Summary

In response to the growing interest of modern society in functional food products, this study attempts to develop a bakery product with high dietary fibre content added in the form of an oat fibre powder. Oat fibre powder with particle sizes of 75 µm (OFP1) and 150 µm (OFP2) was used, substituting 4, 8, 12, 16 and 20% of the flour. The physical properties of the dough and the final bakery products were then measured. Results indicated that dough with added fibre had higher elasticity than the control group. The storage modulus values of dough with OFP1 most closely approximated those of the control group. The addition of OFP1 did not affect significantly the colour compared to the other samples. Increasing the proportion of oat fibre powder resulted in increased firmness, which was most prominent in wheat bread rolls with oat fibre powder of smaller particle sizes. The addition of oat fibre powder with smaller particles resulted in a product with the rheological and colour parameters that more closely resembled control sample.

Key words: dietary fibre, oat fibre, bread, particle size

Introduction

The contemporary consumption model, characterized by high ingestion of products rich in sugar and fat, yet low in vitamins, minerals, and dietary fibre, is responsible for many diseases of affluence, such as diabetes, asthma, coronary heart disease and obesity (1). Meanwhile, general consumption of bread products decreases as the society’s gross domestic product increases (2). However, in developed countries there is also a demand for a greater variety of bread with oat, bran, seeds, etc. (3). In such cases, the most probable solution is to fortify white bread products with dietary fibre that has many functions (e.g. caloric reduction, available carbohydrate reduction, moisture control, anticaking properties, textural modification and structural enhancement) (4, 5).

Dietary fibre is an essential component in nutrition and health (6, 7). Thus, the present study will explore the addition of oat fibre in wheat roll production in accordance with European Food Safety Authority (EFSA) health claims and European Union Commission Regulation No 432/2012 of 16 May 2012 (8, 9), which established a list of permitted health claims for foods, apart from those referring to the reduction of disease risk and to children’s development and health. This health claim states that ‘oats increase the faecal bulk’ when a product has a high level of dietary fibre. This means more than 6 g of dietary fibre in each 100 g of product, therefore complying with European Union Commission Regulation (EU) No 1047/ 2012 of 8 November 2012 amending Regulation (EC) No 1924/2006 (9) regarding the list of nutrition claims. The addition of dietary fibre to the bread matrix can lead consumers to conclude that a product is healthy. This study was conducted to investigate whether that common belief has merit.

Principally, dietary fibre is comprised of a non-carbohydrate component called lignin and non-cellulosic polysaccharides, such as pectin substances and hemicelluloses. The structural components are found mainly in the cell wall of plants (7). Dietary fibre is primarily a constituent of plant foods and includes materials that have diverse morphological and chemical structure.

Basically, the process involved in the production of bread is a highly complex one that entails a range of parameters that must be regulated. According to Almeida et al. (10), rheological measurements are used in the prediction of both the behaviour of wheat dough during bread production and of the final product quality. Despite the fact that there are different sources of dietary fibre, Almeida et al. (10) argue that the dietary fibre used in bread production affects both processing and final product quality.

Baking is the most important step in the bread production that transforms the raw dough to the bread using the heating. During baking, the mass loss is observed due to the loss of water that was incorporated into the dough during mixing. As already documented, dietary fibre may have a negative effect on the final bread quality, leading to reduced volume of the bakery product, i.e. loaf volume (11, 12).

The addition of large amounts of fibre to bread results in a change in the bread physical properties, such as increased crumb firmness, crumb darkening, or changes in taste (13). These negative effects can be reduced by using an appropriate proportion of soluble to insoluble fibre fractions (14), and the addition of enzymes such as hemicellulose and pentosans (15). Reducing fibre powder particle size increases water-holding capacity by increasing the surface area. In the bread production, this is extremely important, because water is involved in the processes of starch gelatinization, protein denaturation, formation of flavour characteristics and it also significantly affects colour (14, 15).

The aim of the study is to investigate the effects of the addition of oat dietary fibre powder of two particle sizes on the physicochemical properties of wheat bread rolls during storage and to provide recommendations on the extent to which it is advisable to fortify wheat bread rolls with oat fibre.

Materials and Methods

Materials

Commercial wheat flour was provided by a local supplier (Mlyny Zbozowe Zabczynscy, Łaskarzew, Poland). It contained (in %): protein 10.62, ash 0.52, gluten 28.14 and moisture 14.23. The composition of the flour was measured with near-infrared spectroscopy (NIRFlex N-500; Buchi, Flawil, Switzerland).

