Abstract

The controlled fabrication of nanometer-scale objects is without doubt one of the central issues in current science and technology. However, existing fabrication techniques suffer from several disadvantages including size-restrictions and a general paucity of applicable materials. Because of this, the development of alternative approaches based on supramolecular self-assembly processes is anticipated as a breakthrough methodology. This review article aims to comprehensively summarize the salient aspects of self-assembly through the introduction of the recent challenges and breakthroughs in three categories: (i) types of self-assembly in bulk media; (ii) types of components for self-assembly in bulk media; and (iii) self-assembly at interfaces.

Keywords: self-assembly, nanomaterials, interfaces, supermolecules, bottom–up

Introduction

Technologies involving nanometer-scale objects continue to improve the quality of our daily lives because the down-sizing of functional units can result in a significant decrease in device energy consumption and more efficient production processes. In addition, novel phenomena have been revealed at the nanometer-scale. Shrinking component size advances nanotechnology, while the related phenomena represent nanoscience. Therefore, the regimented fabrication of nanometer-scale objects is undoubtedly one of the central issues in current science and technology. To date, several excellent top–down-type approaches including photolithography and electron-beam lithography have been used to produce nanostructures. However, in addition to the inherent size, parallelization, and 2-dimensional limitations of lithography and of top–down approaches in general, these relatively new patterning methods lack the well-developed technology that enabled the previous generations of lithography. Because of these challenges to traditional bottom–up lithography, interest has been growing in an alternate means, known as the bottom–up approach. Methods of bottom–up fabrication rely on molecular self-assembly in supramolecular processes. Supramolecular chemistry, which was originally a branch of fundamental science, has now become an important concept in nanotechnology.

Although numerous excellent articles and reviews of independent topics have been published [1–10], a comprehensive review of self-assembly is rare. Therefore, this review article aims to illustrate and summarize all the aspects of self-assembly through a description of recent challenges and breakthroughs. This review describes self-assembly from three different perspectives: (i) types of self-assembly in bulk media; (ii) types of components for self-assembly in bulk media; (iii) self-assembly at interface. In each section, we have tried to select the most appropriate examples and complemented those selections with a comprehensive range of cited research. Despite this categorization the examples contained in (i)–(iii) are actually interrelated. However, here we have attempted to make self-contained descriptions of each subject so that the reader can concentrate on sections relevant to his/her interest.

Self-assembly in bulk media 1; assembly type

Small molecule assembly

There are many types of self-assembly ranging in dimensions from molecular level (nanometric) to macroscopic size (visible to the naked eye). In this section, the smallest oligomolecular self-assemblies, consisting of just a few molecules will be described. Surprisingly, several of them exhibited molecular-level machine-like functions [11–14].

Aida and coworkers designed and developed porphyrin conjugates that induce self-assembly of external guests and possess functions related to their structures. For example, they reported that dynamic host–guest supramolecular interactions resulted in stereochemical harmonization of helical chains contained in the host molecule [15]. In the host structures depicted (figure 1, Host and Host (Phe)), two zinc porphyrin units are connected by two oligo (aminoisobutyric acid) chains, which adopt helical conformations because of the steric requirements of the C(CH3)2 groups and despite their lack of chiral centers. Therefore, thermodynamic interconversion of the chains results in a mixture of right- and left-handed helices. Binding of a pyridyl-substituted helical guest containing an (L)-leucine residue at its center generated an intense chiroptical signal through dynamic stereochemical harmonization between the helical chains. From the sign of the split Cotton effects it is apparent that the oligopeptide chains of the guest-complexed host molecules adopt the same helical conformation as that of the guest. This phenomenon demonstrates that self-assembly through binding of an appropriate guest modulates the dynamics of the helix structures in the host.

Figure 1.

Stereochemical harmonization based on guest binding to chromophoric cyclic hosts with two zinc porphyrin units and two oligo (aminoisobutyric acid) chain connectors.

In other work, Tashiro, Aida, and coworkers reported preferential assembly of hetero-guest pairs by an inter-guest electronic communication through a π-conjugated host molecule (figure 2) [16]. This host compound contained two fused zinc porphyrin dimers bridged by aliphatic chains giving a cofacial arrangement of dimers, and which displayed a strong negative cooperativity in the binding of 4,4′-bipyridine (bpy). Similarly, binding of a second fullerene C60 guest to the host was subject to negative cooperativity despite the easy accommodation of a single C60 guest by the host. The C60 dimer, C120, may also be bound by this host molecule suggesting that from a spatial point-of-view alone, the host should be able to accommodate two C60 molecules. Thus, it was concluded that the negative cooperativity in the binding of the C60 guest is due to a conflicting electronic interaction. On the other hand, the same cyclic host could selectively include one each of C60 and bpy. Equimolar binding of C60 and TMHDA (N,N,N′,N″-tetramethylhexane-1,6-diamine) was due to a similar positive heterotropic cooperativity. Peculiarities in the assembly of these host–guest complexes are probably due to electronic communication occurring between the C60 and diamine guests and mediated by the π-conjugated fused metalloporphyrin arrays. Apart from this prime example, several other new concepts including chiral fullerene detection [17], chemical friction during rotary guest motion [18], and supramolecular polychromatic thermometers [19] have been proposed by the same research group, all by using porphyrin conjugate molecules.

Figure 2.

Preferential assembly of hetero-guest pairs by electronic communication between the two guests through a p-conjugated host molecule.

Fujita and coworkers have performed pioneering research on assembly of coordination capsules using square-cornered Pd(II) complexes and designer co-ligands [20]. For example, assembly of a stable, nanosized capsule from 18 metal ions and six triangular ligands was achieved [21]. The molecular capsule, comprised of six edge-sharing triangles with two metal ions at each edge, is approximately hexahedral with a fully closed 0.9 nm3 internal space and is impervious to all but very small molecules. More recently the same authors reported the ability to control the Diels–Alder reaction of certain substrates within the molecular capsules (figure 3) [22]. The Diels–Alder reaction between anthracene and phthalimide yields two major products. However, if performed within the molecular capsule, the process preferentially yields the product due to reaction of phthalimide at the 1,4 position of anthracene. The site of reaction varies from that observed in the solution state. Use of a half-bowl shaped molecular capsule gave the expected product, as a result of reaction at 9,10 positions of anthracene, although catalyst-like turnover was confirmed. Reaction mediation by the capsule framework could be also demonstrated by mediation of alkane oxidation through the photochemical excitation of a molecular capsule [23].

Figure 3.

Control of a Diels–Alder reaction within pre-designed molecular capsules.

The main advantage of this strategy lies in the versatility of morphology design since an appropriate choice of ligand molecules can result in unique nano-objects of various shapes, such as coordination nanotubes [14, 25], nanoballs [26], nanoboxes [27], and self-assembled cages [28]. These self-assembled objects provide nanospaces where new physical chemistries might be observed. For example, molecular ice formation [29] or color sensing of guest inclusion [30] have been investigated. Coating of self-assembled capsules and aggregate formation with multivalent proteins [31] has also been demonstrated.

Capsules and cages formed through self-assembled processes have been investigated by other research groups. Crego-Camala, Reinhoudt, and coworkers reported calix[4]arene-based molecular boxes and their guest binding capabilities [32]. Atwood and coworkers prepared supramolecular capsules by using large numbers of hydrogen bonds. They reported a chiral spherical molecular assembly held together by 60 hydrogen bonds, consisting of six calix[4]resorcinarenes and eight water molecules [33], and later reported molecular capsules containing 48 intermolecular hydrogen bonds which were stable in polar media [34]. Rebek and coworkers developed molecular capsule formation through self-assembly of cavitands [35–37]. For example, they reported an unusual hetero-guest inclusion by a hydrogen-bonded molecular capsule, with preferential accommodation of a molecule each of benzene and p-xylene [38]. Their self-assembled capsule also provides a medium for stabilization of reactive intermediates [39], to shift the equilibrium between two stereoisomers [40], or to regulate the conformation of a guest species [41]. They expanded their self-assembled cavitand capsules by the addition of appropriate spacers, permitting variation of guest selectivity, while also demonstrating attachment of a rotating door unit to the cavitands [42, 43]. They synthesized an enzyme reaction cavity mimic [44]. Kobayashi and coworkers reported selective formation of self-assembling homo- or hetero-cavitand cages [45]. Stang and coworkers reported synthesis of a cuboctahedral capsule from twenty subunits in a single-step self-assembly [46]. Using similar methods a molecular capsule with a trigonal prismatic framework was prepared by means of spontaneous self-assembly of a predesigned molecular clip with tritopic pyridyl subunits [47]. Recently, Shionoya and coworkers reported molecular switching between fluorescent coordination capsule and nonfluorescent cage [48].

Various components and different interactions have been used in the formation of capsules, cages and closed squares, in which several novel phenomena have been observed. For example, Candau, Lehn, and coworkers reported gel formation through formation of self-assembled G (guanine)-quartets, which are strongly dependent on the nature of both the binding cation and the decorating aldehyde (figure 4) [49]. The interaction of the decorating aldehyde is of particular interest since it indicates a possible method to control the supramolecular self-assembly process by dynamic covalent decoration. Pluth et al reported unusual basicity changes of amines encapsulated in a self-assembled coordination cavity [50]. Mirkin and coworkers demonstrated reversible interconversion of homochiral macrocycles and helical coordination polymers [51]. Severin and coworkers reported formation of an expanded helicate from a ruthenium complex and a piperazine-bridged bis(dihydroxypyridine) ligand, which is able to bind phosphate and acetate anions in aqueous solution at neutral pH [52]. Ballester and coworkers reported solid-state self-assembly of a calix[4]pyrrole-resorcinarene hybrid into a hexameric cage [53]. On–off switching of self-assembly through dynamic covalent bond formation between boronic acids and alcohols has been demonstrated by Iwasawa and Takahagi [54]. Inclusion of fullerene into self-assembled capsules is an attractive research topic. Beer and coworkers proposed use of a polymetallic resorcinarene host for binding of fullerene [55]. Inclusion of metallofullerene into a cavitand-based self-assembled cage was realized by Pirondini et al [56]. Haino and coworkers reported fullerene encapsulation by calix[5]arene [57]. They also reported encapsulation of various guests within similar hosts [58]. A unique inclusion complexation was proposed by Inomata and Konishi who demonstrated preparation of a hexaporphyrin cage using a gold nanocluster template [59].

Figure 4.

G-quartet formation upon binding of cation and a decorating aldehyde.

