Abstract

Abstract

Vegetable fibers have been used lately as ingredients in popular meat products in order to increase its nutritional value. The objective of this study was the physical–chemical characterization of six vegetable fibers in order to apply them in chicken burger formulations as animal fat substitutes. The studied fibers showed moisture content below 14 %, low content of fat, protein and ash, and high levels of carbohydrates. The oat, wheat and bamboo fibers showed the highest content of total dietary fiber. All fibers presented good results of technological characterization, but bamboo, pea and wheat fibers showed the best hygroscopic property results, good emulsifying stability, and color compatible for application in meat products. The use of vegetable fibers in chicken burgers resulted in lower or equal hardness values when the experiments were compared to the control sample. Most samples showed elasticity, adhesiveness, cohesiveness and chewiness values significantly equal to the control sample. The sensory analysis results indicated that all samples had good acceptability. The use of vegetable fibers in chicken burgers proved to be a promising alternative for food manufacturers to combine products deemed unhealthy with functional ingredients that are more appealing for consumers.

Graphical Abstract

Keywords: Meat products, Functional ingredients, Hydration properties, Texture, Sensory analysis

Introduction

Meat is one of the major sources of high biological value protein, B-complex vitamins and minerals such as iron and zinc (Arihara 2006). However, some consumers still have prejudice towards meat, and one of the main reasons for their criticism of meat and meat products is the presence of saturated fatty acids. These are considered a risk factor associated with cases of coronary heart disease and cancers (Olivo and Olivo 2005). Some of studies concerning modifications in meat products to enhance its functional potential are: reduction in fatty acids and cholesterol levels; addition of vegetable oils and/or natural extracts with antioxidant properties; reduction of sodium chloride levels; and also the addition of vegetable fibers (Weiss et al. 2010).

Particularly related to the addition of dietary fibers we may consider its action as: fat substitute in meat products, usually with emulsifier characteristics; texture improvement; and reduction of formulation costs. The largest sources of dietary fibers are vegetable foods such as cereals, legumes, vegetables, fruits and seeds (Gray 2006). Dietary fibers may be considered as functional foods, because they positively affect one or more human body functions (Rodríguez et al. 2006).

The use of vegetable fibers in meat products has been studied in baked good formulations in order to increase cooking yield and improved texture. Various types of fiber have been evaluated individually or combined with other ingredients in meat product formulations in order to reduce the fat intake and also as restructured and emulsified products (Weiss et al. 2010). This application indirectly increases the fiber intake for meat product consumers, which, in general, have not incorporated dietary fibers into their eating habits. However, it is of great importance that the characteristics and properties of these fibers are well known in order to evaluate their role as functional and technological ingredients (Rosell et al. 2009).

The use of ingredients for meat products that promote health benefits, such as vegetable proteins, fibers, natural antioxidants, probiotic and prebiotic components, aids the development of functional foods (Jiménez-Colmenero et al. 2001). Vegetable fibers can be applied to meat product formulations concerning its performance towards the increase in cooking yield, the improvement in texture and also as a fat replacement. Different fiber types have been used, individually or combined with other ingredients, in meat products to reduce the fat content and redesign the final (emulsified) products (Weiss et al. 2010). Fast cooking products considered unhealthy are becoming interesting objects of study in this area (García et al. 2009), however the addition of vegetable fibers on these products should be carefully evaluated to avoid their mischaracterization.

Therefore, the primary objective of this study was to characterize vegetable fibers in terms of physical–chemically and technological properties (represented by hygroscopic, emulsifier and coloring properties). The second objective was to evaluate the technological physicochemical and sensorial parameters of vegetable fibers application in chicken burgers.

Materials and methods

Raw material

Six types of commercial dietary fibers were selected for the physical-chemical and technological characterization: apple fiber (Vitacel® AF 401), bamboo fiber (Vitacel® BAF 200), pea fiber (Vitacel® EF 150), oat fiber (Vitacel® HF 200), potato fiber (Vitacel® KF 200) and wheat fiber (WF Vitacel® 200). All fibers were provided by the manufacturer J. Rettenmaier & Söhne GMBH Co, Rosenberg, Germany.

The chicken (breast and skin) and the other ingredients used for the burger formulation were obtained in a local meat plant.

Nutritional composition of vegetable fibers

The nutritional composition analyzes were performed according to the methods proposed by AACC (1999). The moisture content by 44-15A method, the total protein by 46-12 method, total fat content by 30-25 method, and ash by 08-01 method, while the carbohydrate amount was determined by difference. The total dietary fiber content and fractions of soluble and insoluble dietary fibers were determined by the AOAC (1990) (991.43 method).

Color analysis of vegetable fibers

The color analysis was performed by the CIE-Lab system (L*, a*, b*) using a colorimeter (Chroma Meter CR-400, Konica Minolta Sensing Inc.) calibrated on a white surface, and performed D65 illuminant and the observation angle of 10° (CIE 2004).

Physicochemical and technological properties of vegetable fibers

Swelling capacity

The swelling capacity was determined according to the methodology used by Robertson et al. (2000). The method uses 100 mg of sample, placed in 10 mL of distilled water for its hydration, in a graduated cylinder (1.5 cm diameter) at room temperature. The mixture was gently shaken for complete mixing of sample and water. After 18 h, the volume occupied by the swollen sample was recorded and expressed as volume/g of dry material.

