Abstract

A MoSe2/Si heterojunction photodetector is constructed by depositing MoSe2 film with vertically standing layered structure on Si substrate. Graphene transparent electrode is utilized to further enhance the separation and transport of photogenerated carriers. The device shows excellent performance in terms of wide response spectrum of UV–visible–NIR, high detectivity of 7.13 × 1010 Jones, and ultrafast response speed of ≈270 ns, unveiling the great potential for the heterojunction for high‐performance optoelectronic devices.

Keywords: broadband photodetector, graphene electrode, heterojunction, MoSe2, silicon

2D materials such as graphene, hexagonal boron nitride (h‐BN), VS2, Bi2S3, and GaSe have been widely studied, because of their great potential in the field of catalysis, microelectronics, ion storage, and optoelectronics.1, 2, 3, 4, 5, 6, 7, 8, 9, 10 As one of the most significant members of 2D materials family, transition metal dichalcogenides (TMDs), such as MoS2, MoSe2, WS2, and WSe2, have attracted tremendous attention currently due to their outstanding electronic, optical, and mechanical properties.11, 12, 13, 14, 15, 16, 17, 18, 19 Monolayer MoSe2 is a sandwich structure consisting of one Mo atom and two Se atoms, and the different layers are interacted by van der Waals force.20, 21 Like MoS2, the properties of MoSe2 are also related with layer numbers; monolayer MoSe2 exhibits a direct bandgap of 1.6 eV, whereas it changes into indirect bandgap of 1.1 eV for bulk or multilayer MoSe2.22, 23 N‐type channel behavior with an average mobility of ≈50 cm2 V−1 s−1 has been investigated for field‐effect transistors (FETs) based on monolayer MoSe2,24 while for bulk MoSe2 the carrier mobility is ≈100 cm2 V−1 s−1.25 In comparison with MoS2, MoSe2 shows a stronger light absorption in the solar spectrum range.26 It has been proved that MoSe2 can absorb nearly 5%–10% of incident sunlight in a thickness less than 1 nm.26 Moreover, bandgap engineering on MoSe2 could be accomplished by forming ternary alloy of MoS2(1–x)Se2x.17, 27, 28 Owing to these appealing properties, many efforts have been devoted to exploit the applications of MoSe2 in diverse fields, including ion batteries, FETs, and photovoltaics, etc.29, 30, 31, 32, 33

Photodetectors based on 2D materials have been intensively investigated in recent years.34, 35, 36, 37 They show great potential for broadband, high‐sensitivity, and flexible photodetection due to the large light absorption and ultrathin thickness.34, 38 Although the gapless band structure of graphene offers the capability of ultrawide band detection, the short lifetimes of the photogenerated carriers in graphene (in the ps range) hinder the improvement of photocurrent.36, 39, 40 In comparison to graphene, TMDs such as MoS2 and MoSe2 possess large bandgap and thus higher carrier lifetimes, making them as promising candidates for high‐sensitivity photodetectors.34, 41, 42 For a practical photodetector, fast response speed is particularly important for the applications such as imaging and optical communication. However, due to the difficulty in controllable doping, most of the TMDs‐based photodetectors have a lateral device structure of metal‐semiconductor‐metal (MSM) or phototransistor. The transit time of carriers between two contact electrodes limits the device response speed.34 Moreover, the mono‐/multilayer structure of the nanosheets makes them very susceptible to the surface contamination or molecule adsorption, which also degrades the respond speed due to the carrier trapping/detrapping process.

To date, a few works have been reported for the photodetectors based on mono‐/multilayer MoSe2 nanosheets.43, 44, 45 Although they show outstanding device characteristics such as remarkable light response, their response speed (15 ms–8 s) remains too low to meet the requirements for practical applications, and broadband light detection is yet to be demonstrated.43, 44, 45 In conventional photodetectors, diode structure with vertical p–n junctions are normally adopted. Therefore response speed could be greatly enhanced due to the presence of strong built‐in electric field at junction interface as well as the shorter carrier transit time.46, 47, 48 In light of this, fabrication of MoSe2 homo‐/heterojunction‐based photodetectors is much desirable to further boost their performance. For instance, Duan et al. demonstrated the lateral epitaxial growth of MoSe2/MoS2 heterojunctions, which showed pronounced photoresponse characteristics.49 Choi et al. also reported the construction of MoSe2/graphene van der Waals heterostructures, and investigated the rapid transfer of photogenerated charge carriers between MoSe2 and graphene.50

Herein, we demonstrated the fabrication of MoSe2/Si heterojunctions for high‐speed, broadband response photodetectors. High‐quality p‐n heterojunctions were formed by combing the p‐type Si substrate with n‐type MoSe2 film, thus bypassing the difficulty in controllable doping of MoSe2. More importantly, the MoSe2 film possessed a unique vertically standing layered structure, enabling the fast separation and transport of photogenerated carriers. Graphene (Gr) transparent electrode was adopted to further enhance the carrier collection and consequently reduce the recombination at junction interface. Significantly, the Gr/MoSe2/Si heterojunction photodetector exhibited a wide photoresponse range of 350–1310 nm and an extremely fast response speed of ≈270 ns, which represent the best values reported thus far for MoSe2 or MoS2 based photodetectors (Table 1 ).43, 44, 45, 51, 52, 53, 54 It is expected that the MoSe2/Si heterojunctions will have important applications for high‐performance optoelectronic devices.

Table 1.

Performance comparison of our Gr/MoSe2/Si heterojunction‐based photodetector with other photodetectors in literatures

| Devices | Wavelength [nm] | Detectivity [Jones] | Pulsed light frequency [Hz] | Rise time [μs] | Fall time [μs] | References |

|---|---|---|---|---|---|---|

| Gr/MoSe2/Si heterojunction | 365–1310 | 7.13 × 1010 | 106 | 0.27 | 0.35 | This work |

| Monolayer MoSe2 phototransistor | 532, 650 | _ | _ | 2.5 × 104 | 2.5 × 104 | 43 |

| MoSe2 nanosheets photoconductor | 650 | _ | _ | 2.9 × 106 | 4.6 × 106 | 44 |

| Monolayer MoSe2 photoconductor | 532 | _ | _ | 6 × 104 | 6 × 104 | 45 |

| MoSe2 nanostructure photoconductor | 650 | _ | _ | 7.9 × 106 | 9.8 × 106 | 51 |