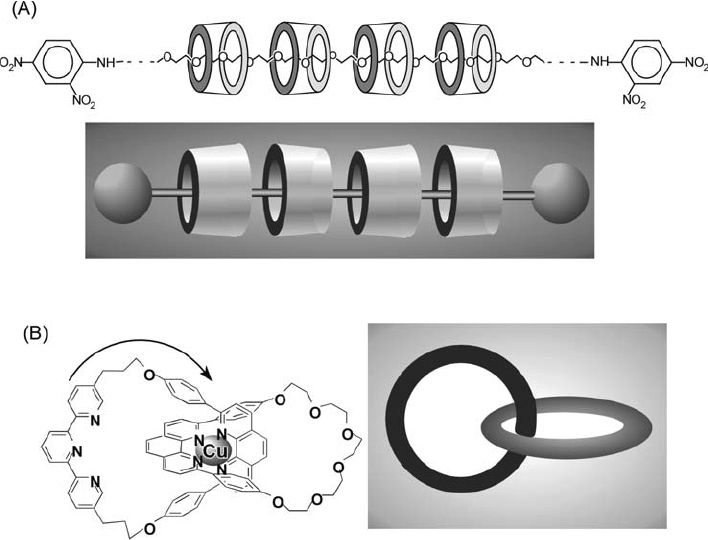

Catenanes and rotaxanes make up a family of compounds that are exceptional in the world of supramolecular chemistry. Rotaxanes consist of molecular rings threaded by molecular wires that have stoppers at both ends to prevent unthreading. Of the various cyclic molecules used as the molecular ring in rotaxanes, cyclodextrin and crown ethers are the most useful because of their self-assembling nature based on molecular recognition properties. In particular, cyclodextrin can accommodate linear polymers such as polyethylene glycol in an aqueous phase. Harada and coworkers reported that polymer chains thread cyclodextrin rings upon the addition of a water-soluble polymer into an aqueous cyclodextrin solution (figure 5A) [60–62]. Subsequent stoppering of the polymer results in the formation of rotaxanes. The cyclodextrins self-align in a head-to-head (tail-to-tail) array, stabilized by hydrogen bond formation between primary hydroxyl groups and between secondary hydroxyl groups. While rotaxanes are composed of wires and rings, catenanes consist of two or more interlocked rings. The example shown in figure 5B illustrates catenane preparation through tetrahedral coordination of Cu(I) [63]. In the first process, two phenanthroline ligands coordinate to Cu(I). Each ligand is individually cyclized through hydroxyl groups attached to the ligand unit. Removal of Cu(I) completes catenane formation. Syntheses of molecular knots and doubly locked catenanes based on a similar strategy have also been reported [64]. Furthermore, molecules with five interlocked rings (similar to the symbol used for the Olympic Games) have also been synthesized [65].

Figure 5.

Typical examples of (A) a rotaxane and (B) a catenane.

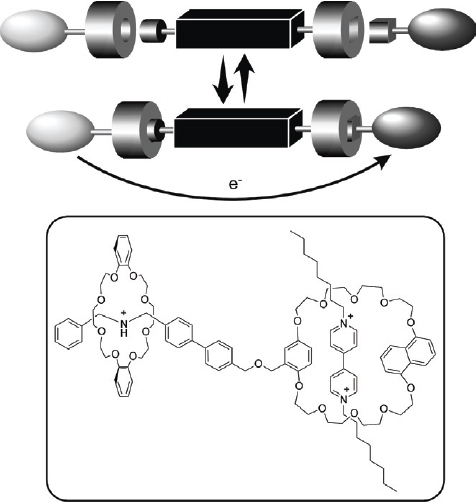

Rotaxanated or catenated objects are often considered as molecular machines. Rotaxane structures are attractive entities for the design of molecular devices because the relative positions of their component parts can be influenced by external stimuli. Controlling the relative position of the rings on the wire permits design of molecular shuttles [66]. In the example shown in figure 6, a rotaxane exhibits translational isomerism with the tetracationic cyclophane ring preferentially occupying the π-electron-rich benzidine station (upper). Electrochemical oxidation of the benzidine unit to the monocationic radical, results in translation of the cyclophane ring to the biphenol station (lower), driven by electrostatic repulsion. Shuttling of the cyclophane is completely reversible depending on the oxidation state of the benzidine unit. Stoddart, Credi, and coworkers used this process to realize preparation of a molecular elevator as illustrated in figure 7 [67, 68]. The design of the molecular elevator relies on two mechanically interlocked molecules that incorporate the features of a pH-switchable [2] rotaxane. At low pH the CH2NH2 sites bind the macrocycles preferentially while at high pH deprotonation occurs disrupting hydrogen bonding so that the macrocycles move to the bipyridinium dication sites, because of stabilization by π–π stacking interactions. These mechanically interlocked molecules were assembled from a trifurcated ‘rig-like’ component containing thread components of three [2] rotaxanes each fused at alternate positions (1,3,5) of a benzenoid core. This rig-like component is mechanically interlocked with a platform based on a tritopic receptor, containing three oligo-ether macrocycles fused to a hexaoxatriphenylene core.

Figure 6.

A molecular shuttle.

Figure 7.

A molecular elevator.

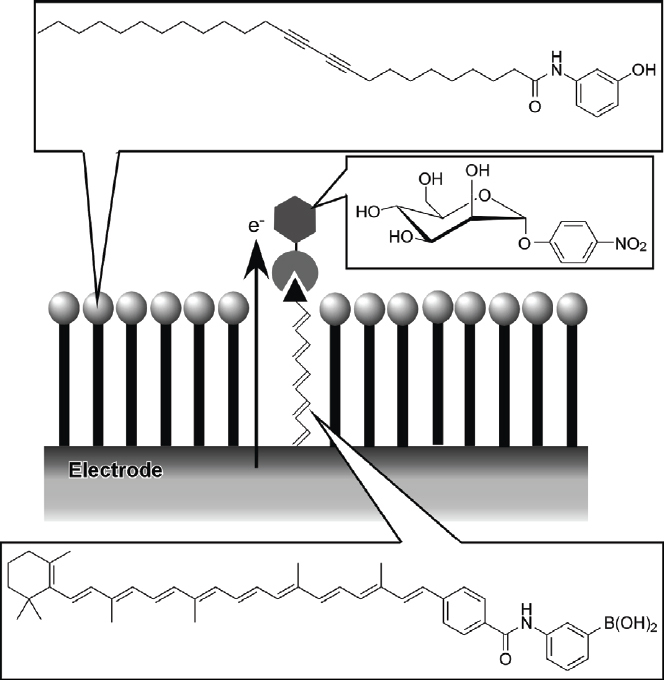

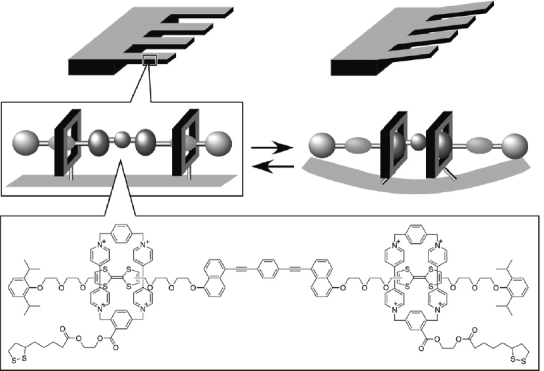

Very recently, Stoddart and coworkers presented a molecular plug–socket connector [69]. Figure 8 illustrates the three components of the molecular level plug–socket connector: (i) a secondary dialkylammonium center which plays the role of a plug for dibenzo[24]crown-8; (ii) a rigid and conducting biphenyl spacer; (iii) 1,4-benzo- 1,5-naphtho[36]crown-10 capable of behaving as a socket for a 4,4′-bipyridinium dicationic plug. Two connections of the three-component assembly were shown to be reversibly controllable by using external acid/base and red/ox inputs. These results represented a key step in the design and construction of a self-assembling supramolecular system in which a molecular electron source could be connected to the molecular electron drain through a molecular elongation cable. Similarly, photoinduced electron flow in a self-assembling supramolecular extension cable has also been reported [70]. In one unique usage of a rotaxane, the same research group reported tethering of pseudorotaxanes at the entrances of the cylindrical pores of mesostructured silica thus creating nanovalves or gates capable of trapping luminescent molecules at the mesopore interior, and able to release them on demand (figure 9) [71]. For the [2] pseudorotaxane gatekeeper structure, a tethered l,5-dioxynaphthalene-containing derivative, acted as the gatepost, and cyclobis(paraquat-p-phenylene), which recognizes dioxynaphthalene units, served as the gate controlling access in and out of the nanopores. Luminescent molecules could be released by introduction of an external reducing reagent, NaCNBH3, which opens the nanovalve. The same research group also demonstrated reversible electrochemical operation of a nanovalve [72]; i.e. molecules could be trapped and released from the maze of nanoscopic passageways in silica by controlling the state of redox-activated bistable[2]rotaxane molecules tethered at the of surface nanopore openings of the nanoscale reservoir.

Figure 8.

Molecular plug–socket connector.

Figure 9.

Pseudorotaxane gates at the entrances of cylindrical pores.

Apart from these examples, a great variety of machine-like self-assembled objects have been developed by Stoddart and [73–75]. Cyclodextrin-based rotaxanes have also seen recent developments [76–82]. Use of other components such as crown ethers [83–85] and fullerenes [86] as components of rotaxane structures have been demonstrated.

Self-assembled structures with few components have been widely reported and some so far unlisted recent examples are also available [87–90]. However, we would like to here mention one important subject of this category. Appropriate molecular design of a host structure and self-assembly with a target guest sometimes induces a specific material conversion similar to that observed for enzyme function so that these examples are often referred to as artificial enzymes [91–96]. Self-assembly operation of functional groups can be observed in naturally-occurring enzyme mechanisms. For example, RNA hydrolysis by ribonuclease, as depicted in figure 10A, is achieved through sequential interaction with self-aggregated amino acid residues. By analogy with this and other similar systems, molecular spaces provided by self-assembly have been employed as artificial enzymes. Molecular spaces for artificial enzymes are designed to recognize specific substrate molecules, stabilize reaction intermediates, and provide reactive groups in appropriate proximity to the trapped substrate molecules. The example shown in figure 10B is of a molecular-cavity-type artificial enzyme. Desper and Breslow designed a cyclodextrin host carrying two imidazole moieties that can hydrolyze a model substrate [97]. Inclusion of the hydrophobic part of the cyclic phosphodiester (the model substrate) at the core of the cyclodextrin disposed the phosphodiester between the two histidines. Activation of a water molecule through deprotonation by the neutral histidine (left), was followed by nucleophilic attack by the activated water at a phosphate group. Protonation of the phosphodiester by protonated histidine (right) assisted this nucleophilic attack. The maximum activity of the artificial ribonuclease was obtained at around the pKa of the histidines (ca. pH 7) because of the essential cooperative function of the neutral and protonated histidines. Figure 10C illustrates a molecular-cleft-type artificial enzyme, which was developed by Anslyn and coworkers, where guanidinium residues connected to a rigid backbone could immobilize an RNA phosphodiester moiety [98–100]. Imidazole in solution activated 2′-OH groups with subsequent nucleophilic attack at the phosphate group. Electrostatic hydrogen bonding with the guanidinium groups stabilized the transition state during hydrolysis. The reaction rate of RNA cleavage was increased by this stabilization.

Figure 10.

(A) Functional relay in ribonuclease; (B) molecular-cavity-type artificial enzyme; (C) molecular-cleft-type artificial enzyme.

