Abstract

Background

Relationships among portable scanning mobility particle sizer (P-SMPS), condensation particle counter (CPC), and surface area monitor (SAM), which are different metric measurement devices, were investigated, and two widely used research grade (RG)-SMPSs were compared to harmonize the measurement protocols.

Methods

Pearson correlation analysis was performed to compare the relation between P-SMPS, CPC, and SAM and two common RG-SMPS.

Results

For laboratory and engineered nanoparticle (ENP) workplaces, correlation among devices showed good relationships. Correlation among devices was fair in unintended nanoparticle (UNP)-emitting workplaces. This is partly explained by the fact that shape of particles was not spherical, although calibration of sampling instruments was performed using spherical particles and the concentration was very high at the UNP workplaces to allow them to aggregate more easily. Chain-like particles were found by scanning electron microscope in UNP workplaces. The CPC or SAM could be used as an alternative instrument instead of SMPS at the ENP-handling workplaces. At the UNP workplaces, where concentration is high, real-time instruments should be used with caution. There are significant differences between the two SMPSs tested. TSI SMPS showed about 20% higher concentration than the Grimm SMPS in all workplaces.

Conclusions

For nanoparticle measurement, CPC and SAM might be useful to find source of emission at laboratory and ENP workplaces instead of P-SMPS in the first stage. An SMPS is required to measure with high accuracy. Caution is necessary when comparing data from different nanoparticle measurement devices and RG-SMPSs.

Keywords: condensation particle counter, nanoparticle exposure assessment, relationship, scanning mobility particle sizer, surface area monitor

1. Introduction

Traditionally, gravimetric sampling which collect the airborne particles on a filter, has been used to assess the workplace. However, nanoparticles are difficult to evaluate by gravimetric sampling because they are very small to affect the mass concentration. Also, it is difficult to find the source of emission during working time. Therefore, many real-time monitoring devices are available to measure airborne nanoparticles, such as scanning mobility particle sizer (SMPS), condensation particle counter (CPC), and surface area monitor (SAM). There is a controversial issue in measurement metrics in exposure assessment as well as toxicity [1], [2], [3]. For this reason, many researchers have employed a combination of measurement devices for nanoparticle exposure assessment and it is necessary to investigate the level of concentration with several metrics [4], [5], [6], [7], [8], [9].

SMPS, CPC, and SAM are the most common combinations for nanoparticle exposure assessment at workplaces [4], [9], [10]. Research grade (RG)-SMPSs, such as Grimm 5.403+C (Grimm Technologies, Douglasville, GA, USA) and TSI Model 3936L75 (TSI, Shoreview, MN, USA), remain the golden standard of aerosol instrumentation even 20 years after their invention. They measure aerosol size distributions with high accuracy, but have long time resolution, and thus cannot be used to measure rapidly changing particle size distributions at workplace because scanning time is over 2 minutes [11]. However, RG-SMPSs are expensive and heavy to move to the sampling site; a portable SMPS (TSI Model 3910 with 1-minute time interval), hereafter referred to as P-SMPS, is cheaper than RG-SMPS, but still expensive [11]. It is necessary to find a possible surrogate measurement device to measure nanoparticles. CPC and SAM are relatively cheaper than SMPS and portable. To compare and find relationships among SMPS, CPC, and SAM, correlation analysis is necessary.

When the number concentration is measured, the measurement devices have different size and concentration ranges. In exposure assessment studies, the potentially different results from different instruments are issues when results obtained simultaneously at the same location or different locations [12]. Two common RG-SMPSs are manufactured by Grimm and TSI [13]. They have different techniques to separate particles size: Grimm SMPS measures large particles to small particles in size and TSI SMPS measures particles from small particles to large particles. Also, sampling time is different between SMPSs. Differences may occur in the concentration when nanoparticles at the same location is measured with different SMPSs. Therefore, harmonization and investigation of difference of devices is necessary and getting the relationships between same metric measurement devices is essential for use of exposure assessment data in the future [14]. There are a few studies that compare nanoparticles measurement instruments in the -controlled laboratories [14], [15] and no studies at workplaces to our knowledge.

The aims of this study were to determine relation among three monitoring devices of nanoparticles—SMPS, CPC, and SAM—and compare two widely used RG-SMPS for better understanding of nanoparticle measurement devices.

2. Materials and methods

2.1. Sampling facility

Three types of workplace were categorized: laboratory (LAB); engineered nanoparticle (ENP) workplace; and unintended nanoparticle (UNP)-emitting workplaces (Table 1). A total of nine workplaces participated.

Table 1.