| Multilayer MoSe2 phototransistor | 532 | _ | _ | 1.5 × 104 | 3 × 104 | 52 |

| Multilayer MoS2 phototransistor | 532 | ≈1010 | _ | 70 | 110 | 53 |

| Gr/Si heterojunction | 400‐900 | 2.1 × 108 | 20 | 1.2 × 103 | 3 × 103 | 54 |

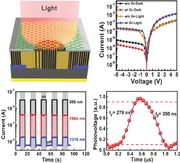

In this study, MoSe2 films with vertically standing layered structure were prepared by magnetron sputtering method with a thickness of ≈200 nm (see Figure S1 in the Supporting Information). The scalable sputtering method ensures the large‐area fabrication of high‐quality MoSe2 films with high uniformity, in contrast to the small size MoSe2 nanosheets obtained by exfoliation or thermal evaporation methods.55, 56 The as‐prepared MoSe2 film has trigonal phase (see Figure S2 in the Supporting Information). After deposition, the film was annealed in a rapid thermal processing systerm (RTP) at 800 °C in Ar for 20 min to further improve its crystal quality. Figure 1 a depicts the Raman spectra of the MoSe2 films of both as‐prepared and annealed MoSe2 films. Two typical Raman active modes, A1g and E2g, for MoSe2 are observed. The prominent A1g mode relates to the out‐of‐plane vibration of Se atoms, while the E2g mode is associated with the in‐plane vibration of Mo and Se atoms (see the inset in Figure 1a). Prior research results indicate that the change in layer number of MoSe2 nanosheets will cause a significant difference in the locations of scattering modes in Raman spectra; the E2g vibration will redshift, whereas the A1g vibration will blueshift, with increasing MoSe2 layer number.20, 57 Considering the large thickness of the MoSe2 film in this work, its Raman spectra are more likely to be identical to that of the MoSe2 bulk material or multilayer nanosheets. From Figure 1a, A1g and E2g scattering modes located at wave numbers of 240.3 and 288.1 cm−1, respectively, can be identified for the annealed film, which is consistent with previous reports for MoSe2 film.58, 59 It is reported that the obvious E2g peak usually occurs for monolayer MoSe2 nanosheet, whereas a thick MoSe2 film (≥2 layers) often exhibits a weak or invisible E2g peak.59, 60 Presumably, the unusually high E2g peak for the sputtering fabricated MoSe2 film may be attributed to the unique vertically standing layered structure.61 Figure 1b reveals an obvious movement of A1g peak from 235.2 cm−1 before annealing to 240.3 cm−1 after annealing, along with the decrease of peak width upon annealing. It is known that the A1g peak location of 240.3 cm−1 is more close to the standard value for high‐quality MoSe2 (240.6 cm−1).58, 59 Therefore, the Raman spectra clearly show that the film quality is significantly improved after annealing treatment. The components of the annealed MoSe2 film were further studied by X‐ray photoemission spectroscopy (XPS), as shown in Figure 1c,d. The Mo 3d shows two peaks at 229.2 and 232.3 eV, which can be attributed to the Mo 3d5/2 and Mo 3d3/2, respectively, confirming the existence of Mo4+.58, 62, 63 The peaks at 54.8 and 55.6 eV are attributed to the doublet Se 3d5/2 and Se 3d3/2, respectively, corresponding to the divalent selenide ions (Se2−).58, 62, 63

Figure 1.

a) Raman spectra of both as‐prepared and annealed MoSe2 films. Schematic illustrations in (a) depict the atomic vibration direction of A1g (left) and E2g (right) Raman modes of MoSe2 film. b) Comparison of the A1g peaks in Raman spectra for the as‐prepared and annealed MoSe2 films. XPS spectra show the binding energies of c) Mo and d) Se for the annealed MoSe2 film.

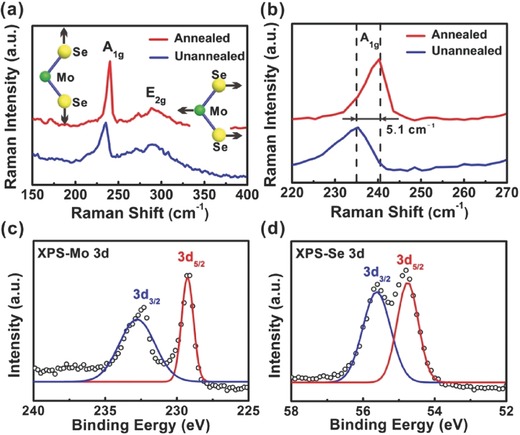

Figure 2 a illustrates the device structure of MoSe2/Si heterojunction photodetector. MoSe2 film was first deposited on p‐type Si substrate with a predefined SiO2 circular window (d = 3 mm) by magnetron sputtering, which determines the effective device area. Ag electrode (50 nm) was deposited around the window as the top ohmic contact to MoSe2 film (see Figure S3 in the Supporting Information). Then three‐layer graphene film with sheet resistance of ≈380 Ω sq–1 (conductivity ≈7740 S/cm) was transferred to the top of MoSe2 film as transparent electrode. The use of graphene electrode ensures the efficient light absorption of MoSe2/Si heterojunction, meanwhile facilitates the transport of photogenerated carriers from MoSe2 film to the Ag top electrode. Afterward, Au electrode (50 nm) was deposited at the rear side of p‐type Si as back ohmic contact. To gain more insight into the structure of the MoSe2/Si heterojunction, cross‐sectional transmission electron microscopy (TEM) investigation was performed, as shown in Figure 2b‐e. The MoSe2 film deposited by sputtering has a uniform thickness of ≈200 nm (Figure 2b). EDS elemental mappings on Si, Mo, and Se at the red square area in Figure 2b prove the formation of MoSe2/Si heterojunction. The uniform colour contrast for Mo and Se elements is an evidence of the high uniformity of the MoSe2 film. The energy dispersive X‐ray spectroscopy (EDS) line‐scanning analysis, Figure 2c, further confirms the compositions of MoSe2/Si heterojunction. From the high‐resolution TEM (HRTEM) image at the junction interface (Figure 2d), we can see that there is a thin interfacial oxide layer (≈5 nm) formed between the Si substrate and the MoSe2 film. Close investigation on the MoSe2 film, Figure 2e, discloses the distinct vertically standing layered structure of the film, i.e., the growth direction of the (001) molecule planes of MoSe2 are perpendicular to the Si substrate, in contrast the parallel growth of the MoSe2 nanosheets fabricated by conventional chemical vapour deposition (CVD) method.57, 64 The dimension of individual crystal grains in the MoSe2 film is 4–6 nm wide, corresponding to about 6–9 MoSe2 monolayers (Figure 2e). As one of the remarkable characteristics of 2D materials, they show pronounced anisotropic conduction in the in‐plane direction and out‐of‐plane direction. The weak van der Waals force and the large layer distance between adjacent layers lead to much lower out‐of‐plane electrical and thermal conductivities compared to those of their in‐plane analogs.65, 66 In this regards, the vertically standing layered structure endows the MoSe2 film distinct electrical properties with much efficient carrier transport from the junction interface to the top electrode.