Porous crystals by metal coordination and hydrogen bonding

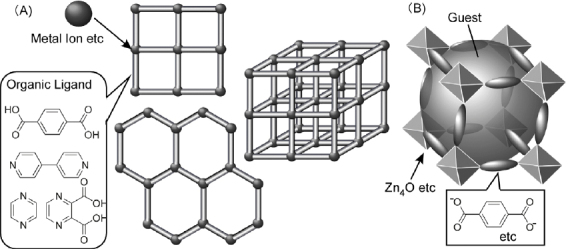

Self-assembly processes based on directionally-defined interactions such as metal cation coordination or hydrogen bonding can be used for syntheses of materials with precise nanostructures. In particular, rigid porous frameworks have been constructed through a coordination-type self-assembly process. Some of these are known as metal organic frameworks (MOFs) and/or coordination polymers. As illustrated in figure 11A, appropriate selection of organic ligands can lead to regular porous structures with various sizes and geometries. For example, Yaghi and coworkers extensively developed MOF families using oxo-bridged coordination complexes and organic ligands (figure 11B) [101]. Because this research field has been recently rapidly expanding, only a brief outline with several highlighted topics will be presented here. Related research has been adequately described in several excellent reviews [102, 103].

Figure 11.

(A) general structure of metal organic frameworks (MOFs); (B) MOF with zinc oxide complex and organic ligands.

Yaghi and coworkers have extensively developed novel types of MOF structures and some of them have even reached commercialization. They recently reported preparation of three-dimensional covalent organic frameworks [104]. These materials are anticipated to have excellent capacities for material storage. Yaghi and coworkers reported use of MOFs for storage of gaseous guests such as methane [105] and hydrogen [106].

Kitagawa and coworkers have developed various coordination polymers and investigated the unusual properties of trapped guest molecules [107]. They reported the direct observation of dioxygen molecules physisorbed in the nanochannels of a microporous copper coordination polymer [108]. The one-dimensional nanochannels of the coordination polymer result in a confinement effect and restricted geometry leading to a specific molecular assembly. The one-dimensional ladder structure of O2 dimers thus obtained is unlikely to exist as a bulk fluid and/or solid. The same research group reported that a combination of framework-builder (Cu(II) ion and 4,4′-bipyridine ligand) and framework-regulator (AF6 type anions; A=Si, Ge, and P) provided a series of novel porous coordination polymers [109]. Immersion of some of the coordination polymer compounds in water stimulated a conversion of three-dimensional networks to interpenetrated networks (two-dimensional interpenetration). The latter network exhibited unique dynamic anion exchange properties, concurrent with drastic structural conversions.

Kitagawa and coworkers also reported high levels of selective sorption of acetylene molecules, relative to the similar molecule carbon dioxide, onto the functionalized surface of some coordination polymers [110]. Hydrogen bonding between two non-coordinated oxygen atoms of the framework material and the two hydrogen atoms of the acetylene molecule resulted in adsorption of acetylene molecules with a regular periodicity in the structure. Using this phenomenon at room temperature, acetylene could be stored at a density 200 times greater than the safe compression limit of free acetylene. Figure 12 illustrates the controlled and selective polymerization of substituted acetylenes in one-dimensional specific nanochannels containing basic carboxylate oxygen atoms as catalytic interaction sites on the pore walls [111].

Figure 12.

Controlled and selective polymerizations of substituted acetylenes in one-dimensional specific nanochannels of a coordination polymer.

Specific interactions and physical phenomena have also been investigated in these structures. Kitagawa and coworkers found an efficient photo-induced charge transfer between confined electron donor guests and anthracene moieties of a porous coordination framework [112]. Hanton and coworkers reported anion encapsulation through anion-π interactions within cordination polymers prepared from Ag(I) salts and a pyrimidine ligand [113]. Molnár, Bousseksou, and coworkers proposed a method for patterning of spin-crossover coordination polymers [114]. Selective material adsorption such as kinetic separation of hexane isomers by Rodrigues, Chen, and coworkers is also an interesting research target for this kind of material [115]. Fundamental studies using the BET method for surface area determination [116] and gas sorption behaviors [117] have also been researched.

Hydrogen bonding can result in formation of self-assembled porous solids. Aoyama and coworkers investigated formation and guest inclusion phenomena of porous hydrogen-bonded networks composed of bisresorcinol derivatives [118]. As shown in figure 13, hydroxyl groups in the derivatives can form hydrogen bonds of specific geometry, resulting in inclusion of appropriate guests. Since design of components for the network structures is not limited an acridinylresorcinol could also be used as a self-complementary building block in formation of a robust hydrogen-bonded two-dimensional network [119]. Guest inclusion properties were statically and kinetically monitored, and host-only cast films of the bisresorcinol on a quartz crystal microbalance were used for analyses [120, 121]. Very recently, Dalrymple and Shimizu reported optimization of both metal complex and organosulfonate pillars enabling an idealized hexagonal hydrogen bonding motif, which in turn provided a permanently porous solid constructed exclusively by charge-assisted hydrogen bonds [122].

Figure 13.

Porous hydrogen-bonded networks composed of bisresorcinol derivatives.

Hydrogen-bonded porous crystals offer a medium for reaction control as can be seen in molecular capsules and coordination polymers. Aoyama and coworkers demonstrated that an anthracene-bisresorcinol derivative, when used as an organic network material, showed a novel catalysis of the acrolein-cyclohexadiene Diels–Alder reaction in the solid state [123–125]. In that reaction, the two reagents have differing polarities and so could be assembled within the same cavity. The subsequent intracavity reactions exhibited high stereoselectivities as well as remarkable rate enhancements. Depending on their structures, the products were either retained or exited the cavities, resulting in either deactivation of the catalyst or turnover, respectively.

Generally speaking, these porous crystals provide well-defined nanospaces, which can be adjusted by appropriate selection of organic ligands and interactive modules (hydrogen bond unit and coordination metals). Therefore, unknown sciences for molecules and supermolecules entrapped within the formed nanospaces will be thoroughly investigated. Supermolecular chemistry in dimension-controlled spaces would become a new challenges.

Apart from the porous crystalline materials, well designed hydrogen bonding arrays provide other types of self-assembled objects. One representative example is nanotube formation by designer cyclic peptides prepared by Ghadiri and coworkers [126, 127]. These self-assembled materials can operate as artificial membrane channels. They are one example amongst a variety of bio-related materials such as peptides, saccharides, proteins, and nucleic acids that can be used as molecular modules for hydrogen-bond-based self-assembled structures. These topics are described later in this review.

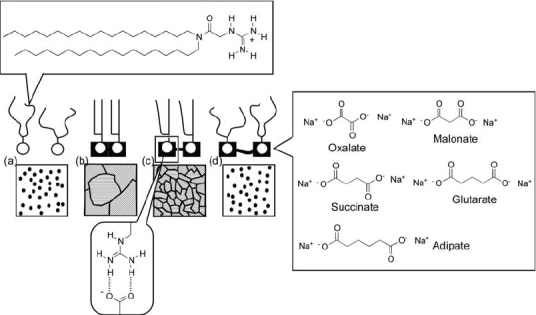

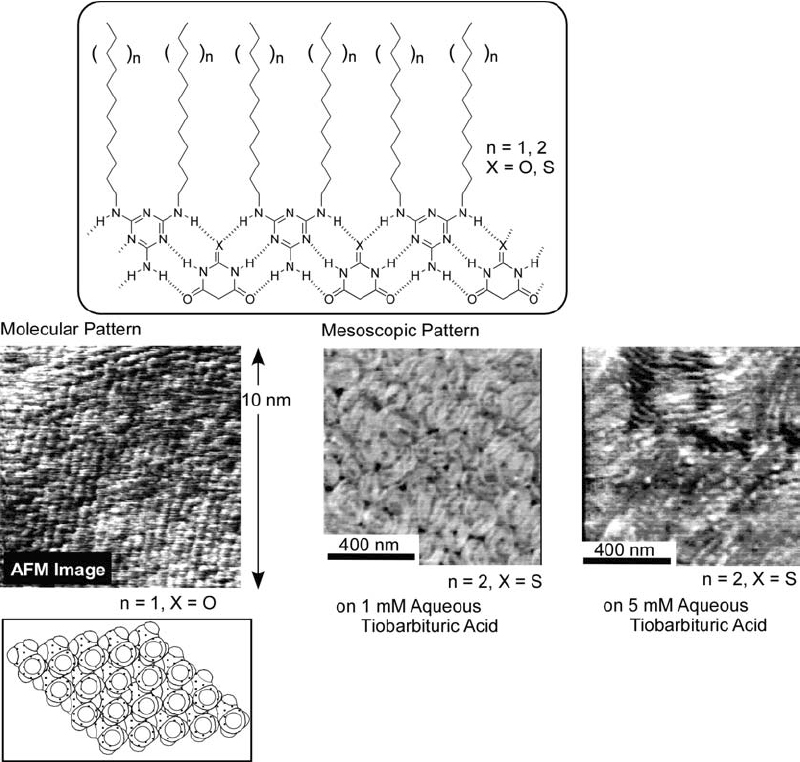

Lipid assembly: liposome, vesicle, fiber, tube

Distinct from the direction-defined interactions such as metal coordination and hydrogen bonding are the solvophilic and solvophobic effects available in appropriate media. Therefore, the self-assembled structures based on these effects should have dynamic nature, which is reflected in both dynamical changes of assembled structures and mechanical flexibility of macroscopic shapes. Typical examples are liposomes and vesicles formed by self-assembly of lipids or related amphiphilic compounds. The amphiphilic natures of the naturally-occurring lipids, including phospholipids and glycolipids (figure 14A), and certain types of synthetic lipids (figure 14B) often result in formation of lipid bilayer structures in aqueous phases [128]. The lipid bilayer structure extends two-dimensionally and forms the ‘skin’ of a closed sphere that contains an aqueous pool (figure 14, upper). This capsule-like structure can be thought of as a simplified model of a cell. The term liposome is coined when the constituent components are naturally-occurring lipids. Kunitake and Okahata found that artificial compounds possessing an appropriate structural balance between hydrophilic and hydrophobic moieties can form similar spherical objects [129], which are usually referred to as vesicles. Examples of artificially designed amphiphiles are shown in figure 14B. A dialkyl structure is often used for the tail, but trialkyl structures, tetraalkyl structures and azobenzene-type rigid structures are also available [130–132].

Figure 14.

Liposome or vesicle structures prepared from: (A) naturally-occurring lipids; (B) synthetic lipids.

Liposomes and vesicles are often proposed for use in biological applications such as drug delivery [133–136] because of their structural similarity to biomembranes. They also provide a medium for studying basic biological phenomena such as the flip-flop motion within lipid bilayers [137] and membrane fusion [138, 139]. Various mimics of biologically important functions such as ion-channeling [140], photosynthetic processes [141], and proton gradient formation [142] have been constructed using these artificial cell membranes. Other artificial systems such as vesicle-based rechargeable batteries have also been proposed [143].

In spite of substantial developments in the science and technology of liposomes and vesicles, several features of the systems still rely on traditional concepts of amphiphile design and useful medium (still usually an aqueous solution). Therefore, the conceptual expansion in molecular design of amphiphiles that are capable of forming vesicilar structures under unusual conditions should be a breakthrough development. For example, Katagiri et al developed a novel concept for fusion of an inorganic framework with lipidic vesicles. They investigated the covalent linkage of a siloxane framework to a lipid bilayer vesicle [144–146]. The resulting vesicles had a siloxane network covalently attached to the bilayer membrane surface and are referred to as cerasomes (ceramics + soma) (figure 15A). Initial dispersion of the alkoxysilane-bearing amphiphiles in an acidic aqueous solution was achieved using a vortex mixer. This translucent sample was morphologically stable over long periods. The formation of the siloxane bonds was confirmed by infrared spectroscopy, which indicated the presence of Si–O–Si and Si–OH groups. Formation of vesicular structures was confirmed by using transmission electron microscopy (TEM) where images of multi-lamellar cerasomes with a bilayer thickness of about 4 nm and vesicular diameter of 150 nm were obtained (figure 15A). Interestingly, TEM images of vesicular aggregates were observed in the same specimen (figure 15B). Suppression of the collapse and fusion of the cerasomes is implied from the fact that some of the aggregates maintained their original spherical structure, probably through formation of an intra- and intermembrane siloxane network. This indicates that a multi-cellular model could be obtained by association of these stable cerasomes.

