Abstract

Background:

Chairside softliners are used more frequently than is reported and studies regarding the bond strength of chairside softliners to heat-polymerized denture base resin are few and limited. Hence, this study was conducted to comparatively evaluate the shear bond strength of two chairside soft relining materials viz., autopolymerizing plasticized acrylic resin liner and a silicone-based liner bonded to heat polymerized polymethyl methacrylate denture base resin and to analyze the mode of interfacial bond failure.

Materials and Methods:

Forty test specimens (n = 40) were prepared by bonding plasticized acrylic- and silicone-based soft liner to heat polymerized acrylic resin blocks. Twenty specimens, ten from each group, were subjected to thermal cycling and later to shear bond strength testing. The debonded specimens were then qualitatively analyzed for the mode of failure using scanning electron microscopy. The results obtained were tabulated and statistically analyzed.

Results:

The mean shear bond strength values obtained for acrylic-based soft liner before and after thermal cycling were 0.3365 ± 0.025 MPa and 0.3164 ± 0.04 MPa, respectively. The mean shear bond strength values obtained for silicone-based soft liner before and after thermal cycling were 0.4159 ± 0.025 MPa and 0.4335 ± 0.02 MPa, respectively. Silicone-based soft liner showed higher shear bond strength than the acrylic-based both before and after thermal cycling (P = 0.0001). Scanning electron microscopy analysis showed a predominantly mixed mode of failure with silicone-based liner and predominantly adhesive mode of failure with acrylic-based soft liner.

Conclusion:

The silicone-based soft liner showed higher shear bond strength to heat polymerized acrylic resin than acrylic-based soft liner both before and after thermal cycling.

KEY WORDS: Heat polymerized acrylic resin, shear bond strength, softliner, thermal cycling

Aconventional removable dental prosthesis relies on the residual alveolar bone and the overlying mucoperiosteum for its support. The condition of these bearing tissues may be adversely affected by high-stress concentrations during function which can cause considerable damage to the supporting tissues resulting in accelerated ridge resorption and soft tissue injury to the denture bearing areas.[1] Relining of such prostheses is an accepted protocol for limiting the damage to the supporting structures. Relining ill-fitting removable dentures improve their stability, support, and retention.[2] A denture may be relined as a laboratory procedure or at the chairside in the dental clinic. The chairside relining procedure with a soft denture liner is used extensively in prosthodontics because of the simplicity of the technique, and the good fit of the prosthesis obtained. Soft denture liners have a key role in modern removable prosthodontics because of their ability to restore health to the inflamed and abused mucosa. They are resilient, viscoelastic materials used to form part of the fitting surface of a denture. They act as a cushion for the denture bearing mucosa through absorption, dampening, and redistribution of forces transmitted to the stress-bearing areas of edentulous ridges, provide more equal force distribution, reduce localized pressure, and improve denture retention by engaging undercuts. The ideal properties for a soft liner include resilience, tear resistance, viscoelasticity, biocompatibility, lack of odor and taste, adhesive bond strength, low solubility in saliva, low adsorption in saliva, ease of adjustability, dimensional stability, color stability, lack of adverse effect on denture base material, resistance to abrasion, and ease of cleaning.[3] There are several problems associated with the use of resilient denture liners, including bond failure between the liner and the denture base, colonization by Candida albicans, porosity, poor tear strength, and loss of softness. One of the most serious problems with these materials is bond failure between the resilient denture liner and denture base. The interfacial bond between the denture base and resilient liner is of much importance since the ability of the liner to effectively absorb and uniformly transmit the masticatory stresses is dependent on the integrity of the bond. Bond failure creates a potential surface for bacterial growth, and plaque and calculus formation. Weakened bond strength promotes the ingress of oral fluids and microorganisms at their interface and finally results in separation of the reline material from the denture base.[4,5] A variety of parameters affects the bond between resilient lining materials and the denture base, including water absorption, surface primer use, denture base composition, and temperature changes.[6,7,8] It is, therefore, essential that there is an adequate bond between the denture base and the soft lining material. Failure of soft lining materials is often attributed to a breakdown of this bonding and hence the quantification of bond strength assumes importance.

