Abstract

Sincere efforts of researchers are underway to understand the functionality of different fats and oils in relation to cookie quality. The quality of cookie primarily relies upon the functionality of fats and oils in cookie system which ultimately is combined result of their physical, chemical, and rheological properties. Effects of some major fats and oils such as butter, bakery fat, hydrogenated fat, lard, margarine, palm oil, sunflower oil, coconut oil, and soybean oil on the physical and sensory characteristics of cookie have been studied. Previous studies reported that fats and oils had radical contribution in cookie quality and most authors agree on the fact that different fats and oils affect the cookie quality to different extent. Furthermore, it was observed by many researchers that with oils, dough was softer and cookie spread was higher as compared with that of fats. It is important to understand the molecular basis of the difference in technological changes in cookies properties with different fats and oils. This review focuses on the current knowledge of quality determining physical, chemical, thermal, microstructural, and functional properties of fats and oils in relation to cookie dough rheology and cookie quality.

Keywords: Cookies quality, Fats and oils, Physicochemical properties, Rheological properties, Spread ratio

Introduction

Cookies are popular snacks consumed by an enormous number of people worldwide. Some of the reasons for the universal appeal of cookie are their attractive features including wider consumption base, ready to eat nature, moderate cost, great nutritional quality, availability in various pleasant tastes and prolonged shelf life. The term biscuits, or cookies as they are brought in numerous parts of the world, refers to baked products containing three major ingredients, i.e. soft wheat flour, sugar and fat with other minor ingredients such as milk, salt, flavoring agent and aerating agents. Moisture content is rather low (1–5 %) in cookies/biscuits (Chevallier et al. 2000). Cookies occupy the prime position for production as well as consumption in contrast to other bakery products. The experimental results achieved by Barak et al. (2013) recommended that the cookie quality is influenced by many variables, for example, protein, damaged starch and gluten protein fractions. The quality of cookies is impacted by numerous other factors such as quality and quantity of ingredients used, processing conditions, baking, and cooling of the cookies (Manohar and Rao 2002). Quantitatively fats and oils are the third most important ingredient used in cookie making. From a sensory quality perspective, fat is one in all the principal ingredient that have an influence on overall cookie texture. As discovered in numerous earlier studies, decreasing the fat content or substituting fat with different components has a huge influence on the texture characteristics of biscuits (Zoulias et al. 2002; Rodriguez-Garcia et al. 2012). It has been found that increasing fat level increases cookie tenderness (Lai and Lin 2006). And, decreasing fat level delivers cookies with higher breaking strength (Pareyt et al. 2010). It can have animal or vegetable origin and is commonly plasticized. Fats and oils are commercially and technically of great importance in food systems and they play a vital function in the quality from a nutritional and functional perspective. Cookies have a complex cellular structure whose breakdown mechanics basically rely upon its heterogeneity, the presence of voids and also the multiplicity of defects from that cracking can develop (Hedjazi et al. 2011). Amid eating, biscuit is compressed till its heterogeneous structure starts to create cracks and inevitably breaks (Booth et al. 2003). Fat assumes an awesome part in the mechanical properties and fracturing behavior of biscuits/cookies since it is responsible for the diminishment of the air cell size which prompts a severe reduction in the fracture stress of the initial products (Baltsavias et al. 1999). Amid baking, the fat melts quickly, which, together with the gradual dissolution of sucrose; boosts the system mobility and cookie dough spread rate (Pareyt et al. 2009). These macromolecules are critical raw materials and functional ingredient for cookies and other bakery products. Textural characteristics of fats and oils that result from their molecular states are of essential significance in baked products. Fats and oils influence finished product texture by means of forming structures of crystalline networks and additionally by means of interrupting the structure on account of their interaction with non-fat components. Further, Ghotra et al. (2002) and Lai and Lin (2006) examined that fats and oils affect the structural integrity and the shelf life of the ultimate product. Wainwright (1999) concluded that selection of fats and oils ought to be in step with their precise performance within the end product in addition to the nutritional profiles. In this review paper, efforts have been made to explain the physical, chemical, rheological, and functional properties of fats and oils and their relationship with the cookie dough and cookie quality.

Physicochemical characteristics of fats and oils

Fats and oils are likely the most crucial ingredients used in cookie manufacture. Fats and oils are more variable in composition than other two major ingredients (flour and sugar) used in cookies. They are obtained from a huge assortment of plant and animal sources. The difference between fat and oil is simply that the former is plastic or semi‐solid at room temperature while the latter is liquid (Manley 2000b). Edible fats and oils are composed of triacylglycerols. The type of fatty acid at every position profoundly affects the physical behavior of the fat and oil and also the comparative proportions of every triacylglycerol in the fat and oil are crucial to their overall performance and stability.

The importance of fats and oils commences from their functionality which is due to their chemical composition and structural aspects (Belton 2000). Fats and oils have a great impact on the texture of the final product. Their physicochemical properties are rather complicated and their features once incorporated in doughs have been the topic of abundant investigation. A fat system for cookies can be portrayed in terms of physical and chemical characteristics as well as performance. Each fat and oil have a range of physical, chemical and compositional parameters. Their important physicochemical properties are melting point, polymorphism, solid fat content and fatty acid composition. These properties assume a noteworthy part in deciding the quality of cookies and other bakery products.

Fatty acid composition

According to deMan (1998) the functional properties of commercial fats are strongly allied to their fatty acid and triacylglycerol compositions. Fatty acids are chains of hydrocarbons that have a methyl (–CH3) and a carboxyl (–COOH) end. The physical and chemical properties of fats and oils are decided by their fatty acid composition and their position in the triacylglycerol (TAG) molecule. Fats and oils contain a high content of saturated fatty acids in the triacylglycerol (TAG) molecules have high melting point, while a higher level of unsaturated fatty acids is responsible for lower melting points. Fatty acid composition of major fats and oils are presented in Table 1. The level of saturated fatty acids in the triacylglycerol determines the hardness and plasticity of the shortening, and it plays a vital role in the properties of the final product (Qarooni 1996).