Figure 2.

a) Schematic illustration of the Gr/MoSe2/Si heterojunction photodetector with graphene transparent electrode. b) Cross‐sectional TEM image of the interface of MoSe2 and Si. Insets show the EDS element mappings of Si, Mo, and Se at the red square area. c) The line‐scan EDS analysis along the red line from Si to MoSe2 film in (b). d) HRTEM image of the heterojunction, indicating the existence of an interfacial oxide layer (≈5 nm). e) HRTEM image of the MoSe2 film, verifying the vertically standing layered structure of the film. Inset shows the enlarged HRTEM image. The distance between two layers is ≈0.62 nm, corresponding to the (001) face of MoSe2.

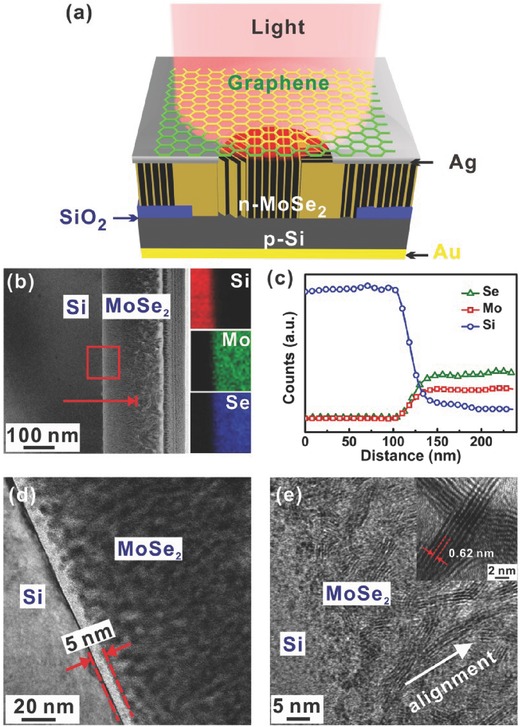

Figure 3 a,b depicts the current versus voltage (I–V) characteristics of the MoSe2/Si heterojunctions in the dark and under light illumination, respectively. Both of the devices with and without graphene transparent electrode were measured to ascertain the role of graphene in determining the device performance. From the dark I–V curves, we note that the dark current at reverse bias direction (−5 V) decreases from 9.35 μA to 2.82 μA, whereas the dark current at forward bias direction (+5 V) increases from 2.6 mA to14.9 mA, after the use of three‐layer graphene transparent electrode. Correspondingly, the rectification ratio improves significantly from 278 for the device without graphene to 5284 for the device with graphene within ±5 V. As a result of the improved diode characteristic, under white light illumination (23 mW cm−2), the photocurrent at −5 V increases remarkably from 202 μA to 263 μA after the use of graphene transparent electrode. Figure 3b depicts the magnified I–V curves around the zero point under light illumination, revealing an open circuit voltage (V oc) of 100 mV for the device with graphene electrode, in contrast to the much lower V oc of 40 mV for the device counterpart without graphene electrode. Ideality factor (n) of the MoSe2/Si heterojunctions were deduced from the slops of the semilog I–V curves at the forward bias direction (Figure 3c), according to the following equation67

| (1) |

where q is the unit charge, k B is the Boltzmann's constant, and T is the absolute temperature. The ideality factor of the MoSe2/Si heterojunction without graphene electrode exhibits a larger value of 2.43, compared to that of 1.79 for the device with graphene electrode. The above results collectively demonstrate that the graphene electrode plays a crucial role in enhancing the device performance of MoSe2/Si heterojunction. To understand the superior performance of MoSe2/Si heterojunction with graphene transparent electrode, Figure 3d,e illustrates the energy band alignments of the MoSe2/Si heterojunctions without and with graphene electrode, respectively. The n‐type MoSe2 film will form type II heterojunction with p‐type Si substrate, allowing the efficient separation of photogenerated electron‐hole pairs at junction interface. Under light illumination, electrons inject into the n‐type MoSe2 film, while holes inject into p‐type Si, forming the photocurrent. Notably, the introduction of graphene at MoSe2 side can greatly enhance the separation of photogenerated carriers. Moreover, the high conductivity of graphene can ensure the fast transport of electrons to the outside electrical circuit. As a result, the accumulation of electrons in MoSe2 film is avoided. This further reduces the electron–hole recombination and contributes to the improved photocurrent of the MoSe2/Si device. The zero bias barrier of the heterojunction, Φ b, was calculated based on following equation68

| (2) |

Figure 3.

a) Typical I–V curves of the MoSe2/Si heterojunction with and without graphene transparent electrode measured in dark and under white light illumination (23 mW cm−2), respectively. b) Magnified I–V curves around zero point under light illumination. c) Semilogarithmic I–V curve at forward bias of 0–0.4 V in the dark. The semilogarithmic curves could be fitted by straight lines. Energy band alignments of the MoSe2/Si heterojunctions d) without graphene and e) with graphene transparent electrode. The conduction band minimum (CBM) and the valence band maximum (VBM) of Si and MoSe2 are represented in blue colour and brown colour, respectively. The work function of graphene (4.5 eV) is also shown in black line. The energy scale is referenced to the vacuum level.

The saturation current of I S is defined by

| (3) |

where A is the area of the device (7.06 mm2), A* is the effective Richadson constant, and it is 32 A cm−2 K−2 for p‐type Si.69 Based on above equations, Φ b is deduced to be 793 mV for the heterojunction device with graphene top electrode. The large bulit‐in electrical field is responsble for the effective spearation of photogenerated carriers.

