Abstract

Plant-based or non-dairy milk alternative is the fast growing segment in newer food product development category of functional and specialty beverage across the globe. Nowadays, cow milk allergy, lactose intolerance, calorie concern and prevalence of hypercholesterolemia, more preference to vegan diets has influenced consumers towards choosing cow milk alternatives. Plant-based milk alternatives are a rising trend, which can serve as an inexpensive alternate to poor economic group of developing countries and in places, where cow’s milk supply is insufficient. Though numerous types of innovative food beverages from plant sources are being exploited for cow milk alternative, many of these faces some/any type of technological issues; either related to processing or preservation. Majority of these milk alternatives lack nutritional balance when compared to bovine milk, however they contain functionally active components with health promoting properties which attracts health conscious consumers. In case of legume based milk alternatives, sensory acceptability is a major limiting factor for its wide popularity. New and advanced non-thermal processing technologies such as ultra high temperature treatment, ultra high pressure homogenization, pulsed electric field processing are being researched for tackling the problems related to increase of shelf life, emulsion stability, nutritional completeness and sensory acceptability of the final product. Concerted research efforts are required in coming years in functional beverages segment to prepare tailor-made newer products which are palatable as well as nutritionally adequate.

Keywords: Plant-based milk alternatives, Lactose intolerance, Non-thermal technologies, Emulsion stability, Shelf life, Fortification

Introduction

Over the past decade, major research emphasis in all sections of food product development is to address the changing needs and to meet the present demands of consumer by creating newer alternative of health foods. Increasing urbanization has accelerated these demands; concerted research effort in functional and speciality beverage for newer products is the recent trend. In today’s world, beverages are no longer considered simply as thirst-quenchers; consumers look for specific functionality in these drinks, which forms a part of their lifestyle. Functionality in these beverages may be to addresses different needs and lifestyles—to boost energy, fight ageing, fatigue and stress, target specific diseases and the sector is still expanding. In recent years, these changes and developments have led to newer products in the beverages sector. One such major functional requirement is milk alternatives to answer problems of cow milk allergy, lactose intolerance, calorie concern and prevalence of hypercholesterolemia (Valencia-Flores et al. 2013). Ethnic origin affects the frequency of lactose intolerance. In adults, white north Europeans, North Americans and Australasians have the lowest rates ranging from 5 % in a British population to 17 % in Finland and northern France. In South America, Africa and Asia, over 50 % of the population has lactase non-persistence and in some Asian countries this rate is almost 100 % (Lomer et al. 2008). As a result, the consumption of plant based milk has been increased due to absence of cholesterol and lactose, making it suitable for a group of population suffering from lactose intolerance and heart disease and in general for all. The market for plant based milk alternatives is projected to grow at a CAGR of 15 % from 2013 to 2018 (Markets and Markets 2013) and is expected to reach a value of $14 billion. In western countries, the use of plant-based milk alternatives is well established not only as a beverage, but has been extensively utilized in recipes as an ingredient. Hence, there is a great scope to explore plant based alternatives for the preparation of milk like beverages. Also, in recent years, plant sources (cereals and legumes) are accepted as functional food and nutraceuticals due to presence of health promoting components such as dietary fibres, minerals, vitamins and antioxidants (Das et al. 2012). In this regard, few legumes and oilseeds have been extensively utilized for preparation of non-dairy, healthy, affordable and nutritious plant based milk alternatives (Sosulski et al. 1978). In past, much attention has been given to soy milk, as it is nutritious and a healthy alternative to bovine milk. But recently, attention has been directed towards exploring the utilization of cereals, oilseeds, nuts for new food uses on the basis of their functional properties, which reveal the physical attributes of food components and their interactions (Toma and Tabekhia 1979). All plant-based milks are preferred over cow’s milk by consumers who are lactose intolerant or are allergic to milk proteins because of their common benefits of being lactose free, cholesterol free and low in calories. Plant-based milk alternatives are prepared by disintegration of plant material, which makes the particle composition and size as non-uniform. The size of particles and the stability of the final product depend on the nature of the raw material, the method used for disintegration and storage conditions (Cruz et al. 2007). Few researches in preparing milk alternates other than soy milk includes peanut milk, rice milk, oat milk, sesame milk, coconut milk, almond milk, hemp milk, hazelnut milk, tiger nut, lupin milk and quinoa milk etc. (Chiba et al. 1979; Farkas and Goldblith 1962; Fujimaki et al. 1965; US patent US4744992; US patent US5686123; Kapadia et al. 2002; Quasem et al. 2009; Zhang et al. 2007; Camacho and Sierra 1988; Ukwuru and Ogbodo 2011). However, technological issues needs to be addressed in order to prepare a plant based milk alternative comparable to that of cow’s milk in respect to appearance, taste, flavor, stability and nutritive value.

This paper aims to give an outline of plant-based milk alternatives with technological interventions applied so far for their quality improvement; and future research efforts that can be carried out in development of quality plant-based milk alternatives.

Plant-based/non-dairy milk alternatives

Plant-based milk alternatives are fluids that results from breakdown (size reduction) of plant material (cereals, pseudo-cereals, legumes oilseeds, nuts) extracted in water and further homogenisation of such fluids, results in particle size distribution in range of 5–20 μm which imitates cow’s milk in appearance and consistency. Although, there is no stated definition and classification of these plant-based milk alternatives in literature, a general classification of the plant based/vegetable milk alternatives into five categories is attempted, which is as follows:

Cereal based: Oat milk, Rice milk, Corn milk, Spelt milk.

Legume based: Soy milk, Peanut milk, Lupin milk, Cowpea milk.

Nut based: Almond milk, Coconut milk, Hazelnut milk, Pistachio milk, Walnut milk.

Seed based: Sesame milk, Flax milk, Hemp milk, Sunflower milk.

Pseudo-cereal based: Quinoa milk, Teff milk, Amaranth milk.