Figure 15.

(A) Cerasome structure and (B) cerasome assembly.

Kimizuka and coworkers developed the formation of aqueous bilayer structures from separate components linked through hydrogen bonding (figure 16) [147]. Thus, alkyl tails were connected to a melamine unit and a polar ammonium head was linked to a cyanuric acid moiety. The melamine and cyanuric acid parts formed infinitely linked ribbon structures by complementary hydrogen bonding, thus leading to a bilayer structure. By using this concept, individually synthesized hydrophobic and hydrophilic components can be combined with a great degree of freedom.

Figure 16.

Aqueous bilayer structures from separated components through hydrogen bonding.

For expansion of vesicle technology to non-aqueous media, Kunitake and coworkers recognized the immiscibility of fluorocarbon components in general organic solvents and subsequently synthesized compounds possessing both hydrocarbon and fluorocarbon segments. These were then studied for their self-assembly behaviors in nonaqueous media (figure 17) [148]. Using appropriate solvents, some compounds containing both fluorocarbon and hydrocarbon parts formed bilayer-like assemblies. The low affinity that the fluorocarbon part has for the organic solvent leads to the label solvophobic, and is in contrast to the solvophilic characteristics exhibited by the hydrocarbon parts. These conceptually novel amphiphilic molecules assembled so that the solvophobic component is hidden inside the assembly while the solvophilic component is exposed to the solvent. Bilayer structures are obtained if there is a good structural balance between the solvophilic and solvophobic parts. Although studies of lipid bilayers and vesicle formation were originally initiated in order to mimic cell membranes in aqueous media, appropriate molecular design has extended this concept to a wide range of molecules. In further advanced developments, Nakashima and Kimizuka demonstrated formation of a vesicle structure using dialkyldimethylammonium salts in ionic liquid media, known as the ‘vesicle in salt’ [149].

Figure 17.

Self-assembling behavior of compounds possessing both hydrocarbon and fluorocarbon segments in nonaqueous media.

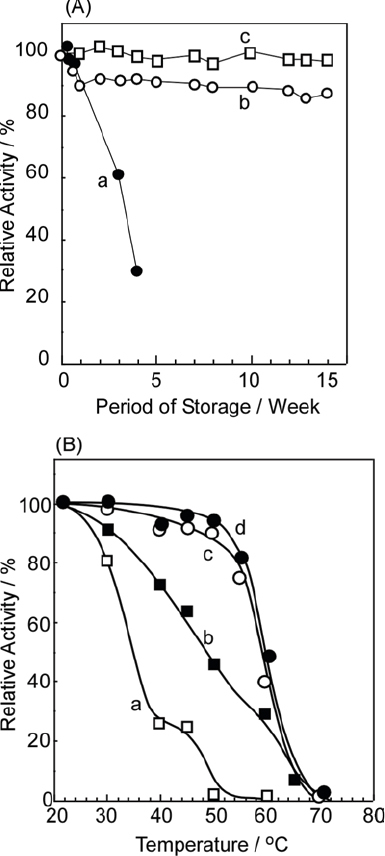

Bilayer membrane structures can provide a fluidic environment where immobilized components can function as relays. For example, Kikuchi and coworkers demonstrated logic-gate-like activity control of an enzyme self-assembled on lipid bilayer structures [150–153]. Figure 18 displays a functional relay at an artificial thin film between an amphiphilic amine receptor and an effector lactate dehydrogenase (LDH). LDH activity is inhibited by the Cu ion so it is in the OFF state. Subsequent addition of an appropriate signal molecule (1-hydroxy-2-naphthaldehyde) removes the Cu ion from LDH and forms a signal-receptor complex (Schiff's base). This removal of the Cu ion reactivates the LDH, restoring the ON state. Photo-regulation of the LDH activity could also be achieved through receptor photo-isomerization. The association behavior of the receptor molecules and binding ability toward the Cu ion changes upon photo-isomerization of the azobenzene moiety. LDH activity was completely suppressed for the cis-isomer system resulting from visible light irradiation (OFF state); afterwards, the high-level of activity for the system (ON state) could be restored by UV irradiation, which gives the trans-isomer. This system can be regarded as a switching device where a primary chemical switching signal, is followed by reversible switching of enzyme activity by using a photosignal. It can also operate as a logic device since activation of the enzymatic reaction (AND-type logic gate) requires appropriate application of both chemical and photo-signals. This is a primitive example but it might provide inspiration for construction of functional relays contained within artificial thin films.

Figure 18.

Logic-gate-like activity control of an enzyme self-assembled at a lipid bilayer membrane.

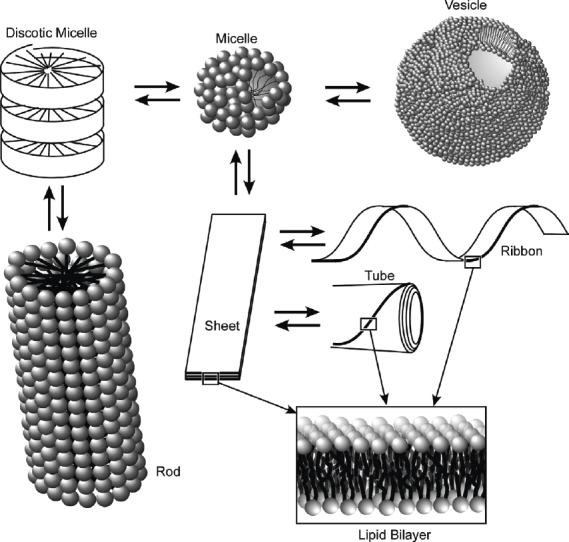

Lipid design allows us to introduce various functional groups into fundamental hydrophilic/hydrophobic amphiphile structures. In particular, the introduction of a hydrogen-bond-forming unit into an amphiphilic structure often leads to formation of higher-order structures with unique shapes through self-assembly processes [154–156], as illustrated in figure 19. These structures include disc-like micelles and rod-like supermolecules. Further development of micelle and vesicle structures sometimes results in sheet structures consisting of a bilayer unit. When the sheet has curvature, helical ribbons and tubules are formed by twisting and rolling of the sheets. This flexibility in structural formation is highly advantageous for the bottom–up fabrication of nano- and micro-objects.

Figure 19.

Formation of higher order structures of amphiphile assemblies with unique shapes.

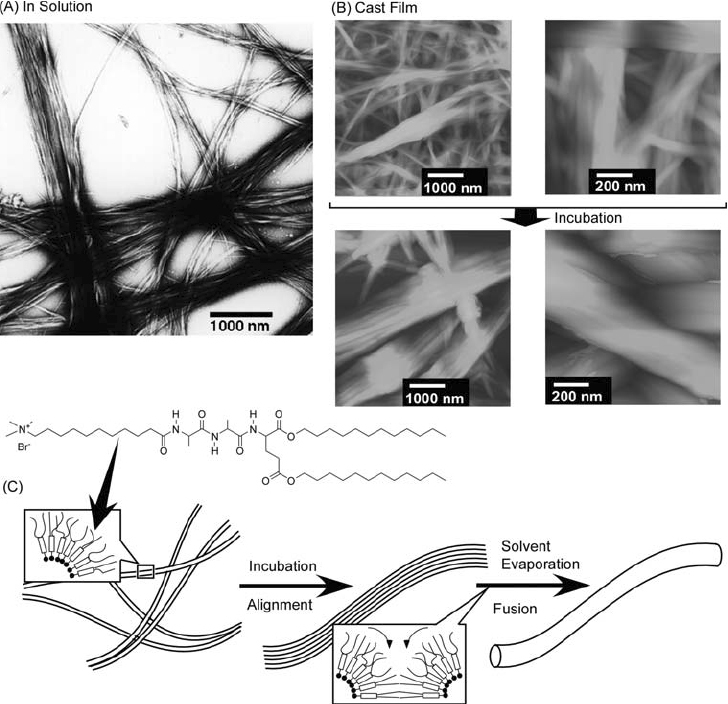

Typical examples are described in the following few figures. Yamada, Ariga, and coworkers exercised control over the morphologies of self-assembled structures using lipids with a tripeptide moiety [157–163]. These peptide lipids can form aggregates not only in water but also in nonpolar organic solvents forming β-sheet structures. Infrared spectra of tripeptide derivatives used in their research in CCl4 solutions contain the amide A, amide I, and amide II bands at ca. 3300, ca. 1630, and ca. 1540 cm−1, respectively, and no peak at ca. 1690 cm−1 indicating that these derivatives form parallel β-sheet structures. The TEM image shown in figure 20A indicates the presence of thin fibers, which are aligned in a parallel arrangement. Self-assembled structures observed in cast films of the peptide lipids obtained from CCl4 solutions are different from those conatined in the films prepared from aqueous solution. AFM images of the cast films from CCl4 solution are shown in figure 20B. Incubation time strongly influences the structure of the fibers. In films prepared immediately after dispersion, formation of numerous entangled thin fibers of widths 20–40 nm is observed. Conversely, thick fibers or rods with widths of 300–400 nm were found in films prepared following a 3-day incubation of the solution. Figure 20C shows the proposed self-assembly mechanism of the peptide lipids in CCl4 solution and in their cast films. Parallel β-sheet structure formation together with exposure of the hydrophobic tails to the nonpolar solvent requires formation of a fibrous structure bearing the cross section of a single or a multiple reversed micelle. Following an appropriate incubation time the fibers become aligned as is apparent from the TEM image. When the solvent is evaporated, fusion of the aligned fibers through solidification of the alkyl chains, results in the broader structure.

Figure 20.

(A) Self-assembled structures of peptide lipids in CCl4; (B) self-assembled structures in cast films; (C) proposed self-assembly mechanism of peptide lipids. © 2000, American Chemical Society, Langmuir 16 (2000) 4929.

A slight increase in the solvent polarity for self-assembly results in cast films that differ substantially from those observed from CCl4. Figure 21 shows AFM images of cast films obtained from CHCl3 solutions of tripeptide-containing lipids. All films possessed a reasonably flat texture with specific patterns. Infrared data for these films indicate that the tripeptide group is in a non-interacting state in CHCl3 solution so that the morphologies observed by AFM were gradually assembled during solvent evaporation. Inspired by this flat film formation, Yamada and coworkers significantly strengthened their self-assembled supramolecular films by utilizing the interaction between oligoleucine side chains [164]. Figure 22 shows preparation of self-standing thin films of a Leu–Leu–Leu–Glu-type peptide lipid by casting and drying from CHCl3 solution. Films prepared by this method are robust and can be manipulated using tweezers or folded without fracture despite the lack of covalent linkages between peptides. This mechanical strength results from the perpendicular arrangement of the parallel β-sheet and leucine ‘fastener’ structures within the films.

Figure 21.

