Abstract

A force and/or torque are induced in a material under the imposition of a magnetic field. Their magnitudes are different from those acting on the surrounding materials because of the difference in their physical properties. Therefore, a magnetic field is a powerful tool for controlling a second phase in a mother phase such as particles suspended in a liquid. In this paper, we focus on two processes. The first one is a novel method of magnetic filtration in which schwertmannite particles in wastewater are controlled using a magnetic field. The second one is a refining process for a metallic alloy structure during solidification in which solid particles suspended in the liquid phase are controlled using the force excited by the simultaneous imposition of a magnetic field and alternating current.

Keywords: schwertmannite, solidification, magnetic fixed bed, Cr removal, refinement of solidified structure

Introduction

When a material is subjected to a magnetic field, a force and/or torque is induced to reduce the magnetization energy. The force and/or torque act not only on the material we are interested in but also on the surrounding materials with a different magnitude because of their different physical properties. Thus, the material moves and/or rotates to a magnetically stable condition. Therefore, a magnetic field is a powerful tool for controlling a second phase in a mother phase. With the development of superconducting magnet technology, not only magnetic materials but also nonmagnetic materials can be affected by a magnetic field. Thus, magnetic fields have been used for processes including crystal alignment, levitation and separation. Functional materials can be produced through these processes because the purity of the materials and their physical properties such as their electric, magnetic, thermal and mechanical properties can be controlled.

Magnetic filtration is a promising practical application of superconducting magnets that has attracted much interest in recent years, particularly after the successful operation of the first generation of industrial superconducting filters in Japan [1], which are now becoming widespread across the country. Because of the new developments in superconducting magnets, which can more easily provide high-gradient magnetic fields, many novel magnetic separation devices are being designed to overcome some of the inherent shortcomings of conventional magnetic filters. For instance, an open-gradient magnetic separator using a high-temperature superconducting magnet has been designed to eliminate the need for a ferromagnetic matrix in a conventional magnetic filter so as to solve the major problem of the filter becoming blocked by the accumulation of particles in the matrix [2].

The mechanical properties of materials such as strength, elongation and toughness strongly depend upon their grain size, which is almost completely determined by the solidification process. Thus, the control of their solidified structure is essential for obtaining products with good mechanical properties. Heat flow control during solidification is a common method of controlling the grain size of solidified structures, although it is difficult to apply this method to the casting of large products. Although inoculation can also be used to refine solidified structures, it is sometimes detrimental to the recycling of products because of the added elements. An increase in the number of small solid particles in the liquid phase during the solidification is required for the refinement of the solidified structure. That is, the solid particles in the liquid should be controlled.

In this paper, a novel method of magnetic filtration involving the direct packing of schwertmannite particles in a glass column under the imposition of a magnetic field, and a refining process for a metallic alloy structure during its solidification are proposed.

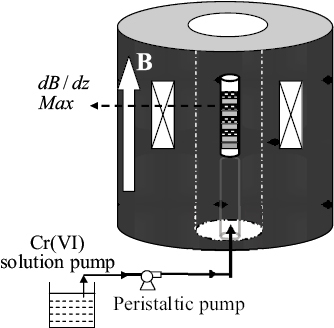

Magnetic filtration

A novel design for a fixed-bed column using a high magnetic field has been presented by our research group, wherein schwertmannite, as a fine particle adsorbent, is used for the continuous removal of Cr(VI) from a liquid. The extremely fine particles and the mud-like properties of the adsorbent cause a variety of problems in the application of ordinary packed beds such as a large drop in pressure. Figures 1 and 2 show a small-scale physical model of the proposed process wherein schwertmannite powder was packed in a glass column with ferromagnetic wool layers alternately laid among the adsorbent layers [3]. 1 g schwertmannite or 0.4 g iron wool was placed in each layer. We fixed the column inside of a high magnetic field of 4 T where the gradient was highest. A solution of distilled water containing Cr(VI) ions was prepared by dissolving a known amount of K2Cr2O7 in deionized water, and then this solution was passed upward through the fixed-bed column located in the high magnetic field using a peristaltic pump. Effluent samples were collected at regular time intervals and analyzed for remaining Cr ions. According to the obtained results, the breakthrough curve of the process is very similar to typical curves obtained using a fixed-bed column, which confirms the successful operation of this process. Moreover, the amount of Cr sorption as a proportion of the total Cr concentration in the initial solution indicates that the maximum Cr adsorption in this system is greater than that obtained by batch sorption. This may be explained by the nanoeffect interaction between the iron wool and Cr ions under the high-gradient magnetic field.

