Abstract

Abstract

Four new copper complexes based on bidentate imino phenoxide ligands were synthesized and characterized by IR, UV–Vis spectroscopy, ESI mass spectrometry, single crystal X-ray diffraction, and electrochemistry. The crystal structures revealed that the copper(II) atoms are surrounded by phenolate oxygen and imine nitrogen atoms of two ligands in a distorted square-planar geometry. The existence of ligand-centered, as well as Cu(II)-centered quasi-reversible and reversible redox reactions are observed in the cyclic voltammetry experiments of all the complexes. All complexes are able to catalyze the ring-opening polymerization of rac-lactide yielding polymers with moderate molecular weights and moderately broad molecular weight distributions.

Graphical abstract

Electronic supplementary material

The online version of this article (doi:10.1007/s00706-016-1830-7) contains supplementary material, which is available to authorized users.

Keywords: Imino phenoxide, Copper, Crystal structure, ROP, rac-Lactide, Cyclic voltammetry, Poly(lactic acid)

Introduction

In a similar fashion to tetradentate salen-type ligands, the related bidentate imino phenoxide ligands have proven to be extremely versatile ligands for main group, as well as transition metals. Such ligands have been used in almost all areas of coordination chemistry to prepare complexes which are catalytic and biological active or which feature interesting structural, electrochemical or magnetic properties [1, 2].

In recent studies, we have used imino phenoxide ligands to prepare early transition and main group metal complexes as polymerization catalysts, in particular, for the preparation of aliphatic polyesters such as poly(lactic acid) (PLA) and poly(caprolactone) (PCL) [3–8]. Such aliphatic polyesters are interesting, as one of the most important families of environmentally benign biodegradable polymers [9–14]. The degradation pathway is well studied: PLA degrades to the metabolisable lactic acid [15–17]. Generally, aliphatic polyesters are synthesized by the ring-opening polymerization (ROP) of cyclic esters using metal-based initiators [18–25]. Sn(Oct)2 is traditionally used for the industrial production of PLA, however, it is not suitable for producing PLA for biomedical applications due to the toxicity of the residual metal [13, 26]. Therefore, the syntheses of complexes with biologically benign metals are important.

Cu(II)-based catalysts have been widely investigated for the ROP of lactide (LA) before [27–33]. All studied catalytic systems are able to polymerize LA, however, with low activity and selectivity and at high temperatures. More recently, Cu(II) complexes bearing either the ligand set diketiminate/isopropoxide or ligands based on cyclohexane-1,2-diamine were used as catalysts for the polymerization of rac-lactide (rac-LA) [34, 35]. The catalysis of these systems was very efficient resulting in the formation of PLA in a controlled manner and displayed very high activities. Also diimino pyrrolide copper alkoxide complexes for the isotactic ROP of rac-LA gives polymers with suitably high M n (44–45 kg/mol) and controlled molecular weight distributions (MWDs) (1.0–1.2) [36]. On the other hand, Wang et al. reported copper complexes bearing bis(imino) phenoxide derived ligands with reactivities which were practically either zero or the formation of only trace polymer was observed for the ROP of ε-caprolactone [37].

In continuation of our previous work on metal complexes containing imino phenoxide ligands, we describe herein the use of these ligands for the synthesis of four novel Cu(II) complexes. In principle, this class of complexes is well studied for different applications [38–55]. These complexes are easy to prepare and stable towards air and moisture and, therefore, they are much easier to handle compared to the sensitive polymerization catalysts based on 1st, 4th, 5th, and 13th group metals [3–7]. The imino phenoxide ligands used in the study were available from previous studies. Due to the fact that these Cu(II) complexes feature interesting structural, electronic, and spectroscopic properties, we also studied these compounds by single crystal X-ray diffraction, UV–Vis spectroscopy, and spectro-electrochemistry. Finally, their catalytic efficiency towards the polymerization of rac-LA was investigated.

Results and discussion

Synthesis and characterisation

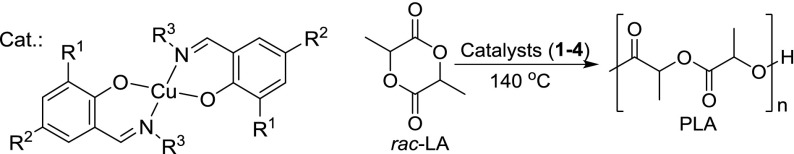

The bidentate imino phenoxide ligands L1–L4 were prepared following a procedure reported in the literature [56, 57]: the complexes were synthesized by mixing a methanolic solution of the Schiff base and copper acetate (0.5 mmol) in 10 cm3 methanol. After refluxing for 2 h the complexes 1–4 could be isolated in high yields and purities (Scheme 1).

The purity of the complexes was confirmed by elemental analysis. Electrospray ionization mass spectra show the presence of L2CuH+/L2CuNa+ ion peaks indicative for a 2:1 structure. The coordination of ligands to the copper(II) atom is also visible in the IR spectra (Figs. S1 and S2): the shift of C=N stretching frequency of the ligands (1623–1632 cm−1) towards lower frequencies (1606–1620 cm−1) upon complexation confirmed the coordination of the azomethine nitrogen to the metal atom. The signals in the 1H NMR spectra of all complexes are very broad due to the paramagnetic nature of the Cu(II) ion and hence, no further NMR analysis was performed.

