Abstract

Three standard foodstuff plastic packaging namely polyethylene (PE), polypropylene (PP), and polyvinylchloride (PVC) were evaluated for management of lesser grain borer Rhyzopertha dominica (F.) (Coleoptera: Bostrichidae) and red flour beetle Tribolium castaneum (Herbst) (Coleoptera: Tenebrionidae). Resistance parameters in packaging were recorded as punctures, holes, penetrations, sealing defects, and invasions with two thicknesses and tested for two lengths of time. Damages like punctures, holes and penetrations by both insects were more in PE packaging however R. dominica made more penetrations in PP than in PE. For both insects sealing defects and invasions were predominant in PVC than in others. Thickness did not affect significantly damage types but significantly more holes and penetrations by R. dominica were in less thickness. Punctures and holes by R. dominica were more after less time period but other damages in packaging were more after more time period. However for T. castaneum all sorts of damages were seen more after more time period. Overall categorization between two insects showed R. dominica made more penetrations and T. castaneum made more invasions compared with their counterparts. Pictures were taken under camera fitted microscope to magnify punctures and holes in different packaging and thicknesses. Insect mortality due to phosphine was more in PP and PE packaging and least in PVC packaging and thickness effect was marginal. T. castaneum mortality was significantly more after 48 h than after 24 h. Damages extent in packaging and fumigation results showed PP to be the best of three packaging materials to manage these insects.

Keywords: Packaging, consumer, damages, insect control, fumigation

At present time plastics use as packaging materials have been increased compared with the past as older packaging bags were made from paper and cardboard (Riudavets et al. 2007). Plastic bags are appropriate to the customer and a reduction in unnecessary load of weight in the form of cardboard packaging (Kindle 2001, Connolly 2011). Plastic packaging materials provide benefits in the form of protection against insects and avoidance of contamination during their use (Paine and Paine 1993). Polyethylene (PE) and polypropylene (PP) are frequently used plastic packaging. Except frozen or preserved food items packed foods are attacked by storage insect pests that have the ability to penetrate packages. Insects can penetrate into packed food items during the dispersal stage, for example during their passage and storing in pantries, or in marketing supplies (Licciardello et al. 2013). Insects and their contaminants are also the microorganism carriers. Their entry into packaged food stuffs have been classified in two ways either as penetrators or as invaders. If they are able to make holes by their sharp mandibles and get entry are called penetrators and most of the times problems come from outside (Highland 1984) and if insects are unable to make holes and use some existing opening to enter into packaging are called invaders (Highland 1991).

Property of plastic packing materials varies against penetration by insects. For example for Chocolate packages PP proved effective against the attack of almond moth larvae and Indian meal moth larvae but unlike this polyvinylchloride (PVC) was not effective (Browditch 1997). Pacheco and Wiendl (1989) revealed that PE is a capable wrapper for packed beans to avoid penetration of common bean weevil. On the other hand it has been described that PE films with <0.08 mm thickness can be penetrated by lesser grain borer, rice weevil, khapra beetle, saw toothed grain beetle, red flour beetles, and cowpea weevil (Shukla et al. 1993). Thus it is important to evaluate the resistant packaging phenomenon against different insects independently keeping in view packaging type, thickness, and insect species concerned. Use of repellents application on the packaging materials is important but it needs a lot of research firstly because food odors emission from packaging can abolish the efficacy of repellents further certain repellents can cross packaging surface and contaminate food stuffs and there are few such chemicals that have been approved by EPA or FDA. Rare examples include Methyl salicylate in controlled release form by a device patented by Radwan and Allin (1997) and approved by EPA and FDA to treat packages. Packaging value is ascertained by the type of material used and its closing (seal). The material is chosen based on the exact requirements of product being packed. Nevertheless, correct seal of package is usually not easy. This may be due to property of the packaging film or some flaws happened during heat sealing of packaging. It has been reported that presence of product in seam lead to improper seal (Adler 2008). Seal impurity can lead to a reduced seal power and therefore a bigger packing failure menace. Besides, this can generate the development of micro channels from where air and germs can arrive and spoil the enclosed foodstuff.

Fumigation is common way of controlling storage insect pests infesting foodstuffs and other materials. It kills insects by toxic gas or through blend of gases. Presently phosphine fumigation is most widely used pest control strategy and usually it is used in the form of metal phosphide tablets to kill insects. To kill insects the poisonous fume must have the ability to reach the pest from the exterior (Subramanyam and Hagstrum 1995). Since penetration of the fumigant into the bags is a critical factor it is evident that fumigations under tarps or plastic sheeting should take into account the properties of the packaging materials (Marouf and Momen 2004). Thus it would be very important to compare different commonly used loose plastic packaging materials for fumigation efficacy against different storage insects infesting packed foodstuffs.

Therefore an ideal loose plastic packaging should be the one which is mostly resistant to penetration and invasion by different storage insect pests. Besides if a packed commodity is already infested with some storage insect pests and upon fumigation to control the given pest species the packaging material should allow the maximum fumigant gas to permeate through the packaging film that results in full mortality of the pest insects infesting foodstuffs within given fumigation period. Owing to the importance of this study subject, present research was designed to study resistance parameters like punctures, holes, penetration into packaging, sealing defects and invasions in some popular packaging materials namely PE, PP, and PVC with two different thicknesses and checked after two time intervals against Rhyzopertha dominica (F.) (Coleoptera: Bostrichidae) and Tribolium castaneum (Herbst) (Coleoptera: Tenebrionidae). Damages made by different storage insects in packing films vary depending on the insect species and type of packaging material as well as their thickness. Some insects primarily are penetrators of packages while others are mostly invaders of packages therefore it would be important to categorize between these two insects acting as penetrators or invaders of packaging materials tested. In order to decide overall about the packaging, mortality of T. castaneum and R. dominica adults was checked with phosphine fumigation infesting packed commodity in relation to three different plastic packaging with two thickness levels checked after two time intervals to see the effect of these factors on phosphine fumigation efficacy administered against these pest species. Till now research is limited regarding overall evaluation of the popular foodstuff plastic packaging for the management of different storage insect pests. In this research for the first time we studied in detail the type of damages in packaging for two insects first damages made by insects as punctures, holes and entry through holes as penetrations second damages due to the plastic packaging character like sealing defects and entry of insects through these defects as invasions which were counted separately. Further overall categorization between these two insects is done for the first time statistically as penetrator or invader of packaging. Fumigation of the undamaged foodstuff packaging infested with these two insects was done with phosphine to decide overall about these packaging.