Figure 1.

Experimental setup of the magnetic filtration system.

Figure 2.

Newly designed magnetic column.

The high magnetic field imposed in this process has a major role in maintaining the shape and the performance of the column bed during the feeding of the bed. In fact, the magnetization force acts as a holding force to maintain the bed under constant conditions. That is, as a result of the ferromagnetic wool being kept in contact with the column wall by the magnetization force without the requirement of any other forces, we can use a simple fixed-bed column compared with that used in conventional devices.

Control of metallic alloy structure during solidification

Some studies have been performed on the refinement of a metallic alloy during solidification using electromagnetic fields [4, 5]. The authors proposed a refining process for a metallic alloy during its solidification in which a static magnetic field and an alternating electric current are simultaneously imposed on a local region of the alloy [6]. To optimize this process, the effect of the operating parameters on the solidified structure are clarified. In this section, the intensity and duration of the electric current are adopted as the operating parameters in the process optimization.

Experimental setup

A sample of a Sn-10mass%Pb alloy was prepared by alloying pure molten Sn (99.9%) and pure molten Pb (99.9%). Its liquidus and eutectic temperatures are 219 and 183 °C, respectively. A schematic view of the experimental apparatus is shown in figure 3. A rectangular glass vessel of length 40 mm and width 25 mm was filled with a 0.3 kg liquid sample (about 40 mm depth) and was set in the bore of a superconducting magnet. This magnet imposed an upward vertical static magnetic field of 10 T on the sample. An alternating current of 2 kHz was supplied to the sample for a particular duration through a pair of copper electrodes inserted into the sample in the vicinity of one of the short walls of the vessel. Furthermore, the superconducting magnet, the sample and the electrodes were separately supported to prevent the propagation of vibrations through the sample, as shown in figure 4.

Figure 3.

Schematic view of experimental apparatus and superconducting magnet.

Figure 4.

Schematic view of experimental apparatus.

Solid particle motion in liquid

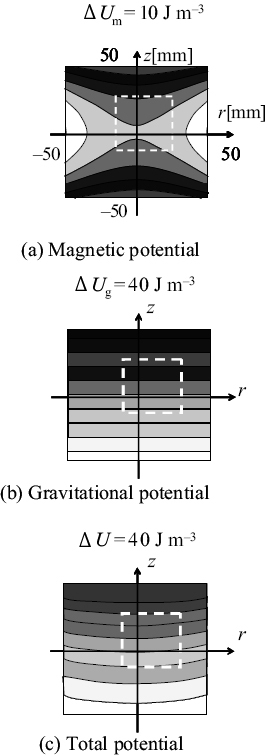

The origins of solid particle motion in the liquid phase in this experimental setup are the gravity force, magnetization force, convection caused by the Lorentz force and the nonuniform temperature distribution. The gravitational potential and magnetic potential are

where Ug is the gravitational potential, Um is the magnetic potential, Δρ is the density difference between liquid phase and solid phase, g is the acceleration due to gravity, z is the vertical position, m0 is the magnetic permeability in vacuum, Δχ is the magnetic susceptibility difference between the solid phase and liquid phase and B is the intensity of the magnetic field.

The sum of these potentials, U is calculated

The calculated potential, U for a Sn-10mass% Pb alloy is shown in figure 5. The dashed squares in the figure show the position of the vessel. The equipotential lines are slightly concave because of the magnetic potential. However, the gravitational potential is still dominant in this experiment. Thus, the motion of the solid particles in the liquid phase is governed by the gravitational force and/or the convection. The solid particles only move in the vertical direction if the convection is neglected. On the other hand, the liquid velocity caused by the convection must have a horizontal component because of its incompressible nature. Thus, the solid particles move in the horizontal direction when the convection affects their motion.

Figure 5.

Equipotential lines for the experimental condition mentioned in section 3.1.