Structural studies

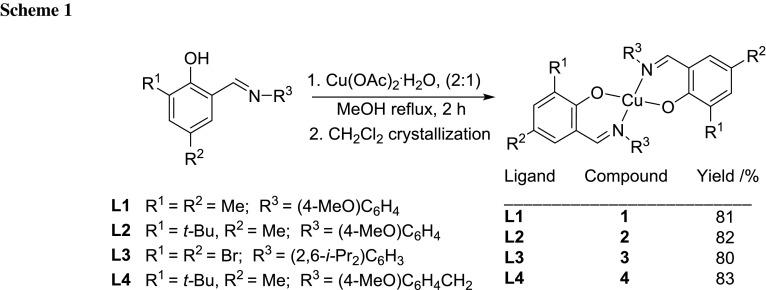

All complexes were obtained as crystalline solids suitable for single crystal X-ray analysis by slow evaporation of dichloromethane from their solutions. Because crystals of 4 were of very low quality also the resulting crystallographic data are very poor. Therefore, these data are not discussed here but can be found in the ESI for the sake of completeness (Fig. S3 and Table S1). Detailed crystallographic data for 1–3 are presented in Table 5. The molecular structures of 1–3 are depicted in Fig. 1 and selected bond lengths and bond angles are summarized in Table 1. Complex 1 was found to crystallize in the orthorhombic space group Fdd2, complex 3 in the triclinic space group P . For both complexes, the asymmetric unit consist of one half of a formula unit. Complex 2 crystallizes in the monoclinic space group C2/c, complex 4 in P with each containing one formula unit per asymmetric unit. In all complexes, the copper atom is coordinated by two phenolate oxygen and two imine nitrogen atoms of the ligands in a trans configuration. For 3, the copper atom exists in a perfect square-planar coordination environment. In the other complexes the coordination geometry deviates considerably from planarity due to steric repulsion of the alkyl-substituents in ortho position of the phenoxide moiety. For 3, the bromine atom is somewhat smaller than the alkyl groups, which reduces the steric hindrance. Additional stabilization is gained by C–Br/π-interactions: the bromine atom points directly to the π-system of the phenyl group of the aniline moiety with a distance between the ring plane and the bromine atom of ~3.38 Å which is typical for such interactions [38, 39]. In the complexes, the Cu–O bond distances are in average only slightly shorter than the Cu–N bonds (~1.92 vs. ~1.97 Å). The bite angle of the ligand in 3 is considerably smaller (87.95°) than the bite angle of the other three complexes (92.1°–93.3°). These structural parameters are very similar to reported examples of this group of complexes [38–51]. For all complexes, the crystal packing is stabilized by multiple interactions like CH/π, π/π, CH/O, and C(benzylic)/π interaction (see crystal packing diagrams in Figs. S4–S6, ESI). The structural parameters for these weak interactions are comparable with literature values [58–61].

Table 5.

Crystal data for the structures of 1–3

| Compound | 1 | 2 | 3 |

|---|---|---|---|

| Empirical formula | C32H32CuN2O4 | C38H44CuN2O4 | C38H40Br4CuN2O2 |

| Formula weight | 572.14 | 656.29 | 939.90 |

| Crystal system | Orthorhombic | Monoclinic | Triclinic |

| Space group | Fdd2 | C2/c | P |

| Temp/K | 300 | 300 | 300 |

| a/Å | 34.075 (2) | 14.640 (2) | 9.3893 (8) |

| b/Å | 12.3830 (9) | 29.944 (3) | 9.4713 (10) |

| c/Å | 13.3134 (10) | 17.637 (2) | 12.4322 (13) |

| α/° | 90 | 90 | 112.224 (3) |

| β/° | 90 | 114.285 (4) | 95.405 (3) |

| γ/° | 90 | 90 | 99.214 (3) |

| V/Å3 | 5617.6 (7) | 7047.5 (16) | 995.65 (17) |

| Z | 8 | 8 | 1 |

| D calc/g cm−3 | 1.353 | 1.237 | 1.568 |

| Reflns collected | 17380 | 63378 | 18297 |

| Indep. reflns | 2016 | 8153 | 3517 |

| Obs. reflns [I > 2σ(I)] | 1931 | 3619 | 2801 |

| Param. refin./restr. | 181/1 | 417/0 | 218/0 |

| Absorption correction | Multi-scan | Multi-scan | Multi-scan |

| R 1 | 0.059 | 0.060 | 0.0459 |

| wR 2 | 0.128 | 0.17 | 0.128 |

| CCDC | 1448157 | 1448158 | 1448159 |

Fig. 1.

Molecular structures of 1–3. Displacement ellipsoids were drawn at 50 % probability level (exception 1: 30 %). Hydrogen atoms are omitted for clarity

Table 1.

Selected bond lengths/Å and bond angles/° for 1–3

| 1 | 2 | 3 | |

|---|---|---|---|

| Cu–O | 1.921 (10) | 1.899 (3) 1.889 (3) |

1.896 (3) |

| Cu–N | 1.968 (9) | 1.982 (4) 1.972 (4) |

1.990 (3) |

| O–Cu–O | 152.4 (7) | 156.33 (17) | 179.999 (1) |

| N–Cu–N | 153.5 (6) | 161.73 (19) | 180.0 |

| O–Cu–Na

O–Cu–N |

93.1 (4) 93.1 (4) |

92.32 (16)/92.03 (15) 91.46 (15)/91.66 (16) |

92.05 (13) 87.95 (13) |

aBite angle of the ligand

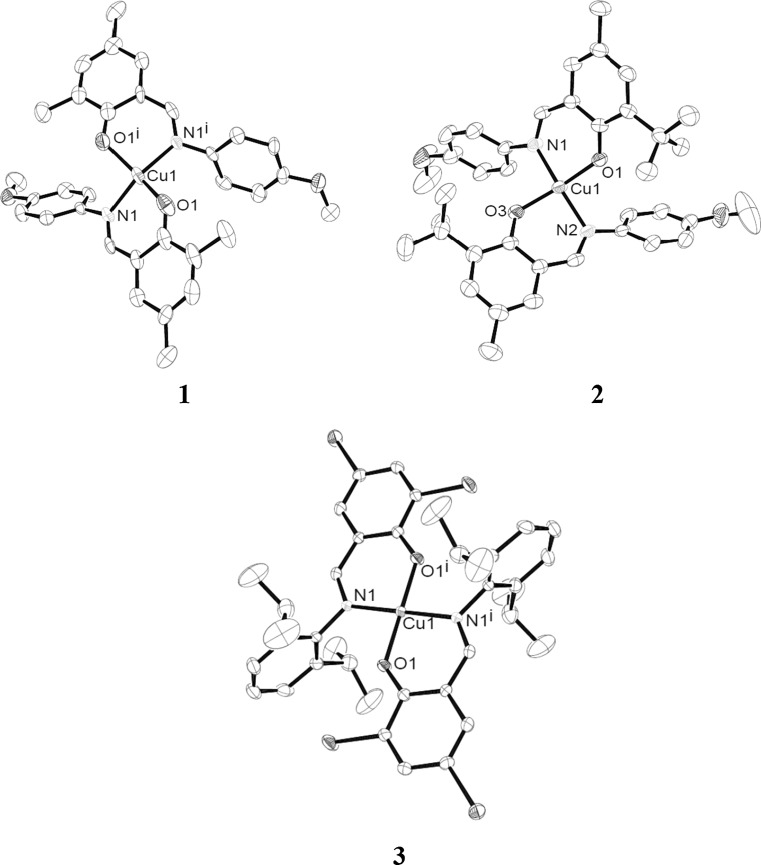

Electronic spectra

The electronic spectra of all complexes were recorded in CH2Cl2 in the range of 200–800 nm. The data are summarized in Table 2. The bands below 350 nm are assigned to ligand π–π* transitions (Fig. 2) [62]. The broad bands between 380 and 410 nm are attributed to ligand-to-metal charge transfers (LMCT) [44]. For 2–4 very weak d–d transitions are found beyond 650 nm at very high concentrations (Fig. S7) [46, 53].

Table 2.

UV–Vis spectroscopic data of the complexes 1–4

| Substance | λ/nm (ε/log(dm3 mol−1 cm−1)) |

|---|---|

| 1 | 281 (sh, 4.40), 302 (4.44), 315 (sh, 4.40), 381 (4.10), 410 (4.07) |

| 2 | 301 (4.46), 314 (4.43), 413 (4.15), 681 |

| 3 | 243 (4.68), 280 (4.44), 306 (sh, 4.19), 384 (4.11), 408 (sh, 4.10), 661 |

| 4 | 245 (sh, 4.46), 277 (4.30), 328 (3.80), 387 (3.83), 757 |

Fig. 2.