Table 1.

Fatty acid composition of some major fats and oils

| Fatty acids | Oils | ||||

|---|---|---|---|---|---|

| Palm oil | Coconut oil | Peanut oil | Sunflower oil | Cottonseed oil | |

| 8:0 (Caprílic acid) | 0.1 | 7.6 | – | – | – |

| 10:0 (Capric acid) | 0.1 | 6.5 | – | – | – |

| 12:0 (Lauric acid) | 0.4 | 48.2 | – | – | – |

| 14:0 (Meristic acid) | 1.1 | 18.5 | 0.1 | – | 0.77 |

| 16:0 (Palmitic acid) | 43.8 | 8.7 | 10.4 | 5.70 | 21.95 |

| 18:0 (Stearic acid) | 4.4 | 2.7 | 3.0 | 4.79 | 2.27 |

| 20:0 (Arachidic acid) | 0.3 | 0.1 | 1.2 | 0.30 | 0.26 |

| 22:0 (Behenic acid) | 0.1 | – | 2.3 | 1.16 | 0.36 |

| 24:0 (Lignoceric acid) | 0.1 | – | 1.4 | 0.31 | 0.12 |

| 16:1 (Palmitoleic acid) | 0.2 | – | 0.2 | – | 0.47 |

| 17:1 (Myristoleic acid) | – | – | 0.1 | 0.06 | 0.11 |

| 18:1 (Oleic acid) | 39.1 | 6.0 | 47.9 | 15.26 | 16.61 |

| 20:1 (Gadoleic acid) | 0.1 | 0.1 | 1.3 | 0.22 | 0.14 |

| 22:1 (Erucic acid) | – | – | 0.1 | – | – |

| 24:1 (Nervonic acid) | – | – | – | 0.39 | 0.16 |

| 18:2 (Linoleic acid) | 10.2 | 1.8 | 30.3 | 71.17 | 56.35 |

| 18:3 (Linolenic acid) | 0.3 | 0.1 | 0.4 | 0.45 | 0.33 |

| 20:2 (Eicosadienoic acid) | – | – | – | 0.09 | 0.10 |

| SFA (Saturated fatty acids) | 50.4 | 92.0 | 18.4 | 12.36 | 25.75 |

| UFA (Unsaturated fatty acids) | 49.6 | 8.0 | 80.3 | 87.64 | 74.27 |

Melting profile

It is the temperatures at which a lipid transforms from solid to liquid state. Fats and oils show a melting range in preference to a properly-defined melting temperature because these are blend of different triacylglycerols (TAGs). As each triacylglycerol has its very own melting point, relying on the nature of the acids on its three positions (Manley 2000b), the mixtures making up fats and oils exhibit softening ranges which are broader or narrower according to the composition of the mixture (Wade 1988). Some fats have a broad melting range (27–45 °C for Palm oil), while others have a fairly narrow melting range (23–26 °C for Coconut oil). The size of the range relies upon on various factors, inclusive of the level of hydrogenation, fatty acid composition, and their distribution within the triacylglycerol (Belitz et al. 2004). The fatty acids may differ in chain length and can be saturated or unsaturated (cis or trans conformation). Short fatty acid chain lengths, the presence of unsaturated fatty acids and the cis‐configuration decrease the melting point (Manley 2000b). The melting point order of fatty acids is saturated fatty acid >trans fatty acid >cis fatty acid. The most familiar fatty acids are palmitic, stearic, oleic, and linoleic acids (Wade 1988; Manley 2000b). The melting profile of fats and oils in cookies impacts how properly they incorporate air, in addition to their rheology, mouthfeel, shelf life and other quality parameters. Within melting temperature range, declines in the temperature results in improving the level of solid to liquid fat.

Solid fat content (SFC)

Solid fat content (SFC) of a fat and oil decides its applications and usages. It is the ratio of solid fat to the entire fat (Ghotra et al. 2002). In cookie making it is generally accepted that, at a given fat level in the formulation, SFC is main criteria while considering the functionality of the fat and oil. SFC has a robust impact on the functional performance and textural nature of fats and fat containing products (Lai and Lin 2006). It impacts the spreadability of a fat. According to Richard (1968), creaming characteristics are traceable to the composition of the solid portions of the shortenings. The cookie produced with fat and oil having higher solid fat content had higher breaking force. The liquid part of fat and oil delivers a great lubricating effect that improves the mixing process and solid part of the fats and oils incorporates air throughout mixing. With effective mixing, the massive volume of air can be entrapped and leads to an excellent volume of the product. The SFC varies with numerous factors, which include the level of hydrogenation and the kind of fat. Whilst Baltsavias et al. (1997) reported no connection between the volume of entrapped air and the solid fat content of the fat. The SFC has a significant relationship with rheology, shelf life, and other characteristics of the baked product (Lai and Lin 2006).

Higher SFC shortenings do not have sufficient oil volume for satisfactory aeration, and lower SFC shortenings do not have the capability to keep the air until mixing is finished. SFC in ranges of 15–20 % at utilization temperature is usually suggested for cookie making (Manley 2000a). Moreover, Sciarini et al. (2013) found upper limit (higher SFC) more critical compared to the lowest limit (lower SFC). Reported values of SFC for major fats and oils at 20 °C are: palm oil 22–25, lard 18–20, and butter 20–22 %. Even though hardness not solely depends on SFC (Narine and Marangoni 1999), it strongly impacts the mechanical nature of fats and oils. The hardness of a fat is a vital property that affects the texture of end food product (Brunello et al. 2003).

