg m−3 quartz. However, any rock dust containing any amount of quartz will contribute additional quartz to dust already present that could lead to an exceedance. For example, 1.25% quartz in 1 mg m−3 respirable rock dust added to 1 mg m−3 respirable coal dust containing 4% quartz would lead to an overall quartz concentration of 52.5 μg m−3. The other dust (marble), untreated and treated, had very low quartz content and the respirable fraction was not significantly enriched compared to the bulk. The rock dusts used in this study are representative of those presented for use in rock dusting, but the conclusions may not be applicable to all available rock dust materials.

Supplementary Material

ACKNOWLEDGMENTS AND FUNDING

This project was funded internally by the National Institute for Occupational Safety and Health.

Footnotes

DISCLAIMER

The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the Centers for Disease Control and Prevention/Agency for Toxic Substances and Disease Registry.

REFERENCES

- 1.U.S. Department of Labor . In: Explosion Hazard in Mining. Nagy J, editor. Mine Safety and Health Administration; 1981. MSHA Information Report No. 1119. [Google Scholar]

- 2.U.S. Department of Labor . MSHA Program Informational Bulletin: Availability of a Report on the use of the Coal Dust Explosibility Meter. Mine Safety and Health Administration; Feb, 2013. Publication No. P13-01. [Google Scholar]

- 3.Amyotte PR, Mintz KJ, Pegg MJ. Effectiveness of various rock dusts as agents of coal dust inerting. J. Loss Prevent Proc. 1992;5(3):196–199. [Google Scholar]

- 4.U.S. Department of Health and Human Services . Non-conforming Rock Dust. Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; Feb, 2012. DHHS (NIOSH) Publication No. 2012-102, HID 16. [Google Scholar]

- 5.U.S. Department of Health and Human Services . In: Coal Dust Explosibility Meter Evaluation and Recommendations for Application. Harris ML, Sapko MJ, Varley FD, editors. Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2012. DHHS (NIOSH) Publication No. 2012-172. [Google Scholar]

- 6.U.S. Department of Health and Human Services . Mining Contract: Development of an Anti-Caking Rock Dust. Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2014. [30 March 2015]. Available: www.cdc.gov/niosh/mining//researchprogram/contracts/contract200-2012-52496.html. [Google Scholar]

- 7.U.S. Department of Health and Human Services . In: Recommendations for a new Rock Dust Standard to Prevent Coal Dust Explosions in Intake Airways. Cashdollar KL, Sapko MJ, Weiss ES, Harris ML, Man C, Harteis SP, Green GM, editors. Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2010. DHHS (NIOSH) Publication No. 2010–151, RI 9679. [Google Scholar]

- 8.U.S. Code of Federal Regulations . Title 30–Mandatory safety standards, Part 75–underground coal mines, Subpart E–Combustible Dusts and rock Dusting. 75.403–Maintenance of incombustible content of rock dust. National Archives and Records Administration; Office of the Federal Register; Washington, DC: [Google Scholar]

- 9.U.S. Code of Federal Regulations . Title 30–Mandatory safety standards, Part 75–underground coal mines, Subpart A–General. 75.2–Definitions (Rock Dust) National Archives and Records Administration; Office of the Federal Register; Washington, DC: [Google Scholar]

- 10.Colinet JF, Listak JM. Silica and respirable content in rock dust samples. Coal Age. 2012;117(12):48–52. [Google Scholar]

- 11.Stricklin KG, Zeiler LF. Rock Dust Composition, 30 C.F.R. Part 75.2. US Department of Labor, Mine Safety and Health Administration; Arlington, VA: Oct 27, 2011. Program Information Bulletin No. P11-50. [Google Scholar]

- 12.Cybulski WG. Translated from Polish. National Center for Scientific, Technical and Economic Information; 1975. Coal dust explosions and their suppression. NTIS No. TT 73-54001. [Google Scholar]

- 13.Lee T, Kim S, Chisholm WP, Slaven J, Harper M. Performance of high flow rate samplers for respirable particle collection. Ann. Occup. Hyg. 2010;54(6):697–709. doi: 10.1093/annhyg/meq050. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Soo JC, Lee T, Kashon M, Kusti M, Harper M. Coal dust deposit on internal surface of respirable size selective samplers. J. Occup. Environ. Hyg. 2014;11:D215–D219. doi: 10.1080/15459624.2014.960575. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.National Institute for Occupational Safety and Health . Particulates not otherwise regulated, respirable. 4th edition NIOSH; Cincinnati, OH.: 1998. Method 0600 In: NIOSH Manual of analytical Methods. [Google Scholar]

- 16.National Institute for Occupational Safety and Health . QUARTZ in coal mine dust. 4th edition. NIOSH; Cincinnati, OH.: 2003a. Method 7603 In: NIOSH Manual of analytical Methods. IR (redeposition) [Google Scholar]

- 17.Farcas D, Lee T, Chisholm WP, Soo JC, Harper M. Replacement of filters for respirable quartz measurement in coal mine dust by infrared. J. Occup. Environ. Hyg. 2016;13:D16–D22. doi: 10.1080/15459624.2015.1091962. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Page SJ. Crystalline silica analysis: A Comparison of calibration materials and recent coal mine dust size distributions. Am. Ind. Hyg. Assoc. J. 2003;64:30–39. doi: 10.1080/15428110308984781. [DOI] [PubMed] [Google Scholar]

- 19.Marple VA, Rubow KL. A dust generator for laboratory use. Am. Ind. Hyg Assoc. J. 1978;39:26–32. doi: 10.1080/0002889778507709. [DOI] [PubMed] [Google Scholar]

- 20.Lee T, Chisholm WP, Slaven J, Harper M. Size Distributions of 0.5 to 20 μm Aerodynamic Diameter Lead-Containing Particles from Aerosol Sampler Walls and Filters. Aerosol Sci. & Tech. 2009;43(10):1042–1050. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.