Abstract

This review shows the highlights of a 4-year-long research project supported by the Japanese Government to explore new superconducting materials and relevant functional materials. The project found several tens of new superconductors by examining ∼1000 materials, each of which was chosen by Japanese experts with a background in solid state chemistry. This review summarizes the major achievements of the project in newly found superconducting materials, and the fabrication wires and tapes of iron-based superconductors; it incorporates a list of ∼700 unsuccessful materials examined for superconductivity in the project. In addition, described are new functional materials and functionalities discovered during the project.

Keywords: superconductivity, iron pnictide, new superconductors, superconducting wire, superconducting tape, functional material, powder in tube

1. Introduction

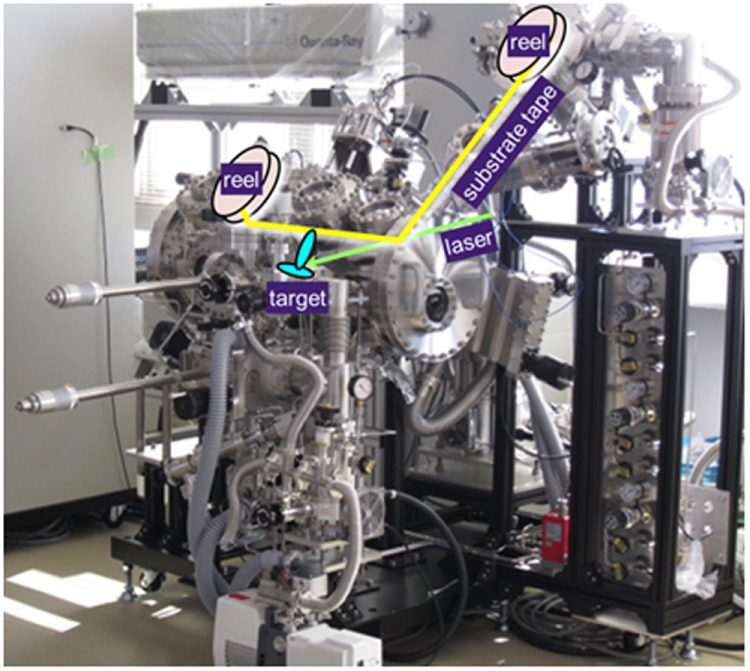

Since the discovery of superconductivity by Heike Kamerling Onnes in 1911 [1], it has been the dream of researchers to realize a room temperature superconductor. Although the fundamental theoretical framework for superconductivity was established in 1957 by the Bardeen–Cooper–Schrieffer (BCS) theory, there exists no theory which can quantitatively predict the critical temperature (Tc) even now [2]. Thus, looking for high Tc superconductors is like a voyage in a big ocean without a precise compass, i.e., researchers have to move ahead believing their sense and/or intuition referring to what theorists say. In this sense, looking for high Tc superconductors is a truly challenging subject and typical ‘all or nothing’ research.

It is a historical fact that materials leading to breakthroughs have been discovered in most cases by chance amidst concentrated research efforts undertaken with a unique but flexible view. This is particularly true for the exploration of new superconductors. The group of one of the present authors (HH) discovered superconductivity in LaFePO in 2006 [3] and LaFeAsO1−xFx in 2008 [4] through LaNiPO (Tc = 3 K) [5] in 2007 in the course of exploring magnetic semiconductors, which started from his extensive research of transparent p-type semiconductors LaCuOCh (where Ch = S and Se) with the same crystal structure as the so-called 1111-type layered compounds. P-type conduction in LaCuOCh originates from the mobile holes at the top of the valence band which is composed of Ch p orbitals and Cu 3d orbitals [6]. It was his idea to novel magnetic semiconductors to utilize strong d–p interactions in LaCuOCh by replacing the nonmagnetic Cu+ ion with a magnetic 3d transition metal cation with a + 2 charge state. In order to keep electro-neutrality upon this substitution, Ch−2 is required to be replaced by Pn3− [7]. This is the reason why his group started to examine the electronic and magnetic properties of LaTMOPn (where TM = 3d transition metal, Pn = P and As). This effort resulted in the discovery of iron-based superconductors (IBSCs) through the concentrated effort to find high performance p-type transparent semiconductors, which is a branch of his research home ground, transparent oxide semiconductors [8].

The discovery of IBSCs was accepted with surprise by the condensed matter community because iron, with a large magnetic moment, was widely believed to be most harmful to the emergence of superconductivity. Extensive research into these materials started globally, particularly in China [7]. As a result, the discovery of IBSCs was chosen as the breakthrough of the year in 2008 by Science Magazine and the paper [4] reporting Tc = 26 K in LaFeAsO1−xFx became the most cited report among all the original research papers published in 2008.

In early 2009, the Japanese Government announced the launch of a new large funding program—FIRST (Funding Program for World-Leading Innovative R&D on Science and Technology). The aim of the FIRST Program is to advance the kind of leading-edge research and development that will strengthen Japan’s international competitiveness while contributing to society and people’s welfare through the application of its results. Hideo Hosono’s proposal ‘exploration for novel superconductors and relevant functional materials, and development of superconducting wires for industrial applications’ was selected as one of 30 projects out of ∼800 applications covering a very broad area of science and technology.

It was his expectation to find novel functionalities and materials with high potential through this tough and really challenging work just as IBSCs were found though the exploration of magnetic semiconductors. Hideo Hosono organized the research team to be mainly composed of solid state chemists who have experience and achievements not only in superconductors, but also in the relevant functional materials. Since research in finding new superconductors typically belongs to the domain of condensed matter physics, this team organization is a unique feature of this project. It was his belief that excellent solid state chemists will find new properties by serendipity, even if they fail to succeed in the hunt for new high Tc materials. This philosophy was set at the beginning of the project, i.e., ‘All or something!’.

This article reviews the major research achievements obtained in our FIRST Project performed over the 4 years from March 2010 through March 2014, along with some background for the research. We have examined more than 1000 materials to seek new superconductors. The fraction of success was relatively small (∼3%), but just as we expected at the outset. So far, unsuccessful results in this field have not been presented in an academic journal. In this review, we have listed the records of materials that we examined in this project, including the unsuccessful materials, based on a consensus among the members of the research team that the consideration of unsuccessful trials will be good fertilizer for future research.

2. Overview

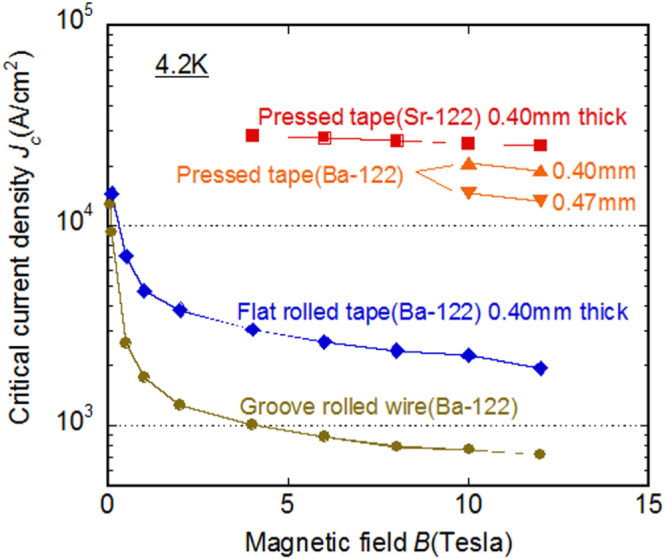

At the beginning of this project, Hosono laid down five research targets. These were: (1) the discovery of a new superconductor with Tc > 77 K, (2) the development of new superconductors with high performance, (3) the development of related materials with outstanding functions, (4) the development of meter-class superconducting wires with a critical current density Jc > 105 A cm−2 based on IBSCs or other novel materials, and (5) the production of prototype Josephson junction and SQUID devices using IBSC thin films. This project consists of six research groups as listed in table 1. Four groups (HH, EM, HKa and SY) have concentrated on the exploration of new superconductors, and the other two groups (KT and HKu) have concentrated on the development of superconducting wires and tapes. The HH group collaborated with five other groups in the field to look for superconductors (MN) and the discovery of catalysis using electride (MH, TS, AS and SK). The HKu group collaborated with YK in the field of superconducting wires. Each group has made an effort to achieve its purpose using its special skills.

Table 1.

Organization of FIRST Hosono Project.

| Team Leader | Mission | |

|---|---|---|

| Exploration of Superconductors | Hideo Hosono (Core-Researcher) (Tokyo Institute of Technology) | Exploration of superconductors of transition metal compounds with layered structure collaborated with Minoru Nohara (Okayama University) |

| Development of superconducting device by thin film technique | ||

| Development of novel functional materials (especially C12A7 electride) collaborated with Michikazu Hara (Tokyo Institute of Technology), Tohru Setoyama (Mitsubishi Chemical Corporation), Alex Shluger (University College London) and Sung Wng Kim (Sungkyunkwan University) | ||

| Eiji Takayama-Muromachi (National Institute of Materials Science) | Exploration of superconductors using high pressure synthesis technique and their characterization | |

| Hiroshi Kageyama (Kyoto University) | Exploration of superconductors using low temperature synthesis technique and their characterization | |

| Shoji Yamanaka (Hiroshima University) | Exploration of superconductors with layered or clathrate structure and their characterization | |

| Development of Superconducting Wire | Keiichi Tanabe (Sub-Core-Researcher) (International Superconductivity Technology Center | Development and evaluation of superconducting wire and superconducting device prepared by thin film technique |

| Hiroaki Kumakura (National Institute of Materials Science) | Development and evaluation of superconducting wire prepared by PIT method collaborated with Yoichi Kamihara (Keio Universty) |

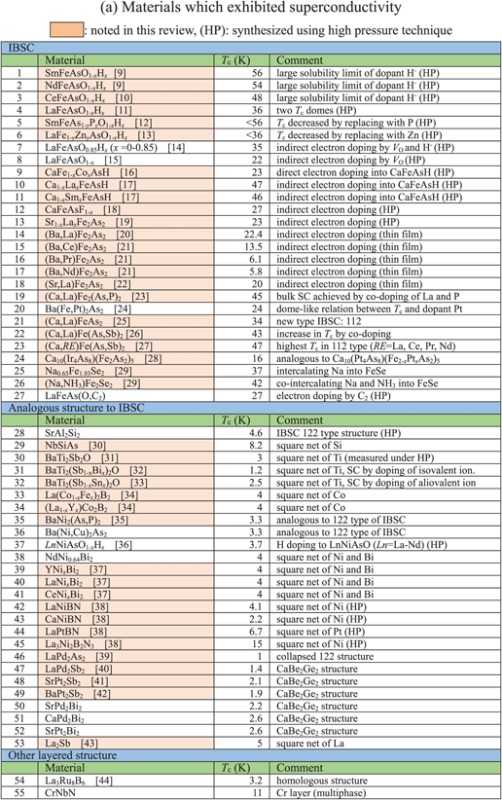

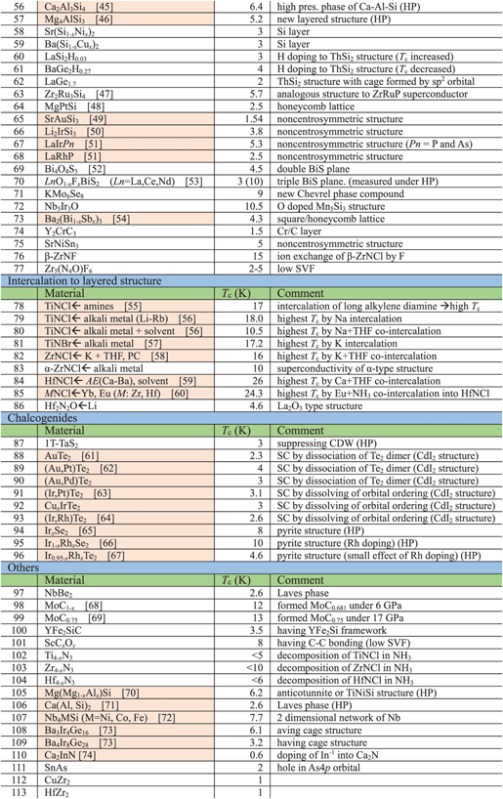

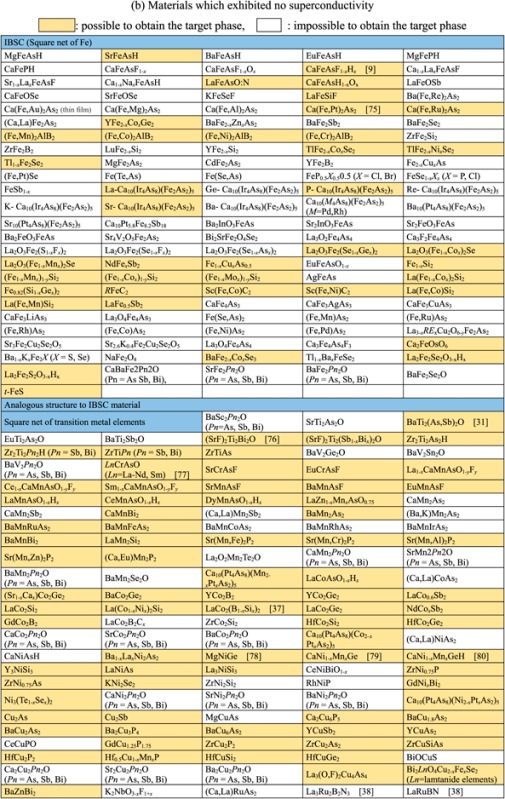

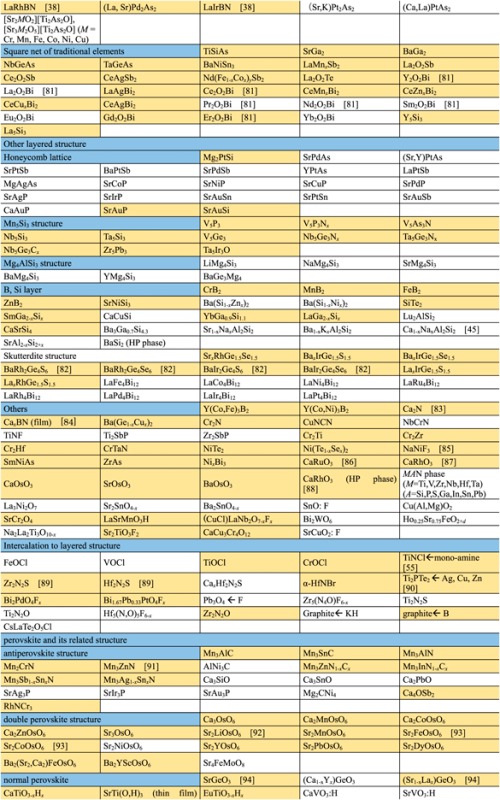

Though the FIRST Project did not discover a new superconductor with Tc > 77 K (56–58 K maximum), over 100 new superconductors have been developed and characterized as new types of IBSC (112) have been found, a new dopant into IBSC (H−) has been employed to induce superconductivity, intercalation type compounds have been found, cobalt-based and titanium-based superconductors have been found, etc. The search for new superconductors is the most important target of the FIRST Project, and over 40 researchers in four groups have worked on this mission. They have examined more than 1000 materials to seek new superconductors. The number of new superconductors found is a relatively small percentage, as envisioned at the onset, which is part of the motivation for the extensive search. We believe that listing all materials examined, including both successes and failures, is meaningful for the people who work in this field or will join this field in the future, and thus show these in table 2. The details of some representative results will be described in section 3.

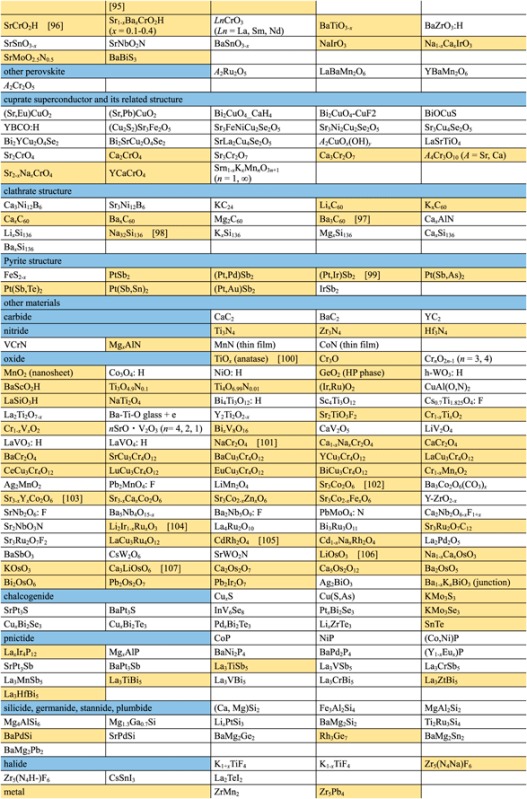

Table 2.

Exploration of new superconductors in this project. (a) Materials which exhibited superconductivity. (b) Materials which exhibited no superconductivity.

|

|

|

|

|

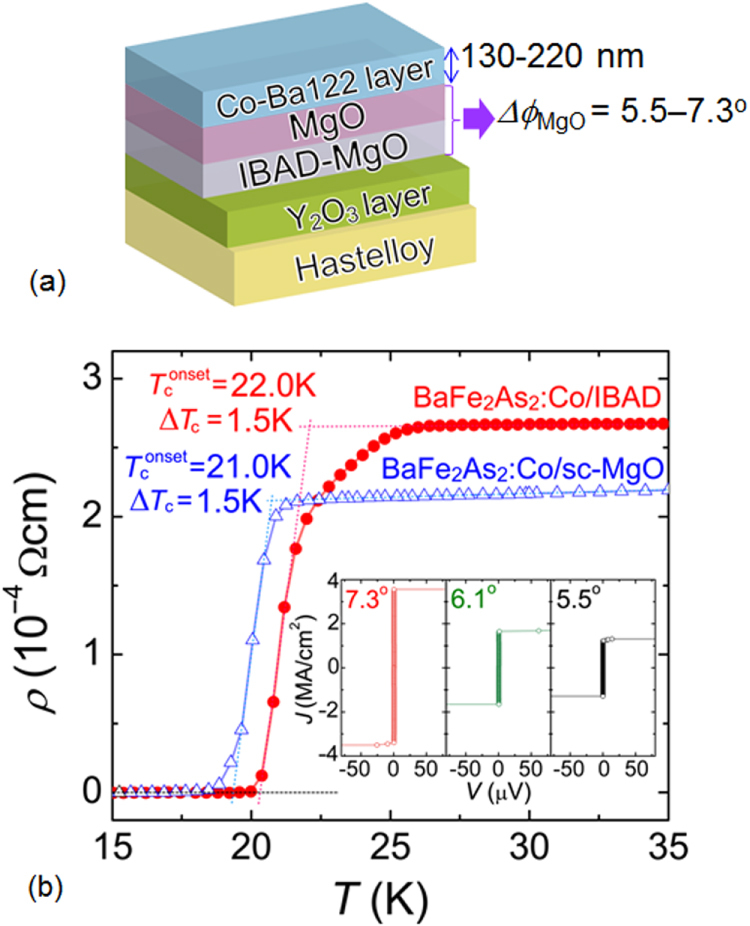

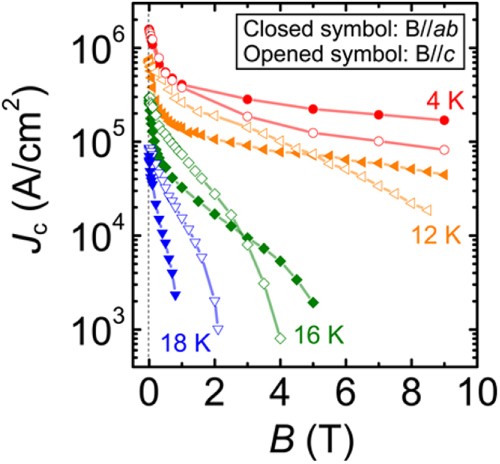

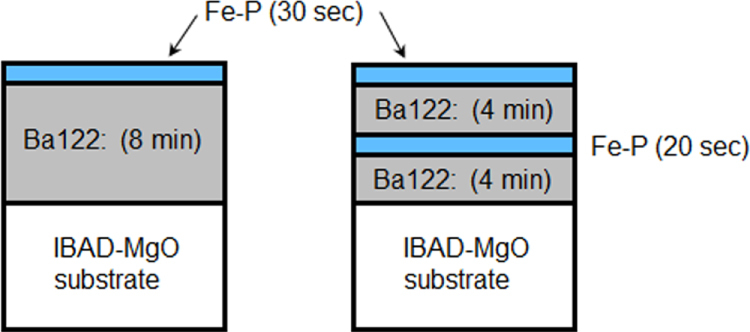

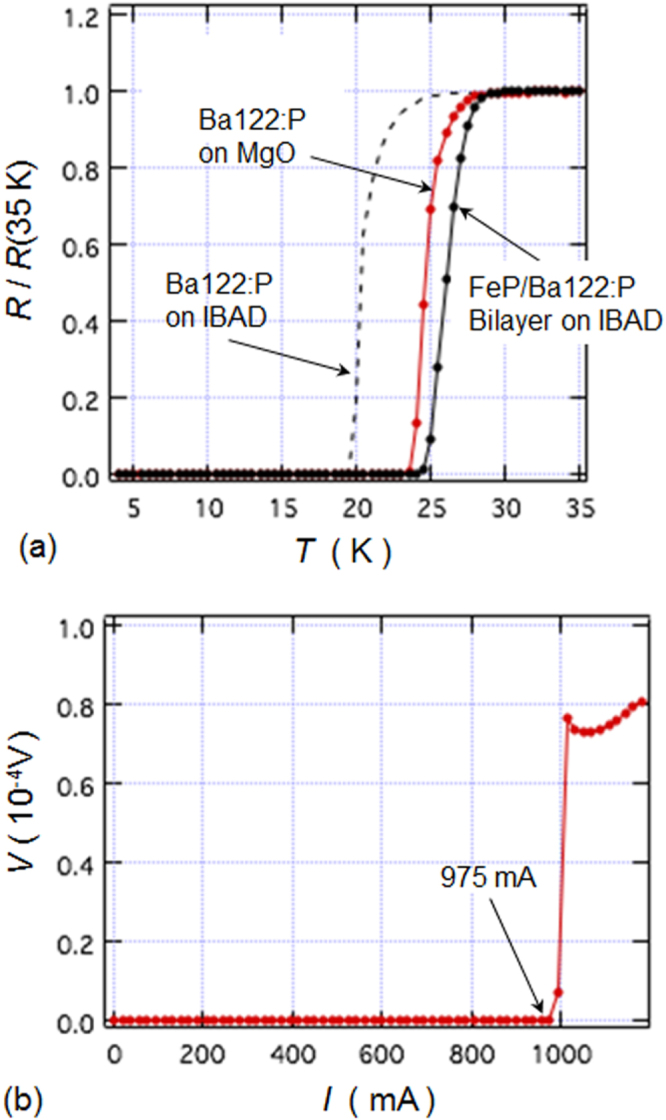

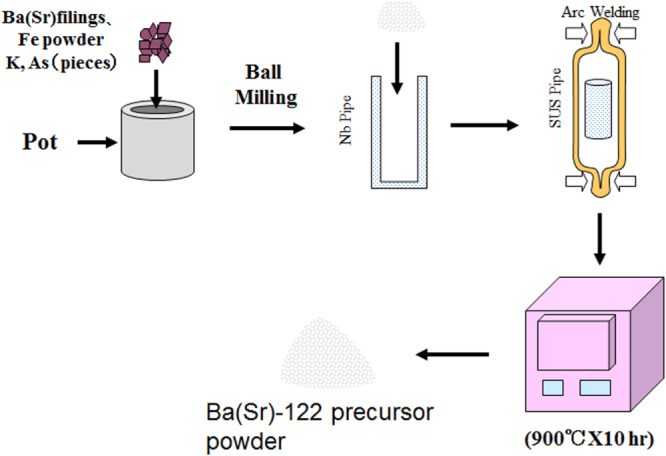

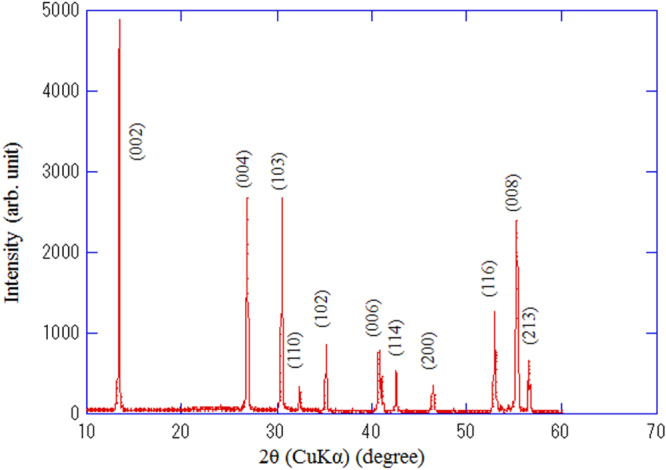

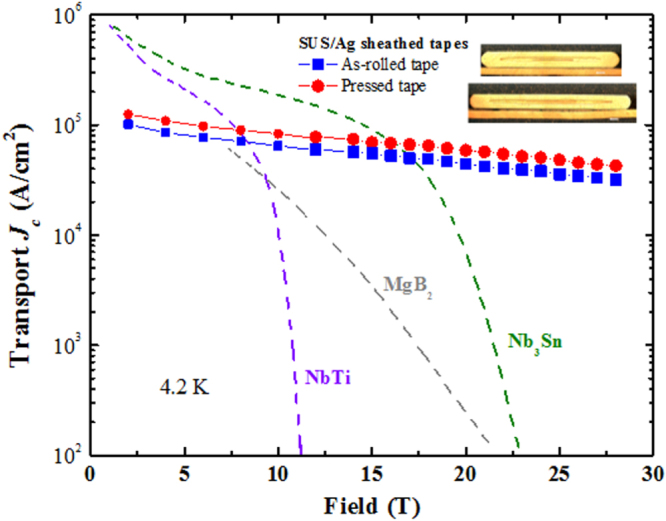

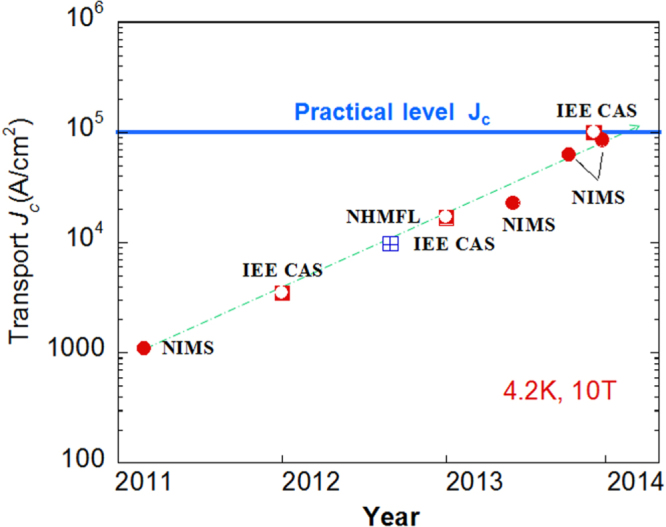

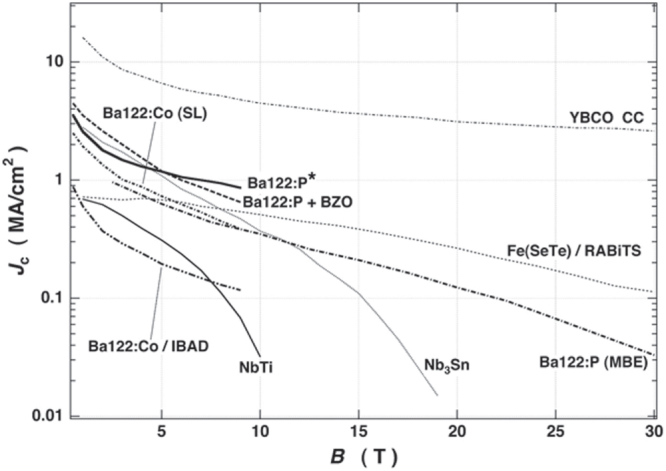

This project produced superconducting wires and tapes with Jc > 105 A cm−2 by the powder-in-tube (PIT) method and has developed efficient magnetic pinning centers for thin film type wires and tapes. Furthermore, the FIRST Project has succeeded in preparing Josephson junction and SQUID devices by using epitaxial thin films of IBSCs, clarifying the physical properties of IBSCs including small anisotropy and high durability in magnetic fields. The induction of a metallic state from an insulating parent material of IBSCs by the electrostatic method was also a result of the research on IBSC thin film devices. We will describe these details in section 4.