Combined results of study of damages in packaging films and those of fumigation by phosphine for the mortality of these two insects would reveal the ideal plastic packaging for the management of these studied pest species.

Materials and Methods

Insects

The heterogeneous populations of R. dominica and T. castaneum were collected from different regions of Punjab. The collected populations were deposited in laboratory of stored product insect pests under given collection units for both species in Department of Entomology, University College of Agriculture and Environmental Sciences, The Islamia University of Bahawalpur, Pakistan. Lesser grain borer was reared in jars containing (1 kg volume) wheat grains while red flour beetles were reared on a diet consisting of whole wheat flour and yeast (95:5 by weight) in jars at optimum conditions of temperature 28 ± 2°C and 65 ± 5 RH under dark conditions (24 h). Cultures are maintained in stored grain insect pests rearing room provided with an air conditioner and humidifier (U650 Plaston, Switzerland) to maintain the optimum temperature and relative humidity ranges. Temperature and relative humidity data are recorded with thermometers and Hygrometers (Hygro – Haar – Synth, Germany).

For the confirmation of insect species, samples of both insects were preserved in 75% ethanol. These were identified as T. castaneum (Herbst) (Coleoptera: Tenebrionidae) and R. dominica (F.) (Coleoptera: Bostrichidae) by using a binocular microscope at 10× and comparison of specimens with our previous cultures and available literature. Newly emerged adults from cultures were taken and used in experiment.

Uniform age populations were obtained by letting 50 pairs (male and females) of T. castaneum to lay eggs on a diet consisting of whole wheat flour in different glass jars for a period of 1 week at optimum conditions of temperature and humidity. After that adults were removed and substrate food with eggs was left for egg development for a period of one month. After one month from the date of sifting parent adults when sufficient adults had emerged as new generation these were used in tests. R. dominica were reared in whole grains of wheat for a period of 3 months. When sufficient adults in the culture were generated these were used in packaging testing.

Packaging Materials

Three different types of packaging materials namely PP, PE, and PVC with two thickness levels were purchased from the wholesale plastic market of Lahore Pakistan @ 350 PKRs/kg. Thicknesses of the packaging materials were measured with digital micrometer (Mitutoyo Corporation, Japan). Plastic packaging materials are available in the form of plastic sheets (10 × 12 inches length). From these sheets small plastic bags (8 × 10 cm size) were prepared using a pair of scissors and sealing machine known as impulse sealer to later fill them with host commodities. Packaging film thickness varies a bit from place to place in a plastic sheet. To ascertain the average thickness of a plastic film, measurements were recorded from 32 plastics bags per each film thickness and film type. Average thickness (mm) of different plastic films was established through descriptive statistics performed by using SPSS v 16 for windows (SPSS 2007) (Table 1).

Table 1.

Determination of average thickness (mm) of plastic packaging by digital micrometer (Mitutoyo Corporation, Japan)

| Packaging type | N | Thickness level available | Minimum thickness measured | Maximum thickness measured | Mean ± SD |

|---|---|---|---|---|---|

| PE1 | 32 | Less thick | 0.02 | 0.02 | 0.0196 ± 0.00101 |

| PP1 | 32 | Less thick | 0.02 | 0.02 | 0.0192 ± 0.00157 |

| PVC1 | 32 | Less thick | 0.03 | 0.04 | 0.0319 ± 0.00191 |

| PE2 | 32 | More thick | 0.04 | 0.05 | 0.0403 ± 0.00275 |

| PP2 | 32 | More thick | 0.04 | 0.04 | 0.0399 ± 0.00221 |

| PVC2 | 18 | More thick | 0.05 | 0.06 | 0.0533 ± 0.00124 |

N, sample size (samples measured); PE, polyethylene; PP, polypropylene; PVC, polyvinylchloride; Less thickness level: 1 = PE1 = 0.02 mm, PP1 = 0.02 mm, PVC1 = 0.03 mm; More thickness level: 2 = PE2 = 0.04 mm, PP2 = 0.04 mm, PVC2 = 0.05 mm.

Substrate Food

Commodities that were not infested previously with insects were used in experiments. Commodities were checked vigorously for any previous insect infestation and insect free fresh commodities were filled appropriately (wheat grains for lesser grain borer and whole wheat flour for red flour beetles) about 50 g each for two insect types in to the bags of each type and thickness. After filling with commodities packages were then sealed from the mouth to represent consumer form small packages or pouches and were used in experiments.

Tests of Packaging

We used bag method for our tests as these are useful since they simulate the type of challenge to which packets are exposed and test the entire package (including strength of seams and closures) (Newton 1988). Three types of plastic packets viz., PE, PP, and PVC of two thickness levels were used to examine the damage types in packaging against red flour beetles and lesser grain borer to create punctures, holes and penetrations made by two insects. Plastic jars of half liter volume were used in experiments and small pinhole size openings were created in their lids for ventilation purpose. A plastic jar of this type into which three packets of one packaging type and thickness filled with whole wheat flour were placed vertically along a wall and 50 red flour beetles adults from our homogeneous age adult population culture were released outside the packed wheat flour pouches in the middle of jar and lid was screwed to close the jar again. A total of four such jars were taken with uniform packaging type and insects units in an experiment in four replications. Similar procedure was repeated to record damage types for second thickness level. Data of creating number of punctures, holes and penetration were recorded after two time spans less time was 7 days. Insect invasions as a result of imperfect seals in packaging were also recorded after given time spans. Experiments were run again for second time span, more time period as 15 d for red flour beetles to record damage types in relation to different packaging and thickness effect. Time periods were 5 and 10 d and packaging contained whole wheat grains instead of whole wheat flour for lesser grain while all other experimental procedures were similar as were for red flour beetles. Lesser grain borer is less dynamic and dies earlier in the culture and test jars in the absence of rearing media based on our previous experiments (unpublished data) compared with red flour beetles therefore testing period was reduced to 5 and 10 d for lesser grain borer compared with that of red flour beetles which had 7 and 15 d time period.

