Summary

The objective of this study is to investigate the influence of cultivar and industrial processing on total polyphenols, anthocyanins, hydroxycinnamic acids and antioxidant activity in concentrated sour cherry (Prunus cerasus L., cvs. Marasca and Oblačinska) juices. Samples were collected during four processing steps: from fresh fruit prior to processing, then from pressed, filtered and concentrated juices. The content of total phenols was the same in both cultivars, but antioxidant activity (Oblačinska>Marasca) and total monomeric anthocyanins (Marasca>Oblačinska) differed. All processing steps significantly influenced the content of total phenols, total monomeric anthocyanins and antioxidant activity. In all samples four major anthocyanins were identified by HPLC with UV/VIS PDA detector, listed in the descending order based on their abundance: cyanidin-3-glucosylrutinoside, cyanidin-3-rutinoside, cyanidin-3-sophoroside and cyanidin-3-glucoside. Marasca cv. contained more total anthocyanins, and contents of cyanidin-3-sophoroside and cyanidin-3- -glucosylrutinoside. The content of total hydroxycinnamic acids was also higher in Marasca than Oblačinska cv. After processing, the concentration of all identified anthocyanins increased in both cultivars. Majority of the highest values of polyphenols were detected in the juice after pressing. The content of polyphenols and their antioxidant activity were considerably stable during industrial processing to concentrated juice. Although Marasca had higher polyphenolic content than Oblačinska, both cultivars showed promising industrial potential for processing to concentrated juice.

Key words: sour cherry, Marasca cv., Oblačinska cv., juice concentrate processing, polyphenolic content, anthocyanins, antioxidant activity

Introduction

Consumers in developed countries are showing increased interest in the consumption of foods that may have added beneficial influence on their health (1) due to improved awareness about illnesses related to poor dieting (2). As a consequence, functional food and drink industry has shown continuous growth on the worldwide markets as well as increased interest in raw materials that may be used for such production (e.g. concentrated juices for production of functional drinks). Sour cherries (Prunus cerasus L.) are potentially good raw material for functional foods because of substantial content of polyphenols, especially anthocyanins (3–8), with antioxidant activity able to neutralise or scavenge free radicals associated with numerous diseases (9–11). Researchers have identified anthocyanins as anti-inflammatory and anticarcinogenic agents (11–13), which are major contributors to the antioxidant activity in sour cherries (6, 7, 14, 15). Apart from common anthocyanins found in sour cherries such as cyanidin-3-glucosylrutinoside (Cy-3-GR), cyanidin-3-rutinoside (Cy-3-R), cyanidin-3-sophoroside (Cy-3-S), cyanidin--3-glucoside (Cy-3-G), they also contain hydroxycinnamic acids (HCA), flavonol glycosides and flavan-3-ols (4, 16–18). The concentration of phenolic acids is usually measured as these compounds are the precursors of flavour (8), thus may influence the final product quality (19). However, variations in polyphenolic content in different cultivars have been reported (4, 7, 8, 11, 16, 20, 21). Additionally, Khoo et al. (11) showed that differences among cultivars significantly influenced their health-promoting effects.

Marasca and Oblačinska are the two main cultivars of sour cherries in Croatia. Marasca is a traditional cultivar (mostly cultivated in the Adriatic region) with excellent food processing qualities (e.g. common soluble solids content above 25%, appealing deep red colour and intense aroma) (22). In comparison with other cultivars, Marasca had higher polyphenolic content (14, 16, 20, 23, 24) and higher antioxidant activity in concentrated juices with documented positive impact on human health (25, 26). The Oblačinska cultivar is grown mostly in continental Croatia and is among cultivars with high anthocyanin content (24, 27). As a result, both cultivars have potential for processing to industrial concentrates that can be used in the production of various functional beverages.

Juice concentration is industrial process with several technological operations involving heating, addition of pectolytic enzymes, pressing, filtration, pasteurisation and evaporation, which can have adverse effects on thermally instable bioactive compounds (e.g. polyphenols). Toydemir et al. (28) reported that heating and enzymatic pretreatment contribute to better extractability and higher anthocyanin content in juices during processing, leading to enriched concentrated juice. Even though available findings on different cultivars seem promising (imply good polyphenolic stability and antioxidant activity with processing) (7, 15, 28), further investigation is necessary to define influences of processing on additional cultivars with food processing potential. Preliminary data for these two cultivars showed higher concentrations of polyphenols in Marasca than in Oblačinska concentrated juice (20, 29); however, there is lack of research focused on the stability of polyphenols during processing to concentrate. Hence, the aim of this research is to study changes in polyphenolic content and antioxidant activity of two Croatian sour cherry cultivars during processing to concentrated juice.

Materials and Methods

Standards and reagents

Ethanol and hydrochloric acid were of reagent grade, purchased from Gram-mol (Zagreb, Croatia). Methanol and formic acid were of HPLC grade, purchased from Gram-mol. Anthocyanin standards (cyanidin-3-O-sophoroside chloride, cyanidin-3-O-glucoside chloride and cyanidin-3-O-rutinoside chloride) were purchased from Extrasynthese (Lyon, France). Phenolic acid (chlorogenic, p-coumaric and caffeic acids) standards were obtained from Sigma- -Aldrich (Steinheim, Germany).