Polymorphism

A further crucial characteristic of fats and oils chemistry which has significance in the manufacture of cookies is the polymorphism. Polymorphism is the ability of a compound to exist in more than one crystalline form. Fats and oils possess three typical polymorphic forms α (alpha), β′ (beta prime) and β (beta). Each form varies in their crystalline structure, free energy and other physical and chemical properties but their chemical composition remain same. The polymorphism is primarily important in baked products because consistency, plasticity, and other physical properties depend on polymorphic forms which are formed during processing of food product. Each polymorphic form of same fat has its characteristic melting point, resolidification point, the heat of crystallization, specific volume and X-ray spacing. Each form has different morphology and they may be dense, opaque crystals or transparent crystals. Each polymorphic form impacts hardness, texture, mouthfeel and stability of cookies. In spite of the fact that β (beta) form is the most stable, however β′ (beta-prime) is typically favored because of its smoothness and unrivaled creaming properties. It seems like a little needle or rod-shaped crystals with a size of under 1 μm which results in a fine crystal network that gives great spreadability, plasticity and excellent creaming properties (deMan 1998). Numerous factors influence the formation of beta prime crystals including the palmitic acid content, the distribution and position of palmitic and stearic acids, the level of hydrogenation, and the randomization of the fatty acids. Change of β′ to β crystals can pulverize the fine crystal structure and subsequently downgrade the textural nature of the end product. Baldwin et al. (1971) performed research at the creaming potential of shortenings stable in the α, β and β′ crystalline forms and determined that it became vital for the fat and oil to be in the β′ crystal form to promote ideal creaming. It has been well known that milk fat, palm oil, and cottonseed oil has β′ crystal forming tendency whereas coconut oil, palm kernel oil, and peanut oil has β crystals forming tendency.

The size of the fat and oil crystals has a significant relationship with their functional performance during baking. As smaller crystals have a more surface area compared to bigger ones and so are more capable of holding massive amounts of liquid oil inside the crystal network. Previous research showed that the crystalline form of fats and oils has a huge influence on their creaming potential. It has been found that small and firmly knit crystals have superior creaming capability (Baldwin et al. 1971; Pyler 1988). It is generally accepted that plasticity of fats decided by their crystal size, collectively with crystal structure of fats (Ghotra et al. 2002). In the course of creaming process, lipid crystals act as vehicles for the exchange of additional interfacial material to the surface of expanding bubbles during baking consequently inhibit the bubble rupture (Brooker 1993). It is assumed that at a given solid fat content in fats and oils, smaller and more crystals have preferable creaming potential over bigger and fewer crystals. However, Zhong et al. (2014) observed that when cookie dough formulated with a shortening with more crystallized material and smaller crystals results in the lower spread.

Rheological properties of fats and oils

Extensive flow but the substantial solid character is a desirable property of fats and oils. These properties of fat materials arise directly from their composition (Gutierrez and Scanlon 2012). Study of deformation and flow of matter in response to an applied stress is termed as rheology. Rheological behavior of fat systems is complex because the biphasic nature (liquid and solid) of a fat system in large measure governs product structure. Fats not just fail to follow the principle of superposition, however also change their rheological characteristics gradually during storage. Microstructure of the fat and oil crystals along with SFC decides their rheological properties. Bell et al. (2007) concluded that the rheology of fats changed from a weak viscoelastic solid system to a weak viscoelastic liquid during the crystallization. Another study from deMan and Beers (1987) states that fats behave like rigid solids until a deforming stress exceeds. Liquid fat systems require only one parameter, the viscosity, to fully define their rheological behavior (Coupland and McClements 1997). However, oils such as canola oil, are mildly shear thinning so that additional rheological parameters are required to adequately define their rheology (Mirzayi et al. 2011). For practical importance, spreadability is main rheological property (Prentice 1972). Spreadability depends on the composition and SFC of fats, collectively with the shape, size and amount of the fat crystals (deMan and Beers 1987; Tang and Marangoni 2007).

Viscosity

Viscosity is the fundamental factor in the rheological study of liquid foods. Viscosity can be expressed as the resistance of one part of the fluid to with respect to another. Oil viscosity has an instantaneous correlation with chemical properties of the lipids, for example, and the level of unsaturation and the chain length of the fatty acids that constitute the triacylglycerols (Dutt and Prasad 1989). The viscosity barely declines with a higher level of unsaturation. Food oils behave as ideal Newtonian liquids over a wide range of shear rates and therefore may be characterized by a single viscosity. It has been proven that temperature sturdily affects the viscosity of fluids. Viscosity usually decreases with a rise in temperature. Close to the melting temperature, the non-Newtonian behavior may happen because of the crystals of fat and oil. However, the sluggish crystallization consequences in stiff and unpleasant texture during storage (West and Rousseau 2016). It has been found that viscosity increases with increasing molecular weight and declines with increasing unsaturation and temperature. Timms (1985) observed around 30 % declines in viscosity of an oil for every 10 °C increase in temperature. Dutt and Prasad (1989) determined the viscosity of butter fat (34 cP), hydrogenated cottonseed oil (45 cP), and palm oil (37 cP) at 40 °C.

Although rheology of fats and oils plays a vital role in cookie making, to the best of our knowledge, little work has been published on the effect of rheological characteristics of fats and oils on cookie dough properties and cookie quality. Additionally, quantitative information on correlations among the rheological aspects and chemical characteristics of fats are scanty due to their complex flow behavior.

Functional characteristics of fats and oils

Plasticity

The plasticity of fat is the capacity to keep its shape yet can be molded or shaped by applying light pressure. It decides spreadability of fats. It is far foremost characteristic to consider when selecting a fat to be used in the cookies formulation and other baked products. Though, maximum fats seem solid at room temperature, however really comprised of liquid oil with a network of solid fat crystals. This combination of solid and liquid proportion permits the fat to be molded into different shapes. Temperature affects plasticity, hard fats, for example, butter turning out to be soft and extra spreadable whilst warmed even as chilled butter has very little or no plasticity. Usually, the unsaturation of fat increases its plasticity. It has been observed that mechanical manipulation and the addition of edible oil, improved plasticity and shortening power of fats (Harvey 1937). Most of the aeration of dough is because of the air trapped in the solid fraction of the fat. As a consequence, a wide plastic range is essential for appropriate aeration.