Although tensile bond strength of various lining materials to different denture base resins have been investigated by many authors,[9,10,11,12,13] shear forces best represent the clinical situation in which the resilient liners function.[14] Studies on shear bond strength of resilient liners to denture base resin are limited. The paucity of data on shear bond between denture relines and denture base polymers prompted the current study, the purpose of which was to characterize the shear bond strength between two chairside denture reline materials and denture base polymers.

Materials and Methods

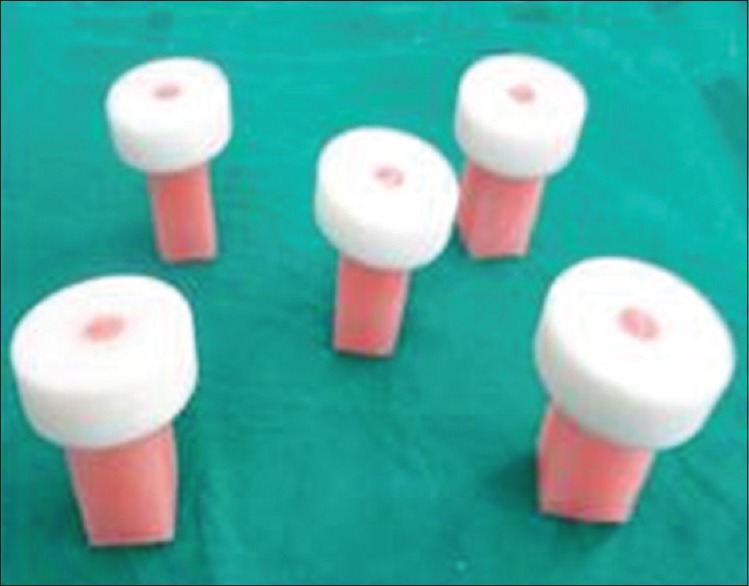

Forty heat processed polymethyl methacrylate (PMMA) acrylic resin blocks of dimension 1.4 cm × 1.4 cm × 0.25 cm were obtained by processing wax blocks of similar size poured out of a custom made stainless steel die. These acrylic blocks were smoothened with sandpaper of grit sizes of 100 and 120 respectively and were stored in distilled water at 37°C ± 1°C for 50 ± 2 h for the denture base polymer to reach water saturation. This procedure was adopted to simulate the effect of saliva during denture wear before relining.[2,4] The denture base resin surface to be bonded was smoothed on silicon carbide paper to simulate clinical relief of the denture base for bonding of the reline resins.[4,5,8] The bonding surfaces of the acrylic blocks were abraded with 50 μm aluminum oxide particles under 0.5 Mpa of pressure for 6 s.[4] The surfaces were then brushed with liquid detergent for 20 s, washed with distilled water and blot dried. A cylindrical Teflon jig, 24 mm in diameter and 6 mm in height was fabricated. The jig had a closed end and an open end. The closed end had a central circular opening, 6 mm in diameter and 3 mm in height so as to limit the bonding of the soft liner to a circular area of 6 mm diameter and standardize the height of the soft liner to 3 mm [Figure 1]. The custom made Teflon jig was placed on the surface treated end of the acrylic resin block. The design of the jig was such that the resin block fits snugly into the internal surface of the cylindrical jig. Thus, the assembly serves the dual purpose of delineating the shape and size of the bonding area and preventing the soft liner from contacting the acrylic resin surface outside the circular bonding area [Figure 2].

Figure 1.

Assembly of Teflon jig – acrylic resin block

Figure 2.

