Sci. Tech. Adv. Mater. 11 044303

Reference numbers after [49] in table 1, table 2, figure 6, figure 7, and the caption of figure 2 should be decreased by 1. The corrected tables and figures are shown below.

Table 1.

The classification of major processing strategies and corresponding compositions of porous ceramics produced from polysiloxane precursors.

| Processing strategy | Composition | Remarks | References | ||||||

|---|---|---|---|---|---|---|---|---|---|

| I. Replica | |||||||||

| SiC | Open cells | [56–60, 62] | |||||||

| Cell size:>150 μm | |||||||||

| Porosity range: 85–96% | |||||||||

| SiC–Si3N4 | [56, 58, 59] | ||||||||

| SiC–TiC | [56] | ||||||||

| SiOC/C | [53] | ||||||||

| II. Sacrificial template | |||||||||

| NaCl compact | SiC | Open cells | [67] | ||||||

| Cell size: 10–100 μm | |||||||||

| LDPE | SiOC | Open or closed cells | [68, 69] | ||||||

| Cell density: >104 cells cm− 3 | |||||||||

| Porosity range: 21–80% | |||||||||

| Expandable or PMMA templates | SiOC | Open, closed or partially interconnected cells | [66, 72–75] | ||||||

| Cell size: 0.5–80 μm | |||||||||

| Cell density: >109 cells cm− 3 | |||||||||

| Porosity range: 56–88% | |||||||||

| SiC | Porosity range: 32–64% | [18] | |||||||

| Expanded (hollow) templates | SiOC | Closed cells | [65] | ||||||

| Cell size: >30 μm. | |||||||||

| Cell density: >109 cells cm−3 | |||||||||

| Porosity range: 70–87% | |||||||||

| III. Direct foaming | |||||||||

| Foaming by chemical agent | SiOC | Open, closed or interconnected cells | [6, 77, 80–84, 86, 138] | ||||||

| Cell size: 80–800 μm | |||||||||

| Porosity range: 75–90% | |||||||||

| SiOC + SiC | Open cells | [81] | |||||||

| Cell size: 100–700 μm | |||||||||

| Foaming using CO2 | |||||||||

| Batch process | SiOC | Closed cells | [78, 89, 91, 95] | ||||||

| Cell size: 2–50 μm | |||||||||

| Cell density: 107–1012 cells cm− 3 | |||||||||

| Porosity: 45% | |||||||||

| SiC | [90] | ||||||||

| Extrusion process | SiOC | Open or closed cells | [92, 93] | ||||||

| Cell density: >107 cells cm− 3 | |||||||||

| Porosity range: 27–90% | |||||||||

| IV. Reaction technique | |||||||||

| SiC | Open cells | [18, 96–101, 103– | |||||||

| Cell size: 10–45 μm | 105] | ||||||||

| Cell density: >109 cells cm− 3 | |||||||||

| Porosity range: 32–94% | |||||||||

| Mullite | Partially interconnected open cells | [106–108] | |||||||

| Cell size: >20 μm | |||||||||

| Cell density: >109 cells cm− 3 | |||||||||

| Porosity range: 32–85% | |||||||||

| Cordierite | Interconnected open cells | [109, 110] | |||||||

| Cell size: 13 μm | |||||||||

| Cell density: 109 cells cm− 3 | |||||||||

| Porosity range: 11–75% | |||||||||

Table 2.

List of polysiloxane-derived ceramic compositions produced by different cross-linking methods.

| Cross-linking method | Ceramic composition | References |

|---|---|---|

| Heat treatment | ||

| SiOC | [94] | |

| SiC | [116–118] | |

| SiC fibers | [14] | |

| SiC nanoparticles | [119, 120] | |

| Si-O-C | [121] | |

| Catalysis | ||

| Boron-containing | SiC | [122–124] |

| catalyst | ||

| Metallocene | SiC | [125, 126] |

| Chlorine-containing | SiC | [127] |

| catalyst | ||

| Amine catalyst | SiOC | [69, 74, 80, 81, 95] |

| condensation | ||

| Laser treatment | ||

| SiC nanopowders | [128, 129] | |

| Radiation | ||

| SiC or SiOC | [130–133] |

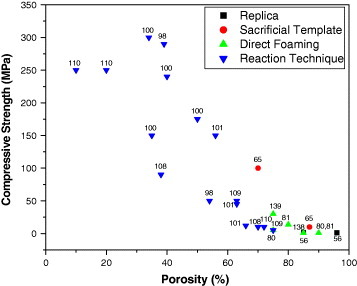

Figure 6.

Compressive strength as a function of porosity of polysiloxane-derived porous ceramics produced by different strategies. Data points are labeled with the corresponding reference numbers.

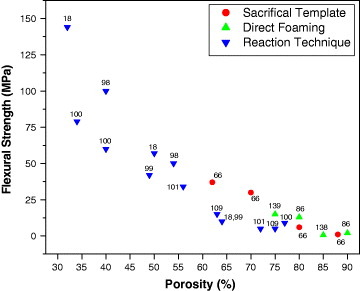

Figure 7.

Flexural strength as a function of porosity of polysiloxane-derived porous ceramics produced by different strategies. Data points are labeled with the corresponding reference numbers.

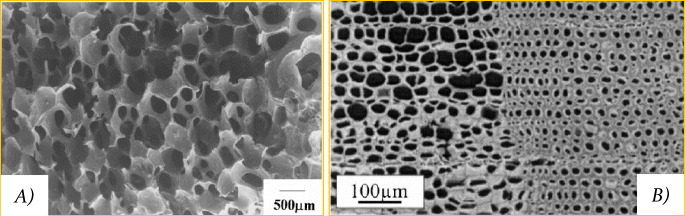

Figure 2.

(A) Macroporous cellar structure of SiC ceramics after pyrolysis of polysilane-infiltrated polyurethane (PU) foams (reproduced with permission from [58] © 2000 Springer). (B) The crack-free SiOC-C ceramic structure developed using extracted, maleic acid anhydrate (MA)-modified and polymethylhydrosiloxane (PMHS)-infiltrated pine wood compounds after pyrolysis at 800 °C in nitrogen atmosphere (reproduced with permission from [53] © 2004 Elsevier).