Shortening power

Fats perform a shortening function in the dough to deliver desirable textural properties in a food product. Shortening acquires its name from the truth that fat by its extremely nature coats the protein molecules in flour, making it hard for them to join and make a stretchy material called gluten. Gluten strands that do develop are “shortened”. Otherwise, more gluten could be developed and successively, lead to undesirable hard or chewy cookie texture. Subsequently, for various texture prerequisites, diverse shortenings will be chosen.

The level of shortening developed by a fat or oil in a given product relies on the surface area of the flour particles covered with the aid of the fat. It is usually considered that unsaturated fatty acids have more prominent covering power compared to saturated fatty acids. Thereby, variations in the shortening power of different fats probably clarified by their level of unsaturation.

Role of fats and oils in dough rheology

Cookie preparation begins with the blending of the ingredients into the dough. Fat is the constituent that primarily liable to binds all ingredients within the dough. In cookie manufacture, rheological behavior of dough is very significant because it impacts the processability as well as the quality of cookie (Piteira et al. 2006). According to Khatkar and Schofield (2002), starch and glutens are the main fractions of wheat flour controlling the rheological properties of wheat flour dough. Gliadin deliberates viscous properties on gluten, whilst glutenin bestows the strength and elasticity that are crucial for retaining the gasses that are generated during baking (Khatkar et al. 1995). Extensible dough that delivers greater diameter and smaller height cookies are counted appropriate for cookie quality. Dough rheology characterization that associates to dough handling properties is a factor in the assessment of wheat quality for cookie making. Various techniques are used to portray the rheological aspects of cookie dough, which includes the Farinograph and Extensograph technique. Low protein content (8–10 %), low water absorption (WA), and low resistance to deformation are the attributes used to explain the suitability of wheat for cookie production. Barak et al. (2015) found highly extensible soft wheat most suitable for cookie making. While, adequate dough strength and extensibility is critical for the noodle making (Gulia et al. 2014).

Dough rheological behavior is perceived to be predominant to the effective production of bakery products. Rheological properties of dough influence significantly the final quality of baked products. Wheat flour dough is viscoelastic with some nonlinear shear thinning and thixotropic behavior. Dough displays viscose “liquid-like” behavior at high strains (>0.1) because of the large deformation of its structure and the breakdown of the interactions between the polymer chains (G″ > G′) (MacRitchie 1986). However, at lower strains, its viscosity increases and dough shows a more viscoelastic “solid-like” behavior (G′ > G″) (Weipert 1990). Storage modulus (G′) shows the solid or elastic characteristics of the dough and the energy stored in the recovered per cycle, whereas the loss modulus (G″) indicates liquid or viscose characteristics of the dough and it is the measurement of energy loss per cycle. Relating the flow and deformation behavior of dough to its authentic structure and baking quality is difficult as dough has a complex composite. One ultimate objective of any rheological test is to determine the baking potential of dough without performing a baking test (Khatkar and Schofield 2002). Each component in dough affects the rheological behavior to some extent. The addition of shortening during mixing influenced the rheological characteristic of dough and its structure development.

Baltsavias et al. (1997) reported that the type and level of fats in cookie formulation has a robust impact on the viscoelastic properties of dough. The level of added fat in cookie dough formulation powerfully influences both the machinability of dough all through the process and also the quality of the ultimate product. In addition, Sahi (1994) investigated that its impact also relies on upon the composition of flour along with the kind of fat and oil added. It has been found that a 30 % addition of fats repressed the starch retrogradation and provided additional plasticity on gluten network (Perego et al. 2007). These perceptions affirm the finding observed by Manohar and Rao (1999), they found that the addition of fat prompted a decline in the development of gluten, henceforth the less elastic dough which is desirable in cookie making. Fu et al. (1997) investigated that the additional fat really postponed the onset of viscous flow, while at the same time diminishing the elastic properties of the gluten. Singh et al. (2002) found that increasing fat level decreases dough development time and peak height. This effect of fat might be because of their lubricating effect in cookie dough. Miller (1985) also investigated that higher level of shortening has a softening impact and decreases the consistency of dough. Similar findings have been reported previously by Olewnik and Kulp (1984). Pareyt et al. (2010) determined that higher fat percentage considerably diminished cookie dough elasticity due to their physical obstruction with gluten development. Most of the work reported till now is on the quality of cookies as affected by different levels or types of shortening or different emulsifiers. However, information on the various rheological attributes of cookie dough and quality of cookie due to the difference in physicochemical and rheological properties of fat and oil is scanty.

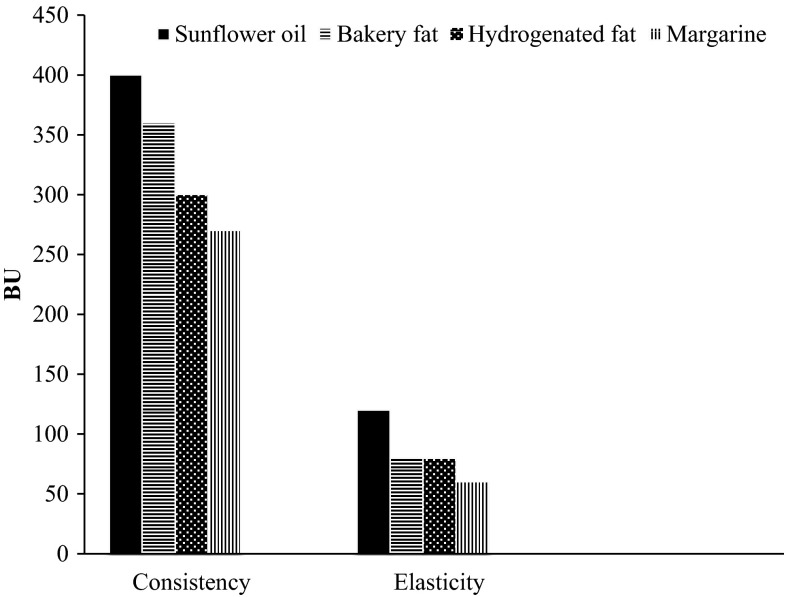

Jacob and Leelavathi (2007) investigated the impact of fat types (sunflower oil, bakery fat, hydrogenated fat, and margarine) on the rheology of the cookie dough (Fig. 1). The difference in the consistency of the cookie dough is because of the differences in solid fat contents of fats and oils used in dough formulation (Jacob and Leelavathi 2007; Manohar and Rao 1999). Ordinary plastic shortening usually contains 20–30 % solid fats phase whereas the remaining 70–80 % represents liquid oil phase (Pyler 1988). Given (1994) reported that an appropriate solids-to-liquid proportion at dough mixing temperature is necessary for the effectiveness of fats.