Types of plant-based/non-dairy milk alternatives

Oat milk

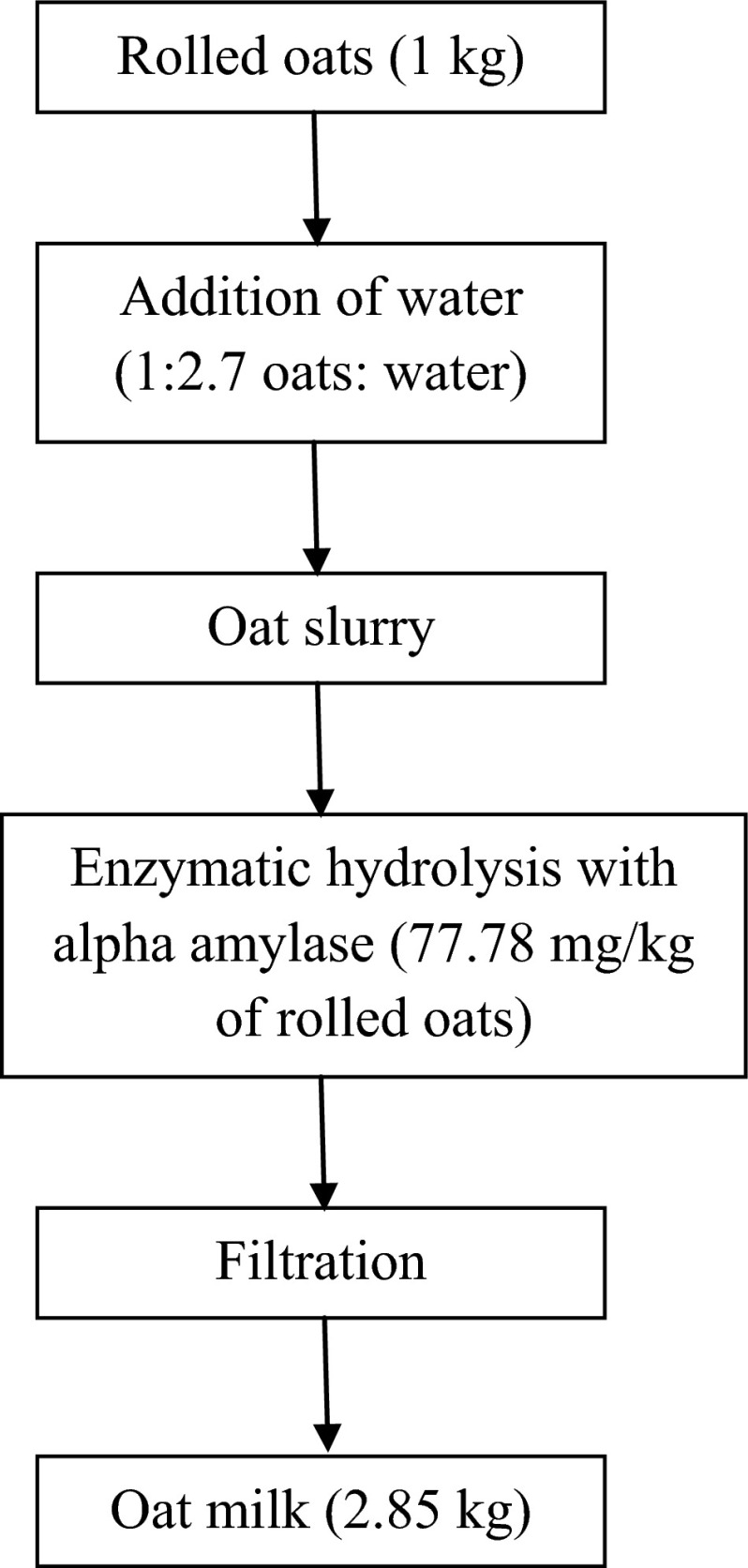

Oat milk is the recent emergent in the market owing to its potential therapeutic benefits. Oats have received extensive interest due to the presence of dietary fibres, phytochemicals and high nutritive value. Oats possess various health benefits such as hypocholesterolaemic and anticancerous properties (Table 1). Health benefits of oats are associated with dietary fibres such as β-glucan, functional protein, lipid and starch components and phytochemicals present in the oat grain and that is why it is one of the promising raw materials for preparation of functional plant-based milk. Oats are good source of quality protein with good amino acid balance. The interest in oats is mainly aroused due to the presence of functionally active component, β-glucan which possesses neutraceutical properties. β-glucan, a soluble fibre, has the ability to increase the solution viscosity and can delay gastric emptying time, increases gastrointestinal transit time which are associated with their reduced blood glucose level (Welch 1995). Oat fibres are also known for their hypocholesterolemic effect by reducing total and LDL cholesterol (Truswell 2002). They are also a good source of antioxidants and polyphenols. Oat contains 60 % starch, 11–15 % total protein, 5–9 % lipids, 2.3–8.5 % dietary fibre and 0.54 % calcium (Rasane et al. 2015). The uses of oats in gluten free or celiac diet are well explored. In order to diversify the oat consumption, attempts have been made to develop oat based beverages or oat milk (Zhang et al. 2007; Deswal et al. 2014). It has been proved in investigations that oat beverages, as such, retain their cholesterol lowering properties (Onning et al. 1998, 1999). Starch constitutes the major portion of the oats (55–60 %) with a gelatinization temperature range of 44.7–73.7 °C (Tester and Karkalas 1996). But, this high concentration of starch poses a problem in preparation of a stable emulsion and during the heat processing of oat beverage. On application of heat, starch begins to gelatinize and liquid milk tends to attain a gel like consistency with high viscosity leading to its lower acceptability. So, in order to maintain the fluidity or beverage like consistency, hydrolysis of starch is only one of the methods allowing its removal, to prevent gelatinization during thermal treatment. To resolve this problem, enzymatic hydrolysis has been investigated by researchers, to obtain an acceptable product. The optimization of enzymatic production process of oat milk (Fig. 1) using response surface methodology has been investigated by Deswal et al. (2014). A yield of 2.85 kg of oat milk having total solids in the range of 25.01 ± 0.15 and consistency index value of 1.01 ± 0.08 Pa s was achieved with 1 kg of rolled oats and an enzyme (alpha amylase) concentration of 2.1 % (w/w). A US patent, US5686123 on homogenous and stable cereal suspension utilized both alpha and beta amylase for hydrolysis of starch (Lennart et al. 1997). Oat contains significant amount of phytic acid, an antinutrient. Phytate phosphorus accounts for 48.7–70.9 % of the total phosphorus in oats (Frolic and Nyman 1988; Lolas et al. 1976). Zhang et al. (2007) treated oat based beverage with phytase in order to improve the nutritional value by liberation of inorganic phosphate from phytic acid. Also, attempts were made by them to restore the inevitably lost nutrients during processing operations, by enrichment. Despite of its health benefits, oat milk lacks calcium which is an essential nutrient for the growth and development; therefore, it needs to be fortified before its consumption as a milk alternative. Commercially, oat milk is available under brand names Oatly (Sweden), Pureharvest (Australia), Alpro (UK), Bioavena drink (Italy), Simpli (Finland), Vitasoy (Hong Kong), Pacific (USA) etc. The milk is available in convenient tetra packs of various sizes and is UHT treated.

Table 1.

Functional components of plant-based milk alternatives and their health benefits

| Type of milk | Functional or bioactive component | Health benefits | References |

|---|---|---|---|

| Soy milk | Isoflavones | Protective effect against cancer, cardiovascular disease, and osteoporosis | Omoni and Aluko (2005) |

| Phytosterols | Cholesterol lowering properties | Fukui et al. (2002) | |

| Peanut milk | Phenolic compounds | Protective role against oxidative damage and diseases like coronary heart disease, stroke, and various cancers | Wien et al. (2014), Settaluri et al. (2012) |

| Rice milk | Phytosterols, especially β-sitosterol and γ-oryzanol | Lowers cholesterol, hypertension, anti-diabetic, anti-inflammatory, anti-oxidative effects | Biswas et al. (2011), Faccin et al. (2009) |

| Oat milk | β-Glucan | Increases solution viscosity and can delay gastric emptying time, increases gastrointestinal transit time which are associated with their reduced blood glucose level, hypocholesterolemic effect by reducing total and LDL cholesterol | Welch (1995), Truswell (2002), Deswal et al. (2014) |

| Sesame milk | lignans such as sesamin, sesamolin, sesaminol | Neutraceutical properties such as antioxidative, hypocholesterolemic, anticarcinogenic, antitumor, and antiviral activities | Namiki (2007) |

| Almond milk | Alpha-tocopherol | Powerful antioxidant which plays a critical role in protecting against free-radical reactions | Burton and Ingold (1989), Niki et al. (1989) |

| Arabinose | Prebiotic properties | Mandalari et al. (2008) | |

| Coconut milk | Lauric acid | Promotes brain development, boosts immune system and maintains the elasticity of the blood vessels | Seow and Gwee (1997) |

| Vitamin E | Fights against ageing, nourishes skin |

Fig. 1.

Flow chart for the preparation of oat milk (Deswal et al. 2014)

Soy milk

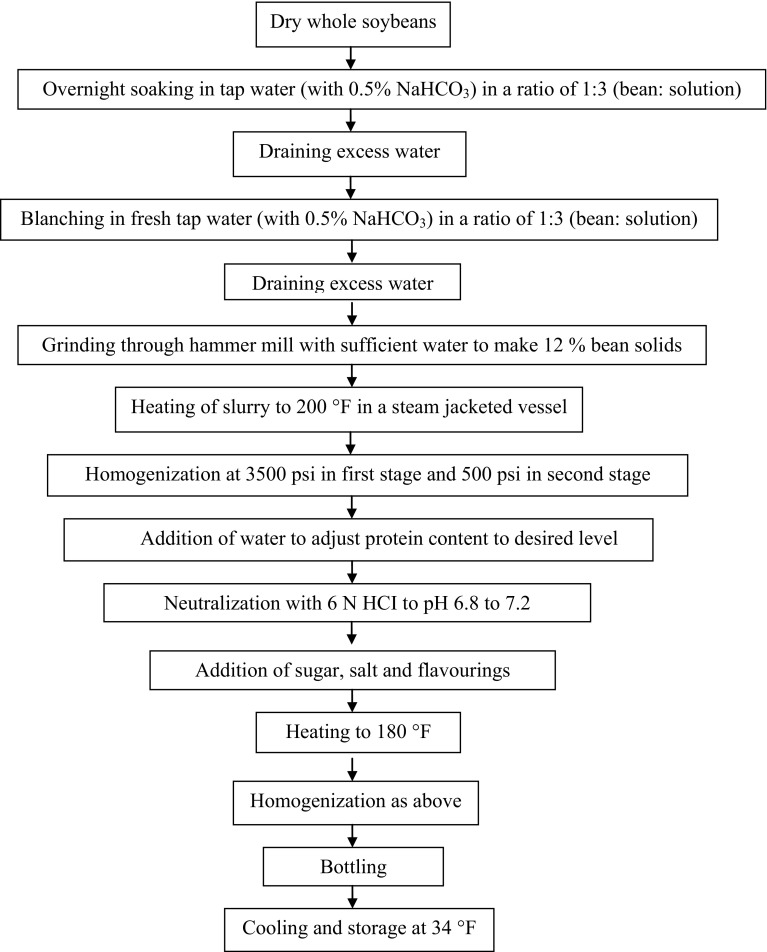

The use of soy milk was first reported about 2000 years ago in China. Soy milk was the first plant-based milk which serves the purpose of providing nutrients to the population where the milk supply was inadequate. It was also popular amongst the populations who are allergic to milk proteins and are lactose intolerant. Soy milk is a good source of essential monounsaturated and polyunsaturated fatty acids which are considered good for cardiovascular health. It serves as an inexpensive, refreshing and nutritional beverage to the consumers. Isoflavones appeared to be the functionally active component responsible for the beneficial effects of soybean. Isoflavones are well known for their protective effect against cancer, cardiovascular disease, and osteoporosis (Omoni and Aluko 2005). Genistein is the most abundant isoflavone in soybean and is proposed to be the most biologically active (Cohen et al. 2000). Apart from isoflavones, soy proteins are also known to provide protective and therapeutic benefits against several diseases. Soy foods are also found to be rich in phytochemicals such as phytosterols, which are recognized for their cholesterol lowering properties (Fukui et al. 2002). On average, dry soybean contains roughly 40 % protein, 20 % oil, 35 % carbohydrate, and 5 % ash (Liu 2004). Traditional process of soy milk preparation leaves a product with limited shelf life and a characteristic beany flavor. Modern soy milk production utilizes advanced technologies and equipments to maximize nutritional value, shelf-life and convenience with reduced beany flavor (Table 2). In view of its popularity, a wide array of variants is available in the market. Based on solids concentration, available variants are light, dairy like, and rich soy milk, with respect to formulation, sweetened, original and flavored soy milk, with respect to fortification, regular, enriched, and blended soy milk (Liu 2004). Several methods were tested for their efficacy in removal of off flavor or beany flavor. Some of the widely accepted methods in order to remove or deodorize the beany flavor of soy milk are: vacuum treatment at high temperature which results in stripping off of most volatile compounds (short chain fatty acids, sterols, sulphur compounds etc.), leading to a better acceptable product to the consumers, Cornell hot grinding method where soaked soybeans were ground with boiling water or steam to obtain a slurry at a temperature of 80 °C, the slurry was then kept at this temperature for 10 min in order to inactivate lipoxygenase, Illinois pre-blanching method (Fig. 2) where soaked soybeans were blanched in boiling water to inactivate lipoxygenase. Apart from these methods, alkaline soaking, use of defatted flour, soy protein isolates and concentrates have reduced beany flavor to some extent. Destruction of growth inhibitors is another important concern in processing of soy milk. Inactivation by heat treatment is the most commonly used method. With advancement of time, several modifications have been applied to equipments used for heat treatment and various combinations of time and temperature (Ikya et al. 2007; Kwok and Niranjan 1995) were applied. It is also known that thermal treatment of soy milk results in dissociation, denaturation and aggregation of soy protein (Zhang et al. 2005) and hence negatively affects the solubility of proteins. Therefore, to minimize these changes and to improve the quality of product pulsed electric field processing (PEF); a non-thermal technology was studied by Xiang (2008). The soy milk samples were treated by PEF with electric field intensities of 18, 20 and 22 kV cm−1, number of pulses of 25, 50, 75 and 100, capacitance from the discharge capacitor of 0.33 µF and pulse frequency of 0.5 Hz at 26 °C and soy milk was evaluated for rheological and color properties. The rheological properties of soy milk were affected by PEF treatments. The apparent viscosity of soy milk increased from 6.62 to 7.46 (10−3 Pa s) with increasing electric field intensity from 18 to 22 kV cm−1 and pulses from 0 to 100. The stated or claimed benefits of soy milk include absence of lactose, cholesterol free, high nutritive value, high digestibility and low cost. Owing to these health benefits, soy milk has also found its applications as a functional ingredient in preparation of processed food products. Rahmati et al. (2014) used soy milk as an emulsifier in preparation of mayonnaise where egg was replaced with full fat soy flour-prepared soy milk at different levels. Sensory evaluation showed no statistical difference in acceptability of samples with substitution levels up to 50 %. The only disadvantage of soy milk consumption is prevalence of soy allergies, making it unsuitable for population who are allergic to soy proteins. It is commercially available under the brands Silk (USA), Vitasoy (Hong Kong), Alpro (UK), Tesco (UK) etc.

