Abstract

The cytochalasins are structurally complex natural products with a broad range of apparently unrelated effects in different biological systems. Different members of the family have variously demonstrated inhibitory activity toward the formation of actin filaments, toward the functioning of HIV protease, and toward the process of angiogenesis. The structural series is defined by a largely conserved, rigid bicyclic isoindolone core that is fused to a macrocyclic appendage. The latter structural component varies widely within the cytochalasins and seems to play an important role in the determination of biological activity. In this work, we describe the development of a convergent and enantioselective synthetic route to the cytochalasins that allows for the late-stage introduction of macrocyclic appendages of different sizes and constitutions. We illustrate the route with the synthesis of the 14-membered macrolactone cytochalasin B (1, an inhibitor of the formation of actin filaments) and the 11-membered macrocarbocyclic cytochalasin L-696,474 (2, an inhibitor of HIV protease) by using common precursors.

The cytochalasins are fungal metabolites with complex and diverse molecular structures and a range of biological effects and thus have been of interest to synthetic chemists (1–12). Many cytochalasins inhibit cell division and are known to induce an apoptotic response, activities that are thought to arise from the ability of these molecules to inhibit the polymerization of actin (13, 14). Cytochalasin B (1), originally named phomin (15), was the first cytochalasin isolated and has been used as a tool for the study of cell division and cell motility, processes that rely critically on the active formation and degradation of actin microfilaments (16). Cytochalasins have also been reported to exhibit diverse biological activities that are unrelated to actin binding. As examples, L-696,474 (2) inhibits HIV-1 protease (17–20), cytochalasin B (1) inhibits glucose transport (21), cytochalasin H derivatives regulate plant growth (22), and cytochalasin E inhibits angiogenesis (23). Few naturally derived structural platforms can rival the cytochalasins in terms of their breadth of activities in different biological processes. For this reason, the development of an efficient, readily diversifiable synthetic route to the cytochalasins seemed to be a worthwhile objective. We describe herein the realization of this goal, as applied to laboratory (total) syntheses of both cytochalasin B and L-696,474, macrolactone and macrocarbocyclic cytochalasins, respectively (see Fig. 1).

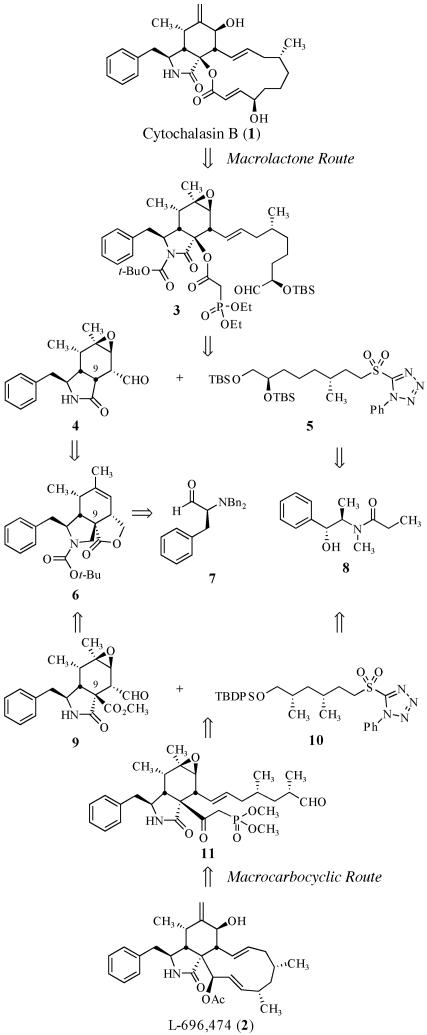

Fig. 1.

Structures of macrolactone and macrocarbocyclic cytochalasins.

Retrosynthetic Analysis

Previous efforts directed toward the synthesis of the cytochalasins fall into two general categories: those that form the six-membered ring of the isoindolone core and the larger, macrocyclic ring simultaneously in a late-stage intramolecular Diels–Alder cyclization (2–7) and those that form the isoindolone core first by using an intermolecular Diels–Alder reaction and then append the macrocycle in a stepwise fashion (8, 9). We planned to pursue a somewhat different implementation of the latter strategy by targeting a different bond pair for Diels–Alder disconnection and by developing much of the stereochemistry of the macrocyclic portion of the molecule before its introduction in a fragment coupling process.

Our retrosynthetic analysis of macrolactone and macrocarbocyclic cytochalasins is shown in Figs. 2 and 3 and leads, in each case, to the common precursors 6 and 8. Both routes use late-stage macrocyclization reactions, forming differently substituted macrolactone and macrocarbocyclic rings, of different ring sizes (14 and 11 members, respectively). We chose to use the intramolecular Horner–Wadsworth–Emmons (HWE) olefination for ring closure in light of the demonstrated versatility of this method (24–26). It was recognized at the outset that both ring closures (see Fig. 2, structures 3 and 11) were potentially complicated beyond the issues that typically confront medium and large ring-closure reactions by the fact that the aldehydic components of each substrate were epimerizable, a concern that in one case did prove to be valid but ultimately did not present an insolvable problem (see below). Further retrosynthetic disconnection, producing precursors of similar sizes, was envisioned to follow by using the Kocienski modification of the (single-step) Julia olefination (27). Here again, aldehyde epimerization was a potential concern, albeit at a different locus (see Fig. 2, intermediates 4 and 9). In addition to epimerization, enolization of aldehyde intermediates 4 and 9 was potentially complicated further by the possibility of β-elimination, leading to fragmentation of the epoxide ring. The objective of targeting the two C–C double bonds of 1 and 2 for retrosynthetic disconnection was to quickly clear (retrosynthetically) the macrocyclic component from the molecule, amounting to its late-stage introduction in the synthetic sense, which was highly desirable given that variation within this component was one of the goals of the project. It should be emphasized, however, that it was unclear at the outset whether such a strategy would prove to be viable; that it did is one of the more important demonstrations of this study.