The oat fibre powder (provided by Micro Inc., Warsaw, Poland) had 80% dietary fibre (78% insoluble fraction and 2% of soluble fractions). Two particle sizes were used in the study: d(v,0.9)=75 µm (OFP1) and d(v,0.9)=150 µm (OFP2) as provided by the manufacturer. The chemical composition of the dietary fibre (provided by the manufacturer) was (in %): protein 4, available carbohydrates 3.2, fat 1.8 and ash 2.5.

Particle size distribution

Fibre particle size distribution was determined using Morphologi® G3SE (Malvern Instruments Ltd, Malvern, UK) equipped with a sample dispersion unit for dry samples and a wet cell for hydrated samples. Size distribution was calculated as the relative volume of particles in size bands presented as size distribution curves (Malvern Micro software v. 5.40, Malvern Instruments Ltd.). Particle size distribution parameters included the largest particle size (d(v,0.9)), mean particle volume (d(v,0.5)), smallest particle size (d(v,0.1)), Sauter mean diameter (d(3,2)), and mean particle diameter (d(4,3)). Water-holding capacity of the fibre was determined as follows: 10 g of dietary fibre was soaked in 100 mL of distilled water and left overnight. Then the bulk was filtered through a Büchner funnel and the water-holding capacity was calculated as the difference between the amount of water used in the soaking process and the amount remaining in the bulk after filtration.

Bread preparation

Components of the bread dough included (in %): flour or flour partly replaced with dietary fibre 92, pressed yeasts 4, salt 2, sugar 1 and vegetable fat 1. Flour was replaced by dietary fibre at 4, 8, 12, 16 and 20% of the flour wet mass. The water content was calculated based on the water-holding capacity of the dietary fibre, and it was: 58, 61, 64, 67, 70 and 72% when the flour was replaced with 0, 4, 8, 12, 16 and 20% of dietary fibre, respectively. The obtained dough had a viscosity of up to 500 Brabender Units (BU) measured with rheometer Rotovisco RT20 (Haake, Vreden, Germany). All components, apart from fat, were mixed with a spiral mixer (TRQ–42; RM Gastro, Ustron, Poland) at 100 rpm for 4 min. After the addition of oil, the dough was mixed for 6 min at 250 rpm, left to rest for 15 min, and then divided into 60-gram rolls. The divided rolls rested for 15 min at room temperature, and were then put into the proofing chamber for 60 min (35 °C, 80% relative humidity) to double in volume. Bread rolls were then baked at 210 °C for 15 min in a convection oven (CPE 110; Kuppersbuch, Gelsenkirchen, Germany). After cooling, the bread was packaged into paper bags and stored for 3, 24 and 48 h at 20 °C.

Rheology

Rheological measurements were conducted with a Rotovisco RT20 rheometer (Haake). The rheological examination was done using standard dough preparation, but without yeast to avoid the influence of fermentation on the results. The creep and recovery test was followed by a five-minute period of relaxation. Next, the examined dough was subjected to the creep test with a constant shear stress of 50 Pa for 60 s, allowing the sample to recover for 180 s after the removal of the load. The forced oscillation test was conducted in the plate-plate geometry with a 2-mm gap. The parameters were chosen after a set of measurements had been performed to determine the viscoelastic region. The frequency of oscillation was 1 Hz, shear stress 600 Pa, angle rotation sensor 2°, and temperature of the measurement 15 °C. Measurements were performed in triplicate and the measured parameters were: G’ (storage modulus, in Pa), G” (loss modulus, in Pa) and γ (deformation).

Specific volume and moisture

The volume and moisture content of baked bread rolls during storage were determined according to the rapeseed displacement method (16). Each roll was weighed and the volume was measured 3, 24 and 48 h after baking. The specific volume was reported in cm3 per g of the loaf. The moisture content of the roll samples was determined by drying them overnight at 105 °C.

Colour

Colour determinations were carried out on bread crumbs using a CR-400 colourimeter (illuminant D65, measurement area ř=8mm, standard observers 2°; Konica Minolta Inc., Tokyo, Japan), and the results were expressed according to the CIELab colour space parameters: L (L=0 (black) and L=100 (white)), a (–a=greenness and +a=redness), and b (–b=blueness and +b=yellowness). The parameters were measured 3, 24 and 48 h after baking. Ten shots of the crumb and crust from three different rolls were taken with the colourimeter. The changes in the roll crust colour were estimated according to the browning index (BI) as follows:

where

Firmness

Firmness was measured 3, 24 and 48 h after baking, using the universal testing machine Instron® 5965 (Instron Corp., Norwood, MA, USA) with a maximal load of 500 N and 50% penetration depth using a 40-mm diameter probe. The test speed was 1.7 mm/s and the crumb cube size was 20 mm×20 mm×20 mm. The results were given as the maximum firmness in N.

