Abstract

Aims and Objectives:

Satisfactory composite restoration depends upon its smooth finish, quality of polishing agents, type of composite material used, and its composition. The present study evaluated the effect of different polishing systems on the surface roughness of composite resin.

Materials and Methods:

Forty discs of composite were prepared and equally subjected to different finishing and polishing procedures; (i) unpolished control group, (ii) sof-lex discs, (iii) diamond tips, and (iv) Astrobrush groups. Later, the surface roughness for the entire specimen was evaluated using Profilomotor. Data were tabulated and statistically analyzed using analysis of variance and Tukey's test at significance level of 0.001.

Results:

Composite surface roughness after polishing was statistically significant between the groups. Sof-lex group produced lesser surface roughness compared to control, Astrobrush, and diamond group.

Conclusion:

The present study indicated that diamond tips can be used to remove rough surface whereas sof-lex can be used for final finish and polish of the composite restoration.

Key words: Composite, polishing, roughness, sof-lex, surface

INTRODUCTION

One of the critical factors in dental restorations is high quality finishing and polishing which improves its longevity and esthetic quality.[1,2] Improper surface finishing of restorations can result in plaque accumulation, gingival inflammation, periodontal problems, demineralization of enamel, staining, caries, and poor esthetic.[1,3,4] Even 0.3 μm of surface changes can be easily detected from the tongue tip.[1] Hence, smooth surface finish of dental restoration is most important. It can be achieved by finishing and polishing of restorations. The finishing procedure can remove excess material with particle size of more than 25 μ, whereas polishing removes particles lesser than 25 μm.[5]

Composite materials are a widely used esthetic restorative material, which varies in its composition and filler content. Composites are classified depending upon its filler load and size as macrofill, microfill, hybrid, and nanofill. Conventional composites (macrofill) have more than 1 μm particle sizes which are difficult to polish. Hence, various types of composites with different filler load and size have been developed to provide smooth surface finish and improve composite strength such as microfill (particle size 0.002–0.04μm), hybrid (0.6–1.0 μm), and nanofilled (20–75 nm). Nanofill contains only nanoscale particles that have improved surface smoothness, lower shrinkage, color stability, and superior esthetics.[2,5,6]

Final finish of the composite restoration depends upon its particle size, degree of hardness, filler load, quality, and polishing material used.[1,2,5,6] Resinous and filler components of composites respond differently to abrasive agents because of difference in hardness.[5] Wide variety of finishing and polishing devices are available in the market such as aluminum oxide coated abrasive (sof-lex), silicone disc, tungsten carbide finishing burs, abrasive impregnated rubber cups, abrasive strips, diamond rotary instruments, and polishing pastes. These are available as one step and multistep polishing systems.[1,2,3,5,7,8]

The hardness of aluminum oxide is significantly higher than that of silicon dioxide. Aluminum oxide and diamond pastes produce smooth surfaces, whereas diamond points can produce surface scratches.[9] Finishing discs can be used for contouring all tooth surfaces as well as bulk reduction of excess material. Aluminum oxide discs are available as coarse, medium, fine, and superfine. Discs help contour and finish curved surfaces, marginal ridge areas, and for lingual and buccal surfaces.[10] Silicone polisher (disc) is used with only light pressure for polishing. The instrument does not remove any additional material.

Multi-tufted Carbide bur uses Tungsten carbides as abrasives. Carbide burs with 10–30 blades (Safe End SE8-20) produce smooth surface finish before polishing. They perform cutting rather than grinding in contrast to diamond points. Non-cutting tips protects soft tissue.

Sof-lex products are flexible, color coded (dark-to-light shade from coarse-to-fine grits) discs made up of Aluminum oxide coated with polyurethane.[5,8,11] They are available as medium (40 μm), fine (24 μm) and ultrafine (8 μm) grit sequence. Sof-lex is multistep finishing and polishing system used in dry field for finishing and polishing under light pressure for 15 s, rinse, and dry with water/air syringe for 6 s. OptraPol (one-step system) are single step polishing system made up of special mixture of silicones.[11] Astrobrush is a three step polishing system (Ivoclar vivadent, AG, Liechtenstein).

Diamond polishers are useful for all types of composites including hybrid composites. It reduces polishing time. Diamond bur system uses ultrafine diamonds. JOTA easy, JOTA, and POGO (Dentsply) diamond polishers can be autoclaved. They are operated at 3000–8000 rpm.[10]

Vyavahare et al. in their study reported that rough surface on restoration can promote accumulation of dental plaque and bacterial adhesion, which can be prevented by polishing the composite surface after restoration.[7] Schmitt et al. observed better surface result with use of sof-lex polishing system.[6]

Finishing and polishing of restoration improves the surface quality and roughness.[1,7] Surface hardness of restorative material predicts wear resistance and its ability to abrade opposing tooth structure.[1] Different polishing systems produce different surface finish. There is lack of sufficient information regarding the best method used for composite polishing. Hence, the present in vitro study was performed to evaluate the effect of different polishing systems on the surface roughness of composite resin.