Schematic representation of Teflon jig – acrylic resin block assembly

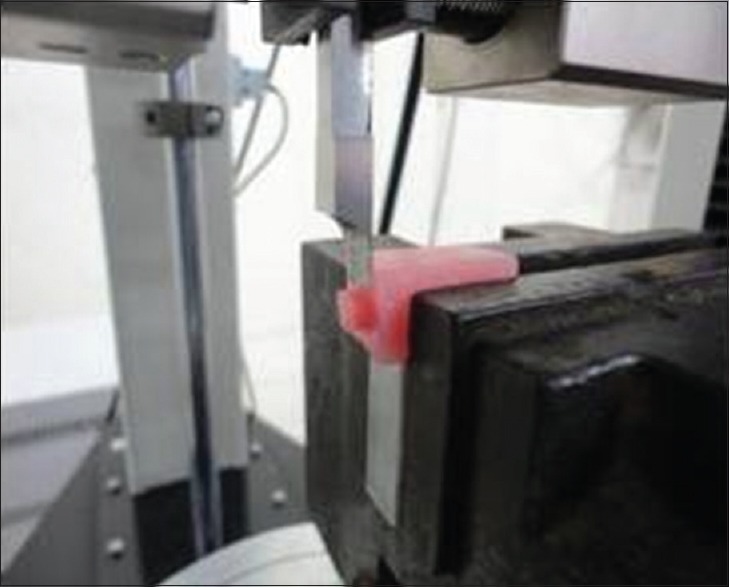

Two types of temporary chairside reline materials-an acrylic-based resilient liner (n = 20), and a silicone-based resilient liner (n = 20) were tested in this study. The materials were mixed according to the manufacturer's instructions and introduced into the Teflon jig – acrylic resin block assembly and covered on top by an acetate sheet and were allowed to set. Thus, 20 bonded specimens were obtained for each type of resilient liner, of which 10 from each group were subjected to thermal cycling for a total of 250 cycles in a distilled water bath between 5°C and 55°C with a dwell time of 60 s and dry time of 10 s at 27°C between the warm and cold cycles using a thermocycling apparatus (Haake, W15, Germany). All the samples were then tested for shear bond strength in a universal testing machine (Instron, Llyod instruments, UK) [Figure 3]. Force was applied to the sample in such a way that shear load was exerted directly to the bonding interface at a crosshead speed of 1 mm/min until failure of the bond occurred. Shear bond force at which the bond failed was recorded in Newton and shear bond strength (Mpa) was calculated by dividing the force (N) at which failure of the bond occurred by the surface area of adhesion (mm2). Surface analysis was carried out on one representative sample per test group selected randomly using scanning electron microscope (SA400N, Canada). The mode of failure of tested samples was assessed under ×14, ×50 and ×150 magnifications.

Figure 3.

Shear bond strength testing

Results

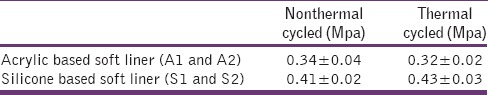

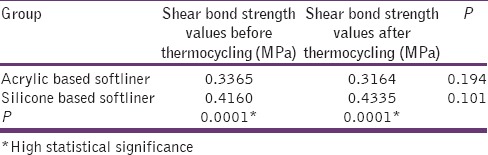

The mean shear bond strength values for the four test groups are summarized in Table 1. The groups were compared using an independent t-test which showed a statistically significant difference (P = 0.0001) between the acrylic and silicone-based soft liners for both the thermal cycled and nonthermal cycled groups [Table 2]. Furthermore, thermal cycling did not result in any significant change in the shear bond strength both for acrylic and silicone-based soft liner groups (P = 0.194 and P = 0.101, respectively).

Table 1.

Mean shear bond strength values (Mpa) for two types of soft resilient liners

Table 2.

Overall comparison of the mean shear bond strength values of acrylic based soft liner and silicone based soft liner before and after thermocycling (Groups A1, A2, S1 and Group S2)

Discussion

Sufficient bond strength between the soft liner material and denture base is required to avoid the interfacial separation at the denture borders. Lack of durable bond between the resilient liner and the denture is a common clinical problem.[15] The bond strength of the liner-denture base interface has been researched extensively by many authors. al-Athel and Jagger studied the various bond strength assessment methods namely peel test, tensile bond strength, and shear bond strength between the liner-denture base interface.[14] He concluded that shear forces best represent the oral conditions in which the liner functions. Hence, shear bond strength of the material is more indicative of its clinical longevity. The peel test is believed to simulate the horizontal component of masticatory forces as it causes lateral displacement of the denture. Tensile test on the other hand predominantly represents the vertical component of the masticatory force.