Fig. 1.

Effect of fat type on the Farinograph characteristics of cookie dough (Jacob and Leelavathi 2007)

The rheological attributes of dough are vital because they influence the handling and processing of the dough in addition to the quality of the ultimate products. At some point when fat blended with the flour before its hydration, it prevents the development of gluten network and delivers poor elastic dough. However, extremely elastic dough is not suitable in biscuit/cookie making because it shrinks after lamination (Faubion and Hoseney 1990). Moreover, if dough lacks in its elastic properties, it is hard to form into required shape of the final product (Khatkar et al. 2013). Wade (1988) stated that extremely stiff and extremely soft dough will not process suitably on the dough forming instrument and will not produce a satisfactory product. Hard fats have a higher solid fat content (SFC) and subsequently results in the stiffer dough (Mamat and Hill 2014; O’Brien et al. 2003). Manohar and Rao (1999) also investigated the same finding and observed that hydrogenated fat produced the hardest dough in comparison to bakery shortening and oil. Baltsavias et al. (1997) clarified that amid mixing, the hard fat could be fragmented to giant lumps, whereas the ordinary fat will be spread around the flour particles. Oils are less powerful in their shortening and aerative properties than plastic fats (Pyler 1988). Liquid oil dispersed on mixing all through the dough in the form of minuscule globules, thus soft dough is produced.

Role of fats and oils in quality of cookies

Fat and oil is the foremost ingredient responsible for tenderness, mouthfeel, lubricity, flavor, spread, general product appearance and shelf life. In addition, cookie color and taste are apparently quality parameters and other major quality deciding parameters are the size of the cookie (both the diameter and height), and cookie bite. Cracking that develops on the top surface of the cookie signified as cookie top grain is another feature of cookie quality (Barak et al. 2014).

Cookie spread is the most eminent quality characteristic. Bigger cookie diameter and greater spread are the alluring quality features in cookies (Yamamoto et al. 1996). Previous research of Vettern (1984) and Rogers (2004) recommends that lipid type is not an essential variable for cookie spread. However, Abboud et al. (1985) observed that the fat type did not appear to be important but the quantity of fat affected the cookie spread. Gajera et al. (2010) reported that the hardness of biscuits increased by replacing vanaspati with peanut butter because of reduction in total fat in the biscuits. Jacob and Leelavathi (2007) investigated that cookies with oil had greater spread when compared to the cookies containing fats. Cookies made by using margarine and bakery fat had comparable spread. Then again, cookie made by using the non-emulsified hydrogenated fat had considerably lower spread. Fundamentally, the sooner the lipid melts in the course of the baking process, the more the cookie spread. Consequently, cookies containing liquid oils have a tendency to have a higher spread. It was also observed that cookies made with the oil had the stiffest texture. Although, the breaking strength of cookies with three kinds of fats (non-emulsified hydrogenated fat, bakery fat, and margarine) was not significantly different from each other. In spite of the fact that massive volume of air often entrapped into liquid oil however, it cannot be held and this would possibly explain the stiff texture of the cookie (Kamel 1994). Mert and Demirkesen (2016) also reported that unlike shortening containing dough, dough formulated with canola oil resulting in the cookies with comparatively lower thickness, higher diameter consequently greater spread and stiffer texture. Shortening power of fat is greater for extra plastic and smooth textured fat (Greethead 1969). In cookies, for softer worked fat the breaking strength is lower.

Mamat and Hill (2014) examined that the hardness of the dough has an impact on the texture of the cookies. It was reported that dough hardness positively correlated to the peak force needed to break the biscuit. The similar impact was also observed by O’Brien et al. (2003) and reported that biscuit made of high solid fat had more breaking strengths. However, it has been reported that cookies formulated with interesterified fat delivered higher spreads than non-interesterified formulated cookies (Dinc et al. 2014). Usually, non-interesterified fat possessed higher SFC compared to interesterified. In the course of mixing, crystals in fat are isolated from the liquid oil phase and get enclosed in a protein membrane. This membrane permits huge amounts of crystals to stick to air bubbles. In the course of baking, the fat crystals melt and the protein membrane is amalgamated into the surface of the bubbles as they enlarge subsequently inhibit rupture (Manley 2000b). Manley (2000b) concluded that dough prepared by using semi-solid fat provides superior structures during baking over dough prepared by using liquid fat. Moreover, Manohar and Rao (1999) observed that biscuit made with hydrogenated fat and oil was considerably thicker whereas biscuits prepared with bakery shortening had improved surface properties and better crispness.

Zohng (2013) concluded that throughout baking, product properties are remarkably influenced by fats and oils melting point and melting enthalpy. Menjivar and Faridi (1994) reported that the melting point and melting enthalpy are foremost aspects affecting lubricant power of fats and oils. Cookies containing butter, margarine, and lard had comparably higher spreads; whereas cookies containing all-purpose shortening had notably poor spread. A low melting point and a low melting enthalpy make the lubricant effect of fats and oils available sooner, leading to higher cookie spread. For instance, butter and margarine, produce cookies with a higher spread as compared to cookies made with lard and all-purpose shortening. Butter and margarine have low melting enthalpy and melting temperatures make them melt earlier and rapidly during baking process. In spite of the comparable melting point, lard, with higher melting enthalpy, displays lubricating effect later because it needs extra energy input to melt fully. Likewise, all-purpose shortening with a high melting point and low enthalpy begins lubricating later during baking. Consequently, cookies made with lard and all-purpose shortening begin to spread later compared to cookies prepared with butter and margarine, leading to lesser spreads. Studies revealed that cookies consist of the oil had tremendously better spread as the cookies containing the oil start spreading earlier and continued to spread for a prolonged time. However, cookies containing oil had relatively stiffer texture and possibly due to insufficient entrapment of air during creaming.

