Abstract

Excessive lead has been found in drinking water in Hong Kong in tests carried out in 2015. Investigations have identified that the problem in public rental housing estates was caused by the problematic solders used in the plumbing, and recommendations on enhancing the quality control system and strengthening the relevant water quality standards have been proposed. The cause for the same problem happening in other premises where soldering has not been adopted for water pipe connections is left unidentified. Considering the unidentified cause and the recommendations made, this study aims to identify the gaps in practice followed in Hong Kong for safeguarding the water quality of new installations. A holistic review of governing ordinances and regulations, products and materials used and the testing and commissioning requirements adopted in Hong Kong and elsewhere in the world were conducted. Based on international practices and parametric analysis, it was found that there are gaps in practices followed in Hong Kong, which are directly and indirectly leading to the lead-in-water crisis. Recommendations for improvement in the quality control system, and the water quality standards including the allowable lead content and leaching limit for products and materials and the testing and commissioning requirements on plumbing installations have been made. The review and the identified gaps would become useful reference for countries in strengthening their relevant water quality standards.

Keywords: lead in water, engineering aspects, quality control system, regulations and ordinances, allowable lead contents, testing and commissioning

1. Introduction

The quality of water that comes out of the tap is affected by both the distribution system that starts from the water treatment plants and the plumbing installation inside buildings. In the entire water supply system, water can become exposed to a range of chemicals, metals and bacteria. Amongst them, the existence of metallic lead can have an acute health impact in the long term [1,2,3] and thus is receiving much attention.

Compared to other countries, Hong Kong has very strict guidelines about how much lead can be in tap water. It adheres to the World Health Organisation (WHO) standard of 10 µg/L [4] which is less than in the United States (US) [5] or in mainland China [6] where the standards are 15 µg/L and 50 µg/L, respectively.

In 2015, samples of potable water from public rental housing (PRH) estates in Hong Kong were found to contain excessive levels of lead. Since such discoveries, water tests using different sampling protocols have been carried out almost everywhere in Hong Kong, including kindergartens, day care centres, schools, private and public housing estates and hospitals. Unfortunately, many have shown lead concentrations more than three times higher than the WHO’s recommended level [7]. This bad news caused widespread concern about a lead-in-water crisis in the city. The residents were panicking over the uncertainty if the tap water was safe to drink.

The quality of water on the distribution side in Hong Kong is the responsibility of the Water Supplies Department (WSD) which actions has always been good because water quality, including the lead concentration, has been closely monitored to ensure conforming to WHO guidelines [8]. As the majority of Hong Kong people are living in high-rise buildings, a small amount of residual chlorine is also maintained in the water to keep it free from bacterial infection during its long journey in the distribution system. The concern is therefore confined to plumbing installations inside buildings where copper pipes and copper and copper alloy fittings are often used. The WSD therefore jointed hands with the Housing Department (HA), the developer for PRH estates in Hong Kong, to lead a review committee (the Committee) on the excess lead-in-water problem in PRH developments.

The Committee’s investigation focused on housing estates completed during and after 2005 where soldering was adopted for water pipe connections. Systematic water sampling tests were conducted at 86 PRH estates, involving 83 PRH developments. A total of 4821 water samples were taken. The report released on 8 January 2016 [9] confirmed that excessive levels of lead were found at 11 PRH developments (approximately 29,077 units), and the problem was caused by the problematic solders used. In connection, WSD and HA have taken a series of immediate measures including the provision of water wagons/tanks, supply of bottled water, the installation of temporary water points by connecting pipes from the roof-top tank to each floor, as well as free installation of water filters (including replacement filter cartridges for two years after installation) for the affected domestic households. Further recommendations were to enhance the work quality of the plumbing contractors/sub-contractors including supervision and on-site monitoring, soldering materials used and training.

Besides the task force, the Chief Executive of the Hong Kong SAR Government also appointed a commission of inquiry into the excess lead-in-drinking water problem in the territory (the Commission) aiming to ascertain the causes for the problem and to make recommendations for improvements.

The Commission’s investigation report was released on 31 May 2016 [10]. A similar cause was identified for the excessive lead-in-water in PRH estates but not for other premises. This has highlighted the inadequacy of the existing legislative framework in safe-guarding the quality of drinking water in Hong Kong. The recommendations made were mainly on measures to enhance the quality control system including the setting up of an international and an independent panel on water safety, establishing the Hong Kong drinking water standard, and legislating the role and responsibilities of different parties responsible for design, construction and maintenance of plumbing system.

Both the Committee and the Commission’s recommendations are targeting to safeguard the water quality of new building developments. However, there are no details on how the recommendations can be practically implemented on the engineering aspects.

Reference was therefore made to relevant research works. For the excess lead-in-water problem, recent research works have been focused on assessing the associated health risk [1,2,11,12,13], developing new filtration technologies [14], computational modelling of different sampling approaches [15], and the corrosion potentials with different water chemistry [16,17,18,19], materials used [20,21,22,23] and disinfection practices [24,25,26,27,28,29,30]. On engineering aspects, many reference guidelines and products/materials standards for ensuring water quality have been published by different authorities worldwide and Hong Kong is no exception. Research works have also been done on evaluating the influences of different sampling methods on the water test results [31,32,33,34,35], optimizing the operational and water quality management strategies [36], and establishing a performance improvement framework [37]. However, there are virtually no single study that has focused on the whole spectrum of engineering aspects to ensure provision of safe drinking water.

2. Methods

To identify the inadequacies in the engineering aspects, in this study, a holistic review of the various project stages of a plumbing installation, involving the governing ordinances and regulations, the products and materials used and the testing and commissioning requirements, will be conducted. The main objectives are to identify inadequacies of practices followed in Hong Kong.

Reference is made to trends and experiences in Hong Kong and outside, to the extent available, including other trades where applicable and available. Amongst overseas practices, through content and bibliometric analysis, the US and Canada no doubt have a representative role [38]. Whilst Australia and New Zealand are at the onset of research on the problem of lead in drinking water [39], the United Kingdom (UK) is the first country to have set up engineering standards for addressing health and safety issues in this context [40]. Most UK practices are often followed by Hong Kong because of the colonial history.

2.1. Governing Ordinances and Regulations

The following reviews the primary instruments governing the provision of safe drinking water in various countries and jurisdictions, aiming to identify regulatory controls over safe drinking water in buildings and the parties/persons involved to ensure compliance.

2.1.1. International Practices

In the US, the Safe Drinking Water Act (SDWA) is the main federal law that ensures safe drinking water [41]. Under SDWA, the Environmental Protection Agency (EPA) sets standards and guidelines for drinking water quality and oversees different states, localities and water suppliers who have to follow and implement those standards.

Canada, Australia and New Zealand also adopt the SDWA as legislative protection for ensuring drinking water supplies are safe. In Canada, the enforcement responsibility is shared between the provincial, territorial, federal and municipal governments. The day-to-day responsibility of providing safe drinking water to the public generally rests with the provinces and territories, while municipalities usually oversee the day to day operations of the treatment facilities [42]. In Australia, the Department of Health and Human Services sets Australian Drinking Water Guidelines [43] and enforces the SDWA regulations. Whilst in New Zealand, the Act is administered by the Ministry of Health which also sets the guidelines for drinking-water quality management for New Zealand [44]. The UK adopts the Water Industry Act to set Water Supply (Water Quality) [45]. The enforcement authority is the Secretary of State for the Environment, Transport and the Regions.

To ensure that plumbing installations are in compliance with SDWA and other relevant regulations, only licensed plumbers (LP) are used for installation and repair works in all the above countries. LPs normally have years of training and/or experience. They need to be registered according to the relevant ordinances and employed by either the building client (or his representative) or the installation contractor. They are licensed to construct, install, maintain, alter, repair or remove plumbing installations.

Other than licensed plumbers, little information is available in the literature on the parties/persons involved in plumbing installations.

A comparison of the enforcing authority, regulatory hierarchy and relevant standards and guidelines are summarized in Table 1. It can be seen that guidance manuals and standards for controlling corrosion and excessive lead in drinking water are available for all of these countries.

Table 1.

