Abstract

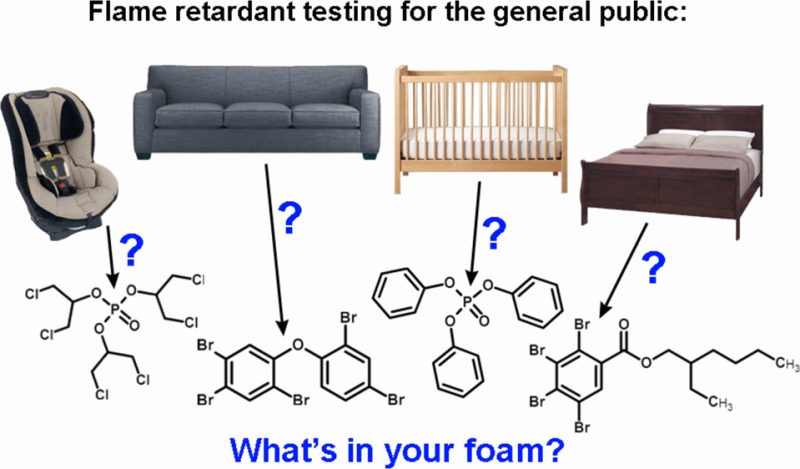

Flame retardant (FR) chemicals have often been added to polyurethane foam to meet required state and federal flammability standards. However, some FRs (e.g., PBDEs and TDCIPP) are associated with health hazards and are now restricted from use in some regions. In addition, California’s residential furniture flammability standard (TB-117) has undergone significant amendments over the past few years, and TDCIPP has been added to California’s Proposition 65 list. These events have likely led to shifts in the types of FRs used, and the products to which they are applied. To provide more information on the use of FRs in products containing polyurethane foam (PUF), we established a screening service for the general public. Participants residing in the US were allowed to submit up to 5 samples from their household for analysis, free of charge, and supplied information on the product category, labeling, and year and state of purchase. Between February 2014 and June 2016, we received 1141 PUF samples for analysis from various products including sofas, chairs, mattresses, car seats and pillows. Of these samples tested, 52% contained a FR at levels greater than 1% by weight. Tris(1,3-dichloroisopropyl)phosphate (TDCIPP) was the most common FR detected in PUF samples, and was the most common FR detected in all product categories. Analysis of the data by purchasing date suggests that the use of TDCIPP decreased in recent years, paralleled with an increase in the use of TCIPP and a nonhalogenated aryl phosphate mixture we call “TBPP.” In addition, we observed significant decreases in FR applications in furniture products and child car seats, suggesting the use of additive FRs in PUF may be declining, perhaps as a reflection of recent changes to TB-117 and Proposition 65. More studies are needed to determine how these changes in FR use relate to changes in exposure among the general population.

Introduction

Due to increasing numbers of home fires in which furniture was often an item first ignited, the California Bureau of Electronic and Appliance Repair, Home Furnishings and Thermal Insulation implemented a residential flammability standard known as Technical Bulletin 117 (TB-117) in 1972.1 This standard required that resilient filling materials used in upholstered furniture meet a 12 s, open-flame test designed to reduce the ignition time and combustibility of the material. To meet this standard, furniture manufacturers have historically used additive chemical treatments, which primarily include applications of brominated and/or organophosphate flame retardants (FRs) to the polyurethane foam used as filling materials.2,3 Brominated FRs work by releasing bromine radicals into the gas phase, which help to quench the reactions that propagate fire. In contrast, organophosphate FRs typically work in the solid phase by increasing a char layer, which reduces oxygen and diminishes the spread of the flame.4,5

The high use of these types of FRs in furniture has been suggested to contribute to higher exposure among the general population, particularly for children, and to increased risks for adverse health outcomes.6,7 In 2001, Noren and Meiryonte published a paper in which they examined the historical trends in persistent organic pollutant levels in breast milk collected from women in Sweden as a means of evaluating temporal changes in exposure.8 Although they observed decreases in dichlorodiphenyl trichloroethane (DDT), dioxins, and polychlorinated biphenyls with time (due to bans and restrictions placed on DDT use), the levels of polybrominated diphenyl ethers (PBDEs) were observed to be increasing rapidly. Several successive studies also observed similar trends for PBDEs in human and animal tissues,9−11 suggesting that exposure was increasing with doubling times ranging from 2 to 7 years. Within the last 10 years alone, hundreds of studies have been conducted examining the environmental distribution, fate and toxicity of PBDEs. Due to mounting evidence suggesting that PBDEs were persistent, highly bioaccumulative, and potentially toxic, the three primary PBDE commercial mixtures (PentaBDE, OctaBDE and DecaBDE) were subsequently either banned from use or voluntarily phased-out of manufacturing, depending on the region.12 This led to a significant shift away from the use of PBDEs (i.e., PentaBDE) and toward other types of brominated and organophosphate FRs to meet TB-117. Based on our previous studies,3,13 our data suggest that manufacturers primarily moved to chlorinated organophosphate flame retardants (e.g., tris(1,3-dichloro-isopropyl)phosphate, TDCIPP), or a mixture known as Firemaster550 [FM550], which consists of a mixture of brominated aryl esters and triaryl phosphate esters.14 New studies are now demonstrating that exposure to TDCIPP and FM550 is also becoming ubiquitous among the general US population.15−18 The other chlorinated organophosphate FRs (e.g., Tris (chloropropyl) phosphate, TCIPP) are now also detected ubiquitously in Australian and European populations as well.19−21 Human exposure to additive FRs may occur through inhalation, ingestion, and dermal absorption.22−24 Given that recent research indicates considerable potential for dermal absorption of the chlorinated FRs commonly found in furniture (TDCIPP, TCIPP),23 concern for human exposure from contact with furniture and other foam-containing consumer products is warranted. Recent animal studies suggest that exposure to TDCIPP and components present in FM550 can lead to reproductive and developmental effects including reduced fecundity, problems with heart development, reductions in bone development25−30 and even cancer.31 Therefore, the use of current FRs in residential furniture may still lead to increased risks for adverse health outcomes.