The general characteristics of workplaces

| Workplace | Emitted/source of nanoparticles | Ventilation type | Process/task | Production rate | Workplace area (m2) | No. of nanoparticle handling workers | Possible other sources | Sampling duration | |

|---|---|---|---|---|---|---|---|---|---|

| LAB | A | Al2O3 | GV, fume hood | Transferred to crucible, transferred from crucible to vial, weighing | – | 120 | 2 | – | One shift + one off-duty time |

| B | Fe2O3, TiO2 | GV, fume hood | Weighing, sonication, Reaction | – | 78 | 7 | – | One shift + one off-duty time | |

| C | Graphene | GV, fume hood | Spraying air using compressor, dip-coater | – | 90 | 5 | – | One shift + one off-duty time | |

| ENP | D | TiO2, ZnO | GV | Reaction, dehydration, mixing, drying, bagging, lunch | TiO2: 10 ton/y ZnO: 50 ton/y |

1,400 | 10 | Fork lift | Two day shifts + one night shift |

| E | Cu-Ni alloy, Ni | LEV and isolation | Collecting, sieving, lunch | Ni: 100 kg/y Cu—Ni: 100 kg/y |

97 | 6 | – | One shift | |

| F | Fumed silica | LEV, GV | Packaging, meal (lunch, dinner), break time, night shift - no works, outdoor, warehouse | 9,000 ton/y | 3,500 | 12 | Fork lift | Two day shifts + one night shift | |

| UNP | G | Welding (Arc, SUS) | GV | Arc welding, SUS welding, break time, lunch | – | Arc: 10,000 SUS: 820 |

100 | Fork lift | Two day shifts |

| H | Welding (Arc) | GV | Arc welding, grinding (day shift, night shift), lunch | – | 2,017 | 30 | Fork lift | Two day shifts + one night shift | |

| I | Smelting process, Welding (Arc) | GV | Smelting, welding, break time, lunch | – | 11,000 | Smelting: 15/shift × 2 welding: 3 |

Fork lift | Two day shifts + one night shift |

ENP, engineered nanoparticle manufacturing workplace; GV, general ventilation; LAB, laboratory; LEV, local exhaust ventilation; UNP, unintended nanoparticle emitted workplace.

Three laboratories at a university were investigated. LAB-A was an earth environment laboratory, and the primary nanoparticle was Al2O3. Two workers performed experiments of transfer to the crucible, transfer from the crucible to a vial, and weighing. LAB-B was involved with development of new materials, with the primary nanoparticles used being Fe2O3 and TiO2. Major experiments were weighing, sonication, and reaction. Seven workers performed the experiments. LAB-C dealt with graphene for space aviation. Dip-coating processes to fabricate graphene were the primary experiments performed; together with spraying the base of the dip coater for cleaning by five workers. A natural ventilation system and a fume hood were installed in all laboratories.

Three ENP manufacturing workplaces examined. ENP-D fabricated Ti and Zn powder for cosmetic sunscreen; reaction, dehydration, mixing, drying, and bagging were the major processes at ENP-D. The reaction was operated at 120 °C and 3 atm, and dehydration was performed at 60 °C. There were a natural ventilation (NV) system and no local exhaust ventilation (LEV). TiO2 was extracted from TiCl4 for the photocatalyst material. The liquid-phase TiO2 was synthesized using low-temperature (i.e., without any heat treatment) by precipitation methods using the hydrolysis process. Electrolysis was used to manufacture aluminum nanoparticles. A welding process took place in the next room, but the door was closed for most of the working duration. ENP-E dealt with metallic nanosized powders such as copper, nickel, and silver. Nano sized powders were fabricated by the high-voltage pulsed-wire evaporation method, and the main products were copper–nickel alloy and nickel nanopowders for use as additives in automobile engines. The main processes were collecting and sieving. Manufacturing equipment for PWE was isolated in a cabinet equipped with an LEV system. During the manufacturing process, the glass door was closed. Amorphous silica was manufactured at ENP-F and an automation system was installed for all processes. Amorphous silica was used for abrasive materials that were applied in the chemical mechanical polishing process for the semiconductor industry. The main process was packaging of a 10-kg bag. A natural ventilation system and LEV were operated during the bagging process.

Three UNP workplaces were investigated. UNP-G produced steel structures and heat exchangers; arc and stainless steel welding were the major processes and a total of 100 workers performed welding. The major product of UNP-H was body frames for back hoes and forklifts. Welding and grinding were the main processes at UNP-I. A total of 30 workers were active. There was an NV system, but no LEV, installed at any of UNP workplaces.

2.2. Measurement strategy

A sampling cart was used to move the sampling devices for portability. We performed the area sampling and tried to capture the airborne particles as close as possible to a worker's breathing zone or emission sources. The sampling cart was moved according to the process or task. The inlets of each instrument were installed together within 30 cm to reduce the measurement error. The heights of the inlets were located between 1.2 m and 1.5 m. During sampling, the researcher observed the worker's activities and recorded it in a time activity diary to get contextual information, which was matched with the concentration profiles obtained by real-time measurement devices. During the night downtime, the sampling devices were operated in the absence of the researcher. All of the instruments were connected to AC power for electrical power.