Table 2.

Limitation in consumption and technological interventions for increased acceptability of plant-based milk alternatives

| Type of milk | Limiting factor in acceptance | Technological intervention to resolve the problem | References |

|---|---|---|---|

| Soy milk | Beany flavor due to action of lipoxygenase on unsaturated fatty acids | Vacuum treatment at high temperature, hot grinding, blanching in boiling water, alkaline soaking, use of soy protein isolates, addition of flavouring compounds | Chiba et al. (1979), Farkas and Goldblith (1962), Fujimaki et al. (1965) |

| Presence of inhibitors | Denaturation and inactivation by heat | Badenhop and Hackler (1970), Kwok et al. (1993) | |

| Peanut milk | Beany flavor | Defatting, roasting, alkali soaking, steaming | Lee and Beuchat (1992) |

| Rice milk | Poor emulsion stability due to high starch content | Enzymatic hydrolysis of starch by alpha and beta amylase or glucosidase | (US4744992 patent), Mitchell et al. (1988) |

| Oat milk | Poor emulsion stability due to high starch content | Enzymatic hydrolysis of starch by alpha and beta amylase | US5686123 patent, Deswal et al. (2014) |

| Presence of inhibitors phytates | Treatment with phytase in order to liberate inorganic phosphate from phytic acid | Zhang et al. (2007) | |

| Sesame milk | Anti-nutritional factors such as oxalates | Decortication to remove oxalates as they are confined to outer hull | Kapadia et al. (2002) |

| Low solubility of sesame proteins in water as they are salt soluble and are susceptible to heat denaturation | Alkali soaking, roasting, defatting, germination, microwave heating to improve functional properties of protein | Quasem et al. (2009) | |

| Bitterness and chalkiness | Roasting and alkali soaking have been observed to improve the overall acceptability and flavor | Prakash and Narasinga Rao (1986) |

Fig. 2.

Illinois process for preparation of soy milk (Nelson et al. 1976)

Peanut milk

Oilseeds are thought to have a high potential as an alternative source of non-dairy beverages. Among oilseeds, peanut is a promising raw material for preparation of plant-based milk but similar to soy milk, presence of beany flavor limits its applications. Peanut milk has been extensively utilized in developing countries by low income group, undernourished children, vegetarians and people allergic to cow’s milk (Diarra et al. 2005). Above all, the increased responsiveness towards health benefits of plant-based milk, contributed to its better consumption. Many volatile compounds present in peanuts are similar to soybeans (Leu 1974). Peanuts are considered healthy because of several bioactive components which are known for their disease preventative properties. Peanuts are good source of proteins, fats, fibres, vitamins, minerals, antioxidants, phytosterols etc. and have potential for improving blood lipid level, blood sugar level and longevity (Wien et al. 2014). Peanuts contain 21.5 % carbohydrates, 49.6 % fats, 23.68 % proteins and 8 % crude fibre (Settaluri et al. 2012). The functional properties of peanuts are mainly associated with presence of phenolic compounds which are known for their antioxidant function and a protective role against oxidative damage diseases like coronary heart disease, stroke, and various cancers. Several researchers have made attempts to prepare peanut milk using various combinations of treatments. Defatting, roasting, alkali soaking, steaming etc. have been applied to have a best quality product. In several investigations, different methods were adopted by researchers to obtain peanut milk (Diarra et al. 2005; Galvez et al. 1990). Wet grinding, to obtain peanut extract was the most widely used method and other method using full fat or partially defatted peanut flour have been successfully reported. Another method of using spray dried peanut protein isolates have been tried but high cost limits its application (Diarra et al. 2005). To improve the acceptability in terms of stability, various treatments like heating, homogenizing, addition of stabilizers and emulsifiers have been studied. It has been observed that the stability of the product is greatly improved by heating at high temperature due to hydration and tenderization of tissues which results in better disruption of tissues during homogenization (Kuntz et al. 1978). The destabilization due to settling of solid particles may be prevented by addition of alkalizing agents, such as disodium phosphate or sodium bicarbonate. Edible emulsifying agents such as alginates, gelatin, or vegetable gums up to 1 % by weight, may be added to improve the stability of the emulsion during freezing, transportation and storage. Flavouring agents to improve the taste or flavor and nutrients in the form of additives may be added to obtain the desired nutritive balance. Commercially peanut milk is available under the brand name signs & wonders (USA) and sweety etc.

Almond milk

The consumption of dried fruits and nuts has become an essential part of healthy living owing to their potential health benefits. Almonds contribute to the largest share in total nuts consumption. Almond contains approximately 25 % of protein, majority of which is present in the form of AMP or amandin (Sathe et al. 2002). Almond is a nutrient dense product and is an excellent source of vitamin E in the form of alpha-tocopherol and manganese. Compared to other plant-based milks, almond milk is naturally a good source of vitamins, especially vitamin E which cannot be synthesized by the body and need to be supplied through diet or supplements. Alpha-tocopherol is the functionally active component of the Vitamin E and is a powerful antioxidant which plays a critical role in protecting against free-radical reactions (Burton and Ingold 1989; Niki et al. 1989). Almonds are rich source of other nutrients such as calcium, magnesium, selenium, potassium, zinc, phosphorus and copper. Apart from all these benefits, almond possesses potential prebiotic properties contributed by arabinose present in cell wall pectic substances which add to the functionality by lowering serum cholesterol level. A patented process (US 5656321 A) for preparing almond milk includes heating an aqueous dispersion of partially de-oiled almond powder, proportioned at 8 ± 1 % and mixed with about 0.1 % of a stabilizing hydrocolloid at 90 °C for a lapse of time that is sufficient to allow the compounds to solubilize. It is followed by grinding in aqueous phase and then a centrifugal clarification was adapted to remove the particles that are large enough to be detected by the tongue or the roof of the mouth. The product is then sterilized by “UHT” (ultra-high temperature) treatment and a homogenization at 180,000 hPa is carried out during cooling followed by aseptic packaging of the product obtained (Berger et al. 1997). In a study, conducted by Mandalari et al. (2008), it has been concluded that almond seeds exhibited the potential to be used as a novel source of prebiotics with increased populations of bifidobacteria and Eubacterium rectale and subsequent increase in butyrate concentrations. Almond consumption is known to be associated with various pharmacological properties such as lipid lowering, antioxidant, laxative and immunostimulant. In a study, influence of high pressure processing (HPP) at 450 and 600 MPa, 30 °C for various holding times (0, 30, 60,180, 300 and 600 s) on almond milk amandin was investigated by Dhakal et al. (2014). The immunoreactivity of pressure treated almond milk was compared with raw and thermally processed (TP) almond milk (72, 85 and 99 °C for 0–300 s) using a sandwich enzyme-linked immunosorbent assay (ELISA), Western blot and dot blot. A maximum reduction of ~70 and ~75 % in protein solubility was observed in HPP and TP treated almond milk. Being a rich source of calcium and fat and low in calorie count, it is nutritionally better than other plant-based milks. Prevalence of tree nut allergy and high cost limits its use as a beverage. Commercially it is available under the brand names Silk (USA), almond breeze (USA), Alpro (UK), Hiland (USA), 365 (USA), Pure harvest (Australia), Pacific (USA) etc.

Coconut milk

Coconut milk plays an important part in the south East Asian cuisine. It is not only consumed as a beverage but used as an ingredient in number of sweet and savory recipes. Coconut milk has high fat content and is generally used in curries as a thickener to give body to the product. Coconut is a nutrient dense product and is a good source of fiber. Coconut milk is rich in vitamin and minerals such as iron, calcium, potassium, magnesium and zinc. It also contains a significant amount of vitamin C and E (Seow and Gwee 1997). The use of coconut milk is associated with health benefits such as anti-carcinogenic, anti-microbial, anti-bacterial, and anti-viral. It contains a saturated fat, lauric acid which is present in mother’s milk and has been related to promote brain development (Belewu and Belewu 2007). Lauric acid is also helpful in boosting immune system and maintaining the elasticity of the blood vessels. Coconut milk is rich in antioxidants such as vitamin E which helps fighting against ageing. Coconut milk consumption is rarely associated with allergenic reactions. Other benefits of coconut milk includes: helps in digestion, nourishes skin and has cooling properties. Inspite of all health benefits, presence of saturated fats limits its consumption. Commercially it is available under the brand names Blue diamond (USA), Silk (USA), Alpro (UK) and Pacific (USA) etc.