Due to these concerns, and to the fact that a majority of home fires involving furniture are ignited via cigarettes and not via an open flame, the state of California recently revised TB-117 (now known as TB117-2013) from an open flame test to a smolder-ignition standard. In 2014, the State of California added a new law (SB1019) requiring all furniture be sold with a label indicating whether or not the furniture is chemically treated with a FR. However, it is currently unclear how these changes to California standards will affect the use of FRs in furniture, and how these changes will relate to exposures among the general population.

To prioritize FRs for human exposure assessments and biomonitoring programs, scientists and policy-makers must understand which FRs are used most frequently, and in what products. Currently, this information is not publicly available, and chemical treatments can be identified only through material analysis. In 2011 and 2012, we reported on the levels of additive FRs in infant products and residential sofas;3,13 however, other types of products containing polyurethane foam were not tested (e.g., mattress pads, chairs, pillows etc.). Furthermore, TB-117 was significantly altered in 2013, which may alter the way FRs are used in furniture. Therefore, to understand better the use of and potential exposure to FRs in products containing polyurethane foam (PUF), we initiated a program in collaboration with Duke University’s Superfund Research Center that allowed members of the general US population to submit samples for testing free of charge. To our knowledge, this is the first and only free service available to the public for testing FRs in foam. Our research objectives were to analyze products containing PUF for 7 common additive FRs to determine which FRs are more commonly used across various products. A secondary objective was to determine if the use of additive FRs has changed over time. When submitting samples for testing, participants were asked to provide information on the type of product (e.g., sofa, chair, mattress, etc.), year and state in which the product was purchased, and whether or not the product contains a TB-117 label. Between February 2014 and June 2016, we received 1141 samples for testing. Here we summarize our findings from these analyses, and report on trends by product category and changes in flame retardant use over time.

Materials and Methods

Participant Recruitment and Sample Submission

Participant enrollment and sample submission is handled through the project Web site (http://foam.pratt.duke.edu). Email advertisements were used to assist recruitment, which was bolstered by news and media reports on flame retardant chemicals, blogs mentioning our project (∼31% of traffic to our Web site), social media (∼5% Web site traffic), academic partners and relevant interest groups. Search engines and direct traffic account for over 50% of Web site traffic. Participants were United States residents age 18 or older. For each sample, participants completed a questionnaire regarding contact information and product details including the product type, whether the product was intended for a child or adult, what kind of flammability standard label was present (e.g., CA TB-117 or CFR 1632), and year and state in which the product was purchased. Product types included sofas and loveseats (i.e., two-seat furniture pieces), chairs, rocking chairs and recliners, other furniture, mattresses, mattress pads (i.e., cushions that sit on top of and are separate from mattresses), child mattresses, child car seats, pillows, other child products, pit cubes/gymnastics equipment, other (miscellaneous). Following completion of the questionnaire, participants were given instructions for sampling, packaging, and mailing the PUF sample to Duke University for testing. Each participant was asked to cut out a small marble-sized piece of PUF from their product, wrap it tightly in aluminum foil, seal it in a plastic bag, and mail it to the address provided. Approximately 6 to 8 weeks later, the participants were mailed a letter providing their results. All study protocols were approved by the institutional review board at Duke University.

Sample Analyses

Materials

Standards of the PentaBDE technical mixture, 2,2-bis(chloromethyl)propane-1,3-diyl-tetrakis(2-chloroethyl)bis(phosphate) (V6), 2-ethylhexyl 2,3,4,5-tetrabromobenzoate (TBB, aka EHTBB) and (2-ethylhexyl) tetrabromophthalate (TBPH, aka BEHTBP) were purchased from Wellington Laboratories. Firemaster 550 (FM550) was a gift provided by Dr. Susan Klosterhaus who had previously received the mixture from Great Lakes Chemical (West Lafayette, IN). H. Stapleton was provided a sample of polyurethane foam from a foam manufacturer in North Carolina that used Firemaster 600 (FM600) in the foam, from which a sample of FM600 was extracted and used as a standard in this project. Triphenyl phosphate (TPHP) was purchased from Sigma-Aldrich (St. Louis, MO). Tris(2-chloroethyl)phosphate (TCEP), tris(1-chloro-2-propyl) phosphate (TCIPP) and tris(1,3-dichloroisopropyl)phosphate (TDCIPP) were purchased from Sigma-Aldrich (St. Louis, MI), Pfaltz & Bauer (Waterbury, CT), and Fluka (St. Louis, MO), respectively. Dichloromethane (DCM), Acetonitrile (ACN), water and methanol were purchased from Honeywell (Muskegon, MI)

Sample Preparation

Preparation of foam samples was adapted from Stapleton et al. 2012.3 Briefly, 5 mL of DCM was added to 50 mg of foam sample in a glass test tube, and the solution was sonicated for 10 min. A 100 μL aliquot of the extract was diluted to 1 mL for analysis by gas chromatography mass spectrometry (GC/MS). A laboratory blank (test tube containing DCM but no foam) was included with each batch of samples processed. Foam extracts were first screened using gas chromatography mass spectrometry (GC/MS). Based on GC analyses, some samples required further analysis by liquid chromatography tandem mass spectrometry (UPLC/MS/MS). For these samples, 100 μL of extract was exchanged to 200 μL of methanol and diluted to 1 mL with water. Due to the generally small sample size, we were not able to conduct thorough testing to characterize physical properties of the foam (e.g., density) or classify the type of polyurethane foam.