Water holding capacity

The water holding capacity is determined as the maximum amount of water that 1 g of material may absorb and hold after centrifugation at low speed, and it was determined according to the 56-30 method of AACC (1999). The method uses 5 g of each vegetable fiber and adds 30 mL of distilled water. The hydrated samples were subjected to stirring in a vortex mixer for homogenization and then centrifuged (2000×g during 10 min) (Q222T Centrifuge tubes, Quimis/Brazil). The supernatant was discarded and the tube was reweighed. The water holding capacity was calculated and expressed in grams of water per gram of solid material.

Oil holding capacity

Evaluation of oil holding capacity was carried out according to the methodology proposed by Wong and Cheung (2005). About 2 grams of each fiber samples were mixed with 20 mL of corn oil (Bunge, Brazil) with predetermined density (0.92 g/cm3). The tubes with each sample were subjected to agitation in a vortex shaker for homogenization during 10 min and then centrifuged (2000×g, 30 min) (Q222T Centrifuge tubes—Quimis, SP, Brazil). The supernatant was discarded and the tube was reweighed. The oil holding capacity of each sample was expressed as the number of grams of oil retained per gram of the fiber.

Bulk density

The bulk density determination was based on the methodology presented by Prakongpan et al. (2002). A pre-weighed graduated cylinder was filled with 50 mL of sample and was gently vibrated during 2 s. The volume was recorded, the cylinder content was weighed and the density was apparent expressed as mass per volume.

Emulsifying capacity and emulsion stability

The emulsifying capacity and the emulsion stability of the evaluated fibers were measured according to the methodology defined by Wong and Cheung (2005). Approximately 1 g of each fiber sample was placed inside a graduated centrifuge tube of 50 mL, added of 12.5 mL of distilled water and the mixture was homogenized on a vortex mixer (ATS 100—Arsec, SP, Brazil) for 1 min. After the homogenization, 12.5 mL corn oil (Salad, Bunge) was added and the mixture was stirred a further 1 min. The emulsion formed was centrifuged (500×g during 10 min) (Centrifuge tubes Q222T—Quimis, SP, Brazil). The emulsion formed in each tube (each fiber sample) was heated in a water bath at 80 °C for 30 min, cooled to 25 °C and centrifuged again. The emulsifying capacity and the emulsion stability were expressed as a percentage and calculated as the ratio between the emulsified layer height and the height of the total tube volume.

Development of chicken burgers

A basic chicken burger formulation was developed (named as the control) and consisted of the following ingredients: 74.5 % chicken breast, 10 % chicken skin (approximately 35 % fat), 10 % water, 2 % salt, 3 % of textured soy protein, 0.2 % of sodium tripolyphosphate, 0.26 % of a blend of spices (pepper, onion and garlic) and 0.04 % sodium erythorbate. The variations performed at the control burger formulation consisted of the replacement of the total chicken skin by a mix of vegetable fibers. The fibers mix (bamboo, pea and wheat) was defined considering the best results combination from 2.4 subsection. The fibers used were Vitacel® BAF 200 bamboo fiber, Vitacel® WF 200 wheat fiber, and the Vitacel® RU 150 pea fiber (J. Rettenmaier & Söhne GMBH Co., Germany) and were added in hydrated way together with the remaining ingredients.

The performance of the fibers was evaluated by means of a 23 full-factorial design (Table 1), which shows the experimental variables (coded and the real values) used for the formulation tests. In this work it was applied a Central Composite Design, which consists in a factorial planning with 8 assays plus 6 axial points and 3 central points, totalizing 17 assays.

Table 1.

Full factorial design for three independent variables (concentration of each vegetable fiber)

| Assay | Coded variablesa | Real variables (%)b | ||||

|---|---|---|---|---|---|---|

| Bamboo x1 | Wheat x2 | Pea x3 | Bamboo X1 | Wheat X2 | Pea X3 | |

| 1 | −1 | −1 | −1 | 0.40 | 0.40 | 0.40 |

| 2 | +1 | −1 | −1 | 1.60 | 0.40 | 0.40 |

| 3 | −1 | +1 | −1 | 0.40 | 1.60 | 0.40 |

| 4 | +1 | +1 | −1 | 1.60 | 1.60 | 0.40 |

| 5 | −1 | −1 | +1 | 0.40 | 0.40 | 1.60 |

| 6 | +1 | −1 | +1 | 1.60 | 0.40 | 1.60 |

| 7 | −1 | +1 | +1 | 0.40 | 1.60 | 1.60 |

| 8 | +1 | +1 | +1 | 1.60 | 1.60 | 1.60 |

| 9 | −1.68 | 0 | 0 | 0.00 | 1.00 | 1.00 |

| 10 | +1.68 | 0 | 0 | 2.00 | 1.00 | 1.00 |

| 11 | 0 | −1.68 | 0 | 1.00 | 0.00 | 1.00 |

| 12 | 0 | +1.68 | 0 | 1.00 | 2.00 | 1.00 |

| 13 | 0 | 0 | −1.68 | 1.00 | 1.00 | 0.00 |

| 14 | 0 | 0 | +1.68 | 1.00 | 1.00 | 2.00 |

| 15 | 0 | 0 | 0 | 1.00 | 1.00 | 1.00 |

| 16 | 0 | 0 | 0 | 1.00 | 1.00 | 1.00 |

| 17 | 0 | 0 | 0 | 1.00 | 1.00 | 1.00 |

ax1, x2, x3 are coded concentration

bX1, X2, X3 are real concentration

The burger ingredients were ground using a 5 mm plate, twice, to ensure complete grinding of them. The pre-hydrated fiber mix was added using the ratio of 1:3 (fiber: water). After mixing the formula for 5 min, the resulting mass was stored at near −1 °C to facilitate the molding. The burgers were molded considering 2.0 cm height and 9.0 cm diameter. The samples were individually sealed in a high-density polyethylene film and, then, frozen at −10 °C. The burgers, thawed, were heated on a hot plate temperature at 175 ± 5 °C (General Electric HGW 1012X—B & D Ltd., Brazil) for 3 min to ensure a minimum temperature of 72 °C at the geometrical center of the pieces. This methodology was adapted from Piñero et al. (2008) and Aleson-Carbonell et al. (2005).