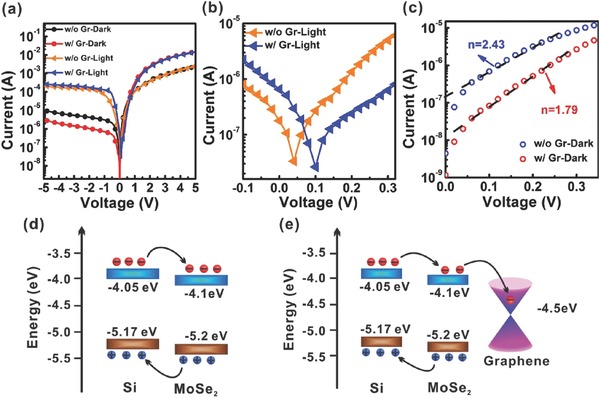

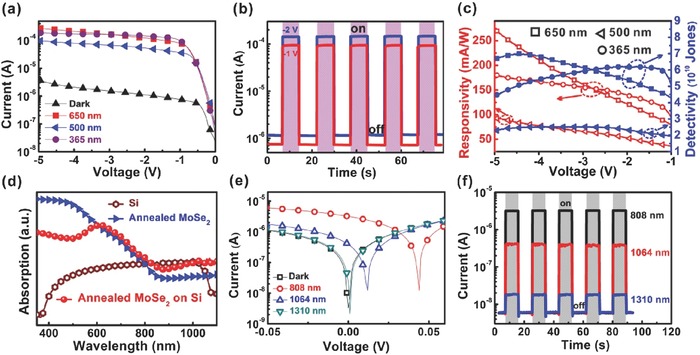

To evaluate the performance of the Gr/MoSe2/Si heterojunction for broadband detection, UV light (365 nm), green light (500 nm), and red light (650 nm) were chosen as exciting light sources. From I–V curves of the device measured at different light wavelengths (Figure 4 a), it is observed that the device shows a remarkable photocurrent upon incident light illumination at reverse bias. The high sensitivity at reverse bias is due to the fact that the photogenerated electron‐hole pairs significantly change the concentration of minority carriers, which dominates the photocurrent under a reverse bias.70 From the time‐dependent photocurrent excited by pulsed UV light (365 nm, 15 mW cm−2) at different reverse bias voltages, Figure 4b, we note that the device exhibits a high sensitivity to the UV light with a large I on/I off ratio of 140 and 130 at −1 V and −2 V, respectively. The fast response and recovery speed can be deduced by the steep rise and fall edges of the response curves, indicating the effective generation and separation of electron–hole pairs in the Gr/MoSe2/Si heterojunction. In addition, excellent stability and reproducibility can also be verified by the unchanged response current of the device illuminated with a pulsed light with about 16 s per cycle. To quantify the performance of the Gr/MoSe2/Si photodetector, two key figure‐of‐merit parameters, i.e., responsivity (R) and detectivity (D*) that indicate the efficiency of a detector responding to optical signals and the ability of a detector to detect weak optical signals, respectively, are calculated by following equations71

| (4) |

| (5) |

where I ph, P in, I d, and J d represent the photocurrent, incident light power, dark current, and dark current density, respectively. Figure 4c plots both the responsivity and detectivity at different light wavelengths as a function of applied reverse bias voltage. It is seen that the responsivity at different wavelengths increases, whereas the detectivity first increases and then decreases, with increasing reverse bias voltage. The higher reverse bias can result in a larger photocurrent under the same incident light intensity since more carriers can pass through the junction, thereby contributing to an increased responsivity. However, the dark current will increase at the meantime, ultimately resulting in the decrease of detectivity at high reverse bias. Based on Equations (4) and (5), the Gr/MoSe2/Si photodetector shows optimal R and D* values of 270 mA W−1 and 7.13 × 1010 Jones (Jones = cm Hz1/2 W−1) at 650 nm, 93 mA W−1 and 2.55 × 1010 Jones at 500 nm, and 182 mA W−1 and 6.22 × 1010 Jones at 365 nm, respectively. Figure 4d depicts the absorption spectrum of the MoSe2/Si heterojunction, with the spectra of both of MoSe2 film on quartz substrate and bare Si substrate for comparison. The MoSe2 film possesses stronger light absorption at both short wavelength direction (<800 nm) and long wavelength direction (>1060 nm) as compared to the bare Si substrate. Therefore, the combination of MoSe2 film with Si substrate makes the system capable of absorption of the broadband light ranging from UV, visible, to NIR light. In addition, it is noted that there is an absorption valley around 500 nm. This may be responsible for the relatively lower responsivity and detectivity at that wavelength.

Figure 4.

a) I–V characteristics of the Gr/MoSe2/Si photodetector measured in the dark and under light illumination with varied wavelengths of 365, 500, and 650 nm, respectively. Three‐layer graphene was used as the transparent electrode. The light intensities of the light sources were fixed at 15 mW cm−2. b) Time‐dependent photocurrent excited by pulsed light at 365 nm (15 mW cm−2). Different bias voltages of −1 V and −2 V were applied. c) Plots of responsivity and detectivity of the device at varied light wavelengths as a function of applied reverse bias. d) Absorption spectrum of the MoSe2 film on Si substrate. The absorption spectra of MoSe2 film grown on quartz substrate under the same conditions and bare Si substrate were also plotted for comparison. e) I–V characteristics of the device measured in the dark and under laser illumination with different wavelengths of 808, 1064, and 1310 nm, respectively. The light intensity was maintained at 15 mW cm−2. f) Photoswitching curves of the device in response to pulsed light illumination with various wavelengths at a bias voltage of 0 V.

The NIR photoresponse of the Gr/MoSe2/Si device was further assessed by using the 808, 1064, and 1310 nm lasers as light sources. In Figure 4e, the device exhibits remarkable photoresponse to 808 and 1064 nm lasers. However, photoresponse becomes weaker for the 1310 nm laser since its energy (0.95 eV) is already smaller than the bandgap of MoSe2 film (1.1 eV). Significantly, owing to the pronounced photovoltaic behavior, the device can operate at zero bias voltage with excellent reproducibility and stability (Figure 4f). The step rise and fall edges to pulsed light also reveal that the photocurrent and photo‐induced voltage are originated from photovoltaic effect, instead of bolometric effect.