Self-assembled structures of peptide lipids in films cast from CHCl3 solutions. © 2000, American Chemical Society, Langmuir 16 (2000) 4929.

Figure 22.

Self-assembled supramolecular films of Lue-Leu-Ley-Glu-type peptide lipid.

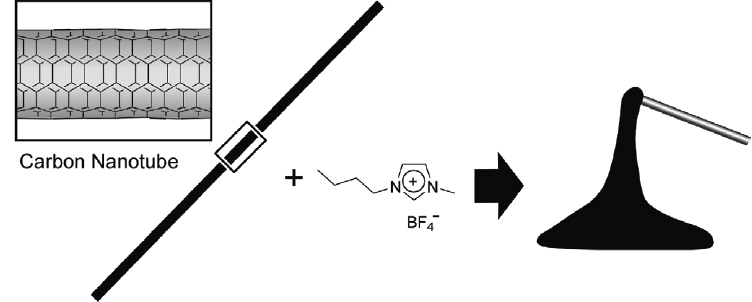

Shimizu and coworkers extensively developed formation of fibrous and tubular structures through self-assembly of bola-type amphiphiles [165–168]. Tube structures require an uneven curvature of opposing sides of a precursor self-assembled membrane. Thus, bola-amphiphiles with terminal groups of differing size should be better candidates for construction of lipid tubes. By careful consideration of lipid structure design, unsymmetrical lipid nanotubes with differing interior and exterior surface structures can be prepared. As shown in figure 23, Masuda and Shimizu realized this concept by designing unsymmetrical bola-amphiphiles, which self-assembled in water to form lipid nano- and microtubes [169]. The nanotubes obtained encapsulated the staining reagent phosphotungstate revealing a hollow cylindrical morphology several hundred micrometers long with 30–43 nm and 14–29 nm outer and inner diameters, respectively. In their pioneering work Shimizu and coworkers realized formation of vesicle-containing tubular structures from a bola-amphiphile where glycylglycine segments are attached at both the end of an aliphatic chain (figure 23) [170, 171]. Infrared spectroscopy revealed that the glycylglycine functional groups in the monolayer form a networked polyglycine II hydrogen bond instead of the conventional β-sheet motif. Detailed AFM observations of the tubes revealed a hierarchical ordering within the structure of this assembly. The structures formed were robust even stable against heating at 100 °C in water or to ultrasonic irradiation. Even after evaporation to dryness, the structure could be regenerated simply by addition of water.

Figure 23.

Tubular structures of self-assembled bola-amphiphiles.

Figure 24.

Tubular structures including vesicles from a bola-amphiphile with glycylglycine segments.

Hybridization of organic self-assembled structures with inorganic materials can also lead to development of novel properties and functions that are not available in the individual components. Figure 25 illustrates formation of an inorganic nanowire within a lipid envelope in work performed by Kimizuka and coworkers [172, 173]. One class of halogen-bridged one-dimensional mixed valence complexes is of great interest due to its unique physicochemical properties. These properties include intense intervalence charge-transfer absorption, semiconductivity, and large third-order nonlinear optical susceptibilities. Chloro-bridged linear platinum chains were dispersed as aggregates of a polyion complex with a sulfonate amphiphile whose lipophilic alkyl chains are oriented toward the organic media. Dispersion of the low-dimensional structures is due to the organized lipid molecules, which can stabilize the mixed valence chains in solution. Heating the linear platinum complex causes dissociation into its individual complexes, which are then re-assembled upon cooling to lower temperatures. A reversible structural transition between aggregated mesoscopic and individual molecular metal complexes was thus realized by the formation of a self-assembling amphiphilic supramolecular structure.

Figure 25.

Inorganic nanowire within a lipid envelope.

Because a huge variety of shapes is accessible using self-assembly of lipids and related amphiphiles through the wide choice of commercial and designer components, and because of their soft, malleable natures, such structures have attracted the attention of many researchers who have reported many excellent results. Other relevant work has been reported [174–184].

Gels and liquid crystals

Unlike many supermolecules that may still remain within basic scientific areas, gels and liquid crystals are well recognized as practical materials, as seen in water preserver/absorber and optical displays. In particular, gels and liquid crystals formed through self-assembly of low molecular-weight components have attracted significant attention [185–188]. In those materials, appropriate design of small molecular structures can lead to drastic changes in the properties of the bulk materials.

Ajayaghosh and coworkers have extensively investigated microstructure formation from conjugate oligomers and their properties of gelation. For example, they have reported the formation of micrometer-size supramolecular tapes and helices through self-assembly of oligo (p-phenylenevinylene) derivatives (figure 26A) [189]. Formation of superstructures of micrometer size in a dried assembly obtained from decane was revealed by SEM imaging. Birefringence exhibited by the gel when viewed through crossed polarizers indicated the molecular anisotropy within the aggregates. The tunable size and morphology of the assemblies resulted in preparation of nanoparticles, microspheres, and superstructured blue light-emitting organogels. These workers also reported self-assembly transformations of squaraine dyes (figure 26B), which could form vesicular structures or helical architectures [190]. Hollow spherical structures of the tripodal squaraines first self-assembled from acetonitrile were transformed into linear helical structures upon introduction of Ca2+ or Mg2+. An interesting target for functionalization of self-assemblies of aromatic oligomers is the potential control of optical properties based on supramolecular structure variation. Ajayaghosh et al also investigated fluorescence resonance energy transfer (FRET) between the tape-like structure of a few tailor-made oligo (p-phenylenevinylene) derivatives (donor, figure 26C) and entrapped rhodamine B (acceptor) [191]. The efficiency of FRET was influenced considerably by the ability to form self-assembled aggregates of the oligo (p-phenylenevinylene) compound and so control could be realized by variation of solvent polarity and/or temperature.

Figure 26.

Gel-forming conjugate oligomers.

Structural control of conductive polymers within gel structures was achieved by Fujita, Shinkai, and coworkers. They proposed molecular design of gel-forming molecules with controllability of effective conjugation length in poly(diacetylene) structure [192]. As shown in figure 27, they attached the well known gel-formation promoting substituents, 3,4,5-trialkoxybenzoic acid moieties, to the diacetylene using flexible alkyl chains. The photopolymerizable unit containing flexible linkers was expected to be strongly stabilized by intermolecular hydrogen bonding involving two amide linkages, which were surrounded by the gelation-promoting moieties. The multiplicity (odd or even) number of alkyl chains was found to be a key factor in determining whether the blue or red phases of poly(diacetylene) was obtained.

Figure 27.

Gel-forming molecules with controllability of effective conjugation length in poly(diacethylene) structure.

A variety of designs of low molecular-weight gelators have been reported. Ihara and coworkers reported chirality control of a self-assembled organogel [193] and self-assembled fibrillar network formation [194] based on molecular design using a glutamate backbone. They have also recently reported enhanced fluorescence emission and photochromism in organogel structures of salicylideneaniline derivatives [195]. Hanabusa and coworkers have worked extensively on low molecular- weight gelators based on molecular structures of ureylene [196], diaminocyclohexane [197], and cyclohexanetricarboxamide [198]. Sakurai and coworkers reported gel fibers from cyclic bisurea derivatives [199]. Shinkai and coworkers developed organogels with cholesterol-based [200] and sugar-based [201] molecular designs.

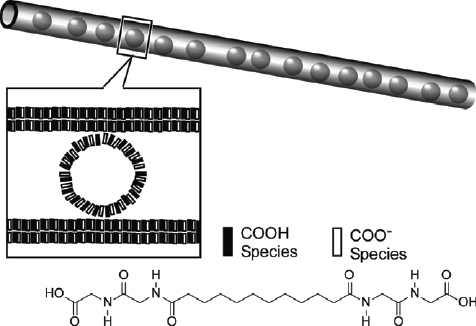

As a final example of gelatinous self-assembly one very unique topic is shown in figure 28. Fukushima, Aida, and coworkers found serendipitous gel formation on intimate mixing of an ionic liquid and carbon nanotubes [202, 203]. Grinding of a mixture of pristine single-walled carbon nanotubes and an imidazolium room-temperature ionic liquid resulted in stable gels. The heavily entangled nanotube bundles were found to untangle within the gel to form much finer bundles. Non-volatility of the ionic liquids imparted on the gels thermal stability and resistance to shriveling even under reduced pressure although they would readily undergo a gel-to-solid transition when physically placed on absorbent materials.

Figure 28.

Gel formation from an ionic liquid and carbon nanotubes.

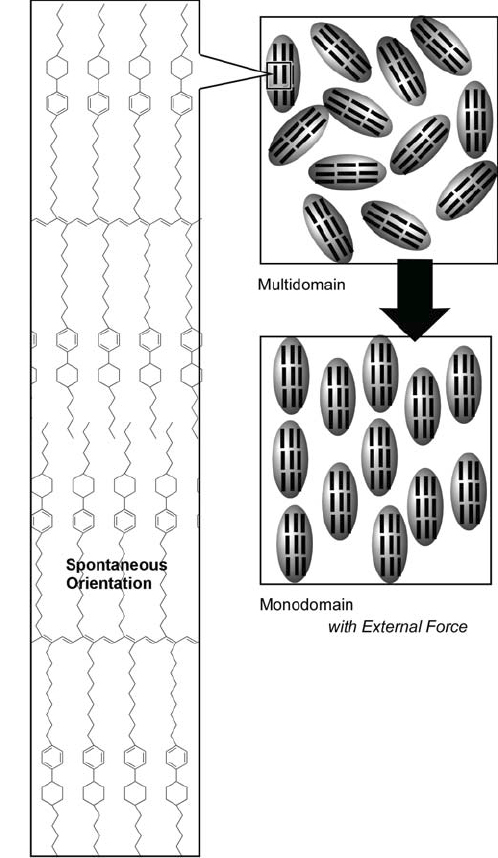

In common with gel materials, liquid crystals have many practical uses. Phase transitions and orientation control of liquid crystalline materials are attractive subjects, especially in relation to possible photonic applications, because of their molecular alignments. Kato and coworkers developed liquid crystalline materials that are stabilized by hydrogen bonding [204, 205]. They demonstrated variation in the self-assembled liquid crystalline structures of folic acid derivatives. Addition of alkali metal salts to a thermotropic folic acid derivative resulted in a transition from smectic to hexagonal columnar phase (figure 29) [206]. With this phase change the hydrogen bond pattern was altered from ribbon to disk because the columnar liquid crystalline structures were stabilized by ion-dipolar interactions between the added sodium ions and the discotic assemblies.

Figure 29.

Change from smectic to hexagonal columnar phases of folic acid derivatives by the addition of alkali metal salts

Ichimura and coworkers pioneered the novel concept of a ‘command surface’ where a single monolayer controls orientation within bulk liquid crystalline films [207]. They developed magnification of structural information by combining photoisomerization of surface monolayer and liquid crystalline materials. In the example shown in figure 30, a photoisomerizable ‘command’ monolayer was immobilized on a solid surface and liquid crystalline materials were then deposited on the monolayer. Orientation of the thick liquid crystalline layer could then be achieved by photoisomerization of the command monolayer so that a phenomenon occurring at the molecular level was amplified leading to a bulk structural change. This concept could be applied in the development or improvement of display devices.

Figure 30.

Orientational changes of a liquid crystal by photoisomerization of a surface monolayer.

