Abstract

Since snacks high in fats are known to be a significant source of fat and energy intake, these have been put in high dietary restraint category. Therefore, an attempt was made to process potato chips through microwave processing without incorporation of any oil in potato chips. Microwave processing of potato chips was done using microwave power varying from 180 to 600 W using constant sample size. Among eleven different drying models, Parabolic model was found to be the best fit through non-linear regression analysis to illustrate drying kinetics of potato chips. The structural, textural and colour attributes of microwaved potato chips were similar to commercial fried potato chips. It was found that at 600 W after 2.5–3.0 min of processing, potato chips gained the fracturability and crispiness index as that of commercial fried chips. Microwave processing was found suitable for processing of potato chips with low fat content (~3.09 vs 35.5 % in commercial preparation) and with acceptable sensory scores (≥7.6 on 9.0 point on hedonic scale vs 8.0 of control preparation).

Keywords: Potato chips, Microwave processing, Drying kinetics, Low fat

Introduction

India is the second largest producer of potato in the world. During the harvesting season there is situation of glut, which causes the price of potatoes to drop rather significantly (Marwaha et al. 2010). Attempts therefore have been made to preserve or add value to the potato. Among several methods for adding value to fresh potato is deep-fat frying. Potato chips and French fries are widely consumed processed products from potatoes. In the conventional production of potato chips, whole potatoes with high dry matter (≥20 %) and low sugar content (≤150 mg/100 g, fwb); are peeled, trimmed, sliced, deep fat fried and salted to yield the final edible potato chips (Kumar and Ezekiel 2005). The so formed potato chips absorb a considerable quantity of fat and their final fat content ranges from about 35 to 38 % based on the total weight of the potato chips (Marwaha et al. 2008).

The high oil content is the major problem associated with potato snacks. There is a trend to develop healthy foods since the number of obese and health conscious persons are increasing day by day (Pandey and Singh 2011) and simultaneously there is increased awareness on health and nutrition among masses. As per the recent report of GAIN (Global Alliance for Improved Nutrition), India is at the third position after America and China for number of obese persons in the world (http://www.dnaindia.com/health/report 2015).

Hence, fried products are facing friction towards its adaptation by health and calorie conscious people which is commonly known as dietary restraint. Moreover, the deep fat frying process shortens the shelf stability of potato chips due to development of rancidity in them (Vinaixaa et al. 2005). Therefore, there is earnest need to develop low/reduced fat potato chips with good sensory quality for widening the scope of its acceptance.

Various hydrocolloid coatings have been reported earlier to reduce the fat content of potato chips (Garmakhany et al. 2008). Through coatings, a reduction of the fat uptake of potato chips by 49.71–57.03 % has been reported. Technology for the development of reduced fat chips has been developed and patented earlier in US patent (US3402049) in which the slices were dipped in edible oil solution (having temperature lower than GT of potato) and then processed.

It is a well-known fact that, a low fat chips cannot be made with deep fat frying process as fat is absorbed throughout the frying process (http://www.google.co.in/patents/US3402049). Hence, there is need to find an alternate technology which has the potential to make potato chips palatable with minimal or no intake of oil and at the same time maintain the crispiness of the product.

Microwave processing can be an alternative technology for the development of potato chips with low or no intake of oil. The high moisture content (~80 %) and less product depth are the two major positive factors enabling processing of potato chips through microwave processing. Slight fat reduction in potato chips through microwave processing has already been reported by Talburt and Smith (1987). Recently, different drying techniques have also been investigated as alternatives to producing fat-free snack products. Therefore, an attempt was made to develop low fat potato chips through microwave processing.

Materials and methods

Material

Potatoes (S. tuberosum L.) of cv. Kufri Chipsona-2 were used for this experiment. This cultivar was grown at CPRIC, Modipuram, India during winters of 2013–14 (Rabi season) using standard package of practices (Kumar et al. 2007). Potato tubers after skin curing were stored at elevated temperature (10–12 °C) storage chambers using sprout suppressant CIPC or Chloropropham treatment (Singh et al. 2004) till utilized. Potato chips of an average thickness of 1.6 mm were cut from a commercially available chips cutter.

Compositional analysis

Composition of peeled potato was done as per the standard methodologies reported by Ranganna (2007). Mineral analysis was done in Micro wave Plasma Atomic Emission Spectroscopy (MPAES) from Agilent Technologies 4100 MP AES, USA.