Porosity

Porosity was estimated using image computer analysis. A loaf was cut into slices, each 2.5 cm thick. Photographs of the slices were taken using a digital camera (MicroPublisher 5.0 RTV; QImagining, Surrey BC, Canada) with illumination from lamps (Dulux L 36W/954, daylight; Osram, Munich, Germany) with the colour temperature 5400 K. Images were saved in TIFF format, then analyzed using ImageJ software, v. 1.44 (National Institute of Health, Bethesda, MD, USA). After selection of the central image of the crumb and determining the area, the image was converted into an 8-bit image to obtain a black and white threshold followed by binary segmentation. The results are presented as a percentage of pore area in the total area. The measured parameter was the mean cell area, expressed in mm2; this was calculated by dividing the total area of cells by the total number of cells.

Total dietary fibre

Total dietary fibre content in baked bread rolls was measured according to the AOAC method 2009.01-2009 (17) modified by the producer using the Fibretec™ 1023 system E (FOSS Inc., Eden Prairie, MN, USA).

Statistical analysis

The statistical calculations, including the analysis of variance and Tukey’s test with significance level at α=0.05, and the Pearson’s correlation matrix, were performed using STATISTICA v. 10 for Windows (StatSoft Inc., Tulsa, OK, USA).

Results and Discussion

Particle size

Table 1 presents the results of static automated image analysis of the oat fibre powder with water-holding capacity used for the wheat roll production. The particle sizes of dietary fibre suggest that the whole mass of the two dietary fibres was not homogenous because of a wide range of particle sizes from 14.7 to 132.5 µm of OFP1, and from 20.3 to 333.7 µm of OFP2. With regard to the water- -holding capacity of oat fibre, different outcomes were obtained compared to those achieved by two groups of researchers (16, 18) who concluded that decreasing particle size leads to reduced hydration properties. The results confirm the theory of Chau et al. (19) that a decrease in fibre particle size results in a larger exposure of hydrophilic groups, which is connected with water absorption capacity.

Table 1. The particle size and shape of dietary fibre powder with water-holding capacity (WHC) used for wheat roll production.

| d(3,2)/µm | d(4,3)/µm | d(v,0.1)/µm | d(v,0.5)/µm | d(v,0.9)/µm | WHC/(mL/g) | |

|---|---|---|---|---|---|---|

| OFP1 | (34.9±1.0)a | (67.3±0.8)a | (14.7±1.1)a | (60.1±2.8)b | (132.5±1.8)c | (5.24±0.2)b |

| OFP2 | (53.3±1.1)b | (141.2±2.5)b | (20.3±1.8)ab | (109.5±1.8)c | (333.7±1.7)d | (2.48±0.1)a |

OFP1 and OFP2=oat fibre powder with particle sizes of 75 and 150 µm, respectively. d(3,2)=Sauter mean diameter, d(4,3)=mean particle diameter, d(v,0.9)=the largest particle size, d(v,0.5)=mean particle volume, and d(v,0.1)=smallest particle size. Values with different letters differ significantly (p≤0.05)