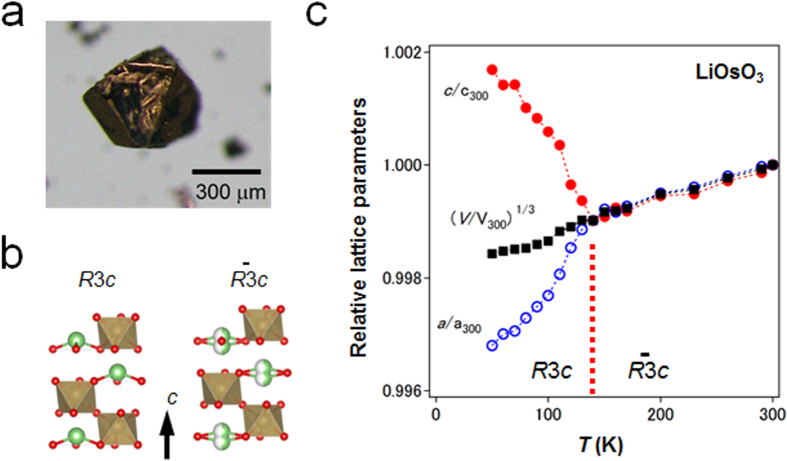

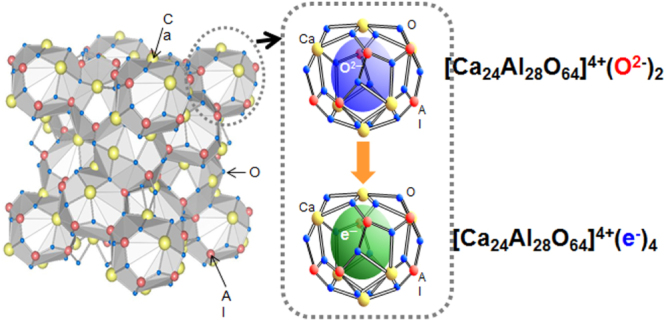

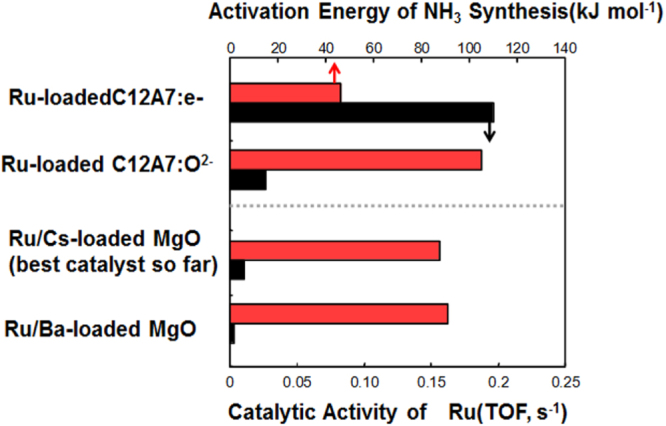

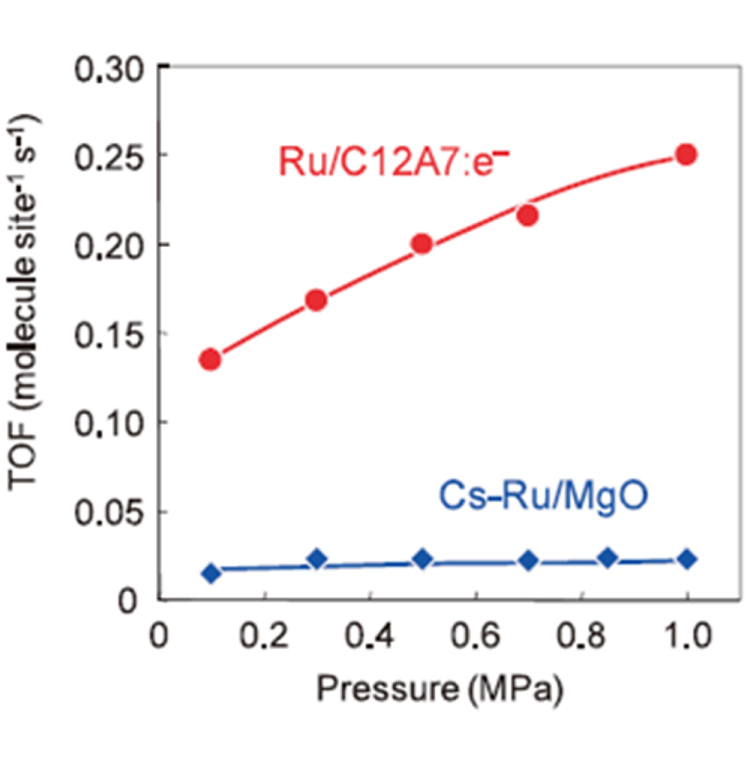

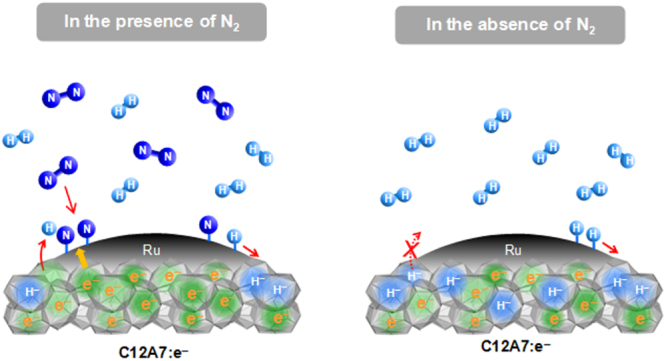

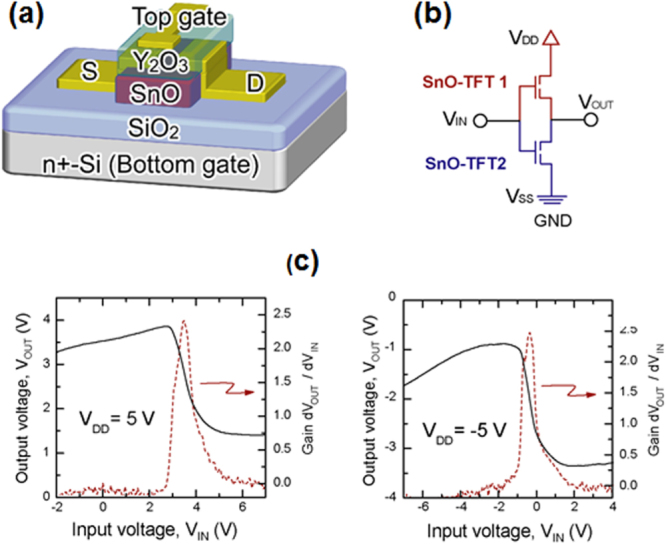

The new functional materials developed in the project are rather diverse. The discovery of a highly efficient catalyst for ammonia synthesis, the 12CaO·7Al2O3 (C12A7) electride, is the most remarkable result [108], which has an impact not only in the academic community, but also in industry. The discovery of the spontaneous decomposition of carbon dioxide gas on the C12A7 electride surface [109], the preparation of stable perovskite titanium oxy-hydride [110], the development of a bipolar oxide semiconductor and its complementary circuit device [111], the development of a new class transparent oxide conductor, SrGeO3 [94], the discovery of the first Slater insulator, LiOsO3, which is a ferroelectric metal [106], the development of a material showing a new type of giant magnetoresistance, NaCr2O4 [94], and the discovery of the two-dimensional electride properties in Ca2N [83], are also representative results. It is interesting that some of these harvests have resulted in the exploration of new superconductors. These results are to be introduced briefly in section 5.

This project has reported these results in more than 330 original papers and numerous oral and poster presentations including over 170 invited and plenary talks at international meetings. Researchers from the FIRST Project have also applied for over 30 patents.

3. New superconductors

In the FIRST Project, four research groups have concentrated on exploring and evaluating novel superconductors, and contributed to the progress of the research of superconductivity through discovery of many novel superconductors and phenomena. We will review these results.

3.1. Iron-based superconductors

The history of IBSCs started in 2006 when LaFePO with Tc = 5 K was found by Hosono’s group [3]. Only a few researchers took notice of this new type of superconductor based on iron with a large magnetic moment. In 2008, the discovery of superconductivity in LaFeAsO1−xFx with Tc = 26 K by the same group [4] rekindled global interest in this area and opened a new frontier of superconductivity. At the early stage, this superconductor family was called ‘pnictide superconductors’. However, researchers now call them ‘iron-based superconductors’ because several measurements and evaluations have clarified that they all have a similar electronic structure where the 3d electrons derived from Fe ion dominate the Fermi level to play a primary role in superconductivity.

Magnetism had long been believed to be incompatible with superconductivity. Thus, the use of elements with a large magnetic moment, typically Fe, Ni and Co, was intentionally avoided in the field of superconductivity. Hence, the discovery of a high-Tc superconductor based on iron impacted research in this field. Condensed matter scientists encountered a new frontier of superconducting materials.

Immediately after Hosono’s group reported an increase in Tc (to 43 K) for La FeAs O0.89F0.11 under high pressure [112], two groups in China [113–115] reported a higher Tc (=55 K) for SmFeAsO1−xFx under ambient pressure. By now, it is reported that the highest Tc values (55–58 K) in non-cuprate bulk superconductors are observed for some IBSCs as SmFeAsO0.74F0.26 [116], SmFeAsO0.85 [117], SmFeAsO0.8H0.2 [9], and Gd0.8Th0.2SmFeAsO [118].

In 2008, Johrendt’s group in Germany reported (Ba,K)Fe2As2 (Tc = 38 K) [119]. Thanks to the ease of growing its single crystals, which have a lateral size of several millimeters using Sn or FeAs as a flux, its physical properties have been well elucidated. In addition, researchers discovered several types of IBSCs and characterized their superconducting properties [120–127].

In this section, we review the recent progress of IBSCs focusing on the results of this project.

3.1.1. Features of IBSCs

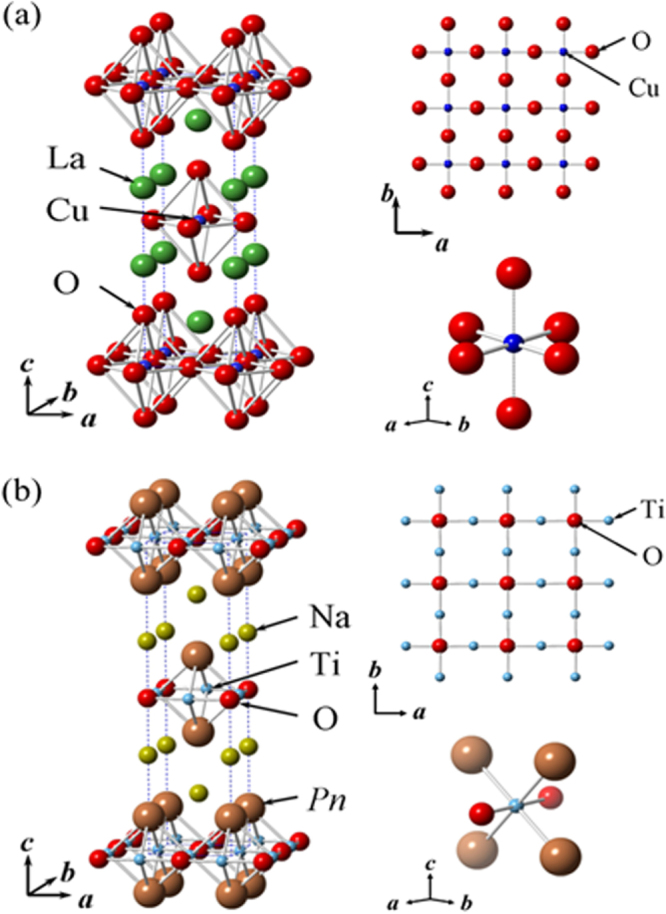

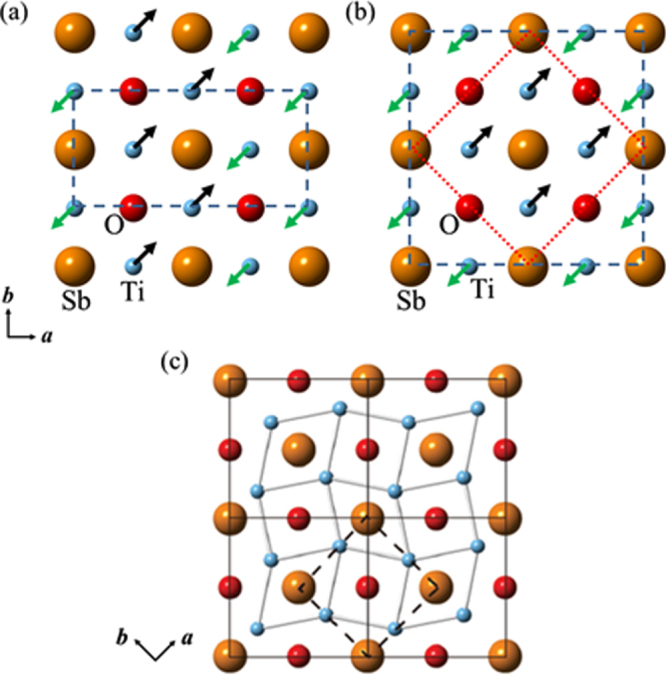

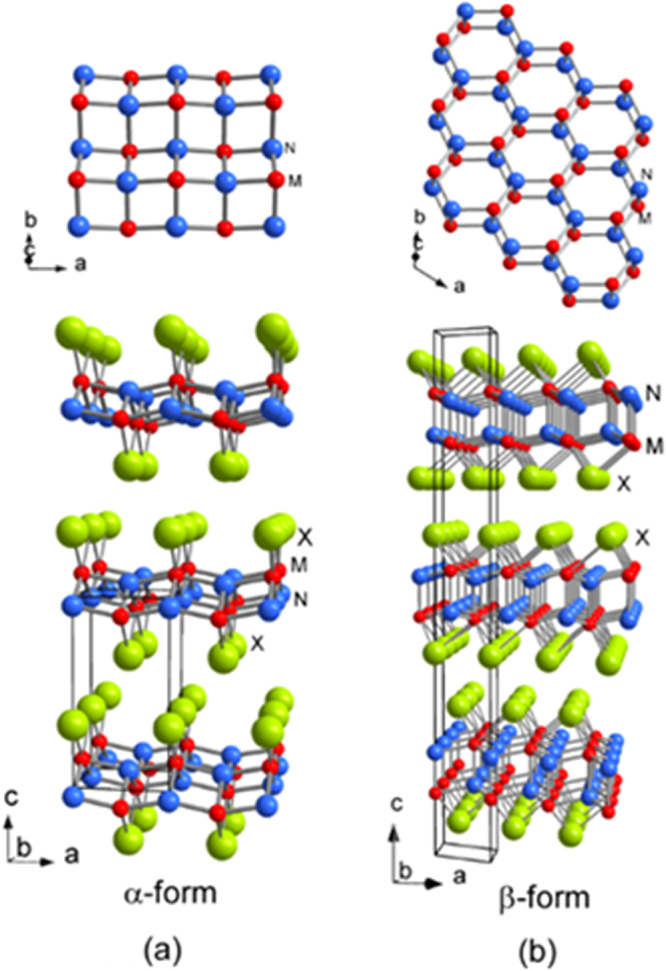

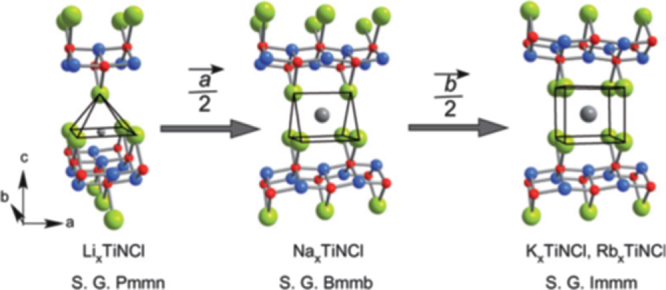

3.1.1.1. Crystal structure

Although approximately 100 IBSCs have been reported, their parent materials may be classified into seven types in terms of crystal structures (figure 1). These materials contain a common structural unit of the FePn (or FeCh) layer formed by the square net of Fe2+ (as the formal charge), which is tetrahedrally coordinated by four pnictogen (Pn) and/or chalcogen (Ch) atoms (see figure 1(a)). Unlike cuprate superconductors, where the parent materials are Mott insulators, this layer shows metallic conductivity without doping. An insulating blocking layer is composed of M, MO or MF etc, where M indicates a metallic element such as an alkali, alkaline earth, or rare earth metal that lies between FePn (or FeCh) layers. Similar to cuprates, this layered structure provides quasi-two-dimensional carrier transport properties, although the magnitude of anisotropy rather differs depending on the blocking layer. The local structure of the FePn layer is affected directly by the atomic (or ionic) size of M because M elements in the blocking layer bond to Fe elements. The crystal structures and the brief introductions of the seven different parent materials for IBSCs are described below.

(i) 1111-type materials (LnFePnO, Ln: lanthanide, AEFeAsF, AE: alkaline earth, Pn: P, As).

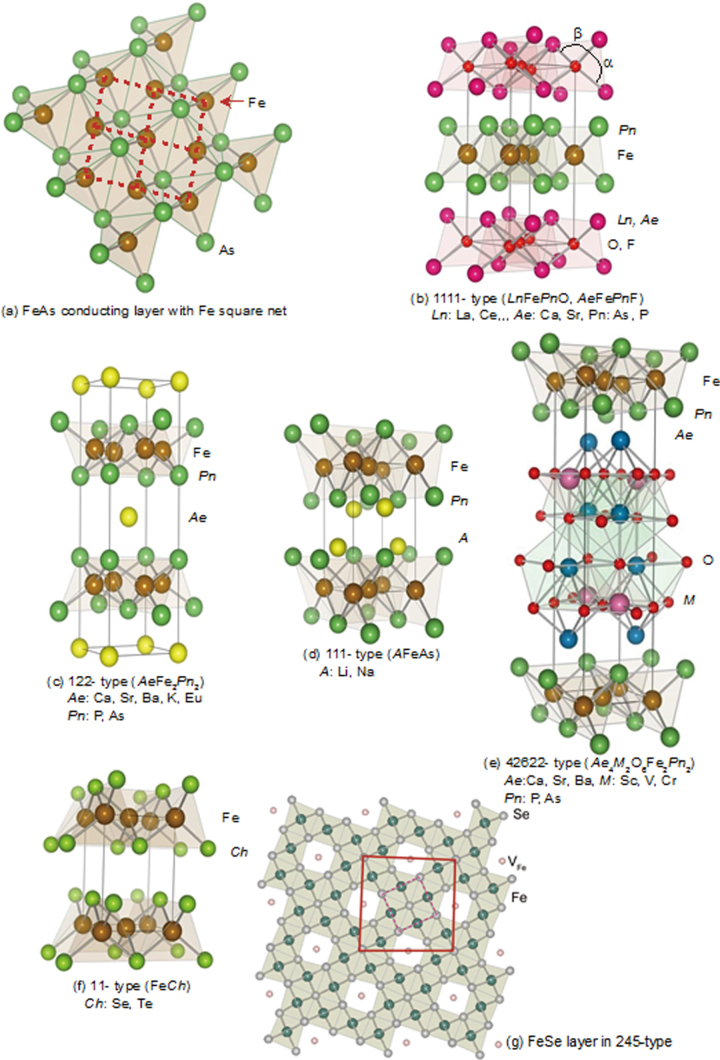

Figure 1.

Crystal structures of iron based superconductors. (a) Structure of the FeAs conducting layer, which is common to all IBSCs. The dotted line indicates the Fe square net. (b) 1111-type, (c) 122-type, (d) 111 type (e) 42622-type and (f) 11-type structures. (g) Structure of K0.775Fe1.613Se2 from the [001] direction in the 51/2 × 51/2 × 1) cell showing fully occupied Fe sites decorated with ordered vacancy sites. The dotted square indicates the basal plane of a 122-type unit cell. Reprinted with permission from [125]. Copyright 2012 by Maney Publishing.

1111-type compounds have the same structure as LaFeAsO, and are the prototype version of IBSCs. Due to their atom composition ratios, they are called ‘1111-type’. Figure 1(b) shows their crystal structure, which is a ZrCuSiAs-type structure [128, 129] with a tetragonal P4/nmm space group. Although LaFePO and LaFeAsO, along with their crystal structures, were identified by Zimmer et al 20 years ago [130], they were discovered to be superconductors in 2006 [3] and 2008 [4], respectively. Moreover, their two-dimensionality is relatively high among the seven types, and only this group has Tc values above 50 K as a bulk form.

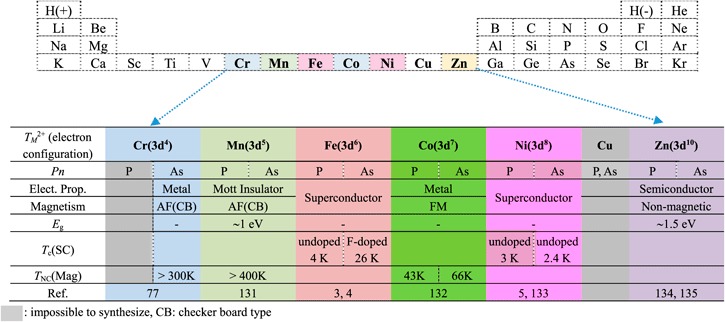

The 1111-type compound is composed of an alternating stack of positively charged LnO layers and negatively charged FeAs (or FeP) layers along the c-axis. As mentioned above, the local structure of the FeAs layer is the same in all types of IBSCs. The distance between the FeAs layers corresponds to the length of the c-axis (∼0.8–0.9 nm). The formal valence state of each atom is Ln3+, Fe2+, As3−, and O2−. Fe2+ contains six electrons in its 3d orbital, and these electrons play an essential role in driving the superconductivity and magnetism. The electronic and magnetic properties of LaTMPnO (TM: 3d transition metal (Cr–Zn)) are summarized in table 3 [120]. The 1111-type compounds composed of Fe and Ni reveal superconductivity.

Table 3.

Summary of electromagnetic properties of LaTMPnO. (TM: 3d transition metal, and Pn=P or As.)

|

The lanthanide elements from La to Gd can occupy the Ln site for the 1111-type of material with Pn = P [130]. In the case of Pn = As, La to Ho and Y can also occupy the Ln site [136]. Additionally, Ca(Fe1−xCox)AsF (Tc = 22 K) is a fluoride-containing superconductor of this type [138].

In this project, the effect of a hydride ion as a new electron donor to this type was studied earnestly and the results are described in section 3.1.2.

(ii) 122-type materials (MFe2Pn2, M: alkali, alkaline earth or Eu)).