UV–Vis absorption spectra of 1–4 in dichloromethane (c ≈ 10−5 mol dm−3)

(Spectro)electrochemistry

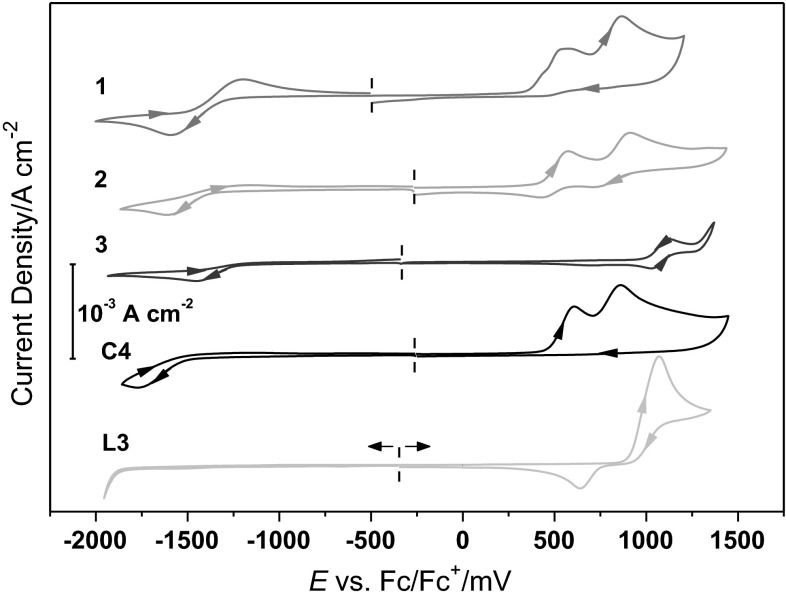

The electrochemical behavior of complexes 1–4, as well as of ligand L3 was investigated by cyclic voltammetry (CV) in CH2Cl2 solutions containing 0.1 M of [Bu4N]PF6 as supporting electrolyte. The ferrocene/ferrocenium (Fc/Fc+) redox pair was used as internal standard. The oxidative and the reductive scan were conducted separately due to the deposition of a brownish-red metallic material (presumably copper) on the working electrode which could be observed after cathodic scanning.

Within the electrochemical potential window of the solvent and electrolyte, all investigated complexes show a single reduction (Fig. 3). Most authors assign this first reduction potential to the reduction of the neutral Cu(II) imino phenoxide complex to the anionic Cu(I) complex. The stability of the reduced form varies significantly among the complexes and this is represented by large differences of the I pa/I pc ratio of the reductive wave which is a measure of different reversibilities of the redox process. The redox potential for Cu(II) alkyl imino phenoxide shows differences for square-planar and non-planar coordination and has been systematically studied by polarography [52]. The authors found that the higher the deviation from the square-planar coordination the higher the reduction potential, i.e., the easier the complex is reduced. However, no such purely structural-based trends could be observed for the Cu(II) aryl imino phenoxide complexes in our study. The substituents of the ligands seem to have strong electronic effects that influence the redox potential more than the structures. Complex 1 shows a quasi-reversible reduction wave with a half-wave potential of −1391 mV vs. Fc/Fc+ (I pa/I pc ~0.9, Table 3). For complex 2, the oxidative peak of the first reduction potential shows much lower current density, hence the ratio I pa/I pc cannot be determined reliably. This effect has been observed earlier with similar compounds and has been ascribed to the decomposition of the complexes due to the instability of the singly reduced species via a process of ligand loss and immediate further reduction from Cu(I) to Cu(0).

Fig. 3.

Cyclic voltammograms of complexes 1–4 and ligand 3

Table 3.

Electrochemical properties of 1–4 measured by cyclic voltammetry; potentials are given against the ferrocene/ferrocenium redox couple in mV Estimated error ±3 %

| Catalyst |

E

red[CuIIL2/CuIL2

−] E pc |

E

½red [CuIIL2/CuIL2

−] E 1/2 |

E

ox [CuIIL2/CuIIL2

+] E a |

E

½ox[CuIIL2/CuIIL2

+] E 1/2 |

|---|---|---|---|---|

| 1 | – | −1391 | 546; 869 | – |

| 2 | – | −1377 | – | 503; 813 |

| 3 | −1457 | – | – | 1077 |

| 4 | −1778 | – | 606; 852 | – |

In a recent publication, the oxidation behavior of similar compounds were ascribed to the formation of a phenoxyl radical [54]. This and further oxidation to a quinine-type oxidation product has been supported by EPR spectroscopy upon chemical oxidation with cerium sulfate for methoxy-substituted imino phenoxide Cu(II) complexes [52]. Complexes 1, 2, and 4 show similar electrochemical behaviors as described before with different degrees of reversibility of the oxidation reaction [52, 55]. The oxidation potential of complex 3 is much higher than for the other complexes (Fig. 3). This observation is in line with the assumption that the oxidation is a ligand based process. Contrary to the other ligands, L3 contains no methyl-substituents but electron-withdrawing bromo-ligands which results in the electron-poorest and hence hardest to oxidize ligand.

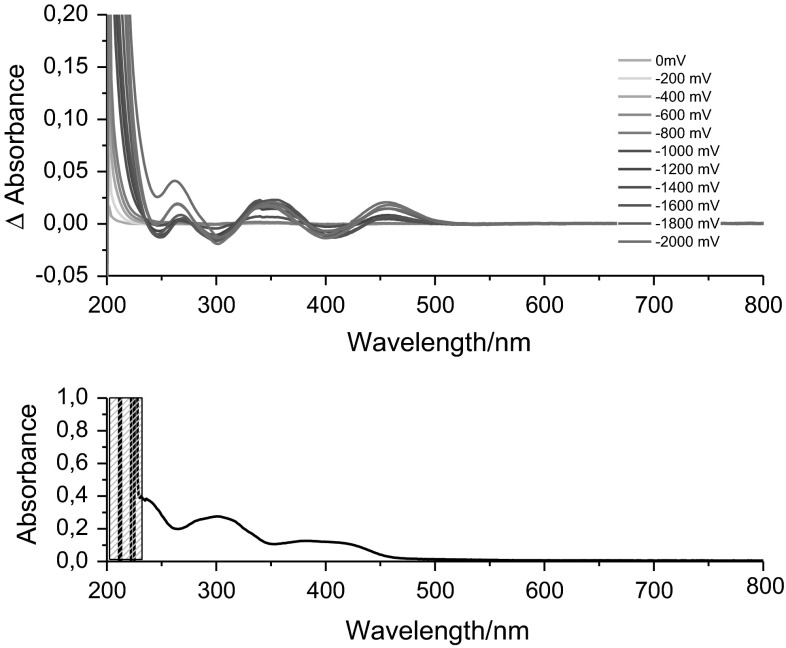

Because it is the only compound featuring a reversible reduction, just 1 was further investigated by spectro-electrochemistry, which was performed in dichloroethane (DCE) solution containing 0.3 M of [Bu4N]PF6 as supporting electrolyte using an optically transparent thin layer electrochemical (OTTLE) cell (Fig. 4). As reported above, Cu(II) is reduced to Cu(I) under reductive conditions. This results in an change of the nature of lowest-energy transition: Cu(I) as a closed-shell d10 ion does not show any d–d or LMCT transitions but metal-to-ligand transition (MLCT) at comparable energies like the LMCTs for Cu(II). Hence, the maximum of the Cu(II) LMCT band at ~400 nm bleaches, whereas two new bands form at ~353 and ~456 nm which are typical for an MLCT of Cu(I) compounds bearing aromatic ligands [63, 64].