Effect of electric current intensity on structure

The effect of electric current intensity on the grain size of the sample was examined. The magnitude of the magnetic field is 10 T and the frequency of the electric current is 2 kHz for every sample. After solidification, the sample is cut to form a vertical cross section and then polished to evaluate its grain size. The macrostructure of the sample solidified with the 10 T magnetic field and the alternating current of 2 kHz and 80 A is shown in figure 6. The structure is refined in the entire observed area even though the electric current was imposed only on a local area of the sample. The grain size is evaluated at two positions. One is in the vicinity of the copper electrodes and the other is on the opposite side from the copper electrodes, as shown in figure 7. The average grain size is shown as a function of the intensity of the electric current in figure 7. As the intensity of the electric current increases, the grain size decreases. The refining effect is saturated above 50 A at position A and above 20 A at position B, and the saturated grain size is the same at both positions under these experimental conditions. Therefore, the refinement of the solidified structure depends on not only the intensity of the electric current but also its position in the sample.

Figure 6.

Macrostructure of the sample under the imposition of a static magnetic field and an alternating current.

Figure 7.

Effect of electric current intensity on grain size.

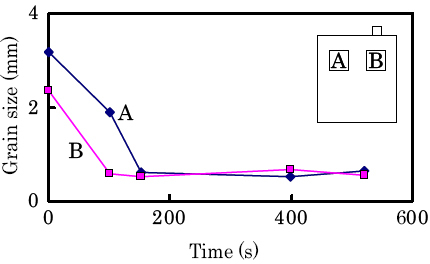

Effect of electric current duration on structure

The sample was also solidified by applying an electric current for various durations. A static magnetic field of 10 T is applied to the sample during the solidification. An electric current of 90 A and 2 kHz is applied for between 100 and 520 s when the sample temperature is 523 K. The grain size is evaluated at the same locations as in the previous experiment. The result is shown in figure 8. The application of electric current for 200 s is sufficient to refine the solidified structure. The grain size at position A is larger than that at position B when the current is applied for 100 s. Thus, the refining effect on the solidified structure is strong in the early stage of the solidification in the vicinity of the copper electrodes.

Figure 8.

Effect of duration of electric current on grain size.

Conclusion

In this paper, two topics have been discussed. The first one is a novel magnetic filtration method involving the direct packing of schwertmannite particles in a glass column under the imposition of the magnetic field. The second one is a refining process of the metallic alloy structure during solidification.

In the former, a magnetic fixed-bed column was introduced as a novel design of a fixed-bed column, which was alternately loaded with schwertmannite as an adsorbent and ferromagnetic wool as a high porous medium, under a high magnetic field. The alternate layers acted as a very efficient medium for the removal of Cr(VI) from water. The application of a magnetic field, which is an important parameter for bed columns dealing with fine-particle adsorbents, maintains the bed under constant conditions.

In the latter, the intensity of the electric current in the electromagnetic refining process has a critical value, above which the refining effect on the solidified structure is saturated. The duration of the electric current also has a critical value, above which the refining effect on the solidified structure is saturated.

Acknowledgment

This work was partially supported by the JSPS Asian Core Program ‘Construction of the World Center on Electromagnetic Processing of Materials’.

References

- Kakihara Y, Fukunishi T, Takeda S, Nishijima S. and Nakahira A. IEEE Trans. Appl. Supercond. 2004;14:1565. doi: 10.1109/TASC.2004.830709. [DOI] [Google Scholar]

- Nakajima H, Kaneko H, Oizumi M, Fukui S, Yamaguchi M, Sato T, Imaizumi H, Nishijima S and Watanabe T. 2003. PhysicaC 392–396 1214 10.1016/S0921-4534(03)01128-6 [DOI] [Google Scholar]

- Eskandarpour A, Bando Y, Iwai K, Okido M and Asai S. 2007The Magneto-Science Society of Japan, 2nd Annual Meetingp 139 [Google Scholar]

- Vives C. 1996. Metall. Trans.B 27 445 [Google Scholar]

- Radjai A, Miwa K and Nishio T. 1998. Metall. Mater. Trans.A 29 1477 10.1007/s11661-998-0363-z [DOI] [Google Scholar]

- Kawai S, Wang Q, Iwai K. and Asai S. Mater. Trans. JIM. 2001;42:275. doi: 10.2320/matertrans.42.275. [DOI] [Google Scholar]