This study was undertaken primarily to evaluate the shear bond strength of two commonly used soft chairside relining materials namely autopolymerizing plasticized acrylic resin (Coe soft, GC USA) and vinyl polysiloxane elastomer (GC reline soft, GC USA) to heat processed PMMA resin (DPI, India) which is a commonly used denture base material for removable prosthesis.

The results showed that the acrylic-based liners demonstrated lower shear bond strength values than the silicone-based liners before and after thermal cycling. The higher bond strength of the silicone-based liners may be attributed to the improved adhesive bonding system used which usually contains silicone polymer in volatile solvents that can penetrate the acrylic resin.[16] The acrylic-based liners though chemically similar to the resin denture base show lower bond strength because of the limited ability of the monomer to penetrate the resin and the varying degrees of polymerization seen. It has been proposed that highly cross-linked denture or denture teeth polymers restrict the penetration of monomers because of the high density of the polymer network, and thus are not as effectively bonded.[12,17]

The mean shear bond strength values obtained for plasticized autopolymerizing acrylic resin-based liner before and after thermal cycling were 0.3365 ± 0.025 MPa and 0.31638 ± 0.04 MPa, respectively. The mean shear bond strength values obtained for silicone baseliner before and after thermal cycling were 0.4159 ± 0.025 MPa and 0.43349 ± 0.02 MPa, respectively. It was noted that the autopolymerizing plasticized acrylic liners demonstrated a marginal decrease in the shear bond strength after thermal cycling, whereas the silicon-based liners demonstrated a marginal increase. The decrease in the bond strength of acrylic-based liners can be attributed to hydration and stress concentration at the bonding interface, in the presence of residual monomer. Furthermore, hydrolytic degradation of the bond occurs when water diffuses into the interface.[18] Silicon-based liners, on the other hand, are hydrophobic and have very low water absorption. After thermocycling, silicone based liner showed an increase in bond strength, which may indicate that the material became more brittle and less viscoelastic. This can also be attributed to its continued polymerization, less water sorption, and changes in the viscoelastic properties which increase the hardness of the liner.[19] It has been suggested that the filler particles present in these materials are responsible for the minimal water absorption seen.[5,20] The improved bonding of the filler to resin by means of an acryloxy silane and the complete polymerization and cross-linking lead to less unreacted monomer and impurities, more dense material and therefore less water sorption.[17]

In this study, surface pretreatment was done to simulate the clinical scenario of chairside relining by removal of a layer of acrylic resin by mechanical abrasion using silicone carbide paper followed by sandblasting. For the silicone liner groups (S1, S2) this was followed by application of primer liquid supplied by the manufacturer since silicone-based soft liners have little or no chemical adhesion to PMMA denture base resin. Thus, the bond strength of silicone based denture liners depends on the strength of the liner and the adhesiveness of primers used. Although the exact chemical composition of such proprietary primers is not known, it is speculated that they may consist of an organic solvent and adhesive monomer which react with both silicone and resin material.[21]

Soft denture liners are expected to function in the adverse oral environment for long periods of time as well as under rapidly changing temperatures. However, it must be noted that with cyclic temperatures, the thermal behavior of the structural components within a material can influence the latter's mechanical and physical properties. In this connection, the thermal cycling process can give useful data on the longevity of denture liners with respect to mechanical properties under conditions that simulate clinical usage. The marginal decrease or increase in the shear bond strength of the materials tested after thermal cycling in this study has been shown to be not statistically significant. The paired t-test yielded a two-tailed P = 0.106 for the acrylic control and thermocycled groups (A1, A2). The same for silicone control and thermocycled groups (S1, S2) was 0.161. The independent t-test between the acrylic and silicone control groups (A1, S1) yielded a P < 0.0001. This difference is considered to be extremely statistically significant. The independent t-test between the thermal cycled groups of acrylic and silicone soft liner (A2, S2) yielded a P < 0.0001. This difference is considered to be extremely statistically significant. The inference is that there is a significance difference in the shear bond strength values between the acrylic-based liner and the silicone-based liner. This is true even after the specimens were subjected to thermal cycling.