2.3. Sampling devices for correlation of SMPS, CPC, and SAM

For the distribution of particle sizes, a P-SMPS (Nanoscan, Model 3910; TSI) with a detectable size range from 10 nm to 420 nm and a concentration range of 0–106 particles/cm3 was utilized. The flow rate of inlet was 0.75 L/min and the flow rate for sample was 0.25 L/min. The sampling time of the P-SMPS was 1 minute per averaging time, and particle sizes from small to large were measured by 13 sequence channels. The cyclone was attached to get rid of the larger particles. The particles were collected from the inlet and passed through the aerosol neutralizer (unipolar charger). Particles were separated by the mobility diameter with a radial differential mobility analyzer (DMA) before being counted using a CPC. The main advantage of this instrument is its portability, battery operation without the need to use a power supply, the use of a nonradioactive unipolar charger, which makes it an appropriate monitor for real time workplace measurement without the transport and application restrictions currently affecting traditional RG-SMPS, the use of isopropanol instead of butanol as a working fluid, and relatively smaller size than RG-SMPS. However, there are only 13 channels, compared with 107 for RG-SMPS.

A CPC (P-Trak Model 8525; TSI) was utilized to measure the number concentration of particles of 20–1,000-nm diameter with a 0.1 L/min sample flow rate. The measurable concentration range was 0–500,000 particles/cm3. Isopropyl alcohol was used for particle condensation, which increases the particle size of optical detection available. A sampling averaging time was fixed as 1 minute in this study. The zero calibration was operated by a HEPA filter before sampling. The CPC is lightweight, has a variable sampling time interval from 1 second, is portable to use, and less expensive than SMPS but does not have comparable size distribution.

For measurement of the surface area concentration, a surface area monitor (SAM) (AeroTrak Model 9000; TSI) was employed. The averaging time was 1 minute; the measurable particle size range was 10–1,000 nm and the aerosol concentration ranged from 1–10,000 μm2/cm3 for alveolar deposition mode. Cyclone was set on the inlet to avoid into the SAM of particles larger than 1 μm. The flow rate of sample was 1.5 L/min. Zero calibration of the electrometer was operated before each sampling. The advantages of SAM are that it is portable, has variable sampling time interval from 1 second, is less expensive than SMPS, and allows calculation of deposition to the alveolar region. However, it is difficult to distinguish particles by size.

2.4. Sampling devices for comparison between two different SMPSs

Table 4 shows the parameters of the RG-SMPSs used for comparison at ENP-E. To investigate the distribution of particle sizes, two research-grade SMPSs were used. One is RG-SMPS Model 3936L75 (TSI) with a measurable size range from 14.6 nm to 661 nm and a concentration range of 0–107 particles/cm3 was used. The sample flow rate was 0.3 L/min, and the sheath flow rate 3 L/min for the sample. The sampling time of the SMPS was 135 seconds per averaging time, and it measured the particle size from small to large (up-scan) with 107 sequence channels. The particles are collected from the inlet and passed through the aerosol neutralizer (krypton-85). Particles are separated by mobility diameter using a differential mobility analyzer before being counted using a CPC. The other is RG-SMPS 5.403+C with long DMA (Grimm Technologies) with the detectable size range 11.1–1,083.3 nm with down-scan and a concentration range of 0–107 particles/cm3 was used. The sample flow rate was 0.3 L/min, and the sheath flow rate was 3 L/min. The sampling time of the SMPS was 213 seconds per averaging time, and it measured the particle size from large to small with 44 sequence channels. The particles were collected from the inlet and passed through the aerosol neutralizer (americium-241). TSI SMPS data were analyzed using Aerosol Instrument Manager (version 7) and Grimm used SMPS version 1.35.

Table 4.

Parameters of the research-grade scanning mobility particle sizers (RG-SMPSs) used for comparison at engineered nanoparticle manufacturing workplace-E

| Grimm RG-SMPS | TSI RG-SMPS | |

|---|---|---|

| Model | 5.403+C | 3936L75 |

| DMA | Vienna type (Larger to smaller) Long-DMA | TSI-3081 |

| Scanning sequences | Larger particles to smaller particles | Smaller particles to larger particles |

| Neutralizer | AM241 (α emitter) | Kr85 (β emitter) |

| Measurement range | 11.1–1083.3 nm | 14.6–661.1 nm |

| Aerosol sampling rate (L/min) | 0.3 | 0.3 |

| Sheath air flow rate (L/min) | 3 | 3 |

| Sampling interval | 333 s | 135 s |

| CPC type | Butanol based | Butanol based |

| CPC maximum concentration | 107 particles/cm3 | 107 particles/cm3 |

CPC, condensation particle counter; DMA, differential mobility analyzer.

2.5. Statistical analysis

Descriptive statistics was performed to show correlation of the concentration levels by measurement device. For comparison among devices (P-SMPS, CPC, and SAM) are analyzed by Pearson correlation. The correlation—good to excellent relationship (> 0.75), moderate to good relationship (0.50–0.75), fair degree of relationship (0.25–0.50), or little or no relationship (0.0–0.25)—was categorized [16]. Pearson correlation coefficient was calculated to investigate the relationship between Grimm and TSI SMPSs. The one cycle of SMPS was different. SMPS data were organized into 5-minute averages. Data for comparison between two RG-SMPS were used with Grimm 5.403+C with long DMA and TSI 3936L75 and for comparison between devices with many metrics are used with TSI P-SMPS (Model 3910). Normalized number concentration dN/dlogDp was used to compare aerosol size distributions taken of the same aerosol using instruments of different resolutions for SMPS. Data analysis was conducted using SPSS (Version 20.0; IBM, Armonk, NY, USA).