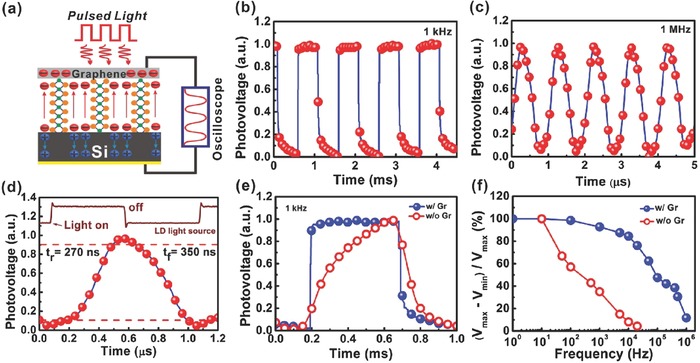

Fast response of a photodetector is requisite for many advanced applications such as optical communication, biological sensing, missile tracking, and so on. In this work, we further investigated response speed of the Gr/MoSe2/Si heterojunction photodetector by using an oscilloscope to monitor variation of photovoltage under pulsed red light illumination (Figure 5 a). The pulsed red light (650 nm) was produced from a laser diode (LD) supplied by a tuneable square‐wave signal generator at 14 V. Figure 5b,c and Figure S4 in the Supporting Information show the photoresponse of the Gr/MoSe2/Si photodetector to pulsed light with frequency ranging from 1 kHz to 1 MHz, manifesting that the device can work well even for high frequency (MHz) optical signals. In addition, from the enlarged photoresponse curve at 1 MHz, Figure 5d, rise time (t r) and fall time (t f) are estimated to be 270 and 350 ns, respectively. The response time of the LD light source is ≈6 ns (Figure 5d), ensuring the accurate evaluation of the device response time. It is noteworthy that this response speed is much quicker than the current reports on MoSe2‐based photodetectors, and even faster than other MoS2‐ or graphene‐based photodetectors (Table 1). This ultrafast response speed can be attributed to the unique device structure of the Gr/MoSe2/Si photodetector: (i) Unlike the conventional photoconductors or phototransistors with MSM structures, whose response speed is usually limited by the transmit time of the carriers between two contacts and the defects/traps in the conduction channels, strong built‐in electric field in the Gr/MoSe2/Si heterojunction photodetector can greatly facilitate the separation and transport of photogenerated carriers. (ii) The distinct vertically standing layered structure of MoSe2 film ensures the fast transport of photogenerated carriers along the vertical direction due to the high in‐plane mobility. The transmit time should be less than 1 ns from the junction interface to the top electrode by assuming a mobility of 100 cm2 V−1 s−1 and a layer thickness of 200 nm for the MoSe2 layer. (iii) The use graphene transparent electrode can further enhance the carrier collection and thus reduce the carrier recombination. This is also evidenced by Figure 5e, in which the temporal responses of both the devices with and without graphene electrodes were measured. The former exhibits much faster light response than the latter. Furthermore, we studied the relative balance (Vmax–Vmin)/Vmax as a function of pulsed light frequency (Figure 5f). It is noteworthy that relative balance of the Gr/MoSe2/Si heterojunction photodetector decreases by less than 15% even at 10 kHz and remains more than 10% at 1 MHz. In contrast, relative balance of the device without graphene transparent electrode diminishes sharply and approximates to zero at 10 kHz.

Figure 5.

a) Schematic illustration shows the rapid separation and transport of electrons and holes along the in‐plane direction of MoSe2 under pulsed light illumination. The electrons were collected by graphene transparent electrode, ensuring the fast transport of electrons to the outside electrical circuit. Variation of photovoltage is monitored by an oscilloscope to determine the response speed. Photoresponse of the self‐powered photodetector to pulsed light illumination with varied frequency of b) 1 kHz, and c) 1 MHz. d) Enlarged photoresponse curve at 1 MHz. Rise time (t r) and fall time (t f) are the time intervals between 10% and 90% of peak response. Response curve of the 650 nm LD light source is also shown in the upper part of the figure for comparison. e) Photoresponse of the MoSe2/Si heterojunction with and without graphene transparent electrode under pulsed light illumination. f) Relative balance (V max–V min)/V max versus switching frequency of the devices with and without graphene.

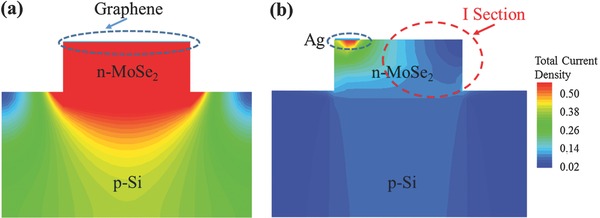

To gain insight into the mechanism of graphene top electrode for carrier collection, device simulation was conducted on the MoSe2/Si heterojunction by using a 2D semiconductor simulation package (ISE‐TCAD). Figure 6 a shows the simulated total current density distribution of the device with graphene top electrode at a forward bias of +1 V. The current distributes uniformly with high current density in the MoSe2 layer with the use of graphene electrode. In contrast, if only side part of the MoSe2 layer contacts with Ag electrode, corresponding to the case without graphene top electrode, the current distribution is very inhomogeneous (Figure 6b); only the region closes to the electrode shows higher current density, while the region (I section) away from the electrode has very low current density, indicating the poor carrier collection capability for the device. This result further confirms the important role of graphene transparent electrode in enhancing the device performance.

Figure 6.

Simulated total current density distributions of the MoSe2/Si photodetectors a) with and b) without graphene top electrode at forward bias of +1 V, respectively.

In summary, high‐performance Gr/MoSe2/Si heterojunction photodetectors were constructed by depositing MoSe2 film with vertically standing layered structure on Si substrate. The heterojunction photodetectors can surpass conventional mono‐/multilayer structured MoSe2 photodetectors in terms of high light sensitivity (due to stronger light absorption of the thick film) and ultrafast response speed (due to presence of strong built‐in electric field and short transmit time). The high in‐plane mobility of MoSe2 ensures the fast separation and transport of photogenerated carriers from the junction interface to top electrode in the vertically aligned MoSe2 film. Moreover, three‐layer graphene was used as transparent electrode to further enhance the carrier collection and thus reduce the recombination at junction interface. As a result, the Gr/MoSe2/Si heterojunction photodetectors exhibited outstanding device characteristics with a wide response spectrum range of 365–1310 nm and an ultrafast response speed of ≈270 ns, which represent the best results achieved for MoSe2‐based photodetectors thus far. This work unveils the great potential of MoSe2/Si heterojunction for high‐performance optoelectronic devices.