Mass Spectrometry Analyses

A suite of mass spectrometric analyses were used to identify individual flame retardant (FR) chemicals and evaluate commercial mixtures. FRs in extracts were analyzed by GC/MS in scan mode with both electron ionization (Agilent 7890 GC, Agilent 5795C MS, Wilmington, DE) and electron capture negative ionization (Agilent 6890 GC, Agilent 5975N MS). Separation was conducted on a DB-5 column (Agilent) using a thermal gradient (40 °C for 1 min, 18 °C/min to 250 °C, 1.5 °C/min to 260 °C, 25 °C/min to 300 °C, 300 °C for 20 min). Initial inlet temperature was 80 °C for 0.3 min and then ramped 600 °C/min to 275 °C. The transfer line was held at 280 °C. Chromatograms were screened against a custom spectral library for known flame retardants. To assist in detecting FRs that were likely intentionally applied to the foam to meet flame retardant standards, FRs were semiquantitatively analyzed using authentic standards (listed above) representing a FR concentration equivalent to 1% by weight of foam. This concentration was selected based on the amounts of FRs typically applied to foam to meet flame retardant standards to limit and avoid false positives. All blanks were screened alongside samples. FRs were rarely detected in blanks, and whenever detected were well below a concentration equivalent to 0.1% by weight of foam. UPLC/MS/MS analysis for V6 was conducted on an Accela UPLC system (ThermoFisher Scientific, Bremen, Germany) with ThermoFisher TSQ Vantage triple quadrupole mass spectrometer. UPLC separation was conducted on Hypersil Gold, C18 column (ThermoFisher, 100 × 2.1 mm, 1.9 μm particle size) using an ACN: water gradient (20% ACN for 2 min to 99% ACN at 13 min, held at 99% ACN for 2 min). Injection volume was 20 μL, and flow rate was 300 μL/min. Ion transition 582.9 m/z to 360.8 m/z was used for quantification, and transitions 582.9 m/z to 296.8 m/z and 582.9 m/z to 98.9 m/z were used for confirmation. In total, seven FR commercial mixtures were evaluated in this screen using authentic standards: FM550 (TPHP, isopropylated TPHP isomers, TBB and TBPH), FM600, TDCIPP, TCIPP, V6, PentaBDE (containing TPHP, isopropylated TPHP isomers, and BDE congeners 47, 85, 99, 100, 153 and 154), “TBPP” (containing TPHP and monodi- and tributylated TPHP). Structures for FR compounds evaluated in this screen are included in Table S1.

Results and Discussion

Samples Received for Screening

Between January 2014 and June 2016, 1141 foam samples were received for testing and which were collected from a wide variety of products including upholstered furniture, mattresses, mattress toppers, a suite of child products and others (Table 1). Foam samples were submitted from 567 different households and products varied substantially by year of purchase (1960 to 2016) and state of purchase. Participant households represent 44 states, with most participants living in the following states: California (24%), North Carolina (16%), Massachusetts (9%), New York (6%), Washington (5%) and New Jersey (5%). Similarly, samples were purchased from the following states: California (22%), North Carolina (10%), New York (7%), Massachusetts (5%), online purchase (5%), Michigan (4%) and Pennsylvania (3%). Products were grouped into 12 categories, of which the most abundant category was sofas and loveseats (n = 451, 40%, Table 1; Figure 1). Child products (e.g., child car seats, child mattresses, sleep positioners) comprised 16% of all samples. Some product categories (e.g., pillows) contained very few samples; therefore, this paper reports primarily on the 7 major nonmiscellaneous product categories: sofas and loveseats, chairs, rocking chairs and recliners, mattress pads, child car seats, child mattresses, and other child products. Results from testing other product categories are provided in the Supporting Information (Figure S1).

Table 1. Description of Foam Samples Received from Project Inception through June 2016.

| category | total products | products with FRa | products with no FR detected | ||

|---|---|---|---|---|---|

| sofas and loveseats | 451 | 250 | (28.4%) | 201 | (14.9%) |

| chairs | 130 | 82 | (15.9%) | 48 | (16.7%) |

| mattress pad | 106 | 31 | (19.4%) | 75 | (18.7%) |

| child car seat | 98 | 72 | (31.9%) | 26 | (54.0%) |

| mattress | 71 | 22 | (18.2%) | 49 | (16.3%) |

| other | 59 | 25 | (20.0%) | 34 | (17.6%) |

| other child products | 49 | 21 | (28.6%) | 28 | (28.6%) |

| rocking chairs and recliners | 44 | 27 | (22.2%) | 17 | (0%) |

| child mattress | 36 | 13 | (15.0%) | 23 | (22.0%) |

| pit cubes | 39 | 33 | (15.2%) | 6 | (50.0%) |

| pillows | 32 | 9 | (11.1%) | 23 | (21.7%) |

| other furniture | 26 | 13 | (23.0%) | 13 | (23.1%) |

| total | 1141 | 598 | (24.2%) | 543 | (19.2%) |

Values in parenthesis are percentages of products purchased in California under each column header.

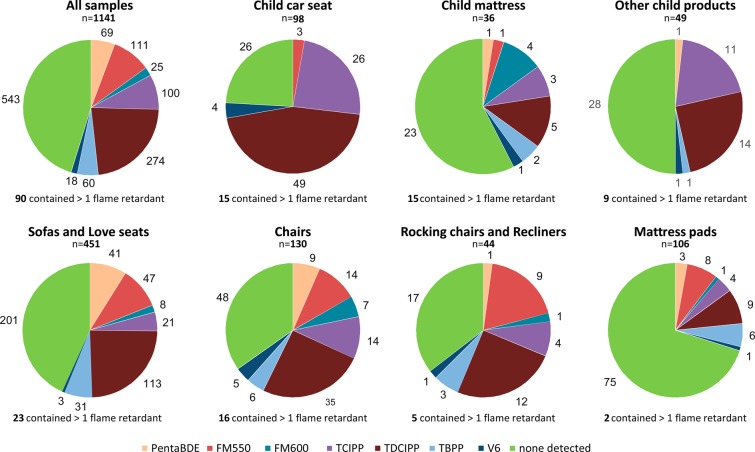

Figure 1.