Fumigation Test

Tin container of 0.7 m3 volume capacity having four equal size partitions was used for fumigation experiment. We used 0.7 m3 tin box volume capacity in order to ensure the phosphine fumigation dose of 1.5 g/m3. A phosphine tablet (Celphos, Excel Crop Care Limited, India) of 3 g (emits one gram gas after contact with ambient air) was used in experiments. We used 3 g phosphine tablet in 0.7 m3 tin box to ensure the 1.5 gm (gas)/m3 dose.

Experimental Setup for Fumigation Test

For fumigation experiment three different types of packaging materials viz., PE, PP, PVC with two different thickness levels were used (same as in penetration or invasion tests). Plastic packets were prepared by using a pair of scissors and an impulse sealer to cut and seal the rectangular plastic film layers into consumer size bags or sachets (8 × 12 cm size) which were packed then with whole wheat flour [Triticum aestivum (L.)]. Three such plastic pouches of PE, PP, and PVC type of plastic films with two different thickness levels were filled with whole wheat flour as a substrate for red flour beetles and were prepared for each replication numerically as 3 × 2 = 6 making a total of 24 bags for four replications. 30 adults of red flour beetles were poured in each plastic packet and the opening of packet through which commodity and insects were filled was sealed with impulse sealer. In this way 24 bags were placed in all 4 replications of tin container. A phosphine tablet (3 g weight) wrapped in a muslin cloth was placed on a plate situated on top in the center of container to hold the tablet and generate phosphine gas from the tablet till the end of fumigation test homogeneously in all four compartments of tin container. When this experimental setup was completed container was closed with its top lid and was sealed properly with a broader sealing tape all around the top lid to make the container completely air tight. Mortality data was recorded after 24 h following this setup. For 48 h experiment an identical experiment was repeated to record data after 48 h. For R. dominica other procedures were similar except that packing contained wheat grains as food material instead of wheat flour and due to scarcity of insect cultures for R. dominica experiment was performed for 24 h time period only and a sample of 15 adults form homogenous population of this species were poured per plastic packet in all treatments. Actual number of insects died out of the total insect samples in all bags was converted into percentages. Percentage of dead insects was obtained by dividing the insects died in samples by the total insects used in those samples and multiplied with hundred.

Control Treatment

To check the mortality of insects not because of phosphine all the treatments (24 identical bags) were placed in the same manner in the container but without phosphine tablet. Mortality data (control mortality) was recorded after 24 h. For 48 h experiments an identical experiment was repeated to record data after 48 h. Mortality in treatments was corrected by using abbot formula (Abbott 1925).

Data Recording for Damages in Packaging Films

After given time period, number of punctures and holes by insects were counted in packets with naked eye and data was recorded. Penetrations were counted after opening the packaging and counting number of insect inside packages. Punctures are scratches made by insects on packing films while the opening in this case is not big enough that it may lead to entry of insects in to packing. Punctures made on one place together were counted as one puncture and so on. Holes on the other hand are characterized by a cut of fair enough size that leads to penetration or entry by insects inside packaging. Packaging which had openings along sealing because sealing was not intact after a give test period was considered as sealing defect. This type of opening on one place was counted as one sealing defect and so on. Packaging with sealing defects and insects inside these packaging were scored as invaders and number of insects due to sealing defects were counted. If a packaging had penetrations by insects and had both holes and sealing defects were discarded and repeated to ascertain accuracy between penetrations and invasions. Experiments were run independently for two lengths of times for both insects.

Data Analysis

Data was analyzed in SPSS v 16 for windows (SPSS 2007). Data were found non-normal by normality test (Shapiro-Wilk test; P < 0.001). Thus a non parametric Kruskal-Wallis H test was used at 5% probability level with punctures, holes, penetrations, sealing defects and invasions as dependent variables while packaging types as independent variable. To check the effect of thickness and duration (with two levels) on these variables Mann-Whitney U test was used at 95% CI. Mann-Whitney U test was also used to study the overall comparison between two insects for damages like penetrations and invasion. For fumigation tests statistics was performed on corrected mortality percentages only within which percent mortality as dependent variable and independent variables were packaging types, thickness levels and time period of fumigation. To check the effect of packaging (having three levels), non parametric Kruskal-Wallis H test was used at 5% probability level of significance as the data was found non-normal by normality test (Shapiro-Wilk test; P < 0.001). Although Mann-Whitney U test was performed for the independent variables having two levels like thickness and time period at 95% CI.

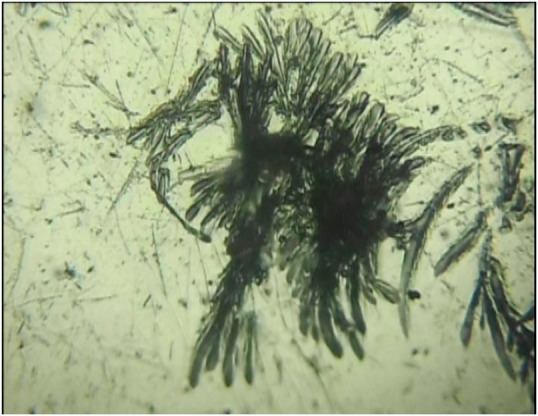

Microphotography

Microphotography was done following data recording for damage types in different plastic packaging for both insects. All the microphotographs were taken using Labomed Digi-2 USA research microscope fitted with digital camera Digi-1500 and coupled with P-IV computer system. The software used was digi pro ver. 4. The microphotographs were taken either at the magnification of 100 or 200×. In order to get the microphotographs with maximum clarity and batter focus under microscope the samples of packaging envelops were flattened between two glass sheets of size 4 × 6 inch having 3-mm thickness.