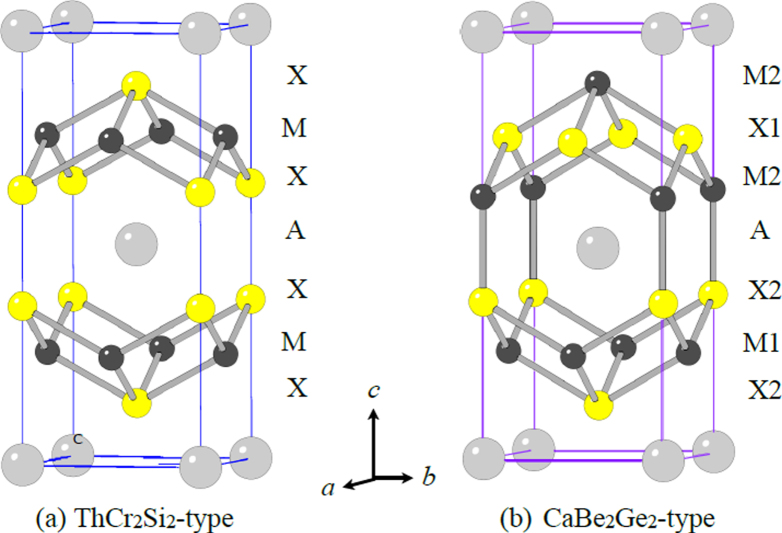

122-type materials have a ‘ThCr2Si2’ type crystal structure with a tetragonal I4/mmm space group [137]. This group contains the largest number of compounds among the five parent families.

In the case of AEFe2P2, not only alkaline earth elements but also lanthanides (La–Pr, Eu) can occupy the AE site. In AEFe2As2, the AE site can be occupied by alkaline earth, alkali metal, or Eu2+. Figure 1(c) shows the crystal structure of the 122-type. The layer composed of AE ions, which is thinner than the Ln-–O layer of 1111-type, is sandwiched between the FeAs conducting layers. The distance between the FeAs layers of 122-type (0.5–0.6 nm) is shorter than that of 1111-type (0.8–0.9 nm). Because the nearest FeAs layers face each other with a mirror plane, the lattice parameter c is twice the FeAs–FeAs distance. The lattice parameter a (∼0.4 nm) is almost the same as that of 1111-type. Consequently, both 1111 and 122-type materials have similar Fe–Fe distance in the FeAs layer. Since single crystals of several millimeters can be obtained using Sn or FeAs as a flux, the physical properties of 122-type are well evaluated compared to other types of IBSCs. Johrendt’s group of Germany was the first to report superconductivity for 122-type materials [119].

In this project, lanthanide element doped 122 superconductors were prepared and evaluated in their bulk and thin-film forms, and these results are described in section 3.1.3.

(iii) 111-type materials (AFePn, A: alkali metal).

While an AE ion (alkaline earth ion with formal charge of 2+) is alternately sandwiched between FePn layers in 122-type, 111-type compounds contain two A ions (A: Li+, Na+) between FePn layers in a unit cell. The crystal structure of this type is known as ‘CeFeSi’ type, with a tetragonal P4/nmm space group (figure 1(d)). This type is compatible with the structure of 1111-type where all the oxygen atoms are removed, and the Ln site is occupied by Li+ or Na+. Wang et al [139] (Tc = 18 K: LiFeAs) and Parker et al [140] (Tc = 10 K: NaFeAs) first reported superconductivity for 111-type materials.

(iv) Materials with thick blocking layer (32522-type (AE3M2O5Fe2Pn2, M: Al, Sc)), (42622-type (AE4M2O6Fe2Pn2, M: Sc, V, Cr)), (homologous type (Can+1ScnOy Fe2As2: n = 3, 4, 5)).

The distance between the FePn/Ch layers is in the order of the 1111, 122, 111 and 11-types. In contrast, these three types of iron oxy-pnictide have a thick blocking layer composed of a quasi-perovskite structure assembled by MO5 pyramids and AE (see figure 1(e) for the 42622-type (Sr4Sc2O6Fe2As2)). The FeAs–FeAs distance is 1.55 nm and 2.45 nm for Sr4Sc2O6Fe2As2 and Ca6(Sc0.4Ti0.6)5OyFe2As2, respectively. The groups of Kishio and Shimoyama have studied these types of materials systematically [141–143]. The highest Tc reported so far is 43 K [143]. Considering the thick blocking layer, this type should have the highest two-dimensionality, but the concrete value of anisotropic properties has not yet been reported because of difficulty of single crystal growth. The 32522-type has been proposed as a promised parent material [144, 145], and the emergence of superconductivity in the 32522-type was reported by Shirage et al in 2011 for (Ca3Al2O5−y)(Fe2Pn2) (Pn = As (Tc = 30.2 K) and P (Tc = 16.8 K)) [146].

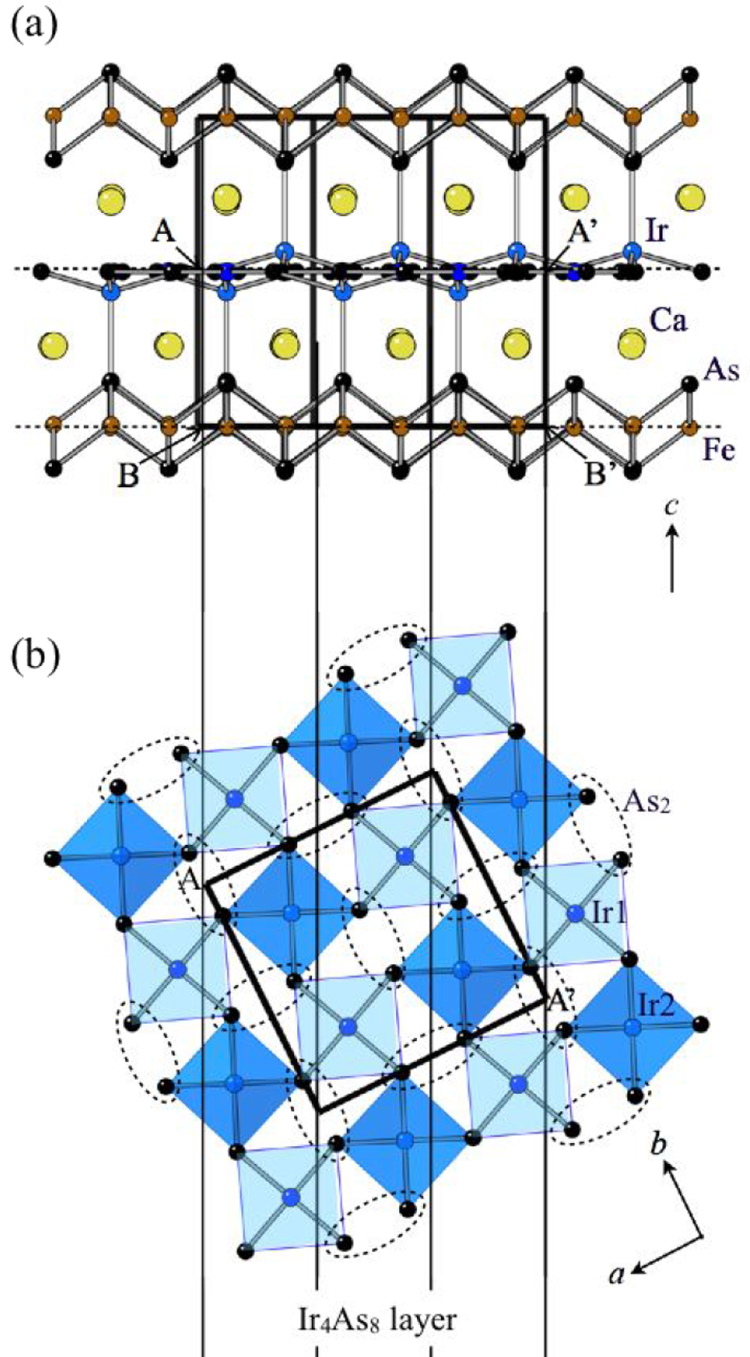

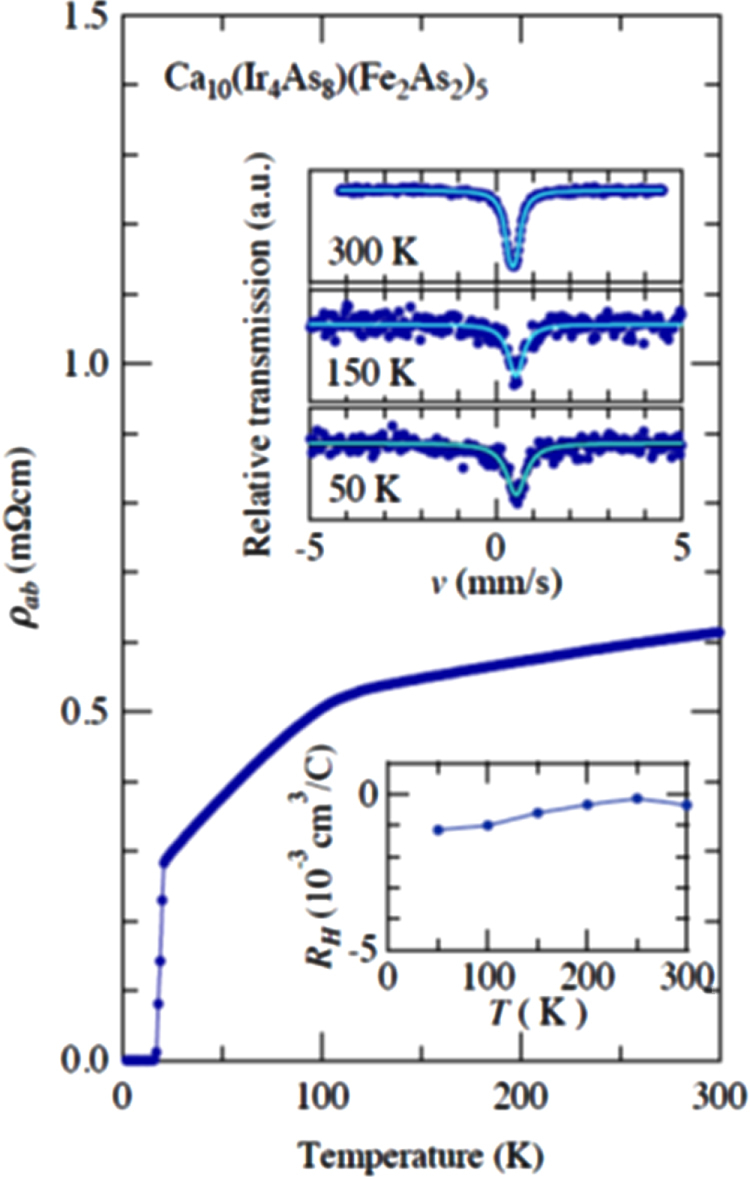

(v) Materials containing additional arsenic (Ca1−xLaxFeAs2), (Ca10(M4As8)(Fe2As2)5, (M: Pr, Ir)).

These new types of iron pnictide superconductor were found by Nohara’s group of this project. The details for (Ca1−xLaxFeAs2) (Tc = 43 K) and (Ca10(M4As8)(Fe2As2)5, (M: Pr, Ir)) (Tc = 38 K) are described in sections 3.1.4 and 3.1.5, respectively.

(vi) 11-type materials (Fe1+xCh, Ch: Se, Te).

The 11-type crystal has the simplest structure among the parent compounds and is essentially the alkali metal-free 111-type. This crystal structure is known as ‘α-PbO’ type with a tetragonal P4/nmm space group (figure 1(f)). A typical 11-type superconductor is β-FeSe (Tc = 8 K) [147]. Medvedev et al reported the 11-type may exhibit a high Tc (=37 K) under 8.9 GPa [148].

Furthermore, FeSe attracts attention as one of the candidates showing higher Tc than boiling temperature of liquid N2. Several groups in China reported that the monolayer of FeSe deposited on a SrTiO3 substrate showed high Tc (65 K) in 2012 and they raised Tc to 100 K [149–153]. Though this superconductivity emerges so far only for monolayers of FeSe deposited on a SrTiO3 substrate, a new route to high Tc materials is expected to be found.

(vii) 245-type materials (A1−xFe2−ySe2: A = K, Cs, Rb, Tl).

In 2010, Guo et al reported a potassium-intercalated iron selenide superconductor with relatively high Tc value (30 K) [154]. The crystal structure changed from 11 to quasi-122-type upon intercalation, of which the space group is assigned to I4/m due to vacancy ordering as shown in figure 1(g). Though Guo et al noted its chemical notation as KxFe2Se2, the detailed chemical and structural analyses for its optimal material showed the composition to be A0.8Fe1.6Se2 (=A2Fe4Se5) and ordering of Fe vacancies with a  supercell in the 122-type crystal structure [155]. This type of material shows a wide range of non-stoichiometry, and with low Fe concentration is an antiferromagnetic insulator. The superconductivity in AxFeySe2 emerges in the proximity of an antiferromagnetic (AFM) Mott insulating state, similar to the cuprate high temperature superconductors [156]. Many unique properties let us classify this as an independent type apart from the 122-type. Ivanovskii reviewed this material [157].

supercell in the 122-type crystal structure [155]. This type of material shows a wide range of non-stoichiometry, and with low Fe concentration is an antiferromagnetic insulator. The superconductivity in AxFeySe2 emerges in the proximity of an antiferromagnetic (AFM) Mott insulating state, similar to the cuprate high temperature superconductors [156]. Many unique properties let us classify this as an independent type apart from the 122-type. Ivanovskii reviewed this material [157].

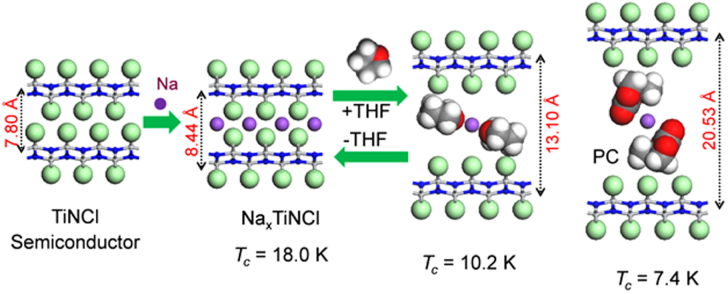

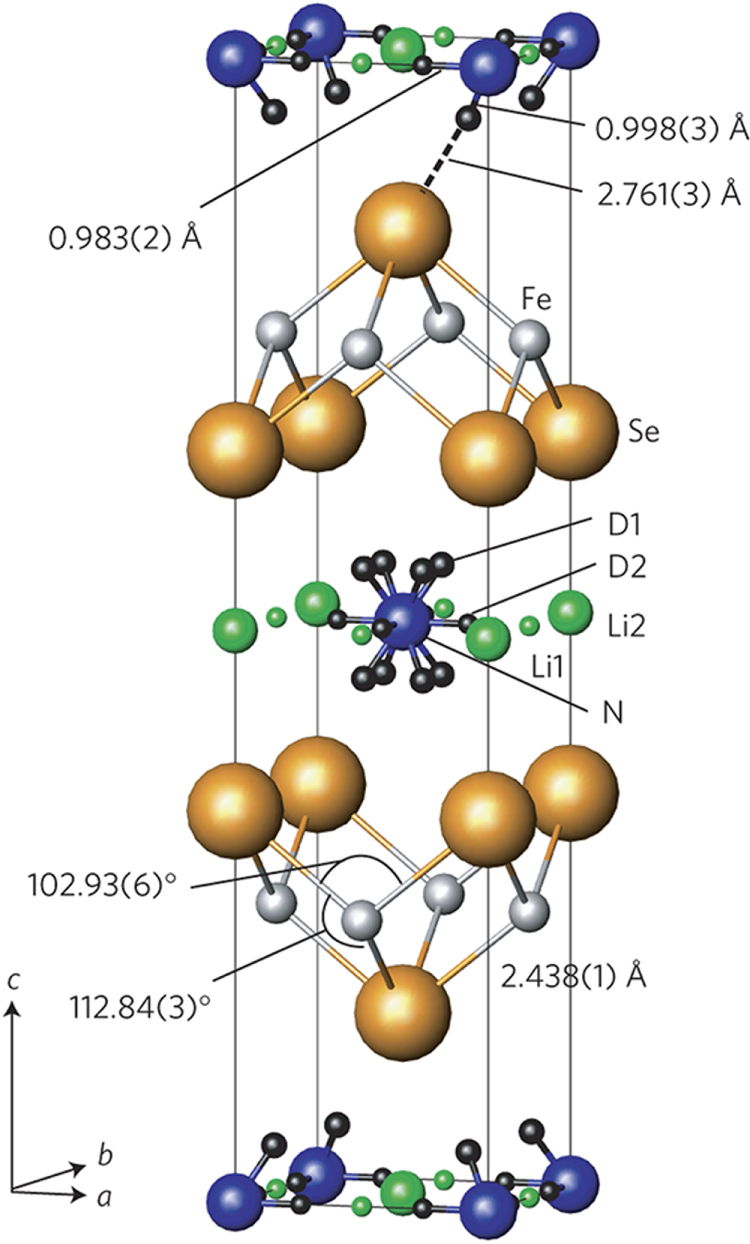

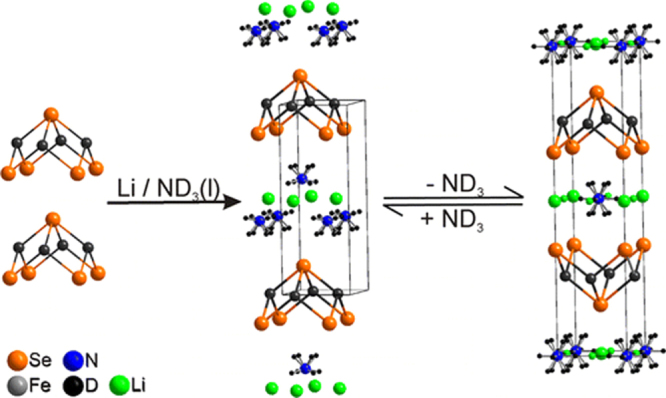

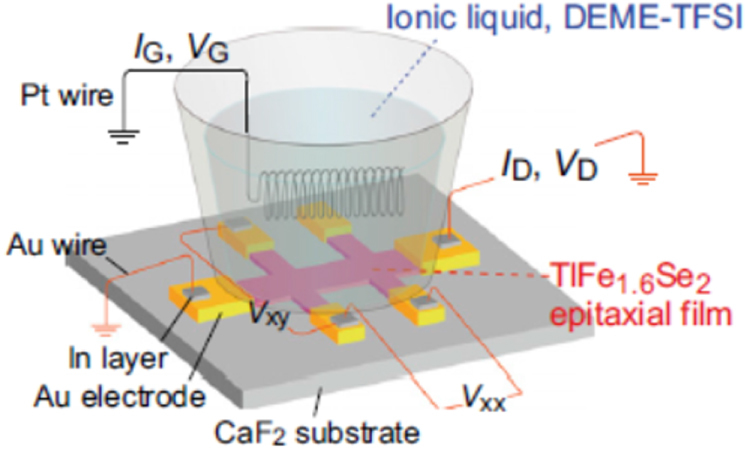

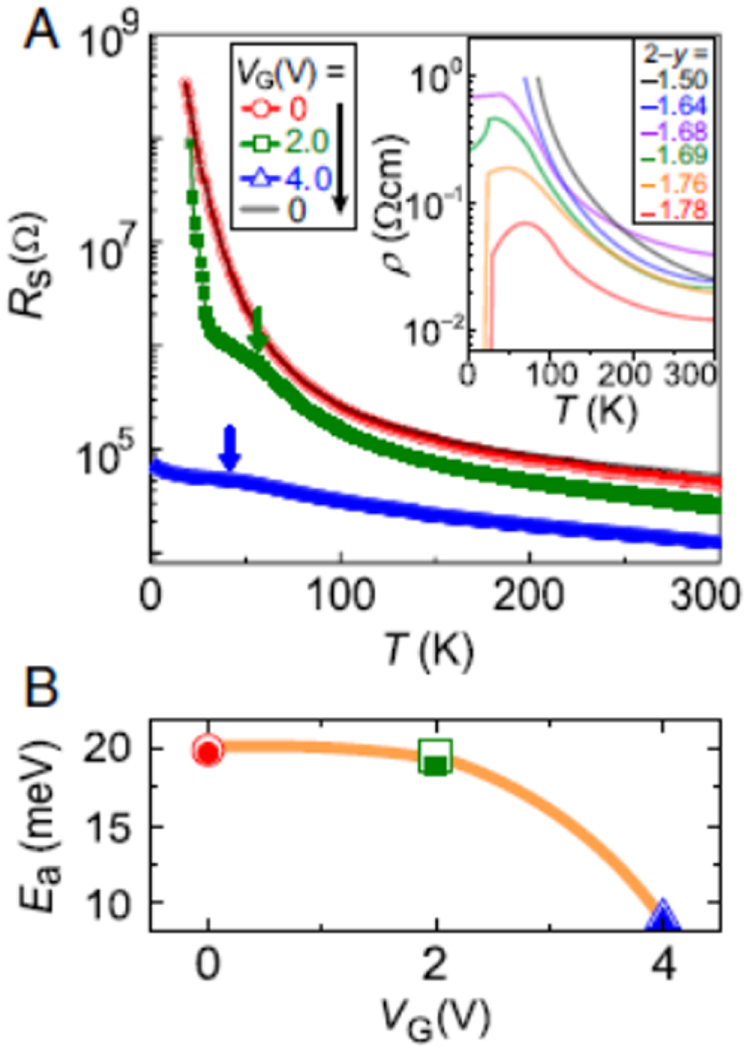

In this project, we intercalated Na to FeSe employing the ammonothermal method, which cannot be prepared using a conventional thermal treatment at high temperatures. The result is described in section 3.1.6. Using this type of material with low Fe content as a Mott insulator, we examined the effect of the electric field on its electrical transport properties. The results are described in section 4.2.5.

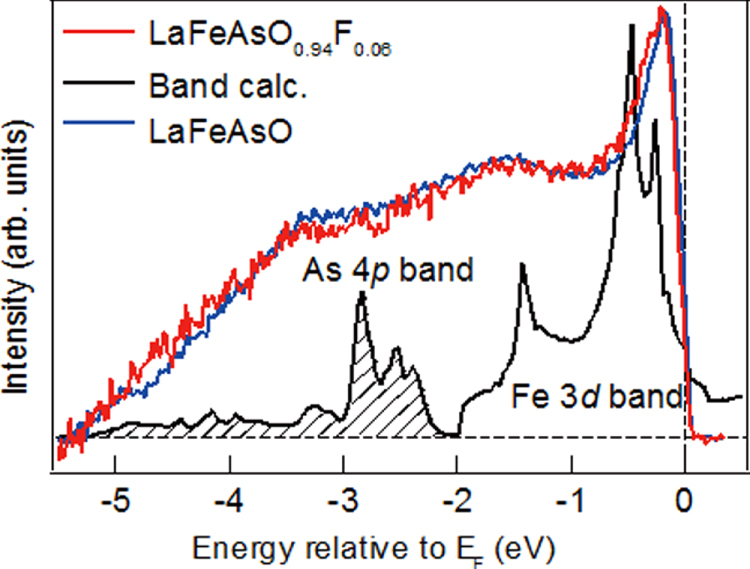

3.1.1.2. Electronic structure

Figure 2 shows the photoemission spectra of LaFeAsO and LaFeAsO0.94F0.06, and calculated partial density of states (PDOS) for Fe 3d and As 4p [158]. The Fermi level (EF) controlling the transport property is primarily formed by a complex tangle of five Fe 3d orbitals, due to the small contribution of As, which is unlike cuprate superconductors where only Cudx2−y2 contributes to the EF. With five bands comprising EF, multi-pockets, i.e., a disconnected Fermi surface (FS), appear on the FS. The energy levels of dx2−y2, dxy, and dyz are sensitive to both changes in the symmetry of the FeAs4 tetrahedron and the carrier density. Such an electronic structure dominates high Tc with the unique pairing mechanism.

Figure 2.

Photoemission spectra of LaFeAsO1−xFx and calculated PDOS. The near-EF peak and the weak peak at about −1.5 eV corresponding to Fe 3d bands survive, and a broad peak corresponding to the As 3p band appears in the range −(3 ∼ 4) eV. Reprinted with permission from [158]. Copyright 2008 by the Physical Society of Japan.