Comparison of legislation structure and relevant standards in various regions.

| Geographic Entity | Enforcing Authority | Regulation | Standards & Guidelines | Installation |

|---|---|---|---|---|

| US | Environmental Protection Agency | Safe Drinking Water Act (SDWA) | Simultaneous Compliance Guidance Manual | Licensed Plumber |

| Canada | Health Canada | SDWA | Guidance on Controlling Corrosion in Drinking Water Distribution Systems | |

| Australia | Department of Health & Medical Research Council | SDWA | Australian Drinking Water Guidelines | |

| New Zealand | Ministry of Health | SDWA | Guidelines for Drinking-Water Quality Management for New Zealand | |

| UK | Secretary of State for the Environment, Transport and the Regions | Water Industry Act and Water Supply (Water Quality) Regulations | Guidance on the Implementation of the Water Supply (Water Quality) Regulations | |

| Hong Kong | Water Supplies Department | Waterworks Ordinance and the Sub-Legislature Waterworks Regulations | Plumbing Installation for Buildings Specific to Hong Kong |

2.1.2. Hong Kong Practice

Hong Kong is no different from other countries. The primary instruments governing the provision of safe drinking water are the Waterworks Ordinance (Cap102) and the sub-legislature Waterworks Regulations (Cap102A) under the Water Authority delegated to WSD for enforcement. WSD is also responsible for setting standards but they largely make reference to British Standards [46]. A handbook on plumbing installations for buildings specific to Hong Kong is also available [47]. However, the handbook focuses on Hong Kong waterworks requirements in respect of policies, and water supply application procedures. Guidance manuals and standards for controlling drinking water quality in the local context is lacking.

For new and major renovation projects, the current Hong Kong building legislation system requires an Authorized Persons (AP) who should be an architect, registered according to the Buildings Ordinance and employed by the building client, to take overall responsibility to ensure building works are in compliance with the relevant Ordinances and Regulations. They need to certify the use of WSD approved pipes and fittings and proper completion of plumbing works [47]. But as most APs do not have the background to understand plumbing installations, their role, as revealed from a survey, is normally restricted to confirm “the correctness of the water meter positions” as indicated by the LP [48]. As for the registered professional engineers (mainly building services engineers), there is no specific role prescribed in the legislation system. Submissions of plumbing system design, materials used and installation details are the responsibility of the LPs and approval of submissions are by the WSD. Thus Hong Kong also relies on the use of LPs to ensure plumbing installations are in compliance with Waterworks and related Regulations.

According to a survey of Hong Kong practices, plumbing installation works are often included under the Main Contract [48]. The plumbing installation contractors (PIC) are therefore employed by the main contractor as a domestic contractor to execute the installation works. The main contractors are typically listed in different classes according to their establishments, liquidity, track records, etc. to bid for projects of different scales and levels of complications but there is no registered list for the PICs. Thus the establishments of different PICs differ largely from each other. They may consist of only one LP for preparing and signing all submissions made to the WSD. As such, the actual installation work is carried out by semi-skilled or skilled plumbers but not a LP.

The LPs are considered as one type of Technical Competent Person (TCP) working in the construction industry [49]. TCPs are classified into five grades (T1–T5). TCPs T4 and T5 carry out engineering safety supervision to ensure compliance with design assumption and requirements. TCPs T1–T3 carry out routine safety supervision to ascertain compliance with approved, accepted or submitted method statements and precautionary and protective measures. The LPs on their own are not classified into different grades. There is only one grade of LP. They receive only vocational education with a minimum of five years working experience [50], which is the qualifying requirement of a TCP T3.

2.2. Products and Materials

Copper pipes have impurities such as lead. Lead is also frequently added to copper and copper alloy fittings to increase their machinability [51]. Thus copper pipes and copper and copper alloy fittings often contain a small amount of lead. The following sections review the standard and certification requirements for products and materials approved for use in plumbing installations to avoid excessive lead level in drinking water. The maximum allowed lead content and lead leaching limits for different products and materials should be stipulated.

2.2.1. Allowable Lead Content

The maximum allowable lead content limit for different products and materials specified in the US [52,53], Canada [52,53,54,55], Australia [56,57,58,59,60], New Zealand [56,57,58,59,60], the UK [61,62,63,64,65,66,67] and Hong Kong [61,62,63,64,65,66,67] are compared in Table 2.

Table 2.

Comparison of maximum allowable lead content (by % of weight) in copper pipe and copper alloy valves and fittings in various geographic entities.

| Geographic Entity | US * | Canada * | Australia | New Zealand | UK | Hong Kong |

|---|---|---|---|---|---|---|

| Copper Pipes | 0.25% | 0.25% | 0.05% | 0.085% | ||

| Copper Alloy Gate Valves | 0.25% | 0.25% | 4.5% | 8% | ||

| Facuets | 0.25% | 0.25% | 4.5% | not specified | ||

| Solder | 0.2% | 0.2% | 0.1% | 0% | ||

| Other Copper Alloy Valves and Fittings | 0.25% | 0.25% | 4.5% | 3% | ||

| Weighted-Average | ≤0.25% | ≤0.25% | Nil | Nil | ||

Remarks: * In total wetted parts.

Table 2 shows that the US adopts a performance-based approach [68] that requires a maximum of 0.25% weighted average lead content (WLC) in the entire plumbing system (the same level is used in Canada). Australia, New Zealand, the UK and Hong Kong adopt an absolute approach which sets the maximum allowed lead content in terms of % of weight of the component. However, there is no literature explaining how the limits were set.

In the US standard, Equation (1) is used for calculating the WLC:

| (1) |

where, LCi = maximum allowable lead content of the ith component, % of weight; WSAi = wetted surface area of the ith component, m2; WSAt = total wetted surface area of all components, m2; n = number of wetted components.

In Australia, New Zealand, the UK and Hong Kong, the requirements set for copper pipes are more or less the same, ranging between 0.085% and 0.05% by weight, but there is a larger difference in requirements set for fittings, gate valves and faucets, ranging between 3% and 8% by weight.

As for soldering material, the UK and Hong Kong have set an absolute lead-free requirement. The US and Canada also set an absolute requirement of 0.2% by weight. The requirement for Australia and New Zealand is 0.1% by weight.

2.2.2. Leaching Limit

The leaching limit and the key test requirements specified for the US [53], Canada [53,69], Australia [70], New Zealand [70], the UK [71] and Hong Kong [72] are compared in Table 3. It is noted that the allowed leaching limits in the US and Canada are identical and the limits in Australia and New Zealand are also identical. Amongst the two groups of countries, the US and Canada set the leaching limit for a single product/material as 0.5 µg/L. The test solutions are with a minimum pH values 6.5 for pipings and 5 for fittings and valves. The sample size for immersion test has to fulfil a minimum surface area to volume ratio of 5000 mm2/L. The Australia/New Zealand group, with different test requirements, sets the leaching limit for a single product/material as 10 µg/L. The test solution for all products/materials is with a minimum pH value of 6.5. The sample size for immersion test has to fulfil a minimum surface area to volume ratio of 1000 mm2/L, and the leaching limit has to be complied with by duplicate test samples.

Table 3.

Leaching limits and leaching test requirements.

| Description | US | Canada | Australia | New Zealand | UK | |

|---|---|---|---|---|---|---|

| Test Sample | Materials or Finished Products | Only for Non-Metallic Products | ||||

| Test Method | in-the-Product (all Samples except Solder); Immersion (Solder) | |||||

| Sample Size | in-the Product | Smallest Inner Diameter | ||||

| Immersion (Minimum Surface Area to Volume Ratio) | 5000 mm2/L | 1000 mm2/L | ||||

| Sample Pre-Test | Cleaning | Rinsed with Contaminate-Free Water | Rinsed in Flowing Tap Water | |||

| Conditioning in Test Water | for Minimum 2 days | for 24 h | ||||

| Test Water | pH value | Minimum 6.5 (Pipings) and 5 (Valves and Fittings) | Minimum 6.5 | |||

| Temperature | 23 ± 2 °C | 20 ± 2 °C | ||||

| Exposure Time | 24 ± 1 h | 24 ± 2 h | ||||

| Container | in-the Product | Capped with Inert Materials | ||||

| Immersion Test | Materials Inert to the Test Water | Glass or Polyethylene Ware | ||||

| Single Product Allowable Leaching Limit | ≤0.5 µg/L | ≤10 µg/L (Duplicate Samples) | ||||

For Hong Kong, the recently issued water supply booklet [72] states that all materials that come into contact with drinking water (including pipes, joints, soldering materials, valves, taps and other fittings) must comply with the relevant British Standards for potable water use. Thus it can be presumed that the lead content limit and leaching test details are identical to that of the UK. However, the UK has lead leaching test standard only for non-metallic components; there is no standard for metallic components.