Detection of FRs in major product categories.

Flame Retardants Detected by Product Category

Identification of a flame retardant in PUF samples was based on comparison to authentic standards and to a FR mass spectral response greater than 1% by weight of the foam. For all samples analyzed, 598 (52%) were positively identified as containing a FR based on our screening process and criteria (Table 1, Figure 1). Among the major product categories, the portion of samples containing a FR ranged from 29% (n = 106) of mattress pads to 74% of child car seats (n = 98). Among sofas and loveseats, 45% contained no identifiable FR, which is much higher than reported by Stapleton et al., (2012) for couches purchased between 1985 and 2010, for which only 12% contained no known FRs. The differences may be attributable to the fact that the current study included many products purchased 2013 and later, for which time period we observed a decrease in FR detection as described below. Of all samples tested, 90 (8%) contained more than one FR, which is similar to results reported in our earlier studies.3,13 There was no clear trend relating multiple FR applications to product type; however, the most commonly observed combination of FRs across all categories was TDCIPP with TCIPP. The presence of more than on FR may be coapplication, or possibly cross-contamination during manufacturing.

Across all samples analyzed tris(1,3,-dichloro-2-propyl)phosphate (TDCIPP) was the most frequently detected FR (24% of all samples tested), followed by FM550 (10%) > tris(2-chloroisopropyl)phosphate (TCIPP) (9%) > PentaBDE (6.0%). This trend varied somewhat among the major product categories; however, TDCIPP was still the most frequently detected FR in all categories. TDCIPP was also observed as the most frequently detected FR in US sofas purchased between 1985 and 2010, followed by FM550 and a mixture of isobutylated triaryl phosphates that we refer to as “TBPP”.3 Although no FRs were detected in 48% of samples, this may not necessarily indicate that these samples are not treated with flame retardants; the screening process is not likely to catch reactive or polymeric FRs that are bound to the foam structure or more strongly sorbed, and our method may overlook FRs for which the chemical composition is unknown.

No general trend was observed based on whether or not products were purchased in the state of CA, even for products that fall under the regulatory guidance of TB-117. For example, 28% of the sofas and loveseats tested contained a FR and were purchased in CA; however, 15% of the sofas and loveseats from CA that were tested did not contain a FR (Table 1). Interestingly, however, a greater percentage of child car seats (54%) and child mattresses (22%) with no FR detected were purchased in CA than observed for FR-containing products in the 7 major categories. This observation may partly reflect changes to FR use in response to the 2011 addition of TDCIPP to Prop 65, given that TDCIPP is the most frequently detected FR for these products, and that 84% of child car seats and 64% of child mattresses were purchased after 2011. Trends on FR use based on state of purchase must be considered with some caution given that CA was the most represented state in the study with regard to where participants lived and where products were purchased.

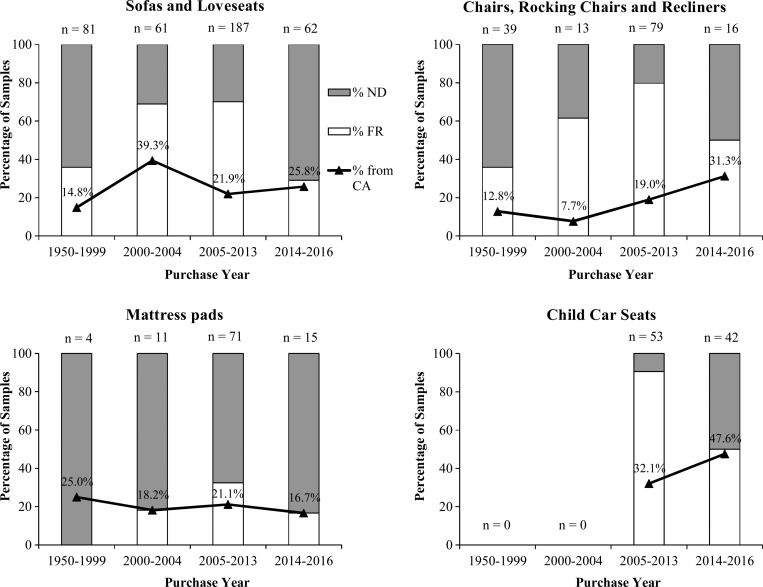

Temporal Trends in FR Use over Time

To understand better potential changes in FR use over time and across products, temporal trends were examined among the product categories with the highest sample submissions: sofas and loveseats; chairs, rocking chairs and recliners; mattress pads; and child car seats (Figure 2). Given that TB-117 is a California standard, we also included the percent of samples purchased in the state of California within each category. Of the 828 samples analyzed in these product categories, 97 had an unknown or uncertain year of purchase, and were thus excluded from this analysis. In all product categories, we observed an increase in the frequency of FR use up until 2014. For these product categories, 35% of samples purchased between 1950 and 1999 (n = 124), 61% of samples purchased between 2000 and 2004 (n = 85), and 68% of samples purchased between 2005 and 2013 (n = 390) contained a FR. However, only 37% of the samples purchased between 2014 and 2016 (n = 132) contained FRs, representing a significant decrease in detection frequency (p < 0.001, one-tailed Fisher’s Exact test) from that observed in products purchased between 2005 and 2013. This may suggest FR use has decreased recently, or it may suggest that other types of FRs are being used that we cannot detect. Our results also indicate that the percentage of sofas and loveseats purchased in the state of California does not relate to FR use across years, and ranged from 26% (2014–2016) to 39% (2000–2004). For chairs, rocking chairs and recliners, FR use similarly increased among samples purchased between 2000 and 2004 (62% of samples, n = 13) when compared to samples purchased before 1999 (36%, n = 39), and continued to increase in products purchased through 2013. As observed with sofas and loveseats, FR detection frequency in chairs, rocking chairs and recliners decreased significantly (p = 0.018) after 2013.