Texture of chicken burgers

The instrumental evaluation of the cooked burgers texture was performed using a texturometer (Stable Micro System Mod. TA.XT 2i/25, Texture Technologies Corp., Scarsdale, USA) with a TA-4 probe, coupled to a computerized information system. The samples were cut into a cylindrical shape with pre-defined size (2 cm high × 2 cm diameter), at room temperature, from the central region of the burgers. The analysis parameters were: 3 mm/s of compression velocity, 70 % of compression percentage, and 3 s of time among cycles, as the methodology proposed by Wan Rosli et al. (2011).

Sensory evaluation of chicken burgers

The sensory evaluation of the burgers was carried out as acceptance test where a hedonic scale with 7 points was applied, with terms defined as “I like very much” to “dislike very much” in the scale extremes (Lawless and Heymann 1998). The samples were evaluated by a panel of 50 untrained judges. Sensory tests were made of the cooked product, served at approximately 45 °C (consumption temperature), with maximum of five samples (15–20 g/each) to avoid sensorial fatigue of the judges. The evaluated attributes were: appearance, aroma, flavor, texture and overall acceptability. The analyses were conducted in individual booths, illuminated with white light. Water was available at room temperature for palate cleansing between evaluations.

This work was approved by the Ethics and Human Research Committee of the Federal University of Santa Catarina (Process 1855—CONEP FR 408307).

Statistical evaluation

The results were evaluated by analysis of variance with one factor (ANOVA), followed by the Tukey test in order to identify the difference among the values (P < 0.05), in the fiber evaluation. The Dunnett’s test was used to check the difference of results between the experiments and the control (P < 0.05) in the burgers evaluation. For the sensory evaluation panel, an analysis of the main components was used, followed by an internal preference map. The results were analyzed using the Statistica software version 8.0 (Statsoft Inc., USA). All results are presented as average, related to the arithmetic average of triplicate assays (average ± standard deviation).

Results and discussion

Nutritional composition of vegetable fibers

Table 2 presents the results obtained by the analysis of nutritional composition for the six vegetable fibers evaluated. The results (Table 2) showed that all fibers have low contents of fat and ash and, as expected, the carbohydrate content of the vegetable fibers was high. The moisture, ash and carbohydrates contents of all fibers were statistically different, probably due to the differences on fibers vegetable structure. The nutritional composition results showed that the fibers could be used as food ingredients with low ash and fat contents, and variable protein content (Rosell et al. 2009).

Table 2.

Nutritional composition of the commercial vegetable fibers

| Vegetable fiber: | Moisture content (g/100 g)1 | Fat content (g/100 g)1 | Protein content (g/100 g)1 | Ash content (g/100 g)1 | Carbohydrate content (g/100 g)1,2 |

|---|---|---|---|---|---|

| Oat | 7.55 ± 0.03d | 0.30 ± 0.04e | 0.96 ± 0.00d | 1.91 ± 0.03c | 89.28 ± 0.02b |

| Bamboo | 7.12 ± 0.02f | 1.03 ± 0.03c | 0.77 ± 0.00d | 0.11 ± 0.03f | 90.96 ± 0.01a |

| Potato | 13.38 ± 0.03a | 1.40 ± 0.06b | 4.2 ± 0.1c | 2.07 ± 0.02b | 78.99 ± 0.07f |

| Pea | 9.50 ± 0.02c | 1.01 ± 0.01c | 6.90 ± 0.08a | 2.97 ± 0.01a | 79.61 ± 0.06e |

| Apple | 7.34 ± 0.04e | 3.16 ± 0.05a | 4.8 ± 0.1b | 1.50 ± 0.02d | 83.3 ± 0.1d |

| Wheat | 9.97 ± 0.01b | 0.72 ± 0.03d | 0.9 ± 0.1d | 0.73 ± 0.03e | 87.8 ± 0.1c |

1a, b, c, d, e, f should read as same letter in same column indicates no statistical difference among values (P < 0.05)

2Carbohydrate content calculated by difference between 100 % and total content of all other nutritional parameters

Grigelmo-Miguel and Martín-Belloso (1999) nutritionally characterized the orange fiber finding moisture content below 10 %, a level that can be considered adequate to prevent the development of most microorganisms. For fruit fibers, the amount of carbohydrates and lipids are related to the ripening degree of the raw material. With the maturing progress, the lipid content tends to decrease and the sugar amount increases. Figuerola et al. (2005) evaluated eight different concentrates of fruits fibers and found a moisture content ranging from 2.0 to 10.5 %, ash content from 0.56 to 3.91 %, and of fat content from 0.89 to 4.46 %. The protein levels were higher than the ones observed in the present study (between 3.12 and 8.42 %), and such differences may be related to the mild treatments of the fiber pulps and peel washing, which enabled a low removal of proteins.