Fig. 2.

Retrosynthetic analysis of macrolactone and macrocarbocyclic cytochalasins.

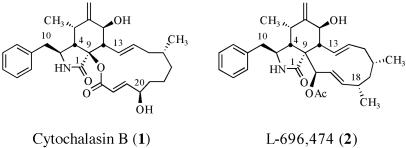

Fig. 3.

The proposed biosynthetic route to the cytochalasins involves the “natural” Diels–Alder disconnection shown (28). Previous syntheses of the cytochalasins have used a similar Diels–Alder disconnection (1–9). Retrosynthetic modification of 6 permits the implementation of an alternative Diels–Alder disconnection.

The isoindolone core fragments 4 and 9, retrosynthetically derived from 1 and 2 (Fig. 2), differ only in their substitution at C-9; both were imagined to arise from the common tricyclic precursor 6. A subtle structural distinction between the proposed precursor 6 and the intermediates 4 and 9, derived from 6, is the stereochemistry of C-9. The transfer of the nitrogen-containing appendage to the α-face in structures 4 and 9 was deliberate, providing a strategic device for stereochemical control of a key intramolecular Diels–Alder reaction. Although the Diels–Alder disconnection has been widely used in syntheses of the isoindolone core of the cytochalasins (1–12), its implementation has almost universally followed the “natural” cycloreversion of a cyclohexene such as 6, whereas our synthetic plan invoked a different Diels–Alder disconnection by prior migration of the cyclohexene double bond (Fig. 3). In this way, we hoped to establish all stereorelationships in the bicyclic core of the cytochalasins and achieve absolute stereochemical control by using l-phenylalanine as a starting material (see Scheme 1).

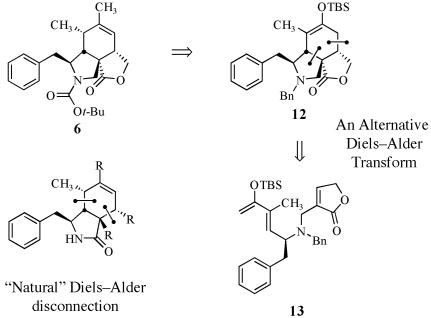

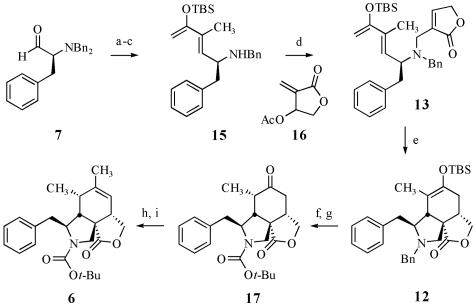

Scheme 1.

Synthesis of a key tricyclic precursor (6) to macrolactone and macrocarbocyclic cytochalasins. Reaction conditions. a: Diethyl 3-oxo-2-butylphosphonate (14), Ba(OH)2, tetrahydrofuran (THF)–H2O, 23°C, 87%. b: 2,3-Dichloro-5,6-dicyanobenzoquinone, CH2Cl2–pH 7 buffer, 23°C, 86%. c: tert-Butyldimethylsilyl trifluoromethanesulfonate, 2,6-lutidine, CH2Cl2, -78°C → 23°C, 99%. d: CH3OH, 23°C, 98%. e: m-Xylene, 150°C, 77%. f: H2, 10% Pd/C, BOC2O, Et3N, EtOH, 23°C, 96%. g: TBAF, AcOH, THF, 0°C. h: KHMDS, THF, -78°C; 2-[N,N-bis(trifluoromethylsulfonyl)amino]-5-chloropyridine, 93% (two steps). i: (CH3)2CuLi, THF, -78°C → 0°C, 95%.

The remaining portions of 1 and 2, in the form of N-phenyltetrazole sulfones 5 and 10, respectively, were envisioned to be accessible by asymmetric alkylation by using (1R,2R)-pseudoephedrine propionamide (8) as the starting material (29). The pseudoephedrine amide alkylation methodology was considered to be particularly well suited for the synthesis of sulfone 10 because of its effectiveness in the alkylative construction of 1,3-skipped alkyl chains using β-branched electrophiles (30).

Materials and Methods

Experimental procedures and spectral data (including x-ray structural data, where applicable) for all compounds created for this study can be found in supporting information, which is published on the PNAS web site.