Conclusion

Fats and oils offer various positive functional attributes in baking products. Textural properties of these products are significantly influenced by fats and oils. In cookie system, oil acts differently as compared to fats. Oil results in the softer dough and higher cookie spread in comparison with fats. It is hard to explain these differences as the correlation of physicochemical properties of fats and oils with cookie quality are not completely understood. Functionality of fats and oils is the combined result of their physical, chemical, functional and rheological properties. Molecular level analysis of these properties is an important step towards improving our understanding of the influence of fats and oils on the final baked products. This review emphasis on the scientific information about fats and oils at the molecular level and their correlation with differences in functional performance in cookies.

Abbreviations

- TAG

Triacylglycerol

- FAs

Fatty acids

- SFA

Saturated fatty acids

- UFA

Unsaturated fatty acids

- SFC

Solid fat content

- WA

Water absorption

References

- Abboud A, Hoseney RC, Rubenthaler G. Effect of fat and sugar in sugar-snap cookies and evaluation of tests to measure cookie our quality. Cereal Chem. 1985;62:124–129. [Google Scholar]

- Baldwin RR, Baldry RP, Johansen RG. Fat systems for bakery products. J Am Oil Chem Soc. 1971;49:473–477. doi: 10.1007/BF02582482. [DOI] [Google Scholar]

- Baltsavias A, Jurgens A, Van Vliet T. Rheological properties of short doughs at small deformation. J Cereal Sci. 1997;26:289–300. doi: 10.1006/jcrs.1997.0133. [DOI] [Google Scholar]

- Baltsavias A, Jurgens A, Van Vliet T. Fracture properties of short-dough biscuits: effect of composition. J Cereal Sci. 1999;29(3):235–244. doi: 10.1006/jcrs.1999.0249. [DOI] [Google Scholar]

- Barak S, Mudgil D, Khatkar BS. Effect of composition of gluten proteins and dough rheological properties on the cookie-making quality. Br Food J. 2013;115(4):564–574. doi: 10.1108/00070701311317847. [DOI] [Google Scholar]

- Barak S, Mudgil D, Khatkar BS. Effect of flour particle size and damaged starch on the quality of cookies. J Food Sci Technol. 2014;51(7):1342–1348. doi: 10.1007/s13197-012-0627-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Barak S, Mudgil D, Khatkar BS. Biochemical and functional properties of wheat gliadins: a review. Crit Rev Food Sci Nutr. 2015;55(3):357–368. doi: 10.1080/10408398.2012.654863. [DOI] [PubMed] [Google Scholar]

- Belitz HD, Grosch W, Schieberle P. Food chemistry. Berlin: Springer; 2004. Lipids; pp. 157–242. [Google Scholar]

- Bell A, Gordon MH, Jirasubkunakorn W, Smith KW. Effects of composition on fat rheology and crystallisation. Food Chem. 2007;101(2):799–805. doi: 10.1016/j.foodchem.2006.02.033. [DOI] [Google Scholar]

- Belton P. The functional properties of fats and oils—a richness of diversity. Grasas Aceites. 2000;51:1–5. doi: 10.3989/gya.2000.v51.i1-2.402. [DOI] [Google Scholar]

- Booth DA, Earl T, Mobini S. Perceptual channels for the texture of a food. Appetite. 2003;40(1):69–76. doi: 10.1016/S0195-6663(02)00141-1. [DOI] [PubMed] [Google Scholar]

- Brooker BE. The stabilisation of air in cake batters—the role of fat. Food Struct. 1993;12:285–296. [Google Scholar]

- Brunello N, Mc Gauley SE, Marangoni AG. Mechanical properties of cocoa butter in relation to its crystallization behavior and microstructure. Lebensm Wiss Technol. 2003;36:525–532. doi: 10.1016/S0023-6438(03)00053-7. [DOI] [Google Scholar]

- Chevallier S, Colonna P, Buléon A, Valle GD. Physicochemical behaviors of sugars, lipids, and gluten in short dough and biscuit. J Agric Food Chem. 2000;48:1322–1326. doi: 10.1021/jf990435+. [DOI] [PubMed] [Google Scholar]

- Coupland JN, McClements DJ. Physical properties of liquid edible oils. J Am Oil Chem Soc. 1997;74(12):1559–1564. doi: 10.1007/s11746-997-0077-1. [DOI] [Google Scholar]

- deMan JM. Functionality of palm oil in foods. J Food Lipids. 1998;5:159–170. doi: 10.1111/j.1745-4522.1998.tb00116.x. [DOI] [Google Scholar]

- deMan JM, Beers AM. Fat crystal networks: structure and rheological properties. J Text Stud. 1987;18:303–318. doi: 10.1111/j.1745-4603.1987.tb00908.x. [DOI] [Google Scholar]

- Dinc S, Javidipour I, Ozbas O, Tekin A. Utilization of zero-trans non-interesterified and interesterified shortenings in cookie production. J Food Sci Technol. 2014;51(2):365–370. doi: 10.1007/s13197-011-0506-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dubois V, Breton S, Linder M, Fanni J, Parmentier M. Fatty acid profiles of 80 vegetable oils with regard to their nutritional potential. Eur J Lipid Sci Technol. 2007;109:710–732. doi: 10.1002/ejlt.200700040. [DOI] [Google Scholar]

- Dutt NVK, Prasad DHL. Inter-relationships among the properties of fatty oils. J Am Oil Chem Soc. 1989;66(5):701–703. doi: 10.1007/BF02669956. [DOI] [Google Scholar]