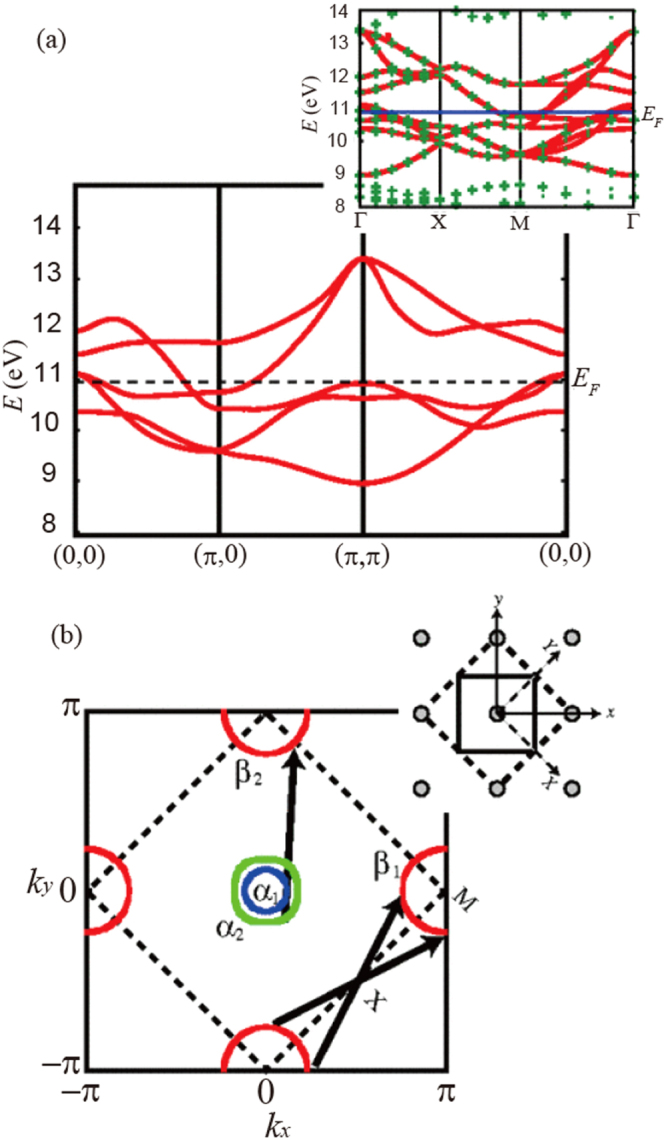

At the early stage of the theoretical approach for the pairing mechanism, several physicists [159–166] suggested the possibility of spin fluctuation mediated pairing, where the spin fluctuation arises around the nesting vector (π, 0) (see figure 3 [160]). The spin fluctuation mediates s±-wave pairing, where the gap function has s-wave symmetry, but its sign is reversed between the electron and hole Fermi surfaces.

Figure 3.

(a) The band structure of the five-band model in the unfolded BZ, where the interlayer hoppings are included. To compare with the ten-band model (thick red lines in the inset; the symbols are the present local-density approximation results), note the original (dashed lines) and the unfolded (solid lines) BZ shown in (b). (b) Fermi surface for n = 6.1 (with the interlayer hoppings ignored), with the arrows indicating the nesting vectors. The inset depicts the original (dashed lines) and reduced (solid lines) unit cell in real space. Reprinted with permission from [160]. Copyright 2008 by the American Physical Society.

In contrast, recent experimental results showed that high Tc is revealed when the nesting is degraded, or even in the absence of the nesting by heavy doping of impurities [11, 149, 151, 154, 167]. To explain the robust superconducting state against impurities, Kontani and Onari [168] proposed a mechanism of the S++-wave superconducting state induced by orbital fluctuations, due to the phonon-mediated electron–electron interaction. On the other hand, Suzuki et al [169] succeeded in reproducing the general trend of composition dependence of Tc in LnFeAsO1−xHx (Ln: La, Ce, Sm and Gd) by the diagonal (next nearest neighbor) electron hopping model, where the next nearest neighbor (diagonal) hoppings between iron sites dominate over the nearest neighbor ones, plays an important role in the enhancement of the spin fluctuation and thus superconductivity. The theoretical and experimental evaluation for the superconducting mechanism will continue from now on.

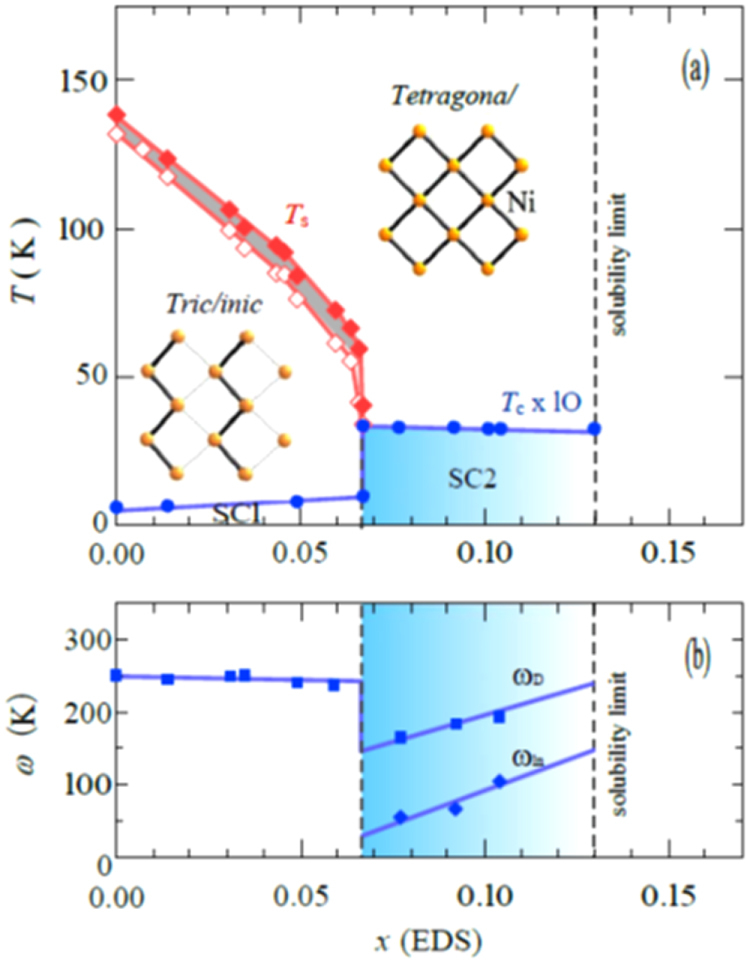

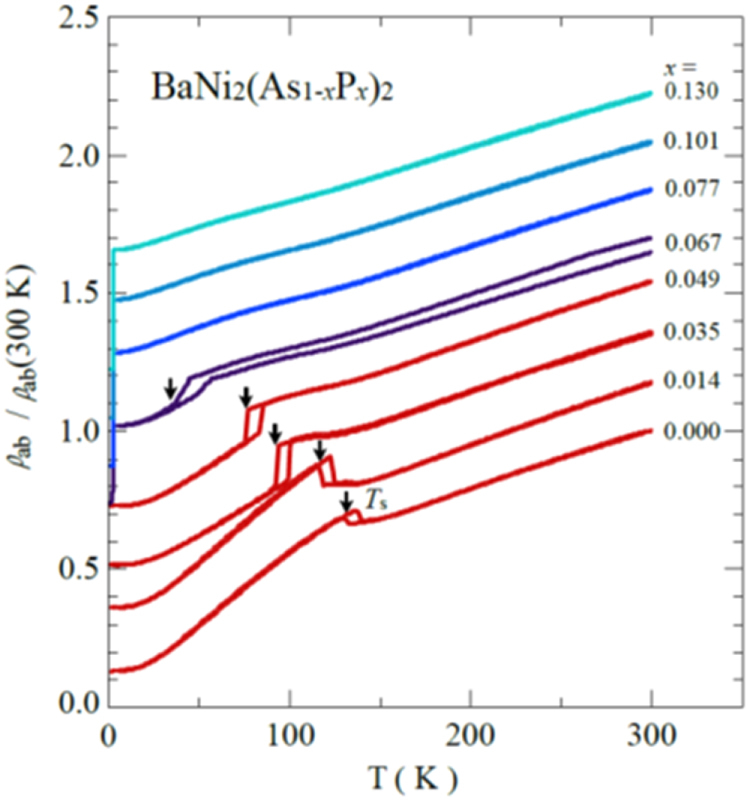

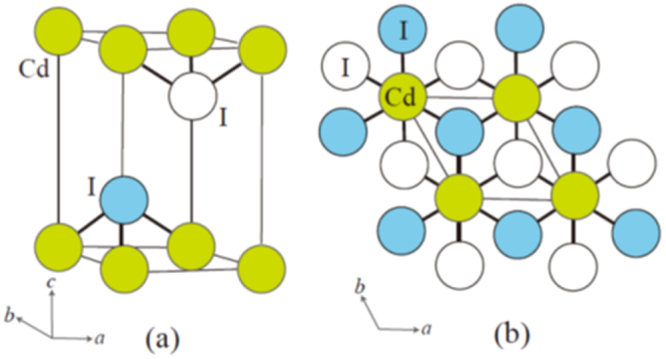

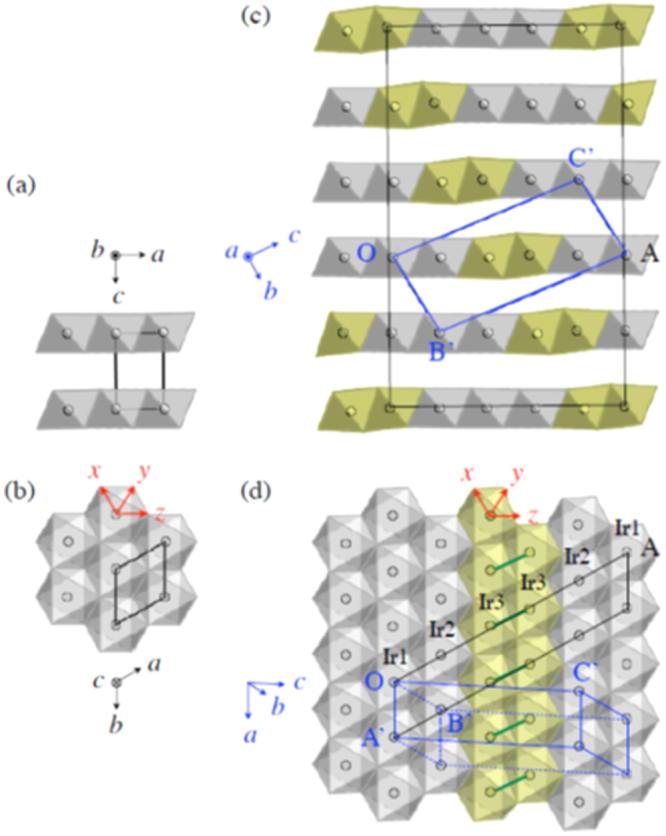

3.1.1.3. Electronic phase diagram

Unlike cuprate superconductors whose parent materials are Mott insulators, the parent materials of IBSCs are antiferromagnetic metals with sufficient conduction carriers. Hence, it is considered that carrier doping into IBSCs mainly alter the FS, which in turn leads to suppression of antiferromagnetism.

Here we mainly describe the electronic phase diagram for the 1111-type (LnFeAsO, Ln: rare earth element). The parent materials for the 1111-type have tetragonal crystal structure at room temperature, but transform into orthorhombic structure at lower temperatures. In LaFeAsO, Pauli paramagnetism (PM) is shown around room temperature, and changes into AFM at a slightly lower temperatures (TN ∼ 140 K) than that of the structural transitions (Ts ∼ 160 K) [170, 171].

Generally, superconductivity occurs in the tetragonal phase and not in the orthorhombic phase due to antiferromagnetic ordering in the orthorhombic phase. With doping (e.g., substituting O for F in LnFeAsO), the tetragonal–orthorhombic transition temperature decreases and is accompanied by suppression of the AFM state and superconductivity emerges in succession. Electrons are doped into the bulk, when an element with more valence electrons is substituted. In contrast, holes are doped by substituting an element with fewer valence electrons. In many cases of both 1111 and 122-type, it is possible to substitute Fe or As in the conducting layer and Ln, AE, O or F in the blocking layer for other elements. The former and the latter are called ‘direct doping’ and ‘indirect doping’, respectively.

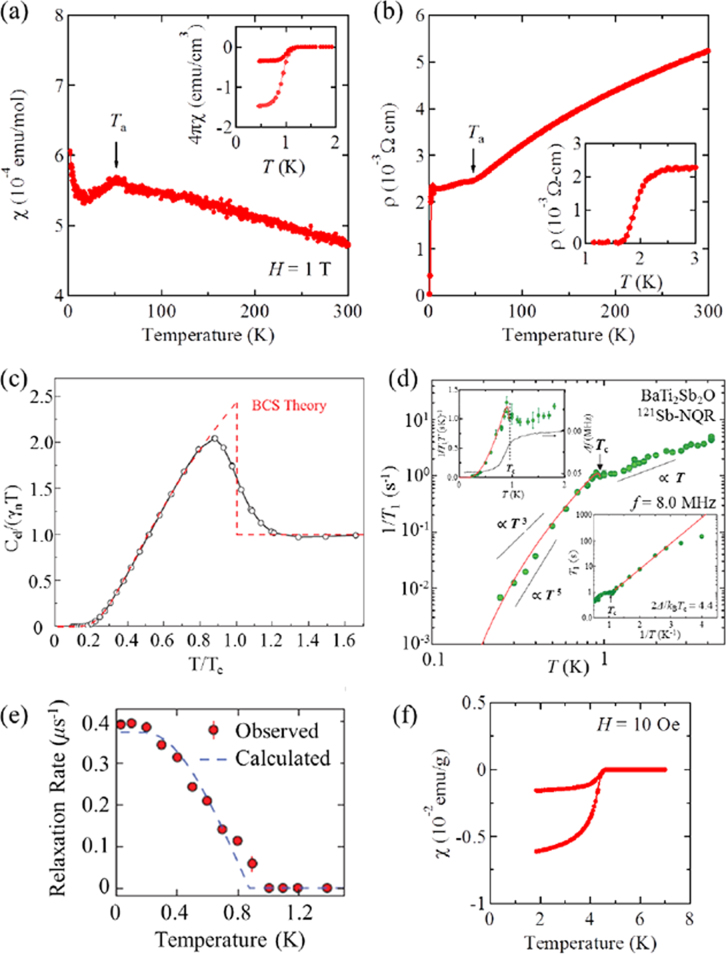

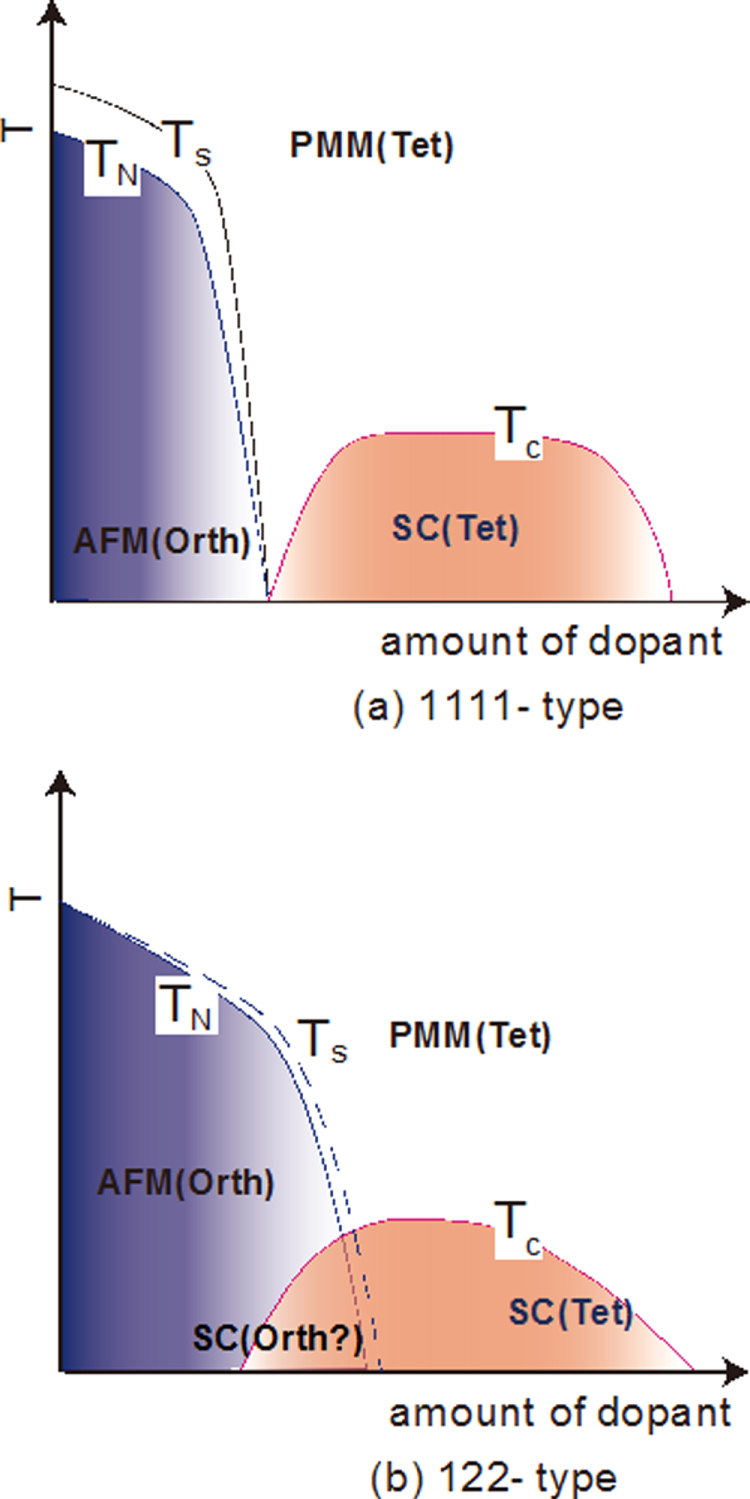

The critical temperature (Tc) increases, reaches a maximum, and then decreases as the dopant level increases. Since the decrease in Tc in the over doping level is due to the precipitation of the secondary phase as SmOF in SmFeAsO1−xFx, the proposed phase diagram for 1111-type doped with F does not show the correct Tc behavior in the over doping region [172–176]. In contrast, Hanna et al [9] prepared SmFeAsO1−xHx and showed its optimal Tc (=55 K) at x = 0.20 and decrease in Tc by additional doping (over doping) without precipitation of the secondary phase, indicating a wide superconducting dome in 1111-type. Figure 4(a) shows the schematic phase diagram for the 1111-type.

Figure 4.

Schematic temperature versus composition phase diagram for (a) 1111-type and (b) 122-type (Ts: structural transition temperature; TN: magnetic transition temperature; AFM: antiferromagnetic phase; PMM: paramagnetic metal phase; SC: superconducting phase). Reprinted with permission from [125]. Copyright 2012 by Maney Publishing.

The first IBSC reported was formed by electron doping as LaFeAsO1−xFx where F substituted the O site as ( [4]. In addition to the substitution of oxygen sites by F (Tc = 55 K for SmFeAsO0.9F0.1) [115], various routes for electron doping have been reported, including the formation of an oxygen vacancy (

[4]. In addition to the substitution of oxygen sites by F (Tc = 55 K for SmFeAsO0.9F0.1) [115], various routes for electron doping have been reported, including the formation of an oxygen vacancy ( Tc = 55 K for SmFeAsO0.85) using a high-pressure synthesis [117, 177, 178] substitution of H− for an O2− site (

Tc = 55 K for SmFeAsO0.85) using a high-pressure synthesis [117, 177, 178] substitution of H− for an O2− site ( Tc = 55 K for SmFeAsO0.8H0.2) [9], substitution of Th for Ln (

Tc = 55 K for SmFeAsO0.8H0.2) [9], substitution of Th for Ln ( Tc = 56 K for Gd0.8Th0.2FeAsO) [118, 179], and substitution of Co, Ni or Ir for Fe (

Tc = 56 K for Gd0.8Th0.2FeAsO) [118, 179], and substitution of Co, Ni or Ir for Fe ( Tc = 14 K for LaFe1−xCoxAsO [180, 181], Tc = 22 K for I1−xCoxAsF [137],

Tc = 14 K for LaFe1−xCoxAsO [180, 181], Tc = 22 K for I1−xCoxAsF [137],  Tc = 6 K for LaFe1−xNixAsO [182],

Tc = 6 K for LaFe1−xNixAsO [182],  Tc = 18 K for SmFe1−x IrxAsO [183]). The optimal amount of doping is 0.1–0.2/Fe atoms for each route, and indirect doping appears to be more effective than direct doping in achieving a high Tc, which should be due to less structural perturbation to the conducting layer.

Tc = 18 K for SmFe1−x IrxAsO [183]). The optimal amount of doping is 0.1–0.2/Fe atoms for each route, and indirect doping appears to be more effective than direct doping in achieving a high Tc, which should be due to less structural perturbation to the conducting layer.

For the 122-type, the shape of the electronic phase diagram is similar to the 1111-type as a general trend. The remarkable difference between the 1111- and 122-types is whether the AFM and superconducting phases are distinctly overlapped or not as shown in figure 4(b). In the 1111-type, the regions showing AFM and superconductivity are separated or barely overlap, whereas the 122-type materials have AFM regions with a high Tc. The optimal Tc is apparently located around the temperature corresponding to the extrapolation of the SDW curve to zero temperature, i.e., a superconducting dome appears around the quantum critical temperature of SDW [184]. The emergence of SC by doping of isoelectronic dopant, such as P for As, is also a unique property of the 122-type.

The comparison in doping between the 122- and the 1111-type is shown in table 4.

Table 4.

Typical example of emergence of superconductivity by doping (Tc and composition).

| 1111 | 122 | |||

|---|---|---|---|---|

| Doping type | indirect | direct | indirect | direct |

| 55 K (SmFeAsO0.9F0.1) [115] | 14 K (LaFe0.89Co0.11AsO) [180] | 45 K (Ca0.83La0.17Fe2(As,P)2 | 22 K (BaFe1.8Co0.2As2) [186] | |

| Electron | 55 K (SmFeAsO0.85) [117] | 22 K(CaFe0.9Co0.1AsF) [137] | [23] | 19 K (BaFe1.908Ni0.092As2) [187] |

| 55 K (SmFeAsO0.8H0.2) [9] | 6 K (LaFe0.96Ni0.04AsO) [182] | 22 K (Sr0.6La0.4Fe2As2) [19] | 24 K (BaFe1.886Rh0.114As2) [188] | |

| 56 K (Gd0.8Th0.2FeAsO) [118] | 18 K (SmFe0.89Ir0.11AsO) [183] | 22 K (Ba0.93La0.07Fe2As2) [20] | 18 K (BaFe1.914Pd0.086As2) [188] | |

| Hole | 13 K(?) (Nd0.8Sr0.2FeAsO) [185] | no | 38 K (Ba0.6K0.4Fe2As2) [119] | no |

| Isoelectronic | no | no | no | 30 K (BaFe2(As0.68P0.32)2) [189] |

| 22 K (Ba(Fe0.56Ru0.44)2As2) [190] |

3.1.1.4. Properties

Compared to MgB2 and cuprates, IBSCs have several distinct characteristics. It is included in the unique characteristic of IBSCs that the Fe 3d multi-orbital form Fermi surface described in (b) and the parent material is the antiferromagnetic metal described in (c).

Generally, Tc decreases upon doping with magnetic impurities such as Fe, Ni, and Co. In the case of cuprate superconductors, Tc of YBa2Cu3O7−y decreases from 90 K to 50 K by substituting Ni (17%) for Cu, and that of La1.85Sr0.15CuO4−y also decreases from 40 K to 4.2 K by substituting Ni (5%) for Cu [191]. The substitution of such elements for Fe on FeSCs with an optimal state shows a similar trend. The superconductivity of NdFeAsO0.89F0.11 (Tc = 48 K) disappears by substituting Co (>11%) or Mn (>4%) [192]. In contrast, the emergence of superconductivity by substitution of Co2+ (3d7), Ni2+ (3d8) or other transition metals for Fe2+ (3d6) in the non-superconducting parent material described in (c) is also a unique nature for IBSC.

The high Tc, large upper critical field (Hc2) and small anisotropy are important merits in applying IBSCs practically. Table 5 summarizes these values of IBSCs along with those of MgB2 and cuprates. Only cuprates achieve higher Tc than the boiling point of liquid N2 (77 K). It has been reported that the anisotropic ratio of the resistivity (γρ) of the 122-type IBSCs is compatible with that of MgB2 and smaller than that of cuprates. The Hc2(0) of IBSCs is higher than that of MgB2, but is smaller than that of a typical cuprate. The anisotropic ratio of the Hc2, γH, of IBSCs is smaller than those of MgB2 and cuprates. The Hc2(0) is defined as the upper critical field at 0 K. The γρ means the ratio of the resistivity along the crystal axes directions, a (ρ(a)) and c (ρ(c)) measured just above Tc. The application of IBSCs to superconducting wires and devices will be described in section 4.

Table 5.

Properties of high Tc superconductors.

| IBSCs | MgB2 | Cuprates | |

|---|---|---|---|

| Parent material | antiferromagnetic metal (TN ∼ 150 K) (excepting for the 245-type) | non-magnetic metal | antiferromagnetic insulator (TN ∼ 400 K) |

| Orbitals composing Fermi level | five Fe 3d orbitals | two B2p orbitals | single Cu3d orbital |

| Tc | 56 K (Gd0.8Th0.2SmFeAsO) [118] | 39 K (pure MgB2) [196] | 92 K (YBa2Cu3O7−δ,) [199] |

| 38 K (Ba0.6K0.4Fe2As2) [119] | 105 K (Bi2Sr2Ca2Cu3O10) [200] | ||

| 134 K (HgBa2Ca2Cu3O8) [201] | |||

| Hc2(0)//ba | ∼90 T ((Ba0.55K))Fe2As2) [193] | ∼40 T (MgB1.87C0.13) [197] | 210 T (YBa2Cu3O7−δ,) [202] |

| ∼150 T (SmFeAsO0.7F0.25) [193] | ∼18 T (pure MgB2) [197] | 400 T (Bi2Sr2CaCu2O8) [202] | |

| γρ = ρ(c)/ρ(ab) | 3–5 (Ba(Fe0.936Co0.074)2As2) [194] | ∼3.5 (pure MgB2) [198] | 30-250 (YBa2Cu3O7−δ,) [203–205] |

| 8-10 (SmFeAsO0.7F0.25) [94] | >1000 (Bi2Sr2CaCu2O8) [206] | ||

| γH=Hc2(0)//b/Hc2(0)//c | 1.1-1.2 ((Ba0.55K))Fe2As2) [193] | ∼4 (MgB1.87C0.13) [197] | 6 (YBa2Cu3O7−δ,) [202] |

| ∼1.5 (SmFeAsO0.7F0.25) [195] | ∼6 (pure MgB2) [197] | 21 (Bi2Sr2CaCu2O8) [202] |

Hc2(0)//ab: estimated by extrapolating the Hc2-T curve, where Hc2 is measured by applying a magnetic field along the ab plane.