Results

Resistance Parameters in Packaging by T. castaneum and R. dominica due to Packaging Types

Table 2 shows damage types in three plastic packaging by two insects. Most punctures were in PE by T. castaneum and least in PP with no significant difference (χ2 [2] = 4.48, P = 0.107). Most punctures by R. dominica were in PE and least in PVC with significant difference (χ2 [2] = 11.28; P = 0.003). Most holes by T. castaneum were in PE and least in PP with no significant difference (χ2 [2] = 4.19; P = 0.123). Most holes by R. dominica were in PE and least in poyvinylchloride with significant difference (χ2 [2] = 7.50; P = 0.023). Penetrations by T. castaneum were mostly in PE and not in other packaging with significant difference (χ2 [2] = 8.53; P = 0.014). Penetrations by R. dominica were more in PP followed by PE with no significant difference (χ2 [2] = 5.70; P = 0.058). Sealing defects were more in PVC and least in PE for T. castaenum but with no significant difference (χ2[2] = 2.16; P = 0.339). For R. dominica most sealing defects were in PVC packaging and least in PP with no significant difference (χ2 [2] = 3.74; P = 0.154). Invasions through sealing defects by T. castaneum were more in PVC and least in PE with no significant difference (χ2 [2] = 3.90; P = 0.142) however for R. dominica most of invasions were seen in PVC packaging with statistically no significant difference (χ2 [2] = 2.00; P = 0.368).

Table 2.

Evaluation of resistance parameters in plastic packaging against T. castaneum and R. dominica in relation to packaging types, thickness and time period

| Damage types | Packaging effect (N: 16) | Mean Ranks for T. castaneum | Mean Ranks for R. dominica | Thickness effect (N: 24) | Mean Ranks for T. castaneum | Mean Ranks for R. dominica | Duration effect (N: 24) | Mean Ranks for T. castaneum | Mean Ranks for R. dominica |

|---|---|---|---|---|---|---|---|---|---|

| Puncture | PVC | 24.500 | 16.375 | Less thick | 24.500 | 25.080 | Less time | 21.500 | 27.583 |

| PP | 21.500 | 27.063 | More thick | 24.500 | 23.920 | More time | 27.500 | 21.416 | |

| PE | 27.500 | 30.063 | |||||||

| Hole | PVC | 24.688 | 20.219 | Less thick | 24.563 | 28.960 | Less time | 21.500 | 25.020 |

| PP | 21.500 | 23.344 | More thick | 24.438 | 20.040 | More time | 27.500 | 23.979 | |

| PE | 27.313 | 29.938 | |||||||

| Penetration | PVC | 22.500 | 20.000 | Less thick | 24.479 | 28.125 | Less time | 22.500 | 21.916 |

| PP | 22.500 | 27.750 | More thick | 24.521 | 20.875 | More time | 26.500 | 27.083 | |

| PE | 28.500 | 25.750 | |||||||

| Sealing defect | PVC | 26.625 | 27.000 | Less thick | 25.396 | 24.500 | Less time | 21.479 | 22.500 |

| PP | 24.906 | 22.500 | More thick | 23.604 | 24.500 | More time | 27.521 | 26.500 | |

| PE | 21.969 | 24.000 | |||||||

| Invasion | PVC | 28.094 | 25.500 | Less thick | 25.521 | 25.000 | Less time | 20.500 | 24.000 |

| PP | 23.313 | 24.000 | More thick | 23.479 | 24.000 | More time | 28.500 | 25.000 | |

| PE | 22.094 | 24.000 |

Kruskal-Wallis H test used for packaging effect and Mann-Whitney U test used for thickness and duration effect to generate mean ranks; Significance is at 0.05 probability level. PVC, polyvinylchloride; PP, polypropylene; PE, polyethylene; Less thick, 0.02 or 0.03 mm; more thick, 0.04 or 0.05 mm; less time: 5 or 7 d; more time: 10 or 15 d.

Resistance Parameters in Packaging by T. castaneum and R. dominica Due to Thickness

Table 2 shows damage types in packaging due to thickness effect. Number of Punctures were similar in two thickness levels by T. castaneum (U = 288; Sig [two–tailed] = 1.000). More punctures by R. dominica were in less thickness than in more thickness with no significant difference (U = 274; Sig [two-tailed] = 0.739). More holes by T. castaneum were in less thickness than in more thickness with no significant difference (U = 286.5; Sig [two-tailed] = 0.957). More holes by R. dominica were in less thickness than in more thickness with significant difference (U = 181; Sig [two-tailed] = 0.002). Penetrations by T. castaneum were more in more thickness than in less thickness with no significant difference (U = 287.5; Sig (two-tailed) = 0.983). Penetration by R. dominica were significantly more in less thickness than in more thickness (U = 201; Sig [two-tailed] = 0.008). Sealing defects by T. castaneum were more in less thickness than in more thickness with no significant difference (U = 266.5; Sig [two-tailed] = 0.493). Sealing defects for R. dominica were similar in two thickness levels (U = 288; Sig [two-tailed] = 1.000). Invasions by T. castaneum were more in less thickness than in more thickness (U = 263.5; Sig [two-tailed] = 0.436). Invasion by R. dominica were more in less thickness than in more thickness (U = 276; Sig [two-tailed] = 0.317).

Resistance Parameters in Packaging Materials by T. castaneum and R. dominica Due to Time Period

Table 2 shows damages in packaging due to time period. More punctures by T. castenum were after more time period than after less time period with significant difference (U = 216; Sig [two-tailed] = 0.009). More punctures by R. dominica were after less time period than after more time period with non-significant difference (U = 214; Sig [two-tailed] = 0.077). More holes by T. castaneum were after more time period than after less time period with significant difference (U = 216; Sig [two-tailed] = 0.009). More holes by R. dominica were after less time period than after more time period with no significant difference (U = 275; Sig [two-tailed] = 0.725). Penetrations by T. castaneum were after more time period than after less time period with significant difference (U = 240; Sig [two-tailed] = 0.039). Penetrations by R. dominica were more after more time period than after less time period with no significant difference (U = 226; Sig [two-tailed] = 0.060). Sealing defects by T. castaneum were more after more time period than after less time period with significant difference between means (U = 215.5; Sig [two-tailed] = 0.021). Sealing defects by R. dominica were more after more time period than after less time period with significant difference between means (U = 240; Sig [two-tailed] = 0.039). Invasions by T. castaneum were more after more time period than after less time period with significant difference between means (U = 192; Sig [two-tailed] = 0.002). Invasions by R. dominica were seen after more time period than after less time period with no significant difference between means (U = 276.0; Sig [two-tailed] = 0.317).