Material

Fresh fruit of sour cherry Marasca and Oblačinska was processed into concentrated juice in an industrial facility of Dona Ltd. company (Gornja Stubica, Croatia). Samples of each cultivar with replicates were collected from four processing steps and total of sixteen samples were analysed: (i) fresh fruit prior to processing (FF), (ii) pressed juice (PJ), (iii) filtered juice (FJ) and (iv) concentrated juice (CJ). Fruit was mashed before pressing, heated at 45–50 °C, treated with 20–40 mL/t of pectolytic and amylolytic enzymes (Endozym Pectofruit PR, AEB group, Brescia, Italy) for one hour, and pressed with Bucher press (Bucher Vaslin SA, Chalonnes sur Loire, France) to obtain PJ-Marasca and PJ-Oblačinska. Pressed juices were pasteurised at 85 °C for 2 min, cooled at 50 °C and treated with 2–3 g/hL of pectolytic enzyme (Endozym Pectofruit, AEB group) for two hours, precipitated and then vacuum- and plate-filtered to obtain FJ-Marasca and FJ-Oblačinska. Filtered juices were evaporated to 65 °Brix in a four-stage evaporator with aroma recovery to obtain concentrated juices (CJ-Marasca and CJ-Oblačinska). Samples FF-Marasca, FF-Oblačinska, PJ-Marasca, PJ-Oblačinska, FJ-Marasca and FJ-Oblačinska were packed in polyethylene bags, while CJ-Marasca and CJ-Oblačinska were put in glass bottles. All samples were stored at –18 °C until analysis. Prior to analysis, samples were thawed at room temperature. Samples FF-Marasca and FF-Oblačinska were manually pitted and homogenised with hand blender (Philips, Amsterdam, the Netherlands).

Determination of total phenols and antioxidant activity

The phenolic compounds were extracted as follows: 10 g of homogenised fruit (FF-Marasca/FF-Oblačinska) or 10 mL of juice (PJ-Marasca, PJ-Oblačinska, FJ-Marasca, FJ--Oblačinska, CJ-Marasca and CJ-Oblačinska) were mixed with 30 mL of 80% aqueous solution of ethanol. The mixture was extracted for 15 min in ultrasonic bath (Bandelin Electronic GmbH&Co. KG, Berlin, Germany) preheated to 50 °C, filtered through Whatman no. 40 filter paper (Whatman International Ltd., Kent, UK) and made up to 50 mL in a volumetric flask with extraction solvent. The obtained extracts were used for the determination of total phenols (TP) and antioxidant activity (AA). TP were determined using the Folin-Ciocalteu colourimetric method (30) with some modifications. Briefly, in 25-mL volumetric flask was added: 0.25 mL of diluted extracts, 15 mL of double distilled water, 1.25 mL of Folin-Ciocalteu reagent and after 5 min, 3.75 mL of 20% Na2CO3 solution. The mixture was made up to 25 mL with extraction solvent and incubated for 30 min at 50 °C. Absorbance was measured at 765 nm and TP were expressed as mg of gallic acid equivalents (GAE) per g of dry matter.

The AA was determined by FRAP method with a few modifications (31). The FRAP reagent was prepared from 2.5 mL of 2,4,6-tripyridyl-s-triazine solution (10 mmol/L) in hydrochloric acid (40 mmol/L) and 2.5 mL of iron(III) chloride solution (20 mmol/L) mixed with 25 mL of acetate buffer (0.3 mol/L, pH=3.6). The volume of 2.08 mL of FRAP reagent was mixed with 240 µL of distilled water and 80 µL of diluted extract. The mixture was incubated for 5 min at 37 °C before the absorbance was measured at 593 nm. The FRAP values were calculated according to the calibration curve for Trolox and expressed as mmol of Trolox equivalents (TE) per g of dry matter.

Determination of total monomeric anthocyanins

For the determination of total monomeric anthocyanins (TMA) in FF-Marasca and FF-Oblačinska, 10 g of homogenised fruit were heat–reflux extracted for 10 min with 20 mL of 80% aqueous solution of ethanol and filtered through Whatman no. 40 filter paper. Extraction of the residue was repeated under the same conditions. The obtained extracts were combined in 50-mL volumetric flask and made up to 25 mL with the extraction solvent.

The TMA in juices (PJ-Marasca, PJ-Oblačinska, FJ- -Marasca, FJ-Oblačinska) and concentrates (CJ-Marasca, CJ-Oblačinska) were determined directly from samples using pH differential method (32). Mass fractions of TMA were calculated and expressed as mg of cyanidin-3-glucoside equivalents per g of dry matter. All spectrophotometric measurements were performed by UV-VIS spectrophotometer (UNICAM HEλIOSβ UV-VIS spectrometer, Thermo Spectronic, Cambridge, UK).

HPLC analysis of individual anthocyanins and HCA

Polyphenols were extracted by modified Wrolstad protocol (33), where 5 g of homogenised fruit or 5 mL of juice was mixed with 15 mL of 0.01% hydrochloric acid in 30% aqueous solution of ethanol. The mixture was sonicated for 15 min in Erlenmeyer flask at 50 °C, filtered through Whatman no. 40 filter paper, and made up to 25 mL in a volumetric flask with extraction solvent. Separation of polyphenols was performed by HPLC, using a Varian ProStar system (Palo Alto, CA, USA) equipped with a ProStar 230 solvent delivery module, injector Rheodyne 7125 and ProStar 330 UV/VIS-photo diode array (PDA) detector. Polyphenols were separated on a Zorbax ODS C18 column (250 mm×4.6 mm i.d., particle size 5 µm) including Zorbax ODS C18 guard column (10 mm×4.6 mm i.d., 5 µm) (Agilent Technologies, Santa Clara, CA, USA). The solvent composition and gradient elution conditions were adopted from Tomás-Barberán et al. (34) with few modifications. Three mobile phases (A, B and C) were used instead of four, and solvents contained 2.5% of formic acid instead of 5%. The solvents for gradient elution were 2.5% formic acid solutions in methanol, and 2.5% formic acid solutions in water, mixed in different proportions: A – water/methanol 95:5; B – water/methanol 88:12 and C – water/methanol 20:80. The following gradient was used: 0–15 min 100% A, 15–35 min 100% B, 35–50 min 75% B and 25% C, 50–52 min 50% B and 50% C, and 52–60 min 100% C. The flow rate was 1 mL/min. Operating conditions were: column temperature 20 °C, injection volume 20 µL, UV/VIS-PDA detection at 278 and 510 nm. Polyphenols were identified by comparing retention times and spectral data with those of standards. Phenolic acids were identified at 278 nm and anthocyanins at 510 nm. Quantification was performed by the external standard method.