Furumi et al investigated electrical control [208] and photonic control [209–112] of the photonic bandgap in chiral liquid crystals for possible use in laser devices. Shape-memory fibers consisting of self-assembled liquid crystalline polymers were proposed by Terentjev and coworkers [213]. Photo-induced polarization inversion in ferroelectric liquid crystals was realized by Lemieux et al using an ambidextrous chiral thioindigo dopant [214]. Schmidt-Mende et al developed high efficiency organic photovoltaics using self-organized discotic liquid crystals of hexa-perihexabenzocoronene derivatives [215]. Clark and coworkers reported a class of fluid polar smectic liquid crystals in which local splay prevails in the form of periodic supermolecular-scale polarization modulation stripes coupled to layer undulation waves [216]. Other recent examples on self-assembled liquid crystal materials are also available [217–221].

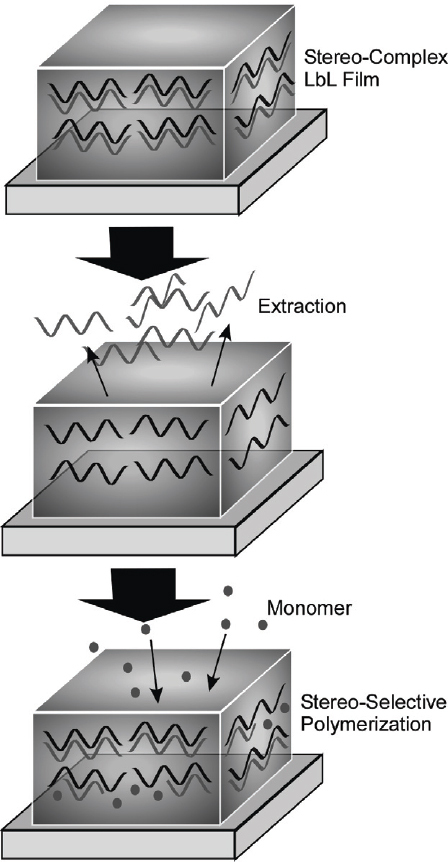

Structure-transcribed material

Self-assembled materials consisting of organic or biological materials are often mechanically fragile. If one could use these structures as templates for nanostructure syntheses of robust stable formations of metallic or inorganic materials, stable objects bearing morphologies reflecting the original self-assembled structures might be obtainable. In fact this strategy has been applied and is referred to as structure transcription from self-assembled objects. It is one of the best methods to produce self-assembled structures for use under harsh conditions.

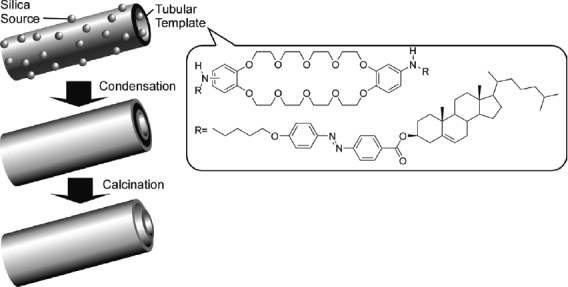

Research based on this concept has recently received attention [222, 223]. Transcription of fibrous and tubular structures of organic gels into inorganic substances has been extensively reported by the groups of Shinkai, Shimizu, and Hanabusa [224–233]. For example, in appropriate media the compound shown in figure 31 forms tubular structures, which, upon sol–gel condensation of the co-reactant tetraethyl orthosilicate and subsequent calcination, are transcribed as double-walled silica nanotubes [234]. Helical ribbon aggregates composed of crown-appended cholesterol derivatives have been used to transcribe chiral silica [235]. Hollow fibers of titanium oxide have been prepared from self-assembled gels of cyclohexanediamide derivatives [236]. With similar synthetic concepts, silica nanostructures containing fullerene [237] and porphyrin [238] moieties have also been reported. Shimizu and coworkers reported metal nanowire formation, where a synthetic glycolipid N-(11-cis-octadecennoyl)-y-D- glucopyranosylamine in a tubular structure was used as a template [239]. First, capillary force was used to encapsulate gold or silver nanoparticles in the hollow cylinders of the lipid nanotubes, followed by removal of the organic components by calcination of the the nanocomposite, yielding gold nanowires of controlled width. Additionally, glycolipid nanotubes were used to prepare helical arrays of CdS nanoparticles [240]. Modulation of structure of the transcribed materials, including regulation of silica nanotube diameter, can be realized using solvent-sensitive morphological changes of the template peptidic-lipid nanotubes [241].

Figure 31.

Transcription of tubular structures of organic gels into double-walled silica nanotubes.

A great deal of other research into fabrication of various types of nano- and micro-structures based on structure transcription has also been reported. For example, Price et al. reported preparation of Cu spiral/helical nanostructures through selective electroless metallization using a phospholipid microtubule template [242]. Ras et al also reported synthesis of hollow nanospheres and nanotubes of Al2O3, having tuned the wall thicknesses by atomic layer deposition on self-assembled polymeric templates [243]. Synthesis of vanadium oxide nanotubes using a self-assembled alkyl amine template was demonstrated by Li and coworkers [244]. One atypical morphology prepared by the structure transcription technique is that of the carbon nano-test tubes fabricated using a cre-sheath Te@carbon nanocomposite as a template, as reported by Yu and coworkers [245]. Corking of silica nano-test tube using chemical self-assembly processes has been reported by Stewart, Martin, and coworkers [246]. By using concepts of self-assembly processes various inorganic nanostructures have been prepared. For example, boron nitride nanotubes [247], Si-core microwires coated with aligned SiO2 nanowires [248], silica-shielded Ga–ZnS nanowires [249], and boron nitride nanomesh [250].

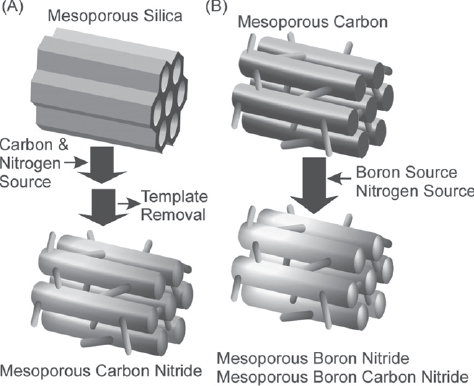

Of the known structure-transcribed objects, mesoporous materials the most popular and many applications are anticipated [251–263]. Mesoporous silica materials can be prepared using micellar assemblies of surfactants or block-copolymers as soft templates (figure 32A). In 1990, Kuroda and coworkers first reported the preparation of mesoporous silica with a uniform pore size distribution through intercalation of cetyltrimethylammonium cations into the layered polysilicate kanemite followed by calcination to remove the organic moiety (FSM-16) [264, 265]. Later, Mobil scientists supplied materials having large uniform pore structures, high specific surface area, with specific pore volume and hexagonal geometry MCM-41 [266, 267], cubic geometry MCM-48 [268], or lamellar geometry MCM-50 [269]. Tanev et al prepared HMS using a neutral amine as template [270], and Bagshaw et al similarly synthesized a disordered mesoporous material designated as MSU-1 using polyethylene oxide (PEO) [271]. Stucky and coworkers developed highly ordered large pore mesoporous silica SBA-15 with thicker pore walls and a two dimensional hexagonal structure using an amphiphilic triblock copolymer of poly(ethylene oxide) and poly(propylene oxide) in highly acidic media [272, 273]. The same group also prepared MCF type materials where triblock copolymers stabilizing oil in water microemulsions were used as templates [274]. Mesoporous carbon materials can be synthesized through carbonization within mesoporous silica as a hard template and subsequent selective removal of the silica (figure 32B). Ryoo et al first realized synthesis of ordered mesoporous carbon CMK-1 using MCM-48 silica as a template and sucrose as the carbon source [275]. The first well ordered mesoporous carbon CMK-3 that was a faithful replica of the template was synthesized using SBA-15 as a template [276]. Hyeon et al reported, independently and somewhat later, a similar approach for preparation of well-ordered mesoporous carbon materials designated SNU-x [277–279].

Figure 32.

Synthesis of (A) mesoporous silica and (B) mesoporous carbon.

Although preparation of mesoporous carbon and related materials has been extensively researched [280–284], breakthrough concepts have been recently proposed by Vinu and coworkers. They applied a similar strategy for the synthesis of mesoporous carbon nitride with combined carbon and nitrogen sources (figure 33A) [285–287]. More recently, they have pioneered a third method for synthesis of mesoporous materials, called the ‘elemental substitution method’ [288]. In this method, component elements are substituted by other elements with retention of the mesoporous structure. For example, they successfully realized the first synthesis of mesoporous boron nitride and mesoporous boron carbon nitride (figure 33B) [289–291].

Figure 33.

Synthesis of (A) mesoporous carbon nitride and (B) mesoporous boron nitride and mesoporous boron carbon nitride.

Vinu and coworkers recently reported synthesis of the novel nanocarbon, ‘carbon nanocage’ [292–295], through template synthesis using a large three-dimensional cage-type face centered cubic mesoporous silica material (KIT-5) as the inorganic template (figure 34A). The specific surface area and specific pore volume of carbon nanocage greatly exceeds those reported for conventional mesoporous carbon materials. Therefore, the capacity for lysozyme adsorption on the carbon nanocage is much larger than that observed with mesoporous carbon CMK-3. The carbon nanocage also exhibits excellent capabilities in the separation of small molecules [296]. In figure 34B, the superior adsorption capability of the carbon nanocage in removal of a dyestuff (Alizarin Yellow) is demonstrated. An aqueous solution was passed through a bed of the respective carbon material deposited on top of a cotton plug in a pipette and with application of a slight pressure. When compared with the control test without carbon (a), the carbon nanocage materials completely removed the dye (c), while activated carbon powder (b) and CMK-3 (d) were not effective for removal of the dye under these conditions. A highly selective separation of catechin and tannic acid by the carbon nanocage material in a one-pot process was also found. Use of carbon nanocage as adsorbent provided a highly selective adsorption of tannic acid (ca. 95%) in a simple one-pot process. This result could originate from the very unique geometry of the carbon nanocage materials.

Figure 34.

(A) Synthesis of carbon nanocage; (B) its TEM image; (C) filtration of aqueous Alizarin Yellow: (a) without carbon, (b) with activated carbon; (c) with carbon nanocage; (d) with mesoporous carbon CMK-3. © 2007, American Chemical Society, J. Am. Chem. Soc. 129 (2007) 11022.