Categorization of R. dominica and T. castaneum as Penetrators or Invaders

To categorize overall between two insects as penetrator or invader of packaging statistics was performed on overall data. Results for overall penetrations showed that more penetrations (mean rank 50.875) were made by R. dominica compared with T. castaneum (mean rank 46.125) with non-significant difference (U = 1038; Sig [two-tailed] = 0.162). Results for overall invasions showed that T. castaneum made more invasions (mean rank 52.052) compared with R. dominica (mean rank 44.948) with significant difference (U = 981.5; Sig [two-tailed] = 0.013).

Damage Pictures

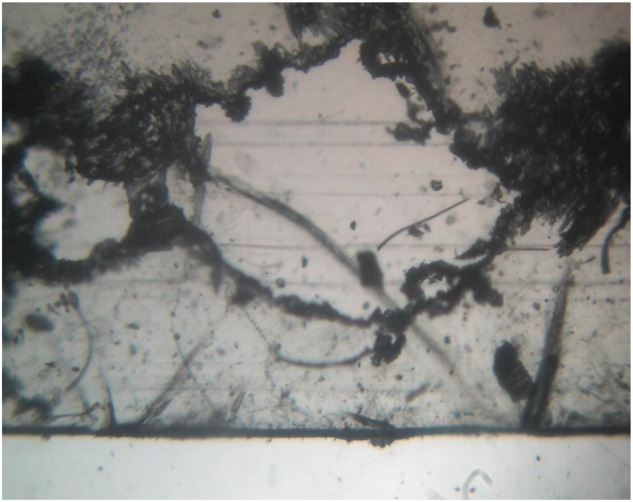

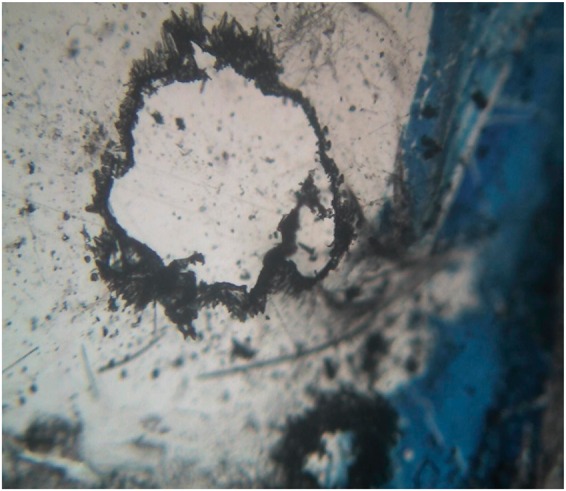

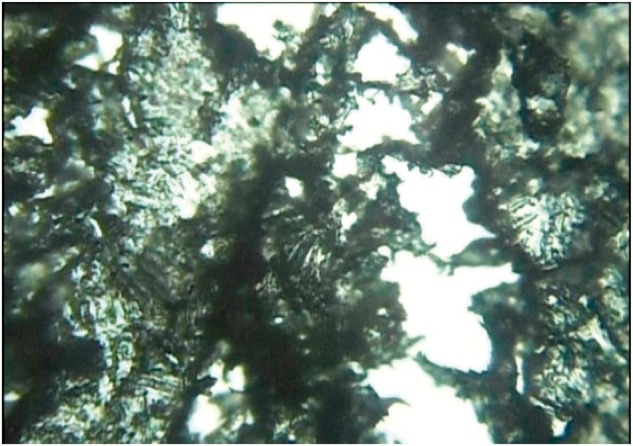

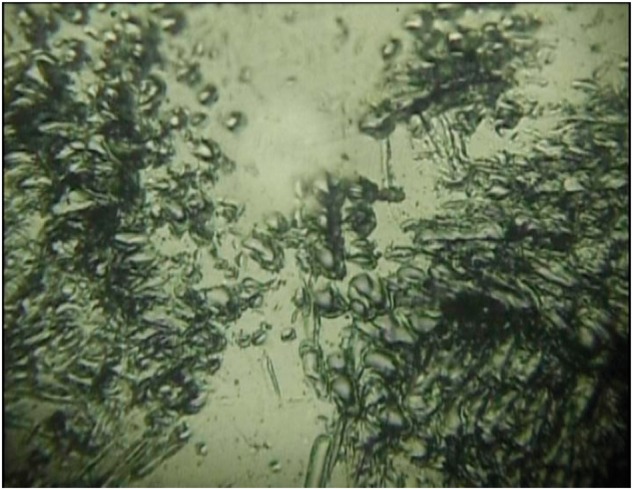

Pictures show holes made in PE packaging with less thickness which proved to be a susceptible packaging material. Punctures are more pronounced in PE packaging type with lower thickness. Packaging with higher thickness did not show any holes. Only punctures are present in packaging with higher thickness (Figs. 1–7).

Fig. 1.

Damage (hole) due to R. dominica. PE packaging with thickness 0.02 mm.

Fig. 2.

Damage (hole) due to T. castaneum. PE packaging with thickness 0.02 mm.

Fig. 3.

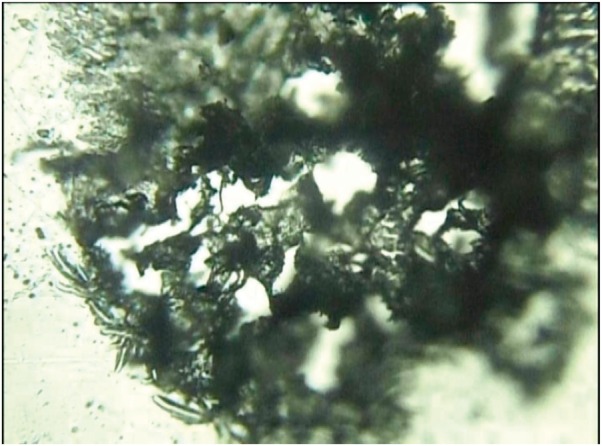

Damage (punctures) due to R. dominica. PE packaging with thickness 0.02 mm.