Microwave processing and drying

Microwave processing of raw potato chips were performed in a domestic digital microwave oven (Samsung CE104VD, Malaysia). The microwave oven had the capability of operating at five different microwave output powers (180, 300, 450, 600 and 900 W). A known weight of sample (25 g) was placed uniformly in the rotating glass plate of microwave oven and placed in the center. The drying experiments were conducted by subjecting the potato chips to predetermined microwave power at varied time intervals with 30 s increments until the weight of the sample was reduced to a level corresponding to moisture content of about 0.12 g water/g dry basis. It was ensured that during drying, microwave application was applied non-intermittently. Three replications of each experiment were performed according to a preset microwave output power and time schedule.

Drying kinetics

For the purpose of drying kinetics study, the moisture ratio was calculated with Eq. (1)

| 1 |

where, is the moisture content at time t, is the initial moisture content and is equilibrium moisture content of microwave dried potato chips.

The microwave drying data was fitted to 11 drying models (Table 1) i.e. Lewis, Page’s, Modified Page, Henderson and Pabis, Diffusion, Two term, Logarithmic, Wang and Singh, Verma et al., Modified Henderson and Pabis and Parabolic for different microwave power to describe the drying kinetics.

Table 1.

Drying model

| S. no. | Model | Mathematical equation | References |

|---|---|---|---|

| 1. | Lewis | MR = exp(−kt) | Lewis (1921) |

| 2. | Page’s | MR = exp(−ktn) | Page (1949) |

| 3. | Modified page | MR = exp(−(kt)n) | Corzo et al. (2008) |

| 4. | Henderson and Pabis | MR = a.exp(−kt) | Henderson and Pabis (1961) |

| 5. | Diffusion | MR = a.exp(−kt) + (1-a).exp(−kat) | Karaaslan and Tuncer (2008) |

| 6 | Two term | MR = a.exp(−kt) + b.exp(−k1t) | Mohapatra and Rao (2005) |

| 7. | Logarithmic | MR = a.exp(−kt) + c | Kingsly and Singh (2007) |

| 8. | Wang and Singh | MR = 1 + a.t + b.t2 | Wang and Singh (1978) |

| 9. | Verma et al. | MR = a.exp(−kt) + (1-a).exp(−k1t) | Verma et al. (1985) |

| 10. | Modified Henderson and Pabis | MR = a.exp(−kt) + b.exp(−k1t) + c.exp (−k2t) | Vega-Gálvez et al. (2010) |

| 11. | Parabolic | MR = a + bt + ct2 | Sharma and Prasad (2004) |

Where, k, a, b, c, k 1 , k 2 were the model constants and t was the drying time (s). Comparative study of different models was done in order to test the applicability of the model/s for microwave drying of potato chips. The parameters of the equation were evaluated using STATISTICA version 6.0 (nonlinear regression analysis). Model adequacy was tested by Correlation coefficient (R2), Root mean square error (RMSE) and by Chi square (χ2) value. Model having maximum R2 and minimum RMSE and χ2 value was chosen as the best fit (Mohapatra and Rao 2005 and Pardeshi et al. 2013). Residual plots were also plotted by plotting residuals on the vertical axis and the independent variable (predicted values of moisture ratio) on the horizontal axis for each model.

Effective Moisture Diffusivity: The effective moisture diffusivity () of potato chips was calculated using following expression Eq. (2) as used by Dak and Prateek (2014):

| 2 |

where, is Fourier number and t is the drying time (t) along with the corresponding average radius of the potato chips. The diameter of fresh chips was measured using a digital caliper having 0.01 cm least count.

Colour measurement

During microwave processing, potato chips samples were removed from the microwave oven at prespecified time intervals (30 s) for colour measurements. The colour parameters for the colour change of the materials were quantified by Hunter L* (whiteness/darkness), a* (redness/greenness), and b* (yellowness/blueness) values with a Hunter colour meter (Hunter Associates Lab Inc (Model No: LabScan XE, USA) in a room with controlled light. The instrument was calibrated before the experiments with a white ceramic plate (X = 79.31, Y = 84.11, Z = 88.94). The potato chips cover the entire surface area of 1 cm pore, were scanned at three different locations to determine the average L*, a*, and b* values during the experiment. In addition, the total colour change () Eq. (2) was calculated from the Hunter L*, a*, b* scale and used to describe the total colour change during microwave processing of potato chips.

| 3 |

where = L*sample-L*standard; a*sample-a*standard; b*sample-b*standard.