Figure 2.

Detection of FRs in selected product categories by year.

The detection of FRs in mattress pads was much lower overall than use among the other three product categories. Of the four samples purchased between 1950 and 1999, none contained a flame retardant. However, 2 of the 11 mattress pads (18%) purchased between 2000 and 2004, and 32% of the samples purchased between 2005 and 2013 (n = 71), and 29% of the samples purchased between 2014 and 2016 (n = 15) did contain a flame retardant. Little variation existed in the percentage of samples purchased in California. No statistically significant trends in FR use were observed over time for mattress pads.

All samples of child car seats submitted for testing were purchased after 2008, likely reflecting the short lifetime of child car seats. Of those purchased between 2009 and 2013, 91% contained FRs (n = 53). However, FR detection frequency (50%, n = 42) decreased significantly (p < 0.0001) in car seats purchased after 2013. These results may indicate a decline in use of FRs in child car seats, or that the industry is switching to a new FR technology.

Temporal Changes in FR Applications

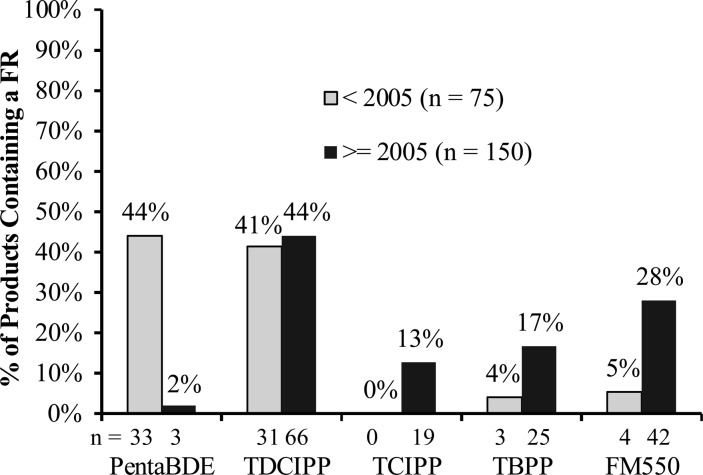

Given the voluntary phase-out of PentaBDE in the US that occurred starting in 2005, we anticipated that a significant shift in the types of FRs detected would be observed based on the year in which the participants reported purchasing these products. In Figure 3, the percentage of PUF samples from sofas and loveseats containing various FRs is presented based on whether the product was purchased before or after 2005. Of 156 sofas and loveseats reportedly purchased before 2005, 75 (48%) contained a FR, with PentaBDE detected most frequently (48% of all samples containing a FR), followed by TDCIPP (44%) > FM550 (5%) > TBPP (4%). Most samples (<2005) that contained PentaBDE were from furniture (i.e., sofa, loveseat, chair, rocking chair, recliner); however, PentaBDE was observed in two mattresses, two pillows and one stroller. PentaBDE was observed in 8 samples purchased after the 2005 phase-out: three sofas, one chair, two mattresses, one mattress pad, and a carpet pad. In contrast, no TCIPP was observed in sofas and loveseats purchased prior to 2005, whereas TCIPP-containing samples comprised 13% of the samples purchased after 2005 (of the samples testing positive for a FR). Across all products, the detection frequencies of TDCIPP, FM550, TCIPP and TBPP increased in samples containing a FR purchased after 2005, suggesting that all of these FRs may serve as PentaBDE replacements. A recent survey of 102 US sofas likewise observed reduced PentaBDE detection in products purchased between 2005 and 2010.3 Authors reported the largest increase in the use of TDCIPP, followed by FM550.

Figure 3.

Presence of TDCIPP, TBPP, PentaBDE, TCIPP and FM550 in sofas and loveseats containing a FR purchased before and after 2005. Note that the sum of products containing a FR purchased after 2005 exceeds 100% because some products (18) contained more than one FR.