Anthocyanin standards Cy-3-S, Cy-3-G, and Cy-3-R were prepared as stock solutions in acidified methanol (0.01% hydrochloric acid in 100% methanol) at the concentration of 200 mg/L. Phenolic acid standards for chlorogenic acid (CHA), p-coumaric acid (pCA) and caffeic acid (CA) were prepared as stock solutions in 80% methanol at the concentration of 50 mg/L. Working standard solutions were prepared by diluting the stock solutions to yield five concentrations of anthocyanins in the range from 7.5 to 200 mg/L and of phenolic acids from 10 to 50 mg/L. Quantitative determinations were carried out using calibration curves of standards. For those compounds lacking reference standards, identification was done according to the retention time, polarity and characteristic UV/VIS spectra of sour cherry polyphenols as previously reported (18, 34). The Cy-3-GR was quantified by Cy-3-G calibration curve, neochlorogenic acid (NCHA) by the CHA curve, and unidentified derivative of caffeic acid (CA-D) by the CA calibration curve. Since anthocyanins are important polyphenols in sour cherry and significant contributors to juice quality (from economical, nutritive and food science perspective), they were monitored individually during processing to observe variations in their stability, while HCA was monitored as total HCA. All analyses were done in duplicates.

Statistical analysis

Experiments were designed as full factorial randomised experimental design (35). Descriptive statistics was used to assess the basic information about the data. Dependent continuous variables were contents of: TP, TMA, AA, Cy-3-S, Cy-3-GR, Cy-3-G, Cy-3-R and HCA. Independent categorical variables were: cultivar type and technological processing steps. Continuous variables were analysed using two-way ANOVA (multivariate analysis). Pearson’s linear correlation tested the relationship between the pairs of continuous variables. Marginal mean values were compared with Tukey’s multiple comparison tests. Data are presented in tables as mean values±standard errors. The significance levels for all tests were α≤0.05, while analyses were performed with IBM SPSS Statistics (v. 22) (IBM Corp., Armonk, NJ, USA).

Results and Discussion

Influence of cultivar and processing on TP, TMA and AA

Data presented in Table 1 show that both sour cherry cultivars had similar amounts of TP, while Marasca had higher TMA than Oblačinska, with 7% higher AA in Oblačinska cv. Higher AA in Oblačinska cv. may be due to the presence of other bioactive compounds besides anthocyanins, which are found in sour cherry, like vitamin C and melatonin (8, 36). Generally, TP and TMA values in fresh fruit of both cultivars (Table 2) were similar to the results previously published by other researchers (4, 5, 7, 37, 38). However, Viljevac et al. (24) found higher values of TP and TMA than those reported in Table 2. This is likely due to extensive extraction with higher amounts of extracted TP and TMA that these authors used. Similar to our results, that study also reported both, higher TP and TMA in Marasca than in Oblačinska cv. Furthermore, TP and TMA values for Oblačinska were close to the results by Khoo et al. (11), who examined Oblačinska among 34 investigated cultivars with 1.88 mg/g of TP and 1.05 mg/g of TMA. In another group of samples (39), our research group detected three times higher values of TMA, but almost fourfold lower values of TP. This was likely due to the influence of different applied methods and environmental cultivation factors (e.g. light, temperature and stress during cultivation), in addition to investigation of one particular ecotype in that study (fruit samples in this study were a mixture of ecotypes harvested for industrial processing). The fresh fruit of both cultivars had the same AA values (Table 2), which was in accordance with previous reports (4, 8, 29).

Table 1. Mass fractions of TP and TMA, and AA in the two sour cherry cultivars during different processing steps.

| w/(mg/g) | AA/(mmol of TE/g) | ||||

|---|---|---|---|---|---|

| TP | TMA | AA | |||

| p=0.27 | p≤0.05 | p≤0.05 | |||

| Cultivar | Marasca | (17.5±0.5)a | (3.83±0.06)a | (0.136±0.001)b | |

| Oblačinska | (16.6±0.5)a | (3.43±0.06)b | (0.146±0.001)a | ||

| p≤0.05 | p≤0.05 | p≤0.05 | |||

| Processing step | Fresh fruit | (12.4±0.8)c | (2.42±0.08)d | (0.083±0.002)d | |

| Pressed juice | (20.5±0.8)a | (4.03±0.08)b | (0.186±0.002)a | ||

| Filtered juice | (18.6±0.8)a,b | (4.64±0.08)a | (0.155±0.002)b | ||

| Concentrated juice | (16.8±0.8)b | (3.42±0.08)c | (0.139±0.002)c | ||

Different letters in the same column indicate significant differences (p≤0.05) Results are expressed on dry mass basis as mean values±standard errors TP=total phenols, TMA=total monomeric anthocyanins, AA=antioxidant activity, TE=Trolox equivalents