Because chemical modifications of mesoporous materials (especially mesoporous silica) are well established [297], further fabrication and functionalization of mesoporous materials has been extensively researched. Recent breakthroughs on fabrication of mesoporous materials involved synthesis of chiral mesoporous silica materials and preparation of periodic mesoporous organosilicates (PMO). Chirality was introduced in mesoporous materials by using a chirally-defined surfactant template, which was demonstrated by Che et al [298–300] who used an N-acyl-type alanine-based surfactant to prepare mesoporous silica containing chiral pores (figure 35). SEM observation of the obtained mesoporous silica revealed that the materials possessed regularly twisted rod-like structures with diameters of 130–180 nm and lengths of 1–6 mm. TEM observation confirmed the presence of hexagonally aligned mesoscopic channels with diameters of 2.2 nm wound together in a particular direction. This finding attracted some researchers to this field who have further developed the synthesis of chiral mesoporous objects [301–303]. As one of the other significant breakthrough materials for this area, PMO materials were introduced by three groups working independently: Inagaki group [304], Ozin group [305], and Stein group [306]) all in 1999. As illustrated in figure 36, this category of materials is synthesized using organic molecules having multiple alkoxysilane groups such as bis(triethoxysilyl)ethene and bis(triethoxysilyl)benzene. Although much work has been done on PMO materials [307–309], one of the most fantastic findings in PMO technology is the formation of crystalline pore walls [310]. Inagaki et al synthesized a PMO material using benzene-bridged organosilane, 1,4-bis(triethoxysilyl)benzene. The powder XRD patterns showed a set of peaks assignable to a two-dimensional hexagonal lattice. Four sharp peaks corresponding to periodic structure with a spacing of 0.76 nm were detected in the small angle region. Many lattice fringes, stacked along the channel axes with a uniform spacing of 0.76 nm, were confirmed by TEM imaging. These results are consistent with a crystal-like pore-wall structure, with an alternate arrangement of hydrophilic silicate layers and hydrophobic benzene layers.

Figure 35.

Mesoporous silica with chiral motifs.

Figure 36.

Periodic mesoporous organosilicates (PMO) with various organic moieties.

As summarized in a recent review by Ariga et al [311], supramolecular functions of mesoporous materials make up a significant new trend in this research field. Of various reported functions, controlled release from mesopores is one of the most attractive topics (one example is described in figure 9 of the previous section). In pioneering work, Fujiwara and coworkers achieved photo-controlled regulation of drug storage and release from mesoporous silica [312, 313]. They functionalized MCM-41 with photoactive coumarin, which showed photo-responsive dimerization resulting in reversible gate operation. Lin and coworkers realized a controlled-release delivery system using colloid capping of mesoporous silica [314]. The same research group demonstrated gate-controlled molecular recognition by selective functionalization at the external and internal surfaces of mesoporous silicates with polylactate and o-phthalic hemithioacetal, respectively [315]. They synthesized a series of room temperature ionic liquid-containing mesoporous silica nanoparticulate materials with various particle morphologies, including spheres, ellipsoids, rods, and tubes [316] and investigated controlled release profiles using ionic liquids as antibacterial agents against the Gram negative microbe Escherichia coli K12. Martnez-Mez and coworkers used an MCM-41 mesoporous solid support functionalized at its external surface with polyamines for controlled entrapment and release of guest anions [317]. Xiao and coworkers also reported a pH-responsive carrier system based on carboxylic acid modified SBA-15 silica rods and poly(dimethyldiallylammonium chloride) for storage and release of drug molecules from pore voids [318]. Vallet-Reg and coworkers used two types of hexagonally ordered mesoporous materials, MCM-41 and SBA-15 as matrices for alendronate (bisphosphonate) adsorption and release [319]. The same research group also reported controlled delivery of macrolide-type antibiotics using SBA-15 [320]. Hyeon and coworkers report a synthetic procedure for the fabrication of mesoporous silica spheres, which was applied to the uptake and controlled release of drugs [321]. A unique example combining molecular assembly techniques and mesoporous materials for controlled release was reported by Wang and Caruso where enzyme immobilization and encapsulation was accomplished in bimodal mesoporous silica spheres with the aid of layer-by-layer (LbL) assembly [322, 323].

Mesoporous materials provide nanospaces of predictable structural dimensions where novel functions as well as unknown phenomena can be investigated in depth. Confinement of polymeric substances in mesopores has been researched [324–328]. Several examples of polymerization in mesoporous media using monomeric templates for preparation of mesoporous materials with conductive polymers contained within the pores have been reported (figure 37). Aida and Tajima used a few kinds of hexadecadiynyl trimethylammonium bromide as templates to synthesize mesoporous silica containing diacetylene in micro-fibrous form [329]. Lu et al used oligo (ethylene glycol)-functionalized diacetylenic surfactants as structure-directing reagents for mesoporous silica films through casting, spin-coating, or dip-coating methods [330]. Diacetylene can be then polymerized upon exposure to UV light. Aida and coworkers also developed poly(pyrrole)-containing mesoporous silica films in hexagonal and lamellar phases [331]. The films obtained were immersed in a solution containing anhydrous FeCl3 to polymerize the pyrrole monomer. The polypyrrole chains are highly constrained and insulated when incorporated within the hexagonal nanoscopic channels and the possibility of polarons recombining into bipolarons is suppressed significantly. In contrast, the two-dimensional lamellar phase afforded spatial freedom for electron recombination. Similarly thiophene polymerization in mesoporous silica channels was reported by Fuhrhop and coworkers [332].

Figure 37.

Polymerization of conjugate polymers in mesopores.

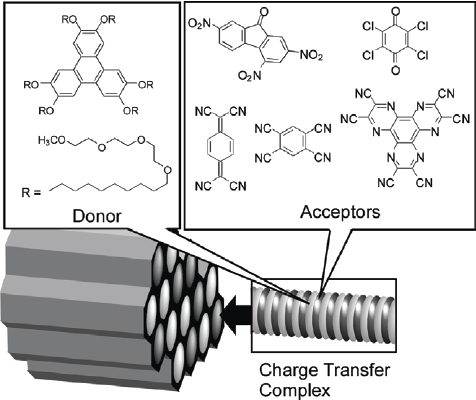

Supramolecular self-assemblies can also be confined in mesopores. Aida and coworkers reported the first example of immobilization of one-dimensional columnar charge-transfer assemblies within mesoporous silica films through the sol–gel reaction involving charge-transfer complexes of an amphiphilic triphenylene donor and various acceptors (figure 38) [333]. The films obtained were highly transparent and color-tunable by varying the intercalated acceptor. The molar ratio of donor and acceptor, related to the photoconductive properties, could be varied over a wide range from 1 : 1 to 9 : 1. In hexagonal mesoporous silica, the silica wall segregates the individual charge-transfer columns, which display neither solvatochromism nor guest-exchange activity. Also, they exhibited red-shifted absorption bands, which are possibly due to a long-range structural ordering.

Figure 38.

Charge-transfer complexes of amphiphilic triphenylene donor and various acceptors within mesoporous channel.

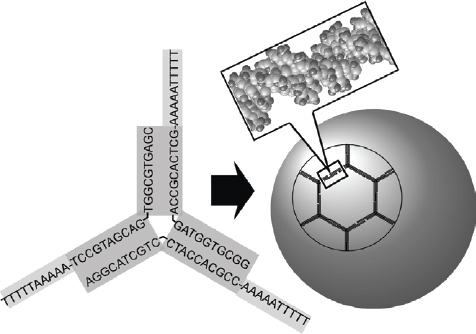

Introduction of biological components is a new challenge in mesoporous science and technology. Ariga and coworkers developed mesoporous silica with densely packed peptide segments known as proteosilica (figure 39) [334, 335]. This nano-composite material provides an asymmetric medium for photochemical reactions [336]. Photochromic dye molecules such as spiropyran can be doped into the chiral environments of the proteosilica films, where asymmetric photoreactions have been demonstrated using alanylalanine-type surfactants. Isomerization between the spiropyran form and the merocyanine form can be repeated upon alternate irradiation of visible light (420 nm) and UV light (280 nm) to the films, respectively. Only negligible CD signals originating from the guest could be observed for the film containing the merocyanine form, while the film with the spiropyran form showed clear CD activity in the region from 250 nm to 400 nm. A complete mirror image of the CD spectrum was obtained depending on whether the L-peptide or D-peptide host was used as the host surfactant. Alternate irradiation with UV and visible light induced repeated changes in the CD spectra with a small degradation in the intensity. The reported system could be applied for development of non-destructive memory devices.

Figure 39.

Isomerization between the spiropyran and merocyanine forms of a merocyanine dye in proteosilica.

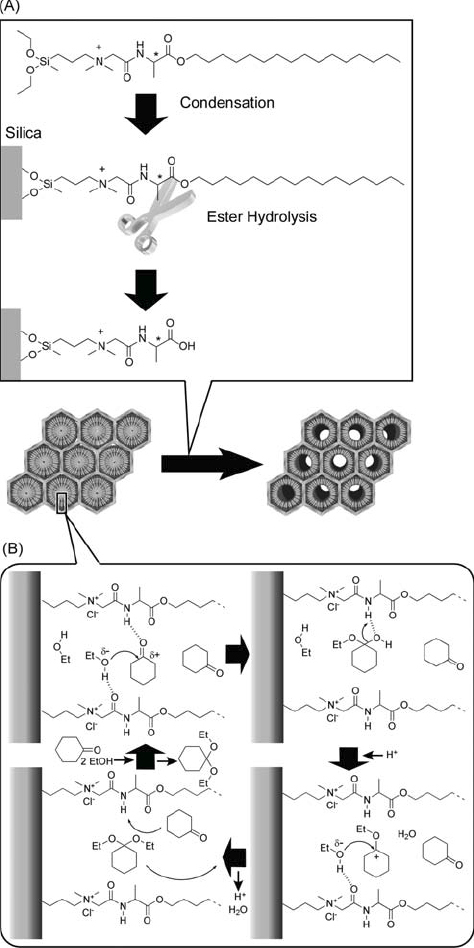

A new synthetic method that addresses the issues of both dense functionalization of the pore interior and increased accessibility for external guests was developed by Ariga, Aida, and coworkers (figure 40A) [337, 338]. The template amphiphile, which had dialkoxysilane functionality as part of the head group, was covalently attached to the silica framework by sol–gel reaction with tetraethyl orthosilicate; this resulted in densely filled mesoporous silica channels. Subsequent cleavage of the alkyl tail by hydrolysis of the ester at the C-terminal left open pores with an internal surface functionalized with alanine moieties. In this case the template behaves like a ‘lizard,’ that bites the silica wall and then sheds its tail. Reactor applications were introduced for similarly prepared hybrid structures. The catalytic capability of these materials prior to hydrolysis on the acetalization of a ketone, such as cyclohexanone, in ethanol (EtOH) under mild conditions was demonstrated by Aida and coworkers (figure 40B) [339]. Simultaneous incorporation into the silica channels of cyclohexanone and EtOH, at the hydrophobic inner domain and hydrophilic (ionic) outer shell, respectively, caused their activation through hydrogen bonding with the amide NH and carbonyl groups of the peptide functionalities at the core-shell interface. Carbocationic intermediates that are probably transiently involved in the acetalization, and generation of these intermediates is favored by the highly polar environment of concentrated ammonium salt functionalities. This work appears to provide a novel and general strategy for rational molecular design of novel types of artificial enzymes as bio-inspired solid catalysts.

Figure 40.

(A) Functionalization of the pore interior by lizard template method and (B) acetalization of a ketone within unhydrolyzed pores. © 2004, American Chemical Society, J. Am. Chem. Soc. 126 (2004) 988.

Immobilization of more complicated biomaterials has been recently investigated with one typical example being the inclusion of proteins in mesopore channels [340–345]. Vinu and coworkers performed systematic investigations on protein adsorption onto mesoporous materials, mesoporous silica and mesoporous carbon [346–358]. Typically, protein adsorption obeys Langmuir monolayer adsorption and much depends on pore size and geometry of the mesoporous adsorbents. Because the charged states of proteins and/or mesoporous materials vary depending on pH, adsorption behaviors of proteins could be regulated by using pH control. Adsorption near the protein isoelectric point tends to be optimum probably because of minimized electronic repulsions.