- Faubion JM, Hoseney RC. The viscoelastic properties of wheat flour dough. In: Faridi H, Faubion JM, editors. Dough rheology and baked product texture. New York: Van Nostrand Reinhold; 1990. pp. 29–66. [Google Scholar]

- Fu J, Mulvaney SJ, Cohen C. Effect of added fat on the rheological properties of wheat flour doughs. Cereal Chem. 1997;74(3):304–311. doi: 10.1094/CCHEM.1997.74.3.304. [DOI] [Google Scholar]

- Gajera HP, Kapopara MB, Patel VH. Application of peanut butter to improve fatty acid composition of biscuits. J Food Sci Technol. 2010;47(3):285–289. doi: 10.1007/s13197-010-0044-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ghotra B, Dyal S, Narine S. Lipid shortenings: a review. Food Res Int. 2002;35:1015–1048. doi: 10.1016/S0963-9969(02)00163-1. [DOI] [Google Scholar]

- Given PS. Influence of fat and oil—physicochemical properties on cookie and cracker manufacture. In: Faridi H, editor. The science of cookie and cracker production. New York: Chapman & Hall; 1994. pp. 157–242. [Google Scholar]

- Greethead GF. The role of fats in bakery products. Food Technol Aust. 1969;21:228–230. [Google Scholar]

- Gulia N, Dhaka V, Khatkar BS. Instant noodles: processing, quality, and nutritional aspects. Crit Rev Food Sci Nutr. 2014;54:1386–1399. doi: 10.1080/10408398.2011.638227. [DOI] [PubMed] [Google Scholar]

- Gutierrez JG, Scanlon MG. Rheological and mechanical properties of fats. In: Marangoni A, editor. Structure-function analysis of edible fats. Champaign: AOCS Press; 2012. pp. 127–172. [Google Scholar]

- Harvey AW. Shortening properties of plastic fats. Ind Eng Chem. 1937;29:1155–1159. doi: 10.1021/ie50334a015. [DOI] [Google Scholar]

- Hedjazi L, Guessasma S, Della Valle G, Benseddiq N. How cracks propagate in a vitreous dense biopolymer material. Eng Fract Mech. 2011;78(6):1328–1340. doi: 10.1016/j.engfracmech.2011.01.030. [DOI] [Google Scholar]

- Jacob J, Leelavathi K. Effect of fat-type on cookie dough and cookie quality. J Food Eng. 2007;79(1):299–305. doi: 10.1016/j.jfoodeng.2006.01.058. [DOI] [Google Scholar]

- Kamel BS. Creaming, emulsions, and emulsifiers. In: Faridi H, editor. The science of cookie and cracker production. New York: Chapman & Hall; 1994. [Google Scholar]

- Khatkar BS, Schofield JD. Dynamic rheology of wheat flour dough. I. Non-linear viscoelastic behavior. J Sci Food Agric. 2002;82:827–829. doi: 10.1002/jsfa.1109. [DOI] [Google Scholar]

- Khatkar BS, Bell AE, Schofield JD. The dynamic rheological properties of glutens and gluten sub-fractions from wheats of good and poor bread making quality. J Cereal Sci. 1995;22:29–44. doi: 10.1016/S0733-5210(05)80005-0. [DOI] [Google Scholar]

- Khatkar BS, Barak S, Mudgil D. Effects of gliadin addition on the rheological, microscopic and thermal characteristics of wheat gluten. Int J Biol Macromol. 2013;53:38–41. doi: 10.1016/j.ijbiomac.2012.11.002. [DOI] [PubMed] [Google Scholar]

- Lai HM, Lin TC. Bakery products: science and technology. In: Hui YH, Corke HH, De Leyn HI, Nip WK, Cross N, editors. Bakery products: science and technology. Hoboken: Blackwell Publishing; 2006. pp. 3–65. [Google Scholar]

- MacRitchie F. Physicochemical process in mixing. In: Blanshard JMV, Frazier FJ, Gaillard T, editors. Chemistry and physics of baking. London: Royal Society of Chemistry; 1986. p. 132. [Google Scholar]

- Mamat H, Hill S. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J Food Sci Technol. 2014;51(9):1998–2005. doi: 10.1007/s13197-012-0708-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Manley D. Short dough biscuits. In: Manley D, editor. Technology of biscuits, crackers and cookies. Boca Raton: CRC Press; 2000. pp. 274–284. [Google Scholar]

- Manley D. Fats and oils. In: Manley D, editor. Technology of biscuits, crackers and cookies. Boca Raton: CRC Press; 2000. pp. 130–150. [Google Scholar]

- Manohar RS, Rao PH. Effect of emulsifiers, fat level and type on the rheological characteristics of biscuit dough and quality of biscuits. J Sci Food Agric. 1999;79:1223–1231. doi: 10.1002/(SICI)1097-0010(19990715)79:10<1223::AID-JSFA346>3.0.CO;2-W. [DOI] [Google Scholar]

- Manohar RS, Rao PH. Interrelationship between rheological characteristics of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Res Int. 2002;35:807–813. doi: 10.1016/S0963-9969(02)00083-2. [DOI] [Google Scholar]

- Menjivar JA, Faridi H. The science of cookie and cracker production. New York: Chapman & Hall; 1994. Rheological properties of cookie and cracker doughs; pp. 283–322. [Google Scholar]

- Mert B, Demirkesen I. Reducing saturated fat with oleogel/shortening blends in a baked product. Food Chem. 2016;199:809–816. doi: 10.1016/j.foodchem.2015.12.087. [DOI] [PubMed] [Google Scholar]

- Miller RA. The use of a penetrometer to measure the consistency of short doughs. In: Faridi H, editor. Rheology of wheat products. St Paul: The AACC; 1985. [Google Scholar]

- Mirzayi B, Heydari A, Noori L, Arjomand R. Viscosity and rheological behavior of castor–canola mixture. Eur J Lipid Sci Technol. 2011;113:1026–1030. doi: 10.1002/ejlt.201000520. [DOI] [Google Scholar]