Results and Discussion

Synthesis of a Common Isoindolone Precursor to the Cytochalasins by an Intramolecular Diels–Alder Reaction. To construct the Diels–Alder substrate proposed in Fig. 3 (13), we used as the starting material N,N-dibenzyl phenylalanal (7), derived from the l-amino acid in three steps, as reported (80%) (31, 32). Intermolecular HWE condensation of 7 with diethyl 3-oxo-2-butylphosphonate (14) (33) in the presence of barium hydroxide at 23°C (34) provided the expected trans-α,β-unsaturated ketone with 99:1 trans/cis selectivity and 98% enantiomeric excess [HPLC analysis, Chiracel OD-H column (Daicel, Fort Lee, NJ), 87% yield; Scheme 1]. Although we (35) and others (36) have shown that α-amino aldehydes with different N-protective groups (e.g., 9-fluorenylmethoxycarbonyl) are suitable substrates for epimerization-free condensations such as the Strecker amino nitrile synthesis, this was not the case under the highly basic conditions required for condensation with the ketophosphonate 14. For this reason, the kinetically robust N,N-dibenzyl protection system of Reetz (37) was adopted here, which proved highly effective. Selective mono-N-debenzylation of the product was achieved by following an interesting and precedented procedure (38) involving the use of 2.5 eq of 2,3-dichloro-5,6-dicyano-1,4-benzoquinone in a biphasic mixture of dichloromethane and pH 7 aqueous phosphate buffer solution (86% yield). Treatment of the mono-N-debenzylated product thus obtained with tert-butyldimethylsilyl triflate and 2,6-lutidine then provided the silyl enol ether 15. The synthesis of the Diels–Alder substrate 13 was completed by an addition–elimination sequence that occurred after mixing of the silyl enol ether 15 (1.0 eq) with the known exo-methylene lactone 16 (racemic, 1.1 eq) (39) in methanol at 23°C (40 min, 98% yield).

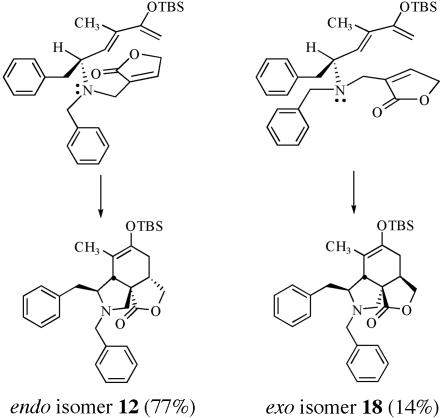

Intramolecular Diels–Alder cyclization of 13 was best achieved at high temperature (xylenes, reflux) by using glassware that had been passivated by prior silylation with bis(trimethylsilyl)trifluoroacetamide. Under these conditions, two diastereomeric Diels–Alder products were obtained (Fig. 4). These diastereomers had unusually different chromatographic mobilities (ΔRf = 0.25), which greatly facilitated their separation by flash column chromatography. The major diastereomer (77% yield) was crystalline (mp, 139°C); x-ray analysis showed that this product was the desired endo diastereomer, stereostructure 12. The minor diastereomer (18, 14% yield) did not crystallize, but the ketone it provided after cleavage of the silyl enol ether group with tetra-n-butylammonium fluoride–acetic acid did (see supporting information), and x-ray analysis of this product showed that it was derived from the exo adduct depicted in Fig. 4. Both Diels–Alder products that were obtained arose from attack on a single face of the diene, corresponding to that predicted on the basis of allylic 1,3-strain considerations (see Fig. 4). Importantly, the major, endo diastereomer possessed the requisite stereochemistry for transformation to macrolactone and macrocarbocyclic cytochalasins by the strategy outlined in Fig. 2.

Fig. 4.

Control of facial selectivity in diene addition by allylic 1,3-strain considerations (40–42).

From the major Diels–Alder adduct (12), just four steps were required to reach the tricyclic alkene 6, the point at which our synthetic routes to macrolactone and macrocarbocyclic cytochalasins diverged. Exchange of the N-benzyl protecting group of 12 with an N-BOC group was accomplished in a single operation that proceeded in 96% yield (Scheme 1). Cleavage of the silyl enol ether group of the resulting carbamate in the presence of tetra-n-butylammonium fluoride–acetic acid afforded only one product, determined to be the diastereomer 17 on the basis of NMR analysis (NOESY). This assignment was later confirmed by the conversion of 17 to the known compounds 1 and 2. The high diastereoselectivity of the protonation reaction that formed 17 was not unexpected; the x-ray crystal structure of the Diels–Alder adduct 12 reveals that the γ-lactone ring is positioned orthogonal to and beneath the plane of the cyclohexene ring, effectively blocking the approach of reactants toward this face of the molecule. Regio-selective deprotonation of the ketone 17 was accomplished by using potassium bis(trimethylsilyl)amide (KHMDS) as base; addition of 2-[N,N-bis(trif luoromethylsulfonyl)amino]-5-chloropyridine (43) then provided the corresponding enol triflate (93%; the regioisomeric enol triflate was not observed). Subsequent reaction of the enol triflate with lithium dimethylcuprate (44) afforded the trisubstituted alkene 6 (95% yield).