Experimental Section

Growth of MoSe2 Film and Graphene: MoSe2 films were deposited on the Si substrate by RF magnetron sputtering (Kurt J Lesker, PVD 75) using a 2 in. MoSe2 target (ZhongNuo Advanced Material (Beijing) Company). The RF power was kept at 50 W with a direct current (DC) bias voltage of 225 V. The pressure in the chamber was 3 mTorr during deposition, and the substrate temperature was controlled to be 400 °C. To increase the quality of MoSe2 film, the as‐prepared MoSe2 films were annealed in a rapid thermal process system (RTP‐500V) at 800 °C for 30 min. Graphene used here was synthesized by CVD method using a mixed gas of H2 (3 sccm) and CH4 (50 sccm) as gas source at 1000 °C, and a 25 μm thick copper foil was used as the catalyst substrate.

Fabrication of Devices: To fabricated the Gr/MoSe2/Si heterojunction photodetectors, a circular photoresist window (d = 3 mm) was first defined on the SiO2 (300 nm)/p‐type (100) Si (resistivity 1–10 Ω cm−1) substrate by photolithography (SUSS, MicroTec‐MJB4), followed by 5% HF etching for 300 s to remove the SiO2 in the window. After removing the residual photoresist by acetone, 200 nm MoSe2 film was deposited onto the window by sputtering. Afterwards, 50 nm Ag were deposited by e‐beam evaporation (Kurt J Lesker, PVD 75) around the circular window on the MoSe2 film using a shadow mask. Three‐layer graphene film was transferred onto the top of the MoSe2 film as transparent electrode. 50 nm Au was deposited by e‐beam evaporation onto the rear side of SiO2/Si substrate as ohmic contact to Si.

Material and Device Characterizations: The thickness and crystal structures of MoSe2 film were determined by atomic force microscopy (AFM, Veeco) and X‐ray diffraction (XRD, PANalytical Empyrean), respectively. Raman spectra of the MoSe2 film were measured in a LabRAMHR800 Raman microscopy system using 514 nm laser as excitation source. XPS measurements were performed using a monochromatic Al Kα source (1486.6 eV) produced by the XPS system (Kratos AXIS UltraDLD). The XPS data were calibrated by comparing with C 1s peak to assure the correction. The absorption spectra of MoSe2 on quartz glass, Si substrate, and MoSe2/Si heterojunction were detected by UV–vis spectrometer (Perkin‐Elmer LAMBDA 750) equipped with an integrating sphere. To observe the interfacial structure of heterojunction, the cross‐section structure, element mapping, and line‐scan EDX were characterized by HRTEM (FEI Tecnai G2). The photoresponse of the photodetectors was detected using a semiconductor parameter analyzer (Keithley 4200‐SCS). The light sources were produced by a Xe lamp (CEL‐HXF300) with tunable output power and a monochromator (Zolix Instruments, Omni‐nx I). To measure the NIR photoresponse, 808, 1064, and 1310 nm lasers were also used as light sources (Changchun Laser Optoelectronics Technology, MW‐GX‐808, MW‐GX‐1064, and MW‐GX‐1310). Light intensity is measured by an optical power meter (CEL‐NP2000). The response speed of the photodetector was measured by using a LD (650 nm) driven by a function signal generator (Shengpu, F‐40), and a digital oscilloscope (Tektronix TDS 2012C) was used to monitor the variation of photovoltage.

Supporting information

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re‐organized for online delivery, but are not copy‐edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

Supplementary

Acknowledgements

J.M. and Y.Q.Y. contributed equally to this work. This work was supported by the National Basic Research Program of China (Grant Nos. 2013CB933500 and 2012CB932400), National Natural Science Foundation of China (Grant Nos. 61422403 and 51401138), the Major Research Plan of the National Natural Science Foundation of China (Grant No. 91333208), Natural Science Foundation of Jiangsu Province (Grant Nos. BK20131162 and BK20140332), Qing Lan Project, and a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Mao J., Yu Y., Wang L., Zhang X., Wang Y., Shao Z., Jie J. (2016). Ultrafast, Broadband Photodetector Based on MoSe2/Silicon Heterojunction with Vertically Standing Layered Structure Using Graphene as Transparent Electrode. Adv. Sci., 3: 1600018. doi: 10.1002/advs.201600018

Contributor Information

Xiujuan Zhang, Email: xjzhang@suda.edu.cn.

Jiansheng Jie, Email: jsjie@suda.edu.cn.

References

- 1. Novoselov K., Geim A. K., Morozov S., Jiang D., Katsnelson M., Grigorieva I., Dubonos S., Firsov A., Nature 2005, 438, 197. [DOI] [PubMed] [Google Scholar]

- 2. Geim A. K., Novoselov K. S., Nat. Mater. 2007, 6, 183. [DOI] [PubMed] [Google Scholar]

- 3. Brar V. W., Jang M. S., Sherrott M., Kim S., Lopez J. J., Kim L. B., Choi M., Atwater H., Nano Lett. 2014, 14, 3876. [DOI] [PubMed] [Google Scholar]

- 4. Ling X., Fang W., Lee Y.‐H., Araujo P. T., Zhang X., Rodriguez‐Nieva J. F., Lin Y., Zhang J., Kong J., Dresselhaus M. S., Nano Lett. 2014, 14, 3033. [DOI] [PubMed] [Google Scholar]

- 5. Feng J., Sun X., Wu C., Peng L., Lin C., Hu S., Yang J., Xie Y., J. Am. Chem. Soc. 2011, 133, 17832. [DOI] [PubMed] [Google Scholar]

- 6. Sun Y., Gao S., Xie Y., Chem. Soc. Rev. 2014, 43, 530. [DOI] [PubMed] [Google Scholar]

- 7. Zhou Y., Nie Y., Liu Y., Yan K., Hong J., Jin C., Zhou Y., Yin J., Liu Z., Peng H., ACS Nano 2014, 8, 1485. [DOI] [PubMed] [Google Scholar]

- 8. Xu M., Liang T., Shi M., Chen H., Chem. Rev. 2013, 113, 3766. [DOI] [PubMed] [Google Scholar]

- 9. Yoo E., Kim J., Hosono E., Zhou H.‐S., Kudo T., Honma I., Nano Lett. 2008, 8, 2277. [DOI] [PubMed] [Google Scholar]

- 10. Chen G. H., Yu Y. Q., Zheng K., Ding T., Wang W. L., Jiang Y., Yang Q., Small 2015, 11, 2848. [DOI] [PubMed] [Google Scholar]

- 11. Wang Q. H., Kalantar‐Zadeh K., Kis A., Coleman J. N., Strano M. S., Nat. Nanotech. 2012, 7, 699. [DOI] [PubMed] [Google Scholar]