First null hypothesis of the study was partially rejected because there was difference in polishing procedures employed for the same composite. Second null hypothesis had to be rejected because finishing and polishing methods affected the surface roughness of tested composites. Diamond finishing tips showed higher roughness values when compared with other polishing systems.

MATERIALS AND METHODS

Forty composite disc specimens of 8 mm diameter and 2 mm thickness were prepared by filling nanofilled composite in custom-made silicon mold placed on glass slab followed by light curing with light emitting device (LED) light. Sample size was calculated with ± 0.5 standard deviation (SD) with minimum expected difference of 0.74 and 0.05 of significance at 90% statistical power. The discs after fabrication were stored at 37°C for 24 h in 100% humidity in an incubator. To maintain uniformity, all the restoration surfaces were roughened on a grinding machine with silicon carbide paper under water-coolant at 200 rpm for 5 s at a pressure of 10 N.

Finishing and polishing procedure

After 24 h all 40 composite discs were divided equally into four groups depending upon the type of finishing and polishing procedures used; (i) unpolished control group with Mylar strip, (ii) Sof-Lex (3M ESPE, St Paul, MN, USA), (iii) diamond polishing tips, and (iv) astrobrush groups (Ivoclar vivadent, AG, Liechtenstein). All the procedures were performed by a single trained investigator to avoid operator variability. Test specimens were polished at a time and polishing was done according to manufacturer instructions. A new polishing disc was used for each specimen. Finishing and polishing of each specimen was done for 5 s.

In Sof-lex group, light pressure for 30 s was applied on discs during polishing. In diamond micropolisher tips, group finishing and polishing was done with light and intermittent pressure followed by decreased pressure with 1:5 high-speed contra-angle handpiece at ≤ 200,000 rpm under water-cooling for 30 s. Polishing was done with astrobrush mounted on contra-angle hand piece under light pressure for 10 s.

The polished resin composite discs were washed, allowed to dry, and kept in 100% humidity for 24 h before measuring the average surface roughness values (Ra).

Surface roughness evaluation

Pre-roughening was standardized using a polishing machine with 320 grit silicon carbide paper, and pre-polishing surface roughness (Ra1) of all 40 tested specimens were measured using surface Profilmotor (SE 700, Kosaka Lab, Sotokanda Chiyoda-ku Tokyo, Japan) on a flat plane to obtain Ra. Following polishing procedure, all specimens were again subjected for evaluation of surface roughness (Ra2). Before measuring the surface roughness, each resin composite specimens were stabilized by mounting with a silicone index in the lower jaw (first molar position) of a mannequin head.

The Ra of each specimen was measured five times with a cut-off value of 0.8 mm, a transverse length of 0.8 mm, and a stylus speed of 0.1 mm/s near the center of each specimen using a profilomotor. Six measurements were recorded on each polished specimen, turning the specimen 45° after each measurement. A mean value was calculated for each specimen, for each finishing method.

The data were tabulated and statistically analyzed using analysis of variance (ANOVA) and Tukey's test at a significance level of 0.001.

RESULTS

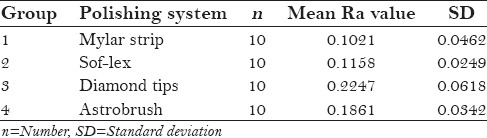

Surface roughness between the groups was statistically significant (P < 0.001). A Mylar strip was used as the control, and the surface roughness values for all polishing systems were compared to that of the Mylar test. Smooth surface finish was found in the control group with Mylar strip (0.1021) compared to other groups, whereas increased surface roughness was found in the tested groups; sof-lex disc (0.1158), diamond (0.2247), and astrobrush groups (0.1861) [Table 1].

Table 1.