3. Results

Table 1 summarizes the general characteristics of workplaces investigated based on the type of workplace, emitted or source of nanoparticles, ventilation type, processes or tasks, size of workplace, number of workers, and other possible sources. Two LABs were dealing with metal and one LAB handled graphene. Three ENPs manufactured metal nanoparticles and one also manufactured fumed silica. All UNP workplaces performed welding, and UNP-J also undertook smelting processes.

All LABs had NV and a fume hood. For ENP workplaces, ENP-D had NV. LEV and isolated cabinets for facilities were installed at ENP-E. NV and LEV were installed at the ENP-F workplace. Only NV was installed at the ENP-G and UNP workplaces in this study.

There were two, seven, and five workers at the LAB workplaces. One to 12 workers were engaged at the ENP workplaces. One hundred, 30, and three welders were employed at UNP-G, UNP-H, and UNP-I workplaces, respectively. At UNP-H, a total of 30 workers participated in two shifts, each of which comprised 15 workers.

3.1. Correlation of metric devices

Table 2 shows descriptive statistics of three workplace types measured by P-SMPS, CPC and SAM. The unit of P-SMPS and CPC are number concentration (particles/cm3). For SAM, the unit is surface area concentration (μm2/cm3). LAB showed the lowest concentration among three different types of workplaces and UNP workplaces showed the highest concentration for all metrics. Also, there were significant differences among three types of workplaces (p < 0.01).

Table 2.

The descriptive statistics of three workplace types and total measured by P-SMPS, CPC, and SAM

| Workplace | Geometric mean (geometric standard deviation) (5th–95th percentile) |

||||

|---|---|---|---|---|---|

| Portable-SMPS (particles/cm3) |

CPC (particles/cm3) | SAM (μm2/cm3) | |||

| Total number concentration | ≤ 100 nm | > 100 nm | |||

| LAB (A, B, C) | 8,458 (1.41) (3,695–16,668) |

5,879 (1.49) (2,600–13,328) |

2,521 (1.30) (665–4,196) |

6,143 (1.45) (3,613–16,209) |

32.79 (1.46) (7.94–98.51) |

| ENP (D, E, F) | 19,612 (2.18) (5,152–54,428) |

14,969 (2.18) (3,047–43,294) |

4,643 (2.00) (1,421–12,089) |

11,955 (2.42) (3,575–58,153) |

93.68 (2.60) (24.57–549.09) |

| UNP (G, H, I) | 84,172 (2.80) (14,249–369,765) |

61,167 (2.94) (10,667–315,822) |

16,539 (3.23) (2,059–91,790) |

38,886 (2.61) (6,039–134,751) |

358.41 (2.74) (61.37–1,514.03) |

CPC, condensation particle counter; ENP, engineered nanoparticle manufacturing workplace; LAB, laboratory; LEV, local exhaust ventilation; SAM, surface area monitor; SMPS, scanning mobility particle sizer; UNP, unintended nanoparticle emitted workplace.

Table 3 shows Pearson correlation among measurement devices. Correlation coefficients for LAB and ENP showed good correlation among P-SMPS, CPC, and SAM (p < 0.001). By contrast, coefficients in UNP workplaces, fair correlation was found for P-SMPS, CPC, and SAM compared to LAB and ENP (p < 0.001).

Table 3.

Pearson correlation coefficient among measurement devices

| LAB (n = 1,631) |

ENP (n = 1,539) |

UNP (n = 3,027) |

Total (n = 6,377) |

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SMPS Total | ≤ 100 nm | > 100 nm | CPC | SAM | SMPS Total | ≤ 100 nm | > 100 nm | CPC | SAM | SMPS Total | ≤ 100 nm | > 100 nm | CPC | SAM | SMPS Total | ≤ 100 nm | > 100 nm | CPC | SAM | |

| SMPS Total | 1 | 1 | 1 | 1 | ||||||||||||||||

| ≤100 nm | 0.963 | 1 | 0.992 | 1 | 0.962 | 1 | 0.970 | 1 | ||||||||||||

| >100 nm | 0.830 | 0.650 | 1 | 0.829 | 0.753 | 1 | 0.671 | 0.445 | 1 | 0.742 | 0.558 | 1 | ||||||||

| CPC | 0.869 | 0.823 | 0.750 | 1 | 0.925 | 0.905 | 0.823 | 1 | 0.457 | 0.427 | 0.349 | 1 | 0.623 | 0.585 | 0.517 | 1 | ||||

| SAM | 0.883 | 0.766 | 0.908 | 0.889 | 1 | 0.857 | 0.825 | 0.824 | 0.834 | 1 | 0.648 | 0.525 | 0.705 | 0.538 | 1 | 0.745 | 0.644 | 0.770 | 0.694 | 1 |

All results of Pearson correlation coefficient were p < 0.001.