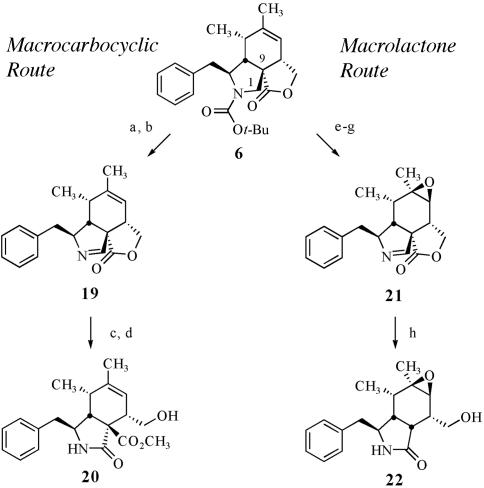

The initial stages of elaboration of the key tricyclic precursor 6 to macrolactone and macrocarbocyclic cytochalasins is shown in Scheme 2. To develop 6 as a precursor to the macrocarbocyclic cytochalasins (2; see Fig. 2, 6 → 9), it was necessary to oxidize the pyrrolidine ring. This provided a means to open the five-membered ring (by “hydrolysis” of the imine 19; see below) and reform it with different stereochemistry at C-9 by attack of the liberated amino group on the α-oriented lactone, forming a lactam. Oxidation of 6 was accomplished by removal of the N-BOC group with trifluoroacetic acid and then oxidation of the resulting amine with [bis(trifluoroacetoxy)iodo]benzene, providing the imine 19 in 90% yield. The oxidation of secondary amines with iodosobenzene to produce imines has been described (45); we found that the regioselectivity of this oxidation was much improved in the presence of trifluoroacetate ion and so developed the procedure using the commercial oxidant [bis(trifluoroacetoxy)iodo]benzene. Both the efficiency and regioselectivity of the oxidation with [bis(trifluoroacetoxy)iodo]-benzene are noteworthy.

Scheme 2.

Reaction conditions. a: Trifluoroacetic acid, CH2Cl2,0°C. b: [Bis(trifluoroacetoxy)iodo]benzene, 2,6-lutidine, 4 Å MS, CH2Cl2, 23°C, 90% (two steps). c: 1,3-Diaminopropane, CF3CH2OH, Et2O, 23°C; Et2O–pH 7 buffer. d: KOH, I2, CH3OH, 23°C, 96% (two steps). e: Dimethyldioxirane, acetone, 23°C, 100%. f: Trifluoroacetic acid, CH2Cl2, 0°C. g: [Bis(trifluoroacetoxy)iodo]benzene, 4 Å MS, CH2Cl2, 23°C, 92% (two steps). h: Ethylenediamine, tert-amyl alcohol, 23°C, 96%.

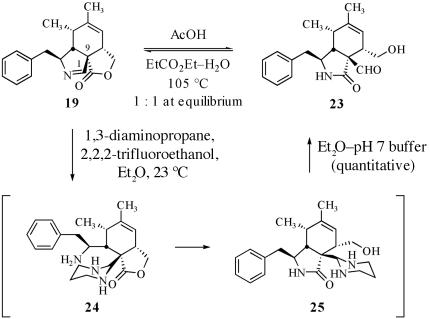

In theory, simple hydrolysis of the imine intermediate 19 should free the amino group for the desired intramolecular attack on the γ-lactone ring (see Scheme 3, 19 → 23). We found that although 19 was, in fact, transformed to lactam 23 after heating in aqueous acetic acid, the product and starting material were of equal energies (1:1 ratio at equilibrium). Other hydrolysis conditions were complicated by competing deformylation of 23, a finding that was used later to advantage in the synthesis of 1. The problem was solved by devising a nonhydrolytic opening of the imine group of 19 using 1,3-diaminopropane as the nucleophile, forming the lactam 25 via the amino lactone 24 (not observed). Mild hydrolysis of 25 (ether–pH 7 aqueous sodium phosphate buffer solution) then provided the desired aldehyde 23 in quantitative yield. Without purification, aldehyde 23 was directly transformed to the methyl ester 20 by treatment with potassium hydroxide and iodine in methanol (46) (see Scheme 2). The yield of 20 from the imine 19 was 96%.

Scheme 3.

To transform the key tricyclic intermediate 6 into a precursor suitable for construction of the macrolactone cytochalasins (1; see Fig. 2, 6 → 4), a somewhat different sequence was developed (summarized in Scheme 2), using to advantage the deformylation reaction discovered in the studies discussed above. In the modified sequence, deformylation was enhanced by prior epoxidation of the cyclohexene ring, a necessary transformation in any event. Thus, epoxidation of 6 [dimethyldioxirane, 100%, single diastereomer (β), as shown in Scheme 2] was followed by cleavage of the N-BOC group and oxidation of the resultant amine with [bis(trifluoroacetoxy)iodo]benzene as before. In this case, however, the epoxy imine 21 was subjected to conditions optimized to induce deformylation (1,2-diaminoethane in tert-amyl alcohol at 23°C), producing the hydroxy lactam 22 in 96% yield.

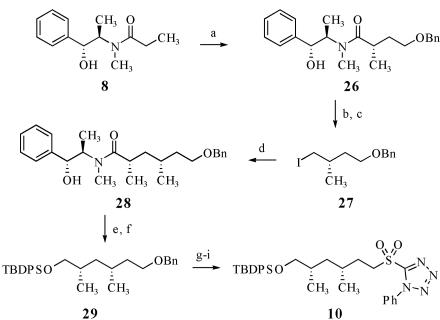

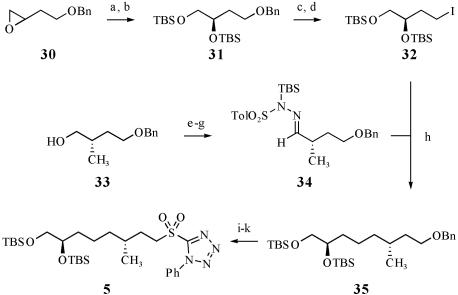

Synthesis of Sulfones 5 and 10, Precursors to the Macrocyclic Portions of Cytochalasin B and L-696,474, Respectively. The N-phenyltetrazole sulfone 10 was synthesized by iterative application of pseudoephedrine amide asymmetric alkylation methodology, using (1R,2R)-pseudoephedrine propionamide (8) as the starting material, and now standard functional-group manipulations (see Scheme 4). The cytochalasin B precursor, N-phenyltetrazole sulfone 5, was synthesized as shown in Scheme 5, in which the key step involved reductive coupling of the N-tert-butyldimethylsilyl tosylhydrazone 34 and an alkyllithium reagent formed in situ from the iodide 32 (47). The stereochemistry of intermediates 32 and 34 has been established by Jacobsen hydrolytic kinetic resolution (48) and asymmetric alkylation methodologies, respectively.