Fig. 4.

Spectro-electrochemistry of complex 1 in 0.3 M DCE vs. Ag/AgCl (top) and UV–Vis spectra of complex 1 in DCM for comparison (bottom)

Polymerization studies

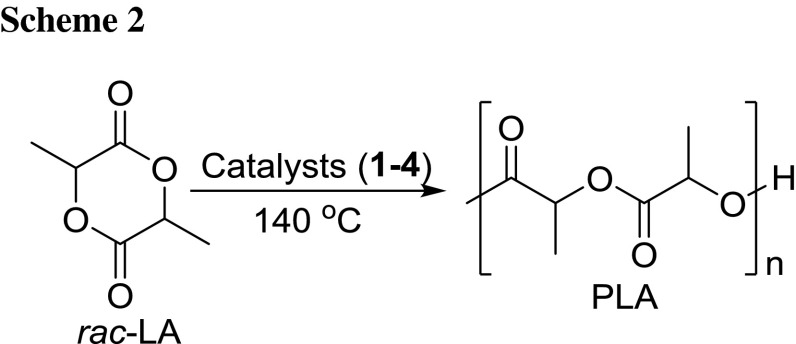

All four complexes were able to initiate the ROP of rac-LA under solvent free conditions generating PLA of moderate molecular weights (5.30–6.04 kg/mol) and relatively high polymer dispersities (MWDs = 1.71–1.83, Scheme 2). The polymerizations were carried out at 140 °C in a ratio of 200:1 (rac-LA:catalyst). The results are summarized in Table 4. The appearances of broader MWDs could be partly explained by transesterification during the polymerization process [65, 66], as well as the slow initiation rates in comparison with a fast propagation. Steric and electronic properties of the ligands affect the catalytic efficiency. Complex 4 is the only one in this series with a benzyl and not an aryl group bound to the imine nitrogen atom, thus rendering the metal center less sterically hindered. Therefore, rac-LA can approach readily towards the metal center, thereby appeared to be the best catalyst amongst the complexes investigated in this study. As the activities of all catalysts were found to be very low under bulk condition compared to published reports using copper complexes [34–36], further polymerizations in solution were not carried out. The low activity might be due to the fact that the Cu(II) atoms are coordinatively saturated in the presented complexes. Both accepted polymerization mechanisms, the coordination-insertion and the monomer-activated mechanism, involve the coordination of the carboxylate oxygen atom to the metal atom of the catalyst [67]. Although it is known that Cu(II) is capable of forming five-coordinate square-pyramidal complexes, the tendency to coordinate an additional donor atom of a substrate molecule seems to be low. Furthermore, the complexes seem to be rather stable. Therefore, the formation of a reactive intermediate with a coordinatively unsaturated metal atom by ligand dissociation is unlikely.

Table 4.

Polymerization data for rac-LA using 1–4 in 200:1 ratio (rac-LA:catalyst) at 140 °C