3.1.2. Hydrogen as an electron donor

The most effective route to achieve high Tc is ‘indirect’ and ‘electron’ doping into the 1111-type (see table 4). As mentioned in the previous section, the solubility limit of F, which is used for the ‘indirect’ and ‘electron’ dopant, is 20% at most. Thus, one could not know the effect on the emergence of SC by the impurity doping for its whole SC dome. So we have explored an appropriate dopant with high solubility limit.

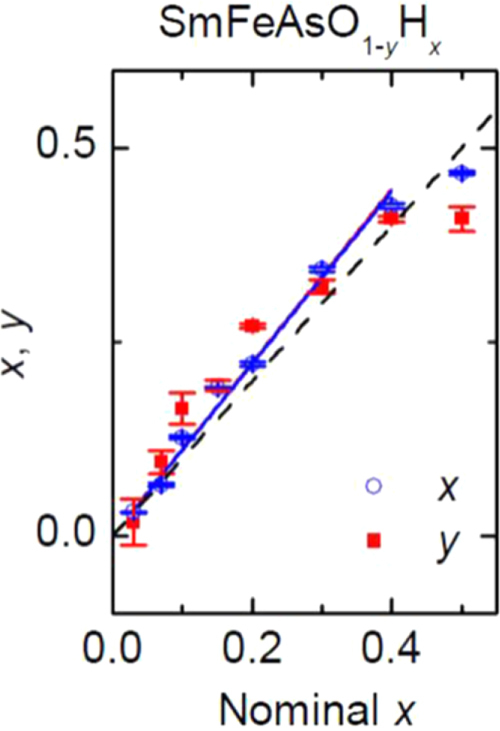

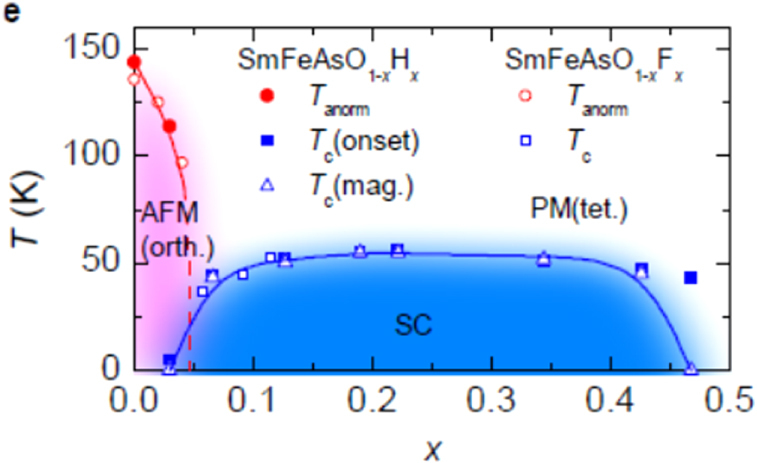

Out of some candidates of monovalent anions ( we choose the hydride ion (H−) as an electron dopant which could substitute for O2− [9, 12]. Though it is generally considered that the ionic state of hydrogen is a proton (H+) in condensed matter, hydrogen is also present as the hydride ion (H−) in stable materials such as LaH2, CaH2 and NaH. Its ionic radius depends on the environment, i.e., 208 pm in Pauling’s estimation, 129 pm in NaH and 106 pm in CaH2. We considered that H− should be able to dissolve into 1111-type superconductors with replacement of O2− because the blocking layer is composed of a lanthanide cation which can form stable hydrides. To prevent the evaporation of hydrogen during the preparation process, we employed a high pressure synthesis technique, i.e., under 2 GPa at 1200 °C. The experimental results clearly showed a high solubility limit of H− doping. While the impurity phases as SmAs and/or SmOF precipitate in SmFeAsO1−xFx (x > 0.15) [207, 208], such phases could not be observed in SmFeAsO1−xHx (x ≤ 0.4). Figure 5 compares the hydrogen content (x) and the deficient amount of oxygen (y) in the prepared samples per the chemical formula (SmFeAsO1−yHx) as a function of nominal x in the starting mixture [9]. The former value was determined by TG-MS, and the latter was measured using EPMA. For nominal x ≤ 0.4, the hydrogen content agrees with y and the nominal x, indicating the oxygen site (O2−) was successfully substituted with hydrogen (H−). Figure 6 shows the electronic phase diagram of SmFeAsO1−xHx superimposed with that of SmFeAsO1−xFx, with the fluorine content x measured by EPMA as reported by Köhler and Behr [207], in which the Tc versus x plots of SmFeAsO1−xHx and SmFeAsO1−xFx overlap at x < 0.15, indicating that hydrogen gives indirect electron doping to the FeAs layer just like fluorine. While the solubility limit of fluorine in the oxygen site is restricted to less than 20% (x = 0.2) [172, 207, 208], that of hydrogen can reach 40% for not only Sm-1111 but also all Ln-1111 compounds. The wider substitution range is useful for the optimization of the electron-doping level to induce superconductivity and to complete the electronic phase diagram, including the overdoped region.

we choose the hydride ion (H−) as an electron dopant which could substitute for O2− [9, 12]. Though it is generally considered that the ionic state of hydrogen is a proton (H+) in condensed matter, hydrogen is also present as the hydride ion (H−) in stable materials such as LaH2, CaH2 and NaH. Its ionic radius depends on the environment, i.e., 208 pm in Pauling’s estimation, 129 pm in NaH and 106 pm in CaH2. We considered that H− should be able to dissolve into 1111-type superconductors with replacement of O2− because the blocking layer is composed of a lanthanide cation which can form stable hydrides. To prevent the evaporation of hydrogen during the preparation process, we employed a high pressure synthesis technique, i.e., under 2 GPa at 1200 °C. The experimental results clearly showed a high solubility limit of H− doping. While the impurity phases as SmAs and/or SmOF precipitate in SmFeAsO1−xFx (x > 0.15) [207, 208], such phases could not be observed in SmFeAsO1−xHx (x ≤ 0.4). Figure 5 compares the hydrogen content (x) and the deficient amount of oxygen (y) in the prepared samples per the chemical formula (SmFeAsO1−yHx) as a function of nominal x in the starting mixture [9]. The former value was determined by TG-MS, and the latter was measured using EPMA. For nominal x ≤ 0.4, the hydrogen content agrees with y and the nominal x, indicating the oxygen site (O2−) was successfully substituted with hydrogen (H−). Figure 6 shows the electronic phase diagram of SmFeAsO1−xHx superimposed with that of SmFeAsO1−xFx, with the fluorine content x measured by EPMA as reported by Köhler and Behr [207], in which the Tc versus x plots of SmFeAsO1−xHx and SmFeAsO1−xFx overlap at x < 0.15, indicating that hydrogen gives indirect electron doping to the FeAs layer just like fluorine. While the solubility limit of fluorine in the oxygen site is restricted to less than 20% (x = 0.2) [172, 207, 208], that of hydrogen can reach 40% for not only Sm-1111 but also all Ln-1111 compounds. The wider substitution range is useful for the optimization of the electron-doping level to induce superconductivity and to complete the electronic phase diagram, including the overdoped region.

Figure 5.

Oxygen deficiency content determined by EPMA (y) and hydrogen content estimated by TG-MS (x) in SmFeAsO1–yHy as a function of nominal x in the starting mixture. The measured x is almost equal to y and nominal x, indicating that the deficiency of the oxygen site is wholly compensated for by the occupation of hydrogen. Reprinted with permission from [9]. Copyright 2011 by the American Physical Society.

Figure 6.

x–T diagram of SmFeAsO1–xHx superimposed by that of SmFeAsO1–xFx. Reprinted with permission from [9]. Copyright 2011 by the American Physical Society.

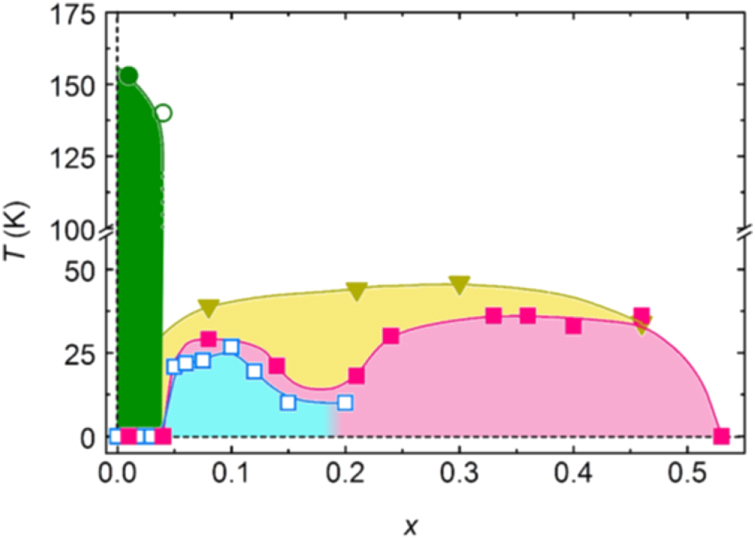

The unique feature of revealed SC is observed in LaFeAsO1−xHx [11]. While Tc–x plots for LnFeAsO1−xHx (Ln = Ce, Sm, Gd) exhibit a single Tc dome as shown in figure 6 (for Sm), LaFeAsO1−xHx has a two Tc dome structure (see figure 7). When the amount of dopant (x) is increased, the SC emerged from x > 0.04, Tc increased and reached a maximum at x = 0.1 (Tc = 26 K) and then decreased for a while. Surprisingly after reaching the minimum at x = 0.2, Tc increased again and showed a broad peak (maximum Tc = 36 K at x = 0.35), which could not be attained by F-doping. The two domes merged into a wider single dome with the optimal Tc (=45 K at x = 0.3) by applying a high pressure of 3 GPa. The characteristics of these two Tc domes in LaFeAsO1−xHx are listed in table 6.

Figure 7.

Electronic phase diagram for LaFeAsO1−xHx (filled symbols) and LaFeAsO1−xFx (open symbols). The Tc under ambient pressure (squares) and 3 GPa (inverted triangles) was determined from the intersection of the two extrapolated lines around the superconducting transition and Ts (circles) was taken as the anomaly kink in the resistivity-temperature (ρ–T) curve. Reprinted with permission from Macmillan Publishers Ltd: [11], Copyright 2012.

Table 6.

Characteristics of two domes in LaFeAsO1−xHx.

| Dome | First | Second |

|---|---|---|

| x | 0.05 ≤ x ≤ 0.2 | 0.2 ≤ x ≤ 0.5 |

| Exponent, n | 0.0 ≤ n ≤ 2.3 | 0.7 ≤ n ≤ 2.0 |

| Tcmax | 29 K | 36 K |

| Tc sensitivity to x | High | Low |

| Under high pressure | Unified | Unified |

| FS nesting between hole and electron pockets | Strong | Weak |

| DOS(EF) | No shoulder | Shoulder |

The exponent (n) was estimated from the curve fitting of ρ-T plots to ρ = ATn+ρ0 near Tc.

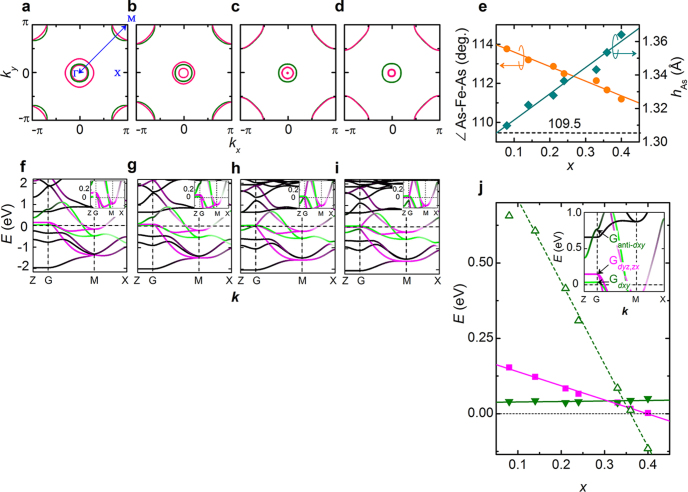

Iimura et al, who found this two dome structure, considered initially that the superconductivity in the low x region (first dome) was due to the spin fluctuation mechanism and that in the high x region (second dome) was due to the orbital fluctuation mechanism. Their density functional theory (DFT) calculations showed the strong FS nesting between the hole (at Γ point) and the electron (at M point) pockets at the low x region, which was the most important glue in the spin fluctuation model (see figures 8(a)–(h)). On the other hand, the FS nesting weakened with increasing x, while the difference between the energy levels of Fe 3d bands (3dxy, 3dyz, and 3dxx) decreased and became almost zero (degeneracy) at x = 0.30–0.35 where the maximum Tc of the second dome occurs (see figure 8(i)).

Figure 8.

Electronic structure of LaFeAsO1−xHx. (a)–(d) Two-dimensional Fermi surface of LaFeAsO1−xHx with x = 0.08 (a), 0.21 (b), 0.36 (c) and 0.40 (d). The blue arrow represents the nesting vector in the (π–π) direction. The contribution of Fe-dxy and dyz,zx orbitals are colored green and pink, respectively. (f)–(i) Band structures of LaFeAsO1−xHx with x = 0.08 (f), 0.21 (g), 0.36 (h) and 0.40 (i). Insets show close-up views of the low energy region. The contribution of Fe-dxy and dyz,zx orbitals are colored green and pink, respectively. (j) Variation in energy level of relevant Fe 3d bands at G point with x. The inset is the band structure of LaFeAsO0.92H0.08. The  (filled green inverted triangles) and Ganti−dxy (open green triangles) signify the bonding and anti-bonding states, respectively, for a bond primary composed of two Fe-dxy orbitals in a unit cell. Also shown is the energy level of degenerate dyx,zx band (Gdyz,zx indicated by filled pink squares). The solid and dashed lines are as a visual guide. Reprinted with permission from Macmillan Publishers Ltd: [11], Copyright 2012.

(filled green inverted triangles) and Ganti−dxy (open green triangles) signify the bonding and anti-bonding states, respectively, for a bond primary composed of two Fe-dxy orbitals in a unit cell. Also shown is the energy level of degenerate dyx,zx band (Gdyz,zx indicated by filled pink squares). The solid and dashed lines are as a visual guide. Reprinted with permission from Macmillan Publishers Ltd: [11], Copyright 2012.

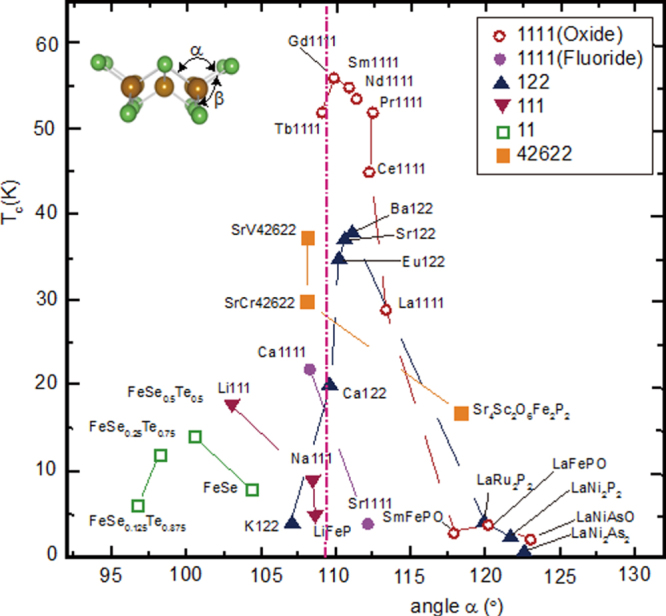

The importance of degeneracy in IBSCs is deduced from the empirical plots reported by Lee et al, where the more the bonding angle of As–Fe–As (α: see figure 1(b)) is near 109.5° (regular FeAs4 tetrahedron), the higher the Tc revealed [209]. The regular FeAs4 tetrahedron is achieved by the degeneracy of Fe 3d bands and hence it should be reasonable to consider that the orbital fluctuation mechanism to mediate superconductivity emerges effectively in such a condition. The effect of the degeneracy of Fe 3d bands for the emergence of superconductivity is clear from the comparison of a lanthanide cation substituted with La. The α of the parent phases of LnFeAsO1−xHx are 114° (La), 112° (Ce), 111° (Sm) and 110° (Gd) and these values increase with doping of F or H. As shown in figure 9, the material of which α is close to 109.5° achieves the degeneracy of Fe 3d bands and regular tetrahedral structure by a small amount of doping and shows Tc maximum simultaneously. From this viewpoint, Iimura et al proposed that the high Tc of 1111-type superconductors was mainly due to the orbital fluctuation mechanism.

Figure 9.

Correlation between Tc and bonding angle α of Pn(Ch)–Fe–Pn(Ch). α is adopted mainly from the data of the parent materials measured at room temperature. Tc shows the highest reported value. Reprinted with permission from [125]. Copyright 2012 by Maney Publishing.

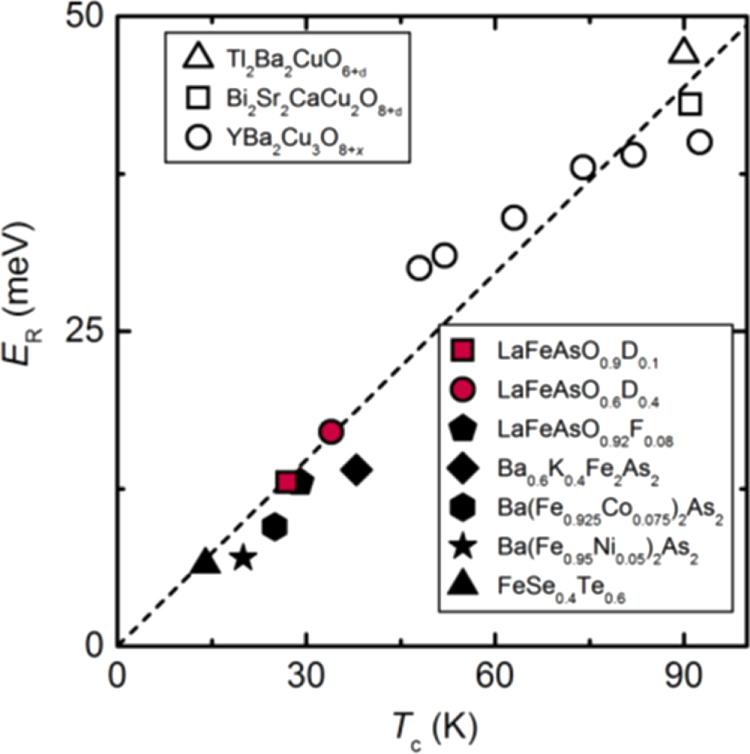

On the other hand, the experimental result using inelastic neutron scattering for LaFeAsO1−xDx suggested the presence of spin fluctuation in both low and high x superconducting regions with different wave number [210]. Such spin fluctuation disappeared at the boundary of x = 0.2. The relationships between Tc and ER of several cuprate materials and IBSCs containing these two regions are plotted in figure 10, where ER is the measured value indicating the strength of spin fluctuation. For superconductors deriving from the spin fluctuation mechanism, it is known that the value of ER/kBTc is 4–6. As shown in figure 10, all plots line up roughly on the straight line with the gradient of 5.7, which indicates that the spin fluctuation mechanism acts primarily to reveal superconductivity in not only the low x but also the high x region. The theoretical calculations based on the random-phase approximation indicate that the spin fluctuations at x = 0.1 are due to intra-orbital nesting within Fe 3dyz,zx, whereas the spin fluctuations at x = 0.4 originate from intra-orbital nesting within Fe 3dx2−y2. These results suggest that the orbital multiplicity plays an important role in the doping and/or material dependence of Tc of the IBSCs.

Figure 10.

The Tc dependence of ER in iron pnictides (filled symbols) and cuprates (open symbols). The red square and circles are the present data for the samples with x = 0.1 and 0.4, respectively. The dashed line is the averaged slope of 5.7kBTc. Reprinted with permission from [210]. Copyright 2013 by the American Physical Society.

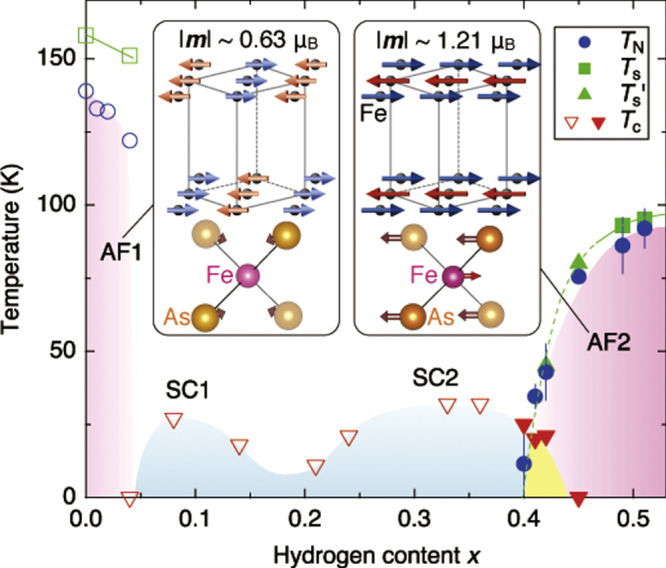

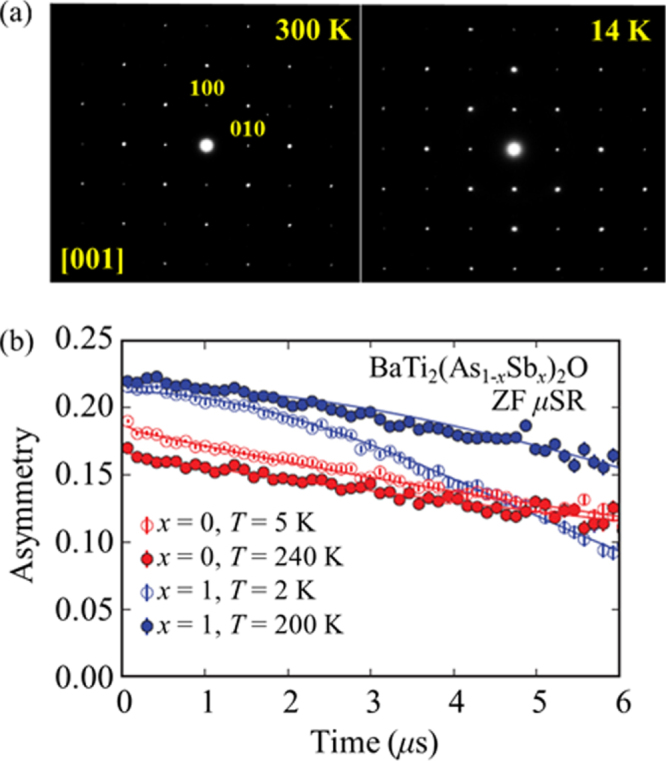

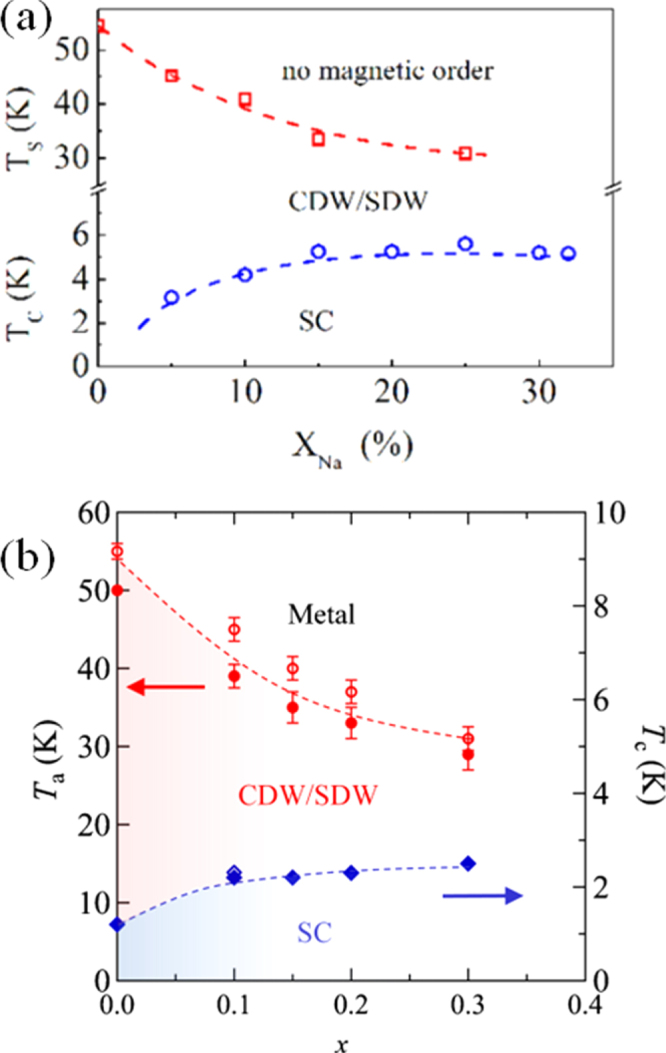

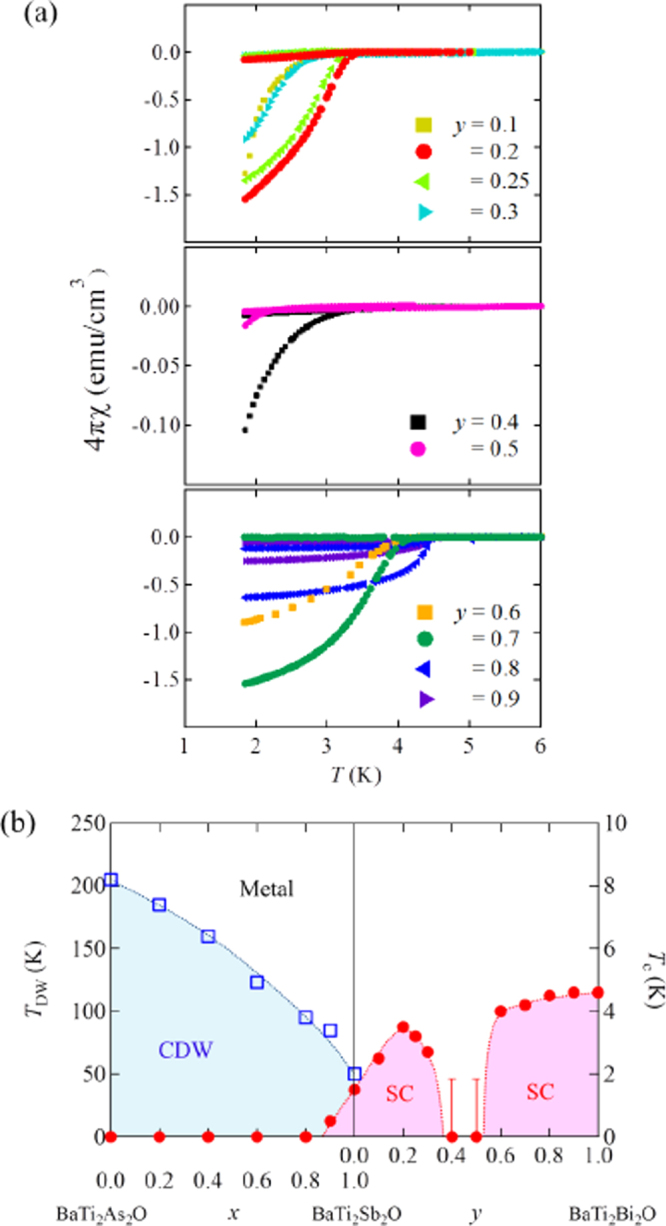

The discovery of a two-SC-dome structure implies the existence of responsible two parent materials. Hiraishi et al found a parent phase in the high x region with different magnetic structure from that on x = 0 using the multi-probe method composed of neutron, muon and synchrotron x-ray beams complementarily [211]. It was clarified by the muon spin relaxation (μSR) that new magnetic ordering phase developed with increasing dopant over x ∼ 0.4. From the experimental results using neutron and synchrotron x-ray diffraction, it was identified that this magnetic phase has a different antiferromagnetic ordering from that on x = 0 and the structural transition occurs at x ∼ 0.5 where the magnetic transition temperature shows maximum. Such features are shown in figure 11. This new magnetic phase is tentatively assigned to the parent phase in the high x region.