Table 3 shows the results of the analysis of total and insoluble dietary fibers fractions for all fibers evaluated. According to the results, potato and apple fibers had a total dietary fiber content considered statistically similar and lower than other vegetable fibers. According Figuerola et al. (2005), food products that contain above 60 % total dietary fiber in their composition can be considered as rich-fiber sources. The analysis results show that oat, bamboo, peas and wheat fibers, evaluated in the present study, can be considered as fibers sources due to their total dietary fiber contents (Table 3). The highest portion of total dietary fiber correspond to the insoluble fraction (Table 3). The same results were found by other studies for lemon, orange and apple fibers (Figuerola et al. 2005), chia, jack bean and passion fruit fibers (Vázquez-Ovando et al. 2009), and fibrous materials from crop residues (Kuan and Liong 2008). Because of the high content of insoluble fiber observed in the present work, the six types of fibers evaluated in this study could provide pronounced effects on intestinal regulation and fecal volume (Gray 2006). In addition, high insoluble fiber content can promote a greater sense of satiety, decrease constipation problems and, consequently, reduce the incidence of colorectal cancer (Vázquez-Ovando et al. 2009).

Table 3.

Fiber composition and color parameters of the commercial vegetable fibers

| Vegetable fiber | Fiber composition | Color parameters | ||||

|---|---|---|---|---|---|---|

| Total1 | Soluble1 | Insoluble1 | L* 1 | a* 1 | b* 1 | |

| Oat | 86.12 ± 0.01c | 2.0 ± 0.3c | 84.1 ± 0.3c | 91.6 ± 0.7a | −2.2 ± 0.1e | 11.5 ± 0.2d |

| Bamboo | 91 ± 1ª | 0 ± 0d | 91 ± 1a | 93.1 ± 0.7a | −0.7 ± 0.1d | 4.1 ± 0.4f |

| Potato | 56.6 ± 0.9e | 6.7 ± 0.1b | 50.0 ± 0.8e | 74.4 ± 0.1c | 2.52 ± 0.01b | 15.8 ± 0.1b |

| Pea | 65.3 ± 0.1d | 1.5 ± 0.1c | 63.75 ± 0.03d | 89.4 ± 0.2b | 0.01 ± 0.01c | 12.48 ± 0.04c |

| Apple | 54.5 ± 0.5e | 11.3 ± 0.1a | 43.2 ± 0.4f | 54.2 ± 0.9d | 8.6 ± 0.3a | 17.8 ± 0.2a |

| Wheat | 87.9 ± 0.4b | 0.7 ± 0.2d | 87.2 ± 0.1b | 89.0 ± 0.6b | −0.4 ± 0.1d | 6.74 ± 0.06e |

1a, b, c, d, e, f should read as same letter in same column indicates no statistical difference among values (P < 0.05)

Color analysis of vegetable fibers

Table 3 also shows the results of the color measurements for the six different vegetable fibers evaluated in this work. The L* value measures the sample brightness, ranging from 0 (pure black) to 100 (pure white). The potato and apple fibers showed the lowest L* values, i.e., presented the darkest brightness, which is due to the darker colors obtained from fibers sources (fruit/vegetable peels). The a* and b* values represent tonality and saturation levels, where: +a* = redness, −a* = greenness, +b* = yellowness, and +b* = blueness, with scales range from −60 to +60. The bamboo and wheat fibers are the closest to the white color (highest L* values and a* and b* values close to zero). The color results of apple fiber showed a tendency toward a brown color whereas the other fibers trended to a yellow color. This information can be useful in predicting the impact of the vegetable fiber color over conventional color of the product where it will be applied.

Physicochemical and technological properties of vegetable fibers

The results for water holding capacity and swelling capacity for the vegetable fibers evaluated in the present study are shown in Table 4. The highest values of water holding capacity and swelling capacity were obtained by pea and by wheat fibers, followed by oat and bamboo fibers. The potato and apple fibers showed the lowest values of water holding capacity and swelling capacity. The water holding capacity values reported by Rosell et al. (2009) for bamboo fiber (4.83) and by Sangnark and Noomhorm (2003) for sugarcane bagasse fiber (4.98) were similar to those of the bamboo fiber in the present study. The hydration properties results of cereal fibers (wheat and oat) presented in Table 4 show some differences when compared with other studies (Rosell et al. 2009; Grigelmo-Miguel and Martín-Belloso 1999; Vázquez-Ovando et al. 2009). These differences can be related to variations in the fibers particle size, in nutritional composition and also on the variety of the cereal that provided the fiber samples (Carvalho et al. 2009).

Table 4.

Physicochemical and technological properties of vegetable fibers evaluated

| Vegetable fiber | Water holding capacity (g water/g solid)1 | Swelling capacity (mL/g dry base)1 | Oil holding capacity (g oil/g solid)1 | Bulk density (g/L)1 | Emulsifying capacity (%)1 | Emulsion stability (%)1 |

|---|---|---|---|---|---|---|

| Oat | 4.59 ± 0.09c | 9.5 ± 0.3c | 3.69 ± 0.09c | 141.8 ± 0.2d | 53.0 ± 0.4c | 51.9 ± 0.2b |

| Bamboo | 4.37 ± 0.08c | 9.1 ± 0.1c | 4.62 ± 0.03a | 117.0 ± 0.1e | 56.4 ± 0.5b | 51.0 ± 0.9b |

| Potato | 3.71 ± 0.09d | 5.7 ± 0.1e | 2.00 ± 0.04d | 370.6 ± 0.3c | 30.6 ± 0.1f | 29.9 ± 0.4e |

| Pea | 6.8 ± 0.2a | 15.9 ± 0.2a | 2.02 ± 0.01d | 408.1 ± 0.3b | 49.0 ± 0.3d | 48.2 ± 0.9c |

| Apple | 3.20 ± 0.07e | 7.0 ± 0.1d | 1.47 ± 0.04e | 494.0 ± 0.2a | 37.0 ± 0.2e | 35.0 ± 0.8d |

| Wheat | 5.3 ± 0.1b | 12.9 ± 0.2b | 4.38 ± 0.05b | 105.7 ± 0.3f | 57.9 ± 0.2a | 56.8 ± 0.9a |