Rheological properties

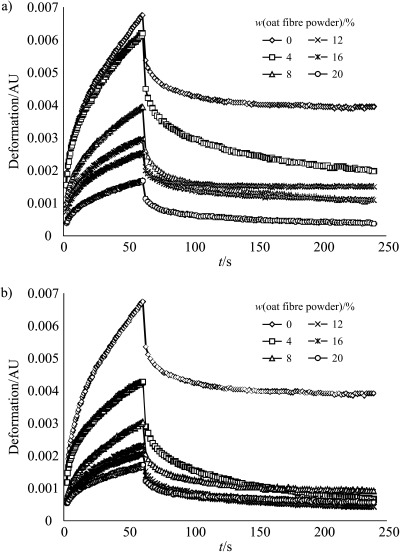

The creep and recovery test indicated that when the flour is replaced with oat fibre powder, the maximum deformation of OFP1 and OFP2 samples obtained after 60 s of the creep test was significantly reduced (p≤0.05). The results are shown in Figs. 1a and b. It is worth noting that the values of deformation of the dough containing OFP1 were higher than of that containing OFP2. The samples of dough containing 4, 8, 12 and 16% OFP1 recovered their primary form after removal of the load more effectively than the dough containing OFP2, indicating higher elasticity of this dough. In the case of dough with the addition of 20% of fibre powder, this tendency was not observed, which may indicate that the dough was oversaturated with the fibre powder. Fibre does not form a gluten structure, it creates a parallel viscoelastic system. This tendency conforms to the outcomes of studies by Ahmed et al. (20), who observed that when the fibre content increases, not only the maximum deformation values decrease, but also elastic recovery is reduced. Dietary fibre is highly hygroscopic, and therefore it significantly affects the rheological properties of dough. It is associated with higher water absorption while kneading, and the phenomenon increases with an increase in the dietary fibre content in dough (13). The rheological properties significantly affect the final quality of the product. The studies by Sabanis et al. (21) indicate that due to higher dough viscosity, small air bubbles formed while kneading showed higher persistance during baking. If viscosity is high, air bubbles may travel upwards during fermentation, but due to their increased amount, the crumbs exhibit better porosity. The creep and recovery test is an effective way to demonstrate physical properties of bakery products. Van Bockstaele et al. (22) observed that the creep and recovery test showed significant correlations with protein content, Zeleny sedimentation value, farinograph water absorption, alveograph extensibility and bread volume.

Fig. 1.

Results of the creep and recovery test of the dough with 0, 4, 8, 12, 16 and 20% of flour replaced with oat fibre powder with particle sizes of: a) 75 µm (OFP1) and b) 150 µm (OFP2)

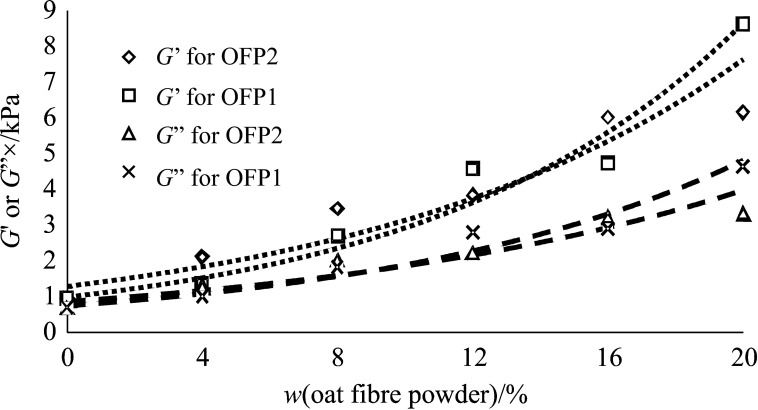

The changes in the values of the storage modulus and loss modulus demonstrate that wheat dough with oat fibre is more elastic than viscous (Fig. 2). However, attention should be paid to the fact that storage modulus values of the OFP1-containing dough were higher than of the OFP2-containing dough.

Fig. 2.

Changes of storage (G’) and loss (G”) moduli of dough with 0, 4, 8, 12, 16 and 20% of flour replaced with the oat fibre powder with particle sizes of 75 µm (OFP1) and 150 µm (OFP2)

Specific volume and moisture content

The specific volume and moisture content of wheat rolls with oat fibre powder are shown in Table 2. The dietary fibre of smaller particle sizes in wheat rolls increased the specific volume of the final product, but it was smaller than of the control. During storage, the loss of volume was recorded, and the rolls with OFP1 lost from 6.1 to 6.7% of volume after 48 h and those with OFP2 lost between 15.1 and 20.7% of volume. Reduced loaf volume may also be caused by gluten dilution and physicochemical reactions among fibre components, water and gluten (21). The moisture content is strongly correlated with the specific volume values. This means that the smaller particles take up more water because of the larger surface area. Moisture content is strongly correlated with the water uptake during mixing of the dough (22). Dough with more water-binding substances (such as fibre) absorbs more water, which can be bound during storage. The moisture of OFP1-containing bread rolls was higher because the smaller particle size and more hydrophilic groups from fibre were prone to binding water (23).