Table 2. Mass fractions of TP and TMA, and AA in the two sour cherry cultivars during various concentrate processing steps.

| Processing step | Cultivar | w/(mg/g) | AA/(mmol of TE/g) | ||

|---|---|---|---|---|---|

| TP | TMA | AA | |||

| p=0.45 | p≤0.05 | p≤0.05 | |||

| Fresh fruit | Marasca | (13.5±1.1)a | (2.7±0.1)a | (0.078±0.003)a | |

| Oblačinska | (11.4±1.1)a | (2.2±0.1)a | (0.089±0.003)a | ||

| Pressed juice | Marasca | (20.4±1.4)a | (4.1±0.1)a | (0.196±0.002)a | |

| Oblačinska | (20.7±1.4)a | (4.0±0.1)a | (0.176±0.002)b | ||

| Filtered juice | Marasca | (18.3±0.9)a | (5.2±0.1)a | (0.145±0.001)b | |

| Oblačinska | (18.8±0.9)a | (4.1±0.1)b | (0.165±0.001)a | ||

| Concentrated juice | Marasca | (17.9±0.8)a | (3.38±0.09)a | (0.123±0.002)b | |

| Oblačinska | (15.7±0.8)a | (3.47±0.09)a | (0.155±0.002)a | ||

Different letters in the same column indicate significant differences (p≤0.05) Results are expressed on dry mass basis as mean values±standard errors TP=total phenols, TMA=total monomeric anthocyanins, AA=antioxidant activity, TE=Trolox equivalents

With regard to processing, the TP content was significantly higher in pressed, filtered and concentrated juices than in the fresh cherry (Table 1). Mild temperature of 50 °C with enzymatic treatment prior to pressing likely triggered the increase of the TP in the pressed juices by breaking the cellular walls and promoting extraction of polyphenols (29, 40–43). Moreover, mild heating inactivates polyphenol oxidase that is present in cherries and responsible for degradation of anthocyanins and other polyphenols (44). In filtered and concentrated juices, TP decreased, but they were not significantly different among pressed compared to filtered juices, and among filtered compared to concentrated juices (Table 1). Compared to another study (15), which documented TP and TMA in pressed, enzymatically treated and pasteurised juices from 11 Turkish sour cherry cultivars, values of TP and TMA in our filtered juice were higher.

Both TMA and AA values increased after pressing, when TMA reached maximum in filtered juices and AA peaked in pressed juices (Table 1). Concentration step negatively influenced TMA, likely due to the increase in thermal instability initiated by high processing temperature (44). However, TMA still remained higher in concentrated juices compared to fresh cherries. Similar to previous reports (45), concentration of our samples modestly decreased TMA. Considering the decrease of AA in filtered juices, it was found that fruit skin has the highest AA (4), and its removal during filtration can cause decrease of AA observed in our results (Table 1), and also reported elsewhere (45).

Both cultivars had similar amounts of TP in various steps of concentrate production, except in the concentrated juice, where Marasca had higher TP content, but it was not significant. Marasca had more TMA only in filtered juice, and AA in pressed juice (Table 2). On the other hand, Oblačinska had higher AA in two out of three processing steps. All other technological stages showed the same amounts of TMA regardless of the cultivar.

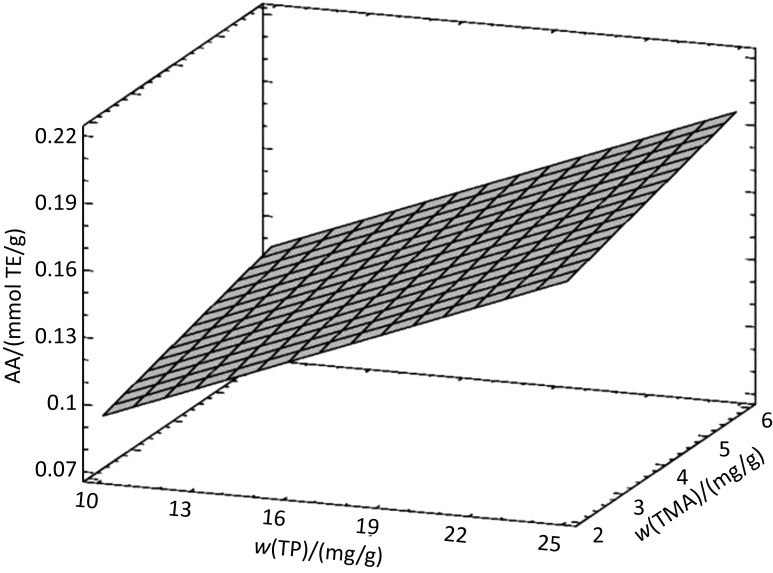

There was no difference in the content of any polyphenols or AA in fresh fruit of both cultivars (Table 2). After the initial TP increase during pressing (Table 1), TP levels decreased with further processing, and settled at 33% in the final product of Marasca, and 38% of Oblačinska (Table 2). The TMA in both cultivars were well preserved during the entire processing (Table 2), whereas filtered juices had the highest amounts (Table 1). Decrease of TMA during concentration (the most deteriorating stage of production with regards to anthocyanins) was lower in Oblačinska than in Marasca (Table 2). The AA values showed somewhat similar trend as TMA in both cultivars, with the highest values observed in pressed juices (Table 2). The Pearson’s linear correlation showed that AA strongly increased with the increase of TP (R=0.6, p≤0.05) and TMA (R=0.5, p≤0.05), indicating that the reported polyphenols appear to be significant contributors to the antioxidant activity (Fig. 1). According to Schüller et al. (46), increase in antioxidant activity does not correlate with anthocyanin content, whereas a strong correlation with total polyphenols was reported. Still, antioxidant activity is strongly related to the content of anthocyanins (15). Our preliminary results on polyphenolic composition and antioxidant activity in filtered Marasca juice showed twofold higher AA (20) than that in the current study (likely due to environmental effects).