2.2.3. Testing and Commissioning

To verify the safety of drinking water upon completion of a plumbing installation for the protection of public health, testing of water samples is often carried out to monitor the presence of lead on both the supply side and the plumbing installations.

The US [5], Canada [42], Australia [43] and New Zealand [44] have developed their own guidance manuals for water sampling protocols. Amongst them, the US and Canada manuals are rather comprehensive, with very detailed information and guidelines while manuals in Australia and New Zealand are relatively brief. They largely refer to the World Health Organisation (WHO) Standard [4] whereby many of the requirements are cross-referenced to the International Organization for Standardization (ISO) standards [73,74,75,76] and their own regional standards [77].

The UK does not have its own guidance manual. The sampling requirements are set in the European Drinking Water Directive [78] which are largely based on WHO and ISO standards [4,73,74,75,76]. However, the Drinking Water Inspectorate (DWI), on behalf of the Secretary of State for Environment, Food and Rural Affairs in England and Welsh Ministers in Wales, have published a guidance manual for implementation of water supply regulations [79] which covers a little bit of water sampling protocol also.

Details of the protocols of the studied jurisdictions are compared in Table 4. The protocols include the number of drawn samples, the sampling size and locations, the container specifications and the compliance requirements.

Table 4.

Sampling protocols for copper pipelines of different regions.

| Description | US | Canada 1 | Australia | New Zealand | UK 2 | Hong Kong | |

|---|---|---|---|---|---|---|---|

| Number of Draws | Two-Tier | One-Tier | |||||

| Drawing Method | Unflushed | after a Stagnation Period of 6–12 h | 30 min | not Specified | |||

| Flushed | Flush for a While to 5 min | Flush for 2–5 min | |||||

| Sample Volume (L) | 1 | 1 | 0.1 | 0.15 | 1 | 0.25 | |

| Sampling Location | Random | Drinking or Cooking Taps | Representative Points | Consumer Taps | Determined by WSD | ||

| Sampling Size Confidence Level | 95% | not Specified | 95% | not Specified | Exact Number of Sampling Points Specified | ||

| Container | Fully Filled | not Specified | Thoroughly Rinsed | ||||

| Sample Holding Time | not Specified | 28 Days | within the Same Day | 7 Days | within the Same Day | ||

| Sampling Water Temperature | Cold | Cold | Constant | Cold | Constant | Cold | |

| Compliance | unflushed | 90% | 90% | 95% | 100% | not Specified | |

| ≤15 µg/L | ≤10 µg/L | ≤10 µg/L | ≤10 µg/L | ||||

| flushed | 100% | 100% | |||||

| ≤15 µg/L | ≤10 µg/L | ||||||

Remarks: 1 Canada’s regulations are provincial. The actual sampling protocol may differ by provinces. 2 UK adopts Random Daytime Sampling approach to estimate the lead problem in a water supply zone. The consumer tap being sampled is not flushed before taking the water sample. Should excessive lead components be present, two-tier sampling protocol at the consumer tap will be adopted. WSD = Water Supplies Department.

It can be seen that they basically adopt two tiers of samplings. Tier-1 sampling is to investigate the dissolved lead from standard plumbing fitting materials for identifying the problematic locations and implementing corrective measures. Sample collection requires a period of stagnation of a minimum of 30 min to 12 h to increase the likelihood that the concentrations of lead in the first 0.1 to 1 L of water are close to a maximum value, often called the “unflushed” sample. For the “unflushed” sample, compliance requirements are generally less stringent and require 90 to 95 percentile non-exceedance of the regulatory limit (10 µg/L to 15 µg/L) but the sampling size should be large enough to achieve 95% confidence of the population size. Sampling locations should be representative points relative to the pipe-work distribution system, which should include the dead end of distribution branches as recommended by a previous study [80]. Sampling volume is preferred to be smaller to increase the accuracy. Should the samples fail the compliance tests, Tier-2 sampling should be introduced to the high risk points.

Tier-2 sampling is to check the supply water quality to ensure 100 percentiles non-exceedance of the regulatory limit (10 µg/L to 15 µg/L). Sample collection requires a flush of the pipeline for 2 to 5 min to check the acceptability of the concentration of lead for daily use so it is often called the “flushed” sample.

In sample collection, there are different requirements on the containers to be used (treated and untreated), the allowed sample holding time, the sample delivery method, and the sampling water temperature. However, despite the differences in requirements, consensus on some basic rules still can be obtained. The consensus rules for the two tiers of sampling approach are summarised in Table 5.

Table 5.

Consensus rules for the two tiers of sampling approach.

| Description | Unflushed | Flushed |

|---|---|---|

| Drawing Method | after a Period of Stagnation of 30 min to 12 h | Flush at a Uniform Rate for 2 to 5 min |

| Sample Volume | 0.1 L | |

| Sample Location | Sample Sites throughout the System and High Risk Areas | High Risk Areas |

| Sample Size | 95% Confidence Level Related to Population Size | 10% of the Tier-1 Sample Sites including the Problematic Sites |

| Compliance | 95% Non-Exceedance | 100% Non-Exceedance |

| Container | thoroughly Rinsed Container Provided by Recognized Laboratory | |

| Sample Holding Time | Deliver to Recognized Laboratory within a Day | |

| Sampling Water Temperature | Cold Water Pipeline at Constant Temperature | |

| Compliance | 10 µg/L | |

3. Results

Based on the above, the gaps in practices followed in Hong Kong in different areas are identified as follows.

3.1. Governing Ordinances and Regulations

It is noted from the above that for a plumbing installation project in Hong Kong, the AP, the main contractor, and the LP are the parties/persons officially involved in ensuring safe drinking water supply to consumers. But as mentioned, the AP and the main contractor play only a limited statutory role. The LP, who is a TCP T3, is the only person to bear the statutory responsibility. Thus there is a lack of a structured quality control system for monitoring the quality of plumbing installations.

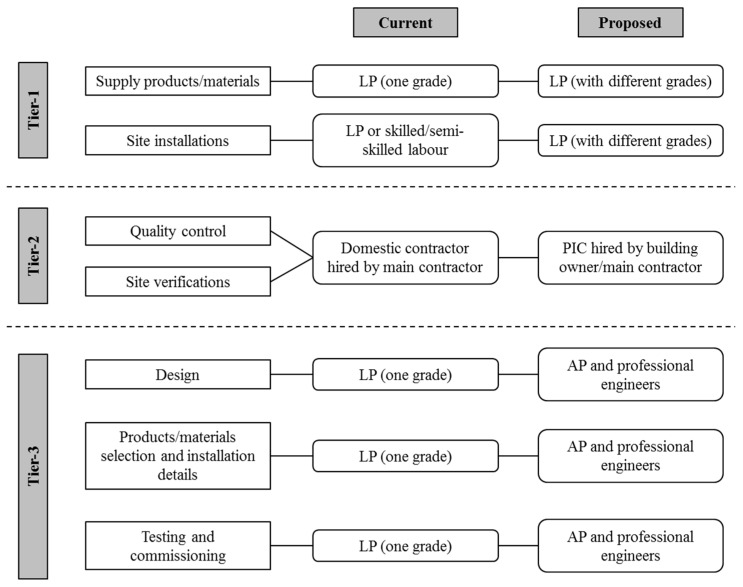

In establishing a structured control system, reference can be made to the existing laws governing fire services installations in Hong Kong [81]. In a fire services installation, three-tier quality control system is adopted to ensure quality installation works [82]. Tier-1 requires that the plumbing installation of a fire services system be carried out by a LP to ensure installations are in compliance with regulations, design assumptions and requirements. Tier-2 requires registered Fire Services Installation Contractor responsible to carry out all fire services installations to ensure the LP’s works are monitored. Tier-3 is to rely on the AP, assisted by other registered professional engineers, who are required to sign on drawings, design calculations and completion report for submissions made to statutory authorities, to ensure design, installation and overall performance are in due compliance with relevant ordinances and regulations.

It should be noted that a LP is needed even for plumbing installation of a fire services system which is much smaller scale than plumbing installation of a water supply system.