1a, b, c, d, e, f should read as same letter in same column indicates no statistical difference among values (P < 0.05)

Apple, potato and pea fibers also presented the lowest values of oil holding capacity (Table 4). The low oil holding capacities of these mentioned fibers are due to their lower amount of total dietary fiber compared to cereals and bamboo fibers. Pea and potato fibers present naturally resistant starch (Rosell et al. 2009) and, according to Kuan and Liong (2008), fibrous materials that contain high starch amounts provide lower oil holding capacity when compared with other fibrous products with lower starch contents. The oil retention capacity is also a property that has physiological effects, since it can interfere in the intestinal fat absorption, influencing in the body weight control and in the regulation of blood lipid profiles (Carvalho et al. 2009). Table 3 also presents the bulk density results of the evaluated vegetable fibers. According to the results, the cereals and bamboo fibers presented lower density values compared to apple, potatoes and pea fibers. This property depends on the typical structural characteristics of each material, besides its particle size and particle size distribution (Grigelmo-Miguel and Martín-Belloso 1999).

The results of emulsifying activity and emulsion stability of the vegetable fibers are shown in Table 4. These results indicated that all studied fibers present important emulsifying activity, i.e., can assist in the emulsions processing, as well as showing good stability after heating and cooling. All the fibers showed emulsifying activity results statistically different. The cereals (wheat and oat) and bamboo fibers presented the highest values of emulsifying activity and emulsion stability. The shape of the particles, the hydrophilic and lipophilic properties, and the fiber components can affect the differences among the emulsion properties results. Wong and Cheung (2005) reported that dietary fibers with emulsifying activity values above 50 %, as for oat, by wheat and by bamboo fibers (Table 4), could be considered good emulsifying agents.

Considering the results combination of the higher values of hygroscopic properties and dietary fiber composition, besides the color parameters similar to the chicken obtained for all the vegetable fibers evaluated, we were able to define bamboo, wheat and pea fibers as the selected materials to be applied in the chicken burger formulations (Sect. 3.4).

Texture of chicken burgers

The results obtained for the texture evaluation for all chicken burger formulations are presented in Table 5. The results for hardness were mostly significantly lower (P < 0.05) than the control sample, except for the formulations from assays 4, 8, 10 and the triplicate center point (assays 15, 16, 17) that are equal or superior than the control. These results indicate that the formulations are softer, i.e., the replacement of animal fat (chicken skin) by hydrated vegetable fibers in the burgers formulations, compared to control burger, changed the product structure, providing less resistance to deformation.

Table 5.

Texture instrumental profile of control burger (with chicken fat) and chicken burgers added with vegetable fibers

| Assay1 | Hardness (kgf)2 | Adhesiveness (kgf.s)2 | Elasticity (mm)2 | Cohesiveness2 | Chewiness (kgf.mm)2 |

|---|---|---|---|---|---|

| Control | 11.0 ± 0.4a | −1.1 ± 0.4a | 0.79 ± 0.04a | 0.38 ± 0.04a | 3.3 ± 0.4a |

| 1 | 7.38 ± 0.03h | −1.3 ± 0.4abcd | 0.76 ± 0.01ab | 0.36 ± 0.02abc | 2.0 ± 0.1f |

| 2 | 10.17 ± 0.05de | −1.1 ± 0.2abc | 0.78 ± 0.01ab | 0.40 ± 0.01abc | 3.16 ± 0.04abcd |

| 3 | 8.9 ± 0.1f | −2.5 ± 0.4d | 0.77 ± 0.02ab | 0.35 ± 0.01abc | 2.4 ± 0.1ef |

| 4 | 12.2 ± 0.2b | −0.7 ± 0.2abc | 0.78 ± 0.01ab | 0.39 ± 0.04abc | 3.7 ± 0.4ab |

| 5 | 10.9 ± 0.2acd | −0.2 ± 0.1ab | 0.78 ± 0.02ab | 0.41 ± 0.04ab | 3.4 ± 0.3ab |

| 6 | 8.29 ± 0.08fg | −2.4 ± 0.4d | 0.78 ± 0.01ab | 0.38 ± 0.02abc | 2.5 ± 0.1ef |

| 7 | 8.11 ± 0.02gh | −1.1 ± 0.4abc | 0.77 ± 0.01ab | 0.37 ± 0.02abc | 2.3 ± 0.2ef |

| 8 | 11 ± 1ac | −0.6 ± 0.4abc | 0.78 ± 0.01ab | 0.38 ± 0.04abc | 3.4 ± 0.2abc |

| 9 | 9.9 ± 0.2e | −1.7 ± 0.4acd | 0.79 ± 0.01ab | 0.36 ± 0.02abc | 2.8 ± 0.2cde |

| 10 | 11.4 ± 0.4ac | −1.5 ± 0.4acd | 0.77 ± 0.01ab | 0.40 ± 0.01abc | 3.5 ± 0.2ab |

| 11 | 10.2 ± 0.1de | −1.1 ± 0.5abc | 0.79 ± 0.02ab | 0.40 ± 0.01abc | 3.2 ± 0.1abc |

| 12 | 9.8 ± 0.2e | −0.6 ± 0.2abc | 0.75 ± 0.01ab | 0.34 ± 0.01ac | 2.5 ± 0.2ef |

| 13 | 8.4 ± 0.2fg | −1.6 ± 0.4acd | 0.77 ± 0.02ab | 0.37 ± 0.01abc | 2.4 ± 0.2ef |

| 14 | 9.0 ± 0.2f | −0.6 ± 0.3abc | 0.77 ± 0.03ab | 0.37 ± 0.02abc | 2.6 ± 0.2def |

| 15 | 11.3 ± 0.2ac | −0.7 ± 0.4abc | 0.78 ± 0.02ab | 0.37 ± 0.03abc | 3.4 ± 0.3ab |

| 16 | 11.4 ± 0.2ac | −1.0 ± 0.6abc | 0.77 ± 0.01ab | 0.40 ± 0.01abc | 3.5 ± 0.2ab |

| 17 | 11.1 ± 0.3ac | −0.8 ± 0.8abc | 0.78 ± 0.01ab | 0.39 ± 0.02abc | 3.4 ± 0.2ab |

