Abstract

Formulated chicken nuggets which are low in fat and, high in dietary fiber and free from phosphate were developed by adding various levels of a konjac flour/xanthan gum (KF/XG) (3:1) mixture (0.2–1.5 %, w/w) and shiitake powder (SP) (1–4 %, w/w). A central composite rotatable design was used to investigate the influence of variables on the physical and sensory properties of nuggets and to optimize the formulated nugget formulation. The addition of the KF/XG mixture and SP was effective in improving nugget firmness and increasing hedonic scores for color, taste, flavor and overall acceptability. The nugget became darker with more SP was added. Optimal nuggets with 0.39 % KF/XG mixture and 1.84 % SP had reduced fat, higher dietary fiber and amino acids. After frozen (−18 ± 2 °C) storage, optimal formulated nuggets showed slower decreased in moisture, hardness and chewiness compared to standard nuggets. Konjac flour and SP also lowered lipid oxidation in frozen formulated nuggets. A slight change in sensory score was observed in both nuggets were microbiologically safe after frozen storage for 75 days.

Keywords: Formulated food, Konjac flour, Meat products, Response surface methodology, Shiitake mushroom

Introduction

Today, formulated meat products that are low in fat and harmful ingredients like phosphates and nitrite, but are high in functional ingredients including dietary fiber and antioxidant-rich substances are being increasingly consumed. This is because most consumers would like to avoid the risks of fat-related diseases including cardiovascular disease, diabetes, obesity, hypertension and some cancers (Singh et al. 2011). Reductions in harmful ingredients such as animal fat, salt and phosphates have been investigated for the manufacture of low-fat meat products (Mahmoud and Badr 2011). Hydrocolloids such as carrageenan, konjac and locust bean gum have contributed as fat replacers because of their very low caloric content, inexpensive cost and versatile applications, as they can be added directly or prepared as fat analogues (Choi et al. 2008). Konjac flour, a non-ionic gum consisting of d-glucose and d-mannose (1:1.6) units with β-1,4-linkages, has been extensively used as an additive for gelling, thickening, texturizing and binding in various food products (Takigami 2000). Konjac gel, either prepared by deacetylation in mild alkali (calcium hydroxide) or by combining it with secondary gums (κ-carrageenan, xanthan or gellan), has been applied to replace for fat in meat products such as low-fat, low-salt frankfurters (Jiménez-Colmenero et al. 2010). Additionally, the flour is also associated with health benefits in terms of providing no caloric value, controlling weight gain, improving intestinal activity to alleviate constipation, providing satiation and lowering blood cholesterol and triglycerides (Delgado-Pando et al. 2011). Due to its β-linkages that cannot be hydrolyzed by human enzymes, konjac also represents an indigestible dietary fiber for other applications in the food industry.

Phosphates in the form of salts of phosphoric acid and sodium or potassium are common additives in meat processing. Appropriate usage levels can contribute to important properties of the final products, such as moisture retention, color protection, texture desirability, oxidative retardation and shelf life extension (Erdogdu et al. 2007). Several studies have been conducted on the influence of phosphates on consumer health, but their results have been contradictory and their safety and health impact are still debatable. Given the information currently available, because they are synthetic substances, it is advisable to be aware of the risks from excessive phosphate intake. They can cause increased levels of parathyroid hormone and hinder mineral deposition into cortical bone, leading to lower bone mineral density and loss of bone mass (Huttenen et al. 2006; Long et al. 2011).

Supplementation of health-promoting ingredients is an approach to make meat products more nutritious. Mushrooms, especially shiitake (Lentinus edodes), have traditionally been consumed or used as a supplement to extend or enhance flavor and taste. They also provide medicinal and health benefits including anti-inflammatory effects, anti-tumor effects, blood pressure regulation and cardiovascular disorders (Reis et al. 2012). Shiitake mushrooms have been reported to be a good source of β-glucan, which shows potential in lowering plasma triglycerides and cholesterol in humans. The mushrooms also contain eritadenine, a substance that shows evidence of lowering plasma lipids, which is not found in oats (Handayani et al. 2012). They are low in fat and caloric value, but high in protein content in relation to most vegetables, and are good sources of vitamin B, vitamin D, various minerals such as potassium, phosphorus, calcium, zinc, selenium and manganese as well as extra dietary fiber, both soluble and insoluble types (Regula and Gramza-Michalowska 2009). Mushrooms are rich in antioxidants such as polyphenols and flavonoid compounds (Zhang et al. 2015). Pil-Nam et al. (2015) showed the potential of shiitake powder that effectively enhanced sensorial characteristics such as taste and flavor in frankfurters on the first day of refrigerated storage, in addition to retarding lipid oxidation. Dietary fiber, another functional ingredient, has been reported for health benefits such as preventing constipation, decreasing blood cholesterol and glucose levels and reducing the risks of cardiovascular diseases, diverticulosis, diabetes mellitus and colon cancer (Raghavendra et al. 2006; Kohajdová et al. 2011). The recommended intake level of dietary fiber ranges from 30 to 45 g per day. Besides its health benefits, dietary fiber is incorporated into food products for many purposes such as a non-caloric bulking agent, improved emulsion stability and water holding capacity (WHC) (Elleuch et al. 2011).

To date, there are no reports in the literature regarding the use of the konjac flour/xanthan gum (KF/XG) mixture incorporated with shiitake powder (SP) to develop more nutritious, reduced fat and phosphate-free formulated chicken nuggets. Response surface methodology (RSM) has been used successfully to describe the effects of independent variables and/or their interactions on responses as well as to optimize product formulation (Anderson and Whitcomb 2005). Therefore, this study aimed to investigate the influence of various levels of KF/XG mixture and SP on the physical and sensory properties of formulated chicken nuggets and to determine the optimal formulation. Chemical composition and amino acid profile of the optimal formulated nugget, as well as storage stability during 75 days of frozen storage (−18 ± 2 °C) were also studied.

Materials and methods

Materials

Hydrocolloids used were konjac flour (Chengdu Newstar Chengming Bio-Tech Co., Ltd., China) and xanthan gum (KELTROL®, CP Kelco, San Diego, CA, USA). Sodium tripolyphosphate (Carlo Erba Reagenti, Rodano, Italy) was used. Nugget ingredients such as chicken breast and fat, salt, black pepper, garlic powder, aniseed, seasoning and white soy sauce were purchased from a local supermarket. Dried shiitake mushroom (Golden fish®, Thailand) was used in this study.

Experimental design

A central composite rotatable design (CCRD) was chosen to investigate the effect of two independent variables that is KF/XG (3:1) mixture (a proper proportion for konjac gel formation) and SP on physical and sensory properties of formulated nuggets. The experimental design for two variables with coded levels, −1.41, −1, 0, 1, 1.41, and actual values is presented in Table 1. The predictive models for the responses are described in the following equation:

| 1 |

where Y is the observed response; X1 and X2 represent the KF/XG mixture and SP, respectively; b0 is the intercept, b1 and b2 are linear, b11 and b22 are quadratic, and b12 is the interaction coefficients, respectively.

Table 1.