Fig. 1.

Mass fractions of total phenols (TP), total monomeric anthocyanins (TMA) and antioxidant activity (AA) on dry mass basis. TE=Trolox equivalents

Influence of cultivar and processing on individual anthocyanins and HCA

The content of individual anthocyanins and HCA (sum of individual phenolic acids) in the studied cultivars during various steps of concentrate production is shown in Table 3. In both cultivars four main anthocyanins were identified, and are listed in the order of elution: Cy-3-S, Cy-3-GR, Cy-3-G and Cy-3-R. The same anthocyanin profile had been reported previously in various sour cherry cultivars (5, 15, 17, 18, 20, 28, 37).

Table 3. Mass fractions of individual anthocyanins and HCA in the two sour cherry cultivars during different processing steps.

| w/(mg/g) | ||||||

|---|---|---|---|---|---|---|

| Cy-3-S | Cy-3-GR | Cy-3-G | Cy-3-R | HCA | ||

| p≤0.05 | p≤0.05 | p=0.20 | p=0.19 | p≤0.05 | ||

| Cultivar | Marasca | (0.307±0.008)a | (2.75±0.05)a | (0.011±0.001)a | (1.10±0.03)a | (2.11±0.01)a |

| Oblačinska | (0.217±0.008)b | (2.30±0.05)b | (0.009±0.001)a | (1.16±0.03)a | (1.70±0.01)b | |

| p≤0.05 | p≤0.05 | p≤0.05 | p≤0.05 | p≤0.05 | ||

| Processing step | Fresh fruit | (0.13±0.01)c | (1.32±0.08)c | (0.008±0.001)b | (0.72±0.04)c | (1.30±0.02)d |

| Pressed juice | (0.25±0.01)b | (2.62±0.08)b | (0.010±0.001)b | (1.18±0.04)a | (2.52±0.02)a | |

| Filtered juice | (0.45±0.01)a | (3.94±0.08)a | (0.013±0.001)a | (1.52±0.04)a | (2.17±0.02)b | |

| Concentrated juice | (0.23±0.01)b | (2.21±0.08)b | (0.009±0.001)b | (1.10±0.04)b | (1.62±0.02)c | |

Different letters in the same column indicate significant differences (p≤0.05) Results are expressed on dry mass basis as mean values±standard errors Cy-3-S=cyanidin-3-sophoroside, Cy-3-GR=cyanidin-3-glucosylrutinoside, Cy-3-G=cyanidin-3-glucoside, Cy-3-R=cyanidin-3-rutinoside, HCA=total hydroxycinnamic acids (sum of neochlorogenic, chlorogenic, caffeic, p-coumaric acids and unidentified derivative of caffeic acid)

Marasca cv. had significantly higher mass fractions of Cy-3-S and Cy-3-GR than Oblačinska cv., while the amounts of Cy-3-G and Cy-3-R in both cultivars did not differ significantly (Table 3). Similar to previous reports (5, 8, 15–18, 20, 37), our results show that Cy-3-GR was the dominant anthocyanin in both cultivars, while Cy-3-G was present in lowest mass fractions (Table 3). Mass fractions of individual anthocyanins in Marasca and Oblačinska cv. showed similar pattern to the already reported one by others (16–18, 21). Differences in anthocyanin content and their composition across different studies may be due to environmental factors, postharvest processing and analytical approaches (8).

Marasca had significantly higher HCA content than Oblačinska (Table 3), and in comparison with our previous research (18), current HCA values were slightly lower (possibly due to use of microwave extraction).

Influence of processing on individual and total anthocyanins was the highest in filtered juices, whereas HCA was the highest in pressed juice (Table 3). Increase of anthocyanins was likely the result of pasteurisation that took place prior to filtration. Samples in this research were pasteurised, enzymatically treated and exposed to high temperatures at short period of time, which likely damaged plant cell walls and induced better extractability of bound pigments. This occurrence was detected in our previous research (29).

Table 4 shows changes in mass fractions of individual anthocyanins and HCA in both cultivars during entire processing to concentrates. Fresh Marasca fruits and their concentrated juices had higher content of Cy-3-S than Oblačinska, while the same amounts were found in other technological stages regardless of cultivar. Both cultivars had the same amounts of Cy-3-G and Cy-3-GR through all stages of production. Oblačinska yielded more of Cy- -3-R than Marasca in pressed and concentrated juices, while filtered Marasca juices had more of this compound. Preliminary results published by our group were similar to these findings with exception of Cy-3-R content, which was lower in Oblačinska concentrates (20). Results showed that Marasca had more HCA than Oblačinska in all analysed samples (Table 4). Similar relations of HCA in Marasca and Oblačinska concentrate had also been observed previously (20).