For satisfactory implementation of the three-tier quality control system in a plumbing installation, at the first-tier level, it is important that all workers engaged in plumbing installations must be LPs. The purpose is to ensure that works are carried out only by qualified plumbers. Thus the LPs should be appropriately qualified. There should be LPs of different grades depending on the qualifications and experience.

At the second-tier level, a registered PIC should be brought into the legislation system. All contractors engaged in plumbing installations must be PICs. The purpose is to ensure that plumbing installation work is carried out only by qualified LPs under supervision of qualified PIC. The PIC should have the competence to ensure design requirements are fulfilled, and materials used are safe. They can be hired directly by the building owner or the main contractor as nominated or a domestic contractor.

At the third-tier level, the AP or the registered professional engineers should be made accountable for the performance of the plumbing installation and the quality of the supply water. Thus submissions of plumbing system design, materials used and installation details, currently untaken by the LP, should be done by the AP, or the registered professional engineers. The proposed 3-tier quality control system in comparison to the current system is shown in Figure 1.

Figure 1.

Proposed and current quality control system. Remarks: LP = licensed plumber; AP = authorized person; PIC = plumbing installation contractor.

3.2. Products and Materials

It is noted that Hong Kong follows exactly the requirements in the UK for the maximum allowable lead content in products and materials. However, considering that Hong Kong is well-known for high-rise residential buildings, plumbing installations are therefore of a much larger scale than in the UK.

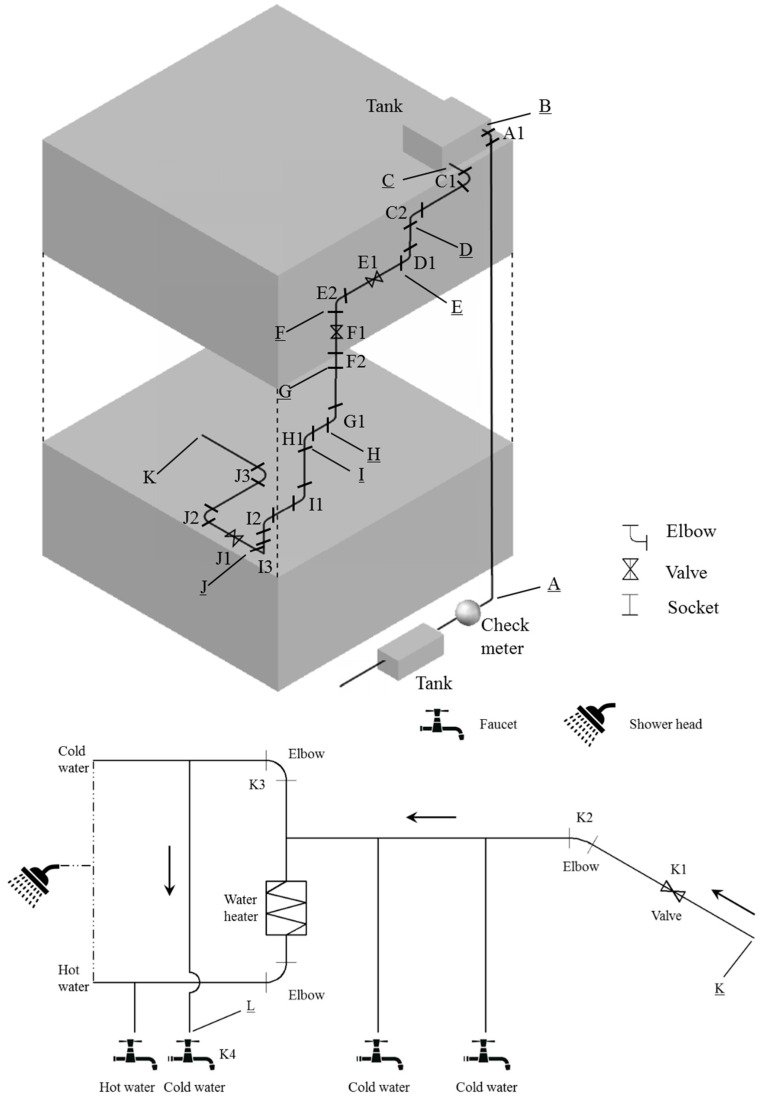

An attempt has been made to estimate the WLC of a plumbing installation supplying drinking water to the ground floor of a 40-storey high-rise residential building in Hong Kong. The studied building is a typical building used for investigation of the lead-in-water crisis in Hong Kong by the HKSAR government. A simplified schematic diagram of the plumbing installation is shown in Figure 2.

Figure 2.

A simplified schematic diagram of the plumbing installation.

The WLC was calculated based on Equation (1). LCi was based on the UK/Hong Kong standard (Table 2), WSAi and WSAt were determined based on the actual plumbing installation. Total length of elbow/socket was assumed to be 2 times the pipe diameter whilst that of the valve/faucet are based on product information. Results are summarised in Table 6. It can be seen that the resultant WLC is 0.1342% which is far smaller than the performance-based requirement adopted in the US (=0.25%).

Table 6.

Weighted lead content (WLC) prediction.

| Item | Diameter | Pipe/Fitting | Length (m) | Wetted Surface Area (m2) | Ratio Wetted Surface Area | UK/Hong Kong | Australia/New Zealand | US/Canada | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % Lead Content | % Lead Contribution | % Lead Content | % Lead Contribution | % Lead Content | % Lead Contribution | ||||||

| AB | 150 | Pipe | 152 | 71,628.5 | 0.5421 | 0.085 | 0.0461 | 0.05 | 0.0271 | 0.25 | 0.1355 |

| A1 | 150 | Elbow | 0.267 | 125.8 | 0.0010 | 3 | 0.0029 | 4.5 | 0.0043 | 0.25 | 0.0002 |

| CD | 150 | Pipe | 15 | 7068.6 | 0.0535 | 0.085 | 0.0045 | 0.05 | 0.0027 | 0.25 | 0.0134 |

| C1 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 3 | 0.0032 | 4.5 | 0.0048 | 0.25 | 0.0003 |

| C2 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 3 | 0.0032 | 4.5 | 0.0048 | 0.25 | 0.0003 |

| DE | 150 | Pipe | 4 | 1885.0 | 0.0143 | 0.085 | 0.0012 | 0.05 | 0.0007 | 0.25 | 0.0036 |

| D1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 8 | 0.0076 | 4.5 | 0.0043 | 0.25 | 0.0002 |

| EF | 150 | Pipe | 10 | 4712.4 | 0.0357 | 0.085 | 0.0030 | 0.05 | 0.0018 | 0.25 | 0.0089 |

| E1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 8 | 0.0076 | 4.5 | 0.0043 | 0.25 | 0.0002 |

| E2 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 3 | 0.0032 | 4.5 | 0.0048 | 0.25 | 0.0003 |

| FG | 150 | Pipe | 38 | 17,907.1 | 0.1355 | 0.085 | 0.0115 | 0.05 | 0.0068 | 0.25 | 0.0339 |

| F1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 8 | 0.0076 | 4.5 | 0.0043 | 0.25 | 0.0002 |

| F2 | 150 | Socket | 0.267 | 125.8 | 0.0010 | 3 | 0.0029 | 4.5 | 0.0043 | 0.25 | 0.0002 |

| GH | 100 | Pipe | 38 | 11,938.1 | 0.0904 | 0.085 | 0.0077 | 0.05 | 0.0045 | 0.25 | 0.0226 |

| G1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 3 | 0.0014 | 4.5 | 0.0021 | 0.25 | 0.0001 |

| HI | 100 | Pipe | 38 | 11,938.1 | 0.0904 | 0.085 | 0.0077 | 0.05 | 0.0045 | 0.25 | 0.0226 |

| H1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 3 | 0.0014 | 4.5 | 0.0021 | 0.25 | 0.0001 |

| IJ | 100 | Pipe | 4 | 1256.6 | 0.0095 | 0.085 | 0.0008 | 0.05 | 0.0005 | 0.25 | 0.0024 |

| I1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 3 | 0.0014 | 4.5 | 0.0021 | 0.25 | 0.0001 |

| I2 | 100 | Valve | 0.203 | 63.8 | 0.0005 | 8 | 0.0039 | 4.5 | 0.0022 | 0.25 | 0.0001 |

| I3 | 100 | Socket | 0.203 | 63.8 | 0.0005 | 3 | 0.0014 | 4.5 | 0.0022 | 0.25 | 0.0001 |