Hence, the choice of a soft liner is based on the expected duration of service of the material in addition to a host of other factors. It can be concluded that both acrylic and silicone based soft liners can be used as temporary and interim resilient liners effectively for a period ranging from 7 days to 3 months. To be used as a permanent liner, silicone-based liners are recommended since they have a better bonding to the denture base and are also known to retain their softness and viscoelastic properties for a longer period. The minimal water sorption, improved polymerization, and biocompatibility favor the use of these materials for long-term relining.

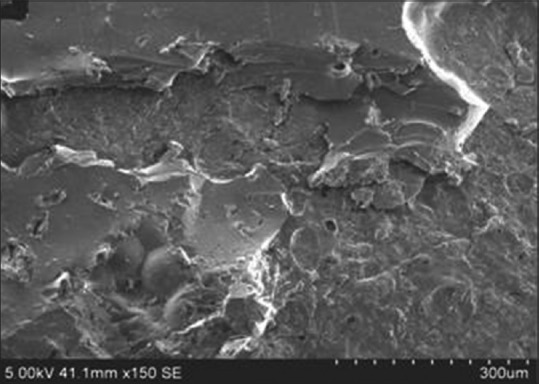

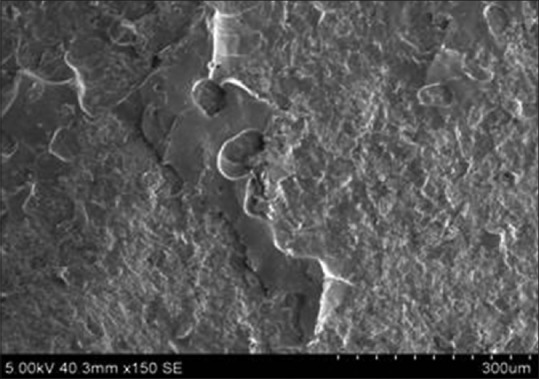

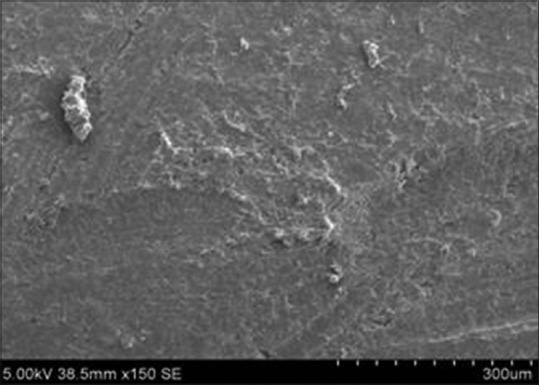

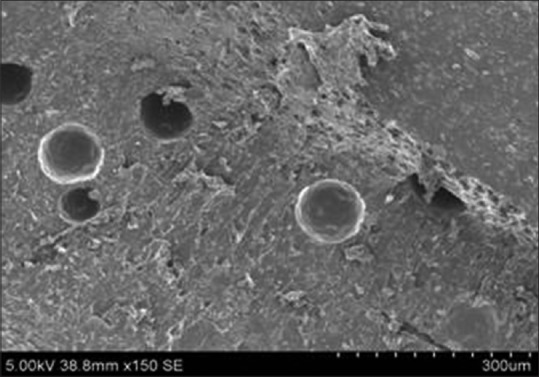

Qualitative analysis of the interface after testing was performed using scanning electron microscopy to characterize the mode of failure. When observed under the scanning electron microscope, both the acrylic liner groups showed a predominantly adhesive mode of failure with only a few areas of liner remaining adhered to the acrylic resin [Figures 4 and 5]. This is indicative of the weak adhesive bond which may be attributed to the poor monomer penetration and failure to form a strong interpenetrating network of polymers. Mixed failure mode was predominant in groups with higher shear bond strength. Silicone based liners under magnification showed mixed mode of failure [Figures 6 and 7]. Areas of both the liner and resin were visible, but the area of liner was more than that which is seen in the acrylic-based liner groups. The predominant mixed mode of failure in silico ne liner groups can be attributed to the primer used. The outline of the primer can be seen as a distinct layer along the boundary of the bonding area. This layer was intact even after thermal cycling. Hence, it can be safely inferred that the bonding of silicone based liner was definitely better than the acrylic based liner to the heat polymerized PMMA resin used in this study. The focus of this study was to evaluate the shear bond strength of soft liners mainly used for a short term such as during healing period of the denture bearing tissues. Therefore, thermal setting period was relatively short compared to other studies. As the clinical relevance of thermal setting varies depending on the protocols, equating thermocycling to actual clinical usage may not be accurate.

Figure 4.

Scanning electron microscope photomicrograph of bonding interface between acrylic based soft liner and heat processed polymethyl methacrylate resin (Nonthermal cycled- ×150)

Figure 5.