Along with this, Hue angle, Chroma and Browning Index were also calculated using the following expression:

| 4 |

| 5 |

| 6 |

where,

‘t’ in subscript shows value of a particular attribute at time t.

Fat estimation

The fat content of microwaved chips as well as commercial chips (Lay’s classic salted) was calculated using solvent extraction principle (Ranganna 2007) in Soxhlet assembly (Model: Socs Plus SCS 4 model made by Pelican Equipments, Chennai, India). Approximately, 0.50–0.75 g (a) triplicate samples of potato chips were crushed and allowed for solvent extraction for 1 h using 70 ml of petroleum ether (B. pt. 40–60 °C) as solvent.

Texture analysis

The texture characteristics of potato chips was evaluated by Texture Analyzer (Model: Stable Micro System, TA.XT.Plus, UK). A chip was placed on a hollow planar base. The force was then applied to the sample by a using cylindrical probe of 0.25 mm diameter at a constant speed of 1 mm/s until the sample was cracked. Force–deformation data were recorded to determine the textural characteristics of the chip. The maximum force of break, initial slope of deformation were indicated as hardness and crispness of the chip, respectively (Aguilera et al. 2004). All tests were performed in duplicate and the average values were reported. The Pre-test speed, Test speed, Post test speed, Distance, Trigger type, Data acquisition Rate and Load cell were set at 1.0 mm/s, 1.0 mm/s, 10 m/s, 3 mm, Auto-10 g, 500pps and 50 kg, respectively.

Sensory evaluation

Potato chips samples were evaluated for their all sensory attributes including textural attributes by 10 semi-trained panelists, on 9-point Hedonic scale, where 9 and 1 represented liked extremely and disliked extremely, respectively (Larmond 1977).

Results and discussion

Compositional analysis

The physico-chemical attributes of potatoes are shown in Table 2. Slight variation in the estimated value from the earlier reported (Rautela et al. 2009) may be due to the fact that in the supported study organic potatoes of Kufri Chipsona-2 variety were used whereas in the present study conventionally grown potatoes of same variety were used to prepare chips. Peel content was higher than reported earlier by Garmakhany et al. (2008) which may be due to the difference in peeling procedure.

Table 2.

Physico chemical characteristics of potato

| Parameters (Physical) | Flesh colour | W (g) |

L (cm) |

D (cm) |

P (%) |

F (%) |

E | S.G. |

|---|---|---|---|---|---|---|---|---|

| Values | Cream L* = 67.27 ± 1.84, a* = −1.075 ± 0.27, b* = 14.82 ± 1.23 |

79.23 ± 4.49 | 5.64 ± 0.19 | 4.70 ± 0.14 | 11.782 | 89.217 | 8–9 | 1.230 |

| Parameters (Chemical) |

M.C. (%) | D.M. (%) | Pr (%) | F (%) | A (%) | C (%) | S (%) | Mineral content (mg/100 g) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Ca | K | Mg | Na | Zn | ||||||||

| Values | 78.8 ± .14 | 21.2 ± 0.14 | 2.21 ± 0.24 | 0.16 ± 0.03 | 0.87 ± 0.04 | 18.65 ± 1.04 | NRS :0.49 ± 0.041 RS :0.32 ± 0.032 TS :0.81 ± 0.052 |

3.2 ± 0.02 | 38.4 ± 0.04 | 513.5 ± 0.08 | 28.4 ± 0.03 | 22.9 ± 0.10 | 0.79 ± 0.06 |

All chemical attributes (Moisture Content-M.C., Dry Matter (D.M.) Protein-Pr, Fat-F, Ash-A, Carbohydrates-C, Sugar-S: Reducing Sugar-RS, Non-reducing sugar-NRS, Total Sugars-TS; Iron-Fe, Calcium-Ca, Potassium-K, Magnesium-Mg, Sodium-Na, Zinc-Zn) are average of three observations whereas all physical attributes like Flesh Colour, Weight(W), Length (L), Diameter(D), %Peel Content (P), % Flesh Content (F), No. of eyes (E) and Specific gravity (S.G.) are average of 10 observations