| JK | 25 | Pipe | 15 | 1178.1 | 0.0089 | 0.085 | 0.0008 | 0.05 | 0.0004 | 0.25 | 0.0022 |

| J1 | 25 | Valve | 0.165 | 13.0 | 0.0001 | 8 | 0.0008 | 4.5 | 0.0004 | 0.25 | 0.0000 |

| J2 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 3 | 0.0001 | 4.5 | 0.0001 | 0.25 | 0.0000 |

| J3 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 3 | 0.0001 | 4.5 | 0.0001 | 0.25 | 0.0000 |

| KL | 25 | Pipe | 15 | 1178.1 | 0.0089 | 0.085 | 0.0008 | 0.05 | 0.0004 | 0.25 | 0.0022 |

| K1 | 25 | Valve | 0.165 | 13.0 | 0.0001 | 8 | 0.0008 | 4.5 | 0.0004 | 0.25 | 0.0000 |

| K2 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 3 | 0.0001 | 4.5 | 0.0001 | 0.25 | 0.0000 |

| K3 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 3 | 0.0001 | 4.5 | 0.0001 | 0.25 | 0.0000 |

| K4 | 25 | Cold water faucet | 0.165 | 13.0 | 0.0001 | 4.5 | 0.0004 | 4.5 | 0.0004 | 0.25 | 0.0000 |

| Misc | 87 | Solder | 0.058 | 15.9 | 0.0001 | 0 | 0 | 0.1 | 0.0000 | 0.2 | 0.0000 |

| WLC (%) | 0.1342 | 0.098 | 0.25 | ||||||||

Remarks: solder joints of 2 mm wide were assumed before and after each fitting; calculations were based on Equation (1), and data on Table 2.

To ascertain whether the US standard can still be fulfilled if Hong Kong follows other international standards, the WLC of the same installation was again calculated based on various international standards. Results are again summarized in Table 6. It can be seen that amongst the three sets of international standards, Australian/New Zealand standards are the most stringent, resulting in a WLC of 0.098%.

However, given that the scale of plumbing installations can have very large variations, in terms of pipe length, the number of gate valves and the associated fittings, to avoid too high a WLC level due to building-specific characteristics, the use of the US’s performance-based approach is recommended.

In respect of the allowed leaching limit for products and materials, it is noted that Hong Kong does not specify the relevant requirement. To confirm whether reference can be made to other international standards, an attempt has been made to calculate if WHO’s recommended lead concentration (=10 µg/L) can be met if all products and materials used in the above-mentioned typical plumbing installation in Hong Kong (Equations (2) and Figure 2) are in compliance with single product allowable leaching (SPAL) limits of the two countries groups (0.5 µg/L for the US and Canada; and 10 µg/L for Australia and New Zealand). The calculation is based on Equations (2) and (3):

| (2) |

and:

| LLi = SPAL × NF × N | (3) |

where, LLC = weighted average lead leaching concentration, µg/L; LLi = maximum allowed leaching limit of the ith component, µg/L; WSAi = wetted surface area of the ith component, m2; WSAt = total wetted surface area of all components, m2; n = number of wetted components; SPAL = single product allowable leaching limit (Table 3), µg/L; NF = normalization factor; N = number of segments (1 for fittings).

NF is used to account for differences between laboratory and field surface-area-to-volume and N is used to account for the pipe/fitting length. For the US/Canada standards [53], a fixed NF is assumed for pipes of different diameters of an assumed length and N is determined based on the assumed and the actual pipe lengths. In case of Australia/New Zealand standards [70], NF is assumed to be a maximum of 0.1 and N is determined by the maximum allowed surface area to volume ratio (=15,000 mm2/L) and the volume of the test solution (=1 L). The calculation results are summarised in Table 7.

Table 7.

Lead leaching concentration (LLC) prediction.

| Item | Diameter | Pipe/Fitting | Length (m) | Wetted Surface Area (m2) | Ratio Wetted Surface Area | US/Canada | Australia/New Zealand | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N × NF | LLi | LLi × Ratio Wetted Surface Area | N × NF | LLi | LLi × Ratio Wetted Surface Area | ||||||

| AB | 150 | Pipe | 152 | 71,628.5 | 0.5421 | 4.18 | 2.09 | 1.1330 | 47.752 | 47,752.3 | 258.868 |

| A1 | 150 | Elbow | 0.267 | 125.8 | 0.0010 | 1 | 0.50 | 0.0005 | 0.084 | 83.9 | 0.001 |

| CD | 150 | Pipe | 15 | 7068.6 | 0.0535 | 0.41 | 0.21 | 0.0110 | 4.712 | 4712.4 | 2.521 |

| C1 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 1 | 0.50 | 0.0005 | 0.094 | 94.2 | 0.001 |

| C2 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 1 | 0.50 | 0.0005 | 0.094 | 94.2 | 0.001 |

| DE | 150 | Pipe | 4 | 1885.0 | 0.0143 | 0.11 | 0.06 | 0.0008 | 1.257 | 1256.6 | 0.179 |

| D1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 1 | 0.50 | 0.0005 | 0.084 | 83.9 | 0.001 |

| EF | 150 | Pipe | 10 | 4712.4 | 0.0357 | 0.28 | 0.14 | 0.0049 | 3.142 | 3141.6 | 1.120 |

| E1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 1 | 0.50 | 0.0005 | 0.084 | 83.9 | 0.001 |

| E2 | 150 | Elbow | 0.3 | 141.4 | 0.0011 | 1 | 0.50 | 0.0005 | 0.094 | 94.2 | 0.001 |

| FG | 150 | Pipe | 38 | 17,907.1 | 0.1355 | 1.05 | 0.52 | 0.0708 | 11.938 | 11,938.1 | 16.179 |

| F1 | 150 | Valve | 0.267 | 125.8 | 0.0010 | 1 | 0.50 | 0.0005 | 0.084 | 83.9 | 0.001 |

| F2 | 150 | Socket | 0.267 | 125.8 | 0.0010 | 1 | 0.50 | 0.0005 | 0.084 | 83.9 | 0.001 |

| GH | 100 | Pipe | 38 | 11,938.1 | 0.0904 | 1.05 | 0.52 | 0.0472 | 7.959 | 7958.7 | 7.191 |

| G1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 1 | 0.50 | 0.0002 | 0.042 | 41.9 | 2.0 × 10−4 |

| HI | 100 | Pipe | 38 | 11,938.1 | 0.0904 | 10.64 | 5.32 | 0.4808 | 7.959 | 7958.7 | 7.191 |

| H1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 1 | 0.50 | 2.4 × 10−4 | 0.042 | 41.9 | 2.0 × 10−4 |

| IJ | 100 | Pipe | 4 | 1256.6 | 0.0095 | 0.11 | 0.06 | 5.2 × 10−4 | 0.838 | 837.8 | 8.0 × 10−2 |

| I1 | 100 | Elbow | 0.2 | 62.8 | 0.0005 | 1 | 0.50 | 2.4 × 10−4 | 0.042 | 41.9 | 2.0 × 10−4 |

| I2 | 100 | Valve | 0.203 | 63.8 | 0.0005 | 1 | 0.50 | 2.4 × 10−4 | 0.043 | 42.5 | 2.1 × 10−4 |

| I3 | 100 | Socket | 0.203 | 63.8 | 0.0005 | 1 | 0.50 | 2.4 × 10−4 | 0.043 | 42.5 | 2.1 × 10−4 |

| JK | 25 | Pipe | 15 | 1178.1 | 0.0089 | 0.08 | 0.04 | 3.7 × 10−4 | 0.785 | 785.4 | 7.0 × 10−2 |

| J1 | 25 | Valve | 0.165 | 13.0 | 0.0001 | 1 | 0.50 | 4.9 × 10−5 | 0.009 | 8.6 | 8.5 × 10−6 |

| J2 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 1 | 0.50 | 1.5 × 10−5 | 0.003 | 2.6 | 7.8 × 10−7 |

| J3 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 1 | 0.50 | 1.5 × 10−5 | 0.003 | 2.6 | 7.8 × 10−7 |

| KL | 25 | Pipe | 15 | 1178.1 | 0.0089 | 0.41 | 0.21 | 1.8 × 10−3 | 0.785 | 785.4 | 0.070 |

| K1 | 25 | Valve | 0.165 | 13.0 | 0.0001 | 1 | 0.50 | 4.9 × 10−5 | 0.009 | 8.6 | 8.5 × 10−6 |

| K2 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 1 | 0.50 | 1.5 × 10−5 | 0.003 | 2.6 | 7.8 × 10−7 |

| K3 | 25 | Elbow | 0.05 | 3.9 | 0.0000 | 1 | 0.50 | 1.5 × 10−5 | 0.003 | 2.6 | 7.8 × 10−7 |

| K4 | 25 | Cold Water Faucet | 0.165 | 13.0 | 0.0001 | 1 | 0.50 | 4.9 × 10−5 | 0.009 | 8.6 | 8.5 × 10−6 |

| Misc | 87 | Solder | 0.058 | 15.9 | 0.0001 | 1 | 0.50 | 6.0 × 10−5 | 0.011 | 10.6 | 1.3 × 10−5 |

| LCC (ug/L) | 1.76 | - | 293.5 | ||||||||

Remarks: LLi was estimated based on Equation (3).