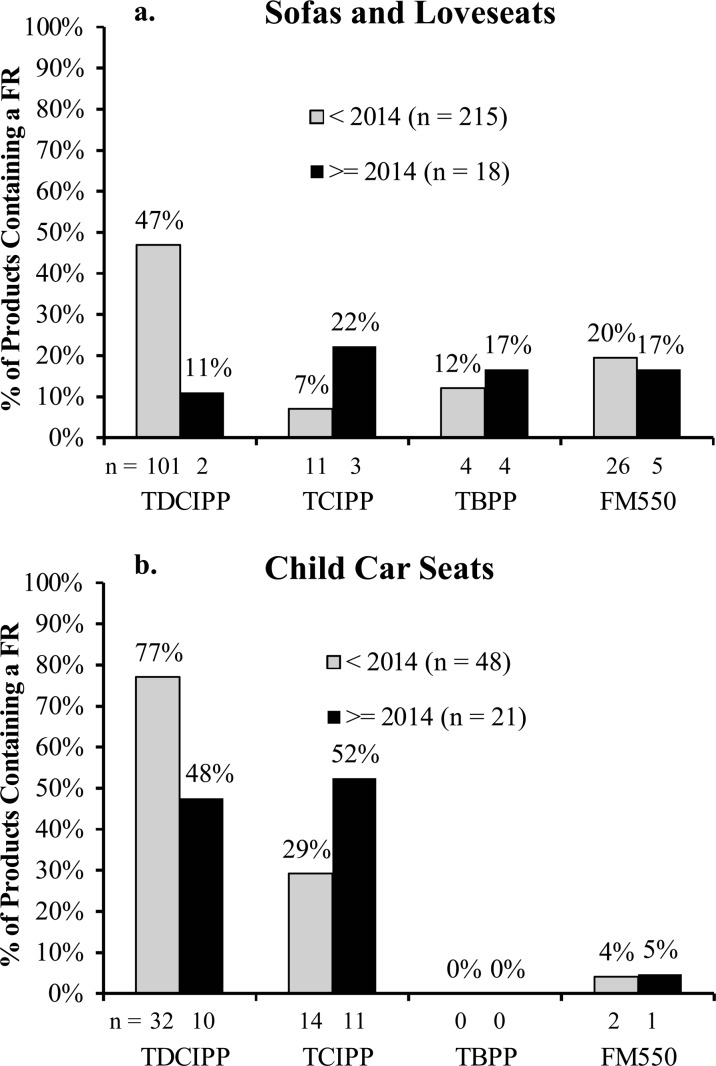

In addition to changes in FR use before and after 2005, we also examined differences before and after 2014 to examine potential shifts in the chemical industry reflecting changes to the TB-117 flammability standard and/or the 2011 addition of TDCIPP to California’s Proposition 65 list. In 2013, the State of California amended TB-117 to require a smolder test instead of an open flame test for compliance purposes, for which enforcement began in 2014. Within sofas and loveseats, which fall under TB-117-2013, FRs were detected in 60% of samples purchased before 2014, which was considerably higher than the detection frequency (29%) observed in samples post 2014 (Figure 4). Among the samples containing a FR, TDCIPP was detected in 47% of sofas and loveseats purchased before 2014, which was in contrast to a detection frequency of only 11% in those purchased after 2014. Conversely, the portion of products containing TBPP and TCIPP increased in more recent years. However, the percentage of samples containing FM550 appeared not to vary, suggesting that the use of FM550 was not altered significantly by the change in TB-117. Although our results may suggest that recent changes to TB-117-2013 may have an impact on the use of FRs overall in these types of products, purchase dates may not reflect manufacturing dates, which may be obfuscating some of our results. Given that this shift in regulation is fairly recent, the number of samples manufactured after 2014 is also relatively small in our sample population. Evaluation of more samples made after 2014 is needed to shed further light on these trends. In addition, TDCIPP was added to California’s Proposition 65 list in 2014, which also may have affected the use of this chemical as a FR in PUF.

Figure 4.

Presence of TDCIPP, TBPP, TCIPP and FM550 in (a) sofas and loveseats and (b) child car seats purchased before and after 2014. Note that the sum of child car seats containing an FR purchased after 2014 exceeds 100% because some products (8) contained more than one FR.

For child car seats, overall FR detection frequency decreased from 91% of samples purchased before 2014 to 50% of samples post 2014. Trends in detection of specific FRs differed from those observed for sofas and loveseats, which may reflect the fact that child car seats do not fall under TB-117-2013, but are federally regulated under FMVSS 302. TDCIPP detection in child car seats decreased noticeably from 77% to 48% in car seats purchased before and after 2014 (Figure 4). Concomitantly, TCIPP detection increased from 29% to 52%, suggesting that TCIPP may be a replacement for TDCIPP. TBPP was not observed in any car seat.

Given the health concerns for several of these FRs, more attention to the use and application of these chemicals in common household goods is needed to evaluate health risks. Studies have found significant associations between levels of FRs in house dust with body burden levels,32,33 and common household products are postulated to be a source of the FRs to the dust.34 Data generated from this FR screening project demonstrate that significant changes have occurred in FR applications over the past few decades, and potentially in the use of these chemicals overall. Given that this project is a public service-derived survey, there are likely some biases and limitations. For example, participants may not report product information (e.g., purchase state, year, label information) accurately. Likewise, all demographic groups may not participate equally, potentially leading to sampling bias, or nonrepresentation of the entire country. Despite these limitations, the database garnered from this project yields valuable insights into FR use. Clearly, PentaBDE is not used any longer as a FR in these products; however, due to their persistent properties, and the anticipated long lifetime of some pieces of furniture (e.g., sofas), emissions of PBDEs from furniture and human exposure may be a concern for decades to come. Furthermore, our data also suggest that TDCIPP use is decreasing, but like PentaBDE, exposure may occur for decades. In addition, some products that were not expected to contain FRs (e.g., pillows), or products that have not been thoroughly tested (e.g., mattress pads) may also be sources of exposure to people and the home environment. Pillows in particular may be a significant source of exposure given the proximity and duration of time that people spend in contact with these products on a daily basis. And last, given the change in the CA flammability standard over the past few years, FR applications overall appear to be decreasing in PUF; however, it is unclear whether use may increase in upholstery and textiles, which may warrant testing of these materials as well.

Acknowledgments

This research was supported by grants from the National Institute of Environmental Health Sciences (P42ES010356). We also thank all participants who submitted samples for testing.

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acs.est.6b01602.

Table listing the flame retardant chemicals that were screened for in the samples, and a figure showing the detection frequencies of flame retardants in all product categories included in the study (PDF).

Author Contributions

Ellen M. Cooper and Gretchen Kroeger are co-first authors.

The authors declare no competing financial interest.