Scheme 4.

Reaction conditions. a: Lithium diisopropylamide, LiCl, THF, -78°C → 23°C; 2-benzyloxy-1-iodoethane, 0°C, 94%. b: LiH2NBH3, THF, 23°C, 88%. c: PPh3,I2, imidazole, CH2Cl2,23°C, 89%. d: 8, Lithium diisopropylamide, LiCl, THF, -78°C → 23°C; 27,23°C. e: LiH2NBH3, THF, 23°C, 91% (two steps). f: tert-Butyldiphenylsilyl chloride (TBDPSCl), Et3N, dimethylaminopyridine, CH2Cl2, 23°C, 89%. g: H2, Pd(OH)2/C, EtOAc, 23°C. h: 1-Phenyl-1H-tetrazole-5-thiol, PPh3, diethyl azodicarboxylate (DEAD), THF, 23°C, 86% (two steps). i: m-Chloroperbenzoic acid, NaHCO3, CH2Cl2, 23°C, 97%.

Scheme 5.

Reaction conditions. a: (1S,2S)-1,2-cyclohexanediamino-N,N′-bis(3,5-di-tert-butylsalicylidene)cobalt(II), AcOH, H2O (0.45 eq), 0°C → 23°C, 41% (45% theoretical yield). b: tert-Butyldimethylsilyl trifluoromethanesulfonate, Et3N, CH2Cl2,0°C → 23°C. c: H2,Pd/C, EtOAc, 23°C, 79% (two steps). d: PPh3, I2, imidazole, CH2Cl2, 23°C, 86%. e: Dess–Martin periodinane, CH2Cl2, 23°C. f: TsNHNH2, THF, 23°C, 94% (two steps). g: tert-Butyldimethylsilyl trifluoromethanesulfonate, Et3N, THF, -78°C. h: 32, tert-BuLi, Et2O, -78°C; 34, THF; AcOH, CF3CH2OH, -78°C → 23°C, 90% (two steps). i: H2, Pd/C, EtOAc, 23°C, 87%. j: 1-Phenyl-1H-tetrazole-5-thiol, PPh3, diisopropyl azodicarboxylate (DIAD), THF, 23°C, 90%. k: m-Chloroperbenzoic acid, NaHCO3, CH2Cl2, 23°C, 84%.

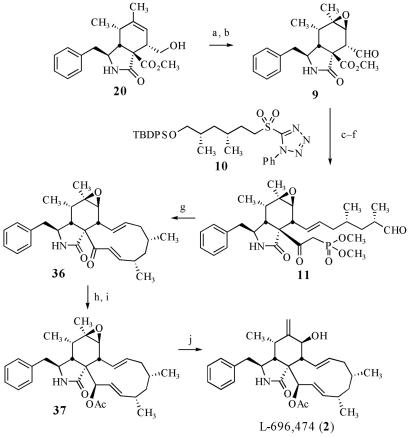

Completion of the Synthesis of the Macrocarbocyclic Cytochalasin L-696,474 (2). The key bicyclic isoindolone intermediate 20 was transformed into a precursor suitable for fragment coupling with the N-phenyltetrazole sulfone 10 by diastereoselective epoxidation with dimethyldioxirane (95% yield of the β-isomer; β/α, 20:1) followed by oxidation of the primary hydroxyl group of the resultant product with the Dess–Martin periodinane (Scheme 6). The β-epoxy aldehyde so obtained (9) then was coupled with the potassium salt of N-phenyltetrazole sulfone 10, formed in situ from 10 and KHMDS, providing the expected trans-olefin in 86% yield. Neither the cis-olefin nor products derived from α-deprotonation of the aldehyde were observed as by-products of this Kocienski–Julia coupling reaction. Addition of lithium dimethyl methylphosphonate to the hindered methyl ester group of the coupling product was exceptionally clean (12); after cleavage of the tert-butyldiphenylsilyl ether group [tetrabutylammonium fluoride (TBAF)–acetic acid] and oxidation of the resultant primary alcohol with the Dess–Martin periodinane, we obtained the aldehyde 11 (81%, three steps), identified as a substrate for macrocyclization by an intramolecular HWE reaction in Fig. 2. From inspection of models, macrocyclization of 11 to form the 11-membered cyclic ketone 36 must involve a conformation with a syn-pentane-like interaction of the “skipped” methyl groups, which may account for the fact that a nearly equal mixture of (C-18) epimeric products was obtained under a variety of conditions examined for macrocyclization, including those that are known to minimize epimerization within base-labile substrates (34, 49). We discovered conditions for macrocyclization that greatly reduced epimerization.† These conditions entailed the use of sodium 2,2,2-trifluoroethoxide as base in hot dimethoxyethane (80°C) containing 2,2,2-trifluroroethanol and led to macrocyclization of 11 to form 36 and its C-18 epimer in a ratio of 5:1 (52% yield; diastereomerically pure 36 was obtained in 43% yield after separation by HPLC). Diastereoselective reduction of the macrocyclic ketone 36 (ceric chloride–sodium borohydride) followed by acetylation then provided the intermediate 37, which was cleanly transformed into L-696,474 (2) after exposure to magnesium sulfate in warm benzene (60°C, 66%, three steps). The latter conditions evolved from a serendipitous discovery and are notable for their mildness and compatibility with other functional groups in the molecule.