- Narine SS, Marangoni AG. Relating structure of fat crystal networks to mechanical properties: a review. Food Res Int. 1999;32(4):227–248. doi: 10.1016/S0963-9969(99)00078-2. [DOI] [Google Scholar]

- O’Brien C, Chapman D, Neville D, Keogh MH, Arendt EK. Effect of varying the microencapsulation process on the functionality of hydrogenated vegetable fat in short dough biscuits. Food Res Int. 2003;36:215–221. doi: 10.1016/S0963-9969(02)00139-4. [DOI] [Google Scholar]

- Olewnik MC, Kulp K. The effect of mixing time and ingredient variation on farinograms of cookie dough. Cereal Chem. 1984;61:532–537. [Google Scholar]

- Pareyt B, Talhaoui F, Kerckhofs G, Brijs K, Goesaert H, Wevers M, Delcour JA. The role of sugar and fat in sugar-snap cookies: structural and textural properties. J Food Eng. 2009;90:400–408. doi: 10.1016/j.jfoodeng.2008.07.010. [DOI] [Google Scholar]

- Pareyt B, Brijs K, Delcour J. Impact of fat on dough and cookie properties of sugar-snap cookies. Cereal Chem. 2010;87:226–230. doi: 10.1094/CCHEM-87-3-0226. [DOI] [Google Scholar]

- Perego P, Sordi A, Guastalli R, Converti A. Effects of changes in ingredient composition on the rheological properties of biscuit industry dough. Int J Food Sci Technol. 2007;42:649–657. doi: 10.1111/j.1365-2621.2006.01330.x. [DOI] [Google Scholar]

- Piteira MF, Maia JM, Raymundo A, Sousa I. Extensional flow behaviour of natural fiber-filled dough and its relationship with structure and properties. Non Newton Fluid Mech. 2006;137:72–80. doi: 10.1016/j.jnnfm.2006.03.008. [DOI] [Google Scholar]

- Prentice JH. Rheology and texture of dairy products. J Text Stud. 1972;3:415–458. doi: 10.1111/j.1745-4603.1972.tb00643.x. [DOI] [Google Scholar]

- Pyler EJ. Baking science and technology. Chicago: Siebel Publication; 1988. Formulating; pp. 321–330. [Google Scholar]

- Qarooni J. Flat bread technology. Alphen aan den Rijn: Aspen Publishers; 1996. [Google Scholar]

- Richard WD (1968) Fluid shortenings. In: Proceedings of the 44th annual meeting of the American society of bakery engineers, p 99

- Rodriguez-Garcia J, Laguna L, Puig A, Salvador A, Hernando I. Effect of fat replacement by inulin on textural and structural properties of short dough biscuits. J Food Sci. 2012;77(2):C189–C197. doi: 10.1111/j.1750-3841.2011.02546.x. [DOI] [PubMed] [Google Scholar]

- Rogers D. Functions of fats and oils in bakery products. Inf Am Oil Chem Soc. 2004;15(9):572–574. [Google Scholar]

- Sahi SS. Interfacial properties of the aqueous phases of wheat flour doughs. J Cereal Sci. 1994;20:119–127. doi: 10.1006/jcrs.1994.1052. [DOI] [Google Scholar]

- Sciarini LS, Bockstaele FV, Nusantoro B, Pérez GT, Dewettinck K. Properties of sugar-snap cookies as influenced by lauric-based shortenings. J Cereal Sci. 2013;58:234–240. doi: 10.1016/j.jcs.2013.07.005. [DOI] [Google Scholar]

- Singh N, Gupta S, Sodhi NS, Singh RP. Effect of additives on dough and cookie making properties of flour. Int J Food Prop. 2002;5(3):547–562. doi: 10.1081/JFP-120015491. [DOI] [Google Scholar]

- Tang D, Marangoni AG. Modeling the rheological properties and structure of colloidal fat crystal networks. Trends Food Sci Technol. 2007;18:474–483. doi: 10.1016/j.tifs.2007.04.015. [DOI] [Google Scholar]

- Timms R. Physical properties of oils and mixtures of oils. J Am Oil Chem Soc. 1985;62:241–249. doi: 10.1007/BF02541385. [DOI] [Google Scholar]

- Vettern JL. Technical bulletin VI. Manhattan: American Institute of Baking; 1984. [Google Scholar]

- Wade P. Biscuits, cookies and crackers: vol. 1. The principles of the craft. London: Elsevier Applied Science; 1988. [Google Scholar]

- Wainwright B. Oils and fats for the baking industry. Cereal Foods World. 1999;44:SR16–SR19. [Google Scholar]

- Weipert D. The benefits of basic rheometry in studying dough rheology. Cereal Chem. 1990;67(4):311–317. [Google Scholar]

- West R, Rousseau D. Crystallization and rheology of palm oil in the presence of sugar. Food Res Int. 2016;85:224–234. doi: 10.1016/j.foodres.2016.05.010. [DOI] [PubMed] [Google Scholar]

- Yamamoto H, Worthington ST, Hou G, Ng P. Rheological properties and baking qualities of selected soft wheats in the United States. Cereal Chem. 1996;73:215–221. [Google Scholar]

- Zambiazi RC, Przybylski R, Zambiaz MW, Mendonca CB. Fatty acid composition of vegetable oils and fats. BCEPPA. 2007;25(1):111–120. [Google Scholar]

- Zhong H, Allen K, Martini S. Effect of lipid physical characteristics on the quality of baked products. Food Res Int. 2014;55:239–246. doi: 10.1016/j.foodres.2013.11.010. [DOI] [Google Scholar]

- Zohng H (2013) Effect of lipid source on the physical and sensory quality of baked products. Thesis, Utah State University

- Zoulias EI, Oreopoulou V, Tzia C. Textural properties of low-fat cookies containing carbohydrate- or protein-based fat replacers. J Food Eng. 2002;55(4):337–342. doi: 10.1016/S0260-8774(02)00111-5. [DOI] [Google Scholar]