Table 2. The specific volume (ν), moisture content, and browning index of wheat rolls with oat fibre powder.

| Composite bread | t/h | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| w(oat fibre) | 3 | 24 | 48 | 3 | 24 | 48 | 3 | 24 | 48 | |||

| % | ν/(cm3/g) | Moisture content/% | Browning index | |||||||||

| Control | 0 | 6.4g | 6.0h | 5.9f | 47.8a | 47.5a | 47.2a | 50.4a | 50.4a | 50.5a | ||

| OFP1 | 4 | 5.8f | 5.5f | 5.4e | 50.6bc | 49.6b | 48.8ab | 53.3b | 52.7b | 53.0b | ||

| 8 | 5.4e | 5.1e | 5.0d | 50.8bc | 49.8ab | 49.0ab | 56.0d | 55.9d | 55.1bc | |||

| 12 | 4.8c | 4.6cd | 4.5cd | 51.2c | 50.2c | 49.0b | 57.3e | 57.4e | 56.8bc | |||

| 16 | 4.3b | 4.1b | 4.0c | 51.3c | 50.7c | 50.2c | 59.3f | 58.3f | 58.8d | |||

| 20 | 4.0ab | 3.8ab | 3.7ab | 51.8c | 51.6d | 51.5e | 60.5g | 60.5g | 61.4e | |||

| OFP2 | 4 | 5.4e | 5.2e | 5.0a | 48.9ab | 48.4ab | 47.76a | 54.1c | 53.2c | 53.0b | ||

| 8 | 5.0bc | 4.8d | 4.7cd | 49.8b | 48.9ab | 48.5ab | 56.4d | 55.6d | 55.4bc | |||

| 12 | 4.5a | 4.3c | 4.2c | 51.7d | 51.2d | 50.78cd | 58.1e | 58.2e | 57.9c | |||

| 16 | 4.1ab | 4.0b | 3.8b | 51.7d | 51.3d | 50.88d | 60.6g | 59.8f | 59.4d | |||

| 20 | 3.6a | 3.5a | 3.4a | 51.5cd | 51.2d | 50.74cd | 62.4h | 60.5ef | 59.8d | |||

OFP1 and OFP2=oat fibre powder with particle sizes of 75 and 150 µm, respectively. Values with different letters in superscript differ significantly (p≤0.05)

Colour parameters of wheat rolls

Golden brown crust and creamy white bread crumbs are the most important appealing factors that indicate the quality of a bakery product to consumers (23). Table 2 shows the browning indices of wheat roll crumbs. The rolls containing OFP1 had a lower browning index due to the smaller particle size, which can bind more effectively into the starch-gluten matrix and do not influence the colour to the same degree as OFP2. It should be noted that the higher the content of dietary fibre, the browner the crust, as the colour change of the crust of the wheat rolls with high content of dietary fibre was caused by oxidation reaction and release of sugars, which participate in caramelization during baking (24).

It was demonstrated that while storing OFP1- and OFP2-containing samples, a significant change in lightness occurred, but it was not observed in the control sample. OFP1 and OFP2 samples did not differ in terms of redness (a) values during storage; however, they were statistically significantly different in terms of yellowness (b). The colour of bakery products with added dietary fibre changes as a result of a caramelization and the Maillard reaction. That is true only if we want to explain the colour of the surface of bakery products directly exposed to high temperatures. In the case of bread crumb, such high temperatures are not reached. Therefore, it is reasonable to perform measurements only for crumbs, the colour of which directly correlates with ingredients used in the dough production (9). Results obtained in this study indicate that smaller sizes of dietary fibre added to bakery products result in fewer differences compared to the control sample. However, it is worth noting that the reduced lightness of bakery products may be a result of water binding to the fibre, creating the environment for reactions between sugars and amino acids (25).