Sesame milk

Sesame is one of the important oilseed crops in the world. It is consumed in variety of preparations like tahini, sweet meats etc. It is a source of high quality protein with a unique balance of amino acids. Sesame seed contains significant amount of lignans such as sesamin, sesamolin, sesaminol and others which are known for their functional properties. Sesame lignans are recognized to have nutraceutical properties such as antioxidative, hypocholesterolemic, anticarcinogenic, antitumor, and antivirus activities (Namiki 2007). It contains significant amount of anti-nutritional factors such as oxalates and phytates (Kapadia et al. 2002). But, the oxalates are confined to outer hull and most of them are removed during decortication. Also, the compounds associated with bitterness of sesame seeds are confined to hulls therefore; decortication also helps in improvement of flavor. Sesame proteins are less soluble in water as they are salt soluble and are susceptible to heat denaturation which limits its use in preparation of plant-based milks. Therefore, modification in functionality of sesame protein is required before its use in preparation of plant-based milk (Quasem et al. 2009). In view of this, various processing methods like soaking, roasting, defatting, germination, fermentation, microwave heating have been investigated for their potential in modifying functional properties of sesame proteins (Quasem et al. 2009). Investigations have shown that the steaming and alkali soaking had significantly improved the yield of total solids (Prakash and Narasinga Rao 1986) and pasteurization had improved the dispersion stability. Roasting and alkali soaking have been observed to improve the overall acceptability and flavor by reducing bitterness and chalkiness in sesame milk. The consumption of sesame milk can overcome the limitations associated with soy milk consumption such as presence of flatulence causing factors, prevalence of allergies towards soy proteins and beany or off flavor (Zahra et al. 2014). Sesame milk is commercially available under the brand name Ecomil (Spain), Vegemil (South Korea) etc.

Other plant-based milk

Lupin, an indigenous legume of Latin America, has several advantages for the preparation of plant-based milk. The Australian lupin has high protein content (29–44 %), high dietary fibre (30 %) and low fat content (6 %). Sweet lupin has a very low glycemic index, therefore, have been utilized in numerous food products ranging from traditional fermented food products (Tempe, Miso etc.) to dairy substitutes to bakery products, pasta and noodles etc. Protein concentrates and isolates of lupin have been utilized as binders and emulsifiers in sausages, fortification of bread etc. It has been explored as an alternate to soybean in number of food products. Lupin is successfully utilized in preparation of plant-based milk, fortified with methionine at the rate of 0.1 % to increase the nutritional value, by Camacho and Sierra (1988). Also, Illinois process developed by Nelson et al. (1976) for soybean was adapted for lupin with few modifications in which an additional step of colloidal milling was introduced to improve dispersion stability of the lupin particles in the liquid phase.

Tigernut is considered healthy and its use is associated with prevention of heart attacks, thrombosis, colon cancer and other cancers. It can be eaten raw or can be utilized in baked products, confectionary etc. as an alternate to almonds. Tiger nuts are very good source of phosphorus, potassium, vitamins E and C, starch, fat, sugars, protein (Belewu and Belewu 2007). Also, tiger nuts are rich source of protein with high biological value. Ukwuru and Ogbodo (2011) studied the effect of processing treatment on quality of tiger nut milk where, processing treatments such as pasteurization, sterilization, ultra-high temperature, fermentation were investigated. It was observed that UHT treated and sterilized samples had no growth of micro-organisms throughout the storage of 6 weeks. Commercially it is available under the brand name Amandin (Canada), Isola Bio (UK), Chufi (Spain) etc.

Other plant-based milk, such as quinoa, hemp, cow pea, hazelnut, sunflower, melon seed milk (Bastıoğlu et al. 2016) etc. are prepared and/or commercially available in some western countries but scientific literature on these milks is hardly available.

Technological interventions in improving the quality and acceptability of plant based milk alternatives

Improving product stability

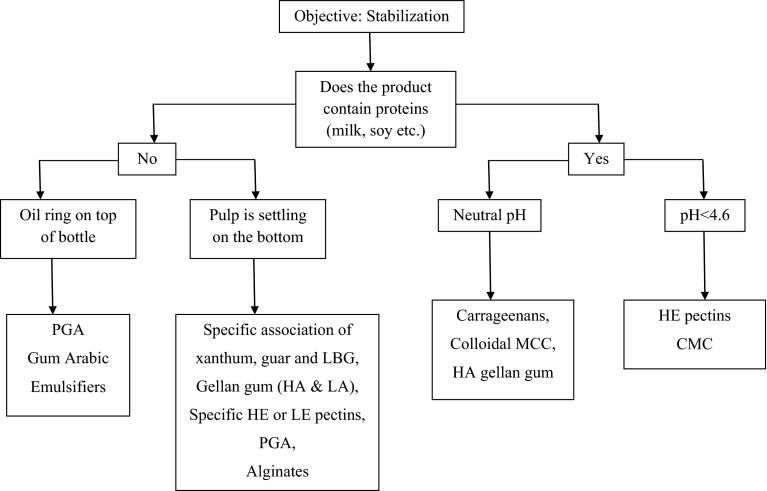

Stability of plant-based milk depends on the size of dispersed phase particles. Plant-based milk are colloidal systems formed by large sized dispersed particles such as fat globules, solid particles from raw materials, proteins and starch granules which make it difficult to obtain a stable product to be stored, not for very long time due to sedimentation or settling of solid particles. The instability of plant-based beverages due to presence of large size particles results in a sandy, gritty or chalky mouth feel and lack of creaminess due to their low fat content (Civille and Szczesniak 1973). The stability of plant-based milk can be improved by reducing the size of dispersed phase particles using various techniques. Traditionally, colloid mill was used to reduce the size of dispersed phase particles in preparation of soy milk and peanut milk. But, microbial spoilage is a limiting factor in the use of colloid mill for size reduction and product needs to be pasteurized further from food safety point of view. Heat treatment such as pasteurization and sterilization may cause changes in the food components especially proteins and lipids that stabilize the emulsion and also heating of starch causes a great increase in viscosity (Fennema 1996), which may also have a significant effect on the stability of the plant-based milk. Ultra high pressure homogenization (UHPH) is one of the promising processing technologies which results in smaller and more uniform sized particles, can be effectively utilized to improve the stability of plant-based milk (Valencia-Flores et al. 2013). UHPH has demonstrated its benefits as an alternative technology to thermal processing. Apart from achieving size reduction of colloidal particles, a simultaneous destruction of micro-organisms can be achieved by UHPH treatment due to stated effects of high-pressure on micro-organisms (Cruz et al. 2007). This technology is suitable for liquid food products, allowing a better stability of the product and at the same time giving preserving effect to the final product. Two UHPH treatments, 200 and 300 MPa, were applied to the soy milk at an inlet temperature of 40 °C and was compared with normal and UHT treated soy milk by Cruz et al. (2007). Results indicated that UHPH treatment significantly improved the emulsion stability by disrupting the colloidal particles and also showed a reduction in the microbial load. Another promising technology for homogenization is ultrasound processing (Jafari et al. 2007) and is studied for cow’s milk but its use in plant-based milk is unexplored. Iswarin and Permadi (2012) studied the effect of ultrasonic waves with varied power levels and exposure time on droplets diameter of coconut milk. For this, power levels ranging from 2.5 to 7.0 W and exposure time from 5 to 25 min were used. Results depicted a reduction in the droplets diameter with an increase in power level and exposure time however; the power level was found more effective in breaking up the droplets than the duration of the exposure. The stability of plant-based beverages can also be improved by using emulsifiers and stabilizers. In plant-based milks three factors namely, size of the particle, formation of an emulsion and solubility of proteins governs the stability. The selection of stabilizer for improvement of emulsion stability depends on the type of beverage, pH etc. Simplified hydrocolloid selection chart (Fig. 3) for processed beverages was given by Fallourd and Viscione (2009).

Fig. 3.

Simplified hydrocolloid selection chart for processed beverages (Fallourd and Viscione 2009)