Scanning electron microscope photomicrograph of bonding interface between acrylic based soft liner and heat processed polymethyl methacrylate resin (Thermal cycled-under ×150)

Figure 6.

Scanning electron microscope photomicrographs of bonding interface between silicone based soft liner and heat processed polymethyl methacrylate resin (Nonthermal cycled-under ×150)

Figure 7.

Scanning electron microscope photomicrographs of bonding interface between silicone based soft liner and heat processed polymethyl methacrylate resin (Thermal cycled-under ×150)

Conclusion

On overall comparison, the silicone-based soft liner showed higher shear bond strength than acrylic-based soft liner both before and after thermal cycling. Shear bond strength was found to decrease in case of acrylic-based soft liner while it increased for silicone-based soft liner after thermal cycling

-

The qualitative evaluation of the mode of failure of the tested samples using scanning electron microscopy revealed the following:

- Acrylic-based soft liner exhibited predominantly adhesive failure pattern at the liner-acrylic resin interface

- Silicone-based soft liner exhibited a mixed adhesive and cohesive failure pattern at the liner-acrylic resin interface.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

References

- 1.Amin WM, Fletcher AM, Ritchie GM. The nature of the interface between polymethyl methacrylate denture base materials and soft lining materials. J Dent. 1981;9:336–46. doi: 10.1016/0300-5712(81)90007-5. [DOI] [PubMed] [Google Scholar]

- 2.Mese A, Guzel KG. Effect of storage duration on the hardness and tensile bond strength of silicone- and acrylic resin-based resilient denture liners to a processed denture base acrylic resin. J Prosthet Dent. 2008;99:153–9. doi: 10.1016/S0022-3913(08)60032-3. [DOI] [PubMed] [Google Scholar]

- 3.Craig RG, Gibbons P. Properties of resilient denture liners. J Am Dent Assoc. 1961;63:382–90. doi: 10.14219/jada.archive.1961.0218. [DOI] [PubMed] [Google Scholar]

- 4.Al Rifaiy MQ. Shear bond strength between light polymerized hard reline resin and denture base resin subjected to long term water immersion. Saudi Dent J. 2012;24:23–7. doi: 10.1016/j.sdentj.2011.10.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Anusavice KJ. Phillips’ Science of Dental Materials. 11th ed. Philadelphia: Elsevier Saunders; 2003. pp. 750–1. [Google Scholar]

- 6.León BL, Del Bel Cury AA, Rodrigues Garcia RC. Water sorption, solubility, and tensile bond strength of resilient denture lining materials polymerized by different methods after thermal cycling. J Prosthet Dent. 2005;93:282–7. doi: 10.1016/j.prosdent.2004.11.014. [DOI] [PubMed] [Google Scholar]

- 7.Garcia LT, Jones JD. Soft liners. Dent Clin North Am. 2004;48:709–20, vii. doi: 10.1016/j.cden.2004.03.001. [DOI] [PubMed] [Google Scholar]