1Control: no addition of vegetable fibers and with 10 % of chicken skin; 1: 0.4 % B, 0.4 % W e 0.4 % P; 2: 1.6 % B, 0.4 % W e 0.4 % P; 3: 0.4 % B, 1.6 % W e 0.4 % P; 4: 1.6 % B, 1.6 % W e 0.4 % P; 5: 0.4 % B, 0.4 % W e 1.6 % P; 6: 1.6 % B, 0.4 % W e 1.6 % P; 7: 0.4 % B, 1.6 % W e 1.6 % P; 8: 1.6 % B, 1.6 % W e 1.6 % P; 9: 1.0 % W e 1.0 % P; 10: 2.0 % B, 1.0 % W e 1.0 % P; 11: 1.0 % B e 1.0 % P; 12: 1.0 % B, 2.0 % W e 1.0 % P; 13: 1.0 % B e 1.0 % W; 14: 1.0 % B, 1.0 % W e 2.0 % P; 15: 1.0 % B, 1.0 % W e 1.0 % P; 16: 1.0 % B, 1.0 % W e 1.0 % P; 17: 1.0 % B, 1.0 % W e 1.0 % P—where: B bamboo fiber, W wheat fiber, P pea fiber

2a, b, c, d, e, f, g, h should read as same letter in same column indicates no statistical difference among values (P < 0.05): (a) Dunnett Test; (b–f) Tukey Test

The elasticity and the cohesiveness of the burger samples were considered, in general, statistically equal among each formulation and compared to the control (P > 0.05). Particularly, (a) adhesiveness values are statistically equal to the control (P > 0.05), except for samples 3 and 6; (b) Assays 1, 3, 6, 7, 9, 12, 13 and 14 showed chewiness results statistically lower than the control sample, indicating a lower elastic resistance of the respective formulations of chicken burgers. This behavior was probably due to the lower hardness values detected by the mentioned assays.

The mentioned texture results may be considered satisfactory from the industrial point of view, because it does not mischaracterized the textural properties already known and accepted by the consumers for this type of product currently marketed without the addition of vegetable fibers. However, it was not possible to establish a correlation among all the fibers contents and the texture attributes.

Some authors evaluated the impact of adding functional ingredients in the textural parameters of restructured meat products. According Aleson-Carbonell et al. (2005), if there are variations in the cohesiveness parameter in the raw product, after preparation they tend to disappear due to several factors, including the proteins coagulation. In the present work, this fact can be observed where there was no significant difference in cohesiveness values for the cooked product. Martínez et al. (2011) also found that pretreatment with transglutaminase, at 40 °C and 17 min-reaction, could enhance the texture of beef burger enriched with oat and inulin fibers, reaching values close to regular texture values (products without fibers).

Sensory evaluation of chicken burgers

The internal preference map is a valuable tool for exploring and understanding the structure and tendencies of consumers’ preferences. It is similar to a principal component analysis (PCA) performed on the matrix of hedonic data obtained in a consumer test. The algorithm initially computed the intercorrelations among the variables (assays and judges). Then the data matrix was transformed through estimation of a factor model to obtain a factor matrix. Combinations of the loadings of each variable formed sensory dimensions (like factors on the PCA model), upon which the underlying structures of consumer preferences were represented. The number of dimensions derived in the analysis depends on the extent to which each variable can be explained, so that new dimensions are derived until 100 per cent of the whole variability in liking can be represented. As the first two dimensions account for most of the explanation, they were used to build the biplots (Miquelim et al. 2008).

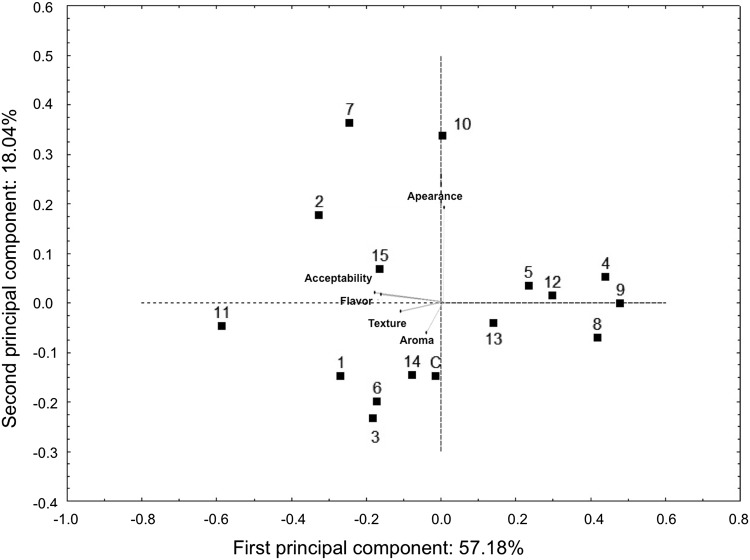

Figure 1 shows a graphical representation of the principal component analysis performed for the sensory evaluations rates obtained in this study. The first principal component explained 57.18 % of the total discrimination among samples, while the second component elucidated 18.04 %, totalling 75.22 %. The two components were considered sufficient to represent the samples dispersion, as they explain most of the data variation obtained in terms of their sensory acceptability. 57.18 % of the variability among samples, explained by the first principal component, was due mainly to the overall acceptability, flavor and texture attributes, which showed a correlation coefficient above 0.89 with this component. With respect to the second principal component (18.04 %), the variability is associated with appearance attribute (correlation coefficient >0.97).