| Entry | Catalyst | Yield/% | M obsn/kg mol−1a | M w/M n | k app/×10−3 min−1b |

|---|---|---|---|---|---|

| 1 | 1 | 94 | 5.45 | 1.78 | 9.361 |

| 2 | 2 | 95 | 5.76 | 1.75 | 10.58 |

| 3 | 3 | 93 | 5.30 | 1.83 | 7.562 |

| 4 | 4 | 95 | 6.04 | 1.71 | 12.78 |

aMeasured by GPC at 60 °C in DMF relative to polystyrene standards

bAs measured from the NMR study

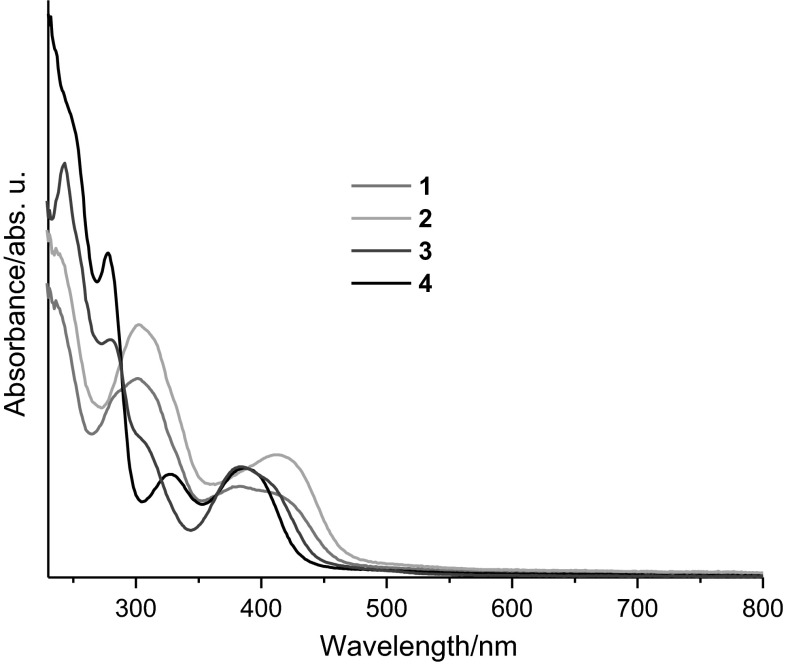

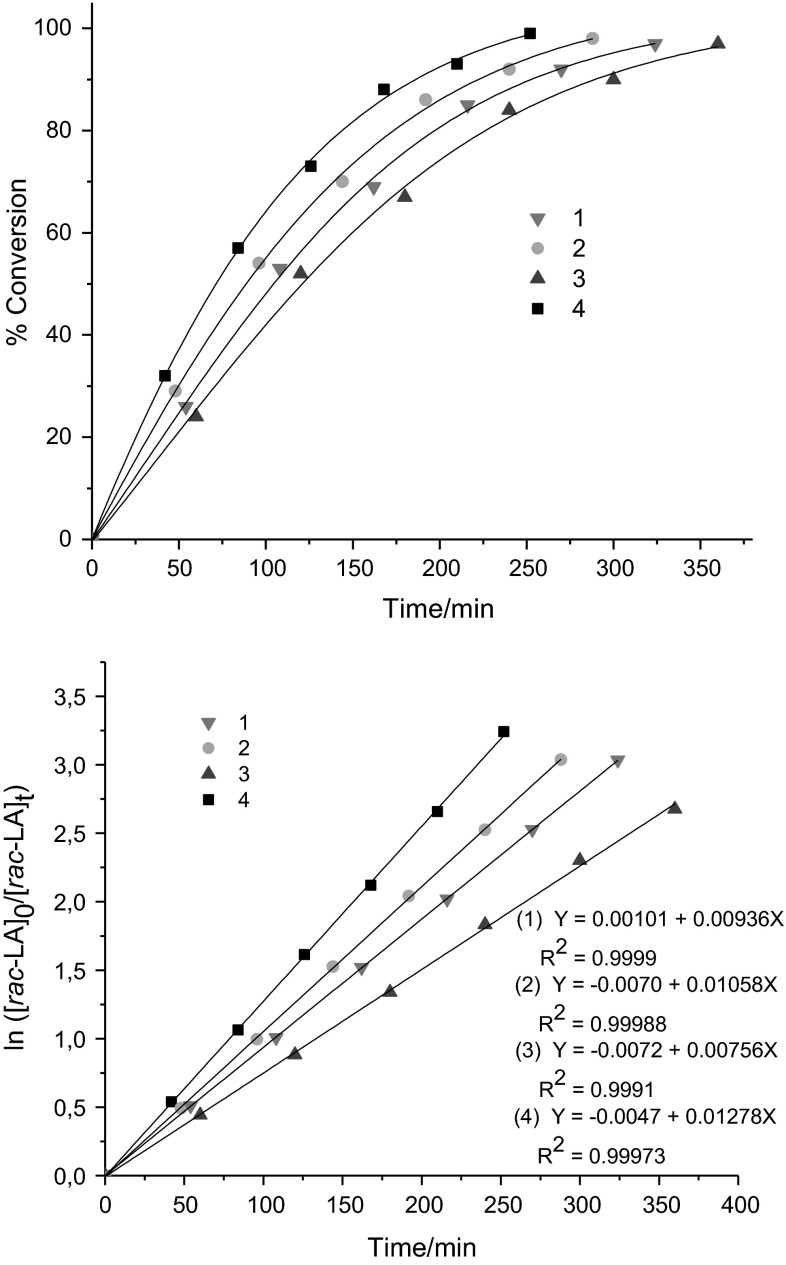

The polymerization kinetics of rac-LA in 200:1 ratio ([rac-LA]0:[Cat]0) using complexes 1–4 were investigated by monitoring the reaction via 1H NMR spectroscopy. Aliquots of the reaction mixtures were taken out at regular time intervals and the percentage conversion of unreacted monomer to polymer was measured by comparing the peaks at 4.99–5.06 ppm (unreacted monomer) and 5.11–5.25 (polymer). The plot of %-conversion of rac-LA against time described a sigmoid curve (Fig. 5, left). The plot of ln([LA]0/[LA]t) vs. time exhibited a good linear relation and indicates that the polymerization proceeds with first order dependence on monomer concentration (Fig. 5, right). The values of the apparent rate constant (k app) for rac-LA polymerization catalyzed by 1–4 were evaluated from the slope of these regression lines and are found to be 9.36 × 10−3, 10.6 × 10−3, 7.56 × 10−3, and 12.8 × 10−3 min−1 for 1–4, respectively. The polymerization rate is fastest for 4 and slowest for 3.

Fig. 5.

rac-LA conversion vs. time (top) and ln([LA]0/[LA]t) vs. time plot (bottom) using 1–4: [rac-LA]0:[Cat]0 = 200:1 at 140 °C

Conclusion

In summary, we have synthesized four new copper(II) complexes containing imino phenoxide ligands. These compounds were characterized by spectroscopy (IR, UV–Vis), mass spectrometry, single crystal X-ray crystallography, electrochemistry, and elemental analysis. All complexes feature a metal-based reduction from Cu(II) to Cu(I) and a ligand-centered oxidation. Only for complex 1, the reduction is quasi-reversible, whereas oxidation of all complexes is irreversible. All complexes exhibited low activity towards the ROP of rac-LA in comparison to the literature reported protocols using Cu(II) complexes. The catalytic activity of 4 was found to be highest.

Experimental

All manipulations were carried out in an atmosphere of dry nitrogen using standard Schlenk techniques. CDCl3 used for NMR spectral measurements was dried over calcium hydride for 48 h, distilled and stored in a glove box. IR spectroscopy was performed on a Shimadzu IRAffinity-1 FTIR spectrophotometer that was equipped with a Specac Golden Gate™ single-reflection diamond ATR accessory. Mass spectra were collected on a Finnigan LCQ DecaXPPlus Ion Trap Mass spectrometer with an ESI ion source. Elemental analyses were carried out at the Institute for Chemical Technology of Organic Materials at JKU. For photophysical characterization, spectroscopic grade solvents were used throughout all measurements. Absorption spectra were recorded with a Varian Cary 300 or 50 spectrophotometer. All ε values are given in dm3 mol−1 cm−1. Cyclic voltammetry (CV) experiments were carried out under inert conditions in a glovebox using an Eco Autolab potentiostat with a self-made three-electrode cell consisting of a BASi platinum working electrode, a platinum wire as a counter electrode and a silver/silver chloride quasi-reference electrode. The Pt working electrode was polished with 0.1 mm alumina powder and washed with dilute HNO3 and double distilled water. The complexes were dissolved in dichloromethane with 0.1 M tetrabutylammonium hexafluorophosphate (TBAPF6) as the supporting electrolyte. Scanning rates of 50–200 mV/s were applied. Ferrocene was employed as internal standard for potential referencing, and the potentials were subsequently referenced vs. SCE accordingly [68]. Cyclic voltammograms of all complexes were recorded in the potential range of +1.6 to −1.6 V. Spectro-electrochemistry was performed in a thin layer OTTLE cell [69] with a platinum working electrode, a platinum wire as a counter electrode, and a silver reference electrode. The corresponding UV–Vis absorption spectra were collected with a Jasco V670 Spectrometer.

Materials

Dichloromethane was dried and distilled over K2CO3, and methanol was dried and distilled over Na. Cu(OAc)2·2H2O was purchased from Sigma-Aldrich and used without further purification. rac-LA was purchased from Sigma-Aldrich and sublimed under a nitrogen atmosphere repeatedly for further purification and stored in a glove box. All other solvents and reagents were commercially available and used as received. Ligands L1–L4 were prepared according to literature reported procedures [56, 57].