Firmness parameters

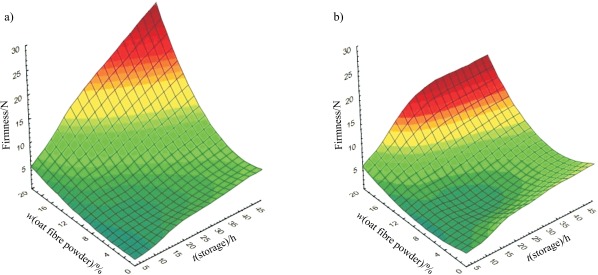

Firmness was measured during storage of wheat rolls in order to determine the effects of the addition of oat fibre powder on staling (Fig. 3). Staling is one of the most important changes that affect bakery products during storage, and it has a significant effect on the aroma and firmness, perceived by consumers as quality indicators. Staling can be described as increased firmness of bakery products over time caused by retrogradation of amylose and amylopectin. For that reason, increasing interest has been devoted to producing complex compounds with amylopectin and amylose with substances belonging to a dietary fibre group in order to inhibit retrogradation (26). Fig. 3 shows changes of crumb firmness of wheat rolls after the addition of the fibre powder. It can be seen that the addition of dietary fibre resulted in increased firmness 3 h after baking, which is statistically more significant (p≤0.05) in samples with the OFP1 than in those containing OFP2. Firmness increased significantly with the length of storage, especially of the samples containing 16 and 20% OFP1, which is associated with a high amount of insoluble fibre in the used fibre powder (27). Both lack of firmness and volume are affected by the content of hydrocolloids in fibre powder. When bread with high mass fraction of dietary fibre is heated, hydrocolloids with strong bonds are formed, and these bonds cannot be broken by enzymes in flour due to their low amount (27). Smaller changes in the firmness value were observed in the fibre with larger particles than in the fibre with smaller particles. However, in this study, it was determined that the addition of both OFP1 and OFP2 increased the firmness of bakery products. A correlation analysis demonstrated a significant positive correlation between firmness and the storage modulus G’ (R=0.77) and loss modulus G” (R=0.78). Strong correlations between rheological parameters and texture indicate that firmness depends on the storage modulus. The fact that firmness increases with increased fibre content may be due to the increased water-holding capacity of the fibre. Therefore, chemical reactions can occur more easily, affecting the physical parameters (28). Fibre micronization may also be associated with the destruction of the aleurone layer of cells during grinding. As a result, enzymes, glutathione or phytates are released and they may impair gluten formation due to chemical reactions (29).

Fig. 3.

Changes of firmness of wheat rolls during storage depending on the flour replacement with 0, 4, 8, 12, 16 and 20% oat fibre powder with particle sizes of: a) 75 µm (OFP1) and b) 150 µm (OFP2)

Porosity of baked wheat rolls

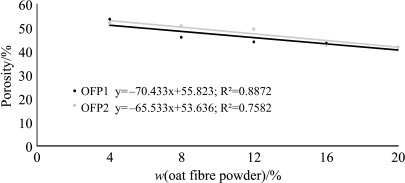

Visual characteristics of crumbs, such as mean cell area, are among the elements that constitute the quality of the final product (30). As can be seen in Fig. 4 only the average size of bread crumb pores was altered by the addition of dietary fibre. The crumbs containing OFP1 had less porous structure, which could be explained by lower viscosity of the dough caused by dietary fibre, resulting in lower carbon dioxide formation during fermentation (31).

Fig. 4.

The porosity of wheat bread rolls with 0, 4, 8, 12, 16 and 20% of flour replaced with oat fibre powder with particle sizes of 75 µm (OFP1) and 150 µm (OFP2), expressed as percentage of whole area of bread slice

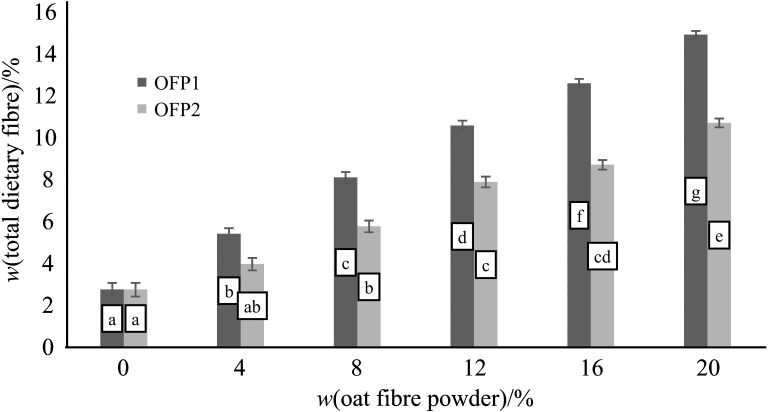

Total dietary fibre

Fig. 5 shows the total dietary fibre content of the tested rolls. An interesting tendency is that bakery products with OFP1 contained more fibre than bakery products with OFP2. This is associated with the fact that smaller fibre particles have larger surface, and consequently, their water-binding capacity is higher, and water is released faster during baking and storage. Therefore, a lower mass is obtained, and there is a relative increase in the fibre content in bread rolls (32).

Fig. 5.

The total dietary fibre content in wheat bread rolls with 0, 4, 8, 12, 16 and 20% of flour replaced with oat fibre powder with particle sizes of 75 µm (OFP1) and 150 µm (OFP2). Values with different letters differ significantly (p≤0.05)

Conclusion

There are only few scientific reports focused on the use of oat fibre as an additive to bakery products. This study has demonstrated that reducing the particle size of fibre powder affects the characteristics of bakery products. Because of greater granulation of bakery products, it is possible to obtain dough with better rheological properties and colour parameters than when using products without the addition of fibre. The problem of increased firmness of bakery products accompanying the addition of fibre may be associated with the high water-binding capacity of dietary fibre. It is therefore necessary to prepare a formula that optimises the amount of water.