Removal of off-flavor

Soy products are gaining popularity as economical source of quality protein and their positive effects on health but presence of disagreeable or beany or unpleasant flavor needs to be eliminated or reduced in order to increase the acceptability of products in terms of taste and flavor (Friedman and Brandon 2001). The two main reasons responsible for off flavor are: presence of unsaturated fatty acids and the presence of lipoxygenases (Maestri et al. 2000). Substantial efforts have been made by several researchers in exploring technologies and processes to eliminate beany flavor (Chiba et al. 1979; Farkas and Goldblith 1962; Fujimaki et al. 1965; Kon et al. 1970; Nelson et al. 1976; Wilkens et al. 1967) but, this area still needs a consideration with further exploration by the use of newer and advanced technologies. Commonly practiced approaches to solve this problem are: inactivation of enzymes, removal of off-flavours by deodourization and masking of off-flavour by addition of artificial or natural flavourings (Table 2). Lipoxidases catalyze the formation of nonvolatile hydroperoxides from unsaturated fatty acids which, in turn, decompose into medium-chain aldehydes and alcohols such as n-hexanal and n-hexanol and are associated with beany or off flavor. Lipoxygenase inactivation by heat is the most common technology to improve the flavor of soy milk that has been utilized for decades (Nelson et al. 1971). Wilkens et al. (1967) proposed a method of producing soybean milk free of rancid off-flavor by use of a high-temperature, rapid-hydration grinding process to inactivate the lipoxidase. Although thermal inactivation is widely used to inactivate lipoxidase but, undesirable alterations in proteins have limited its use as a promising technology (Davies et al. 1987). The effects of pH upon lipoxidase activities have also been studied extensively. Kon et al. (1970) studied the effect of pH on off flavours during grinding of raw legumes. Results indicated no detectable off flavor below pH 3.85 however, this pH range severely declined the protein extractability because most of the legume proteins have an isoelectric point at pH 4.0–4.5 whereas, at pH 2.0, maximum extractability was obtained with no detectable off flavours. Enzymatic treatment was also studied for its application in improvement of flavor of soy food products. Medium-chain aldehydes and alcohols such as n-hexanal and n-hexanol are mainly responsible for off flavor in soy milk. Aldehyde dehydrogenase (ALDH) is the enzyme which catalyzes the irreversible conversion of aldehydes into their corresponding acids, therefore, was used for flavor removal in soybean extract and soy milk. Soybean milk was incubated with 30 units of ALDH and 1.5 mmol of NAD+ at 30 °C, with stirring, for an incubation period of 3 h. Thereafter, organoleptic testing was carried out and a significant reduction in green beany flavor was observed (Chiba et al. 1979). US patent 4744524 issued on 17 May, 1988 described the equipment used to produce soy milk with no beany flavor and bitter taste of traditionally processed soy milk. The equipment prepares soy milk by grinding soy beans in an aqueous medium at room temperature without entrapping any air, cooking the slurry, and separating the undissolved solids to obtain stable soy milk. No use of heat treatment, results in high yield of dissolved solids with increased protein solubility in soy milk. The equipment eliminates the free oxygen by carrying out the disintegration completely in an aqueous medium and preventing the entry of air in that area (Gupta and Gupta 1988). It was also stated that the same equipment can be used for preparing bland beverages from other protein rich seeds which possesses problem of off-flavours during disintegration and preparation of beverages. Further US patent 7258889 B2, describes a method of preparing bean-less flavor soy milk using carbon dioxide in a state of sublimation. The process did not involve thermal and chemical treatment and comprised of various stages, holding soybeans with deaerated water under an atmosphere of carbon dioxide for a combination of time and temperature effective to allow soaking and swelling of soybeans, washing of soaked and swollen soybeans with water to remove oligosaccharides and ripening enzymes (as they are water soluble and gets dissolved in water used for soaking), grinding of washed soybeans in an atmosphere of carbon dioxide by bubbling in carbon dioxide in a sublimed state (−78 °C at atmospheric pressure) to form a slurry followed by filtration of slurry to obtain soy milk. The product obtained had high protein yields as process did not involve denaturation due to thermal treatment and no beany or bitter flavor (Alejandro 2007). The advantages of this process are: little resident time, continuous process and soft process conditions. The product need not to be homogenized as the soy milk obtained was highly stable. It is a well known fact that the modification of traditional processing method by introducing steps like roasting, blanching and soaking in alkaline conditions have been known to reduce beany flavor in legume based milk and hence, improved the acceptability of the product. Addition of flavorings and sugar has been also found to increase the overall acceptability of plant-based milk. Blending of legume milk with cereal milk and nut milk have also helped in improving quality and wider acceptability of plant-based milk.

Inactivation/removal of inhibitors

Apart from removal of off flavors, destruction of trypsin inhibitors is an important area of concern which is thought to be a cause of pancreatic hypertrophy. They are known to reduce protein absorption and hence adversely affect the human nutrition. Trypsin inhibitors are subject to denaturation and inactivation by heat but overheating to completely inactivate trypsin inhibitors may cause amino acid degradation, decrease in nutritional value and other deteriorative changes (Liener 1972). Therefore, careful selection of time–temperature combination in thermal processing is required for processing of soy milk to obtain a product with high nutritional value. The role of pH in combination with heat treatment was also investigated for its inactivation potential towards trypsin inhibitor (Badenhop and Hackler 1970; Kwok et al. 1993; Lei et al. 1981). On heating at a temperature range of 93–132 °C, trypsin inhibitor activity (TIA) in soy milk was found to be more heat-labile at high pH than at lower pH however, the effect of pH on thermal inactivation was less pronounced at temperature 143 and 154 °C. Inactivation of 90 % of the TIA in soy milk was observed at pH 6.5 in the temperature range of 93–154 °C (Kwok et al. 1993). Trypsin inhibitor activity in soy milk processed by traditional, steam injection, blanching, and UHT treatment was estimated by Yuan et al. (2008). Traditional and steam injection to 100 °C for 20 min resulted in a residual trypsin inhibitor activity of 13 % whereas, blanching inactivated 25–50 % of TIAs of the raw soy milk. UHT treatment with increase in temperature and time has been found to result in a product with low residual trypsin inhibitor activity of app. 10 %. Other inhibitors present in soybean are phytic acid and saponins. Phytates are stable to heat and are not degraded during cooking (Davies and Reid 1979) are known to cause poor mineral bioavailability. Effective reduction of phytates can be achieved by the action of enzyme phytase (Zhang et al. 2007). Murugkar (2014) studied sprouting as a non-chemical, non-thermal tool to improve the quality of soy products (soy milk and tofu). Sprouting of soybean increases protein content and also reduces fat, trypsin inhibitor and phytic acid whose reduction otherwise requires intense heat treatment or methods like ultrafiltration The results inferred that apart from improved nutritional profiles soy milk from sprouted beans had higher soy milk index, good colour characteristics and high sensory acceptability due to absence of beany flavour and odour.

Shelf life improvement

Plant-based milk being rich source of nutrients serves an ideal medium for growth of micro-organisms, and therefore, its quality is adversely affected by the rapid growth of micro-organisms. Thermal treatment has long been used as a processing method to extend the shelf life of food products by eliminating or reducing spoilage and pathogenic micro-organisms. Heat treatment has been utilized to increase the shelf life of plant-based milk along with the objectives of increasing total solids yield and improvement of flavor whereas, excessive heating found to cause detrimental effects on nutrients (vitamins and amino acids), browning and development of cooked flavor (Kwok and Niranjan 1995). So, in order to eliminate or reduce the destructive effects on plant-based milk, various combinations of time–temperature have been employed to have best quality product. Different heat treatments such as pasteurization (heating below 100 °C, to destroy pathogenic micro-organisms), in-container sterilization (121 °C for 15–20 min to attain commercial sterility), ultra high temperature treatment (at high temperatures 135–150 °C for few seconds) have been investigated by several researchers (Sizer 1989). UHT processing involves direct heating methods which include steam injection and steam infusion or indirect heating in plate or tubular heat exchangers. After any of the above mentioned treatment, packaging under aseptic condition is required to maintain the sterility. Product needs to be stored under refrigeration conditions after pasteurization whereas, after in-container sterilization or UHT treatment product can be stored at room temperature for a few weeks. Tan (1958) studied the effect of pasteurization and sterilization on soy milk. Pasteurized soy milk, heated for 30 min at 60 °C, could be stored for 3 days with no significant spoilage and sterilized soy milk heat treated at 120 °C for 5 min could keep well on 1 year of storage. Thermal treatments are well applied to plant-based milk such as soy milk and peanut milk but presence of high starch concentration in oat milk, rice milk etc. limits its application, and therefore, these types of plant-based milk require application of non-thermal processing technologies to extend the shelf-life. There is only little scientific literature available on the application of non-thermal technologies on plant-based milk. High-pressure throttling, ultra high pressure homogenization (UHPH), high pressure processing technologies have been investigated for their use in shelf-life extension of soy milk (Cruz et al. 2007; Singh 2013). The effect of ultra high pressure homogenization in combination with thermal treatment on microbial stability of almond milk was studied by Valencia-Flores et al. (2013). The UHPH treatment was compared with pasteurization and UHT treatment, microbiological analysis, physical stability and chemical analysis indicated a high quality product when compared to pasteurized and UHT treated samples. Combination of 300 MPa pressure and 65 and/or 75 °C temperature with a holding time of less than 0.7 s resulted in a product with no bacterial growth after incubation at 30 °C for 20 days. Pulsed electric field processing, a promising non-thermal processing technology, has been investigated for its potential in microbial reduction in cow’s milk (Valizadeh et al. 2009). Therefore, its potential along with other non-thermal technologies such as pulsed light, ultrasound needs to be explored for their preservative effects on plant-based milk.

Blending for nutritional balance and improvement in sensory acceptability

Plant-based milks are different from one another with respect to their nutritional value. Therefore, blending two or more types of plant-based milk, to have a product with high nutritive value comparable with cow’s milk, is an important step of processing. Scientific literature dealing with blending of plant-based milk is scarce. Deshpande et al. (2008) used response surface methodology to optimize chocolate flavored peanut-soy beverage on the basis of sensory parameters and it was observed that the beverages prepared with soy protein isolates were more acceptable than those with soy flour. Also, soy protein isolates are expected to increase the nutritional value. In another study, plant-based milks were developed from fermented and unfermented African yam bean (AYB) flours and maize blends. The protein content of the developed milk was comparable to that of soybean with appreciable quantities of carbohydrate and minerals and traces of ascorbate (Nnam 1997). As soy milk contains one-fifth of calcium than cow’s milk, deficient in amino acid methionine and is nutritionally less acceptable than cow’s milk, US patent 3386833 was aimed at the development of simulated milk comprising soy bean flour, sesame seed flour and coconut meal with the objectives to improve the nutritional value and palatability, characterized by minimum enzyme destruction in the preparation of powdered mixture used for the formation of the milk, and can be suitably used for infant consumption (Johnson and Linda 1968). The simulated milk developed had relatively high proportion of the two essential amino acids lysine and methionine, a much higher calcium content than that of cow’s milk and conventional soy milk, approximately six times as much iron as found in cow’s milk, the fats present principally in unsaturated form and the final product showed long keeping quality due to presence of natural antioxidants particularly found in sesame seeds. Sosulski et al. (1978) compared protein isolates from ten legume species for preparation of imitation milk. All the legumes had same protein content but, exhibited a wide range in solubility, fat homogenization, viscosity and conductivity. Sensory evaluation scores showed some legume-protein based imitation milk as similar to cow’s milk in color and viscosity but all were deficient in odor and taste. Based on functional and organoleptic properties of the protein isolates and imitation milk, ranking was given in the following order of preference: lima bean = mung bean = pea bean > northern bean = lupin > lentil = soybean > chickpea > field pea > fababean (Sosulski et al. 1978). Blending of plant-based milk with cow milk has also been carried out by researchers and found better taste scores for blended milk than plant-based milk alone (Singh and Bains 1988). Commercially available milk under this category is Pacific organic 7 grain milk (USA) which is made up of seven grains namely: Oats, rice, triticale, wheat, barley, spelt and millets.