Synthesis of complexes 1–4

General procedure for the synthesis of 1–4: a methanolic solution (20 cm3) of the Schiff base (1 mmol) and copper acetate (0.5 mmol) in 10 cm3 methanol were mixed thoroughly and the mixture was heated under reflux for 2 h and then cooled to room temperature. After filtration the resulting solution was evaporated to dryness and the residue was recrystallized from dichloromethane.

Bis[2-[(4-methoxyphenyl)iminomethyl]-4,6-dimethylphenolato-κ2N,O1]copper(II) (1, C32H32CuN2O4)

Yield 0.08 g (81 %); ESI–MS: m/z calculated for C32H32CuN2O4Na ([M+Na]+) 594.17, found 594.33; IR (ATR): = 1619 (–CH=N), 1506 (Ar–OMe) cm−1.

Bis[2-[(4-methoxyphenyl)iminomethyl]-4-methyl-6-(tert-butyl)phenolato-κ2N,O1]copper(II) (2, C38H44CuN2O4)

Yield 0.07 g (82 %); ESI–MS: m/z calculated for C38H44CuN2O4Na ([M+Na]+) 678.30, found 678.40; IR (ATR): = 1616 (–CH=N), 1506 (Ar–OMe) cm−1.

Bis[2,4-dibromo-6-[(2,6-diisopropylphenyl)iminomethyl]phenolato-κ2N,O1]copper(II) (3, C38H40Br4CuN2O2)

Yield 0.07 g (80 %); ESI–MS: m/z calculated for C38H41Br4CuN2O2 ([M+H]+) 935.93, found 935.13; IR (ATR): = 1606 (–CH=N) cm−1.

Bis[2-[(4-methoxybenzyl)iminomethyl]-4-methyl-6-(tert-butyl)phenolato-κ2N,O1]copper(II) (4, C40H48CuN2O4)

Yield 0.06 g (83 %); ESI–MS: m/z calculated for C40H48CuN2O4Na ([M+Na]+) 706.29, found 706.33; IR (ATR): = 1620 (–CH=N), 1513 (Ar–OMe) cm−1.

X-ray structure determination of complexes 1–4

Suitable single crystals for X-ray diffraction were obtained for all four compounds under ambient conditions from concentrated dichloromethane solution of the respective compounds over a period of 7 days. Diffraction data were collected on a Bruker Smart X2S diffractometer operating with Mo Kα radiation (λ = 0.71073 Å). The structures were solved by direct methods (SHELXS-97) [70, 71] and refined by full-matrix least squares on F 2 (SHELXL-97) [72, 73]. The H atoms were calculated geometrically, and a riding model was applied in the refinement process. These data were deposited with CCDC with the following numbers: CCDC 1448157–1448160 and can be obtained free of charge from the Cambridge Crystallographic Data Centre at https://summary.ccdc.cam.ac.uk/structure-summary-form. Crystal data are given in Table 5 and S1.

General procedure for the bulk polymerization of rac-LA

The polymerizations were performed under solvent free conditions in 200:1 ratio of rac-LA and the complexes with 173 μmol of 1–4 and 5.00 g of rac-LA (34.7 mmol) under a nitrogen atmosphere in a 50 cm3 flask. Under stirring, the flask was heated to 140 °C. Once the monomer melted fully, a rise in viscosity due to the polymerization reaction was observed and finally the stirring ceased. Then the reaction mixture was dissolved into a minimum quantity of CH2Cl2 and poured into cold methanol. The polymer precipitated immediately and was collected by filtration. The filtered product was dried in vacuum until a constant weight was achieved. Cold methanol was used for the quenching of the polymerization reaction. The formed polymer was filtered and dried in vacuum.

Kinetics of rac-LA polymerization

To determine the kinetics of the polymerization of rac-LA, a polymerization reaction in small scale at a temperature of 140 °C under nitrogen atmosphere were carried out. At 200:1 ratio the polymerizations were performed by charging 11.6 μmol of 1–4 (7 mg of 1, 8 mg of 2, 11 mg of 3, and 8 mg of 4) and 1.00 g of rac-LA (6.94 mmol). Aliquots were taken out at regular time intervals from the glass reactor under argon atmosphere and 1H NMR spectra were recorded to determine the % conversion of monomer into the corresponding polymer by comparing the methine proton of the unreacted monomer and polymer. Apparent rate constant (k app) were obtained from the slopes of the best fit lines from a plot of ln([rac-LA]0/[rac-LA]t) vs. time.

Characterization of polymers

Molecular weights (M n) and molecular weight distributions (MWDs) of the polymer samples produced by the ROP of rac-LA were determined using gel permeation chromatography (GPC). GPC was performed on a Viscothek GPCmax instrument using a PFG column from PSS (Mainz, Germany, 300 mm × 8 mm, 5 μm particle size). The samples were eluted with DMF containing 5 mM LiBr as the mobile phase at a flow rate of 0.75 cm3 min−1 at 60 °C. The molecular weights were calculated relative to polystyrene standards from PSS using a conventional calibration of the refractive index detector. The samples were filtered through a nylon microfilter (0.2 μm) prior to the measurement.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgments

Open access funding provided by Johannes Kepler University Linz. M.M. thanks for a scholarship within the framework of Erasmus Mundus Action 2 doctoral exchange program of the European Commission. We thank the JKU and Prof. Knör (JKU) for his generous support of the experimental work. The NMR spectrometers were acquired in collaboration with the University of South Bohemia (CZ) with financial support from the European Union through the EFRE INTERREG IV ETC-AT-CZ program (project M00146, “RERI-uasb”).

Contributor Information

Debashis Chakraborty, Email: dchakraborty@iitm.ac.in.

Uwe Monkowius, Email: uwe.monkowius@jku.at.

References

- 1.Cozzi PG. Chem Soc Rev. 2004;33:410. doi: 10.1039/B307853C. [DOI] [PubMed] [Google Scholar]

- 2.Hernández-Molina R, Mederos A. Compr Coord Chem II. 2003;2:411. [Google Scholar]

- 3.Saha TK, Mandal M, Chakraborty D, Ramkumar V. New J Chem. 2013;37:949. doi: 10.1039/c3nj40916c. [DOI] [Google Scholar]

- 4.Ghosh S, Chakraborty D, Varghese B. Eur Polym J. 2015;62:51. doi: 10.1016/j.eurpolymj.2014.10.010. [DOI] [Google Scholar]

- 5.Roymuhury SK, Chakraborty D, Ramkumar V. Dalton Trans. 2015;44:10352. doi: 10.1039/C5DT01092F. [DOI] [PubMed] [Google Scholar]

- 6.Chakraborty D, Mandal M (2016) A process for the preparation of biopolymers. Indian Pat IN2014KO01271 A, 10 Jun 2016, (2016) Chem Abstr 967690

- 7.Ghosh S, Gowda RR, Jagana R, Chakraborty D. Dalton Trans. 2015;44:10410. doi: 10.1039/C5DT00811E. [DOI] [PubMed] [Google Scholar]