Figure 11.

Magnetic, structural and superconducting phase diagram of LaFeAsO1−xHx. The original parent compound with x = 0 exhibits a structural transition at Ts = 155 K, followed by an antiferromagnetic state (AF1) at TN = 137 K. With increasing x, two superconductivity domes appear: 0.05 ≤ x ≤ 0.20 (SC1) with Tc,max = 26 K, and 0.20 ≤ x ≤ 0.42 (SC2) with Tc,max = 36 K. Eventually, another antiferromagnetic phase (AF2) appears in the range 0.40 ≤ x ≤ 0.51. In the advanced parent compound at x = 0.51, structural and magnetic transitions occur at Ts ∼ 95 K and TN = 89 K, respectively. Ts’ indicates the c axis upturn temperature observed in x-ray measurements. The filled and open marks are obtained from the present and previous results, respectively. The magnetic structures of AF1 (left) and AF2 (right) are shown with their magnetic moments m, where the solid lines represent the tetragonal cell. The displacements of the Fe and As atoms across the structural transitions are schematically described by the arrows on the FeAs4 tetrahedra from the view of the orthorhombic long axis, in which the Fe and As atoms move by 0.07 Å (0 Å) and 0.06 Å (0.01 Å) in x = 0.51 (x = 0), respectively. The error bars represent the uncertainty in the least-squares fitting routines. Reprinted with permission from Macmillan Publishers Ltd: [211], Copyright 2014.

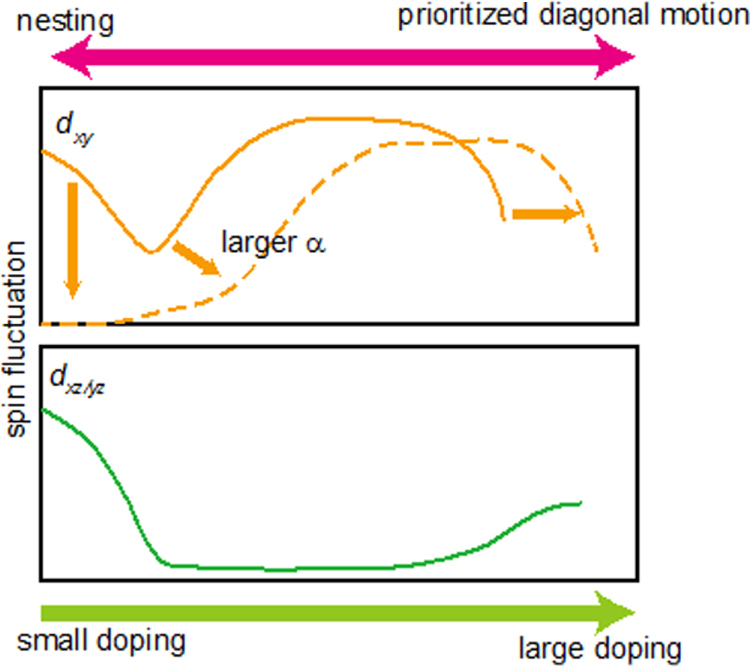

In theoretical approach, Suzuki et al successfully explained the composition dependence for LnFeAsO1−xHx (Ln: La, Ce, Sm, Gd) [169]. They showed that, besides the Fermi surface nesting, a peculiar motion of electrons, where the next nearest neighbor (diagonal) hopping between iron sites dominates over nearest neighbor ones, plays an important role in the enhancement of the spin fluctuation and thus superconductivity. According to their explanation, the crossover between the Fermi surface and this ‘prioritized diagonal motion’ regime occurs smoothly with doping in the Ce, Sm and Gd case, while the two regimes are separated to give a double dome Tc phase diagram in the La case. The feature of this change is schematically drawn in figure 12.

Figure 12.

Schematic figure of the spin fluctuation contribution to superconductivity. Reprinted with permission from [169]. Copyright 2014 by the American Physical Society.

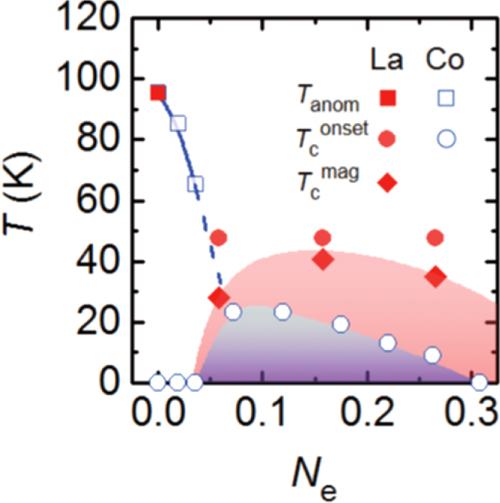

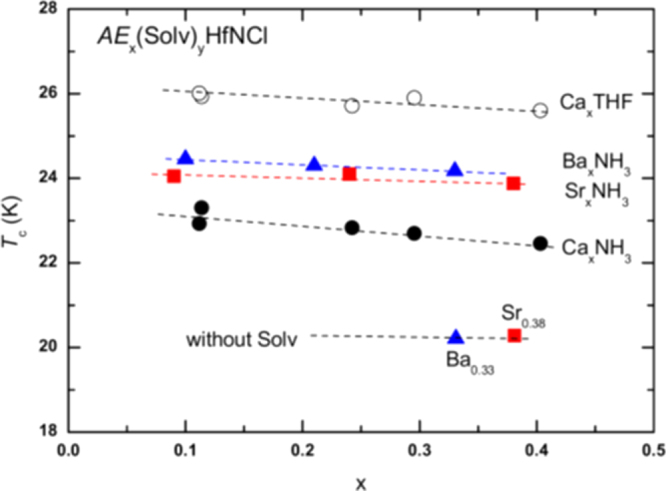

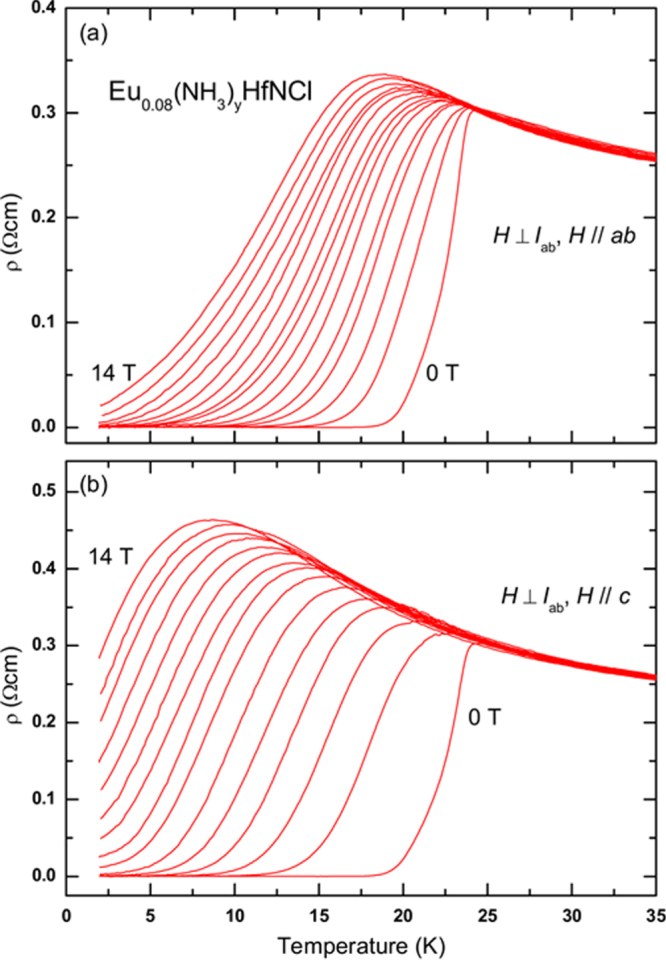

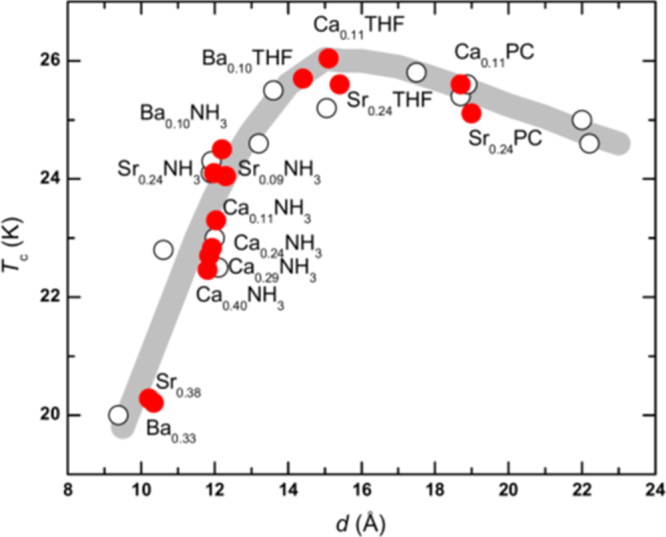

The hydrogen doping technique was applied to the alkaline earth metal 1111-type materials, such as CaFeAsF. It reveals superconductivity by replacing Fe with Co (Tc = 26 K) [137]. Hanna et al realized the electron doping by partially replacing F with H and heating them in He to selectively eliminate H as CaFeAsF1−xHx → CaFeAsF1−x + x/2H2 [18]. The Tc of 29 K was attained by forming an F vacancy (20% of the F site). In the case of direct electron doping into CaFeAsH, the substitution of Fe with Co led this material to become a superconductor (max Tc = 29 K) [16]. Indirect electron doping (substitution of Ca with La) showed higher Tc than that of Co doping as shown in figure 13 [17]. The material obtained by substitution of 20% of Ca with La showed the highest Tc (47 K) in IBSCs without a rare-earth element as the main component.

Figure 13.

(a) Electronic phase diagram of Ca1−xLaxFeAsH1−yOy as a function of the total number of doped electrons per iron (Ne = x–y), superimposed on that of CaFe1−xCoxAsH. Reprinted with permission from [17]. Copyright 2014 by the Physical Society of Japan.

3.1.3. Rare-earth doped 122 iron arsenides

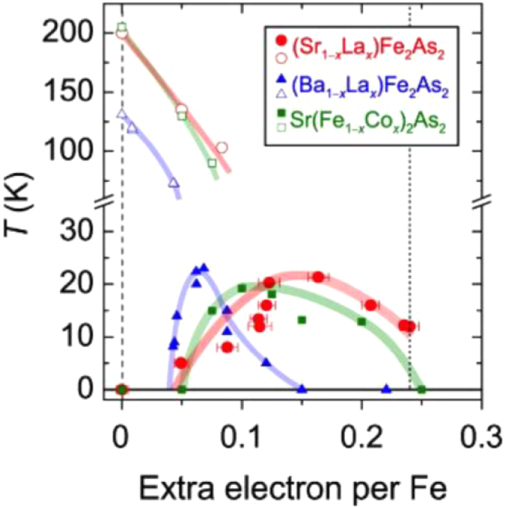

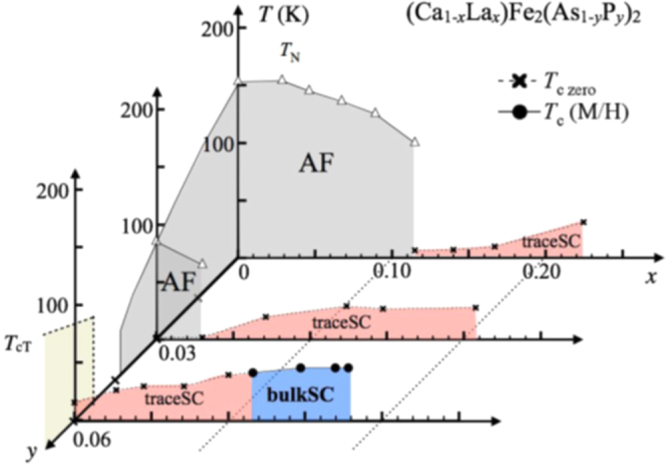

Rare-earth (RE) doping of 122-type iron arsenides has been intensively studied as part of the FIRST Project. The major achievements in this regard include the high-pressure synthesis of (Sr1–xLax)Fe2As2 with a maximum Tc of 22 K [19] and the growth of thin films of (Sr1–xLax)Fe2As2 (maximum Tc = 20.8 K) [22] and (Ba1–xLax)Fe2As2 (maximum Tc = 22.4 K) by pulsed laser deposition (PLD) [20, 21]. Further, (Ba1–xREx)Fe2As2 with RE = Ce, Pr and Nd has also been obtained by means of a nonequilibrium film growth process [21]. The success of RE doping enabled us to compare the phase diagrams of electron (La) and hole (K) doped BaFe2As2 as well as those of indirectly (La or K) and directly (Co) doped BaFe2As2. Another achievement is the simultaneous La and P doping of CaFe2As2 [23]: melt-grown crystals of (Ca1–xLax)Fe2(As1–y Py)2 exhibited bulk superconductivity with a maximum Tc of 45 K for 0.12 ≤ x ≤ 0.18 with y = 0.06, while (Ca1–xLax)Fe2As2 without phosphorus exhibited filamentary superconductivity [23]. Characteristic two-dimensional Fermi surfaces were observed by means of angle-resolved photoemission spectroscopy (ARPES) in the 45 K phase of La- and P-doped CaFe2As2 [212].

To induce superconductivity in 122-type AEFe2As2 (where AE = alkaline-earth elements), both types of doping carrier, i.e., holes and electrons, are typically used by substituting appropriate aliovalent elements, which include alkali metals (A) such as K, which substitute for AE sites as in hole-doped (Ba1–xKx)Fe2As2 [119], and transition metals (TM) such as Co, which substitute for Fe sites as in electron-doped Ba(Fe1–xCox)2As2 [186, 193]. The doping can be classified into two types for the 122-type AEFe2As2, namely, ‘indirect doping’ for doping at sites other than the Fe sites and ‘direct doping’ for doping at the Fe sites [21]. Because the superconducting FeAs and intermediary AE layers are spatially separated, direct doping has a major influence on carrier transport and thus superconductivity. Tables 7 and 8 summarize the maximum Tc of directly doped AE(Fe1–x TMx)2As2 and indirectly doped (AE1–xAx)Fe2As2, respectively. The indirectly hole-doped (Ba1–xKx)Fe2As2 exhibits a maximum Tc of 38 K, which is considerably higher than those for directly electron-doped AE(Fe1–xTMx)2As2. Therefore, we expected that a new indirect ‘electron’ doping at the AE sites for AEFe2As2 would lead to high-Tc superconductivity, as expected from the markedly higher Tc observed for indirectly electron-doped SmFeAs(O1–xFx) (55 K) [115] than that for directly electron-doped Sm(Fe1–xCox)AsO (17 K) [232].

Table 7.

The maximum superconducting transition temperature Tc (K) of transition metal (TM)-doped AE(Fe1–xTMx)2As2, where AE=Ca, Sr and Ba; and TM=Co, Ni, Ru, Rh, Pd, Ir and Pt. For instance, Tc = 20 K for Ca(Fe1–xCox)2As2. Pt-doped Ca(Fe1–x Ptx)2As2 does not exhibit superconductivity [75].

Table 8.

The maximum superconducting transition temperature Tc (K) of the alkali metal (A)-doped (AE1–x Ax)Fe2As2, where AE=Ca, Sr and Ba; and A=Na, K, Rb and Cs.

However, indirect electron doping of Sr(Ba)Fe2As2 by substituting the divalent Sr(Ba) sites with trivalent RE ions was difficult to perform by means of conventional solid-state reactions. While Muraba et al [19] and Wu et al [233] examined the La substitution for SrFe2As2 and BaFe2As2, respectively, solid-state reactions of the ingredient mixture for (Sr1–xLax)Fe2As2 or (Ba1–xLax)Fe2As2 did not yield the La-substituted 122 phase upon using the conventional glass-tube technique.

In contrast, the indirect RE doping of CaFe2As2 was possible by a conventional melt-growth technique for RE = La, Ce, Pr and Nd [234–237]. These materials exhibited superconductivity at Tc = 40–49 K: Saha et al [234] reported Tc = 47 K in (Ca1–xPrx)Fe2As2; Gao et al [235] reported Tc = 42.7 K in (Ca1–xLax)Fe2As2; and Lv et al [236] reported Tc = 49 K in (Ca1–xPrx)Fe2As2. These values of Tc are considerably higher than those reported for directly electron-doped Ca(Fe1–xTMx)2As2 and indirectly hole-doped (Ca1–xAx)Fe2As2 listed in tables 7 and 8, respectively. However, the shielding volume fractions of RE-doped CaFe2As2 were as low as <1% at 40 K [234, 235] or the shielding signal around 40 K was completely suppressed by the application of a weak magnetic field of 20 Oe [236].

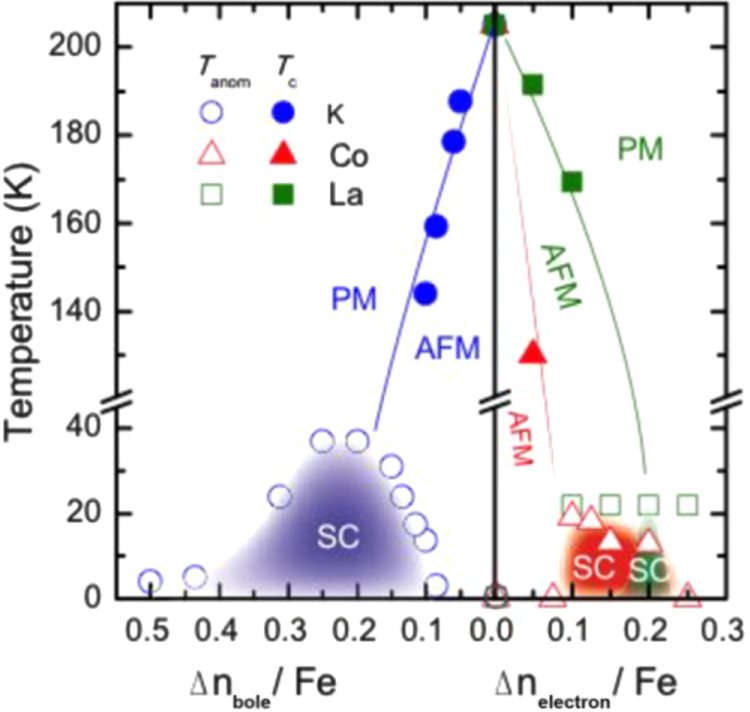

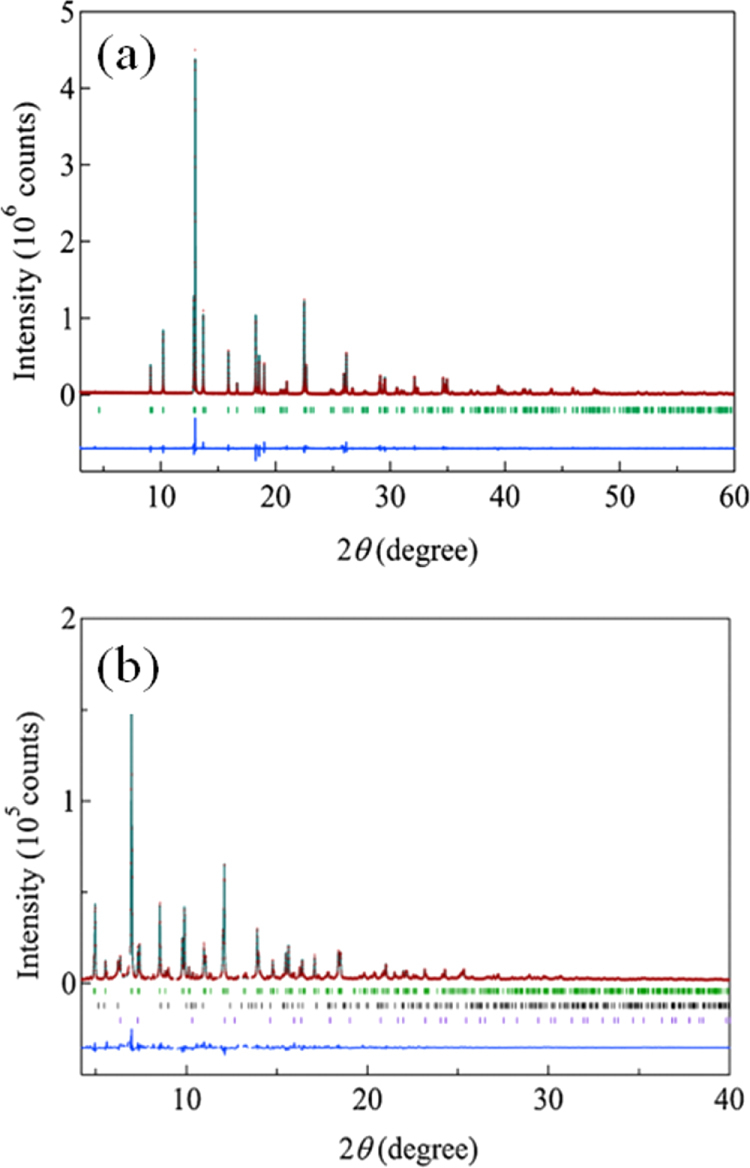

Under such circumstances, Muraba et al have succeeded in the indirect La doping of SrFe2As2 by applying a high-pressure synthesis process to obtain (Sr1–xLax)Fe2As2 polycrystals [19]. The ionic radius of La3+ (116 pm) is smaller than that of Sr2+ (126 pm) and therefore, it is natural that high-pressure synthesis is effective for obtaining La-substituted SrFe2As2. Muraba et al used a belt-type anvil cell to generate a pressure of 2 or 3 GPa at 1000 °C for 2 h and obtained solid solutions of (Sr1–xLax)Fe2As2 for 0 ≤ x ≤ 0.5. Further, (Sr1–x Lax)Fe2As2 exhibited bulk superconductivity over a narrow range around x = 0.4. The almost x-independent Tc (shown in figure 14) suggested the inhomogeneous replacement of La dopants at the Sr sites. Figure 14 compares the electronic phase diagram of (Sr1–xLax)Fe2As2 [19] with those of Sr(Fe1–x Cox)2As2 [215] and (Sr1–xKx)Fe2As2 [229]. Here, the doped carrier number per Fe, i.e., Δn/Fe = x/2 for (Sr1–xLax)Fe2As2 and (Sr1–xLax)Fe2As2 and Δn/Fe = x for Sr(Fe1–xCox)2As2, is plotted in place of the doping composition x. The directly electron-doped Sr(Fe1–xCox)2As2 exhibits superconductivity for 0.1 ≤ Δn/Fe ≤ 0.2 with a maximum Tc of 19 K at Δn/Fe ∼ 0.1, at which point the antiferromagnetic ordering vanishes [215]. The maximum Tc of the indirectly electron-doped (Sr1–xLax)Fe2As2 is slightly higher than but close to that of directly electron-doped Sr(Fe1–xCox)2As2. These results contrast markedly with the observed higher Tc and wider superconducting range of the direct hole-doped system (Sr1–x Kx)Fe2As2 (37 K) [228, 229], shown in figure 14, and (Sr1–x Csx)Fe2As2 (37 K) [228]. The superconducting dome continues to the end member of this family, i.e., KFe2As2 [228, 229] and CsFe2As2 [228] at Δn/Fe = 0.5.