- 8.Gale MS, Darvell BW. Thermal cycling procedures for laboratory testing of dental restorations. J Dent. 1999;27:89–99. doi: 10.1016/s0300-5712(98)00037-2. [DOI] [PubMed] [Google Scholar]

- 9.Akin H, Tugut F, Guney U, Kirmali O, Akar T. Tensile bond strength of silicone-based soft denture liner to two chemically different denture base resins after various surface treatments. Lasers Med Sci. 2013;28:119–23. doi: 10.1007/s10103-012-1082-7. [DOI] [PubMed] [Google Scholar]

- 10.Aydin AK, Terzioglu H, Akinay AE, Ulubayram K, Hasirci N. Bond strength and failure analysis of lining materials to denture resin. Dent Mater. 1999;15:211–8. doi: 10.1016/s0109-5641(99)00038-x. [DOI] [PubMed] [Google Scholar]

- 11.Philip JM, Ganapathy DM, Ariga P. Comparative evaluation of tensile bond strength of a polyvinyl acetate-based resilient liner following various denture base surface pre-treatment methods and immersion in artificial salivary medium: An in vitro study. Contemp Clin Dent. 2012;3(3):298–301. doi: 10.4103/0976-237X.103622. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Emmer TJ, Jr, Emmer TJ, Sr, Vaidynathan J, Vaidynathan TK. Bond strength of permanent soft denture liners bonded to the denture base. J Prosthet Dent. 1995;74:595–601. doi: 10.1016/s0022-3913(05)80311-7. [DOI] [PubMed] [Google Scholar]

- 13.Oguz S, Mutluay MM, Dogan OM, Bek B. Effect of thermocycling on tensile strength and tear resistance of four soft denture liners. Dent Mater J. 2007;26:296–302. doi: 10.4012/dmj.26.296. [DOI] [PubMed] [Google Scholar]

- 14.al-Athel MS, Jagger RG. Effect of test method on the bond strength of a silicone resilient denture lining material. J Prosthet Dent. 1996;76:535–40. doi: 10.1016/s0022-3913(96)90014-1. [DOI] [PubMed] [Google Scholar]

- 15.Botega DM, Sanchez JL, Mesquita MF, Henriques GE, Consani RL. Effects of thermocycling on the tensile bond strength of three permanent soft denture liners. J Prosthodont. 2008;17:550–4. doi: 10.1111/j.1532-849X.2008.00342.x. [DOI] [PubMed] [Google Scholar]

- 16.Madan N, Datta K. Evaluation of tensile bond strength of heat cure and autopolymerizing silicone-based resilient denture liners before and after thermocycling. Indian J Dent Res. 2012;23:64–8. doi: 10.4103/0970-9290.99041. [DOI] [PubMed] [Google Scholar]

- 17.Kulkarni RS, Parkhedkar R. The effect of denture base surface pretreatments on bond strengths of two long term resilient liners. J Adv Prosthodont. 2011;3:16–9. doi: 10.4047/jap.2011.3.1.16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Minami H, Suzuki S, Ohashi H, Kurashige H, Tanaka T. Effect of surface treatment on the bonding of an autopolymerizing soft denture liner to a denture base resin. Int J Prosthodont. 2004;17:297–301. [PubMed] [Google Scholar]

- 19.Kulak-Ozkan Y, Sertgoz A, Gedik H. Effect of thermocycling on tensile bond strength of six silicone-based, resilient denture liners. J Prosthet Dent. 2003;89:303–10. doi: 10.1067/mpr.2003.41. [DOI] [PubMed] [Google Scholar]

- 20.Braden M, Wright PS. Water absorption and water solubility of soft lining materials for acrylic dentures. J Dent Res. 1983;62:764–8. doi: 10.1177/00220345830620061601. [DOI] [PubMed] [Google Scholar]

- 21.El-Hadary A, Drummond JL. Comparative study of water sorption, solubility, and tensile bond strength of two soft lining materials. J Prosthet Dent. 2000;83:356–61. doi: 10.1016/s0022-3913(00)70140-5. [DOI] [PubMed] [Google Scholar]