- 8.Saha TK, Mandal M, Thunga M, Ramkumar V, Chakraborty D. Dalton Trans. 2013;42:10304. doi: 10.1039/c3dt50752a. [DOI] [PubMed] [Google Scholar]

- 9.Ragauskas AJ, Williams CK, Davison BH, Tschaplinski T. Science. 2006;311:484. doi: 10.1126/science.1114736. [DOI] [PubMed] [Google Scholar]

- 10.Williams CK, Hillmyer MA. Polym Rev. 2008;48:1. doi: 10.1080/15583720701834133. [DOI] [Google Scholar]

- 11.Dove AP. Chem Commun. 2008;48:6446. doi: 10.1039/b813059k. [DOI] [PubMed] [Google Scholar]

- 12.Nicolas J, Mura S, Brambilla D, Mackiewicz N, Couvreur P. Chem Soc Rev. 2013;42:1147. doi: 10.1039/C2CS35265F. [DOI] [PubMed] [Google Scholar]

- 13.Dechy-Cabaret O, Martin-Vaca B, Bourissou D. Chem Rev. 2004;104:6147. doi: 10.1021/cr040002s. [DOI] [PubMed] [Google Scholar]

- 14.Jerome C, Lecomte P. Adv Drug Deliv Rev. 2008;60:1056. doi: 10.1016/j.addr.2008.02.008. [DOI] [PubMed] [Google Scholar]

- 15.Tschan MJ-L, Brulé E, Haquette P, Thomas CM. Polym Chem. 2012;3:836. doi: 10.1039/C2PY00452F. [DOI] [Google Scholar]

- 16.Wu J, Yu T-L, Chen C-T, Lin C-C. Coord Chem Rev. 2006;250:602. doi: 10.1016/j.ccr.2005.07.010. [DOI] [Google Scholar]

- 17.Drumright RE, Gruber PR, Henton DE. Adv Mater. 2000;12:1841. doi: 10.1002/1521-4095(200012)12:23<1841::AID-ADMA1841>3.0.CO;2-E. [DOI] [Google Scholar]

- 18.Mandal M, Chakraborty D. J Polym Sci Part A Polym Chem. 2016;54:809. doi: 10.1002/pola.27918. [DOI] [Google Scholar]

- 19.Mandal M, Chakraborty D, Ramkumar V. RSC Adv. 2015;5:28536. doi: 10.1039/C4RA17201A. [DOI] [Google Scholar]

- 20.Tsai C-Y, Du H-C, Chang J-C, Huang B-H, Ko B-T, Lin C-C. RSC Adv. 2014;4:14527. doi: 10.1039/c4ra00201f. [DOI] [Google Scholar]

- 21.Wang L, Poirier V, Ghiotto F, Bochmann M, Cannon RD, Carpentier J-F, Sarazin Y. Macromolecules. 2014;47:2574. doi: 10.1021/ma500124k. [DOI] [Google Scholar]

- 22.Aluthge DC, Patrick BO, Mehrkhodavandi P. Chem Commun. 2013;49:4295. doi: 10.1039/C2CC33519K. [DOI] [PubMed] [Google Scholar]

- 23.Sauer A, Kapelski A, Fliedel C, Dagorne S, Kol M, Okuda J. Dalton Trans. 2013;42:9007. doi: 10.1039/c3dt00010a. [DOI] [PubMed] [Google Scholar]

- 24.Dagorne S, Normand M, Kirillov E, Carpentier J-F. Coord Chem Rev. 2013;257:1869. doi: 10.1016/j.ccr.2013.02.012. [DOI] [Google Scholar]

- 25.Nie K, Gu W, Yao Y, Zhang Y, Shen Q. Organometallics. 2013;32:2608. doi: 10.1021/om4001023. [DOI] [Google Scholar]

- 26.Gilding DK, Read AM. Polymer. 1979;20:1459. doi: 10.1016/0032-3861(79)90009-0. [DOI] [Google Scholar]

- 27.John A, Katiyar V, Pang K, Shaikh MM, Nanavati H, Ghosh P. Polyhedron. 2007;26:4033. doi: 10.1016/j.poly.2007.04.039. [DOI] [Google Scholar]

- 28.Chen L-L, Ding L-Q, Zeng C, Long Y, Lu X-Q, Song J-R, Fan D-D, Jin W-J. Appl Organomet Chem. 2011;25:310. doi: 10.1002/aoc.1760. [DOI] [Google Scholar]

- 29.Gowda RR, Chakraborty D. J Mol Catal A Chem. 2011;349:86. doi: 10.1016/j.molcata.2011.08.024. [DOI] [Google Scholar]

- 30.Whitehorne TJJ, Schaper F. Chem Commun. 2012;48:10334. doi: 10.1039/c2cc34247b. [DOI] [PubMed] [Google Scholar]

- 31.Li C-Y, Hsu S-J, Lin C-L, Tsai C-Y, Wang J-H, Ko B-T, Linand C-H, Huang H-Y. J Polym Sci Part A Polym Chem. 2013;51:3840. doi: 10.1002/pola.26780. [DOI] [Google Scholar]

- 32.Appavoo D, Omondi B, Guzei IA, Wyk JLV, Zinyemba O, Darkwa J. Polyhedron. 2014;69:55. doi: 10.1016/j.poly.2013.11.011. [DOI] [Google Scholar]

- 33.Routaray A, Nath N, Maharana T, Sutar AK. J Macromol Sci Pure Appl Chem. 2015;52:444. doi: 10.1080/10601325.2015.1029370. [DOI] [Google Scholar]

- 34.Whitehorne TJJ, Schaper F. Inorg Chem. 2013;52:13612. doi: 10.1021/ic402133c. [DOI] [PubMed] [Google Scholar]

- 35.Kwon KS, Cho J, Nayab S, Jeong JH. Inorg Chem Commun. 2015;55:36. doi: 10.1016/j.inoche.2015.03.003. [DOI] [Google Scholar]

- 36.Fortun S, Daneshmand P, Schaper F. Angew Chem Int Ed. 2015;54:13669. doi: 10.1002/anie.201505674. [DOI] [PubMed] [Google Scholar]

- 37.Wang X, Zhao K-Q, Elsegood MRJ, Prior TJ, Liu X, Wu L, Sanz S, Brechine EK, Redshaw C. RSC Adv. 2015;5:57414. doi: 10.1039/C5RA08696E. [DOI] [Google Scholar]

- 38.Swierczynski D, Luboradzki R, Dolgonos G, Lipkowski J, Schneider H-J. Eur J Org Chem. 2005;6:1172. doi: 10.1002/ejoc.200400446. [DOI] [Google Scholar]

- 39.Nagels N, Hauchecorne D, Herrebout WA. Molecules. 2013;18:6829. doi: 10.3390/molecules18066829. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Sundaravel K, Suresh E, Palaniandavar M. Inorg Chim Acta. 2009;362:199. doi: 10.1016/j.ica.2008.03.083. [DOI] [Google Scholar]