Fortification of plant-based milk

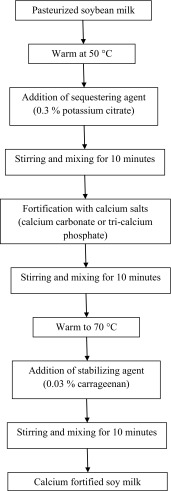

A substitute food is a food designed to resemble a common food in appearance, texture, flavor and odour, and is intended to be used as a complete or partial replacement for the food it resembles (Codex Alimentarius Commission 1994). According to codex, where a substitute food is intended to replace a food which has been identified as a significant source of energy and/or essential nutrients in the food supply, and particularly where there is demonstrated evidence of public health need, nutritional equivalence in terms of the essential nutrients of concern should be strongly recommended. Essential nutrient is defined as “any substance normally consumed as a constituent of food which is needed for growth and development and maintenance of healthy life and which cannot be synthesized in adequate amounts by the body”. Plant-based milks in general are inexpensive substitutes to cow’s milk to those who cannot afford cow’s milk because of high cost and limited availability and to those who are allergic to cow’s milk but, nutritionally they are not comparable or equivalent to cow’s milk (Table 3). People who consume cereal milk in place of bovine milk are more prone to nutritional inadequacy. So, in order to use plant-based milk as substitute of cow’s milk, fortification with protein, essential vitamins and minerals is generally performed. Cereal-based beverages that contain less protein than cow’s milk are required by law to have advice on the label that the product is not suitable as a complete milk replacement for children under 5 years old (http://www.foodstandards.gov.au/consumer/nutrition/milkaltern). Children of growing age needs sufficient protein for their growth and development and bovine milk is a part of child’s daily diet but plant-based milks such as rice and almonds contains less amount of protein as compared to cow’s milk therefore, such products needs to be fortified when used as a milk substitute. Calcium is another essential nutrient required for growth and development and is a limiting nutrient in cereals such as rice and oats. Therefore, to assure the consumers in order to meet their nutritional requirements and to reduce the requirement of nutritional supplementation, calcium fortification is generally adopted in preparation of plant-based milk substitutes. Soy milk contains equivalent quantities of protein but contains only one-fifth of calcium. Calcium carbonate and tri-calcium phosphate salts were used as fortificants, among the two fortificants used, tri-calcium phosphate with the combination of sequestering and stabilizing agents, presented a satisfied suspension in fortified soybean milk (Fig. 4) with an optimum Ca:P ratio of 1.3:1 in the final product. Calcium carbonate showed reduced calcium stability on fortification but the bioavailability was better (Chaiwanon et al. 2000). Also, processing treatments such as, flaking, blanching, hot grinding and ultra high temperature treatment etc. could cause loss of nutrients especially vitamins and minerals. Therefore, to meet nutritional requirements, enrichment of nutrients is done to restore nutrients inevitably lost during processing. The form of nutrients used for enrichment or fortification is important as nutrients differ in stability, in the final fortified product (Richardson 1983). Attempts were made by Zhang et al. (2007) to fortify oat based beverage with mixture of various vitamins and minerals using an industrial-scale filter sterilization system and studied the effect of storage on the retention of vitamins and fatty acids in UHT-treated beverages. The results indicated that holding the UHT for 5 or 20 s did not significantly affect the retention of most of the investigated vitamins when they were heated by direct steam injection. Plant-based beverages are inappropriate alternatives to breast milk, infant formula or cow’s milk in the first 2 years of life as they are low in protein, fat, calories and iron. For children above 2 years of age, who cannot consume milk due to medical reasons, fortified plant-based beverages are recommended which should contain at least 6 g of protein per 250 ml.

Table 3.

Nutritional Comparison of commercially available, selected plant-based milk alternatives

| Type of milk (per serving of 240 ml) | Calories (g) | Protein (g) | Fat (g) | Carbohydrates (g) | Dietary fibres (g) | Calcium (% daily value) | Iron (% daily value) | Vitamin A (% daily value) |

|---|---|---|---|---|---|---|---|---|

| Soy milk (Silk) | 80 | 7 | 4 | 4 | 1 | 30 | – | 10 |

| Quinoa milk (Ecomil) | 104 | 4.5 | 6 | 9 | – | – | – | – |

| Rice milk (Pacific) | 130 | 1 | 2 | 27 | 0 | 30 | 6 | 10 |

| Oat milk (Oatly) | 80 | 2.5 | 4 | 16 | 2 | 15 | 0 | 10 |

| Sesame milk (Ecomil, with agave syrup) | 140 | 1.5 | 6 | 16.5 | 0.5 | – | – | – |

| Almond milk (Silk) | 40 | 1 | 3 | 2 | 1 | 20 | 2 | 10 |

| Coconut milk (Silk) | 80 | <1 | 5 | 7 | 0 | 45 | 4 | 10 |

| Hemp milk (Living harvest) | 70 | 2 | 6 | 1 | 0 | 30 | 6 | 10 |

| Hazelnut milk (Ecomil) | 124 | 1.4 | 6 | 14 | – | – | – | – |

| Multigrain milk (Pacific Organic 7 grain milk) | 140 | 3 | 2 | 27 | 1 | 35 | 8 | 15 |

| Cow’s milk (Amul Gold standardized UHT milk) | 168 | 8 | 10 | 11 | – | 338 mg | 1.25 µg | 168 µg |

Source: nutritional information available on respective product labels

Fig. 4.

Schematic diagram for preparation of calcium-fortified soy milk (Chaiwanon et al. 2000)

Labeling and marketing requirements

Since national legislation on food labelling varies from country to country, principle terminology in categorizing these plant based milk alternatives has been under debate at international level. The Codex General Standard for the Use of Dairy Terms, CODEX STAN 206 (GSUDT), prevent the use of the term ‘soybean milk’ and recommends to use the term ‘Soybean-based beverages’. The legislation and labelling requirements allows names in accordance with the composition and the law and custom of the country so that the product is sold and in a manner, not to mislead the consumer. In United states, the FDA covers these plant based milk alternatives under the definition of Imitation milk and imitation milk products and defines them as ‘those foods that have the physical characteristics, such as taste, flavor, body, texture, or appearance, of milk or milk products but do not come within the definition of “milk” or “milk products” and are nutritionally inferior to the product imitated’. All imitation and substitute milk and milk products sold in retail food stores shall be physically separated from milk or milk products by a partition or other device or divider in the dairy display case or other display-and-sale area. In the interest of public health, imitation or substitute milk and milk products shall comply with the following standards (http://www.leg.state.fl.us):

Temperature—They shall be cooled to and maintained at 45 °F or 7 °C or less.

Bacterial limits—Bacterial limits shall be no greater than 20,000 per mL. However, these limits shall not apply to cultured products.

Coliform—Coliform shall not exceed 10 per mL.

Soy milk is labeled all over the world as “soy milk”, except in European countries where legislation prohibits the use of the word “milk” for drinks that are not made from mammary secretions. Council Regulation 1234/2007 clearly specifies that “the term milk shall mean exclusively the normal mammary secretions obtained from one or more milkings without either addition there to or extraction there from” with an exception for coconut milk and almond milk (http://www.soya.be).

Future research and conclusion

Plant-based milk alternatives represents an enormous expansion prospective for health food market, and needs to be widely investigated through the development of advanced processing, technological interventions, fortification techniques, for developing a nutritionally complete beverage with high overall acceptability. Due to benefits associated with plant based milk alternatives as detailed above, advanced non-thermal technologies like pulse electric field technology can be helpful in targeting factors responsible for limiting success in processing of such plant based milks on wide scale thus, for helping in providing low cost, nutritious newer alternatives to all-those cow milk allergic population. The advanced non-thermal technologies which are well adapted in cow’s milk processing needs to be fully explored; for their potential in processing, as well as preservation of plant-based milk. To enable plant-based milk to be used as nutritionally equivalent alternatives for bovine milk by population who is sensitive to milk, fortification with a suitable form of fortificant using appropriate technology, and maintaining the bioavailability of nutrients throughout the storage is a major area of research. Also, to meet the consumer’s acceptability through technological interventions, plant-based milk alternatives will continue to be a major research area in the newer product development category of food science and technology.

Acknowledgments

This manuscript was prepared under the research activity on “oat milk and sesame milk processing” and financial support, facilities received from Indian Council of Agricultural Research (ICAR) and Central Institute of Post-Harvest Engineering and Technology (CIPHET) is gratefully acknowledged.