It can be seen in Table 7 that if all products and components leach out the maximum allowed SPAL, the resultant lead concentration in drinking water will be 1.76 µg/L and 293.5 µg/L for compliance with the US/Canada and Australia/New Zealand standards, respectively. The results obviously indicate that if the allowed leaching limit set by the Australia/New Zealand group, is applied to Hong Kong, the resultant lead concentration in drinking water will not be able to meet WHO’s requirement of 10 µg/L [4].

Furthermore, considering that lead leaching generally increases as acidity level of drinking water increases [83], pH values of drinking water in the four studied countries [42,43,84,85], together with that for the UK [79] and Hong Kong [8], are compared in Table 8. It can be seen that pH value of the test solutions specified in their test requirements (minimum 6.5 for pipings) are generally in-line with the acidity level of their drinking water (6–10.5).

Table 8.

Drinking water pH value.

Based on the acidity level of drinking water and the scale of the plumbing installations, it is evident from the above that Hong Kong has no stipulated leaching limit and leaching tests requirements should make reference to the relevant requirements adopted in the US.

3.3. Testing and Commissioning

Hong Kong does not have a guidance manual but it has been stated in WSD’s recent circular letter that the sampling protocol is by reference to the ISO Standards [86] which is a one-tier approach. However, the water sampling requirement in fact has never been mentioned in the relevant Ordinances and Regulations. Regarding water sampling approach, two tiers sampling protocol (Table 5) is recommended to ensure the quality of water on both the supply side and the plumbing installations.

4. Conclusions

To acknowledge the recommendations made for improvement in the quality control system, and the water quality standards for safeguarding the drinking water quality of new housing developments in Hong Kong, international and Hong Kong practices in terms of the governing ordinances and regulations, the products and materials used and the testing and commissioning requirements, to ensure safe drinking water supply to consumers are reviewed. The inadequacies of Hong Kong practices, which directly and indirectly lead to the lead-in-water crisis in Hong Kong, were identified. The recommended changes to the current practices can be summarised as below:

A 3-tier quality control system is proposed to ensure that design, installation and materials used are in accordance with requirements specified in various governing ordinances and regulations.

Performance-based approach should be adopted for specifying the allowable lead content in products and materials used.

Leaching limit and leaching test for products and materials used should be introduced to align with US requirements.

Two tiers sampling protocol should be adopted to ensure the quality of water on both the supply side and the plumbing installations.

The international practices reviewed and the identified gaps in practice in Hong Kong as summarized above would become useful reference for countries in strengthening their relevant water quality standards.

Acknowledgments

The authors wish to thank the “Task Force on Episode of Lead Residue Found in Tap Water“ of the Hong Kong Institution of Engineers for their approval in publishing this paper with the overall Task Force chaired by Peter Y. S. Wong, the editorial and research chaired by Pak Leung Yuen and Andrew M. W. Wong respectively, and to the contributions of all of the Task Force members including those as named in the Task Force’s report titled “Study of Lead in Drinking Water in Public Housing Estates“ released on 2 November 2015.

Author Contributions

All authors contributed equally in the preparation of this manuscript. Wai Ling Lee wrote the paper; Jie Jia and Yani Bao collected and analyzed the data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Cabral M., Toure A., Garçon G., Diop C., Bouhsina S., Dewaele D., Cazier F. Lead exposure on adults neighboring a discharge: Evidences of adverse health effects. Environ. Pollut. 2015;206:247–255. doi: 10.1016/j.envpol.2015.06.032. [DOI] [PubMed] [Google Scholar]

- 2.Adeyemi J.A., Adedire C.O., Paulelli A.C., Martins A.C., Jr., Ileke K.D., Barbosa F., Jr. Levels and daily intake of lead (Pb) and six essential elements in gari samples from Ondo State, Southwest Nigeria: A potential risk factor of health status. J. Food Comp. Anal. 2016;45:34–38. doi: 10.1016/j.jfca.2015.09.015. [DOI] [Google Scholar]

- 3.Ab Razak N.H., Praveena S.M., Aris A.Z., Hashim Z. Quality of Kelantan drinking water and knowledge, attitude and practice among the population of Pasir Mas, Malaysia. Public Health. 2016;131:103–111. doi: 10.1016/j.puhe.2015.11.006. [DOI] [PubMed] [Google Scholar]

- 4.World Health Organization . Guidelines for Drinking-Water Quality. 4th ed. World Health Organization; Geneva, Switzerland: 2011. [Google Scholar]

- 5.American Water Works Association . Guidance Manual for Monitoring Distribution System Water Quality. American Water Works Association Research Foundation; Denver, CO, USA: 2002. [Google Scholar]

- 6.National Health Commission of China . China National Health Inspection 2001[161] National Health Commission of China; Beijing, China: 2001. Sanitary standards for drinking water. [Google Scholar]

- 7.Chan G. Lead 80 Times the Safe Limit Found in Water at Hong Kong Public Housing Estate Where Scandal Broke. [(accessed on 25 July 2016)]. Available online: http://www.scmp.com/news/hong-kong/health-environment/article/1857252/lead-levels-80-times-who-safety-limit-found-water.

- 8.Water Services Department . Water Security Conservation, Annual Report 2013/2014. Water Services Department, HKSARG; Hong Kong, China: 2014. [Google Scholar]

- 9.Water Services Department and Housing Authority Report of the Task Force on Investigation of Excessive Lead Content in Drinking Water. [(accessed on 25 July 2016)]; Available online: https://www.devb.gov.hk/filemanager/en/Content_3/TF_Final_Report.pdf.

- 10.Chan H.W.A., Lai N.A. Report of the Commission of Inquiry into Excess Lead Found in Drinking Water. [(accessed on 25 July 2016)]; Available online: http://www.gov.hk/en/theme/coi-drinkingwater/pdf/COI_Report.pdf.

- 11.Kadir M.M., Janjua N.Z., Kristensen S., Fatmi Z., Sathiakumar N. Status of children’s blood lead levels in Pakistan: Implications for research and policy. Public Health. 2008;122:708–715. doi: 10.1016/j.puhe.2007.08.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Edwards M. Fetal death and reduced birth rates associated with exposure to lead contaminated drinking water. Environ. Sci. Technol. 2014;48:739–746. doi: 10.1021/es4034952. [DOI] [PubMed] [Google Scholar]

- 13.Hanna-Attisha M., Lachance J., Sadler R.C., Champney Schnepp A. Elevated blood lead levels in children associated with the flint drinking water crisis: A spatial analysis of risk and public health response. Am. J. Public Health. 2016;106:283–290. doi: 10.2105/AJPH.2015.303003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Mimoso J., Pronk W., Morgenroth E., Hammes F. Bacterial growth in batch-operated membrane filtration systems for drinking water treatment. Sep. Purif. Technol. 2015;156:165–174. doi: 10.1016/j.seppur.2015.09.070. [DOI] [Google Scholar]

- 15.Hayes C.R. Computational modelling to investigate the sampling of lead in drinking water. Water Res. 2009;43:2647–2656. doi: 10.1016/j.watres.2009.03.023. [DOI] [PubMed] [Google Scholar]

- 16.D’Antonio L., Fabbricino M., Nasso M., Trifuoggi M. Copper release in low and high alkaline water. Environ. Technol. 2008;29:473–478. doi: 10.1080/09593330801984381. [DOI] [PubMed] [Google Scholar]