- 41.Garnovskii AD, Nivorozhkin AL, Minkin VI. Coord Chem Rev. 1993;126:1. doi: 10.1016/0010-8545(93)85032-Y. [DOI] [Google Scholar]

- 42.Carlini C, Giaiacopi S, Marchetti F, Pinzino C, Galletti AMR, Sbrana G. Organometallics. 2006;25:3659. doi: 10.1021/om060173i. [DOI] [Google Scholar]

- 43.Safaei E, Kabir MM, Wojtczak A, Jagličić Z, Kozakiewicz A, Lee Y-I. Inorg Chim Acta. 2011;366:275. doi: 10.1016/j.ica.2010.11.017. [DOI] [Google Scholar]

- 44.Lacroix PG, Averseng F, Malfant I, Nakatani K. Inorg Chim Acta. 2004;357:3825. doi: 10.1016/j.ica.2004.03.004. [DOI] [PubMed] [Google Scholar]

- 45.Upadhyay A, Vaidya S, Venkatasai VS, Jayapal P, Srivastava AK, Shanmugam M, Shanmugam M. Polyhedron. 2013;66:87. doi: 10.1016/j.poly.2013.02.039. [DOI] [Google Scholar]

- 46.Costamagna J, Caruso F, Vargas J, Manriquez V. Inorg Chim Acta. 1998;267:151. doi: 10.1016/S0020-1693(97)05571-0. [DOI] [Google Scholar]

- 47.Aguilar-Martínez M, Saloma-Aguilar R, Macías-Ruvalcaba N, Cetina-Rosado R, Navarrete-Vázquez A, Gómez-Vidales V, Zentella-Dehesa A, Toscano RA, Hernández-Ortega S, Fernández-G JM (2001) J Chem Soc Dalton Trans: 2346

- 48.Şenol C, Hayvali Z, Dal H, Hökelek T. J Mol Struct. 2011;997:53. doi: 10.1016/j.molstruc.2011.04.037. [DOI] [Google Scholar]

- 49.Zhang X-L. Z Kristallogr NCS. 2010;225:711. doi: 10.1524/zkri.2010.1202. [DOI] [Google Scholar]

- 50.Kasumov VT, Uçar İ, Bulutand A, Köksal F. Z Naturforsch. 2007;62b:1133. [Google Scholar]

- 51.Eren T, Kose M, Kurtoglu N, Ceyhan G, McKee V, Kurtoglu M. Inorg Chim Acta. 2015;430:268. doi: 10.1016/j.ica.2015.03.010. [DOI] [Google Scholar]

- 52.Patterson GS, Holm RH. Bioinorg Chem. 1975;4:257. doi: 10.1016/S0006-3061(00)80108-8. [DOI] [PubMed] [Google Scholar]

- 53.Kasumov VT, Köksal F. Spectrochim Acta Part A. 2002;58:2199. doi: 10.1016/S1386-1425(01)00689-8. [DOI] [PubMed] [Google Scholar]

- 54.Kasumov VT, Köksal F. Spectrochim Acta Part A. 2012;98:207. doi: 10.1016/j.saa.2012.07.122. [DOI] [PubMed] [Google Scholar]

- 55.Raja KK, Easwaramoorthy D, Rani SK, Rajesh J, Jorapur Y, Thambidurai S, Athappan PR, Rajagopal G. J Mol Catal A Chem. 2009;303:52. doi: 10.1016/j.molcata.2008.12.021. [DOI] [Google Scholar]

- 56.Kasumov VT, Köksal F, Sezer A. Polyhedron. 2005;24:1203. doi: 10.1016/j.poly.2005.04.003. [DOI] [Google Scholar]

- 57.Bhunora S, Mugo J, Bhaw-Luximon A, Mapolie S, Wyk JV, Darkwa J, Nordlander E. Appl Organomet Chem. 2011;25:133. doi: 10.1002/aoc.1728. [DOI] [Google Scholar]

- 58.Toda F, Tanaka K, Miyahara I, Akutsu S, Hirotsu K. J Chem Soc Chem Commun. 1994;15:1795. doi: 10.1039/C39940001795. [DOI] [Google Scholar]

- 59.Nishio M. CrystEngComm. 2004;6:130. doi: 10.1039/b313104a. [DOI] [Google Scholar]

- 60.Nishio M. Tetrahedron. 2005;61:6923. doi: 10.1016/j.tet.2005.04.041. [DOI] [Google Scholar]

- 61.Percino MJ, Cerón M, Soriano-Moro G, Castro ME, Chapela VM, Bonilla J, Reyes-Reyes M, López-Sandoval R. CrystEngComm. 2014;16:8591. doi: 10.1039/C4CE00327F. [DOI] [Google Scholar]

- 62.Kasumov VT, Medjidov AA, Yayli N, Zeren Y. Spectrochim Acta Part A. 2004;60:3037. doi: 10.1016/j.saa.2004.02.021. [DOI] [PubMed] [Google Scholar]

- 63.Kern T, Monkowius U, Zabel M, Knör G. Inorg Chim Acta. 2011;374:632. doi: 10.1016/j.ica.2011.02.042. [DOI] [Google Scholar]

- 64.Monkowius U, Svartsov YN, Fischer T, Zabel M, Yersin H. Inorg Chem Commun. 2007;10:1473. doi: 10.1016/j.inoche.2007.09.010. [DOI] [Google Scholar]

- 65.Dubois P, Jacobs C, Jérôme R, Teyssié P. Macromolecules. 1991;24:2266. doi: 10.1021/ma00009a022. [DOI] [Google Scholar]

- 66.Chamberlain BM, Jazdzewski BA, Pink M, Hillmyer MA, Tolman WB. Macromolecules. 2000;33:3970. doi: 10.1021/ma0000834. [DOI] [Google Scholar]

- 67.Silvernail CM, Yao LJ, Hill LMR, Hillmyer MA, Tolman WB. Inorg Chem. 2007;46:6565. doi: 10.1021/ic700581s. [DOI] [PubMed] [Google Scholar]

- 68.Pavlishchuk VV, Addison AW. Inorg Chim Acta. 2000;298:97. doi: 10.1016/S0020-1693(99)00407-7. [DOI] [Google Scholar]

- 69.Krejčik M, Daněk M, Hartl F. J Electroanal Chem Interfac Electrochem. 1991;317:179. doi: 10.1016/0022-0728(91)85012-E. [DOI] [Google Scholar]

- 70.Sheldrick GM (1997) SHELXS-97, program for the solution of crystal structures, Göttingen, Germany

- 71.Sheldrick GM. Acta Crystallogr A. 1990;46:467. doi: 10.1107/S0108767390000277. [DOI] [Google Scholar]

- 72.Sheldrick GM (1997) SHELXL-97, program for crystal structure refinement, Göttingen, Germany

- 73.Sheldrick GM. Acta Crystallogr A. 2008;64:112. doi: 10.1107/S0108767307043930. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.