CPC, condensation particle counter; ENP, engineered nanoparticle manufacturing workplace; LAB, laboratory; LEV, local exhaust ventilation; SAM, surface area monitor; SMPS, scanning mobility particle sizer; UNP, unintended nanoparticle emitted workplace.

Fig. 1 shows the concentrations for number concentration measured by P-SMPS (black line), and CPC (red line) and surface area concentration measured by SAM (blue line) in the workplaces (A) LAB-A, (B) ENP-F, and (C) UNP-H on the same graph to investigate responses. Figs. 1A and 1B show similar response, but Fig. 1C shows relatively poor response .

Fig. 1.

The concentration profiles measured by three sampling devices [scanning mobility particle sizer (SMPS), condensation particle counter (CPC), and surface area monitor] at (A) laboratory-A, (B) engineered nanoparticle-F, and (C) unintended nanoparticle emitting workplace-H.

Fig. 2 shows the scanning electron microscopy (SEM) images magnified by 50,000 at (A) LAB-B, (B) ENP-E, (C) UNP-H. SEM images indicate that particles at LAB-C (Fig. 2A), ENP-E (Fig. 2B) with diameters of 50–60 nm and UNP (Fig. 2C) with diameters of 30–40 nm formed agglomerates/aggregates. Particles shape spherical at LAB-C and ENP-E. The SEM image from UNP-H illustrates a chain-like form of particles (Fig. 2C).

Fig. 2.

Scanning electron microscopy images magnified by 50,000 at (A) laboratory-C, (B) engineered nanoparticle workplace-E, (C) unintended nanoparticle emitting workplace-H.

3.2. Comparison between two different SMPSs

Table 4 presents specifications of the RG-SMPS used. Table 5 shows the descriptive statistics for comparison between Grimm and TSI RG-SMPS at LAB-C, ENP-E, and UNP-H. There were significant differences in total number concentration between SMPSs at LAB-C, ENP-E, and UNP-H workplaces (p < 0.01). Also, particle size of SMPS ≤ 100 nm and > 100 nm results show the significant differences (p < 0.01).

Table 5.

Nanoparticle concentrations measured by Grimm and TSI research-grade scanning mobility particle sizers (RG-SMPSs) at ENP-E (unit: dN/dlogDp [particles/cm3])

| SMPS Total | Grimm RG-SMPS |

SMPS Total | TSI RG-SMPS |

||||

|---|---|---|---|---|---|---|---|

| ≤ 100 nm | > 100 nm | ≤ 100 nm | > 100 nm | ||||

| ENP-E (n = 232) | Mean | 122,429* | 91,389* | 31,040* | 147,031 | 104,317 | 42,713 |

| SD | 2,359 | 1,834 | 631 | 2,637 | 1,898 | 1,018 | |

| Median | 125,462 | 96,036 | 28,418 | 145,627 | 107,767 | 39,617 | |

| Percentile (5th–95th) | 62,134–173,921 | 42,422–131,046 | 18,625–46,620 | 87,221–204,526 | 59,393–145,322 | 25,758–61,954 | |

* p < 0.01.

ENP, engineered nanoparticle manufacturing workplace.