Drying characterization

Drying kinetics

The microwave drying data of potato chips was fitted to 11 different drying models (Table 1) to describe the drying kinetics. Model having maximum R2 and minimum RMSE and χ2 value was chosen as the best fit. The Parabolic model was superior to the other models, having the lowest RMSE, ranging from 0.010053 to 0.009018, the lowest χ2 ranging from 0.0847 to 0.103313 and the highest correlation coefficient (R2) ranging from 0.9718 to 0.9846. Moreover, the residual plot of the Parabolic model was not systematic and very close to horizontal axis. Therefore, Parabolic model was found to be the best fit to illustrate drying kinetics of potato chips in microwave heating followed by Diffusion and Verma et al. model. All the three models had the correlation coefficient value (R2) higher than 96 % for most of the drying conditions which shows a good fit between the predicted as well as the actual moisture ratios of potato chips.

Microwave drying of potato chips

The average drying rates at 180, 300, 450, 600 and 900 W of microwave power were in the range of 3.12 × 10−4–9.72 × 10−3, 1.95 × 10−3–1.24 × 10−2, 1.01 × 10−2–1.54 × 10−2, 0.76 × 10−2–2.30 × 10−2 and 0.49 × 10−2–2.20 × 10−2 kg H2O/kg db, respectively at the experimental conditions of present study. Almost all drying of potato chips took place in falling rate period. At the beginning of the drying, the moisture content of the potato chips reduced quickly due to significant vapour pressure gradient developed between the centre and the surface of the product (Krishna Murthy et al. 2014). As drying continues, the loss of moisture from the product decreases as the vapour pressure gradient decreases and results in a fall in the drying rate during the later part of microwave drying (Kharaisheh et al. 1995).

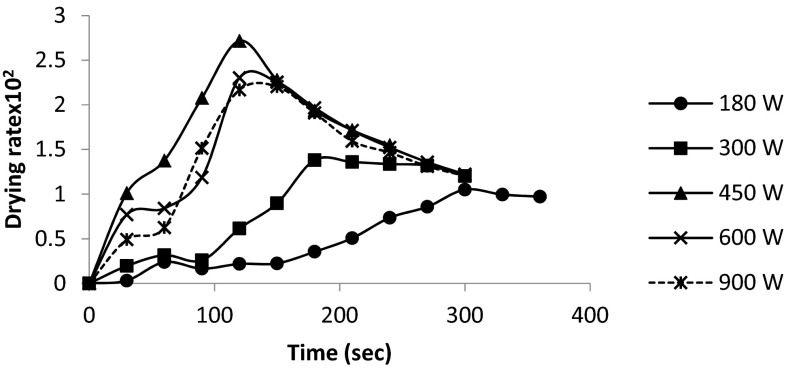

However, increasing the microwave power intensity from 7.21 to 36.32 W/g−1 enhanced the moisture reduction due to higher drying rate (Fig. 1 and Table 3). This agreed with other studies, including those on mushrooms (Giri and Prasad 2007) and apple pomace (Wang et al. 2007). Therefore, the drying times required to reduce the moisture content to less than 0.14 kg water kg dry solid−1 were 5.5, 4.0, 2.5, 3.0 and 3.0 min for 180, 300, 450, 600 and 900 W, respectively. The highest drying rate was observed at 450 W and lowest was observed in 180 W (Table 3). The change in the moisture content slowed down later, when the moisture content had decreased, because the dielectric constant of food samples tends to decrease as the moisture content decreases (Scaman and Durance 2005). When the moisture content of the Potato chips samples was reduced to 0.50 kg water kg dry solid−1, the rates of moisture change in the potato slices for various microwave power levels were almost similar (Fig. 1). This indicated the significance of internal resistance to mass transfer at low moisture content in the materials (Giri and Prasad 2007).

Fig. 1.

Changes in drying rate of potato chips under different microwave power

Table 3.

Estimated drying time at different wattage to reach the moisture content of ≤0.14 % (d.w.b.)