Fig. 4.

Damage (punctures) due to R. dominica. PE packaging with thickness 0.04 mm.

Fig. 5.

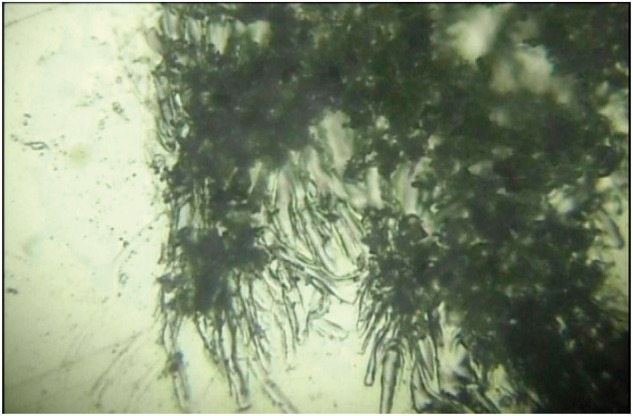

Damage (punctures) due to T. castaneum. PE packaging with thickness 0.02 mm.

Fig. 6.

Damage (punctures) due to R. dominica. Polypropylene packaging with thickness 0.02 mm.

Fig. 7.

Damage (punctures) due to R. dominica. Polypropylene packaging with thickness 0.04 mm.

Mortality of T. castaneum due to Phosphine Fumigation (1.5 g/m3) in Relation to Different Plastic Packaging, Thickness, and Duration

Table 3 shows maximum mortality was generated in PP and minimum was in PVC packaging with no significant difference (χ2 [2] = 0.94; P = 0.626). Effect of thickness showed more mortality in more thickness than in less thickness but with no significant difference (U = 284.5; Sig [two-tailed] = 0.931). Effect of time period showed significantly more mortality occurred after more time period than after less time period (U = 113.5; Sig [two-tailed] = 0.000).

Table 3.

Mortality of T. castaneum adults with phosphine fumigation (1.5 g/m3) in relation to different plastic packaging, thickness, and time period

| Packaging | N | Mean rank | Thickness | N | Mean Rank | Duration | N | Mean rank |

|---|---|---|---|---|---|---|---|---|

| E | 16 | 25.500 | 1 | 24 | 24.354 | 1 | 24 | 17.229 |

| PP | 16 | 25.810 | 2 | 24 | 24.646 | 2 | 24 | 31.771 |

| PVC | 16 | 22.190 | Total | 48 | Total | 48 | ||

| Total | 48 |

Kruskal-Wallis H test used for packaging effect and Mann-Whitney U test used for thickness and duration effect to generate mean ranks; Significance is at 0.05 probability level. PVC, polyvinylchlorde; PP, polypropylene; PE, Polyethylene; less thick = 1 = 0.02 or 0.03 mm; more thick = 2 = 0.04 or 0.05 mm; less time = 1 = 5 or 7 d; more time = 2 = 10 or 15 d.

Mortality of R. dominica due to Phosphine Fumigation (1.5 g/m3) in Relation to Different Plastic Packaging and Thickness

Table 4 shows more mortality of R. dominica occurred in PP or PE and least in PVC packaging with significant difference (χ2 [2] = 6.54; P = 0.038). Effect of thickness showed more mortality of R. dominica occurred in more thickness than in less thickness with no significant difference (U = 65; Sig [two-tailed] = 0.71).

Table 4.

Mortality of R. dominica with phosphine fumigation (1.5 g/m3) in relation to packaging types and thickness levels

| Packing | N | Mean rank | Thickness | N | Mean rank |

|---|---|---|---|---|---|

| PE | 8 | 14 | 1 | 12 | 11.917 |

| PP | 8 | 14 | 2 | 12 | 13.083 |

| PVC | 8 | 9.5 | Total | 24 | |

| Total | 24 |

Kruskal-Wallis H test used for packaging effect and Mann-Whitney U test used for thickness effect to generate mean ranks; Significance is at 0.05 probability level. PVC, polyvinylchloridea; PP, polypropylene; PE, polyethylene; less thick = 1 = 0.02 or 0.03 mm; more thick = 2 = 0.04 or 0.05 mm.

Discussion

Results of this study can be viewed from three aspects; damages in packaging by two storage insects, overall comparison between two insects as penetrator and invader of packages and mortality of insects with phosphine fumigation in relation to different plastic packaging. Damages in packaging were in the form of punctures, holes, penetrations, sealing defects and invasions. Punctures and holes by both insects were more in PE packaging however the damages by R. dominica were more and were significant compared with T. castaneum. Penetrations by T. castaneum were only in PE and by R. dominica more penetration were in PP than in others and these results remained non-significant. More punctures and holes in polyethylene are due to susceptibility of this film against T. castaneum and R. dominica. In a study penetration ability of R. dominica, Sitophilus oryzae, and Oryzaephilus surinamensis was checked through PE, PP, polyester and a multilayer film. Results showed intensity of damage by all three species was more in PE than in PP and polyester (Riudavets and Salas 2006). Sealing defects were more in PVC packaging for R. dominica and T. castaneum. Subsequently invasions by insects were seen more in PVC than in others. During the heat sealing of plastic films seal quality is determined by different factors like platen temperature, dwell time and pressure. It has been stated that PVC type of plastics are hard and brittle material and modification is necessary for it to be used successfully (Kirwan and Strawbridge 2003). Sharp folds and buckles should be avoided because they weaken the material and provide easier access by pest insects (Wohlgemuth 1979). Therefore more sealing defects in PVC packaging could be due to the nature of polymer type. Sealing defects in PP and PE might be due to some impurities like food particles in sealing surfaces that lead to invasions by red flour beetles into these packages. However further investigations on this phenomenon would be much more beneficial.