- 17.Kim E.J., Herrera J.E. Characteristics of lead corrosion scales formed during drinking water distribution and their potential influence on the release of lead and other contaminants. Environ. Sci. Technol. 2010;44:6054–6061. doi: 10.1021/es101328u. [DOI] [PubMed] [Google Scholar]

- 18.Xie Y., Giammar D.E. Effects of flow and water chemistry on lead release rates from pipe scales. Water Res. 2011;45:6525–6534. doi: 10.1016/j.watres.2011.09.050. [DOI] [PubMed] [Google Scholar]

- 19.Ng D.Q., Lin Y.P. Effects of pH value, chloride and sulfate concentrations on galvanic corrosion between lead and copper in drinking water. Environ. Chem. 2016;13:602–610. doi: 10.1071/EN15156. [DOI] [Google Scholar]

- 20.Wang Y., Jing H., Mehta V., Welter G.J., Giammar D.E. Impact of galvanic corrosion on lead release from aged lead service lines. Water Res. 2012;46:5049–5060. doi: 10.1016/j.watres.2012.06.046. [DOI] [PubMed] [Google Scholar]

- 21.Rajasärkkä J., Pernic M., Kuta J., Lašňák J., Šimek Z., Bláha L. Drinking water contaminants from epoxy resin-coated pipes: A field study. Water Res. 2016;103:133–140. doi: 10.1016/j.watres.2016.07.027. [DOI] [PubMed] [Google Scholar]

- 22.Triantafyllidou S., Edwards M. Critical evaluation of the NSF 61 Section 9 test water for lead. J. Am. Water Works Assoc. 2007;99:133–143. [Google Scholar]

- 23.Sarver E., Edwards M. Effects of flow, brass location, tube materials and temperature on corrosion of brass plumbing devices. Corros. Sci. 2011;53:1813–1824. doi: 10.1016/j.corsci.2011.01.060. [DOI] [Google Scholar]

- 24.Massimiliano F., Korshin G.V. Changes of the corrosion potential of iron in stagnation and flow conditions and their relationship with metal release. Water Res. 2014;62:136–146. doi: 10.1016/j.watres.2014.05.053. [DOI] [PubMed] [Google Scholar]

- 25.Edwards M., Abhijeet D. Role of chlorine and chloramine in corrosion of lead-bearing plumbing materials. J. Am. Water Works Assoc. 2004;96:69–81. [Google Scholar]

- 26.Lytle D.A., Schock M.R. Formation of Pb(IV) oxides in chlorinated water. J Am. Water Works Assoc. 2005;97:102–114. [Google Scholar]

- 27.Switzer J.A., Rajasekharan V.V., Boonsalee S., Kulp E.A., Bohannan E.W. Evidence that monochloramine disinfectant could lead to elevated Pb levels in drinking water. Environ. Sci. Technol. 2006;40:3384–3387. doi: 10.1021/es052411r. [DOI] [PubMed] [Google Scholar]

- 28.Lin Y.P., Valentine R.L. Reduction of lead oxide (PbO2) and release of Pb(II) in mixtures of natural organic matter, free chlorine and monochloramine. Environ. Sci. Technol. 2009;43:3872–3877. doi: 10.1021/es900375a. [DOI] [PubMed] [Google Scholar]

- 29.Lin Y.P., Valentine R.L. Release of Pb (II) from monochloramine mediated dissolution of lead oxide (PbO2) Environ. Sci. Technol. 2008;42:9137–9143. doi: 10.1021/es801037n. [DOI] [PubMed] [Google Scholar]

- 30.Ng D.Q., Strathmann T.J., Lin Y.P. Role of orthophosphate as a corrosion inhibitor in chloraminated solutions containing tetravalent lead corrosion product PbO2. Environ. Sci. Technol. 2012;46:11062–11069. doi: 10.1021/es302220t. [DOI] [PubMed] [Google Scholar]

- 31.Santos Q.M.B., Schroeder J.L., Blakemore O., Moses J., Haffey M., Sloan W., Pinto A.J. The impact of sampling, PCR, and sequencing replication on discerning changes in drinking water bacterial community over diurnal time-scales. Water Res. 2016;90:216–224. doi: 10.1016/j.watres.2015.12.010. [DOI] [PubMed] [Google Scholar]

- 32.Cartier C., Laroche L., Deshommes E., Nour S., Richard G., Edwards M., Prévost M. Investigating dissolved lead at the tap using various sampling protocols. J. Am. Water Works Assoc. 2011;103:55–67. [Google Scholar]

- 33.Hayes C.R., Croft T.N. An investigation into the representativeness of random daytime sampling for lead in drinking water, using computational modelling. J. Water Supply Res. Technol. 2012;61:142–152. doi: 10.2166/aqua.2012.092. [DOI] [Google Scholar]

- 34.Del Toral M.A., Porter A., Schock M.R. Detection and evaluation of elevated lead release from service lines: A field study. Environ. Sci. Technol. 2013;47:9300–9307. doi: 10.1021/es4003636. [DOI] [PubMed] [Google Scholar]

- 35.Ng D.Q., Lin Y.P. Evaluation of lead release in a simulated lead-free premise plumbing system using a sequential sampling approach. Int. J. Environ. Res. Public Health. 2016;13:266. doi: 10.3390/ijerph13030266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Meng F., Fu G., Butler D. Water quality permitting: From end-of-pipe to operational strategies. Water Res. 2016;101:114–126. doi: 10.1016/j.watres.2016.05.078. [DOI] [PubMed] [Google Scholar]

- 37.Bereskie T., Haider H., Rodriguez M.J., Sadiq R. Framework for continuous performance improvement in small drinking water systems. Sci. Total Environ. 2016 doi: 10.1016/j.scitotenv.2016.08.067. in press. [DOI] [PubMed] [Google Scholar]

- 38.Hu J., Ma Y., Zhang L., Gan F., Ho Y. A historical review and bibliometric analysis of research on lead in drinking water field from 1991 to 2007. Sci. Total Environ. 2010;408:1738–1744. doi: 10.1016/j.scitotenv.2009.12.038. [DOI] [PubMed] [Google Scholar]

- 39.Dieter H.H. Drinking water toxicology in its regulatory framework. In: Wilderer P., editor. Treatise on Water Science. 1st ed. Volume 3. Elsevier Ltd., Academic Press; Cambridge, MA, USA: 2011. pp. 377–416. [Google Scholar]

- 40.British Standards Institution . The British Standards Institution Annual Report and Financial Statements. British Standards Institution; London, UK: 2010. [Google Scholar]

- 41.Tiemann M. Safe Drinking Water Act (SDWA): A Summary of the Act and Its Major Requirements. [(accessed on 25 July 2016)]. Available online: https://www.fas.org/sgp/crs/misc/RL31243.pdf.

- 42.Health Canada . Guidance on Controlling Corrosion in Drinking Water Distribution Systems. Health Canada; Ottawa, ON, Canada: 2009. [Google Scholar]

- 43.Australian Government Australian Drinking Water Guidelines 6, 2011, Version 3.1. [(accessed on 25 July 2016)]; Available online: https://www.clearwater.asn.au/user-data/resource-files/2015_australian_drinking_water_guidelines_6_3-1_150527.pdf.

- 44.Ministry of Health . Guidelines for Drinking-Water Quality Management for New Zealand. 3rd ed. Ministry of Health, New Zealand Government; Wellington, New Zealand: 2013. [Google Scholar]

- 45.Drinking Water Inspectorate . Drinking Water Inspectorate Guidance Document. Drinking Water Inspectorate; London, UK: 2012. Guidance on the implementation of the water supply (water quality) regulations 2000 (as amended) in England. [Google Scholar]

- 46.Water Works Department . Waterworks Ordinance. Water Works Department, HKSARG; Hong Kong, China: 2012. Waterworks Regulations. Chapter 102A. [Google Scholar]

- 47.Water Supplies Department Handbook on Plumbing Installation for Buildings. [(accessed on 25 July 2016)]; Available online: http://www.wsd.gov.hk/filemanager/en/content_150/HBonPIB.pdf.

- 48.Hong Kong Institution of Engineers . Study of Lead in Drinking Water in Public Housing Estates: Task Force on Episode of Lead Residue Found in Tap Water. The Hong Kong Institution of Engineers; Hong Kong, China: 2015. [Google Scholar]

- 49.Suen M.M.Y. Technical Memorandum for Supervision Plans 2005. [(accessed on 25 July 2016)]; Available online: http://www.legco.gov.hk/yr04-05/english/subleg/negative/sub_no05_e.pdf.