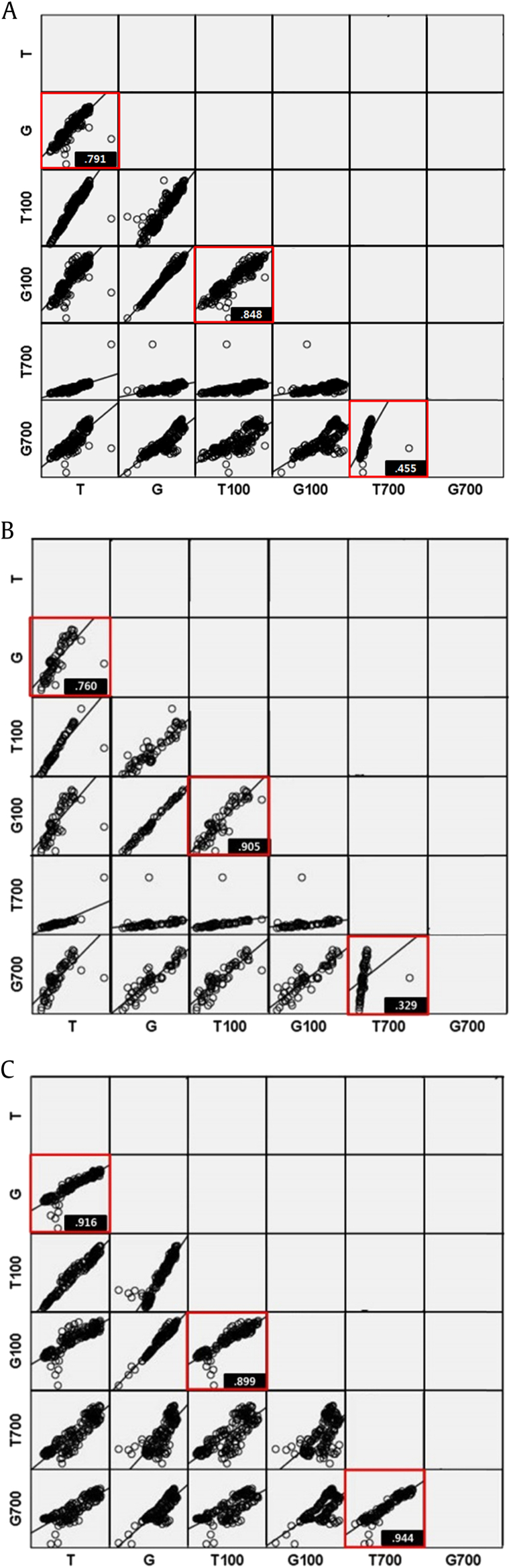

Fig. 4 shows size distributions for particles from workplaces, measured with the two different SMPSs in the test with same location at ENP-E. TSI SMPS showed higher number concentration than Grimm SMPS.

Fig. 4.

Size distributions for particles measured with the two different scanning mobility particle sizers in the test with same sampling location, engineered nanoparticle workplace-E.

4. Discussion

This study had two different objectives. The first was to perform comparison analysis for P-SMPS (number concentration with particle size distribution), CPC (number concentration), and SAM (surface area concentration). The concentration of nanoparticles at workplaces categorized by three different types of workplaces to examine relationships of concentration based on real-time data. For the second objective, the relationships two common RG-SMPSs were compared. This is the first challenge to compare two common SMPSs at workplaces with real field data.

4.1. Correlation among P-SMPS, CPC, and SAM

The RG-SMPS is known to be the golden standard measurement devices for nanoparticle measurement because it can collect the number concentration in size distribution with many channels with high accuracy. However, the RG-SMPS is expensive and needs a longer time resolution for one cycle to measure changing of exposure rapidly [11]. The P-SMPS used in this study is a common measurement device for number concentration by size with a 1-minute sampling cycle [17]. Compared to the RG-SMPS, P-SMPS has fewer channels, but it is portable and less expensive. However, P-SMPS is more expensive and heavier than CPC or SAM.

We compared the relationship between P-SMPS, CPC, and SAM even they measure different metrics. Because in the prescreening step, an industrial hygienist needs the device to find the source of nanoparticle emission and measure the amount of exposure using simple devices. CPC and SAM could be useful for the first stage of measurement at LAB and ENP workplaces because they showed good correlation with P-SMPS. As seen in Fig. 1, the concentration changing trend was similar when emission of nanoparticles occurred. Also, particles exist as single particles as well as aggregated or agglomerated particles, which are larger than 100 nm (Fig. 2). Therefore, a simpler measurement device such as CPC or SAM is necessary to use as a surrogate for nanoparticle exposure assessment in the field. This study is meaningful because there is no study to investigate the relationship between the most common nanoparticle measurement devices. For high accuracy measurements, RG-SMPS or at least P-SMPS might be required.

Pearson correlation analysis was performed to measure relationship of exposure profile during sampling among three measurement devices. The results of LAB and ENP showed good correlation among P-SMPS, CPC, and SAM (Table 3) because the particle shape is close to spherical (Fig. 1A and B). However, correlation in UNP workplaces, lower correlation was found for P-SMPS, CPC, and SAM. The responses of P-SMPS, CPC, and SAM were similar during lunch time but had large variances during working time. It might be assumed that particles during lunch time are not from processes which is from outside of UNP workplace. P-SMPS is usually calibrated by the manufactures only by spherical particles [18], [19], as are CPC and SAM. However, the particles in the real world are not spherical, as seen in Fig. 2. Particles from UNP-H showed a chain-like form (Fig. 2C), which may result in errors. An SEM image could be useful to find the characteristics of nanoparticles at workplaces [4], [20].

The variations between workplaces might be caused by different measurement range of sampling devices, response time, particle agglomeration status, and principles. The measurement range of SMPS was 10–420 nm with 13 channels. CPC and SAM had the measurement ranges 20–1,000 nm and 10–1,000 nm, respectively. The measurement ranges among devices overlapped but were not exactly matched. CPC and SAM could not categorize into size such as < 100 nm. The response times were different. One cycle of P-SMPS was 1 minute (45 seconds of sampling and 15 seconds of retrace time). This 1-minute sampling cycle is a fixed condition. CPC and SAM had flexible cycles from 1 second to 1 minute. The difference of total number of measured concentrations between P-SMPS and CPC was about two-fold in ENP and UNP (Table 2). Agglomeration could be one of factor of difference of measurement between P-SMPS and CPC. According to a recent study, fast mobility particle sizer could overestimate in total number concentration about three-fold compared to the CPC when the particles are agglomerated [21], which was a similar result as our study (Table 2). The particles shown in Fig. 2B and C are characteristic agglomerated collected samples.

There are advantages and disadvantages of devices. Compared to the SAM, CPC is light weight to use portably (CPC: 1.7 kg vs. SAM: 8.2 kg with 2 battery packs). CPC requires isopropyl alcohol inside the instrument and regular refills. However, it is difficult to use in hot or warm conditions such as UNP workplaces (welding, smelting, etc.) because the rate of consumption is very high. By contrast, SAM is very robust in hot and warm conditions, but it is difficult to compare with P-SMPS number concentration directly. P-SMPS consumes isopropyl alcohol for condensation but there is cooling fan inside the instrument and an extension bottle is available to exhaust heat from the condensation heater. Therefore, the instrument check should be done in the short term when temperature is over 35°C for all measurement devices.