Figure 14.

Electronic phase diagrams for electron-doped (Sr1–xLax)Fe2As2 [19] and Sr(Fe1–xCox)2As2 [215] and for hole-doped (Sr1–xKx)Fe2As2 [229]. The ratio Δnelectron/Fe and Δnhole/Fe denote the injected number of electrons and holes per Fe atom, respectively. Reprinted with permission from [19]. Copyright 2010 by the American Physical Society.

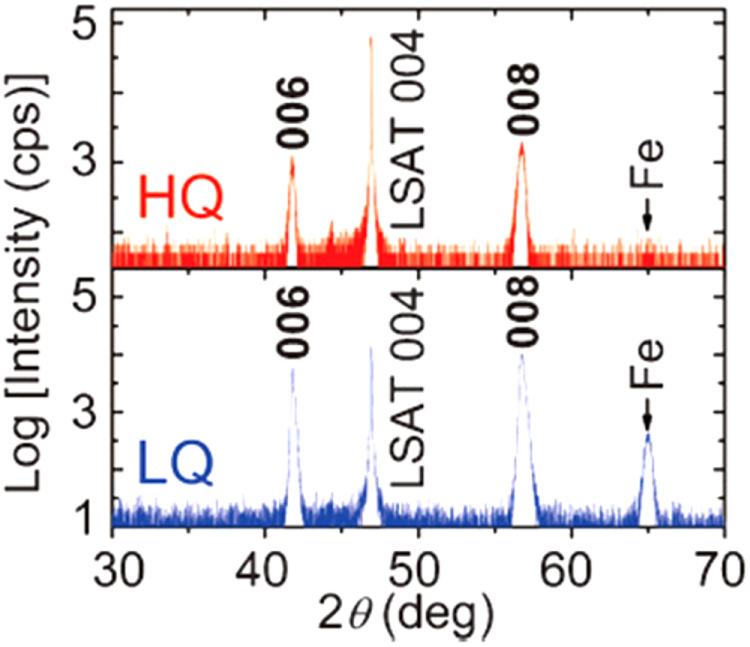

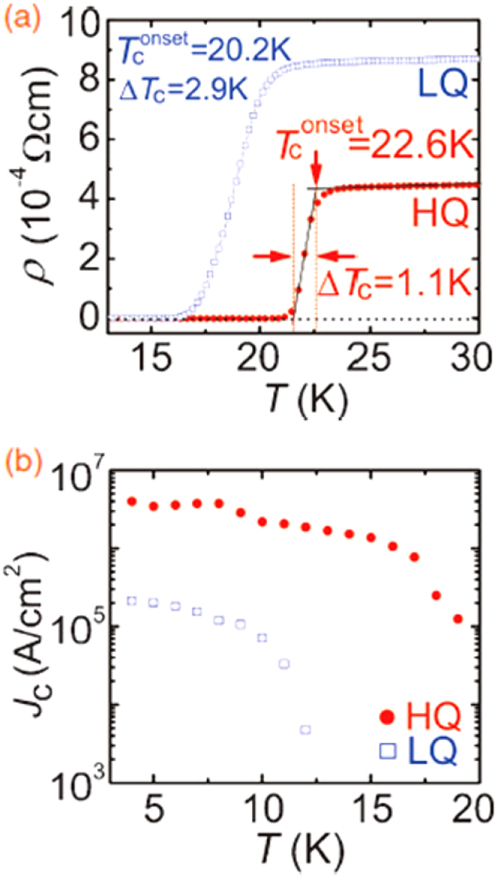

Another promising technique that we have developed for the indirect RE doping of SrFe2As2 and BaFe2As2 is the non-equilibrium pulsed laser deposition (PLD) method [20–22]. Hiramatsu et al [22] and Katase et al [20, 21] have succeeded in the homogeneous doping of RE dopants in the films fabricated by PLD, and they have reported observing a superconducting dome from underdoped to overdoped regions irrespective of the largely different ionic radii of Ba2+ (142 pm), Sr2+ (126 pm) and La3+ (116 pm). Here, we mention that CaFe2As2 epitaxial films could not be obtained by PLD [238]. Thin films of (Sr1–xLax)Fe2As2 (thickness = 200 nm) were grown on (La,Sr)(Al,Ta)O3 (LSAT) (001) single crystals at a film-growth temperature of 750 °C [22], while thin films of (Ba1–xREx)Fe2As2 (thickness = 150–250 nm) were grown on MgO (001) single crystals at an optimized film-growth temperature of 850 °C [20, 21]. Further, (Sr1–xLax)Fe2As2 thin films were successfully obtained for 0.0 ≤ x ≤ 0.48 and (Ba1–xLax)Fe2As2 for 0.0 ≤ x ≤ 0.44. The lattice parameters showed monotonic decrease with increasing x (La content), thereby indicating that the substitution of the La3+ ion for the Sr2+ and Ba2+ ions was achieved in the epitaxial films [20, 22]. Figure 15 shows the electronic phase diagrams of (Sr1–xLax)Fe2As2 [22] and (Ba1–xLax)Fe2As2 [20] epitaxial films. Here, the doped carriers per Fe (=x/2) for these two compounds are plotted for comparison with the phase diagram of the directly electron-doped Sr(Fe1–xCox)2As2 [215]. The antiferromagnetic ordering at Tanom, which is determined by the anomaly in resistivity, is suppressed as the La content (x) increases. The maximum onset superconducting transition temperatures  are 20.8 and 22.4 K at x/2 = 0.16 and 0.07 for (Sr1–xLax)Fe2As2 [22] and (Ba1–xLax)Fe2As2 [20], respectively. The maximum values of

are 20.8 and 22.4 K at x/2 = 0.16 and 0.07 for (Sr1–xLax)Fe2As2 [22] and (Ba1–xLax)Fe2As2 [20], respectively. The maximum values of  and the corresponding x values of (Sr1–xLax)Fe2As2 and (Ba1–xLax)Fe2As2 are very close to those reported for directly doped Sr(Fe1–xCox)2As2 [215] (shown in figure 15) and Ba(Fe1–xCox)2As2 [193] (not shown), respectively. In addition, the suppression rate of Tanom is similar for both compounds. These results sharply contrast with those of the 1111-type system, in which the maximum Tc of indirectly electron-doped SmFeAs(O1–xFx) (55 K) [115] is considerably higher than that for directly electron-doped Sm(Fe1–xCox)AsO (17 K) [232]. These results can yield a clue to elucidate the mechanism of superconductivity in iron-based materials.

and the corresponding x values of (Sr1–xLax)Fe2As2 and (Ba1–xLax)Fe2As2 are very close to those reported for directly doped Sr(Fe1–xCox)2As2 [215] (shown in figure 15) and Ba(Fe1–xCox)2As2 [193] (not shown), respectively. In addition, the suppression rate of Tanom is similar for both compounds. These results sharply contrast with those of the 1111-type system, in which the maximum Tc of indirectly electron-doped SmFeAs(O1–xFx) (55 K) [115] is considerably higher than that for directly electron-doped Sm(Fe1–xCox)AsO (17 K) [232]. These results can yield a clue to elucidate the mechanism of superconductivity in iron-based materials.

Figure 15.

Electronic phase diagrams of (Sr1–xLax)Fe2As2 [22] and (Ba1–xLax)Fe2As2 [20] epitaxial films. The Tanom and  values are indicated by open and closed symbols, respectively. Those of Sr(Fe1–xCox)2As2 [215] are shown for comparison. Reprinted with permission from [22]. Copyright 2013 by IEEE.

values are indicated by open and closed symbols, respectively. Those of Sr(Fe1–xCox)2As2 [215] are shown for comparison. Reprinted with permission from [22]. Copyright 2013 by IEEE.

Katase et al [21] have also succeeded in obtaining (Ba1–xREx)Fe2As2 thin films with RE = Ce, Pr and Nd with reduced solubility limits of x = 0.29, 0.18 and 0.13, respectively. Thin films of (Ba1–xREx)Fe2As2 exhibited superconductivity at 13.4, 6.2 and 5.8 K for Ce, Pr and Nd dopants, respectively [21]. The Tc values of RE-doped SrFe2As2 and BaFe2As2 are listed in table 9.

Table 9.

The maximum superconducting transition temperature Tc (K) of rare-earth (RE) doped (AE1–x REx)Fe2As2, where AE=Ca, Sr and Ba; and RE=La, Ce, Pr and Nd.

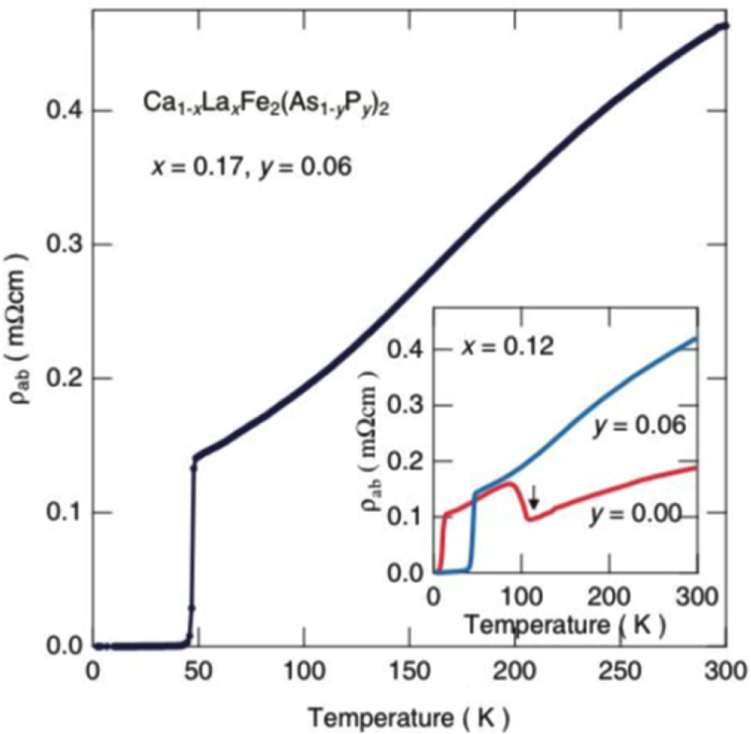

A conventional melt-growth method can be used to achieve indirect RE doping of CaFe2As2, although the obtained samples do not exhibit bulk superconductivity. In this project, two kinds of indirect doping, i.e., aliovalent La doping at the Ca sites and isovalent P doping at the As sites, were combined to induce bulk superconductivity in CaFe2As2 [23]. The substitution of aliovalent La for Ca resulted in electron doping without leading to a change in the lattice parameters because the ionic radius of La3+ (116 pm) and Ca2+ (112 pm) are similar, while the substitution of isovalent P for As resulted in a decrease in the lattice parameters without leading to a change in the number of carriers. This enabled us to tune the number of charge carriers and lattice parameters independently, and thus to optimize superconductivity in (Ca1–xLax)Fe2(As1–yPy)2, which resulted in bulk superconductivity at x = 0.17 and y = 0.06. The resistivity shows a sharp drop at 48 K and becomes zero at 45 K [23], as shown in figure 16. A clear diamagnetic signal, together with robust diamagnetism against the increase in magnetic field, is the reason for the bulk superconductivity at 45 K in this material [23]. Figure 17 shows the T–x–y phase diagram of (Ca1–xLax)Fe2(As1–yPy)2 [23]. Bulk superconductivity emerges in the range of 0.12 ≤ x ≤ 0.18 and y = 0.06.

Figure 16.

Temperature dependence of electrical resistivity ρab for (Ca1–xLax)Fe2(As1–yPy)2 (x = 0.17 and y = 0.06) [23]. The resistivity starts to decrease at a transition temperature  of 48 K and becomes zero below 45 K. The inset shows ρab for x = 0.12 and y = 0.00 and 0.06. The arrow indicates the antiferromagnetic/tetragonal–orthorhombic structural transition. Reprinted with permission from Macmillan Publishers Ltd: [23], Copyright 2014.

of 48 K and becomes zero below 45 K. The inset shows ρab for x = 0.12 and y = 0.00 and 0.06. The arrow indicates the antiferromagnetic/tetragonal–orthorhombic structural transition. Reprinted with permission from Macmillan Publishers Ltd: [23], Copyright 2014.

Figure 17.

T–x–y electronic phase diagrams for (Ca1–xLax)Fe2(As1–yPy)2. Tc(M/H) denotes the bulk superconducting transition temperature determined from the magnetization.  denotes the temperature below which the electrical resistivity becomes negligibly small. TN represents the antiferromagnetic and structural transition temperature. TcT denotes the transition temperature at which the high-temperature uncollapsed tetragonal (ucT) phase transforms into the low-temperature collapsed tetragonal (cT) phase. AF and SC indicate the antiferromagnetic and superconducting phases, respectively. Reprinted with permission from Macmillan Publishers Ltd: [23], Copyright 2014.

denotes the temperature below which the electrical resistivity becomes negligibly small. TN represents the antiferromagnetic and structural transition temperature. TcT denotes the transition temperature at which the high-temperature uncollapsed tetragonal (ucT) phase transforms into the low-temperature collapsed tetragonal (cT) phase. AF and SC indicate the antiferromagnetic and superconducting phases, respectively. Reprinted with permission from Macmillan Publishers Ltd: [23], Copyright 2014.

Angle-resolved photoemission spectroscopy (ARPES) [212] revealed that (Ca0.82La0.18)Fe2(As0.94P0.06)2 with Tc = 45 K possesses only cylindrical hole- and electron-like Fermi surfaces (FS). The size of the β hole-like FS is nearly the same as that of the ε electron-like FS, and both FS have a weak kz dispersion, thus giving rise to a quasi-nesting. This feature is similar to that for directly electron-doped Ba(Fe1–x Cox)2As2 (Tc = 23 K). Sunagawa et al [212] pointed out that a noticeable difference between (Ca0.82La0.18)Fe2(As0.94P0.06)2 and Ba(Fe1–xCox)2As2 is the dimensionality of the inner hole-like FS; the inner hole-like FS (α2) of the former shows a cylindrical shape, while that of the latter shows a strong kz dispersion and is closed near the Γ point. It has been suggested that the tendency toward quasi-nesting between α2 and β, together with β and ε, can induce high Tc in (Ca0.82La0.18)Fe2(As0.94P0.06)2 [212].

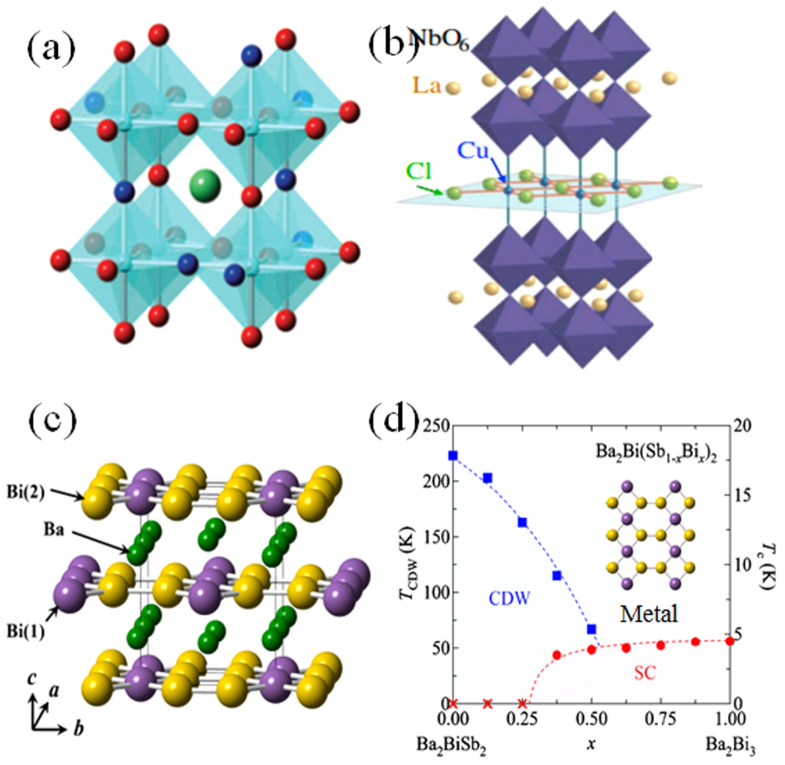

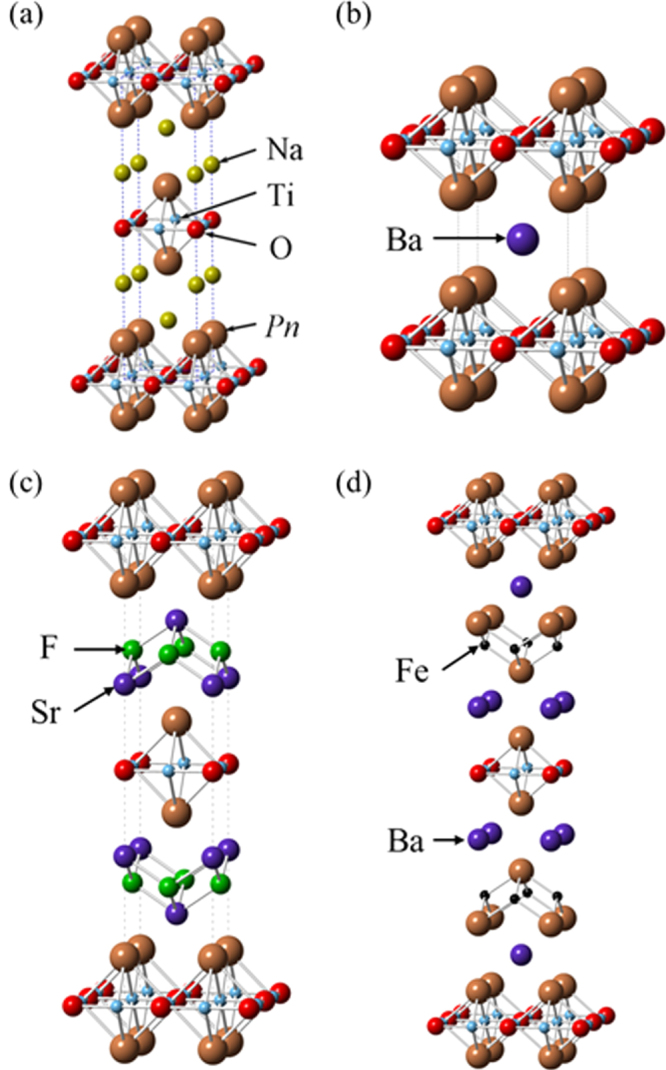

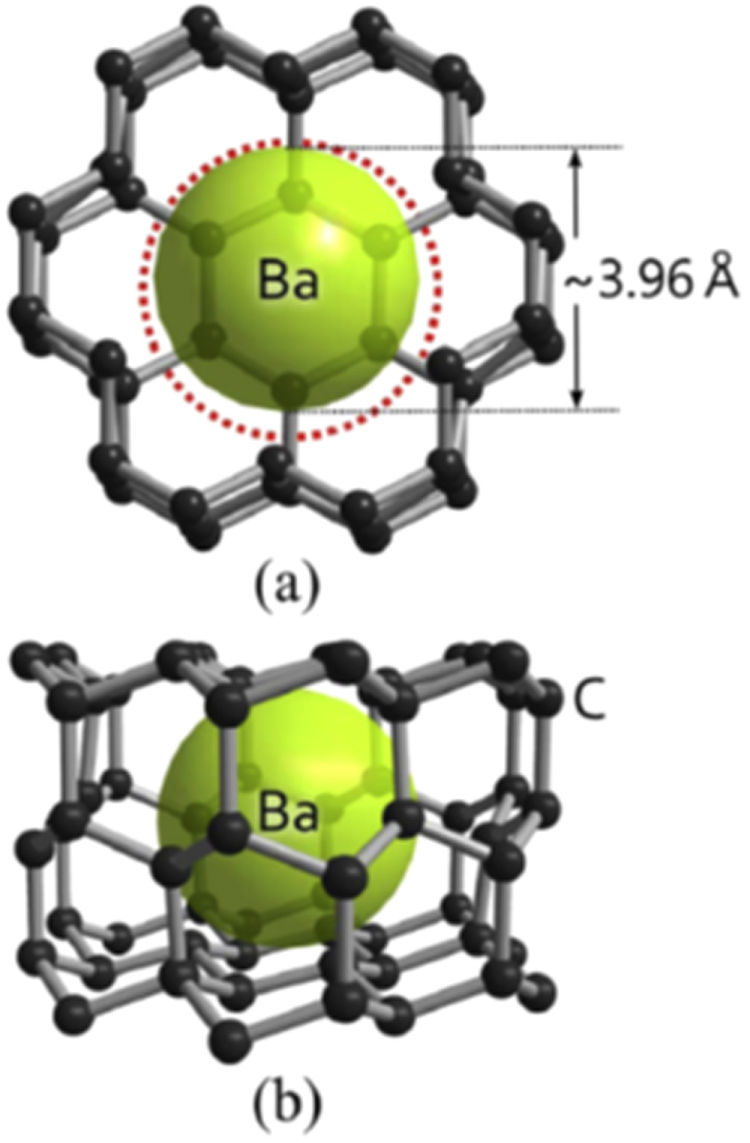

3.1.4. New type of 112 IBSC

The prominent achievements of the FIRST Project include the discovery of the 112-type iron arsenide superconductor (Ca1–xLax)FeAs2 [25], whose structure is shown in figure 18, and the enhancement of superconducting transition temperature Tc up to 47 K by the simultaneous La and Sb doping of the 112 phase [26, 27]. In this subsection, we overview the crystal structure and superconducting properties of the newly discovered 112 phase.

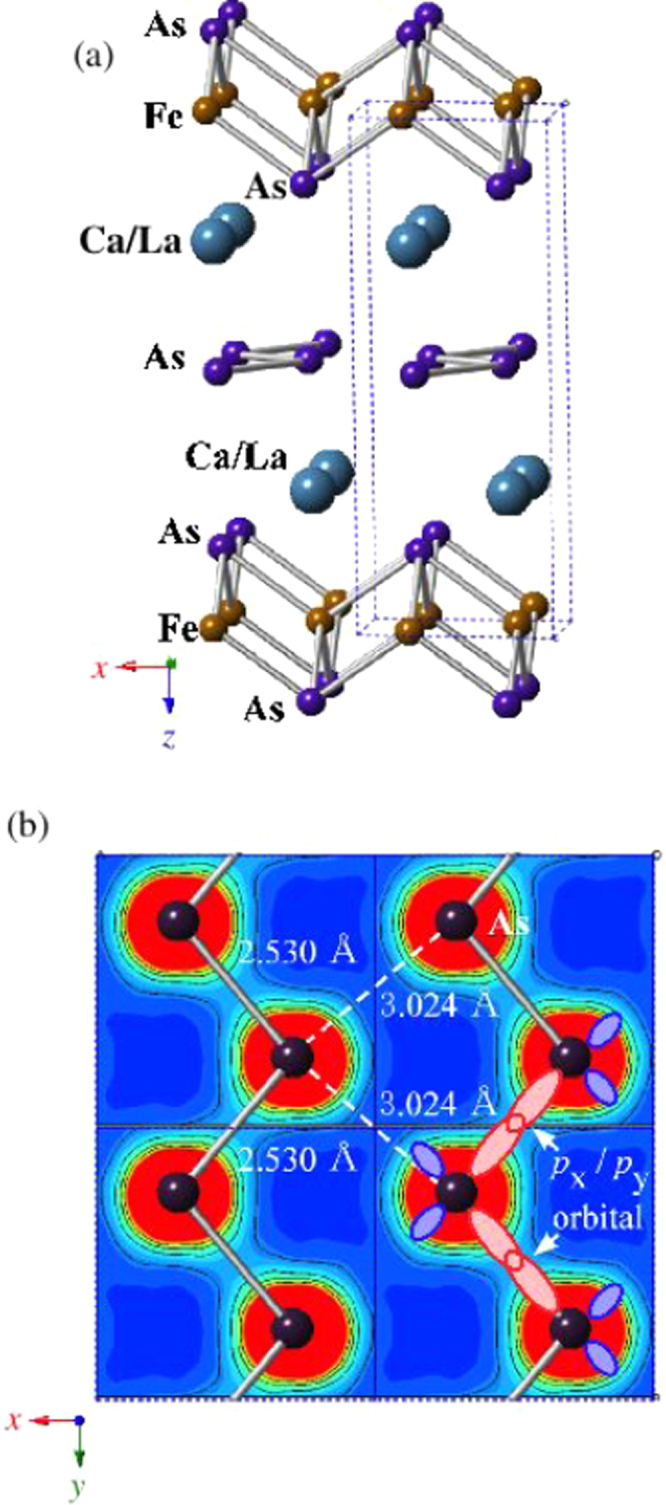

Figure 18.

(a) The crystal structure of (Ca1–xLax)FeAs2 (monoclinic, space group P21). (b) Top view of the arsenic zigzag chains. Arsenic 4px and 4py orbitals are schematically shown. The background color contour map shows the charge distributions obtained by synchrotron x-ray diffraction analysis. The charge accumulation between the adjacent As atoms in the zigzag chains suggests the formation of covalent bonds. Reprinted with permission from [25]. Copyright 2013 by the Physical Society of Japan.