Scheme 6.

Reaction conditions. a: Dimethyldioxirane, acetone, 23°C, 95%. b: Dess–Martin periodinane, NaHCO3,CH2Cl2,23°C. c: 10, KHMDS, THF, -78°C; 9, -100°C → -40°C, 86% (two steps). d: (CH3O)2POCH2Li, THF, -78°C → 23°C. e: TBAF, AcOH, THF, 23°C, 81% (two steps). f: Dess–Martin periodinane, NaHCO3,CH2Cl2,23°C. g: NaOCH2CF3,CF3CH2OH, DME, 80°C, 52% (two steps, 5:1 mixture of diastereomers). h: CeCl3·7H2O, NaBH4, THF–CH3OH, -40°C. i: Ac2O, pyridine, 23°C, 86% (two steps). j: MgSO4, benzene, 60°C, 77%.

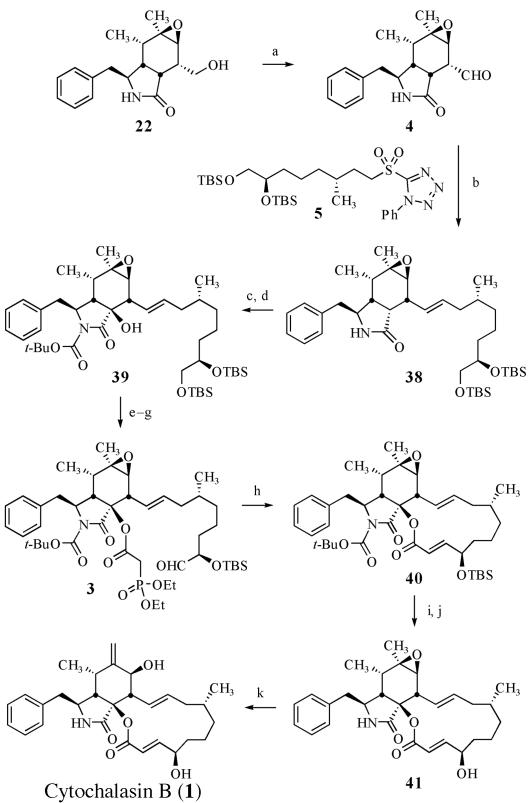

Completion of the Cytochalasin B Synthesis. Cytochalasin B was synthesized from the bicyclic intermediate 22 as outlined in Scheme 7. This route closely parallels our synthesis of L-696,474, described above. Thus, an analogous sequence of hydroxyl oxidation followed by Kocienski–Julia coupling, now with an anion formed from the N-phenyltetrazole sulfone 5, transformed 22 to the trans-olefin 38 in 60% yield. Protection of the lactam group within 38 by N-tert-butoxycarbonylation (80%) allowed for efficient enolization of the resultant imide with KHMDS; trapping of the enolate with trans-2-(phenylsulfonyl)-3-phenyloxaziridine then afforded the tertiary alcohol 39 in 85% yield. Acylation of the sterically hindered, electron-deficient tertiary alcohol 39 with diethylphosphonoacetic acid was conducted under conditions described by Shelkov et al. (50) (81% yield). Selective monodeprotection of the less hindered tert-butyldimethylsilyl ether of the resultant product occurred in the presence of HF·pyridine; oxidation of the primary hydroxyl group that was liberated then afforded the substrate for HWE closure identified in Fig. 2, aldehyde 3 (69% yield, two steps). Ring closure within substrate 3 was achieved by using the conditions developed for the closure of substrate 11 discussed above, albeit at lower temperature (23°C vs. 80°C), and provided the macrolactone 40 in 65% yield.

Scheme 7.

Reaction conditions. a: Dess–Martin periodinane, NaHCO3, CH2Cl2,23°C. b: 5, KHMDS, THF, -78°C; 4, -100°C → -40°C, 60% (two steps). c: Lithium bis(trimethylsilyl)amide, THF, -78°C; BOC2O, -78°C → -40°C, 80%. d: KHMDS, THF, -78°C; trans-2-(phenylsulfonyl)-3-phenyloxaziridine, -100°C → -78°C, 85%. e: Diethylphosphonoacetic acid, 1,3-dicyclohexylcarbodiimide, CH2Cl2, 23°C, 81%. f: HF·pyridine, THF, -20°C, 69%. g: Dess–Martin periodinane, NaHCO3, CH2Cl2, 23°C. h: NaOCH2CF3, CF3CH2OH, DME, 23°C, 65% (two steps). i: Mg(OCH3)2,CH3OH, 23°C, 95%. j: TBAF, THF, 23°C, 96%. k: MgSO4, benzene, 70°C, 66%.