4.2. Comparison between two different SMPSs

In this study, Grimm SMPS showed lower concentration than TSI SMPS. However, Grimm SMPS showed higher concentration than TSI SMPS in other comparison studies [12], [14]. Asbach et al [14], in their study on laboratory comparisons with NaCl aerosols, obtained a factor of 1.42–1.7 with Grimm SMPS showing higher number concentrations. Sodium chloride and ammonium sulfate were tested in the laboratory and ambient exposure by Joshi et al [15]. The reported results from Grimm SMPS were a factor of 1.25 higher than TSI SMPS at ambient air. In this study, size distributions were similar (Fig. 3) but there are significant differences in concentrations (Table 5). This might be the cause of systemic errors between SMPSs.

Fig. 3.

Correlation graph and coefficient values between TSI and Grimm scanning mobility particle sizer by size ranges for number concentration at engineered nanoparticle workplace-E: (A) total, (B) working, and (C) background.

Differences between SMPSs may be related to differences in particle charging efficiency due to the neutralized charge distribution (Am, Kr), diffusion loss, CPC responses, DMA transfer function [12], [13], [15], effect of aerosol flow changes, and insufficient neutralization [22]. In this study, correlation coefficients were higher during background, which was no working at ENP-E (Fig. 2). During working time, variations of nanoparticle emission fluctuate. Instabilities in the aerosol are likely to cause uncertainties in the particle number concentration and sizing [13]. For background measurement during no working at workplaces, results showed very good relationship between the two SMPSs even though there are significant differences in concentration because the air might be stable (Fig. 2C). However, during working time, a fair relationship was found due the fluctuation of aerosol.

Also, sampling time is different between RG-SMPSs. The sampling intervals for Grimm SMPS is 213 seconds for one cycle, and 135 seconds for TSI SMPS. It might lose the emissions of nanoparticles during certain tasks because the task might be short duration. The other source of differences in the principle is transfer to DMA between RG-SMPSs [13]. They have a different technique to separate particles size. Grimm SMPS measures large particles to small particles (down-scan) in size and TSI SMPS measures small particles to large particles (up-scan) because the electrical polarity of rod voltage in the DMA is positive (+) for Grimm and opposite polarity (−) for TSI DMA rod.

Data gathered by real-time monitors are highly correlated. This problem can be overcome using the concordance correlation coefficient [23], which measures the agreement between two variables with the same metric for highly correlated data such as two different blood pressure measurement devices for the same person. Despite these limitations, this study may provide an understanding of nanoparticle sources, both engineered and unintended, because only limited data are currently available concerning nanoparticle exposure assessments in the workplace even though the number of workers handling nanoparticles continues to increase.

5. Conclusions

This is the first study to compare measurement devices, specialized on nanoparticles in the workplace. Two parts were performed: (1) investigation of correlation among P-SMPS, CPC, and SAM, which are widely used nanoparticle measurement devices; and (2) comparison between two commercial RG-SMPS to assess the comparability in an engineered nanoparticle manufacturing workplace.

There are good relationships among P-SMPS, CPC, and SAM at LAB and ENP workplaces. However, only a fair relationship was found at UNP workplaces. Therefore, CPC and SAM with SEM images may be a good alternative instruments for nanoparticle exposure assessment for prescreening test instead of SMPS, which is a relatively expensive instrument.

There are significant differences between the two different SMPSs. Caution is necessary and interpretation to compare the exposure-monitoring data gathered from workplaces when using different RG-SMPS.

Conflicts of interest

All authors have no conflicts of interest to declare.

Acknowledgments

This work was supported by the Korean Occupational Safety and Health Agency (2013-OSHRI-597); BK21 Plus project (No. 5280-20140100); the National Institute of Environmental Research of Korea (2012-Nano R&D).

References

- 1.Wittmaack K. In search of the most relevant parameter for quantifying lung inflammatory response to nanoparticle exposure: particle number, surface area, or what? Env Health Persp. 2007;115:187–194. doi: 10.1289/ehp.9254. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Oberdörster G., Oberdörster E., Oberdörster J. Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Env Health Persp. 2005;113:823–839. doi: 10.1289/ehp.7339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Maynard A.D. Nanotechnology: the next big thing, or much ado about nothing? Ann Occup Hyg. 2007;51:1–12. doi: 10.1093/annhyg/mel071. [DOI] [PubMed] [Google Scholar]

- 4.Ham S., Yoon C., Lee E., Lee K., Park D., Chung E., Kim P., Lee B. Task-based exposure assessment of nanoparticles in the workplace. J Nanopart Res. 2012;14:1–17. [Google Scholar]

- 5.Park J.Y., Raynor P.C., Maynard A.D., Eberly L.E., Ramachandran G. Comparison of two estimation methods for surface area concentration using number concentration and mass concentration of combustion-related ultrafine particles. Atmos Env. 2009;43:502–509. [Google Scholar]