References

- Alejandro JDA (2007) Method for preparing a beanless-flavor soy milk and/okara using carbon dioxide in a state of sublimation. US7258889B2. 21.08.2007

- Badenhop AF, Hackler LR. Effect of soaking soybeans in sodium hydroxide solution as pretreatment for soy milk production. Cereal Sci Today. 1970;15(3):84–88. [Google Scholar]

- Bastıoğlu AZ, Tomruk D, Koç M, Ertekin FK. Spray dried melon seed milk powder: physical, rheological and sensory properties. J Food Sci Technol. 2016;53(5):2396–2404. doi: 10.1007/s13197-016-2214-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Belewu MA, Belewu KY. Comparative physicochemical evaluation of tiger nut, soybean and coconut milk sources. Int J Agric Biol. 2007;9(5):785–787. [Google Scholar]

- Berger J, Bravay G, Berger M (1997) Almond milk preparation process and products obtained. US5656321 A. 12.08.1997

- Biswas S, Sircar D, Mitra A, De B. Phenolic constituents and antioxidant properties of some varieties of Indian rice. Nutr Food Sci. 2011;41(2):123–135. [Google Scholar]

- Burton GW, Ingold KU. Vitamin E as an in vitro and in vivo antioxidant. Ann N Y Acad Sci. 1989;570:7–22. doi: 10.1111/j.1749-6632.1989.tb14904.x. [DOI] [PubMed] [Google Scholar]

- Camacho L, Sierra C (1988) Lupin processing for the obtainment of a tofu-like product. In: Twardowski (ed) Proceedings of the 5th international lupin conference. International Lupin Association, Poznan, pp 682–685

- Chaiwanon P, Puwastien P, Nitithamyong A, Sirichakwal PP. Calcium fortification in soybean milk and in vitro bioavailability. J Food Compos Anal. 2000;13(4):319–327. [Google Scholar]

- Chiba H, Takahashi N, Sasaki R. Enzymatic improvement of food flavor II. Removal of Beany flavor from soybean products by aldehyde dehydrogenase. Agric Biol Chem. 1979;43(9):1883–1889. [Google Scholar]

- Civille GV, Szczesniak AS. Guidelines to training a texture profile panel. J Texture Stud. 1973;4:204. [Google Scholar]

- Codex Alimentarius Commission (1994) Food for special dietary uses (including foods for infants and children), 2nd edn, vol 4. Joint FAO/WHO Food Standards Programme Codex Alimentarius Commission

- Cohen LA, Zhao Z, Pittman B, Scimeca JA. Effect of intact and isoflavone-depleted soy protein on NMU-induced rat mammary tumorigenesis. Carcinogenesis. 2000;21(5):929–935. doi: 10.1093/carcin/21.5.929. [DOI] [PubMed] [Google Scholar]

- Cruz N, Capellas M, Hernandez M, Trujillo AJ, Guamis B, Ferragut V. Ultra high pressure homogenization of soymilk: microbiological, physicochemical and microstructural characteristics. Food Res Int. 2007;40:725–732. [Google Scholar]

- Das A, Chaudhuri UR, Chakraborty R. Cereal based functional food of Indian subcontinent: a review. J Food Sci Technol. 2012;49(6):665–672. doi: 10.1007/s13197-011-0474-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Davies NT, Reid H. An evaluation of the phytate, zinc, copper, iron and manganese contents of, and Zn availability from, soya-based textured-vegetable-protein meat-substitutes or meat-extenders. Br J Nutr. 1979;41:579–589. doi: 10.1079/bjn19790073. [DOI] [PubMed] [Google Scholar]

- Davies CS, Nielsen SS, Nielsen NC. Flavor improvement of soybean preparations by genetic removal of lipoxygenase-2. J Am Oil Chem Soc. 1987;64(10):1428–1433. [Google Scholar]

- Deshpande RP, Chinnan MS, McWatters KH. Optimization of a chocolate-flavored, peanut–soy beverage using response surface methodology (RSM) as applied to consumer acceptability data. LWT Food Sci Technol. 2008;41:1485–1492. [Google Scholar]

- Deswal A, Deora NS, Mishra HN. Optimization of enzymatic production process of oat milk using response surface methodology. Food Bioprocess Technol. 2014;7(2):610–618. [Google Scholar]

- Dhakal S, Liu C, Zhang Y, Roux KH, Sathe SK, Shridhar K, Balasubramaniam VM. Effect of high pressure processing on the immunoreactivity of almond milk. Food Res Int. 2014;62:215–222. [Google Scholar]

- Diarra K, Zhang GN, Chen J. Peanut milk and peanut milk based products production: a review. Crit Rev Food Sci Nutr. 2005;45(5):405–423. doi: 10.1080/10408390590967685. [DOI] [PubMed] [Google Scholar]

- Faccin GL, Miotto LA, Vieira LN, Barreto PLM, Amante ER. Chemical, sensorial and rheological properties of a new organic rice bran beverage. Rice Sci. 2009;16(3):226–234. [Google Scholar]

- Fallourd MJ, Viscione L. Ingredient selection for stabilisation and texture optimisation of functional beverages and the inclusion of dietary fibre. In: Paquin Paul., editor. Functional and speciality beverage technology. Cambridge: Woodhead Publishing Limited; 2009. pp. 19–22. [Google Scholar]

- Farkas DE, Goldblith SA. Studies on the kinetics of lipoxygenase inactivation using thermal and ionizing energy. J Food Sci. 1962;27:262–276. [Google Scholar]

- Fennema OR. Food chemistry. 3. New York: Marcel Dekker; 1996. [Google Scholar]

- Friedman M, Brandon DL. Nutritional and health benefits of soy proteins. J Agric Food Chem. 2001;49(3):1069–1086. doi: 10.1021/jf0009246. [DOI] [PubMed] [Google Scholar]

- Frolic W, Nyman M. Minerals, phytate and dietary fibre in different fractions of oat grain. J Cereal Sci. 1988;7:73–82. [Google Scholar]

- Fujimaki M, Arai S, Kirigaya N, Sakurai Y. Studies on flavor components in soybean. Part 1. Aliphatic carbonyl compounds. Agric Biol Chem. 1965;29:855. [Google Scholar]

- Fukui K, Tachibana N, Wanezaki S. Isoflavone free soy protein prepared by column chromatography reduces plasma cholesterol in rats. J Agric Food Chem. 2002;50(20):5717–5721. doi: 10.1021/jf025642f. [DOI] [PubMed] [Google Scholar]

- Galvez FC, Resurreccion AV, Koehler P. Optimization of processing of peanut beverage. J Sens Stud. 1990;5:1–17. [Google Scholar]

- Gupta RP, Gupta RR (1988) Equipment for making no-beany flavor soymilk. US4744524. 17.05.1988

- http://www.leg.state.fl.us/statutes/index.cfm?App_mode=Display_Statute&Search_String=&URL=0500-0599/0502/Sections/0502.165.html. Accessed 20 Mar 2015

- http://www.soya.be/soy-drink.php. Accessed 20 Mar 2015

- http://www.foodstandards.gov.au/consumer/nutrition/milkaltern. Accessed 10 Mar 2016

- Ikya JK, Gernah DI, Ojobo HE, Oni OK. Effect of cooking temperature on some quality characteristics of soy milk. Adv J Food Sci Technol. 2007;5(5):543–546. [Google Scholar]

- Iswarin SJ, Permadi B. Coconut milk’s fat breaking by means of ultrasound. Int J Basic Appl Sci. 2012;12(1):1–5. [Google Scholar]

- Jafari SM, He Y, Bhandari B. Production of sub-micron emulsions by ultrasound and microfluidization techniques. J Food Eng. 2007;82:478–488. [Google Scholar]

- Johnson GW, Linda Y (1968) Simulated milk comprising soy bean flour, sesame seed flour and coco nut meal. US33868333. 04.06.1968

- Kapadia GJ, Azuine MA, Tokuda H, Takasaki M, Mukainaka T, Konoshima T, Nishino H. Chemopreventive effect of resveratrol, sesamol, sesame oil and sunflower oil in the epstein-barr virus early antigen activation assay and the mouse skin two-stage carcinogenesis. Pharmacol Res. 2002;45:499–505. doi: 10.1006/phrs.2002.0992. [DOI] [PubMed] [Google Scholar]

- Kon S, Wagner JR, Guadagni DG, Horvat RJ. pH adjustment control of oxidative off-flavors during grinding of raw legume seeds. J Food Sci. 1970;35(4):343–345. [Google Scholar]

- Kuntz DA, Nelson AI, Steinberg MP, Wei LS. Control of chalkiness in soymilk. J Food Sci. 1978;43:1279–1283. [Google Scholar]

- Kwok KC, Niranjan K. Review: effect of thermal processing on soy milk. Int J Food Sci Technol. 1995;30:263–295. [Google Scholar]

- Kwok KC, Qin WH, Bang JC. Heat inactivation of trypsin inhibitors in soymilk at ultra-high temperatures. J Food Sci. 1993;58(4):859–862. [Google Scholar]

- Lee C, Beuchat LR. Chemical, physical and sensory characteristics of peanut milk as affected by processing conditions. J Food Sci. 1992;57(2):401–405. [Google Scholar]

- Lei MG, Bassette R, Reeck GR. Effect of cysteine on heat inactivation of soybean trypsin inhibitors. J Agric Food Chem. 1981;29(5):1196–1199. doi: 10.1021/jf00108a025. [DOI] [PubMed] [Google Scholar]

- Lennart L, Inger A, Rickard O, Ingegerd S (1997) Homogeneous and stable cereal suspension and a method of making the same. US5686123. 11.11.1997

- Leu K. Analysis of volatile compounds produced in linoleic acid oxidation catalyzed by lipoxygenase from peas, soybeans and corn germs. LWT Food Sci Technol. 1974;7:98–100. [Google Scholar]

- Liener IR. Nutritional value of food protein, products. In: Smith AK, Circle SJ, editors. Soybeans: chemistry and technology, vol. I: proteins. Westport: AVI Publishing; 1972. [Google Scholar]

- Liu K. Soybeans as functional foods and ingredients. Champaign, Illinois, USA: AOCS Press; 2004. [Google Scholar]