Completion of the synthesis of cytochalasin B (1) was achieved by N-BOC cleavage within the macrocyclic intermediate 40 (magnesium methoxide, 95%) (51), hydrolysis of the tert-butyldimethylsilyl ether of the resultant product (TBAF, 96%), then epoxide → allylic alcohol rearrangement as a final step (induced by heating of the penultimate intermediate at 70°C in the presence of magnesium sulfate, 66% yield). The epoxide that served as the precursor to cytochalasin B is also a natural product (cytochalasin F, intermediate 41; Scheme 7). It is noteworthy that our routes to 1 and 2 involved in both cases the use of a mild, Mg(II)-induced epoxide → allylic alcohol rearrangement as a final step. Thus, both epoxide and allylic alcohol structural series are accessible by the omission or inclusion, respectively, of this final step. The value of this versatility with respect to structural diversification is obvious.

In conclusion, we have described enantioselective, convergent synthetic routes to both macrolactone and macrocarbocyclic cytochalasins from a common structural platform. Our route to cytochalasin B (1) is 24 steps in the longest linear sequence (4.6% yield from the aldehyde 7), and that to L-696,474 (2) is 23 steps (7.7% yield from the same precursor). We have shown that late-stage macrocyclization to form cytochalasins of different ring sizes and substitution patterns is viable in at least two cases. By using the platform we have identified, it is envisioned that large numbers (≥103) of diverse nonnatural structures are attainable by a parallel synthesis strategy.

Supplementary Material

Acknowledgments

We thank Merck, Inc. for an authentic sample of L-696,474. Financial support from the National Science Foundation is gratefully acknowledged. A.M.H. acknowledges a Fannie and John Hertz Foundation predoctoral fellowship.

This paper was submitted directly (Track II) to the PNAS office.

Abbreviations: HWE, Horner–Wadsworth–Emmons; KHMDS, potassium bis(trimethylsilyl)-amide; THF, tetrahydrofuran; TBAF, tetrabutylammonium fluoride.

Footnotes

Preliminary experiments suggest that closely related conditions are effective in minimizing epimerization during intermolecular HWE reactions as well.

References

- 1.Stork, G., Nakahara, Y., Nakahara, Y. & Greenlee, W. J. (1978) J. Am. Chem. Soc. 100, 7775-7777. [Google Scholar]

- 2.Stork, G. & Nakamura, E. (1983) J. Am. Chem. Soc. 105, 5510-5512. [Google Scholar]

- 3.Thomas, E. J. & Whitehead, J. W. F. (1986) J. Chem. Soc. Chem. Commun. 727-728.

- 4.Dyke, H., Sauter, R., Steel, P. & Thomas, E. J. (1986) J. Chem. Soc. Chem. Commun., 1447-1449.

- 5.Thomas, E. J. & Whitehead, J. W. F. (1989) J. Chem. Soc. Perkin Trans. 1, 499-505.

- 6.Merifield, E. & Thomas, E. J. (1990) J. Chem. Soc. Chem. Commun., 464-466.

- 7.Merifield, E. & Thomas, E. J. (1999) J. Chem. Soc. Perkin Trans. 1, 3269-3283.

- 8.Vedjes, E., Rodgers, J. D. & Wittenberger, S. J. (1988) J. Am. Chem. Soc. 110, 4822-4823. [Google Scholar]

- 9.Trost, B. M., Ohmori, M., Boyd, S. A., Okawara, H. & Brickner, S. J. (1989) J. Am. Chem. Soc. 111, 8281-8284. [Google Scholar]

- 10.Auerbach, J. & Weinreb, S. M. (1975) J. Org. Chem. 40, 3311-3312. [DOI] [PubMed] [Google Scholar]

- 11.Hensel, M. J., Palmer, J. T., Learn, K. S. & Fuchs, P. L. (1986) Synth. Commun. 16, 1297-1314. [Google Scholar]

- 12.Boutellier, M., Wallach, D. & Tamm, C. (1993) Helv. Chim. Acta 76, 2515-2527. [Google Scholar]

- 13.Cooper, J. A. (1987) J. Cell Biol. 105, 1473-1478. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Rubtsova, S. N., Kondratov, R. V., Kopnin, P. B., Chumakov, P. M., Kopnin, B. P. & Vasiliev, J. M. (1998) FEBS Lett. 430, 353-357. [DOI] [PubMed] [Google Scholar]

- 15.Rothweiler, W. & Tamm, C. (1966) Experientia 22, 750-752. [Google Scholar]

- 16.Wessells, N. K., Spooner, B. S., Ash, J. F., Bradley, M. O., Luduena, M. A., Taylor, E. L., Wrenn, J. T. & Yamada, K. M. (1971) Science 171, 135-143. [DOI] [PubMed] [Google Scholar]

- 17.Dombrowski, A. W., Bills, G. F., Sabnis, G., Koupal, L. R., Meyer, R., Ondeyka, J. G., Giacobbe, R. A., Monaghan, R. L. & Lingham, R. B. (1992) J. Antibiot. 45, 671-678. [DOI] [PubMed] [Google Scholar]

- 18.Ondeyka, J., Hensens, O. D., Zink, D., Ball, R., Lingham, R. B., Bills, G., Dombrowski, A. & Goetz, M. (1992) J. Antibiot. 45, 679-685. [DOI] [PubMed] [Google Scholar]

- 19.Lingham, R. B., Hsu, A., Silverman, K. C., Bills, G. F., Dombrowski, A., Goldman, M. E., Darke, P. L., Huang, L., Koch, G., Ondeyka, J. G., et al. (1992) J. Antibiot. 45, 686-691. [DOI] [PubMed] [Google Scholar]