Supplementary Material

References

- Requirements, test procedure and apparatus for testing the flame retardance of resilient filling materials used in upholstered furniture; California Department of Consumer Affairs: North Highlands, CA, 2000. [Google Scholar]

- Stapleton H. M.; Klosterhaus S.; Eagle S.; Fuh J.; Meeker J. D.; Blum A.; Webster T. F. Detection of Organophosphate Flame Retardants in Furniture Foam and US House Dust. Environ. Sci. Technol. 2009, 43 (19), 7490–7495. 10.1021/es9014019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stapleton H. M.; Sharma S.; Getzinger G.; Ferguson P. L.; Gabriel M.; Webster T. F.; Blum A. Novel and High Volume Use Flame Retardants in US Couches Reflective of the 2005 PentaBDE Phase Out. Environ. Sci. Technol. 2012, 46 (24), 13432–13439. 10.1021/es303471d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- van der Veen I.; de Boer J. Phosphorus flame retardants: Properties, production, environmental occurrence, toxicity and analysis. Chemosphere 2012, 88 (10), 1119–1153. 10.1016/j.chemosphere.2012.03.067. [DOI] [PubMed] [Google Scholar]

- Alaee M.; Arias P.; Sjodin A.; Bergman A. An overview of commercially used brominated flame retardants, their applications, their use patterns in different countries/regions and possible modes of release. Environ. Int. 2003, 29 (6), 683–689. 10.1016/S0160-4120(03)00121-1. [DOI] [PubMed] [Google Scholar]

- Hale R. C.; Alaee M.; Manchester-Neesvig J. B.; Stapleton H. M.; Ikonomou M. G. Polybrominated diphenyl ether flame retardants in the North American environment. Environ. Int. 2003, 29 (6), 771–779. 10.1016/S0160-4120(03)00113-2. [DOI] [PubMed] [Google Scholar]

- Birnbaum L. S.; Staskal D. F. Brominated flame retardants: Cause for concern?. Environ. Health Perspect. 2004, 112 (1), 9–17. 10.1289/ehp.6559. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Noren K.; Meironyte D. Certain organochlorine and organobromine contaminants in Swedish human milk in perspective of past 20–30 years. Chemosphere 2000, 40 (9–11), 1111–1123. 10.1016/S0045-6535(99)00360-4. [DOI] [PubMed] [Google Scholar]

- Hites R. A. Polybrominated diphenyl ethers in the environment and in people: A meta-analysis of concentrations. Environ. Sci. Technol. 2004, 38 (4), 945–956. 10.1021/es035082g. [DOI] [PubMed] [Google Scholar]

- Law R. J.; Allchin C. R.; de Boer J.; Covaci A.; Herzke D.; Lepom P.; Morris S.; Tronczynski J.; de Wit C. A. Levels and trends of brominated flame retardants in the European environment. Chemosphere 2006, 64 (2), 187–208. 10.1016/j.chemosphere.2005.12.007. [DOI] [PubMed] [Google Scholar]

- Schecter A.; Papke O.; Tung K. C.; Joseph J.; Harris T. R.; Dahlgren J. Polybrominated diphenyl ether flame retardants in the US population: Current levels, temporal trends, and comparison with dioxins, dibenzofurans, and polychlorinated biphenyls. J. Occup. Environ. Med. 2005, 47 (3), 199–211. 10.1097/01.jom.0000158704.27536.d2. [DOI] [PubMed] [Google Scholar]

- Tullo A. Great Lakes to phase out flame retardants. Chem. Eng. News 2003, 81 (45), 13. [Google Scholar]

- Stapleton H. M.; Klosterhaus S.; Keller A.; Ferguson P. L.; van Bergen S.; Cooper E.; Webster T. F.; Blum A. Identification of Flame Retardants in Polyurethane Foam Collected from Baby Products. Environ. Sci. Technol. 2011, 45 (12), 5323–5331. 10.1021/es2007462. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stapleton H. M.; Allen J. G.; Kelly S. M.; Konstantinov A.; Klosterhaus S.; Watkins D.; McClean M. D.; Webster T. F. Alternate and new brominated flame retardants detected in US house dust. Environ. Sci. Technol. 2008, 42 (18), 6910–6916. 10.1021/es801070p. [DOI] [PubMed] [Google Scholar]

- Hoffman K.; Fang M.; Horman B.; Patisaul H. B.; Garantziotis S.; Birnbaum L. S.; Stapleton H. M. Urinary Tetrabromobenzoic Acid (TBBA) as a Biomarker of Exposure to the Flame Retardant Mixture Firemaster (R) 550. Environ. Health Perspect. 2014, 122 (9), 963–969. 10.1289/ehp.1308028. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hoffman K.; Garantziotis S.; Birnbaum L. S.; Stapleton H. M. Monitoring Indoor Exposure to Organophosphate Flame Retardants: Hand Wipes and House Dust. Environ. Health Perspect. 2015, 123 (2), 160–165. 10.1289/ehp.1408669. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dodson R. E.; Perovich L. J.; Covaci A.; Van den Eede N.; Ionas A. C.; Dirtu A. C.; Brody J. G.; Rudel R. A. After the PBDE Phase-Out: A Broad Suite of Flame Retardants in Repeat House Dust Samples from California. Environ. Sci. Technol. 2012, 46 (24), 13056–13066. 10.1021/es303879n. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dodson R. E.; Van den Eede N.; Covaci A.; Perovich L. J.; Brody J. G.; Rudel R. A. Urinary Biomonitoring of Phosphate Flame Retardants: Levels in California Adults and Recommendations for Future Studies. Environ. Sci. Technol. 2014, 48 (23), 13625–13633. 10.1021/es503445c. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cequier E.; Sakhi A. K.; Marce R. M.; Becher G.; Thomsen C. Human exposure pathways to organophosphate triesters - A biomonitoring study of mother-child pairs. Environ. Int. 2015, 75, 159–165. 10.1016/j.envint.2014.11.009. [DOI] [PubMed] [Google Scholar]