Damages by both species were relatively more in thin packaging than that in thick packaging materials and results were significant for R. dominica compared with T. castaneum as the former made significantly more holes and penetrations in thin packages than in thick packages. Chung et al. (2011) described that packaging thickness was one of the important factors that affected penetration of insects into different packaging. Their results showed relatively more penetrations by insects were in packaging with less thickness. Similar results were also found about thickness effect on penetration by larvae (Li et al. 2014) and when packaging were used with extra cover these were resistant to insect penetration than when used alone (Mullen and Mowery 2000).

More damages in packaging were recorded for R. dominica in less time period than in more time period however penetrations were more after more time period. On the other hand sealing defects and invasions were more after more time period. For T. castaneum all sorts of damages were recorded after more time period than after less time period. A possible explanation to this would be that T. castaneum is primarily an invader of packaging and at first it might be looking for any previous defects or entries made by other insects and then it enters into packages through previous openings called invasions. Therefore it took time to make damages in the packaging and more damages were noted after more time period than after less time period. Time taken by different insects may vary to penetrate into packages. Effect of time period on penetration of packages showed R. dominica penetrated different packages in less average time compared with any other insects in the tests (Gerhardt and Lindgren 1954). However for T. castaneum these results are in contrast with our previous research conducted on T. castaneum that showed red flour beetles made more penetrations in less time compared with more time period test (Qasim et al. 2013, Hassan et al. 2014).

For overall categorization of two insects for penetrations and invasions, data were analyzed statistically by Mann-Whiteny U test. Analysis of overall data showed R. dominica made more penetrations than T. castaneum and attained a mean rank of penetrator greater than T. castaneum. Similarly for invasions T. castaneum made more invasions than R. dominica and former attained mean rank of invader greater than R. dominica. These findings are similar to those of Mullen et al. (2012) that reported R. dominica primarily as a penetrator and T. castaneum primarily as an invader. Therefore our present study is in agreement about these two insects as penetrators or invaders based on statistical analysis of overall data.

Pictures show that holes made in PE packaging with less thickness which proved to be a susceptible packaging material. Punctures are more pronounced in PE packaging type with less thickness. Packaging with more thickness did not show any holes. Only punctures are present in packaging with higher thickness. These results are in agreement with those of earlier authors showing PE as susceptible packaging compared with other films (Riudavets and Salas 2006) and thick packages proved resistant against insect attack for both species. Film type and thickness affects insect penetration ability which is the result of scratches and holes produced and PE has been reported as susceptible packaging material to insect attack by other authors (Cline 1978, Highland and Wilson 1981).

Phosphine fumigation of infested packages showed mortality was more in PP followed by PE and least in PVC packaging. Thickness of packaging had little effect on mortality of these insects by phosphine. A bit more mortality though for both species was observed in more thickness than in less thickness. Significantly more mortality of T. castaneum was observed after 48 h than after 24 h. These results are somewhat similar to some earlier studies conducted by others which showed significantly less mortality of pest insects in PVC packaging due to phosphine than in PE or PP packaging. On the other hand their studies showed significant difference in mortality of insects due to thickness and significantly more mortality of insects observed in less thick packaging (Marouf and Momen 2004). These studies are in agreement with our earlier research that showed significant effect of time period on mortality of insects due to phosphine. Our earlier research showed significantly more mortality of beetles after more time period than after less time period (Qasim et al. 2013).

To decide overall about the standard packaging for the management of both insect species results showed punctures and holes were more in PE compared with other packaging. Penetrations by T. castaneum were more in PE and by R. dominica in PP. Sealing defects were greater in PVC for both insects and invasions were often in PVC by both insects. Less thickness proved comparatively susceptible to damages for both insects particularly for R. dominica as it made significantly more punctures and holes in less thick packaging. But thickness did not affect much results of damaging for T. castaneum. Time period showed different effect for tested insects. For T. castaneum more time lead to susceptibility of packaging and for R. dominica susceptibility became greater after shorter time period than after more time period. Sealing defects are merely due to packaging and not by insects so these were more after more time period and invasions were also after more time period.

Fumigation results showed PVC packaging as ineffective packaging material of foodstuffs compared with PE and PP. Maximum mortality of insects was observed in PP packaging. Effect of time period showed maximum mortality of T. castaneum was after 48 h time period. Therefore time period may be a critical factor to manage these storage insects infesting packaged foodstuffs. These factors are worth considering as improper fumigation can lead to control failure of insects infesting packaged foodstuffs.

To summarize our current results PP was best packaging material for both species in terms of fumigation efficacy by phosphine. Similarly PP also proved resistant to damage by insects like punctures, holes and penetrations compared with PE. It had least sealing defects and invasions. Sealing defects are due to packaging themselves and sealing defects and invasions through these defects were obvious in PVC packaging. Thickness did not affect much fumigation results for both insects. However damages were more in thin packaging. Based on our current findings PP with more thickness (0.04 mm) can be successfully employed as packaging material for both R. dominica and T. castaneum keeping in view fumigation efficacy due to phosphine as well as resistance phenomenon against penetration and invasion by both of these species.

Acknowledgment

This research belongs to a research project “Achievement of Standard Loose Packaging Materials for Food Stuffs against Major Stored Grain Insect Pests” funded by Higher Education Commission of Pakistan (PM-IPFP/HRD/HEC/2012/4023) in favor of Dr. Muhammad Waqar Hassan as principal Investigator.