- 20.Hungate, R. W., Chen, J. L., Starbuck, K. E., Macaluso, S. A. & Rubino, R. S. (1996) Tetrahedron Lett. 37, 4113-4116. [Google Scholar]

- 21.Rampal, A. M., Pinkofsky, H. B. & Jung, C. Y. (1980) Biochemistry 19, 679-683. [DOI] [PubMed] [Google Scholar]

- 22.Cox, R. H., Cutler, H. G., Hurd, R. E. & Cole, R. J. (1983) J. Agric. Food Chem. 31, 405-408. [Google Scholar]

- 23.Udagawa, T., Yuan, J., Panigrahy, D., Chang, Y.-H., Shah, J. & D'Amato, R. J. (2000) J. Pharmacol. Exp. Ther. 294, 421-427. [PubMed] [Google Scholar]

- 24.Wadsworth, W. S. (1977) Org. React. 25, 73-253. [Google Scholar]

- 25.Kelly, S. E. (1991) in Comprehensive Organic Synthesis, eds. Trost, B. M. & Fleming, I. (Pergamon, Oxford), Vol. 1, pp. 729-817. [Google Scholar]

- 26.Nicolaou, K. C., Härtner, M. W., Gunzner, J. L., Nadin, A. (1997) Liebigs Ann./Recueil., 1283-1301.

- 27.Blakemore, P. R., Cole, W. J., Kocienski, P. J. & Morley, A. (1998) Synlett, 26-28.

- 28.Oikawa, H., Murakami, Y. & Ichihara, A. (1992) J. Chem. Soc. Perkin Trans. 1, 2955-2959.

- 29.Myers, A. G., Yang, B. H., Chen, H., McKinstry, L., Kopecky, D. J. & Gleason, J. L. (1997) J. Am. Chem. Soc. 119, 6496-6511. [Google Scholar]

- 30.Myers, A. G., Yang, B. H., Chen, H. & Kopecky, D. J. (1997) Synlett, 457-459.

- 31.Christoffers, J. (1998) Helv. Chim. Acta 81, 845-852. [Google Scholar]

- 32.Beaulieu, P. L. & Wernic, D. (1996) J. Org. Chem. 61, 3635-3645. [DOI] [PubMed] [Google Scholar]

- 33.Aboujaoude, E. E., Collignon, N. & Savignac, P. (1984) J. Organomet. Chem. 264, 9-17. [Google Scholar]

- 34.Paterson, I, Yeung, K.-S. & Smaill, J. B. (1993) Synlett, 774-776.

- 35.Myers, A. G., Zhong, B., Kung, D. W., Movassaghi, M., Lanman, B. & Kwon, S. (2000) Org. Lett. 2, 3337-3340. [DOI] [PubMed] [Google Scholar]

- 36.Lubell, W. D. & Rapoport, H. (1987) J. Am. Chem. Soc. 109, 236-239. [Google Scholar]

- 37.Reetz, M. T. (1999) Chem. Rev. (Washington, DC) 99, 1121-1162. [DOI] [PubMed] [Google Scholar]

- 38.Hungerhoff, B., Samanta, S. S., Roels, J. & Metz, P. (2000) Synlett, 77-79.

- 39.Barbier, P. & Benezra, C. (1986) J. Med. Chem. 29, 868-871. [DOI] [PubMed] [Google Scholar]

- 40.Boeckman, R. K., Jr., & Barta, T. E. (1985) J. Org. Chem. 50, 3421-3423. [Google Scholar]

- 41.Hoffman, R. W. (1989) Chem. Rev. (Washington, DC) 89, 1841-1860. [Google Scholar]

- 42.Roush, W. R., Koyama, K., Curtin, M. L. & Moriarty, K. J. (1996) J. Am. Chem. Soc. 118, 7502-7512. [Google Scholar]

- 43.Comins, D. L. & Dehghani, A. (1992) Tetrahedron Lett. 33, 6299-6302. [Google Scholar]

- 44.McMurry, J. E. & Scott, W. J. (1980) Tetrahedron Lett. 21, 4313-4316. [Google Scholar]

- 45.Larsen, J. & Jørgensen, K. A. (1992) J. Chem. Soc. Perkin Trans. 2, 1213-1217.

- 46.Yamada, S., Morizono, D. & Yamamoto, K. (1992) Tetrahedron Lett. 30, 4329-4332. [Google Scholar]

- 47.Myers, A. G. & Movassaghi, M. (1998) J. Am. Chem. Soc. 120, 8891-8892. [Google Scholar]

- 48.Schaus, S. E., Brandes, B. D., Larrow, J. F., Tokunaga, M., Hansen, K. B., Gould, A. E., Furrow, M. E. & Jacobsen, E. N. (2002) J. Am. Chem. Soc. 124, 1307-1315. [DOI] [PubMed] [Google Scholar]

- 49.Blanchette, M. A., Choy, W., Davis, J. T., Essenfeld, A. P., Masamune, S., Roush, W. R. & Sakai, T. (1984) Tetrahedron Lett. 25, 2183-2186. [Google Scholar]

- 50.Shelkov, R., Nahmany, M. & Melman, A. (2002) J. Org. Chem. 67, 8975-8982. [DOI] [PubMed] [Google Scholar]

- 51.Wei, Z.-Y. & Knaus, E. E. (1994) Tetrahedron Lett. 35, 847-848. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.