Fig. 1.

Principal component analysis of sensory attributes evaluated for burgers prepared using different formulations

Figure 1 also illustrates that the first principal component allows greater discrimination between the samples 11, 4, 8 and 9, placing them on opposite ends of the axis. The second principal component indicated a difference of 7, 10 and 2 samples from the 1, 3, 6, 14 and control samples. In the principal component analysis, the samples are located in the same region of the attributes vector that characterize them. Then, sample 11 was the most accepted flavor and overall acceptability, while samples 4, 8 and 9 had a worse performance in these attributes. For the second principal component, it was observed that samples 7 and 10 were characterized by a better appearance and, finally, samples 6 and 3 showed better aroma.

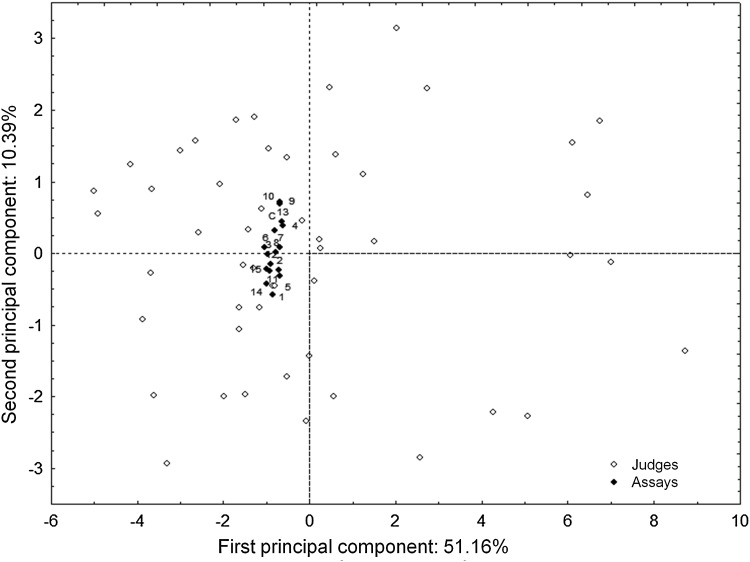

Figure 2 shows the internal preference map related to the overall acceptability of the burgers. The map could be considered satisfactory, since the first and second principal components explained 61.5 % of the variance of the evaluated data. According Lawless and Heymann (1998), points near zero-intersection of the axes indicate low variability among the judges’ opinions for a given sample. In this case, samples 6, 9, 14 and 15 showed the highest divergences of opinion as to the general acceptability attribute. However, samples 2, 4, 5 and 7 showed the highest agreement (smaller vectors). With the exception of the assay 9, it was observed that all samples were well accepted (average rating of 5.0 that corresponds to “like very much”), and this is evidenced by the samples aggregation in the same map area, with no sample located in opposite direction. Regarding the judges’ preference, it is evident a separation of them into two groups: a larger group of judges next to the samples (left side of the map) and another smaller group a little farther. Individuals with similarities in the general acceptability were closer to each other, showing that the samples had good performance on this attribute. It was not shown a preference or clear rejection by a particular sample, since all were very well accepted. This lack of definition is illustrated by the absence of a large concentration of judges in a given map region.

Fig. 2.

Internal preference map of burgers formulations developed in relation to the general acceptability attributes

Conclusion

All fibers evaluated in this study have some physicochemical or technological characteristic that allow their application in meat products. Regarding color, wheat, bamboo, oat, potato and pea fibers could be used in chicken base products, since they have light tonality (white or yellow/beige). All fibers were hydrophilic and, with lesser degree of lipophilicity. The bamboo and cereals fibers showed the best emulsifying properties among the tested fibers. Therefore, the evaluated plant fibers may be an interesting alternative for the production of meat products with prebiotic and functional appeal. In this way, the use of a mixture of vegetable fibers as fat substitutes in chicken burger demonstrated a promising option to check the functionality of foods considered unhealthy. Much of the formulations developed in the present work had a positive performance in the sensory evaluation (greater or equal in comparison with the control sample). However, the formulation containing the mix of 0.40 % bamboo fiber, 1.60 % wheat fiber and 1.60 % pea fiber had the highest sensorial acceptance index, besides presenting a higher tenderness compared to the control sample. The preference map methodology illustrates that all samples were considered with good acceptability, since the addition of the vegetable fiber mix did not affect the average scores of the sensory attributes evaluated.

Acknowledgments

The authors wish to thank CNPq and CAPES (Project Number 23038.007787/2011-70; AUXPE: 2516/2011), Brazilian funding agencies, for the financial support and scholarships that sustain this work.