Two independent variables with coded and actual values and results of physical and sensory properties of formulated nuggets

| Run | Coded (actual) variables | Physical properties | Sensory scores | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | Firmness (N) |

L * | a * | b * | Appearance | Color | Taste | Flavor | Texture | Overall acceptability | |

| 1 | −1 (0.39) | −1 (1.44) | 34.02 ± 0.32 | 63.12 ± 0.24 | 3.20 ± 0.09 | 14.02 ± 0.96 | 6.9 ± 0.4 | 6.5 ± 0.6 | 6.8 ± 0.4 | 6.7 ± 0.5 | 7.2 ± 0.5 | 6.9 ± 0.4 |

| 2 | +1 (1.31) | −1 (1.44) | 35.43 ± 0.86 | 62.29 ± 0.38 | 3.31 ± 0.12 | 14.43 ± 0.72 | 6.3 ± 0.5 | 6.8 ± 0.7 | 6.6 ± 0.7 | 6.8 ± 0.8 | 6.9 ± 0.5 | 6.4 ± 0.8 |

| 3 | −1 (0.39) | +1 (3.56) | 34.03 ± 0.77 | 59.10 ± 0.35 | 3.48 ± 0.08 | 16.48 ± 1.08 | 5.4 ± 0.7 | 5.6 ± 0.6 | 6.3 ± 0.3 | 6.3 ± 0.4 | 5.8 ± 0.4 | 6.3 ± 0.4 |

| 4 | +1 (1.31) | +1 (3.56) | 22.52 ± 1.24 | 58.18 ± 0.43 | 3.70 ± 0.43 | 17.23 ± 1.12 | 5.6 ± 0.6 | 5.5 ± 0.2 | 6.1 ± 0.4 | 6.2 ± 0.7 | 5.6 ± 0.7 | 6.0 ± 0.5 |

| 5 | −1.41 (0.2) | 0 (2.50) | 30.25 ± 0.65 | 59.94 ± 0.56 | 3.40 ± 0.22 | 14.66 ± 0.94 | 6.2 ± 0.3 | 7.1 ± 0.5 | 7.3 ± 0.5 | 7.3 ± 0.8 | 6.5 ± 0.8 | 7.0 ± 0.8 |

| 6 | +1.41 (1.5) | 0 (2.50) | 28.25 ± 0.29 | 59.66 ± 0.35 | 3.27 ± 0.38 | 17.09 ± 0.82 | 6.1 ± 0.6 | 6.8 ± 0.6 | 6.7 ± 0.6 | 7.0 ± 0.5 | 6.2 ± 0.5 | 6.8 ± 0.5 |

| 7 | 0 (0.85) | −1.41 (1.0) | 35.35 ± 1.12 | 62.79 ± 0.27 | 3.26 ± 0.08 | 14.50 ± 1.05 | 6.8 ± 0.2 | 6.1 ± 0.4 | 5.9 ± 0.5 | 6.2 ± 0.4 | 6.6 ± 0.8 | 5.9 ± 0.6 |

| 8 | 0 (0.85) | +1.41 (4.0) | 24.22 ± 0.93 | 57.39 ± 0.84 | 4.07 ± 0.19 | 17.81 ± 0.42 | 5.1 ± 0.3 | 4.6 ± 0.3 | 5.4 ± 0.3 | 5.3 ± 0.6 | 5.5 ± 0.3 | 5.1 ± 0.3 |

| 9 | 0 (0.85) | 0 (2.50) | 30.85 ± 0.64 | 58.88 ± 0.76 | 3.16 ± 0.20 | 16.81 ± 0.38 | 6.2 ± 0.7 | 6.9 ± 0.5 | 6.8 ± 0.3 | 6.5 ± 0.4 | 6.5 ± 0.5 | 7.0 ± 0.6 |

| 10 | 0 (0.85) | 0 (2.50) | 31.65 ± 0.91 | 60.35 ± 0.92 | 3.10 ± 0.35 | 17.41 ± 0.55 | 5.9 ± 0.5 | 6.5 ± 0.8 | 6.5 ± 0.5 | 6.3 ± 0.5 | 6.4 ± 0.7 | 6.9 ± 0.4 |

| 11 | 0 (0.85) | 0 (2.50) | 30.84 ± 0.84 | 59.39 ± 1.18 | 2.90 ± 0.28 | 17.40 ± 0.80 | 5.8 ± 0.5 | 6.7 ± 0.3 | 6.4 ± 0.6 | 6.4 ± 0.3 | 6.1 ± 0.5 | 6.6 ± 0.8 |

| 12 | 0 (0.85) | 0 (2.50) | 31.26 ± 0.66 | 59.19 ± 0.57 | 3.35 ± 0.33 | 16.93 ± 0.75 | 6.2 ± 0.5 | 6.8 ± 0.6 | 6.5 ± 0.7 | 6.5 ± 0.5 | 6.3 ± 0.3 | 6.7 ± 0.3 |

| 13 | 0 (0.85) | 0 (2.50) | 33.32 ± 0.85 | 59.95 ± 0.49 | 3.23 ± 0.40 | 17.27 ± 0.84 | 6.9 ± 0.4 | 6.4 ± 0.6 | 6.6 ± 0.9 | 6.7 ± 0.2 | 6.5 ± 0.6 | 6.8 ± 0.4 |

X1 = % (w/w) konjac/xanthan (3:1) mixture and X2 = % (w/w) SP

Preparation of dried mushroom powder

Dried shiitake mushroom was cleaned with tap water, and then dried in a hot air oven (UM400, Memmert GmbH, Schwabach, Germany) at 70 ± 2 °C for 5 h. The dried shiitake was ground by a Waring® blender (Model 7011S, Waring Commercial, CT, USA) and sieved through Restch test sieves (Verder Scientific Inc., PA, USA). Dried SP (180–425 µm) was selected for use in this study and it contained 5.6 % moisture, 15.2 % protein, 2.9 % fat, 6.1 % ash and 70.2 % carbohydrate.

Processing of chicken nugget

The standard formulation of chicken nugget (% by total weight) contained 91 % chicken meat, 3.5 % chicken fat, 3 % water, 0.8 % white soy sauce, 0.5 % salt, 0.45 % black pepper, 0.35 % sodium tripolyphosphate, 0.2 % seasoning, 0.1 % garlic powder, 0.05 % aniseed and 0.05 % clove. A non-breaded nugget style was used in the study. Initially, chicken meat and fat were minced by a food chopper (Model 320, Moulinex, France) before adding into a bowl. The brine solution, previously dissolved the salt in water, was thoroughly mixed with the minced chicken meat and fat for 30 s using a food processor (Model MK-F300, Panasonic, Malaysia). Other ingredients such as white soy sauce, salt, black pepper, sodium tripolyphosphate, seasoning, garlic powder, aniseed and clove were added and mixed homogeneously (about 1 min). Each 25 g nugget (4 × 2 × 1 cm3) was manually formed and kept in a freezer at −18 °C for 1 h. The nuggets were cooked by deep fat frying (180 °C) in palm oil for 3 min (internal temperature about 80 ± 2 °C). In RSM study where chicken fat and sodium tripolyphosphate were removed, the nuggets were prepared by varying different levels of the KF/XG mixture and SP based on the experimental design.

Shelf life studies

Standard and recommended formulated nuggets were packed in low density polyethylene bags, sealed and then kept at frozen storage (−18 ± 2 °C) for 0, 25, 50 and 75 days. The products were analyzed at studied interval after thawing in a refrigerator (4 ± 1 °C) for 5–6 h.