The superconductivity of the 112 phase was first reported in (Ca1–xLax)FeAs2 and (Ca1–xPrx)FeAs2 by Katayama et al [25] and Yakita et al [239], respectively. The substitution of a rare-earth element is essential to obtaining the 112 phase [25, 239]. A conventional melt-growth technique was used to obtain tiny single crystals [25, 239]. (Ca1–xLax)FeAs2 exhibited superconductivity at Tc = 34 K [25], while (Ca1–x Prx)FeAs2 exhibited Tc of ~20 K with a broad resistive transition [239]. In a subsequent study, Sala et al [240] performed a high-pressure synthesis and obtained (Ca1–xREx)FeAs2 for RE = La–Gd. Moreover, (Ca1–xREx)FeAs2 for RE = Pr, Nd, Sm, Eu and Gd showed superconductivity at 10–15 K with a small shielding fraction of 5–20% [27, 240], while (Ca1–xCex)FeAs2 did not exhibit superconductivity [27, 240]. The Tc of (Ca1–xREx)FeAs2 is summarized in table 10.

Table 10.

The superconducting transition temperature Tc (K) of RE-doped (Ca1–xREx)FeAs2 and RE- and Sb-doped (Ca1–xREx)Fe(As1–ySby)2 as determined by magnetic measurements.

The 112-type (Ca1–xREx)FeAs2 compound crystallizes in a monoclinic structure with the space group of  (no. 4) [25] or

(no. 4) [25] or  (No. 11) [239, 240]. The structure consists of alternately stacked FeAs and zigzag As bond layers with a Ca/La layer between them, as shown in figure 18(a). The most prominent feature of this structure is the presence of the one-dimensional zigzag As chains along the b-axis, as shown in figure 18(b). The short As–As bond length of approximately 2.53 Å indicates the formation of arsenic single bonds where arsenic has a formal valence of As– (4p4 configuration). The presence of two unpaired electrons in As– underlies the formation of two chemical bonds per As atom that yield a zigzag chain. In contrast, the arsenic at FeAs layers forms the As3– valence state with the filled 4p6 configuration. Thus, the chemical formula of the 112 phase can be written as (Ca2+1–x

RE3+x)(Fe2+As3–)As– · xe– with excess charge of xe–/Fe, which is injected into the superconducting FeAs layers. This formula can be compared with that of the 1111-type fluoride, (Ca2+1–x

RE3+x)(Fe2+As3–)F– · xe– [137, 241], where F– with filled 2p6 orbitals forms an undistorted square network. In this manner, the 112-type structure can be related to the 1111-type structure of CaFeAsF. However, the chemical bonding of the intermediary layer is completely different between CaFeAsF and CaFeAs2; the intermediary CaF layers consist of strong ionic bonds, while the CaAs layers consist of zigzag As chains with covalent bonds, which are weakly coupled to the adjacent Ca layers. Thus, the interlayer distance between the adjacent FeAs layers of (Ca1–xLax)FeAs2 (~10.35 Å) [27] is considerably larger than that of CaFeAsF (~8.6 Å) [137], but is comparable to that of Ca10(Pt4As8)(Fe2–xPtxAs2)5 (~10 Å) with the Pt4As8 intermediary layers exhibiting a covalent nature [242, 243].

(No. 11) [239, 240]. The structure consists of alternately stacked FeAs and zigzag As bond layers with a Ca/La layer between them, as shown in figure 18(a). The most prominent feature of this structure is the presence of the one-dimensional zigzag As chains along the b-axis, as shown in figure 18(b). The short As–As bond length of approximately 2.53 Å indicates the formation of arsenic single bonds where arsenic has a formal valence of As– (4p4 configuration). The presence of two unpaired electrons in As– underlies the formation of two chemical bonds per As atom that yield a zigzag chain. In contrast, the arsenic at FeAs layers forms the As3– valence state with the filled 4p6 configuration. Thus, the chemical formula of the 112 phase can be written as (Ca2+1–x

RE3+x)(Fe2+As3–)As– · xe– with excess charge of xe–/Fe, which is injected into the superconducting FeAs layers. This formula can be compared with that of the 1111-type fluoride, (Ca2+1–x

RE3+x)(Fe2+As3–)F– · xe– [137, 241], where F– with filled 2p6 orbitals forms an undistorted square network. In this manner, the 112-type structure can be related to the 1111-type structure of CaFeAsF. However, the chemical bonding of the intermediary layer is completely different between CaFeAsF and CaFeAs2; the intermediary CaF layers consist of strong ionic bonds, while the CaAs layers consist of zigzag As chains with covalent bonds, which are weakly coupled to the adjacent Ca layers. Thus, the interlayer distance between the adjacent FeAs layers of (Ca1–xLax)FeAs2 (~10.35 Å) [27] is considerably larger than that of CaFeAsF (~8.6 Å) [137], but is comparable to that of Ca10(Pt4As8)(Fe2–xPtxAs2)5 (~10 Å) with the Pt4As8 intermediary layers exhibiting a covalent nature [242, 243].

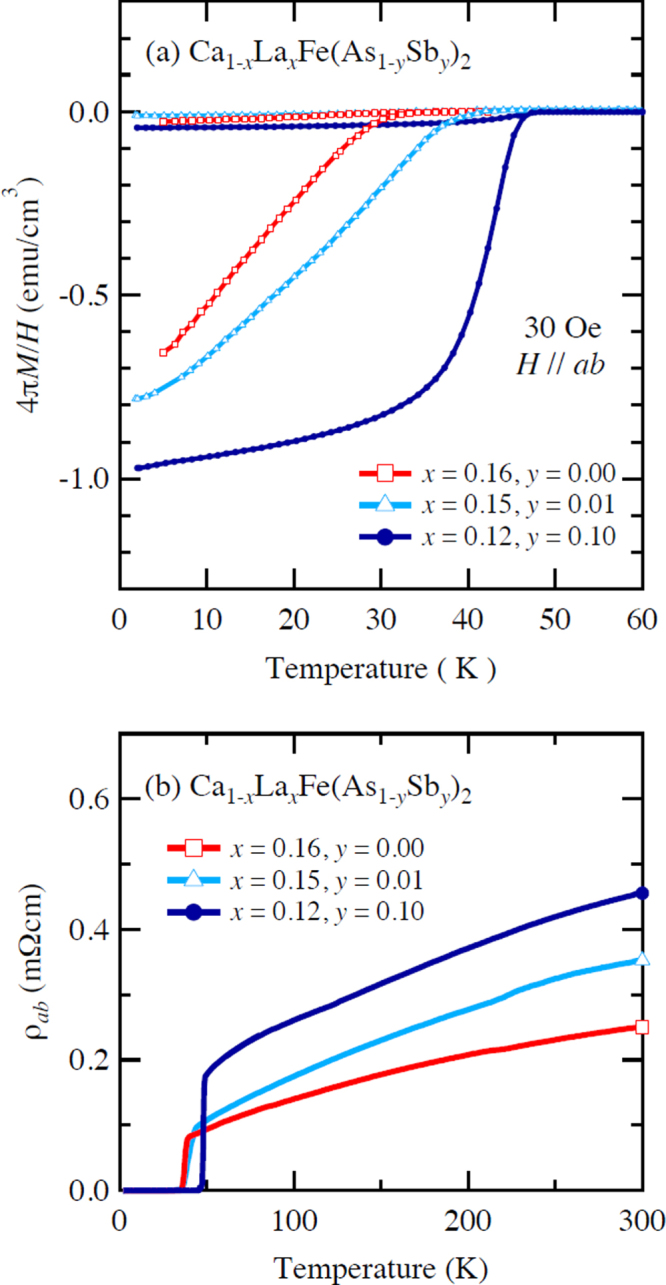

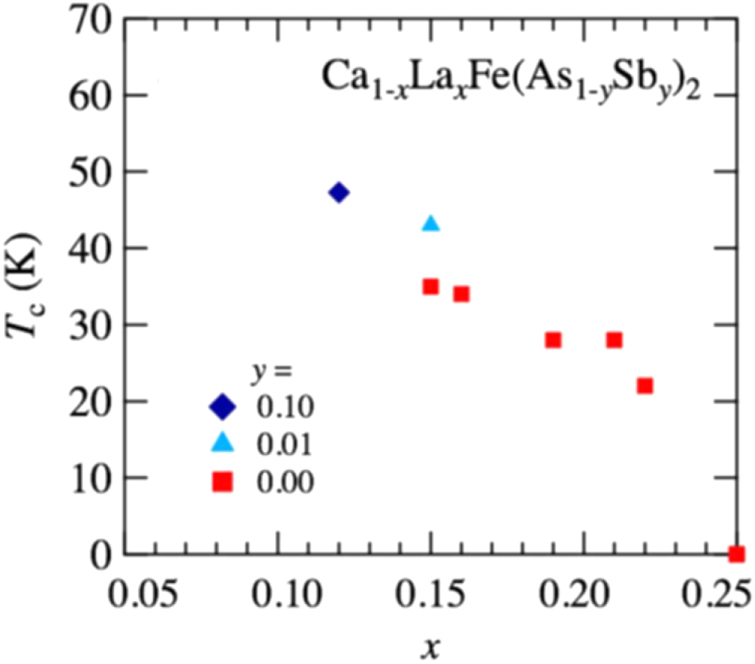

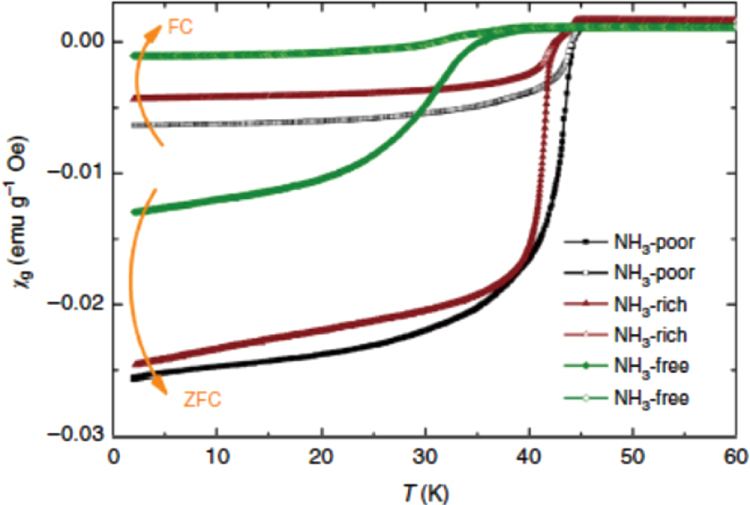

Kudo et al [26, 27] examined simultaneous doping, i.e., aliovalent La doping at the Ca sites and isovalent P or Sb doping at the As sites, and they observed that Tc increased up to 47 K for La- and Sb-doped (Ca1–xLax)Fe(As1–ySby)2 [27]. Figure 19(a) shows the temperature dependence of the magnetization of (Ca1–xLax)Fe(As1–ySby)2. The La-doped sample without Sb (y = 0) shows superconductivity at Tc = 34 K. The Sb doping results in an increase in Tc to 43 K for y = 0.01 and 47 K for y = 0.10. The enhancement of Tc is also evident in the electrical resistivity ρab of the La-doped y = 0.10 sample. The resistivity ρab exhibits a sharp drop at 49 K, and zero resistivity is observed at 47 K, as shown in figure 19(b). Tc was also enhanced by Sb doping of (Ca1–xREx)Fe(As1–ySby)2 for RE = Ce, Pr and Nd [27], as summarized in table 10. Figure 20 shows the T–x phase diagram of (Ca1–xREx)Fe(As1–ySby)2 [27]. The 112 phase can be obtained at x ≥ 0.15 for y = 0.0. The superconducting transition temperature Tc is highest (35 K) at the lowest boundary of x = 0.15, and it decreases monotonically with the La content x. Superconductivity disappears at x ≥ 0.25. The lower limit of x is extended down to x = 0.12 for y = 0.10, at which the highest Tc of 47 K is observed [27].

Figure 19.

(a) Temperature dependence of the magnetization M of (Ca1–xLax)Fe(As1–ySby)2 measured at a magnetic field H of 30 Oe parallel to the ab plane under zero-field-cooling and field-cooling conditions. (b) Temperature dependence of the electrical resistivity ρab of (Ca1–xLax)Fe(As1–ySby)2 parallel to the ab-plane. Reprinted with permission from [27]. Copyright 2014 by the Physical Society of Japan.

Figure 20.

Dependence of the superconducting transition temperature Tc of (Ca1–xLax)Fe(As1–ySby)2 on the La content x. Reprinted with permission from [27]. Copyright 2014 by the Physical Society of Japan.

Recently, Zhou et al [244] have successfully grown large single crystals of (Ca1–xLax)FeAs2 with Tc = 42.6 K. Using these crystals, they estimated a critical current density Jc of 3.5 × 105 A cm−2 from the magnetic hysteresis loops at 5 K, which indicates a strong bulk pinning. The anisotropic upper critical field Hc2(0) was estimated to be 39 and 166 T for the out-of-plane (H//c) and in-plane (H//ab) directions, respectively. The Hc2 anisotropy parameter γ was ~2 near Tc. The moderate anisotropy and high Tc indicates the potential of (Ca1–xLax)FeAs2 for practical applications.

105 A cm−2 from the magnetic hysteresis loops at 5 K, which indicates a strong bulk pinning. The anisotropic upper critical field Hc2(0) was estimated to be 39 and 166 T for the out-of-plane (H//c) and in-plane (H//ab) directions, respectively. The Hc2 anisotropy parameter γ was ~2 near Tc. The moderate anisotropy and high Tc indicates the potential of (Ca1–xLax)FeAs2 for practical applications.

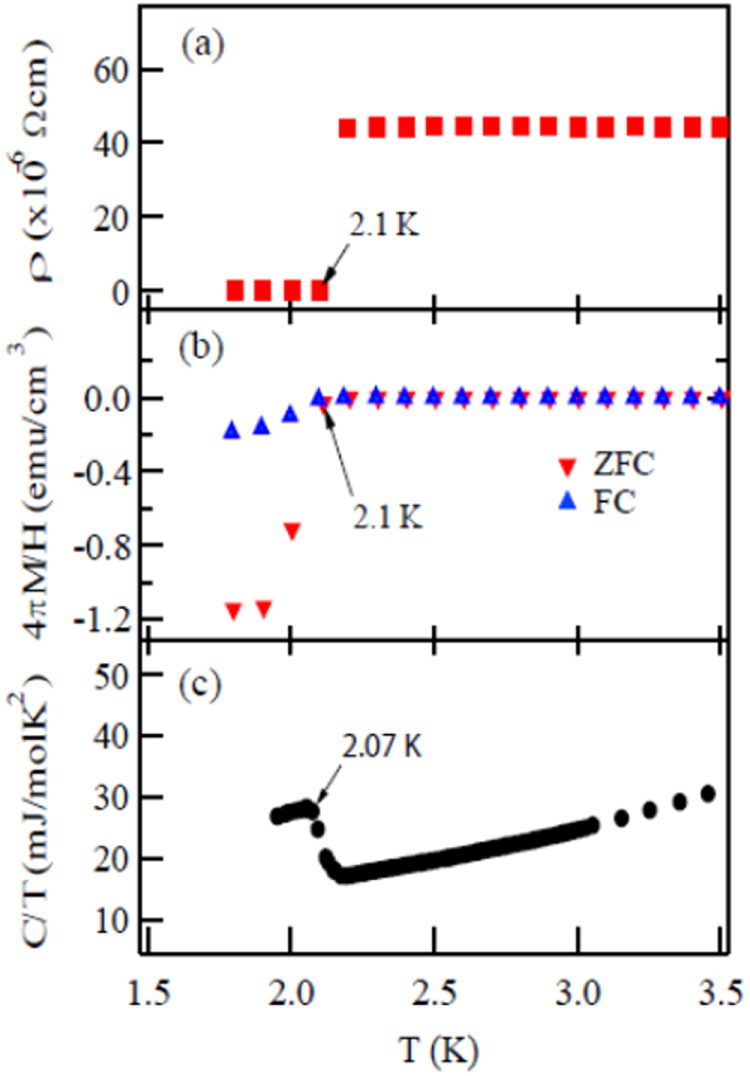

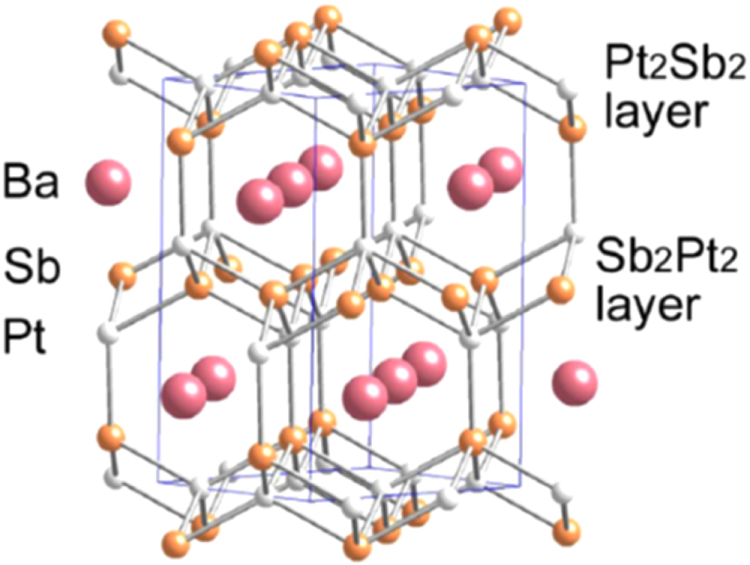

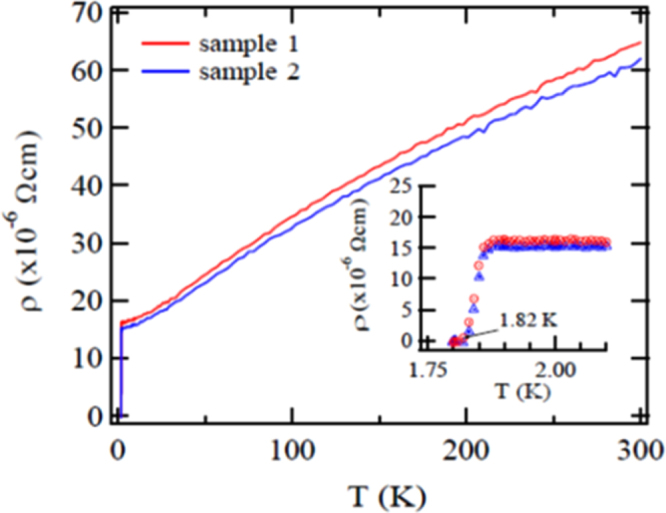

3.1.5. 10-3-8 and 10-4-8 iron arsenide superconductors

The rich chemistry of arsenic allowed us to develop various iron arsenide superconductors. Arsenic exhibits a wide variety of chemical networks, which are known as catenation, depending on the number of valence electrons. For instance, neutral arsenic has three unpaired electrons (4p3), and thus, it forms three single bonds per As atom, thereby resulting in a buckled honeycomb network of α-As (trigonal, space group  Monovalent arsenic (As–) has two unpaired electrons (4p4), and thus forms two single bonds per As atom, which results in either one-dimensional zigzag chains or cis–trans chains, or molecular-like

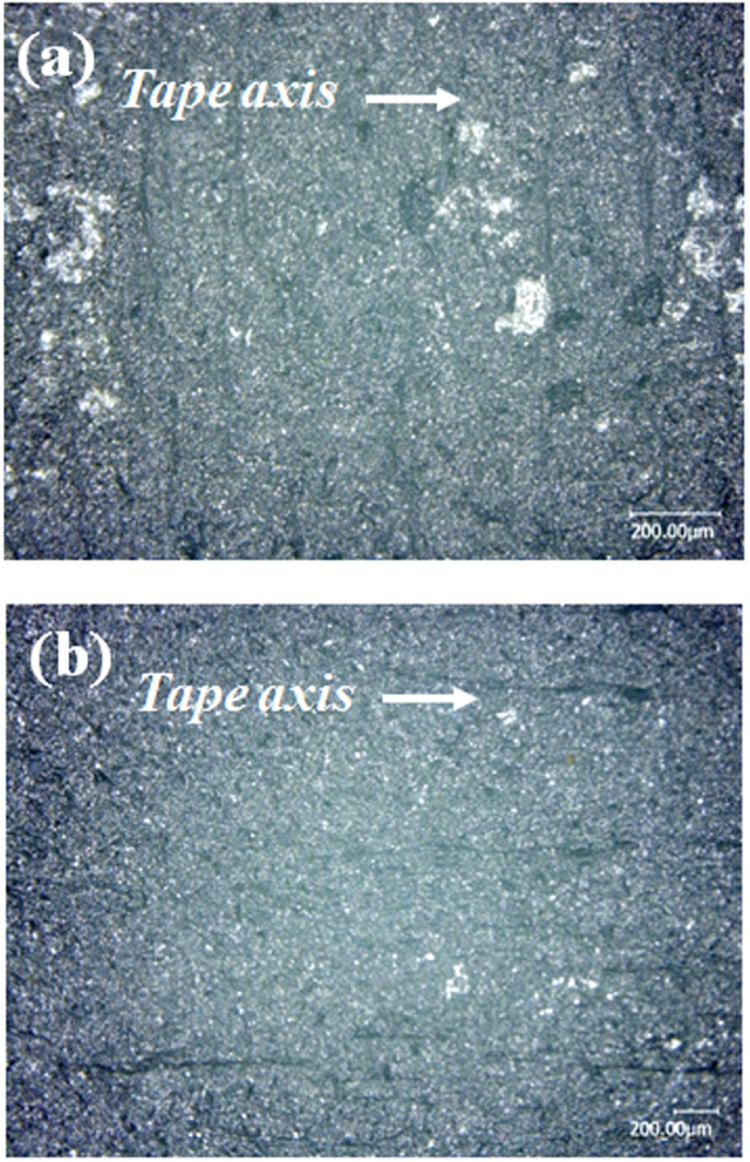

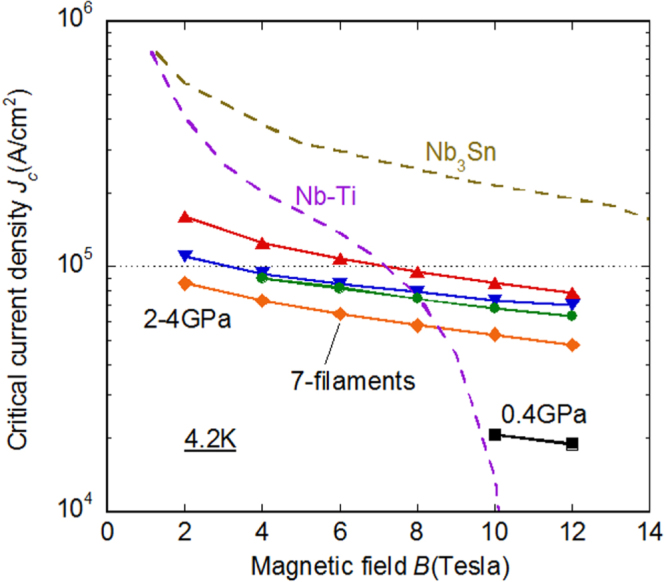

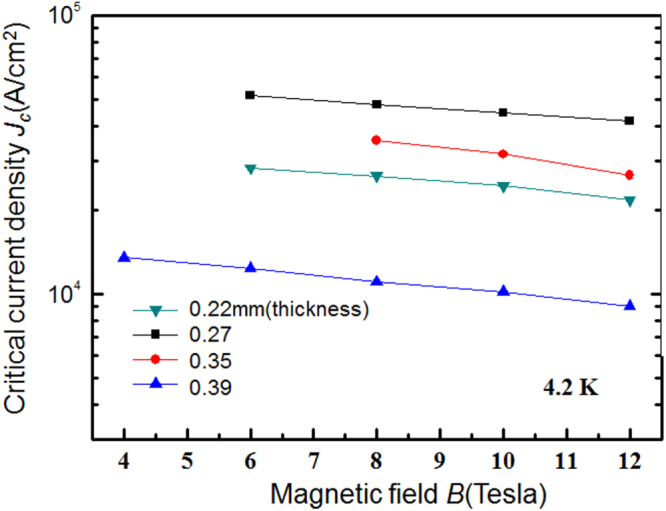

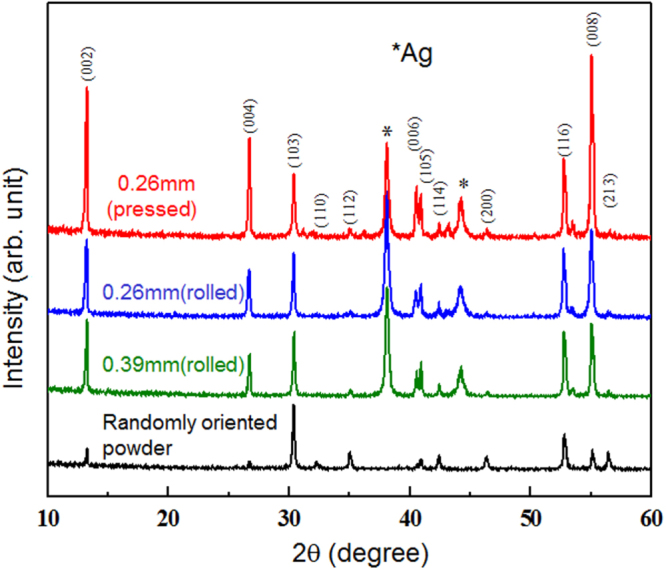

Monovalent arsenic (As–) has two unpaired electrons (4p4), and thus forms two single bonds per As atom, which results in either one-dimensional zigzag chains or cis–trans chains, or molecular-like  tetramers. The 112-type iron arsenide superconductor (Ca1–xLax)FeAs2 consists of As zigzag chains [25], as described in the previous subsection. Cis–trans chains can be observed in LaAgAs2 [245] and As4 tetramers in skutterudite CoAs3, for instance. Divalent arsenic (As2–) has one unpaired electron (4p5), and thus forms a single bond per As atom, which results in molecular-like