- 12. Yun W. S., Han S., Hong S. C., Kim I. G., Lee J., Phys. Rev. B 2012, 85, 033305. [Google Scholar]

- 13. Chhowalla M., Shin H. S., Eda G., Li L.‐J., Loh K. P., Zhang H., Nat. Chem. 2013, 5, 263. [DOI] [PubMed] [Google Scholar]

- 14. Li S.‐L., Komatsu K., Nakaharai S., Lin Y.‐F., Yamamoto M., Duan X., Tsukagoshi K., ACS Nano 2014, 8, 12836. [DOI] [PubMed] [Google Scholar]

- 15. Cheng R., Li D., Zhou H., Wang C., Yin A., Jiang S., Liu Y., Chen Y., Huang Y., Duan X., Nano Lett. 2014, 14, 5590. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16. Voiry D., Yamaguchi H., Li J., Silva R., Alves D. C., Fujita T., Chen M., Asefa T., Shenoy V. B., Eda G., Nat. Mater. 2013, 12, 850. [DOI] [PubMed] [Google Scholar]

- 17. Li H., Duan X., Wu X., Zhuang X., Zhou H., Zhang Q., Zhu X., Hu W., Ren P., Guo P., J. Am. Chem. Soc. 2014, 136, 3756. [DOI] [PubMed] [Google Scholar]

- 18. Fang H., Chuang S., Chang T. C., Takei K., Takahashi T., Javey A., Nano Lett. 2012, 12, 3788. [DOI] [PubMed] [Google Scholar]

- 19. Jones A. M., Yu H., Ghimire N. J., Wu S., Aivazian G., Ross J. S., Zhao B., Yan J., Mandrus D. G., Xiao D., Nat. Nanotech. 2013, 8, 634. [DOI] [PubMed] [Google Scholar]

- 20. Huang X., Zeng Z., Zhang H., Chem. Soc. Rev. 2013, 42, 1934. [DOI] [PubMed] [Google Scholar]

- 21. Ataca C., Sahin H., Ciraci S., J. Phys. Chem. C 2012, 116, 8983. [DOI] [PubMed] [Google Scholar]

- 22. Mak K. F., Lee C., Hone J., Shan J., Heinz T. F., Phys. Rev. Lett. 2010, 105, 136805. [DOI] [PubMed] [Google Scholar]

- 23. Yoon Y., Ganapathi K., Salahuddin S., Nano Lett. 2011, 11, 3768. [DOI] [PubMed] [Google Scholar]

- 24. Wang X., Gong Y., Shi G., Chow W. L., Keyshar K., Ye G., Vajtai R., Lou J., Liu Z., Ringe E., ACS Nano 2014, 8, 5125. [DOI] [PubMed] [Google Scholar]

- 25. Kumar N., Cui Q., Ceballos F., He D., Wang Y., Zhao H., Nanoscale 2014, 6, 4915. [DOI] [PubMed] [Google Scholar]

- 26. Bernardi M., Palummo M., Grossman J. C., Nano Lett. 2013, 13, 3664. [DOI] [PubMed] [Google Scholar]

- 27. Li H., Zhang Q., Duan X., Wu X., Fan X., Zhu X., Zhuang X., Hu W., Zhou H., Pan A., J. Am. Chem. Soc. 2015, 137, 5284. [DOI] [PubMed] [Google Scholar]

- 28. Lee L. T. L., He J., Wang B., Ma Y., Wong K. Y., Li Q., Xiao X., Chen T., Sci. Rep. 2014, 4, 4063. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29. Shi Y., Hua C., Li B., Fang X., Yao C., Zhang Y., Hu Y. S., Wang Z., Chen L., Zhao D., Adv. Funct. Mater. 2013, 23, 1832. [Google Scholar]

- 30. Larentis S., Fallahazad B., Tutuc E., Appl. Phys. Lett. 2012, 101, 223104. [Google Scholar]

- 31. Pathak V., Patel K., Pathak R., Srivastava R., Sol. Energy Mater. Sol. Cells 2002, 73, 117. [Google Scholar]

- 32. Shin B., Zhu Y., Bojarczuk N. A., Chey S. J., Guha S., Appl. Phys. Lett. 2012, 101, 053903. [Google Scholar]

- 33. Fontana M., Deppe T., Boyd A. K., Rinzan M., Liu A. Y., Paranjape M., Barbara P., Sci. Rep. 2013, 3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34. Lopez‐Sanchez O., Lembke D., Kayci M., Radenovic A., Kis A., Nat. Nanotech. 2013, 8, 497. [DOI] [PubMed] [Google Scholar]

- 35. Zhang C., Wang S., Yang L., Liu Y., Xu T., Ning Z., Zak A., Zhang Z., Tenne R., Chen Q., Appl. Phys. Lett. 2012, 100, 243101. [Google Scholar]

- 36. Xia F., Mueller T., Lin Y.‐M., Valdes‐Garcia A., Avouris P., Nat. Nanotech. 2009, 4, 839. [DOI] [PubMed] [Google Scholar]

- 37. Wang X., Cheng Z., Xu K., Tsang H. K., Xu J.‐B., Nat. Photon. 2013, 7, 888. [Google Scholar]

- 38. Zhang Y., Liu T., Meng B., Li X., Liang G., Hu X., Wang Q. J., Nat. Commun. 2013, 4, 1811. [DOI] [PubMed] [Google Scholar]

- 39. Sun Z., Chang H., ACS Nano 2014, 8, 4133. [DOI] [PubMed] [Google Scholar]

- 40. Zhang Q., Jie J., Diao S., Shao Z., Zhang Q., Wang L., Deng W., Hu W., Xia H., Yuan X., ACS Nano 2015, 9, 1561. [DOI] [PubMed] [Google Scholar]

- 41. Zhang W., Chiu M.‐H., Chen C.‐H., Chen W., Li L.‐J., Wee A. T. S., ACS Nano 2014, 8, 8653. [DOI] [PubMed] [Google Scholar]

- 42. Liu B., Chen L., Liu G., Abbas A. N., Fathi M., Zhou C., ACS Nano 2014, 8, 5304. [DOI] [PubMed] [Google Scholar]

- 43. Chang Y.‐H., Zhang W., Zhu Y., Han Y., Pu J., Chang J.‐K., Hsu W.‐T., Huang J.‐K., Hsu C.‐L., Chiu M.‐H., ACS Nano 2014, 8, 8582. [DOI] [PubMed] [Google Scholar]