Physicochemical analysis

pH measurement

A 10 g of sample was blended with 50 ml of distilled water for 1 min. The pH was measured using a pH-meter (Model 320, Metler–Toledo Ltd, Essex, UK).

Firmness

The firmness which is expressed as the force needed to shear a cooked sample was determined using a Lloyd texture analyzer (Model LRX, Lloyd Instruments, Hampshire, UK). A shearing test cell with a crosshead speed of 250 mm min−1 was used. All analyses were performed in five replications and the peak force (N) was recorded.

Texture profile analysis (TPA)

A Lloyd texture analyzer was used for determining TPA parameters; hardness, cohesiveness, springiness and chewiness of nuggets. The TPA test was performed with a test cell (50 mm × 50 mm) working with a 2 mm s−1 crosshead speed and 50 % of strain using a Nexygen® software. All analyses were performed in five replications.

Color

The internal color of cooked samples was measured using a Hunter Lab colorimeter (Model ColorFlex, Hunter Associates Laboratory, Reston, VA). Lightness (L *) (0 = black, 100 = white), red/green (a *) (+ = red, − = green) and yellow/blue (b *) (+ = yellow, − = blue) were recorded. Five replications were made per treatment.

Thiobarbituric acid (TBA) value

TBA value was determined using the procedure described by Tarladgis et al. (1960). A UV–Vis spectrophotometer (UV-1601, Shimadzu Corporation, Kyoto, Japan) was used in this study.

Proximate analysis and dietary fiber determination

Moisture, protein, fat, ash and dietary fiber were determined according to AOAC (1990) procedures.

Free amino acid assays

Samples were determined for free amino acids according to the method described by Hagen et al. (1989).

Sensory evaluation

Forty panelists who have some experience in sensory evaluation and usually consumed nuggets were drawn from Department of Food Science and Technology, University of the Thai Chamber of Commerce. A 9-point hedonic scale (1 = extremely dislike, 9 = extremely like) was used for evaluating appearance, color, texture, flavor, taste and overall acceptability. In case of shelf life studies, frozen cooked chicken nuggets for each storage time were warmed in a microwave oven (800 W) for 30 s before serving. Panelists were invited to sit in a partitioned sensory booth, clean and rinse the palate between samples by unsalted cracker, grape juice, and water.

Microbiological determination

Samples of 10 g (0, 25, 50, and 75 days) were aseptically weighed and placed in a stomacher bag containing 90 ml of sterile 0.1 % peptone (Difco) diluent and pummeled for 1 min with a Stomacher-400 (Tekmar Company, Cincinnati, OH). Appropriate dilutions of samples were prepared in sterile 0.1 % peptone and plated, in duplicate, on the growth media. The following media and incubation conditions were used: (a) Petrifilm™ Aerobic Plate Count; 35 ± 2 °C for 1–2 days for total plate count and 4 ± 1 °C for 7–10 days for Psychrotrophic count, and (b) Petrifilm™ Yeast and Mold Count: 25 ± 2 °C for 3–5 days. The microbial counts were expressed as log CFU/g.

Statistical analysis

All analyses were carried out in triplicate unless otherwise indicated. The data generated for different responses were analyzed for the analysis of variance (ANOVA) and multiple regression using the Design-Expert® Trial version 8.0.2 software (State-Ease Inc., Minneapolis, MN). In the shelf life studies, physicochemical and sensory data were conducted on completely randomized design (CRD) and randomized complete block design (RCBD), respectively. Means with a significant difference (P < 0.05) were compared using Duncan’s new multiple range test and t test.

Results and discussion

Statistical analysis and model fitting

The data obtained for physical properties, i.e. firmness and color, are presented in Table 1. Firmness values ranged from 22.52 to 35.43 N, and those for color parameters were as follows: L * from 57.39 to 63.12, a * from 2.90 to 4.07 and b * from 14.02 to 17.81. Sensory scores of appearance, color, taste, flavor, texture and overall acceptability were in the range of 5.1–6.9, 4.6–7.1, 5.4–7.3, 5.3–7.3, 5.5–7.2 and 5.1–7.0, respectively (Table 1). Regarding analysis of variance and regression, the models with the significant factor at least the 95 % probability are given below.

Physical properties

| 2 |

| 3 |

| 4 |

| 5 |

Sensory properties

| 6 |

| 7 |

| 8 |

| 9 |

| 10 |

| 11 |

where X1 = konjac/xanthan (3:1) mixture (%) and X2 = shiitake powder (%). *Significant at P < 0.05; **significant at P < 0.01; ***significant at P < 0.001.

It was observed that values of the determination coefficient (R2) in equations of physical properties (R2 = 0.8177–0.9355) and sensory properties (R2 = 0.8416–0.9625) are high, in addition to their insignificant lack of fit values (data not shown). Hence, all models were fitting and reliable.

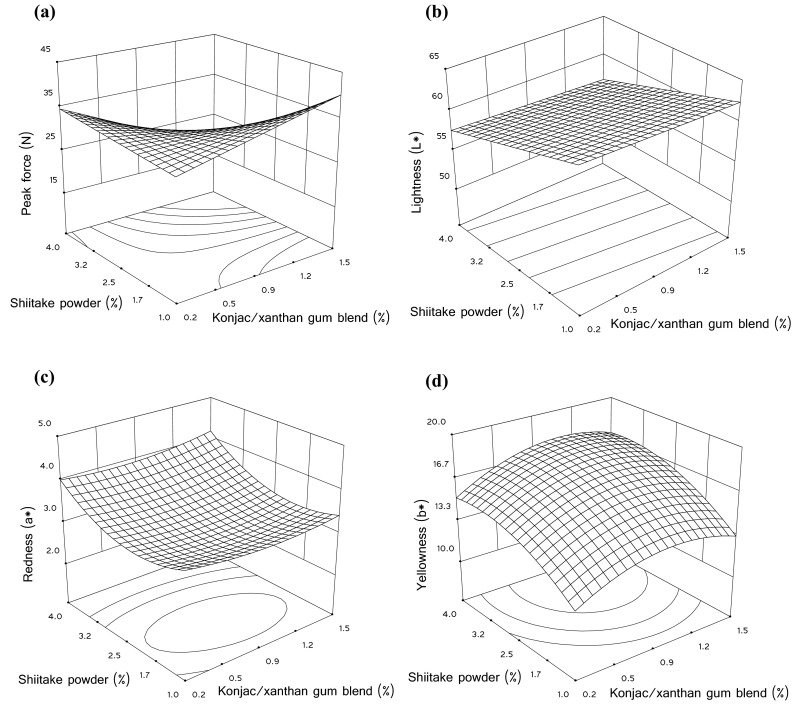

Effect of KF/XG mixture and SP on firmness

Firmness is measured as peak force; a higher peak force indicates a firmer nugget texture. Higher protein extraction and good water- and fat-binding properties are factors concerning the desirable firmness of chicken nuggets (Devatkal et al. 2014). As seen in Fig. 1a, firmness was increased with increasing the KF/XG mixture when the SP was maintained at 1–2 %. A hydrated and viscous meat, developed by water binding and swelling properties of konjac, xanthan and SP, could render fat- and water binding and hold nugget constituents together. These principles promote a well-emulsified meat, as fat globules were physically entrapped and uniformly distributed within a protein gel/emulsion matrix. The better rheological properties of the continuous phase might decrease a chance for fat globules moving to coalesce in emulsified meat. This maintained particle size of fat globules correspond to stabilized meat emulsion during cooking, contributing to qualified nugget texture (Devatkal et al. 2014). However, there was a negative interaction effect between the KF/XG mixture and SP (Eq. 2), resulting in decreased firmness at high levels of these two variables applied. Andrès et al. (2006) reported that in chicken nuggets (0.22–6.09 % lipids), the addition of guar-xanthan (3:7) mixture approximately 0.32 % disrupted the protein–protein gel network, thus decreasing gel strength and nugget firmness. Furthermore, too much SP might interfere with solubilized proteins for protein–protein and protein-polysaccharide interactions, resulting in a weaker gel network.