| Microwave power wattage (W) | Required drying time (sec/min) | Drying rate* (Kg H2O/Kg db) | Moisture diffusivity* (m2/s) | ||

|---|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | ||

| 180 | 330/5.5 | 3.12 × 10−4 | 9.72 × 10−3 | 3.28 × 10−8 | 1.96 × 10−7 |

| 300 | 240/4.0 | 1.95 × 10−3 | 1.24 × 10−2 | 2.06 × 10−7 | 5.36 × 10−7 |

| 450 | 150/2.5 | 1.01 × 10−2 | 1.54 × 10−2 | 1.49 × 10−7 | 7.04 × 10−7 |

| 600 | 180/3.0 | 0.76 × 10−2 | 2.30 × 10−2 | 4.41 × 10−7 | 8.29 × 10−7 |

| 900 | 180/3.0 | 0.49 × 10−2 | 2.20 × 10−2 | 5.99 × 10−8 | 7.50 × 10−7 |

* Considering for the whole drying period

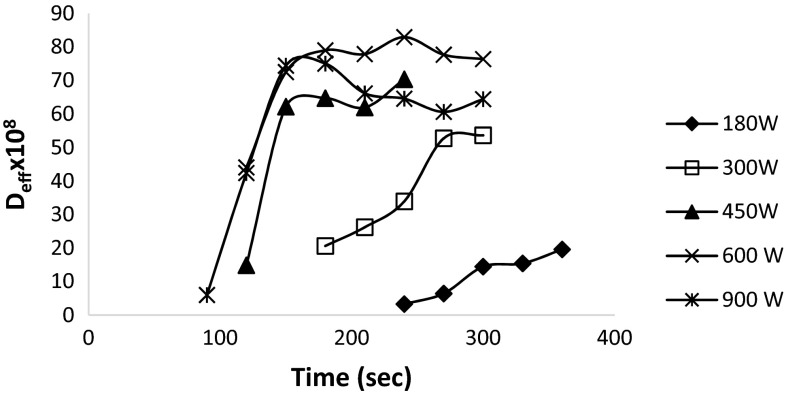

Effective moisture diffusivity

Similar to drying rate, initially effective moisture diffusivity (Deff) increased with time as the microwave power increased (Fig. 2). The highest has been observed for 600 W whereas the lowest has been observed for 180 wattage till constant weight achieved (Table 3). From Fig. 2, it was also observed that towards the end of drying process, moisture diffusivity remained constant or rather decreased. It may be due to the shrinkage defect of drying on potato chips. Because of this shrinkage, diameter of pores decreased and therefore, moisture diffusion decreased. Such effect of porosity on moisture diffusivity of bakery products was also observed by Tong and Lund (1990).

Fig. 2.

Changes in effective moisture diffusivity of potato chips under different microwave power

Microwave processing of potato chips

Process kinetics

As moisture content directly affects the textural attributes of food products therefore, microwave processing was continued till the moisture content similar to fried potato chips (~1.90 %, fwb) was achieved by the microwaved potato chips at each wattage. At 180 and 300 W, chips became soggy due to lower drying rates whereas at 900 W, as drying time progressed, browning of potato chips occurred due to high temperature.

It is also important to note that the highest drying rate was observed at 450 W and ≤0.12 moisture content (dwb) was achieved in less than 2.5 min of processing (Fig. 1 and Table 3). Therefore, for processing of potato chips, 450 W was not suitable as high drying rate is associated with quick removal of water molecules which reduces the moisture content of potato chips without making them palatable. For that reason, 600 W was found to be the most suitable for processing the potato chips by microwave heating. After 2.5–3.0 min of processing at 600 W, the average moisture content of chips was 1.92 % (fwb) which was similar to control and commercial preparation of potato chips (Shiroma and Rodrigues-Saona 2007).

Colour quantification

The colors of the samples were measured in terms of Hunter parameters (L*, a* and b*) in order to investigate the color changes of potato chips as affected by different microwave power. The L*, a* and b* of raw potato chips were 68.00 ± 1.831, −1.0675 ± 0.273 and 13.821 ± 1.315, respectively. The L value did not change much and almost remains unchanged for whole drying experiment and almost all values were lying between 64.00 and 69.00. It may be due the fact that microwave drying did not induced browning much as it inhibited enzymatic action responsible for browning rapidly (Barbosa-Canovas and Vega-Mercado 1996). Therefore, potato chips which were actually unblanched did not show any sign of enzymatic browning during whole drying process. Bai-Ngew et al. (2011) also observed that the non-significant change in L-value when they vacuum dried durian chips with microwave heating. For greenness/redness scale (a value), as microwave power increases a* value changes from −1.8 to −0.4, −3.505 to 4.7, −3.065 to −1.395, −3.28 to 15.425 and 10.225 to 32.635 at microwave power level of 180, 300, 450, 600 and 900 W, respectively. All dried potato chips had high reddish tint than fresh potato slices (a value = −1.125). It was noted that the microwave wattage had an influence on the redness, particularly at the wattage like 600 and 900 W. This is because Maillard reaction (non enzymatic browning) or other thermal damages occurred more at higher drying temperatures. The increase in a* value for each drying conditions shows an overall shift of chips colour towards redness. An increase in the b* value was also observed during microwave drying with time for each wattage. This shows change in colour towards yellowness. This increase might be developed from an increase of carotenoid content per unit weight during drying (Park 1987). Pimpaporn et al. (2007) also observed increase in a* and b* values in potato chips dried through low-pressure superheated steam after various pretreatments. Therefore, overall colour of potato chips can be described as slight reddish yellow.