Table 4. Mass fractions of individual anthocyanins and HCA in the two sour cherry cultivars during various concentrate processing steps.

| w/(mg/g) | ||||||

|---|---|---|---|---|---|---|

| Cy-3-S | Cy-3-GR | Cy-3-G | Cy-3-R | HCA | ||

| p≤0.05 | p=0.24 | p=0.45 | p≤0.05 | p≤0.05 | ||

| Fresh fruit | Marasca | (0.169±0.006)a | (1.6±0.1)a | (0.008±0.001)a | (0.61±0.04)b | (1.71±0.02)a |

| Oblačinska | (0.084±0.006)b | (1.0±0.1)a | (0.007±0.001)a | (0.83±0.04)a | (0.90±0.02)b | |

| Pressed juice | Marasca | (0.27±0.01)a | (2.7±0.1)a | (0.010±0.001)a | (1.09±0.01)b | (2.79±0.04)a |

| Oblačinska | (0.22±0.01)a | (2.5±0.1)a | (0.011±0.001)a | (1.28±0.01)a | (2.25±0.04)b | |

| Filtered juice | Marasca | (0.48±0.03)a | (4.2±0.1)a | (0.015±0.001)a | (1.82±0.08)a | (2.221±0.007)a |

| Oblačinska | (0.42±0.03)a | (3.7±0.1)a | (0.012±0.001)a | (1.22±0.08)b | (2.116±0.007)b | |

| Concentrated juice | Marasca | (0.312±0.009)a | (2.5±0.1)a | (0.010±0.001)a | (0.89±0.07)b | (1.740±0.003)a |

| Oblačinska | (0.146±0.009)b | (1.9±0.1)a | (0.009±0.001)a | (1.30±0.07)a | (1.502±0.003)b | |

Different letters in the same column indicate significant differences (p≤0.05) Results are expressed on dry mass basis as mean values±standard errors Cy-3-S=cyanidin-3-sophoroside, Cy-3-GR=cyanidin-3-glucosylrutinoside, Cy-3-G=cyanidin-3-glucoside, Cy-3-R=cyanidin-3-rutinoside, HCA=total hydroxycinnamic acids (sum of neochlorogenic, chlorogenic, caffeic, p-coumaric acids and unidentified derivative of caffeic acid)

In conclusion, anthocyanins and phenolic acids were well recovered in the final products, which is in the interest of both consumers and food industry (28). Results of our study demonstrated that industrial processing of sour cherry Marasca and Oblačinska to concentrate retained polyphenolic content and antioxidant activity, showing that these cultivars are potentially good ingredients for functional foods, especially Marasca due to rich polyphenolic content.

Conclusion

The obtained results showed that concentrated juices from both sour cherry cultivars were rich in phenolic compounds, with Marasca having higher polyphenolic content than Oblačinska. The content of total phenols was the highest in pressed juice, and of total anthocyanins in filtered juice. Increase of individual and total anthocyanin content was observed during processing from pressed to filtered juice. Despite slight decrease of individual and total anthocyanins in concentrated juice, their amounts remained higher in the final product as compared to the fresh fruit. Considering polyphenolic content, their composition and stability, processing of both cultivars to concentrated juice showed promising potential for the industrial purposes. Further investigations are required to give precise evaluation of polyphenolic content and its changes with processing of Marasca and Oblačinska sour cherries.

Acknowledgements

This work was supported by the Ministry of Science, Education and Sports of the Republic of Croatia. The authors kindly thank Dona Ltd. for providing the samples.

References

- 1.Siddiqui MW, Chakraborty I, Ayala-Zavala JF, Dhua RS. Advances in minimal processing of fruits and vegetables: a review. J Sci Ind Res (India). 2011;70:823–34. [Google Scholar]

- 2.Watson RR, Preedy VR, Zibadi S. Polyphenols in human health and disease. San Diego, CA, USA: Academic Press, Elsevier; 2014. [Google Scholar]

- 3.Wang H, Nair MG, Iezzoni AF, Strasburg GM, Booren AM, Gray JI. Quantification and characterization of anthocyanins in Balaton tart cherries. J Agric Food Chem. 1997;45:2556–60. 10.1021/jf960896k [DOI] [Google Scholar]

- 4.Chaovanalikit A, Wrolstad R. Total anthocyanins and total phenolics of fresh and processed cherries and their antioxidant properties. J Food Sci. 2004;69:FCT67–72. 10.1111/j.1365-2621.2004.tb17858.x [DOI] [Google Scholar]

- 5.Jakobek L, Šeruga M, Medvidović-Kosanović M, Novak I. Anthocyanin content and antioxidant activity of various red fruit juices. Deut Lebensm-Rundsch. 2007;103:58–64. [Google Scholar]

- 6.Jakobek L, Šeruga M, Novak I, Medvidović-Kosanović M. Flavonols, phenolic acids and antioxidant activity of some red fruits. Deut Lebensm-Rundsch. 2007;103:369–78. [Google Scholar]

- 7.Kirakosyan A, Seymour EM, Llanes DEU, Kaufman PB, Bolling SF. Chemical profile and antioxidant capacities of tart cherry products. Food Chem. 2009;115:20–5. 10.1016/j.foodchem.2008.11.042 [DOI] [Google Scholar]

- 8.Wojdyło A, Nowicka P, Laskowski P, Oszmianski J. Evaluation of sour cherry (Prunus cerasus L.) fruits for their polyphenol content, antioxidant properties, and nutritional components. J Agric Food Chem. 2014;62:12332–45. 10.1021/jf504023z [DOI] [PubMed] [Google Scholar]

- 9.Machlin LJ, Bendich A. Free-radical tissue-damage – protective role of antioxidant nutrients. FASEB J. 1987;1:441–5. [PubMed] [Google Scholar]