Fig. 1.

Response surface graphs of physical properties of formulated nuggets with various levels of KF/XG mixture and SP: a firmness, b L * value, c a * value and d b * value

Effect of KF/XG mixture and SP on internal color

RSM graphs for internal color of the nuggets are presented in Fig. 1b–d. The results showed that an increase in SP caused a decreased L * value (Fig. 1b), but increased a * and b * values (Fig. 1c, d), while the KF/XG mixture affected b * value only (Fig. 1d). This finding indicated that nuggets with a larger amount of SP were darker, possibly due to the light brown color of SP (L * = 76.83, a * = 2.47, b * = 19.12 and hue = 82.64). Converse result was reported by Wan Rosli et al. (2011), showing a lighter color in chicken nuggets with increasing hiratake mushrooms (Pleurotus sajor-caju) or oyster mushrooms in range of 13.5–27 %. Hence, lightness or darkness of nuggets may be attributed to the type and quantity of added mushrooms. A higher a * value observed with increasing SP suggested that the nuggets had more redness. Generally, redness is an important criteria concerning the consumer preference of cooked meat products. This reflected by increased sensory color scores in the nuggets incorporated with 1.8–3 % SP (Fig. 2b).

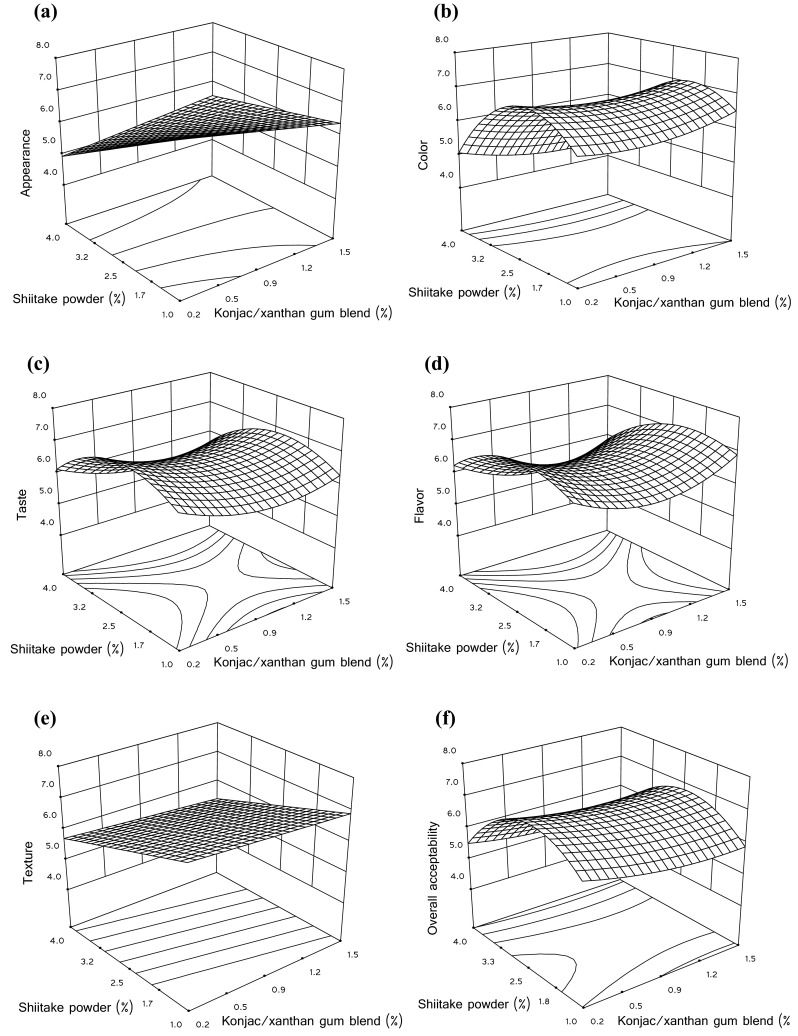

Fig. 2.

Response surface graphs of sensory evaluation of formulated nuggets with various levels of KF/XG mixture and SP: a appearance, b color, c taste, d flavor, e texture and f overall acceptability

Effect of KF/XG mixture and SP on sensory evaluation

Appearance

Figure 2a indicates that SP greatly affected sensory attributes in comparison to the KF/XG mixture. The increase in SP decreased appearance scores of the nuggets, possibly because most of panelists were not accustomed to the nugget containing more dispersed SP. Panelists noted that the nuggets appeared smaller (shrinkaged) when 2.5–4 % SP was included. This may be a reason why panelists scored lowered. The interaction of the KF/XG mixture and SP was negative (P < 0.05), thus increasing of these variables decreased the appearance score.

Color

The RSM graph of color is shown in Fig. 2b. SP was the only variable that affected nugget color. There was an initial increase in the color score along with increasing SP from 1 to 2.5 %, but beyond this level, it decreased continuously. This suggested that most panelists preferred nuggets with SP levels of approximately 1.8–3 %, when nugget color was moderately intense.

Taste

Figure 2c denotes that taste score was affected by the KF/XG mixture and SP. Nuggets were scored higher when SP levels of 1 % to about 3 % were used, but beyond this level the taste scores were lowered. Most panelists preferred nuggets containing SP around 2–3 %. This is because shiitake mushrooms are high in the non-essential amino acids; glutamic and aspartic acids, and the 5′-nucleotides, especially 5′-guanosine monophosphate (5′-GMP), which were recognized as umami taste compounds (Tseng et al. 2011). Dermiki et al. (2013) showed the enhanced umami and salty characteristics in cooked meat products added with natural umami-containing ingredients such as yeast extract, shiitake extract, low-salt soy sauce and beef stock paste. They concluded that the synergistic effects of glutamic acid and 5′-nucleotides, stimulated by the heat treatment, led to enhance the perception of taste and savoury flavor attributes in the cooked products. However, panelists gave lower scores if the nuggets contained high amount of SP (>3 %). The stronger mushroom odor and aftertaste was found to affect nugget taste preference.

Flavor

The flavor graph presented in Fig. 2d revealed a similar pattern to that found in the taste graph, where the flavor was mostly affected by the SP. Panelists preferred the flavor of nuggets containing 2–3 % SP, in consonance with many studies that revealed the pleasantness and fullness of savoury flavors were increased by umami taste (Dermiki et al. 2013). However, nugget scored lower when high SP levels (>3 %) were used, possibly a high amount of SP interfered meaty flavor of the nuggets (Chun et al. 2005). The finding indicates a potential for use of SP to amplify the flavor of the nuggets, but should be used in a proper level.