References

- AACC-American Association of Cereal Chemists (1999) Approved methods of analysis. AACC International Inc., St. Paul, MN

- Aleson-Carbonell L, et al. Characteristics of beef burger as influenced by various types of lemon albedo. Innov Food Sci Emerg Technol. 2005;6(2):247–255. doi: 10.1016/j.ifset.2005.01.002. [DOI] [Google Scholar]

- AOAC-Association of Official Analytical Chemists (1990) Official methods of analysis of AOAC international, vol 2, 16 ed. Association of Official Analytical Chemists, Inc., Gaithersburg, MD

- Arihara K. Strategies for designing novel functional meat products. Meat Sci. 2006;74(1):219–229. doi: 10.1016/j.meatsci.2006.04.028. [DOI] [PubMed] [Google Scholar]

- Carvalho AFU, et al. Physiological and physico-chemical characterization of dietary fibre from the green seaweed Ulva fasciata Delile. Braz J Biol. 2009;69(3):969–977. doi: 10.1590/S1519-69842009000400028. [DOI] [PubMed] [Google Scholar]

- CIE (2004) Colorimetry, 3. ed. Publication CIE 15.3:2004: Commission Internationale de l’Eclairage. Paris, France

- Dutcosky SD. Análise Sensorial de Alimentos. 3. Curitiba: Champagnat; 2011. p. 426. [Google Scholar]

- Figuerola F, et al. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005;91(3):395–401. doi: 10.1016/j.foodchem.2004.04.036. [DOI] [Google Scholar]

- García ML, et al. Beef hamburgers enriched in lycopene using dry tomato peel as an ingredient. Meat Sci. 2009;83(1):45–49. doi: 10.1016/j.meatsci.2009.03.009. [DOI] [PubMed] [Google Scholar]

- Gray J. Dietary fiber: definition, analysis, physiology and health. Belgium: International Life Sciences Institute (ILSI); 2006. [Google Scholar]

- Grigelmo-Miguel N, Martín-Belloso O. Characterization of dietary fiber from orange juice extraction. Food Res Int. 1999;31(5):355–361. doi: 10.1016/S0963-9969(98)00087-8. [DOI] [Google Scholar]

- Jiménez-Colmenero F, et al. Healthier meat and meat products: their role as functional foods. Meat Sci. 2001;59(1):5–13. doi: 10.1016/S0309-1740(01)00053-5. [DOI] [PubMed] [Google Scholar]

- Kemp SE, et al. Sensory evaluation: a practical handbook. Oxford: Wiley-Blackwell; 2009. [Google Scholar]

- Kuan YH, Liong MT. Chemical and physicochemical characterization of agrowaste fibrous materials and residues. J Agric Food Chem. 2008;56:9252–9257. doi: 10.1021/jf802011j. [DOI] [PubMed] [Google Scholar]

- Lawless HT, Heymann H. Sensory evaluation of food. New York: Chapman & Hall; 1998. [Google Scholar]

- Martínez B, et al. Evaluation of transglutaminase and caseinate for a novel formulation of beef patties enriched in healthier lipid and dietary fiber. LWT Food Sci Technol. 2011;44(4):949–956. doi: 10.1016/j.lwt.2010.11.026. [DOI] [Google Scholar]

- Miquelim JN, et al. Analysis of Brazilian conzumer preference of filled chocolate. Ciência e Tecnologia de Alimentos. 2008;28:493–497. doi: 10.1590/S0101-20612008000200034. [DOI] [Google Scholar]

- Olivo R, Olivo N. O mundo das carnes: ciência, tecnologia & mercado. Criciúma: Ed. autor; 2005. [Google Scholar]

- Piñero MP, et al. Effect of oat´s soluble fibre (β-glucan) as a fat replacer on physical, chemical, microbiological and sensory properties of low-fat beef patties. Meat Sci. 2008;80(3):675–680. doi: 10.1016/j.meatsci.2008.03.006. [DOI] [PubMed] [Google Scholar]

- Prakongpan T, et al. Extraction and application of dietary fiber and cellulose from pineapple cores. J Food Sci. 2002;67(4):1308–1313. doi: 10.1111/j.1365-2621.2002.tb10279.x. [DOI] [Google Scholar]

- Robertson J, et al. Hydration properties of dietary fibre and resistant starch: a European collaborative study. Lebensm Wiss Technol. 2000;33:72–79. doi: 10.1006/fstl.1999.0595. [DOI] [Google Scholar]

- Rodríguez R, et al. Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci Technol. 2006;17(1):3–15. doi: 10.1016/j.tifs.2005.10.002. [DOI] [Google Scholar]

- Rosell CM, et al. Physico-chemical properties of commercial fibres from different sources: a comparative approach. Food Res Int. 2009;42(1):176–184. doi: 10.1016/j.foodres.2008.10.003. [DOI] [Google Scholar]

- Sangnark A, Noomhorm A. Effect of particle sizes on functional properties of dietary fibre prepared from sugarcane bagasse. Food Chem. 2003;80(2):221–229. doi: 10.1016/S0308-8146(02)00257-1. [DOI] [Google Scholar]

- Vázquez-Ovando A, et al. Physicochemical properties of a fibrous fraction from chia (Salvia hispanica L.) Lebensm Wiss Technol. 2009;42:168–173. doi: 10.1016/j.lwt.2008.05.012. [DOI] [Google Scholar]

- Wan Rosli WI, et al. Colour, textural properties, cooking characteristics and fibre content of chicken patty added with oyster mushroom (Pleurotus sajor-caju) Int Food Res J. 2011;18(2):612–618. [Google Scholar]

- Weiss J, et al. Advances in ingredient and processing systems for meat and meat products. Meat Sci. 2010;86(1):196–213. doi: 10.1016/j.meatsci.2010.05.008. [DOI] [PubMed] [Google Scholar]

- Wong K, Cheung PCK. Dietary fibers from mushroom sclerotia: 1. Preparation and physicochemical and functional properties. J Agric Food Chem. 2005;53(24):9395–9400. doi: 10.1021/jf0510788. [DOI] [PubMed] [Google Scholar]