- 10.Mulabagal V, Lang GA, Dewitt DL, Dalavoy SS, Nair MG. Anthocyanin content, lipid peroxidation and cyclooxygenase enzyme inhibitory activities of sweet and sour cherries. J Agric Food Chem. 2009;57:1239–46. 10.1021/jf8032039 [DOI] [PubMed] [Google Scholar]

- 11.Khoo GM, Clausen MR, Pedersen BH, Larsen E. Bioactivity and total phenolic content of 34 sour cherry cultivars. J Food Compos Anal. 2011;24:772–6. 10.1016/j.jfca.2011.03.004 [DOI] [Google Scholar]

- 12.Wang H, Nair MG, Strasburg GM, Chang YC, Booren AM, Gray JI, et al. Antioxidant and antiinflammatory activities of anthocyanins and their aglycon, cyanidin, from tart cherries. J Nat Prod. 1999;62:294–6. 10.1021/np980501m [DOI] [PubMed] [Google Scholar]

- 13.Kang SY, Seeram NP, Nair MG, Bourquin LD. Tart cherry anthocyanins inhibit tumor development in ApcMin mice and reduce proliferation of human colon cancer cells. Cancer Lett. 2003;194:13–9. 10.1016/S0304-3835(02)00583-9 [DOI] [PubMed] [Google Scholar]

- 14.Dragović-Uzelac V, Bursać Kovačević D, Levaj B, Pedisić S, Mezak M, Tomljenović A. Polyphenols and antioxidant capacity in fruits and vegetables common in the Croatian diet. Agric Conspec Sci. 2009;74:175–9. [Google Scholar]

- 15.Damar I, Eksi A. Antioxidant capacity and anthocyanin profile of sour cherry (Prunus cerasus L.) juice. Food Chem. 2012;135:2910–4. 10.1016/j.foodchem.2012.07.032 [DOI] [PubMed] [Google Scholar]

- 16.Pedisić S, Dragović-Uzelac V, Levaj B, Škevin D. Effect of maturity and geographical region on anthocyanin content of sour cherries (Prunus cerasus var. marasca). Food Technol Biotechnol. 2010;48:86–93. [Google Scholar]

- 17.Elez Garofulić I, Režek Jambrak A, Milošević S. Dragović- -Uzelac V, Zorić Z, Herceg Z. The effect of gas phase plasma treatment on the anthocyanin and phenolic acid content of sour cherry Marasca (Prunus cerasus var. Marasca) juice. LWT-Food Sci Technol. 2015;62:894–900. 10.1016/j.lwt.2014.08.036 [DOI] [Google Scholar]

- 18.Elez Garofulić I, Dragović-Uzelac V, Jambrak AR, Jukić M. The effect of microwave assisted extraction on the isolation of anthocyanins and phenolic acids from sour cherry Marasca (Prunus cerasus var. Marasca). J Food Eng. 2013;117:437–42. 10.1016/j.jfoodeng.2012.12.043 [DOI] [Google Scholar]

- 19.Obon JM, Diaz-Garcia MC, Castellar MR. Red fruit juice quality and authenticity control by HPLC. J Food Compos Anal. 2011;24:760–71. 10.1016/j.jfca.2011.03.012 [DOI] [Google Scholar]

- 20.Levaj B, Dragović-Uzelac V, Bursać Kovačević D, Repajić M, Ćošić Z. Comparison of individual polyphenolic composition and antioxidant capacity in different sour cherry juices. Proceedings of 8th International Congress of Food Technologists, Biotechnologists and Nutritionists, Croatian Society of Food Technologists, Biotechnologists and Nutritionists, Opatija, Croatia; 2014. pp. 81–7. [Google Scholar]

- 21.Šimunic V, Kovač S, Gašo-Sokač D, Pfannhauser W, Murkovic M. Determination of anthocyanins in four Croatian cultivars of sour cherries (Prunus cerasus). Eur Food Res Technol. 2005;220:575–8. 10.1007/s00217-004-1103-2 [DOI] [Google Scholar]

- 22.Medin A. Sour cherry Marasca. Mediterranean agricultural library, Cooperative Union of Dalmatia, Split, Croatia; 1997. [Google Scholar]

- 23.Levaj B, Dragović-Uzelac V, Delonga K, Kovačević Ganić K, Banović M, Bursać Kovačević D. Polyphenols and volatiles in fruits of two sour cherry cultivars, some berry fruits and their jams. Food Technol Biotechnol. 2010;48:538–47. [Google Scholar]

- 24.Viljevac M, Dugalić K, Jurković V, Mihaljević I, Tomaš V, Puškar B, et al. Relation between polyphenols content and skin colour in sour cherry fruits. J Agric Sci. 2012;57:57–67. 10.2298/JAS1202057V [DOI] [Google Scholar]

- 25.Šarić A, Sobočanec S, Balog T, Kušić B, Šverko V, Dragović- -Uzelac V, et al. Improved antioxidant and anti-inflammatory potential in mice consuming sour cherry juice (Prunus cerasus cv. Maraska). Plant Foods Hum Nutr. 2009;64:231–7. 10.1007/s11130-009-0135-y [DOI] [PubMed] [Google Scholar]

- 26.Zavoreo I. Impact on polyphenols and melatonin in Prunus cerasus cv. Marasca on blood vessel wall elasticity in humans [PhD Thesis]. Zagreb, Croatia: University of Zagreb; 2008. [Google Scholar]

- 27.Puškar B. Listing and evaluation of Oblačinska cherry types with the aim of further selection. Pomol Cro. 2002;8:1–4. [Google Scholar]