Texture

A strong reduction in texture scores was observed in the nuggets with increasing SP while the KF/XG mixture showed no significant effect (Fig. 2e). Nuggets with a KF/XG mixture at any level (0.2–1.5 %) and SP at 1 %, achieved a texture score of 7.0, indicating moderate preference. This is likely because both the KF/XG mixture and SP were able to increase the WHC of the nuggets, which in turn may had allow water to move in between protein molecules. Additionally, a formation of stable, elastic and rigid protein/konjac gel matrix with good water and fat binding properties may have formed (Akesowan 2010). An excessive SP (>3 %) was found to decrease texture scores. The result was relative to the study of Wan Rosli et al. (2011) who found the decrease in firmness, cohesiveness and chewiness of chicken nuggets upon addition of hiratake mushroom (Pleurotus sajor-caju). Similar result was found by Lin and Lin (2004) who reported a decrease in cohesiveness with the increasing of bacterial cellulose (Nata) in Chinese style meatballs.

Overall acceptability

The overall acceptability was mainly affected by the SP in relation to the KF/XG mixture (Fig. 2f). Overall acceptability was highly rated in the nuggets where a moderate level of SP (1.8–3 %) was used. Panelists lowered their scores as SP levels were increased from 3 to 4 %. Some panelists suggested that nugget acceptability would be better if some seasonings such as pepper and soy sauce were reduced, as they observed the product too strong in taste and flavor.

Optimization and validation

The optimal formulated chicken nugget was designed to have maximum evaluator preference, thus sensory evaluation was used for optimizing the best nugget formulation. Optimization was achieved by Design Expert software, which showed that the addition of 0.39 % KF/XG mixture and 1.84 % SP was optimal. Sensory scores of appearance, color, taste, flavor, texture and overall acceptability predicted by the recommended model were 6.6, 6.8, 6.9, 6.9, 6.8 and 7.0, respectively, which had an overall desirability value of 0.83. This value, defined as the geometric mean of the desirability for each sensory response, could range from 0.0 for undesirable to 1.0 for very desirable. Thus, the overall desirability is a single factor combining all goals of sensory attributes into one desirability function, thereby the maximized value shows adequate levels of KF/XG mixture and SP required for overall nugget quality.

The optimal nugget was validated by panelist testing. Sensory scores of each attribute were found to be 6.7 for appearance, 7.0 for color, 7.0 for taste, 7.1 for flavor, 7.1 for texture and 7.3 for overall acceptability. As compared with the above predicted sensory scores, percentage relative errors were 1.5, 2.9, 1.4, 2.8, 4.2 and 4.1 %, respectively. These results showed that the model for the optimal nugget, predicting 0.39 % KF/XG mixture and 1.84 % SP, was reliable.

Proximate composition and amino acid profile

Results of proximate composition are shown in Table 2. Moisture and ash content did not differ (P > 0.05) whereas the protein content significantly increased (P < 0.05) in formulated nuggets compared to standard nuggets. Formulated nuggets showed a decrease in fat from 7.95 to 6.55 % (17.6 % reduction in fat) as well as an increase in dietary fiber from 0.37 to 1.80 % (386.5 % increase in dietary fiber or 4.9-fold higher), in relation to standard nuggets. Most amino acids, especially leucine, glutamic and aspartic acids, were increased in formulated nuggets (Table 2), which was influenced by shiitake addition. Tseng et al. (2011) reported that coarse SP (100 g) was composed of about 2490 mg of free amino acids, thus it directly increased total free amino acid content in white steamed buns with increasing amount of SP. In view of taste components, classified by sensory taste intensity evaluation (Table 2), the increase in aspartic and glutamic amino acids (approximately 15.61 %), which contributed to the monosodium glutamate-like taste, led to enhance umami flavor in formulated nuggets (Yamaguchi et al. 1971). It was proposed that the palatability of formulated nuggets could be improved by incorporating with SP. Other taste components depending on taste characteristics such as total sweet taste (alanine, glycine, proline, serine and threonine) and tasteless (lysine, tyrosine and cystine) were also increased, while a total bitter taste (arginine, histidine, isoleucine, leucine, methionine, phenylalanine, tryptophan and valine) was slightly decreased.

Table 2.

Chemical composition and amino acid profile of chicken nuggets

| Chemical composition (g 100 g−1) | Standard nugget | Formulated nugget |

|---|---|---|

| Moisture | 61.80 ± 0.12a | 60.82 ± 0.32a |

| Fat | 7.95 ± 0.46a | 6.55 ± 0.55b |

| Protein | 27.20 ± 0.08b | 28.46 ± 1.12a |

| Ash | 2.68 ± 0.06a | 2.37 ± 0.09a |

| Dietary fiber | 0.37 ± 0.05b | 1.80 ± 0.10a |

| Amino acid profile (mg 100 g −1) | ||

| Alanine | 1,570.72 ± 20.46a | 1,546.84 ± 19.24a |

| Arginine | 2,169.58 ± 34.25a | 2,013.60 ± 40.16b |

| Aspartic acid | 2,651.12 ± 26.28b | 2,947.59 ± 30.10a |

| Cystine | 250.36 ± 18.06b | 263.51 ± 26.92a |

| Glutamic acid | 4,223.59 ± 60.22b | 4,411.05 ± 47.56a |

| Glycine | 1,238.31 ± 35.61b | 1,435.87 ± 28.75a |

| Histidine | 4,372.48 ± 42.96a | 3,283.73 ± 56.70b |

| Isoleucine | 1,707.25 ± 28.88a | 1,320.49 ± 39.06b |

| Leucine | 2,166.04 ± 34.62b | 3,055.78 ± 56.37a |

| Lysine | 2,067.21 ± 44.15a | 2,088.89 ± 29.27a |

| Methionine | 719.21 ± 19.33b | 819.11 ± 30.85a |

| Phenylalanine | 1,072.99 ± 68.12b | 1,302.67 ± 45.40a |

| Proline | 1,124.73 ± 42.96a | 1,089.14 ± 36.02a |

| Serine | 1,206.46 ± 56.04b | 1,442.93 ± 19.38a |

| Threonine | 1,234.73 ± 24.33b | 1,317.43 ± 20.76a |

| Tryptophan | 303.67 ± 11.58a | 315.81 ± 18.85a |

| Tyrosine | 1,090.29 ± 50.46b | 1,133.25 ± 37.24a |

| Valine | 1,114.26 ± 33.08b | 1,355.23 ± 46.92a |

| Taste component a | ||

| MSG-like | 6,874.71 ± 38.04b | 7,358.64 ± 42.48a |

| Sweet | 6,374.95 ± 28.34b | 6,832.21 ± 35.05a |

| Bitter | 13,625.48 ± 42.52a | 13,466.42 ± 39.26b |

| Tasteless | 3,407.86 ± 30.77a | 3,485.65 ± 54.82a |

| Total | 30,283.00 ± 31.76b | 31,142.92 ± 40.52a |

Means within rows with different superscripts are significantly different (P < 0.05)

aMSG-like = monosodium glutamate-like = Asp + Glu; sweet = Ala + Gly + Pro + Ser + Thr; bitter = Arg + His + Ile + Leu + Met + Phe + Try + Val and tasteless = Lys + Tyr + Cys

Storage stability

pH and moisture

There was no significant change in pH (P > 0.05), but both standard and formulated nuggets showed a decrease moisture (P < 0.05) during 75 days of storage (Table 3). Moisture reduction was slower in formulated nuggets compared to standard as the ingredients used (konjac, xanthan and shiitake powder) have effective water binding properties. The decrease in moisture with increase in storage time may be attributed to an increase in size of ice crystals. Enlarged ice crystals may bring about the protein denaturation, causing a loss of WHC (Muela et al. 2012).