- Lolas GM, Palamidis N, Markakis P. The phytic acid, total phosphorus relationship in barley, oats, soybeans and wheat. Cereal Chem. 1976;53:867–870. [Google Scholar]

- Lomer MCE, Parkes GC, Sanderson JD. Review article: lactose intolerance in clinical practice—myths and realities. Aliment Pharmacol Ther. 2008;27(2):93–103. doi: 10.1111/j.1365-2036.2007.03557.x. [DOI] [PubMed] [Google Scholar]

- Maestri DM, Labuckas DO, Guzman CA. Chemical and physical characteristics of a soybean beverage with improved flavor by addition of ethylenediaminetetraacetic acid. Grasas Aceites. 2000;51(5):316–319. [Google Scholar]

- Mandalari G, Nueno-Palop C, Bisignano G, Wickham MSJ, Narbad A. Potential prebiotic properties of almond (Amygdalus communis L.) seeds. Appl Environ Microbiol. 2008;74(14):4264–4270. doi: 10.1128/AEM.00739-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Markets and Markets (2013) Dairy alternative (beverage) market by type (Soy, almond, rice), formulation (plain, flavored, sweetened, unsweetened), channel (supermarket, health store, pharmacy, convenience store) & geography—global trends & forecast to 2018. http://www.marketsandmarkets.com/Market-Reports/dairy-alternative-plant-milk-beverages-market-677.html

- Mitchell CR, Mitchell PR, Nissenbaum R (1988) Nutritional rice milk production. US4744992. 17.05.1988

- Murugkar DA. Effect of sprouting of soybean on the chemical composition and quality of soymilk and tofu. J Food Sci Technol. 2014;51(5):915–921. doi: 10.1007/s13197-011-0576-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Namiki M. Nutraceutical functions of sesame: a review. Crit Rev Food Sci Nutr. 2007;47(7):651–673. doi: 10.1080/10408390600919114. [DOI] [PubMed] [Google Scholar]

- Nelson AI, Wei LS, Steinberg MP. Food products from whole soybeans. Soybean Digest. 1971;31(3):32–34. [Google Scholar]

- Nelson AI, Steinberg MP, Wei LS. Illinois process for preparation of soymilk. J Food Sci. 1976;41:57–61. [Google Scholar]

- Niki E, Yamamoto Y, Takahashi M, Komuro E, Miyama Y. Inhibition of oxidation of biomembranes by tocopherol. Ann N Y Acad Sci. 1989;570:23–31. doi: 10.1111/j.1749-6632.1989.tb14905.x. [DOI] [PubMed] [Google Scholar]

- Nnam NM. Chemical and sensory evaluation of vegetable milks from African yam bean Sphenostylis stenocarpa (Hochst ex A Rich) Harms and maize (Zea mays L.) Plant Foods Hum Nutr. 1997;51(3):265–275. doi: 10.1023/a:1007918011504. [DOI] [PubMed] [Google Scholar]

- Omoni AO, Aluko RE. Soybean foods and their benefits: potential mechanisms of action. Nutr Rev. 2005;63(8):272–283. doi: 10.1111/j.1753-4887.2005.tb00141.x. [DOI] [PubMed] [Google Scholar]

- Onning G, Akesson B, Oste R, Lundquist I. Effects of consumption of oat milk, soya milk, or cow’s milk on plasma lipids and antioxidative capacity in healthy subjects. Ann Nutr Metab. 1998;42:211–220. doi: 10.1159/000012736. [DOI] [PubMed] [Google Scholar]

- Onning G, Wallmark A, Persson M, Akesson B, Elmstahl S, Oste R. Consumption of oat milk for 5 weeks lowers serum cholesterol and LDL cholesterol in free-living men with moderate hypercholesterolemia. Ann Nutr Metab. 1999;43:301–309. doi: 10.1159/000012798. [DOI] [PubMed] [Google Scholar]

- Prakash V, Narasinga Rao MS. Physicochemical properties of oilseed protein. CRC Crit Rev Biochem Mol. 1986;20(3):265–363. doi: 10.3109/10409238609083736. [DOI] [PubMed] [Google Scholar]

- Quasem JM, Mazahreh AS, Abu-Alruz K. Development of vegetable based milk from decorticated sesame (Sesamum Indicum) Am J Appl Sci. 2009;6(5):888–896. [Google Scholar]

- Rahmati K, Tehrani MM, Daneshvar K. Soy milk as an emulsifier in mayonnaise: physico-chemical, stability and sensory evaluation. J Food Sci Technol. 2014;51(11):3341–3347. doi: 10.1007/s13197-012-0806-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rasane P, Jha A, Sabhiki L, Kumar A, Unnikrishnan VS. Nutritional advantages of oats and opportunities for its processing as value added foods: a review. J Food Sci Technol. 2015;52(2):662–675. doi: 10.1007/s13197-013-1072-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Richardson DP. Iron fortification of foods and drinks. Chem Ind. 1983;13:498–501. [Google Scholar]

- Sathe SK, Wolf WJ, Roux KH, Teuber SS, Venkatachalam M, Sze-Tao KWC. Biochemical characterization of amandin, the major storage protein in almond (Prunus dulcis L.) J Agric Food Chem. 2002;50(15):4333–4341. doi: 10.1021/jf020007v. [DOI] [PubMed] [Google Scholar]

- Seow CC, Gwee CN. Coconut milk: chemistry and technology. Int J Food Sci Technol. 1997;32:189–201. [Google Scholar]

- Settaluri VS, Kandala CVK, Puppala N, Sundaram J. Peanuts and their nutritional aspects—a review. Food Nutr Sci. 2012;3:1644–1650. [Google Scholar]

- Singh JS (2013) Effect of continuous flow high pressure throttling (CFHPT) on quality attributes of soymilk and changes during storage. A thesis submitted to the Graduate Faculty of The University of Georgia in Partial Fulfillment of the Requirements for the Degree Master of Science

- Singh T, Bains GS. Grain extract-milk beverage: processing and physicochemical characteristics. J Food Sci. 1988;53(5):1387. [Google Scholar]

- Sizer CE. Aseptic packaging of soymilk. Ch. 6. In: Lucas EW, Erickson DR, Nip WK, editors. Food uses of whole oil and protein seeds. Champaign: American Oil Chemists’ Society; 1989. pp. 98–101. [Google Scholar]

- Sosulski FW, Chakrabotry P, Humbert ES. Legume-based imitation and blended milk products. Can Inst Food Sci Technol J. 1978;11(3):117–123. [Google Scholar]

- Tester RF, Karkalas J. Swelling and gelatinization of oat starches. Cereal Chem. 1996;73(2):271–277. [Google Scholar]

- Toma RB, Tabekhia MM. Phytate and oxalate contents in sesame seed. Nutr Rep Int. 1979;20:25–31. [Google Scholar]

- Truswell AS. Cereal grains and coronary heart disease. Eur J Clin Nutr. 2002;56(1):1–14. doi: 10.1038/sj.ejcn.1601283. [DOI] [PubMed] [Google Scholar]

- Ukwuru MU, Ogbodo AC. Effect of processing treatment on the quality of tigernut milk. Pak J Nutr. 2011;10(1):95–100. [Google Scholar]

- Valencia-Flores DC, Hernández-Herrero M, Guamis B, Ferragut V. Comparing the effects of ultra-high-pressure homogenization and conventional thermal treatments on the microbiological, physical, and chemical quality of almond beverages. J Food Sci. 2013;78(2):E199–E205. doi: 10.1111/1750-3841.12029. [DOI] [PubMed] [Google Scholar]

- Valizadeh R, Kargarsana H, Shojaei M, Mehbodnia M. Effect of high intensity pulsed electric fields on microbial inactivation of cow milk. J Anim Vet Adv. 2009;8(12):2638–2643. [Google Scholar]

- Welch RW. Oats in human nutrition and health. In: Welch RW, editor. The oat crop. Production and utilization. London: Chapman and Hall; 1995. pp. 433–479. [Google Scholar]

- Wien M, Oda K, Sabaté J. A randomized controlled trial to evaluate the effect of incorporating peanuts into an American Diabetes Association meal plan on the nutrient profile of the total diet and cardiometabolic parameters of adults with type 2 diabetes. Nutr J. 2014;13:10. doi: 10.1186/1475-2891-13-10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wilkens WF, Mattick LR, Hand DB. Effect of processing method on oxidative off-flavors of soybean milk. Food Technol. 1967;21:1630. [Google Scholar]

- Xiang BY (2008) Effects of pulsed electric fields on structural modification and rheological properties for selected food proteins. A Thesis is submitted to Graduate Studies and Research Office in partial fulfillment of the requirements for the degree of Doctor of Philosophy. Department of Bioresource Engineering Macdonald Campus, McGill University Sainte-Anne-de-Bellevue, Québec, Canada

- Tan BH (1958) Technology of soymilk and some derivatives. Thesis. Agricultural University of Wageningen

- Yuan S, Chang SKC, Liu Z, Xu B. Elimination of trypsin inhibitor activity and beany flavor in soy milk by consecutive blanching and ultrahigh-temperature (UHT) processing. J Agric Food Chem. 2008;56(17):7957–7963. doi: 10.1021/jf801039h. [DOI] [PubMed] [Google Scholar]

- Zahra AK, Varidi M, Varidi MJ, Pourazarang H. Influence of processing conditions on the physicochemical and sensory properties of sesame milk: a novel nutritional beverage. LWT Food Sci Technol. 2014;57(1):299–305. [Google Scholar]

- Zhang H, Li L, Tatsumi E, Isobe S. High-pressure effects on proteins in soy milk. LWT Food Sci Technol. 2005;38:7–14. [Google Scholar]

- Zhang H, Onning G, Triantafyllou AO, Oste R. Nutritional properties of oat-based beverages as affected by processing and storage. J Sci Food Agr. 2007;87(12):2294–2301. [Google Scholar]