- 44. Fan C., Yue Q., Yang J., Wei Z., Yang S., Li J., Appl. Phys. Lett. 2014, 104, 202105. [Google Scholar]

- 45. Xia J., Huang X., Liu L.‐Z., Wang M., Wang L., Huang B., Zhu D.‐D., Li J.‐J., Gu C.‐Z., Meng X.‐M., Nanoscale 2014, 6, 8949. [DOI] [PubMed] [Google Scholar]

- 46. Xu H., Xiao X., Li X., Hu Y., Li Z., Chu T., Yu Y., Yu J., Opt. Express 2012, 20, 15093. [DOI] [PubMed] [Google Scholar]

- 47. Xing J., Jin K., He M., Lu H., Liu G., Yang G., J. Phys. D: Appl. Phys. 2008, 41, 195103. [Google Scholar]

- 48. Bie Y. Q., Liao Z. M., Zhang H. Z., Li G. R., Ye Y., Zhou Y. B., Xu J., Qin Z. X., Dai L., Yu D. P., Adv. Mater. 2011, 23, 649. [DOI] [PubMed] [Google Scholar]

- 49. Duan X., Wang C., Shaw J. C., Cheng R., Chen Y., Li H., Wu X., Tang Y., Zhang Q., Pan A., Nat. Nanotech. 2014, 9, 1024. [DOI] [PubMed] [Google Scholar]

- 50. Shim G. W., Yoo K., Seo S.‐B., Shin J., Jung D. Y., Kang I.‐S., Ahn C. W., Cho B. J., Choi S.‐Y., ACS Nano 2014, 8, 6655. [DOI] [PubMed] [Google Scholar]

- 51. Fan C., Wei Z., Yang S., Li J., RSC Adv. 2014, 4, 775. [Google Scholar]

- 52. Abderrahmane A., Ko P. J., Thu T. V., Ishizawa S., Takamura T., Sandhu A., Nanotechnology 2014, 25, 365202. [DOI] [PubMed] [Google Scholar]

- 53. Tsai D.‐S., Liu K.‐K., Lien D.‐H., Tsai M.‐L., Kang C.‐F., Lin C.‐A., Li L.‐J., He J.‐H., Acs Nano 2013, 7, 3905. [DOI] [PubMed] [Google Scholar]

- 54. An X., Liu F., Jung Y. J., Kar S., Nano Lett. 2013, 13, 909. [DOI] [PubMed] [Google Scholar]

- 55. Li H., Lu G., Wang Y., Yin Z., Cong C., He Q., Wang L., Ding F., Yu T., Zhang H., Small 2013, 9, 1974. [DOI] [PubMed] [Google Scholar]

- 56. Yu Q., Jauregui L. A., Wu W., Colby R., Tian J., Su Z., Cao H., Liu Z., Pandey D., Wei D., Nat. Mater. 2011, 10, 443. [DOI] [PubMed] [Google Scholar]

- 57. Lu X., Utama M. I. B., Lin J., Gong X., Zhang J., Zhao Y., Pantelides S. T., Wang J., Dong Z., Liu Z., Nano Lett. 2014, 14, 2419. [DOI] [PubMed] [Google Scholar]

- 58. Mutlu Z., Wickramaratne D., Bay H. H., Favors Z. J., Ozkan M., Lake R., Ozkan C. S., Phys. Status Solidi A 2014, 211, 2671. [Google Scholar]

- 59. Xia J., Huang X., Liu L., Wang M., Wang L., Huang B., Zhu D., Li J. J., Gu C.‐Z., Meng X., Nanoscale 2014, 6, 8949. [DOI] [PubMed] [Google Scholar]

- 60. Lee C., Yan H., Brus L. E., Heinz T. F., Hone J., Ryu S., ACS Nano 2010, 4, 2695. [DOI] [PubMed] [Google Scholar]

- 61. Kong D., Wang H., Cha J. J., Pasta M., Koski K. J., Yao J., Cui Y., Nano Lett. 2013, 13, 1341. [DOI] [PubMed] [Google Scholar]

- 62. Tang H., Dou K., Kaun C.‐C., Kuang Q., Yang S., J. Mater. Chem. A 2014, 2, 360. [Google Scholar]

- 63. Abdallah W. e. A., Nelson A., J. Mater. Sci. 2005, 40, 2679. [Google Scholar]

- 64. Shaw J. C., Zhou H., Chen Y., Weiss N. O., Liu Y., Huang Y., Duan X., Nano Res. 2014, 7, 511. [Google Scholar]

- 65. Chen R.‐S., Tang C.‐C., Shen W.‐C., Huang Y.‐S., Nanotechnology 2014, 25, 415706. [DOI] [PubMed] [Google Scholar]

- 66. Buscema M., Island J. O., Groenendijk D. J., Blanter S. I., Steele G. A., van der Zant H. S., Castellanos‐Gomez A., Chem. Soc. Rev. 2015, 44, 3691. [DOI] [PubMed] [Google Scholar]

- 67. Zhang X., Zhang X., Zhang X., Zhang Y., Bian L., Wu Y., Xie C., Han Y., Wang Y., Gao P., J. Mater. Chem. 2012, 22, 22873. [Google Scholar]

- 68. Xie C., Nie B., Zeng L., Liang F.‐X., Wang M.‐Z., Luo L., Feng M., Yu Y., Wu C.‐Y., Wu Y., ACS Nano 2014, 8, 4015. [DOI] [PubMed] [Google Scholar]

- 69. Karataş Ş., Altındal Ş., Türüt A., Özmen A., Appl. Surf. Sci. 2003, 217, 250. [Google Scholar]

- 70. Yu Y.‐Q., Luo L.‐B., Zhu Z.‐F., Nie B., Zhang Y.‐G., Zeng L.‐H., Zhang Y., Wu C.‐Y., Wang L., Jiang Y., CrystEngComm 2013, 15, 1635. [Google Scholar]

- 71. Choi M. S., Qu D., Lee D., Liu X., Watanabe K., Taniguchi T., Yoo W. J., ACS Nano 2014, 8, 9332. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

As a service to our authors and readers, this journal provides supporting information supplied by the authors. Such materials are peer reviewed and may be re‐organized for online delivery, but are not copy‐edited or typeset. Technical support issues arising from supporting information (other than missing files) should be addressed to the authors.

Supplementary