Table 3.

Characteristics of chicken nuggets during frozen storage

| Treatment | Storage period (days) | |||

|---|---|---|---|---|

| 0 | 25 | 50 | 75 | |

| pH | ||||

| Standard | 6.22 ± 0.23aA | 6.22 ± 0.25aA | 6.18 ± 0.08aA | 6.18 ± 0.15aA |

| Formulated | 6.15 ± 0.10bA | 6.12 ± 0.14bA | 6.16 ± 0.20aA | 6.13 ± 0.16aA |

| Moisture (%) | ||||

| Standard | 60.84 ± 1.25aA | 58.25 ± 1.09aAB | 57.86 ± 1.12aB | 56.46 ± 0.93aB |

| Formulated | 59.68 ± 1.06bA | 58.06 ± 1.32aA | 57.32 ± 1.45aB | 56.13 ± 0.85aB |

| Hardness (N) | ||||

| Standard | 45.74 ± 1.49aA | 34.55 ± 1.45aB | 29.67 ± 0.93bC | 32.95 ± 1.03aB |

| Formulated | 38.65 ± 1.36bA | 31.01 ± 2.10bBC | 32.35 ± 1.12aB | 29.26 ± 1.74bC |

| Cohesiveness | ||||

| Standard | 0.45 ± 0.08aA | 0.38 ± 0.09bB | 0.41 ± 0.07bA | 0.35 ± 0.08bB |

| Formulated | 0.41 ± 0.06bA | 0.46 ± 0.10aA | 0.45 ± 0.08aA | 0.44 ± 0.07aA |

| Springiness (mm) | ||||

| Standard | 5.27 ± 0.34aA | 5.17 ± 0.19aA | 5.30 ± 0.13aA | 4.80 ± 0.23bB |

| Formulated | 5.07 ± 0.15bB | 5.20 ± 0.09aA | 5.11 ± 0.18bAB | 5.19 ± 0.20aA |

| Chewiness (Nmm) | ||||

| Standard | 97.63 ± 2.63aA | 64.98 ± 2.06bB | 55.78 ± 1.76bC | 56.24 ± 0.98bC |

| Formulated | 84.62 ± 2.84bA | 75.54 ± 1.53aBC | 78.92 ± 1.68aB | 74.05 ± 1.12aC |

| Lightness (L * value) | ||||

| Standard | 63.89 ± 0.29bA | 62.01 ± 0.18aB | 59.08 ± 0.32bC | 59.22 ± 0.43bC |

| Formulated | 65.45 ± 0.57aA | 62.76 ± 0.28aB | 61.25 ± 0.43aC | 61.52 ± 0.60bC |

| Redness (a * value) | ||||

| Standard | 1.62 ± 0.05bA | 1.37 ± 0.09bB | 1.32 ± 0.12bB | 1.40 ± 0.08bB |

| Formulated | 1.85 ± 0.09aA | 1.78 ± 0.04aB | 1.61 ± 0.12aC | 1.67 ± 0.08aBC |

| TBA (mg malonaldehyde kg −1) | ||||

| Standard | 0.05 ± 0.00aC | 0.07 ± 0.01aBC | 0.13 ± 0.02aB | 0.58 ± 0.04aA |

| Formulated | 0.04 ± 0.00aC | 0.08 ± 0.00aC | 0.14 ± 0.04aB | 0.36 ± 0.06bA |

A−CMeans within rows with different superscripts are significantly different (P < 0.05)

a−bMeans within columns with different superscripts are significantly different (P < 0.05)

TPA

Table 3 shows the changes in hardness, cohesiveness, springiness and chewiness in standard and formulated nuggets with change in formulation and storage time. The standard nugget at day 0 showed higher (P < 0.05) hardness, cohesiveness, springiness and chewiness compared to the formulated sample, which might be influenced by the difference in formulations (fat, sodium tripolyphosphate, konjac, xanthan and SP). Although, the KF/XG mixture and SP may be feasibly used for fat and phosphate replacement that resulted into nuggets with, textural characteristics comparable to standard. It was notable that a lower change in TPA was found in formulated nuggets throughout storage. The reduction in hardness indicated that the nuggets became softer, and were less cohesive. Springiness was decreased for standard nuggets after 75 days of storage, while a slight change was observed in formulated nuggets. Chewiness tended to decrease as observed for hardness and cohesiveness. This observation implies that incorporation of functional ingredients (konjac and SP) effectively retarded changes of textural parameters, primarily through binding properties of these ingredients which lower the water diffusion in formulated nuggets during storage. The more moisture transfer is related to cause larger ice crystals which adversely affect the nugget texture.

Color

The L * and a * values were significantly affected (P < 0.05) by the nugget formulation and storage time (Table 3). Comparing the two samples, higher L * and a * values observed for formulated nuggets may be due to the reduction of fat and color due to incorporation of SP and konjac flour. The L * of both nuggets decreased with increasing storage time, indicating that the nuggets were darker (Table 3). In general, changes in frozen meat products might be influenced by various factors, e.g., interaction of ingredients, packaging condition, degree of light and oxygen exposure and method of processing (Reis et al. 2012). The standard nugget highly progressed to darkness than formulated sample, possibly because it contained higher fat content and no antioxidant ingredients like SP. This was in agreement with the study of Singh et al. (2011) who showed that the decrease in L * in chicken nuggets with partial soybean oil replacement by linseed oil was attributable to less of a browning effect due to lower lipid oxidation. A significant decrease in redness value of both nuggets during storage was corresponded to protein denaturation/concentration, fat and water content, meat pigments and degree of oxidative reactions (Devatkal et al. 2014). During frozen storage, malonaldehyde, an oxidative product generated by lipid oxidation, can react with myosins, resulting in the discoloration of stored meat products (Cagdas and Kumcuoglu 2015).

TBA

The TBA value represents the formation of secondary lipid oxidation products in meat. TBA levels in both nuggets increased gradually throughout storage period (Table 3). At the end of storage however, a lower TBA was observed in formulated nuggets. It was possibly due to the SP retarded lipid oxidation (Reis et al. 2012). Polyphenols and flavonoid components in the mushrooms have antioxidant effects via direct scavenging of oxygen free radicals (Zhang et al. 2015). This was in agreement with Sharma et al. (2015) who showed that nuggets (warian) had increased antioxidant/free radical scavenging activity, which was attributed to increase in total phenolics with increasing of mushroom fortification. Pil-Nam et al. (2015) reported a longer refrigerated storage of shiitake frankfurters compared to the control, as SP provided its high bioactivity contributing to prevent lipid oxidation and microbial growth. The presence of konjac flour, which is rich source of soluble dietary fiber, may also retarded lipid oxidation. This was in accordance with the work of Kumar et al. (2013) who revealed the slower rate of lipid oxidation in chicken nuggets, as the added dietary fibers (green banana and soybean hull flours) were capable of reducing the free fat. The difference in fat content between formulated nuggets (6.55 % fat) and standard nuggets (7.95 % fat) may also have contributed to difference in TBA (Table 2), thereby the standard nuggets with more fat may be more prone to lipid oxidation which may had led to the formation of off-flavors, protein denaturation and nutritional losses. With regard to 75 days of storage, the TBA values determined in standard (0.58 mg malonaldehyde per kg) and formulated (0.36 mg malonaldehyde per kg) nuggets (Table 3) were below the acceptable range for oxidative rancidity (<1.0 mg malonaldehyde per kg) (Candogan and Kolsarici 2003).