The values of L* remained almost constant whereas a* and b* values increased continuously. As per the Eq. (3) the total colour change is the function of L*, a* and b* values therefore, total color change () of potato chips was increased significantly during microwave drying with drying time and ranged from 1.630 to 38.214 as the microwave output power increased from 180 to 900 W, respectively. Dadali et al. (2007) also observed that during microwave drying of okra, value of delta E increases.

Chroma increased during drying and closely followed the b values. During microwave drying, the final chroma changed slightly with the microwave output powers applied. This indicates the stability of yellowness in potato chips. Hue angle was also increased during microwave drying. The final values approached by hue angle observed were almost same for all microwave output powers applied. Dadali et al. (2007) also observed that in okra, Hue angle was approached to a constant value for all microwave output powers applied. The Browning index was increased and totally depend on microwave wattage and drying time.

Colour of microwaved potato chips after 2.5–3.0 min of microwave processing at 600 W can be described as slight creamish yellow (L*: 69.38; a*: −2.31; b*: 19.22) which was quite similar to control preparation i.e. fried potato chips (L*: 64.60; a*: −2.09; b*: 17.51) (Fig. 3a, b). Bai-Ngew et al. 2011 also reported that colour of microwaved durian chips (under vacuum) were lighter than control preparation and was quite desirable.

Fig. 3.

a Fried potato chips, b Microwaved potato chips

Quality characteristics of microwaved chips

Fat content

The estimated fat content of commercial available chips (Lay’s classic salted) and control samples was found to be 35.52–36.37 %, respectively. The fat content of fried potato chips available in market from various brands found to vary between 35.0 and 36.0 %. Various researchers had reported the fat content of potato chips to be in this range (Rautela et al. 2009) earlier also. The fat content of microwaved potato chips was 3.09 %, which was approximately 90 % less than the commercial and control preparations, therefore, the developed chips can be considered as low fat chips.

Texture profile and sensory evaluation

Texture is a very important criteria for deciding the overall acceptability of any food product by the consumers. Therefore, texture was evaluated by texture analyzer as well as subjectively by sensory analysis. Texture Profile Analysis showed that after 2.5–3.0 min of processing at 600 W, the fracturability of developed microwaved potato chips was similar to commercially available potato chips. It was found that at 600 W after 2.5–3.0 min of processing, potato chips gained the fracturability (452.21 g) and crispiness index (18 positive peaks) as that of commercial fried chips. Average fracturability of commercial available chips (Lay’s classic salted) was 456.03 g with 21 positive peaks. It indicates that microwave heating at power level of 600 W has the potential to produce the chips from unblanched raw potato chips after 2.5–3.0 min of processing without addition of fat. The crispy texture was obtained by tissue consisting of air cavities surrounded by a brittle structural phase (Scaman and Durance 2005). Air spaces of microwaved chips can easily be observed by the Fig. 3b. Thus, microwave processing was found suitable to process the potato chips with acceptable sensory and textural scores (≥7.6 and 8.0, respectively on 9.0 point on hedonic scale vs 8.0 and 8.5 of control preparation).

Conclusion

The thin layer models were used to describe the drying kinetics of the potato slices. The Parabolic model provided the best fit. Upon increasing the microwave power intensity, the effective moisture diffusivity and drying rate increased. Therefore, drying time could be reduced significantly by microwave heating of potato chips. Microwave heating has the potential for drying as well processing of the potato chips. At power level of 600 W potato chips can be produced from unblanched raw potato slices without addition of fat within 2.5–3.0 min of processing. The structure, texture and colour of the microwaved potato chips were comparable to those of conventionally fried potato chips with lesser fat content (~3.09 vs 35.52 % in commercial preparation). Since till date microwave processing of potato chips has not been reported, it could emerge as a useful technique for making crispy chips with minimum oil content. The present study was conducted with small sample size (25 g) and thus before final recommendation of this technology for its industrial use, confirmations are required using bigger sample sizes in continuous microwave lines.