References Cited

- Abbott W. S. 1925. A method of computing the effectiveness of an insecticide. J. Econ. Entomol. 18: 265–267. [Google Scholar]

- Adler C. 2008. Insect-proof packaging to avoid stored product insects. IOBC/Wprs Bull. 40: 363–369. [Google Scholar]

- Browditch T. G. 1997. Penetration of polyvinyl chloride and polypropylene packaging films by Ephestia cautella (Lepidoptera: Pyralidae) and Plodia interpunctella (Lepidoptera: Pyralidae) larvae, and Tribolium confusum (Coleoptera: Tenebrionidae) adults. J. Econ. Entomol. 90: 1028–31. [Google Scholar]

- Chung S. K., Seo J. Y., Lim J. H., Park H. H., Kim Y. T., Song K. H., Park S. J., Han S. S., Park Y. S. 2011. Barrier property and penetration traces in packaging films against Plodia interpunctella (Hubner) larvae Tribolium castaneum (Herbst) adults. J. Stored Prod. Res. 47: 101–5. [Google Scholar]

- Cline L. D. 1978. Penetration of seven common flexible packaging materials by larvae and adults of eleven species of stored-product insects. J. Econ. Entomol. 71: 726–9. [Google Scholar]

- Connolly K. B. 2011. Less impactful. Food Process. 72: 69–73. [Google Scholar]

- Gerhardt D., Lindgren D. L. 1954. Penetration of packaging film: Film materials used for food packaging tested for resistance to some common stored product insects. California Agric. 8: 3–4. [Google Scholar]

- Hassan M. W., Qasim M. U., Iqbal J., Jamil M. 2014. Study of penetration ability by Tribolium castaneum (Herbst.) (Coleoptera: Tenebrionidae) through different loose plastic packaging. J. Pure App. Sci. 24-33: 17–20. [Google Scholar]

- Highland H. A. 1984. Insect infestation of packages, pp. 309-320.In Baur F. J. (ed.), Insect Management for Food Storage and Processing. American Association of Cereal Chemists International, St. Paul, Minnesota, USA. [Google Scholar]

- Highland H. A. 1991. Protecting packages against insects, pp. 345-350. In Gorham J. R. (ed.), Ecology and Management of Food-Industry Pests, FDA Technical Bulletin 4, Association of Official Analytical Chemists, Arlington, Virginia, USA. [Google Scholar]

- Highland H. A., Wilson R. 1981. Resistance of polymer films to penetration by lesser grain borer and description of a device for measuring resistance. J. Econ. Entomol. 74: 67–70. [Google Scholar]

- Kindle L. K. 2001. Packaging. 2001. Bending to meet a changing society. Food Process. 61: 63–5. [Google Scholar]

- Kirwan M. J., Strawbridge J. W. 2003. Plastics in food packaging, pp. 174–240. In Coles R., McDowell D., Kirwan M. J. (eds.), Food packaging technology. Blackwell Publishing, CRC Press, London, UK. [Google Scholar]

- Li S. H., Kwon S. J., Lee S. E., Kim J. H., Lee J. S., Na J. H., Han J. 2014. Effect of type and thickness of flexible packaging films on perforation by Plodia interpunctella. Korean. J. Food Sci. Technol. 46: 739–42. [Google Scholar]

- Licciardello F., Muratore G., Suma P., Russo A., Nerín C. 2013. Effectiveness of a novel insect-repellent food packaging incorporating essential oils against the red flour beetle (Tribolium castaneum). Innov. Food Sci. Emerg. Technol. 19: 173–80. [Google Scholar]

- Marouf A., Momen R. F. 2004. An evaluation of the permeability to phosphine through different polymers used for the bag storage of grain. International Conference on ControlledAtmosphere and Fumigation in Stored Product. Gold-Coast Australia. FTICLtd. Publishing, Israel.

- Mullen M. A., Mowery S. V. 2000. Insect-resistant packaging. Intern. Food Hyg. J. 11: 13–4. [Google Scholar]

- Mullen M. A., Vardeman J. M., Bagwell J. 2012. Insect resistance packaging, pp. 135–41. In Hagstrum D. W., Phillips T. W., Cuperus G. (eds.), Stored Product Protection. Kansas State University, Manhattan, Kansas. [Google Scholar]

- Newton J. 1988. Insects and packaging—a review. Intern. Biodet. J. 24: 175–87. [Google Scholar]

- Pacheco I. A., Wiendl F. M. 1989. Resistencia de materiais utilizados para embalagens a perfuracoes por Acanthoscelides obtectus (Say) e Zabrotes subfasciatus (Boh.) (Coleoptera: Bruchidae). Estimativa de perda de peso de feijao decorrente da infestacao por esses carunchos. Coletanea Do Instituto De Tecnologia De Alimentos. 19: 165–72. [Google Scholar]

- Paine F. A., Paine H. Y. 1993. Manual de envasado de alimentos. A.M. Vicente Ediciones, Madrid, España.

- Qasim M. U., Hassan M. W., Wang J. J., Jamil M., Iqbal J., Hassan M. U. 2013. Management of Tribolium castaneum (Coleoptera: Tenebrionidae) with phosphine fumigation in relation to packaging materials and food types. Pak. J. Zool. 45: 1639–45. [Google Scholar]

- Radwan R. N., Allin G. P. 1997. Controlled-release insect repellent device. U. S. Patent 5,688,509.

- Riudavets J., Salas I. 2006. Evaluation and characterization of damage produced by insect pests in packaging. In Proceedings of the Conference of the International Organization for Biological and Integrated Control of Noxious Animals and Plants (IOBC). West Palaearctic Regional Section (WPRS) (OILB SROP) Working Group on Integrated Protection of Stored Products.

- Riudavets J., Salas I., Pons M. J. 2007. Damage characteristics produced by insect pests in packaging film. J. Stored Prod. Res. 43: 564–70. [Google Scholar]

- Shukla R. M., Chand G., Chandra M., Saini M. L. 1993. Comparative resistance of different packaging materials to stored grain insects. Plant Prot. Bull. (Faridabad). 45: 21–3. [Google Scholar]

- SPSS Inc. 2007. SPSS for Windows, Version 16.0. SPSS Inc, Chicago. [Google Scholar]

- Subramanyam B., Hagstrum D. W. 1995. Resistance measurement and management of insect in stored products, pp. 331–397. In Subramanyam B., Hagstrum D. W. (eds.), Integrated Management of Insects in Stored Products. Marcel Dekker, New York. [Google Scholar]

- Wohlgemuth R. 1979. Protection of stored foodstuffs against insect infestation by packaging. Chem Indus. 10: 330–4. [Google Scholar]