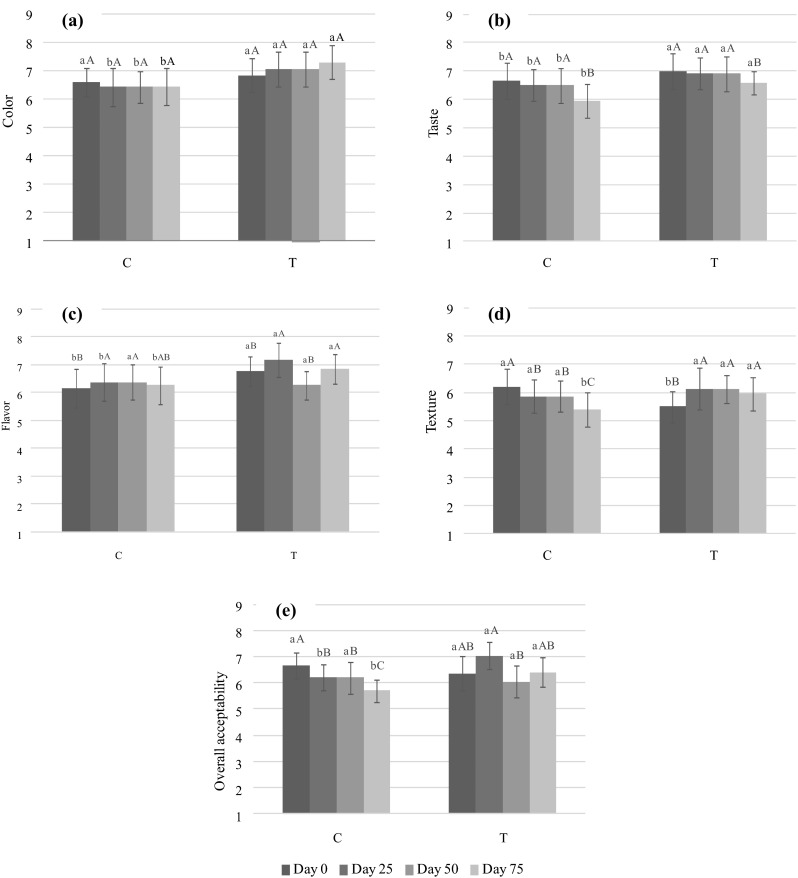

Sensory quality

Figure 3 reveals that both formulation and storage time had significant effects (P < 0.05) on sensorial characteristics of standard and formulated nuggets, with exception of the color attribute which had a non-significant change. The addition of SP was found to enhance consumer acceptance in formulated nuggets, as confirmed by increasing scores of taste and flavor. This might be attributed to SP has high amount of glutamate and aspartate which are recognized as flavor enhancers. A similar result was reported by Pil-Nam et al. (2015), showing the better scores for flavor, taste and overall acceptability of shiitake frankfurters compared to the control and 100 ppm sodium nitrite added frankfurters. Panelists gave higher scores in texture of formulated nuggets against the standard. Overall acceptability scores, as influenced by taste, flavor and texture attributes, were higher for formulated nuggets.

Fig. 3.

Sensory evaluation of chicken nuggets during frozen storage: a color, b taste, c flavor, d texture and e overall acceptability. C and T are standard and formulated nuggets. Different capital letters are significantly different regarding storage time (P < 0.05). Different lowercase letters are significantly different regarding formulation (P < 0.05)

Regarding storage time, sensory attributes tended to decrease with the increase in storage period. The decrease in flavor and taste scores can be correlated with the increase in lipid oxidation products such as malonaldehyde components which were measured as the TBA value. Moisture reduction may be an alternative reason that influenced the juiciness, in accordance with the decreases in all TPA parameters, thus decreasing texture scores. This observation was in accordance with Kumar et al. (2013) who reported that sensory acceptance of chicken nuggets made with green banana and soybean hull flours was decreased with increasing storage time. After storage, formulated nuggets were preferable to standard nuggets, as the KF/XG mixture and SP were able to decrease changes in lipid oxidation and moisture loss, which were the factors affecting sensory perception of the nuggets.

Microbiological quality

Total aerobic bacteria, psychrotrophic bacteria, yeast and mold were not detected in standard or formulated nuggets throughout the storage period (data not shown). This indicates that both products are microbiologically safe in frozen storage for 75 days.

Conclusion

This study suggested that the KF/XG mixture and SP have the potential to completely replace chicken fat and sodium tripolyphosphate in formulated chicken nuggets. The variation in SP had a greater effect on both physical properties (firmness and internal color) and sensory scores. High levels of both lowered firmness and sensory attributes of the nuggets. The optimal nugget formulation, achieved by the addition of a KF/XG mixture at 0.39 % (w/w) and SP at 1.84 % (w/w), provided a 17.6 % fat reduction, a 386 % increase in dietary fiber as compared to the standard nugget. Both nugget formulations showed a decreases in moisture and L * value during storage for 75 days. The products were less hard and cohesive, but showed slight changes in sensorial characteristics and were microbiologically safe after storage. Formulated nuggets had lowered oxidative rancidity compared to standard ones.

Acknowledgments

The author is thankful to the University of the Thai Chamber of Commerce, Thailand, for financial support.

References

- Akesowan A. Quality characteristics of light pork burgers fortified with soy protein isolate. Food Sci Biotechnol. 2010;19:143–149. doi: 10.1007/s10068-010-0163-2. [DOI] [Google Scholar]

- Anderson MJ, Whitcomb PJ. RSM simplified: optimizing processes using response surface methods for design of experiments. New York: Productivity Press; 2005. [Google Scholar]

- Andrès SC, Garcia ME, Zaritzky NE, Califano AN. Storage stability of low fat chicken sausages. J Food Eng. 2006;72:311–319. doi: 10.1016/j.jfoodeng.2004.08.043. [DOI] [Google Scholar]

- AOAC . Official method of analysis. 15. Washington, DC: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Cagdas E, Kumcuoglu S. Effect of grape seed powder on oxidative stability of precooked chicken nuggets during frozen storage. J Food Sci Technol. 2015;52:2918–2925. doi: 10.1007/s13197-014-1333-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Candogan K, Kolsarici N. Storage stability of low fat beef frankfurters formulated with carrageenan or carrageenan with pectin. Meat Sci. 2003;64:207–214. doi: 10.1016/S0309-1740(02)00182-1. [DOI] [PubMed] [Google Scholar]

- Choi YS, Choi JH, Han DJ, Kim HY, Lee MA, Lee ES, Jeong JY, Paik HD, Kim CJ. Effects of rice bran fiber on quality of less fat Tteokgalbi. Food Sci Biotechnol. 2008;17:959–964. [Google Scholar]

- Chun S, Chambers E, IV, Chambers D. Perception of pork patties with shiitake (Lentinus edode P.) mushroom powder and sodium tripolyphosphate as measured by Korean and United States consumers. J Sens Stud. 2005;20:156–166. doi: 10.1111/j.1745-459X.2005.00016.x. [DOI] [Google Scholar]