- 50.Water Services Department Water Works Regulations Part V, Licensing of Plumbers, WSD Circular Letter 2/92. [(accessed on 25 July 2016)]; Available online: http://www.wsd.gov.hk/filemanager/en/content_138/deleted/cir0292.pdf.

- 51.García P., Rivera S., Palacios M., Belzunce J. Comparative study of the parameters influencing the machinability of leaded brasses. Eng. Fail. Anal. 2010;17:771–776. doi: 10.1016/j.engfailanal.2009.08.012. [DOI] [Google Scholar]

- 52.Drinking Water System Components—Lead Content. NSF International; Ann Arbor, MI, USA: 2011. NSF/ANSI 372-2011. [Google Scholar]

- 53.American National Standards Institute . NSF/ANSI 61-2014a, Drinking Water System Components—Health Effects. NSF International; Ann Arbor, MI, USA: 2014. [Google Scholar]

- 54.Plumbing Fittings. Canadian Standards Association; Toronto, ON, Canada: 2012. ASME/CSAB125.3-2012. [Google Scholar]

- 55.Canadian Institute of Plumbing & Heating Press Release Status of Low Lead Requirements for Potable Plumbing Products in Canada. [(accessed on 25 July 2016)]. Available online: http://www.hc-sc.gc.ca/ahc-asc/index-eng.php.

- 56.Water Supply—Metallic Gate, Globe and Non-Return Valves. Standards Australia; Sydney, Australia: 1999. AS1628-1999. [Google Scholar]

- 57.Copper and Copper Alloys—Seamless Tubes for Engineering Purposes. Standards Australia; Sydney, Australia: 1988. AS1572-1988. [Google Scholar]

- 58.Copper and Copper Alloys—Compositions and Designations of Refinery Products, Wrought Products, Ingots and Castings. Standards Australia; Sydney, Australia: 2000. AS2738-2000. [Google Scholar]

- 59.Water Supply—Metallic Fittings and End Connectors. Standards Australia; Sydney, Australia: 2005. AS3688-2005. [Google Scholar]

- 60.Water Supply—Tap Ware. Standards Australia; Sydney, Australia: 2005. AS/NZS 3718-2005. [Google Scholar]

- 61.Copper and Copper Alloys—Seamless, Round Copper Tubes for Water and Gas in Sanitary and Heating Applications. British Standards Institution; London, UK: 2010. BSEN1057-201. [Google Scholar]

- 62.Industrial Valves—Copper Alloy Gate Valves. British Standards Institution; London, UK: 2010. BSEN 12288-2010. [Google Scholar]

- 63.Copper and Copper Alloys—Rod for Free Machining Purposes. British Standards Institution; London, UK: 2011. BSEN12164-2011. [Google Scholar]

- 64.Specification for Copper Alloy Globe, Globe Stop and Check, Check and Gate Valves. British Standards Institution; London, UK: 1991. BS5154-1991. [Google Scholar]

- 65.Copper and Copper Alloys—Plumbing Fittings—Part 1: Fittings with Ends for Capillary Soldering or Capillary Brazing to Copper Tubes. British Standards Institution; London, UK: 1998. BS1254-1-1998. [Google Scholar]

- 66.Copper and Copper Alloys—Ingots and Castings. British Standards Institution; London, UK: 2008. BS1982-2008. [Google Scholar]

- 67.Copper and Copper Alloys—Seamless, Round Tubes for General Purposes. British Standards Institution; London, UK: 2012. BS12449-2012. [Google Scholar]

- 68.Lee W.L., Yik F.W.H., Burnett J. Assessing energy performance in the latest versions of Hong Kong Building Environmental Assessment Method (HK-BEAM) Energy Build. 2007;39:343–354. doi: 10.1016/j.enbuild.2006.08.003. [DOI] [Google Scholar]

- 69.Plumbing Supply Fittings. Canadian Standards Association; Toronto, ON, Canada: 2012. ASME A112.18.1/CSA B125.1. [Google Scholar]

- 70.Testing of Products for Use in Contact with Drinking Water. Standards Australia; Sydney, Australia: 2005. AS/NZS 4020-2005. [Google Scholar]

- 71.Suitability of Non-Metallic Materials and Products for Use in Contact with Water Intended for Human Consumption with Regard to Their Effect on the Quality of the Water Part 1: Specification. British Standards Institution; London, UK: 2014. BS 6920-1-2014. [Google Scholar]

- 72.Water Services Department . Hong Kong’s Water Supply—Reducing Lead in Drinking Water. Water Services Department, HKSARG; Hong Kong, China: 2015. [Google Scholar]

- 73.Water Quality—Sampling—Part 1: Guidance on the Design of Sampling Programmes and Sampling Techniques. 2nd ed. International Organization for Standardization; Geneva, Switzerland: 2006. ISO5667-1. [Google Scholar]

- 74.Water Quality—Sampling—Part 5: Guidance on Sampling of Drinking Water from Treatment Works and Piped Distribution Systems. 2nd ed. International Organization for Standardization; Geneva, Switzerland: 2006. ISO5667-5. [Google Scholar]

- 75.Water Quality—Sampling—Part 3: Preservation and Handling of Water Samples. 4th ed. International Organization for Standardization; Geneva, Switzerland: 2012. ISO5667-3. [Google Scholar]

- 76.Water Quality—Sampling—Part 14: Guidance on Quality Assurance and Quality Control of Environmental Water Sampling and Handling. 2nd ed. International Organization for Standardization; Geneva, Switzerland: 2014. ISO5667-14. [Google Scholar]

- 77.Water Quality—Sampling Part 1: Guidance on the Design of Sampling Programs, Sampling Techniques and the Preservation and Handling of Samples. Australia and New Zealand Standards; Sydney, Australia: 1998. AS/NZS 5667.1-1998. [Google Scholar]

- 78.Hoekstra E.J., Hayes C.R., Aertgeerts R., Becker A., Jung M., Postawa A., Russell L., Witczak S. Guidance on Sampling and Monitoring for Lead in Drinking Water. [(accessed on 25 July 2016)]. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC51562/jrc51562.pdf.

- 79.Drinking Water Inspectorate . Drinking Water Inspectorate Guidance Document. Drinking Water Inspectorate; London, UK: 2015. Drinking water quality in England—The position after 25 years of regulation. [Google Scholar]

- 80.Abokifa A.A., Yang Y.J., Lo C.S., Biswas P. Water quality modeling in the dead end sections of drinking water distribution networks. Water Res. 2016;89:107–117. doi: 10.1016/j.watres.2015.11.025. [DOI] [PubMed] [Google Scholar]

- 81.Lai J., Yik F.W.H., Chan K.T., Lee W.L., Chau C.K. Regulatory controls on building services works in Hong Kong. Constr. Law J. 2011;27:459–479. [Google Scholar]

- 82.Fire Services Department Consultation Paper on the Implementation of Third Party Fire Safety Certification by Introducing a Registered Fire Engineers Scheme in Hong Kong. [(accessed on 25 July 2016)]; Available online: http://www.gov.hk/en/theme/bf/consultation/pdf/fsc_consppr_en.pdf.

- 83.Kim E.J., Herrera J.E., Huggins D., Braam J., Koshowski S. Effect of pH on the concentrations of lead and trace contaminants in drinking water: A combined batch, pipe loop and sentinel home study. Water Res. 2011;45:2763–2774. doi: 10.1016/j.watres.2011.02.023. [DOI] [PubMed] [Google Scholar]

- 84.US Environmental Protection Agency National Primary Drinking Water Regulations. [(accessed on 25 July 2016)]; Available online: https://www.epa.gov/sites/production/files/2016-06/documents/npwdr_complete_table.pdf.

- 85.Ministry of Health Drinking-Water Standards for New Zealand 2000. [(accessed on 25 July 2016)]; Available online: https://www.health.govt.nz/system/files/documents/publications/drinking-waterstandards-2000.pdf.

- 86.Water Supplies Department Water Sampling Procedure. [(accessed on 20 May 2016)]; Available online: http://www.wsd.gov.hk/filemanager/en/share/pdf/Water_Sampling_Procedure_and_Cleaning_Procedure_for_Sampling_Bottles-e.pdf.