Mean and standard deviation of surface roughness with different polishing systems

DISCUSSION

Final finishing of composite restoration is a critical step in the success of restorative procedure. It has been observed that use of a polyester strip or matrix can produce smooth surface finish of restoration. Insufficient polymerization of outer surface of restoration reduces its surface hardness.[1]

Coarse finishing can be done with diamond finishing and fine finishing with carbide finishing burs, whereas aluminum oxide discs or silicone-based points are best-suited for final polish of composites. Several researchers observed visibly rough surface with diamond burs.[1] Some researchers reported that better marginal seal can be obtained if polishing is postponed for 24 h. Others stated that immediate finishing and polishing can result into plastic deformation of the resin.[1,12,13]

Nanofilled composite are used in the present study because they have nanofillers, which gives better handling property, polishability similar to microfilled, wear resistance and strength similar to macrofilled composites.[2]

In the present study, surface profilometer was used to check surface roughness. It has vertical resolution at nm level, high speed, reliability, and cannot be damaged easily on use. It helps to obtain two-dimensional as well as three-dimensional images of the specimens. Different polishing techniques give different surface Ra values. Ra is defined as the arithmetic average height of roughness from the mean line measured within the sample length. Finishing and polishing can improve the mechanical properties of composite restoration. Composite consists of hard filler component and soft resin matrix. After polishing of restoration, filler particle are left protruding while resin matrix remains shorter.[3] This results into surface roughness. This can be reduced with use of an effective polishing system.

In our study, smooth surface was found in control group (0.1021, P < 0.001), which was cured under Mylar strip without subjecting to any polishing procedures; this is in accordance to Kumari et al.[2] Increased surface roughness was found in other tested groups; sof-lex (0.1158), diamond (0.2247), and astrobrush (0.1861) (P < 0.001) [Table 1], which is in contrast to the study by Kumari et al. They stated that the smoothest finish was observed in diamond polish groups compared to other groups, and concluded that it could be due to the abrasive action of diamond points which removes the resin matrix and filler part.[2] In contrast, we observed smooth finish with sof-lex than diamond polishing paste because sof-lex has fine abrasive particles compared to diamond. Similar to our result, Kaminedi et al. found a smooth finish with Mylar strip.[14] Vyavahare et al. found different biofilm adhesion on restoration after polishing with different polishing system. They found lower adhesion in Mylar strip compared to Sof-lex and astrobrush depending on its surface finish, which is in accordance to our study.[7] In accordance to the study by Madyastha et al., the present study also observed good surface finish with Sof-lex disc compared to diamond bur and astrobrush.[1]

Chinelatti et al. observed the highest surface hardness with minifilled resin compared to other materials.[4] de Paula et al. found lower surface roughness and higher hardness than glass ionomer cement.[15] Tuncer et al. found that application of modeling resin did not affect the microhardness and surface roughness of the tested composites.[16]

Kaminedi et al. concluded that immediate finishing and polishing under coolant resulted in the best surface smoothness and hardness values in microhybrid composite; however, immediate dry finishing and polishing gave the best smoothness and hardness values in nanohybrid composite.[14] Venturini et al. concluded that the timing and type of polishing system can affect the surface roughness of the composite.[12] Viana et al. observed no significant difference in roughness related to thermocycling and the type of polishing.[17] Chinwlatti et al. concluded that regardless of the composite resin, surface hardness was considerably increased when polishing was delayed and performed 1 week after preparation of the samples.[4] Meena Kumari et al. in their study found no difference in surface roughness among the tested groups when polished with shofu multistep polishing system.[18] Madhyastha et al. concluded from their study that smooth surface can be obtained by delaying the finishing and polishing procedures,[1] whereas Venturini et al. found no negative influence on the immediate polishing of restoration.[12]

To minimize the changes in variability, the present study was performed by a single trained investigator, and by standardizing baseline surface roughness. Rougher restorative surfaces decrease esthetic quality and increase chances of plaque accumulation and gingivitis. Hence, polishing of restorations prevents plaque accumulation and thus improves quality of restorations. Present study indicated that diamond polishing paste can be used to remove rough surface whereas sof-lex for final finish and polish of the composite restoration.

Limitations of the study

The present study is an in vitro test and there could be changes in in-vivo results. In our study, sample size was less and we only examined three polishing systems. There is a need of further research to check other polishing systems with larger samples size.

CONCLUSION

The present study indicated that diamond polishing paste can be used to remove rough surface whereas sof-lex for final finish and polish of the composite restoration. Polishing prevents plaque accumulation on restoration, and thus, helps in successful outcome of restoration.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Madhyastha PS, Naik DG, Srikant N, kotian R, Bhat KM. Effect of finishing/polishing techniques and time on surface roughness of silorane and methacrylate based restorative materials. Oral Health Dent Manag. 2015;14:212–8. [Google Scholar]

- 2.Kumari RV, Nagaraj H, Siddaraju K, Poluri RK. Evaluation of the effect of surface polishing, oral beverages and food colorants on color stability and surface roughness of nanocomposite resins. J Int Oral Health. 2015;7:63–70. [PMC free article] [PubMed] [Google Scholar]