- Delgado-Pando G, Cofrades S, Rodríguez-Salas L, Jiménez-Colmenero F. A healthier oil combination and konjac gel as functional ingredients in less fat pork liver pâté. Meat Sci. 2011;88:241–248. doi: 10.1016/j.meatsci.2010.12.028. [DOI] [PubMed] [Google Scholar]

- Dermiki M, Mounayar R, Suwankanit C, Scott J, Kennedy OB, Mottram DS, Gosney MA, Blumenthal H, Methven L. Maximising umami taste in meat using natural ingredients: effects on chemistry, sensory perception and hedonic liking in young and old consumers. J Sci Food Agric. 2013;93:3312–3321. doi: 10.1002/jsfa.6177. [DOI] [PubMed] [Google Scholar]

- Devatkal SK, Manjunatha M, Narsaiah K, Patil RT. Evaluation of quality characteristics of chicken meat emulsion/nuggets prepared by using different equipment. J Food Sci Technol. 2014;51:511–518. doi: 10.1007/s13197-011-0518-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 2011;124:411–421. doi: 10.1016/j.foodchem.2010.06.077. [DOI] [Google Scholar]

- Erdogdu SB, Erdogdu F, Ekiz HI. Influence of sodium tripolyphosphate (STP) treatment and cooking time on cook losses and textural properties of red meats. J Food Process Eng. 2007;30:685–700. doi: 10.1111/j.1745-4530.2007.00139.x. [DOI] [Google Scholar]

- Hagen SR, Frost B, Augustin J. Precolumn phenylisothiocyanate derivatization and liquid chromatography of amino acids in food. J AOAC. 1989;72(6):912–916. [PubMed] [Google Scholar]

- Handayani D, Meyer BJ, Chen J, Tang P, Kwok PCL, Chan HK, Huang XF. The comparison of the effect of oat and shiitake mushroom powder to prevent body weight gain in rats fed high fat diet. Food Nutr Sci. 2012;3:1009–1019. doi: 10.4236/fns.2012.37134. [DOI] [Google Scholar]

- Huttenan MM, Pietilá PE, Viljakainen HT, Lamberg-Allardt CJE. Prolonged increase in dietary phosphate intake alters bone mineralization in adult male rats. J Nutr Biochem. 2006;17:479–484. doi: 10.1016/j.jnutbio.2005.09.001. [DOI] [PubMed] [Google Scholar]

- Jiménez-Colmenero F, Cofrades S, Herrero AM, Fernández-Martin F, Rodríguez-Salas L, Ruiz-Capillas C. Konjac gel fat analogue for use in meat products: comparison with pork fats. Food Hydrocolloid. 2010;26:63–72. doi: 10.1016/j.foodhyd.2011.04.007. [DOI] [Google Scholar]

- Kohajdová Z, Karoviová J, Jurasová M, Kukurová K. Application of citrus dietary fibre preparations in biscuit production. J Food Nutr Res. 2011;50:182–190. [Google Scholar]

- Kumar V, Biswas AK, Sahoo J, Chati MK, Sivakumar S. Quality and storability of chicken nuggets formulated with green banana and soybean hulls flours. J Food Sci Technol. 2013;50:1058–1068. doi: 10.1007/s13197-011-0442-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin KW, Lin HY. Quality characteristics of Chinese-style meatball containing bacterial cellulose (Nata) J Food Sci. 2004;69:107–111. [Google Scholar]

- Long NHBS, Gál R, Buñka F. Use of phosphate in meat products. Afr J Biotechnol. 2011;10:19874–19882. doi: 10.5897/AJB11.916. [DOI] [Google Scholar]

- Mahmoud KA, Badr HM. Quality characteristics of gamma irradiated beef burger formulated with partial replacement of beef fat with olive oil and wheat bran fibers. Food Nutr Sci. 2011;2:655–666. doi: 10.4236/fns.2011.26091. [DOI] [Google Scholar]

- Muela E, Sañudo C, Campo MM, Medel I, Beltrán JA. Effect of freezing method and frozen storage duration on lamb sensory quality. Meat Sci. 2012;90:209–215. doi: 10.1016/j.meatsci.2011.07.003. [DOI] [PubMed] [Google Scholar]

- Pil-Nam S, Park K-M, Kang G-H, Cho S-H, Park B-Y, Van Ba H. The impact of addition of shiitake on quality characteristics of frankfurter during refrigerated storage. LWT Food Sci Technol. 2015;62:62–68. doi: 10.1016/j.lwt.2015.01.032. [DOI] [Google Scholar]

- Raghavendra SN, Swamy SRR, Rastogi NK, Raghavarao KSMS, Kumar S, Tharanathan RN. Grinding characteristics and hydration properties of coconut residues: a source of dietary fiber. J Food Eng. 2006;72:281–286. doi: 10.1016/j.jfoodeng.2004.12.008. [DOI] [Google Scholar]

- Regula J, Gramza-Michalowska A. Effect of the addition of dried shiitake (Lentinula edodes) to corn crackers on their chemical composition and ability to bind Fe(III) and Zn(II)—a short report. Pol J Food Nutr Sci. 2009;59:275–278. [Google Scholar]

- Reis FS, Martins A, Barros L, Ferreira ICFR. Antioxidant properties and phenolic profile of the most widely appreciated cultivated mushrooms: a comparative study between in vivo and in vitro samples. Food Chem Toxicol. 2012;50:1201–1207. doi: 10.1016/j.fct.2012.02.013. [DOI] [PubMed] [Google Scholar]

- Sharma A, Vaidya D, Abrol GS, Rana N, Chauhan N. Functional and textural properties of Indian nuggets assorted with mushroom for lysine enrichment. J Food Sci Technol. 2015;52:3837–3842. doi: 10.1007/s13197-014-1445-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh R, Chatli MK, Biswas AK, Sahoo J. Quality of omega-3 fatty acids enriched low-fat chicken meat patties incorporated with selected levels of linseed flour/oil and canola flour/oil. J Food Sci Technol. 2011;51:353–358. doi: 10.1007/s13197-011-0507-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Takigami S. Konjac mannan. In: Phillips GO, Williams PA, editors. Handbook of hydrocolloids. New York: CRC Press; 2000. pp. 413–424. [Google Scholar]

- Tarladgis BG, Watts BM, Younathan MT, Dugan LR. A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc. 1960;37:44–48. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Tseng YH, Yang JH, Lee CE, Mau JL. Quality of shiitake stipe steamed bun. Czech J Food Sci. 2011;29:79–86. [Google Scholar]

- Wan Rosli WI, Solihah MA, Aishah M, Nikfakurudin NA, Moshin SSJ. Colour, textural properties, cooking characteristics and fibre content of chicken patty added with oyster mushroom (Pleurotus sajor-caju) Int Food Res J. 2011;18:621–627. [Google Scholar]

- Yamaguchi S, Yoshikawa T, Ikeda S, Ninomiya T. Measurement of the relative taste intensity of some α-amino acid and 5′-nucleotides. J Food Sci. 1971;36:846–849. doi: 10.1111/j.1365-2621.1971.tb15541.x. [DOI] [Google Scholar]

- Zhang N, Chen H, Zhang Y, Xing L, Li S, Wang X, Sun Z. Chemical composition and antioxidant properties of five edible hymenomycetes mushrooms. J Food Sci. 2015;50:466–471. [Google Scholar]