- 28.Toydemir G, Capanoglu E, Roldan MVG, de Vos RCH, Boyacioglu D, Hall RD, et al. Industrial processing effects on phenolic compounds in sour cherry (Prunus cerasus L.) fruit. Food Res Int. 2013;53:218–25. 10.1016/j.foodres.2013.04.009 [DOI] [Google Scholar]

- 29.Levaj B, Repajić M, Mušić A, Bursać Kovačević D. Effect of maceration and pasteurization on colour of cloudy sour cherry Marasca (Prunus cerasus var. Marasca) juice. Proceedings of 6th Central European Congress on Food, Novi Sad, Serbia; 2012. pp. 861–7. [Google Scholar]

- 30.Singleton VL, Rossi JA., Jr Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic. 1965;16:144–58. [Google Scholar]

- 31.Benzie IF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of ‘antioxidant power’: The FRAP assay. Anal Biochem. 1996;239:70–6. 10.1006/abio.1996.0292 [DOI] [PubMed] [Google Scholar]

- 32.Lee J, Durst RW, Wrolstad RE. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: collaborative study. J AOAC Int. 2005;88:1269–78. [PubMed] [Google Scholar]

- 33.Extraction, isolation, and purification of anthocyanins. In: Wrolstad RE, editor. Current protocols in food analytical chemistry. New York, NY, USA: John Wiley & Sons, Inc; 2003. pp. F1.1. [Google Scholar]

- 34.Tomás-Barberán FA, Gil MI, Cremin P, Waterhouse AL, Hess-Pierce B, Kader AA. HPLC-DAD-ESIMS analysis of phenolic compounds in nectarines, peaches, and plums. J Agric Food Chem. 2001;49:4748–60. 10.1021/jf0104681 [DOI] [PubMed] [Google Scholar]

- 35.NIST/SEMATECH e-Handbook of Statistical Methods. NIST/SEMATECH; 2012. http://www.itl.nist.gov/div898/handbook/

- 36.Burkhardt S, Tan DX, Manchester LC, Hardeland R, Reiter RJ. Detection and quantification of the antioxidant melatonin in Montmorency and Balaton tart cherries (Prunus cerasus). J Agric Food Chem. 2001;49:4898–902. 10.1021/jf010321+ [DOI] [PubMed] [Google Scholar]

- 37.Kim DO, Padilla-Zakour OI. Jam processing effect on phenolics and antioxidant capacity in anthocyanin-rich fruits: cherry, plum, and raspberry. J Food Sci. 2004;69:S395–400. 10.1111/j.1365-2621.2004.tb09956.x [DOI] [Google Scholar]

- 38.Dóka O, Ficzek G, Bicanic D, Spruijt R, Luterotti S, Tóth M, et al. Direct photothermal techniques for rapid quantification of total anthocyanin content in sour cherry cultivars. Talanta. 2011;84:341–6. 10.1016/j.talanta.2011.01.007 [DOI] [PubMed] [Google Scholar]

- 39.Pedisić S, Levaj B, Dragović-Uzelac V, Kos K. Physicochemical composition, phenolic content and antioxidant activity of sour cherry cv. Marasca during ripening. Agric Conspec Sci. 2007;72:295–300. [Google Scholar]

- 40.Chang TS, Siddiq M, Sinha NK, Cash JN. Plum juice quality affected by enzyme treatment and fining. J Food Sci. 1994;59:1065–9. 10.1111/j.1365-2621.1994.tb08191.x [DOI] [Google Scholar]

- 41.Pap N, Pongrácz E, Jaakkola M, Tolonen T, Virtanen V, Turkki A, et al. The effect of pre-treatment on the anthocyanin and flavonol content of black currant juice (Ribes nigrum L.) in concentration by reverse osmosis. J Food Eng. 2010;98:429–36. 10.1016/j.jfoodeng.2010.01.024 [DOI] [Google Scholar]

- 42.Mieszczakowska-Frąc M, Markowski J, Zbrzeźniak M, Płocharski W. Impact of enzyme on quality of blackcurrant and plum juices. LWT-Food Sci Technol. 2012;49:251–6. 10.1016/j.lwt.2011.12.034 [DOI] [Google Scholar]

- 43.Laaksonen O, Sandell M, Nordlund E, Heinio RL, Malinen HL, Jaakkola M, et al. The effect of enzymatic treatment on blackcurrant (Ribes nigrum) juice flavour and its stability. Food Chem. 2012;130:31–41. 10.1016/j.foodchem.2011.06.048 [DOI] [Google Scholar]

- 44.Patras A, Brunton NP, O’Donnell CP, Tiwari BK. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci Technol. 2010;21:3–11. 10.1016/j.tifs.2009.07.004 [DOI] [Google Scholar]

- 45.Toydemir G, Capanoglu E, Kamiloglu S, Boyacioglu D, de Vos RCH, Hall RD, et al. Changes in sour cherry (Prunus cerasus L.) antioxidants during nectar processing and in vitro gastrointestinal digestion. J Funct Foods. 2013;5:1402–13. 10.1016/j.jff.2013.05.008 [DOI] [Google Scholar]

- 46.Schüller E, Halbwirth H, Mikulic-Petkovsek M, Slatnar A, Veberic R, Forneck A, et al. High concentrations of anthocyanins in genuine cherry-juice of old local Austrian Prunus avium varieties. Food Chem. 2015;173:935–42. 10.1016/j.foodchem.2014.10.113 [DOI] [PubMed] [Google Scholar]