Acknowledgments

Authors are grateful to Director, ICAR-IARI for extending the facilities for conducting this study.

Contributor Information

A. Joshi, Phone: 0177-2624830, Email: alka.foodtech@gmail.com

S. G. Rudra, Email: gaurshalini@gmail.com

V. R. Sagar, Email: head_pht@iari.res.in

P. Raigond, Email: jariapink@gmail.com

S. Dutt, Email: sd_bio@yahoo.com

B. Singh, Email: birju16@gmail.com

B. P. Singh, Email: directorcpri@gmail.com

References

- Aguilera JM, Castro L, Cadoche L (2004) Structure property relationships in starch amorphous model. In: Proceedings of the 14th international drying symposium, Sao Paulo, Brazil, pp. 1468–1472

- Bai-Ngew S, Therdthai N, Dhamvithee P. Characterization of microwave vacuum-dried durian chips. J Food Eng. 2011;104:114–122. doi: 10.1016/j.jfoodeng.2010.12.003. [DOI] [Google Scholar]

- Barbosa-Canovas GV, Vega-Mercado H. Dehydration of foods. Ist. New York: Chapman & Hall; 1996. [Google Scholar]

- Corzo O, Bracho N, Pereira A, Vásquez A. Weibull distribution for modelling air drying of coroba slices. LWT-Food Sci Technol. 2008;41:2023–2028. doi: 10.1016/j.lwt.2008.01.002. [DOI] [Google Scholar]

- Dadali G, Apar DK, Ozbek B. Color change kinetics of okra undergoing microwave drying. Dry Technol. 2007;25:925–937. doi: 10.1080/07373930701372296. [DOI] [Google Scholar]

- Dak M, Prateek NK. Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J of Food Eng. 2014;122:117–121. doi: 10.1016/j.jfoodeng.2013.08.040. [DOI] [Google Scholar]

- Garmakhany AD, Mirzaei HO, Nejad MK, Maghsuldlo Y. Study of oil uptake and quality attributes of potato chips affected by hydrocolloids. Eur J Lipid Sci Technol. 2008;110:1045–1049. doi: 10.1002/ejlt.200700255. [DOI] [Google Scholar]

- Giri SK, Prasad S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng. 2007;78(2):512–521. doi: 10.1016/j.jfoodeng.2005.10.021. [DOI] [Google Scholar]

- Henderson SM, Pabis S. Grain drying theory I: temperature effect on drying coefficient. J Agricul Res Eng. 1961;6:169–174. [Google Scholar]

- http://www.dnaindia.com/health/report (2015) India has third-highest number of obese people, reveals study. Accessed 09 Apr 2015 (Dainik Bhaskar dated 13/04/2015, p 10)

- http://www.google.co.in/patents/US3402049. Process for preparing low fat potato chips. Accessed 27 Feb 2014

- Karaaslan SN, Tuncer IK. Development of a drying model for combined microwave-fan-assisted convection drying of spinach. Biosyst Eng. 2008;100(1):44–52. doi: 10.1016/j.biosystemseng.2007.12.012. [DOI] [Google Scholar]

- Kharaisheh MAM, Cooper TJR, Magee TRA. Investigation and modeling of combined microwave and air drying. Food Bioprod Process. 1995;73:121–126. [Google Scholar]

- Kingsly ARP, Singh DB. Drying kinetics of pomegranate arils. J Food Eng. 2007;79:741–744. doi: 10.1016/j.jfoodeng.2006.02.033. [DOI] [Google Scholar]

- Krishna Murthy TP, Harish A, Rashmi M, Mathew Blessy B, Monisha J. Effect of blanching and microwave power on drying behavior of green peas. Res J Eng Sci. 2014;3(4):10–18. [Google Scholar]

- Kumar D, Ezekiel R. Changes in sugar content and processing quality of potatoes during storage and reconditioning. J Food Sci Technol. 2005;42:400–404. [Google Scholar]

- Kumar P, Pandey SK, Singh SV, Kumar D. Irrigation requirements of chipping potato cultivars under West Central Indian plains. Potato J. 2007;34:193–198. [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of foods. Ottawa: Canada Dept Agric Ottawa; 1977. [Google Scholar]