Acknowledgements

This study was supported by Project no POIG.01. 03.01-14-041/12 ‘Bioproducts’, innovative technologies of pro-health bakery products and pasta with reduced caloric value, co-financed by the European Regional Development Fund under the Innovative Economy Operational Programme 2007–2013.

References

- 1.Melanson KJ, Angelopoulos TJ, Nguyen VT, Martini M, Zukley L, Lowndes J, et al. Consumption of whole-grain cereals during weight loss: effects on dietary quality, dietary fiber, magnesium, vitamin B6, and obesity. J Am Diet Assoc. 2006;106:1380–8. 10.1016/j.jada.2006.06.003 [DOI] [PubMed] [Google Scholar]

- 2.Quilez J, Salas-Salvado J. Salt in bread in Europe: potential benefits of reduction. Nutr Rev. 2012;70:666–78. 10.1111/j.1753-4887.2012.00540.x [DOI] [PubMed] [Google Scholar]

- 3.Bautista-Castańo I, Serra-Majem L. Relationship between bread consumption, body weight, and abdominal fat distribution: evidence from epidemiological studies. Nutr Rev. 2012;70:218–33. 10.1111/j.1753-4887.2012.00454.x [DOI] [PubMed] [Google Scholar]

- 4.Angioloni A, Collar C. Gel, dough and fibre enriched fresh breads: relationships between quality feats and staling kinetics. J Food Eng. 2009;91:526–32. 10.1016/j.jfoodeng.2008.09.033 [DOI] [Google Scholar]

- 5.Gélinas P. Preventing constipation: a review of the laxative potential of food ingredients. Int J Food Sci Technol. 2013;48:445–67. 10.1111/j.1365-2621.2012.03207.x [DOI] [Google Scholar]

- 6.Mora YN, Contreras JC, Aguilar CN, Meléndez P, Garza IDL, Rodríguez R. Chemical composition and functional properties from different sources of dietary fibre. Am J Food and Nutr. 2013;1:27–33. 10.12691/ajfn-1-3-2 [DOI] [Google Scholar]

- 7.Klosterbuer A, Roughead ZF, Slavin J. Benefits of dietary fibre in clinical nutrition. Nutr Clin Pract. 2011;26:625–35. 10.1177/0884533611416126 [DOI] [PubMed] [Google Scholar]

- 8.Scientific opinion on the substantiation of a health claim related to oat beta-glucan and lowering blood cholesterol and reduced risk of (coronary) heart disease pursuant to Article 14 of Regulation (EC) No 1924/2006. EFSA J. 2010;8(12):1885 10.2903/j.efsa.2010.1885 [DOI] [Google Scholar]

- 9.European Union Commission Regulation (EU) No 1047/2012 of 8 November 2012 amending Regulation (EC) No 1924/2006. Off J EU. 2012;L310:36–7. [Google Scholar]

- 10.Almeida EL, Chang YK, Steel CJ. Effect of adding different dietary fiber sources on farinographic parameters of wheat flour. Cereal Chem. 2010;87:566–73. 10.1094/CCHEM-05-10-0063 [DOI] [Google Scholar]

- 11.Rubel IA, Pérez EE, Manrique GD, Genovese DB. Fibre enrichment of wheat bread with Jerusalem artichoke inulin: effect on dough rheology and bread quality. Food Struct. 2015;3:21–9. 10.1016/j.foostr.2014.11.001 [DOI] [Google Scholar]

- 12.Khater ESG, Bahnasawy AH. Heat and mass balance for baking process. J Bioprocess Biotech. 2014;4:190190 10.4172/2155-9821.1000190 [DOI] [Google Scholar]

- 13.Gómez M, Ronda F, Blanco CA, Caballero PA, Apesteguía A. Effect of dietary fibre on dough rheology and bread quality. Eur Food Res Technol. 2003;216:51–6. 10.1007/s00217-002-0632-9 [DOI] [Google Scholar]

- 14.Dhingra D, Mona M, Rajput H, Patil RT. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49:255–66. 10.1007/s13197-011-0365-5 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Collar C, Santos E, Rosell CM. Assessment of the rheological profile of fibre-enriched bread doughs by response surface methodology. J Food Eng. 2007;78:820–6. 10.1016/j.jfoodeng.2005.11.026 [DOI] [Google Scholar]

- 16.Laurikainen T, Härkönen H, Autio K, Poutanen K. Effects of enzymes in fibre-enriched baking. J Sci Food Agric. 1998;76:239–49. [DOI] [Google Scholar]