- Kucharska A.; Cequier E.; Thomsen C.; Becher G.; Covaci A.; Voorspoels S. Assessment of human hair as an indicator of exposure to organophosphate flame retardants. Case study on a Norwegian mother-child cohort. Environ. Int. 2015, 83, 50–57. 10.1016/j.envint.2015.05.015. [DOI] [PubMed] [Google Scholar]

- Van den Eede N.; Heffernan A. L.; Aylward L. L.; Hobson P.; Neels H.; Mueller J. F.; Covaci A. Age as a determinant of phosphate flame retardant exposure of the Australian population and identification of novel urinary PFR metabolites. Environ. Int. 2015, 74, 1–8. 10.1016/j.envint.2014.09.005. [DOI] [PubMed] [Google Scholar]

- Schreder E. D.; Uding N.; La Guardia M. J. Inhalation a significant exposure route for chlorinated organophosphate flame retardants. Chemosphere 2016, 150, 499–504. 10.1016/j.chemosphere.2015.11.084. [DOI] [PubMed] [Google Scholar]

- Abdallah M. A.; Pawar G.; Harrad S. Human dermal absorption of chlorinated organophosphate flame retardants; implications for human exposure. Toxicol. Appl. Pharmacol. 2016, 291, 28–37. 10.1016/j.taap.2015.12.004. [DOI] [PubMed] [Google Scholar]

- Xu F.; Giovanoulis G.; van Waes S.; Padilla-Sanchez J. A.; Papadopoulou E.; Magner J.; Haug L. S.; Neels H.; Covaci A. Comprehensive Study of Human External Exposure to Organophosphate Flame Retardants via Air, Dust, and Hand Wipes: The Importance of Sampling and Assessment Strategy. Environ. Sci. Technol. 2016, 50, 7752–7760. 10.1021/acs.est.6b00246. [DOI] [PubMed] [Google Scholar]

- Patisaul H. B.; Roberts S. C.; Mabrey N.; McCaffrey K. A.; Gear R. B.; Braun J.; Belcher S. M.; Stapleton H. M. Accumulation and Endocrine Disrupting Effects of the Flame Retardant Mixture Firemaster (R) 550 in Rats: An Exploratory Assessment. J. Biochem. Mol. Toxicol. 2013, 27 (2), 124–136. 10.1002/jbt.21439. [DOI] [PMC free article] [PubMed] [Google Scholar]

- McGee S. P.; Cooper E. M.; Stapleton H. M.; Volz D. C. Early Zebrafish Embryogenesis Is Susceptible to Developmental TDCPP Exposure. Environ. Health Perspect. 2012, 120 (11), 1585–1591. 10.1289/ehp.1205316. [DOI] [PMC free article] [PubMed] [Google Scholar]

- McGee S. P.; Konstantinov A.; Stapleton H. M.; Volz D. C. Aryl Phosphate Esters Within a Major PentaBDE Replacement Product Induce Cardiotoxicity in Developing Zebrafish Embryos: Potential Role of the Aryl Hydrocarbon Receptor. Toxicol. Sci. 2013, 133 (1), 144–156. 10.1093/toxsci/kft020. [DOI] [PubMed] [Google Scholar]

- Li H.; Su G.; Zou M.; Yu L.; Letcher R. J.; Yu H.; Giesy J. P.; Zhou B.; Liu C. Effects of Tris(1,3-dichloro-2-propyl) Phosphate on Growth, Reproduction, and Gene Transcription of Daphnia magna at Environmentally Relevant Concentrations. Environ. Sci. Technol. 2015, 49 (21), 12975–12983. 10.1021/acs.est.5b03294. [DOI] [PubMed] [Google Scholar]

- Moser V. C.; Phillips P. M.; Hedge J. M.; McDaniel K. L. Neurotoxicological and thyroid evaluations of rats developmentally exposed to tris(1,3-dichloro-2-propyl)phosphate (TDCIPP) and tris(2-chloro-2-ethyl)phosphate (TCEP). Neurotoxicol. Teratol. 2015, 52, 236–247. 10.1016/j.ntt.2015.08.004. [DOI] [PubMed] [Google Scholar]

- Xu T.; Wang Q.; Shi Q.; Fang Q.; Guo Y.; Zhou B. Bioconcentration, metabolism and alterations of thyroid hormones of Tris(1,3-dichloro-2-propyl) phosphate (TDCPP) in Zebrafish. Environ. Toxicol. Pharmacol. 2015, 40 (2), 581–586. 10.1016/j.etap.2015.08.020. [DOI] [PubMed] [Google Scholar]

- NRC. Toxicological Risks of Selected Flame-Retardant Chemicals; National Academy Press: Washington DC, 2000. [PubMed] [Google Scholar]

- Johnson P. I.; Stapleton H. M.; Sjodin A.; Meeker J. D. Relationships between Polybrominated Diphenyl Ether Concentrations in House Dust and Serum. Environ. Sci. Technol. 2010, 44 (14), 5627–5632. 10.1021/es100697q. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stapleton H. M.; Eagle S.; Sjoedin A.; Webster T. F. Serum PBDEs in a North Carolina Toddler Cohort: Associations with Handwipes, House Dust, and Socioeconomic Variables. Environ. Health Perspect. 2012, 120 (7), 1049–1054. 10.1289/ehp.1104802. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Allen J. G.; McClean M. D.; Stapleton H. M.; Webster T. F. Linking PBDEs in house dust to consumer products using X-ray fluorescence. Environ. Sci. Technol. 2008, 42 (11), 4222–4228. 10.1021/es702964a. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.