- Lewis WK. The rate of drying of solid materials. J Ind Eng. 1921;13:427–443. [Google Scholar]

- Marwaha RS, Kumar D, Singh SV, Pandey SK. Influence of blanching of slices of potato varieties on chipping quality. J Food Sci Technol. 2008;45:364–367. [Google Scholar]

- Marwaha RS, Pandey SK, Kumar D, Singh SV, Kumar P. Potato processing scenario in India: industrial constraints, future projections, challenges ahead and remedies—a review. J Food Sci Technol. 2010;47(2):137–156. doi: 10.1007/s13197-010-0026-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mohapatra D, Rao PS. A thin layer drying model of parboiled wheat. J Food Eng. 2005;66:513–518. doi: 10.1016/j.jfoodeng.2004.04.023. [DOI] [Google Scholar]

- Page G (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. MSc Thesis, Purdue University, Indiana, USA

- Pandey A, Singh G. Development of reduced sugar soy containing compound chocolate and its storage study. J Food Sci Technol. 2011;48(1):76–82. doi: 10.1007/s13197-010-0136-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pardeshi I, Burbade RG, Khod RN. Cost effective drying for high quality tender wheatgrass powder. J Food Res Technol. 2013;1(1):1–10. [Google Scholar]

- Park YW. Effect of freezing, thawing, drying, and cooking on carotene retention in carrots, broccoli and spinach. J Food Sci. 1987;52:1022–1025. doi: 10.1111/j.1365-2621.1987.tb14266.x. [DOI] [Google Scholar]

- Pimpaporn P, Devahastin S, Chiewchan N. Effects of combined pretreatments on drying kinetics and quality of potato chips undergoing low-pressure superheated steam drying. J Food Eng. 2007;81:318–329. doi: 10.1016/j.jfoodeng.2006.11.009. [DOI] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: Tata McGraw Hill; 2007. [Google Scholar]

- Rautela S, Chopra CS, Pandey A, Raghav M (2009) Physico-chemical characteristics and chipping performance of organic potatoes (Solanum tuberosum). In: Proceedings: National conference on Engineering for food & Bio-processing, pp. 312–316

- Scaman CH, Durance TD. Emerging technologies for food processing. London: Elsevier Academic Press; 2005. p. 768. [Google Scholar]

- Sharma GP, Prasad S. Effective diffusivity of garlic cloves undergoing microwave convective drying. J Food Eng. 2004;65:609–617. doi: 10.1016/j.jfoodeng.2004.02.027. [DOI] [Google Scholar]

- Shiroma C, Rodrigues-Saona L (2007) Rapid quality control of potato chips using near and mid infrared spectroscopy. Poster presentation. http://kb.osu.edu/dspace/handle/1811/24730 Accessed 23 May 2015

- Singh B, Kaul HN, Ezekiel R. Effect of Isopropyl-N (3-chlorophenyl) carbamate (CIPC) dusting on potatoes during non-refrigerated storage: sprout suppression and residues. J Food Sci Technol. 2004;41:550–553. [Google Scholar]

- Talburt WF, Smith O. Potato processing. 2. Eastern Pennsylvania: Mack Printing Company; 1987. p. 588. [Google Scholar]

- Tong CH, Lund DB. Effective moisture diffusivity in porous materials as a function of temperature and moisture content. Biotechnol Prog. 1990;6(1):67–75. doi: 10.1021/bp00001a011. [DOI] [Google Scholar]

- Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K. Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour Technol. 2010;101:7265–7270. doi: 10.1016/j.biortech.2010.04.040. [DOI] [PubMed] [Google Scholar]

- Verma LR, Bucklin RA, Endan JB, Wratten FT. Effects of drying air parameters on rice drying models. Trans ASAE. 1985;28:296–301. doi: 10.13031/2013.32245. [DOI] [Google Scholar]

- Vinaixaa M, Vergaraa A, Durana C, Llobet E, Badiaa C. Fast detection of rancidity in potato crisps using e-noses based on mass spectrometry or gas sensors. Sens Actuators B. 2005;106:67–75. doi: 10.1016/j.snb.2004.05.038. [DOI] [Google Scholar]

- Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE Paper No: 78-3001

- Wang Z, Sun J, Chen F, Liao X, Hu X. Mathematical modeling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J Food Eng. 2007;80(2):536–544. doi: 10.1016/j.jfoodeng.2006.06.019. [DOI] [Google Scholar]