- 17.Official Method AOAC. 2009.01-2009. Total dietary fiber in foods. Enzymatic-gravimetric- liquid chromatographic method. Gaithersburg, MD, USA: AOAC International, 2009. [Google Scholar]

- 18.Rosell CM, Santos E, Collar C. Mixing properties of fibre-enriched wheat bread doughs: a response surface methodology study. Eur Food Res Technol. 2006;223:333–40. 10.1007/s00217-005-0208-6 [DOI] [Google Scholar]

- 19.Chau CF, Wen YL, Wang YT. Improvement of the functionality of a potential fruit insoluble fibre by micron technology. Int J Food Sci Technol. 2006;41:1054–60. 10.1111/j.1365-2621.2006.01171.x [DOI] [Google Scholar]

- 20.Ahmed AR, Mohammed I, Senge B. Oscillation measurements and creep test of bread prepared from wheat-lupin flours and wheat flour-lupin fibre dough’s blends. Ann Transac Nord Rheol Soc. 2012;20:145–52. [Google Scholar]

- 21.Sabanis D, Lebesi D, Tzia C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT –. Food Sci Technol (Campinas). 2009;42:1380–9. 10.1016/j.lwt.2009.03.010 [DOI] [Google Scholar]

- 22.Van Bockstaele F, De Leyn I, Eeckhout M, Dewettinck K. Rheological properties of wheat flour dough and the relationship with bread volume. I. Creep-recovery measurements. Cereal Chem. J. 2008;85:753–61. 10.1094/CCHEM-85-6-0753 [DOI] [Google Scholar]

- 23.Kurek M, Wyrwisz J, Piwińska M, Wierzbicka A. Application of response surface methodology in optimizing oat fibre particle size and flour replacement in wheat bread rolls. CyTA – J Food. 2016;14:18–26. 10.1080/19476337.2015.1036309 [DOI] [Google Scholar]

- 24.Rosell CM, Santos E, Collar C. Physico-chemical properties of commercial fibres from different sources: a comparative approach. Food Res Int. 2009;42:176–84. 10.1016/j.foodres.2008.10.003 [DOI] [Google Scholar]

- 25.Zhang LH, Xu HD, Li SF. Effects of micronization on properties of Chaenomeles sinensis (Thouin) Koehne fruit powder. Innov Food Sci Emerg Technol. 2009;10:633–7. 10.1016/j.ifset.2009.05.010 [DOI] [Google Scholar]

- 26.Sivam AS, Sun-Waterhouse D, Waterhouse GIN, Quek SY, Perera CO. Physicochemical properties of bread dough and finished bread with added pectin fiber and phenolic antioxidants. J Food Sci. 2011;76:H97–107. 10.1111/j.1750-3841.2011.02086.x [DOI] [PubMed] [Google Scholar]

- 27.Anil M. Using of hazelnut testa as a source of dietary fiber in bread making. J Food Eng. 2007;80:61–7. 10.1016/j.jfoodeng.2006.05.003 [DOI] [Google Scholar]

- 28.Ho LH, Abdul Aziza NA, Rajeev B, Azaharib B. Storage studies of bread prepared by incorporation of the banana pseudo-stem flour and the composite breads containing hydrocolloids. CyTA – J Food. 2014;12:141–9. 10.1080/19476337.2013.806597 [DOI] [Google Scholar]

- 29.Gelinas P, McKinnon C. Dietary fibre and β-glucan in strong bread wheat cultivars: does it matter? Int J Food Sci Technol. 2013;48:670–2. 10.1111/j.1365-2621.2012.03216.x [DOI] [Google Scholar]

- 30.Yi J, Kerr WL. Combined effects of freezing rate, storage temperature and time on bread dough and baking properties. LWT –. Food Sci Technol (Campinas). 2009;42:1474–83. 10.1016/j.lwt.2009.05.017 [DOI] [Google Scholar]

- 31.Kurek M, Wyrwisz J, Piwińska M, Wierzbicka A. Influence of the wheat flour extraction degree in the quality of bread made with high proportions of β-glucan. Food Sci Technol (Campinas). 2015;35:273–8. 10.1590/1678-457X.6537 [DOI] [Google Scholar]

- 32.Pourfarzad A, Mahdavian-Mehr H, Sedaghat N. Coffee silverskin as a source of dietary fibre in bread-making: optimization of chemical treatment using response surface methodology. LWT –. Food Sci Technol (Campinas). 2013;50:599–606. 10.1016/j.lwt.2012.08.001 [DOI] [Google Scholar]