Macroscopic assembly

Since self-assembly is a very general concept, material formation through self-assembly is not limited to molecular-scale and nanometer-level objects. It can be applied even to macro-sized objects. In this section, unique examples of this will be briefly summarized.

Mirkin et al reported self-assembly processes of metal-polymer amphiphiles fabricated by sequential electrodeposition of gold and polypyrrole into a porous aluminum template (figure 41) [359]. These micron-sized assemblies had outside diameters of 400 nm for the gold and 360 nm for the polypyrrole portions. The hydrophobic attraction between polymer moieties in water caused contraction of the polypyrrole domains resulting in a designed curvature of the self-assembled microstructures of gold-polypyrrole amphiphilic rods. They mostly formed tubular structures with diameters in the range 10–100 mm, depending on the ratio between gold and polypyrrole domains. The rod units themselves can behave like well designed amphiphilic molecules. Yan et al reported the macroscopic molecular self-assembly of an amphiphilic hyperbranched copolymer in acetone, which generated multi-walled tubes millimeters in diameter and centimeters in length (figure 42) [360]. The thickness of the tube walls approached 400 nm, and the walls had an inhomogeneous lamellar structure that alternates between amorphous, partly irregular hydrophilic domains and well-ordered hydrophilic domains.

Figure 41.

Micron-sized assemblies from metal-polymer amphiphiles.

Figure 42.

Macroscopic molecular self-assembly of an amphiphilic hyperbranched copolymer in acetone.

In this particular field of self-assembly, Whitesides and coworkers have been making extremely significant contributions [361–363]. They have reported a series of results based on visual models of supramolecular self-assembly. One example of their work is shown in figure 43 and is based on millimeter-sized hexagonal sections bearing hydrophilic and hydrophobic faces in an alternating arrangement [364]. Upon positioning of these pieces at an interface of hydrophobic perfluorodecalin and water, the pieces assembled spontaneously so that hydrophobic faces grouped together thus avoiding an unfavorable exposure of these faces to water. This assembly process resulted in the formation of a regular honeycomb structure. Altering the shape of the unit pieces changed the arrangement of the hydrophobic faces and led to creation of a variety of regular macroscopic assemblies. Using four different pieces with differently shaped hydrophobic faces so that four pieces form two kinds of pair by contact between complementary shapes, matching of linked structures could also be demonstrated [365]. This macromodel can be regarded as a mimic of hybridization processes of nucleic acids in the visible regime. Such approaches are not limited to self-assembly within two-dimensional space, and construction of three-dimensional systems has also been reported [366–368]. For example, spontaneous folding of three-dimensional tape-like objects was demonstrated and can be regarded as mimicry of folding in protein and peptide segments [369, 370].

Figure 43.

Visible models of supramolecular self-assembly on millimeter-sized hexagonal pieces with hydrophilic and hydrophobic faces at the interface of perfluorodecalin and water.

Self-assembly in bulk media 2; component type

In the following sections, we have selected several of these molecular types and objects and summarized recent research of their self-assembling behaviors and properties.

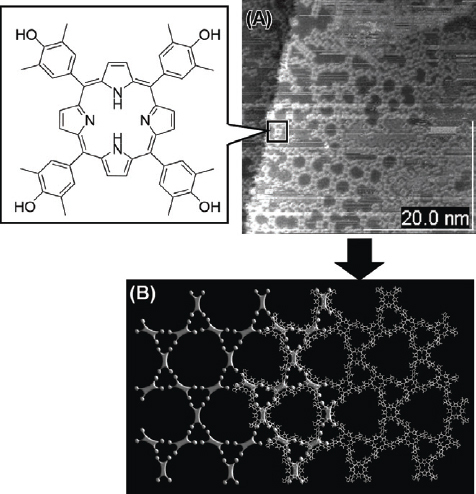

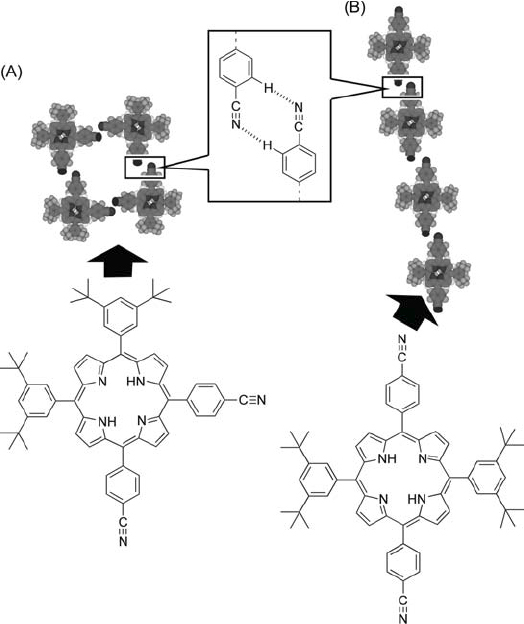

Porphyrin

Porphyrins and related molecules play essential roles in many biological systems. For example, they are involved in the crucial reactions within photosynthetic systems that are composed of sophisticated supramolecular assemblies of proteins and dyes. The antenna complexes of photosynthetic bacteria consist of a core light-harvesting antenna (LH1) and a peripheral light-harvesting antenna (LH2) that contribute to the collection of light energy. The excitation energy migrates within the wheel-like arrays of chlorophylls in the LH1 and LH2 complexes and is finally funneled into the chlorophyll dimer (special pair) at the photosynthetic reaction center. These elegant processes associated with assemblies of porphyrin molecules have attracted many organic, biological, and supramolecular chemists [371–383]. In particular, the formation of structures containing multiple porphyrin molecules using self-assembly processes is an attractive research target. A wide variety of structures can be obtained through supramolecular self-assembly thanks to the molecular design flexibility of porphyrins, since they can be easily modified with relatively little synthetic effort.

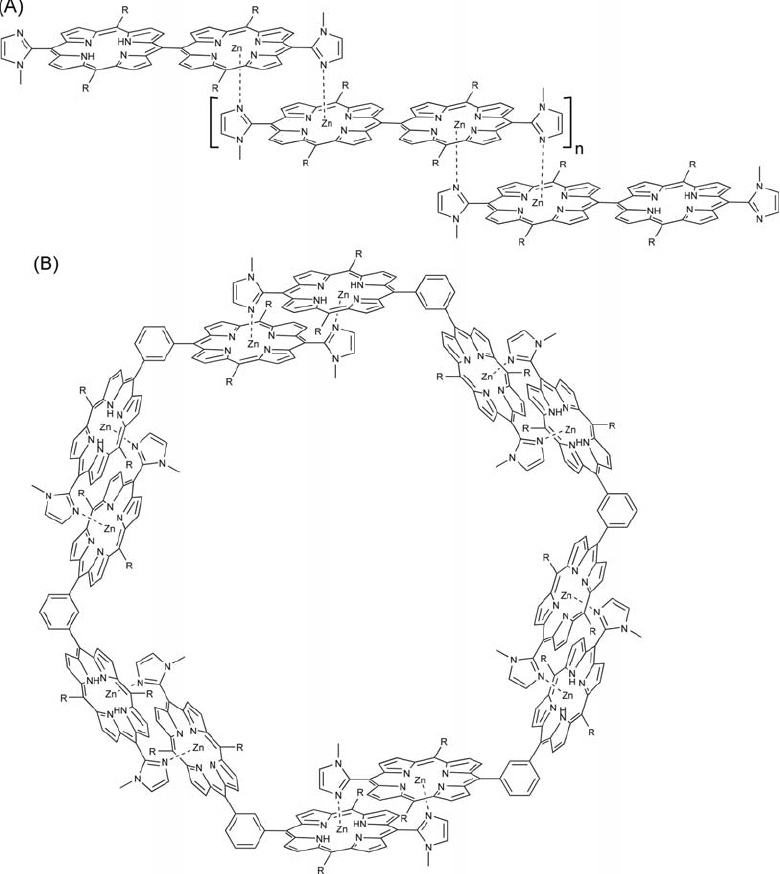

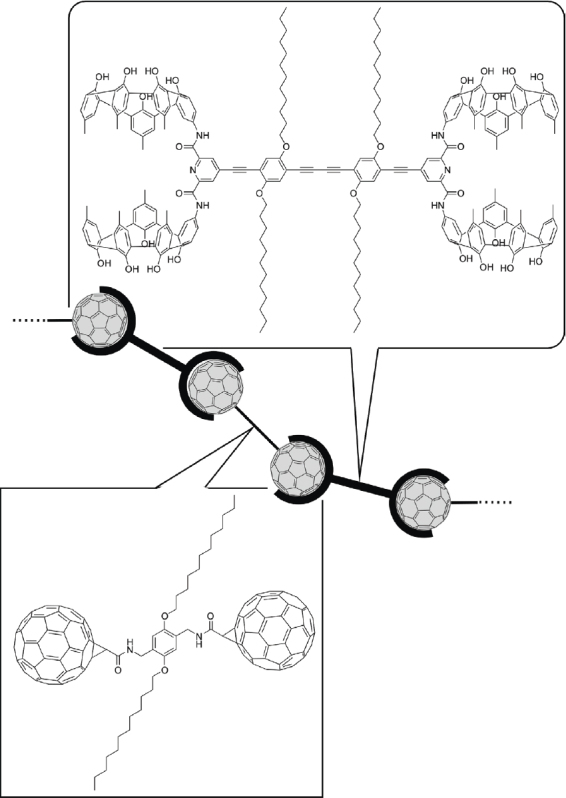

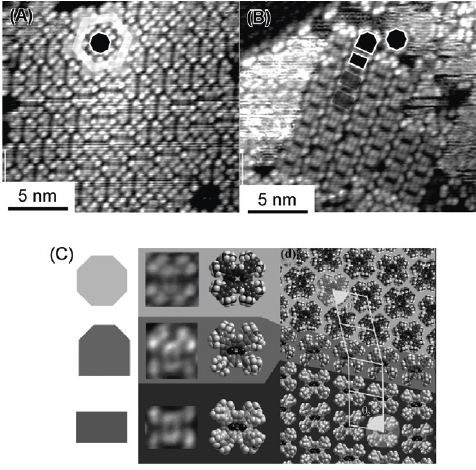

Kobuke and coworkers developed a non-covalent supramolecular approach for construction of porphyrin arrays from rather simple units [384], principally using coordination between central metal and imidazole groups attached at the meso-position (figure 44A) [385, 386]. The lengths of the supramolecular arrays can be controlled simply by fixing the ratio between a porphyrin dimer with two zinc centers and a porphyrin dimer with a single zinc center. A straightforward mimic of the natural light harvesting antenna system was provided using imidazolylporphyrinatozinc(II) dimers connected with a 1,3-phenylene spacer as the linking subunit. Under appropriate conditions, the conformation of this unit resulted in formation of a closed ring (figure 44B) [387, 388]. Such a model may be important for understanding the evolutional strategy for ring structures in the natural photosynthetic system.

Figure 44.

Self-assembled structures of (A) porphyrin with imidazole attached at the meso-position and (B) imidazolylporphyrinatozinc(II) dimers connected with a 1,3-phenylene spacer.