- 6.Tsai C., Huang C., Chen S., Ho C., Huang C., Chen C., Chang C., Tsai S., Ellenbecker M. Exposure assessment of nano-sized and respirable particles at different workplaces. J Nanopart Res. 2011;13:4161–4172. [Google Scholar]

- 7.Maynard A.D., Aitken R.J. Assessing exposure to airborne nanomaterials: Current abilities and future requirements. Nanotoxicology. 2007;1:26–41. [Google Scholar]

- 8.Kaminski H., Beyer M., Fissan H., Asbach C., Kuhlbusch T.A. Measurements of nanoscale TiO2 and Al2O3 in industrial workplace environments–methodology and results. Aero Air Qual Res. 2015;15:129–141. [Google Scholar]

- 9.Heitbrink W.A., Evans D.E., Ku B.K., Maynard A.D., Slavin T.J., Peters T.M. Relationships among particle number, surface area, and respirable mass concentrations in automotive engine manufacturing. J Occup Env Hyg. 2008;6:19–31. doi: 10.1080/15459620802530096. [DOI] [PubMed] [Google Scholar]

- 10.Asbach C., Kaminski H., Von Barany D., Kuhlbusch T.A.J., Monz C., Dziirowitz N., Pelzer J., Vossen K., Berlin K., Dietrich S., Götz U., Kiesling H.J., Schierl R., Dahmann D. Comparability of portable nanoparticle exposure monitors. Ann Occup Hyg. 2012;56:606–621. doi: 10.1093/annhyg/mes033. [DOI] [PubMed] [Google Scholar]

- 11.Fierz M., Weimer S., Burtscher H. Design and performance of an optimized electrical diffusion battery. J Aero Sci. 2009;40:152–163. [Google Scholar]

- 12.Watson J.G., Chow J.C., Sodeman D.A., Lowenthal D.H., Chang M.C.O., Park K., Wang X. Comparison of four scanning mobility particle sizers at the Fresno Supersite. Particuology. 2011;9:204–209. [Google Scholar]

- 13.Wiedensohler A., Birmili W., Nowak A., Sonntag A., Weinhold K., Merkel M., Wehner B., Tuch T., Pfeifer S., Fiebig M. Mobility particle size spectrometers: harmonization of technical standards and data structure to facilitate high quality long-term observations of atmospheric particle number size distributions. Atmos Meas Tech. 2012;5:657–685. [Google Scholar]

- 14.Asbach C., Kaminski H., Fissan H., Monz C., Dahmann D., Mülhopt S., Paur H.R., Kiesling H.J., Herrmann F., Voetz M. Comparison of four mobility particle sizers with different time resolution for stationary exposure measurements. J Nanopart Res. 2009;11:1593–1609. [Google Scholar]

- 15.Joshi M., Sapra B., Khan A., Tripathi S., Shamjad P., Gupta T., Mayya Y. Harmonisation of nanoparticle concentration measurements using GRIMM and TSI scanning mobility particle sizers. J Nanopart Res. 2012;14:1–14. [Google Scholar]

- 16.Reiman M.P., Manske R.C. Human Kinetics; Champaign (IL): 2009. Functional testing in human performance. [Google Scholar]

- 17.Tritscher T., Beeston M., Zerrath A.F., Elzey S., Krinke T.J., Filimundi E., Bischof O.F. NanoScan SMPS–A novel, portable nanoparticle sizing and counting instrument. J Phys. 2013;429:012061. [Google Scholar]

- 18.Mulholland G.W., Donnelly M.K., Hagwood C.R., Kukuck S.R., Hackley V.A., Pui D.Y. Measurement of 100 nm and 60 nm particle standards by differential mobility analysis. J Res Natl Inst Stand Technol. 2006;111:257–312. doi: 10.6028/jres.111.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Kinney P.D., Pui D.Y. Use of the electrostatic classification method to 0.1 tm SRM particles-a feasibility study. J Res Natl Inst Stand Technol. 1991;96:147–176. doi: 10.6028/jres.096.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Ham S., Kim S., Lee N., Kim P., Eom I., Tsai P.J., Lee K., Yoon C. Comparison of nanoparticle exposure levels based on facility type—small-scale laboratories, large-scale manufacturing workplaces, and unintended nanoparticle-emitting workplaces. Aero Air Qual Res. 2015;15:1967–1978. [Google Scholar]

- 21.Zimmerman N., Godri Pollitt K.J., Jeong C.-H., Wang J.M., Jung T., Cooper J.M., Wallace J.S., Evans G.J. Comparison of three nanoparticle sizing instruments: the influence of particle morphology. Atmos Environ. 2014;86:140–147. [Google Scholar]

- 22.Liu P.S., Deshler T. Causes of concentration differences between a scanning mobility particle sizer and a condensation particle counter. Aero Sci Tech. 2003;37:916–923. [Google Scholar]

- 23.Lawrence I., Lin K. A concordance correlation coefficient to evaluate reproducibility. Biometrics. 1989;45:255–268. [PubMed] [Google Scholar]