- 3.Abzal MS, Rathakrishnan M, Prakash V, Vivekanandhan P, Subbiya A, Sukumaran VG. Evaluation of surface roughness of three different composite resins with three different polishing systems. J Conserv Dent. 2016;19:171–4. doi: 10.4103/0972-0707.178703. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Chinelatti MA, Chimello DT, Ramos RP, Palma-Dibb RG. Evaluation of the surface hardness of composite resins before and after polishing at different times. J Appl Oral Sci. 2006;14:188–92. doi: 10.1590/S1678-77572006000300008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Gonçalves MA, Teixeira VC, Rodrigues SS, de Oliveira RS, Salvio LA. Evaluation of the roughness of composite resins submitted to different surface treatments. Acta Odontol Latinoam. 2012;25:89–95. [PubMed] [Google Scholar]

- 6.Schmitt VL, Puppin-Rontani RM, Naufel FS, Nahsan FP, Sinhoreti MA, Baseggio W. Effect of the Polishing Procedures on Color Stability and Surface Roughness of Composite Resins. ISRN Dent. 2011;2011:617672. doi: 10.5402/2011/617672. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Vyavahare N, Gaikwad S, Raghavendra SS, Kazi MM. Effect of finishing and polishing procedures on biofilm adhesion to composite surfaces: An ex vivo study. J Dent Allied Sci. 2014;3:70–3. [Google Scholar]

- 8.de Oliveira Lima M, Catelan A, Hernandes NM, Giorgi MC, Ambosano GM, Lima DA. In vitro evaluation of the effect of different polishing techniques on the surface roughness of composite resins submitted to at-home and in-office bleaching procedures. J Conserv Dent. 2015;18(6):483–7. doi: 10.4103/0972-0707.168820. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Reis AF, Giannini M, Lovadino JR, Santos Dias CT. The effect of six polishing systems on the surface roughness of two packable resin-based composites. Am J Dent. 2002;15:193–7. [PubMed] [Google Scholar]

- 10.Mopper KW. Contouring, Finishing, and polishing posterior composites. Inside Dentistry. 2011;7:62–70. [Google Scholar]

- 11.Gupta S, Dhawan R. The effect of various finishing and polishing systems on the surface roughness of four composite resin materials-An in vitro study. Int J Contemp Dent. 2012;3:93–102. [Google Scholar]

- 12.Venturini D, Cenci MS, Demarco FF, Camacho GB, Powers JM. Effect of Polishing Techniques and Time on Surface Roughness, Hardness and Microleakage of Resin Composite Restorations. Oper Dent. 2006;31:11–7. doi: 10.2341/04-155. [DOI] [PubMed] [Google Scholar]

- 13.Endo T, Finger WJ, Kanehira M, Utterodt A, Komatsu M. Surface texture and roughness of polished nanofill and nanohybrid resin composites. Dent Mater J. 2010;29:213–23. doi: 10.4012/dmj.2009-019. [DOI] [PubMed] [Google Scholar]

- 14.Kaminedi RR, Penumatsa NV, Priya T, Baroudi K. The influence of finishing/polishing time and cooling system on surface roughness and microhardness of two different types of composite resin restorations. J Int Soc Prevent Community Dent. 2014;4(Suppl S2):99–104. doi: 10.4103/2231-0762.146211. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.de Paula AB, de Fúcio SB, Alonso RC, Ambrosano GM, Puppin-Rontani RM. Influence of chemical degradation on the surface properties of nano restorative materials. Oper Dent. 2014;39:E109–17. doi: 10.2341/12-340. [DOI] [PubMed] [Google Scholar]

- 16.Tuncer S, Demirci M, Tiryaki M, Unlü N, Uysal Ö. The effect of a modeling resin and thermocycling on the surface hardness, roughness, and color of different resin composites. J Esthet Restor Dent. 2013;25:404–19. doi: 10.1111/jerd.12063. [DOI] [PubMed] [Google Scholar]

- 17.Viana MO, Dias AA, Vedovello S, Motta RH, Rodrigues JA, Flório FM. Evaluation of different types of polishing of composite resin surfaces after the removal of metal and ceramic brackets. Braz Dent Sci. 2015;18:102–10. [Google Scholar]

- 18.Meena Kumari CM, Bhat KM, Bansal R. Evaluation of surface roughness of different restorative composites after polishing using atomic force microscopy. J Conserv Dent. 2016;19:56–62. doi: 10.4103/0972-0707.173200. [DOI] [PMC free article] [PubMed] [Google Scholar]