Abstract

U.S. Mine Safety and Health Administration (MSHA) regulations require underground coal mines to use refuge alternatives (RAs) to provide a breathable air environment for 96 hours. One of the main concerns with the use of mobile RAs is heat and humidity buildup inside the RA. The accumulation of heat and humidity can result in miners suffering heat stress or even death. MSHA regulations require that the apparent temperature in an occupied RA not exceed 95 °F. To investigate this, the U.S. National Institute for Occupational Safety and Health (NIOSH) conducted testing on a 23-person tent-type RA in its Experimental Mine in a test area that was isolated from the mine ventilation system. The test results showed that the average measured air temperature within the RA increased by 9.4 °C (17 °F) and the relative humidity approached 94 percent at the end of a 96-hour test. The test results were used to benchmark a thermal simulation model of the tested RA. The validated thermal simulation model predicted the volume-weighted average air temperature inside the RA tent at the end of 96 hours to within 0.06 °C (0.1 °F) of the average measured air temperature.

Introduction

If an accident occurs in an underground coal mine, miners who fail to escape from the mine can enter a refuge alternative (RA) for protection from adverse conditions, such as high carbon monoxide levels. One of the main concerns with the use of mobile RAs is the potentially adverse thermal environment inside an RA from the metabolic heat of the occupants and the heat released by the carbon dioxide (CO2) scrubbing system. Moreover, the humidity within the RA will increase through occupants’ respiration and perspiration, and from the chemical reaction within the CO2 scrubbing system. The accumulation of heat and humidity can result in miners suffering heat stress, heat stroke or even death.

In its 2007 report to Congress, the U.S. National Institute for Occupational Safety and Health (NIOSH, 2007) recommended that RAs should be designed to ensure that the internal apparent temperature, which is a temperature-humidity metric, in an occupied RA does not exceed 35 °C (95 °F). However, a standard method to determine compliance with this metric does not exist. The heat transfer process within and surrounding an RA is very complex and is not easily defined analytically or experimentally.

To investigate the related issues, heat and humidity testing on a 23-person tent-type RA was conducted in NIOSH’s Experimental Mine in a test area isolated from the mine ventilation system. During the testing, numerous parameters were measured: heat input to the chamber; air temperature and relative humidity inside the RA; mine air temperature; mine strata temperatures near the RA versus depth; and airflow inside and outside the chamber.

TAITherm heat transfer analysis software from ThermoAnalytics Inc. was used to develop a thermal simulation model of the RA as it was tested in the mine, using the test results as the benchmark. TAITherm is a thermal modeling software that predicts the full range of temperature and humidity distribution in a system. Both sensible and latent heat were used in the test and the model. Simulated miners were used to input heat to represent the metabolic heat input of actual miners, and heated water tanks were used to input heat to represent the heat generated by the CO2 scrubbing system.

Heat production and transfer within an RA

There are various levels of research needed to quantify the heat production and transfer within a confined space such as an RA. The temperature and humidity within a confined space is critical because of the relatively narrow range in which the unprotected human body can operate without developing heat stress (Johnson, 2008). The human body maintains a normal core temperature between 36.0 °C (96.8 °F) and 38.0 °C (100.4 °F) (Macpherson, 1993). In hot environments, the body is able to cool itself through the evaporation of sweat to maintain a viable core temperature. The heat sources within an RA include metabolic activity and heat contributed from equipment, such as the CO2 scrubbing system. Heat within an RA is dissipated through conduction, convection, radiation, sweat evaporation from occupants, and condensation on the RA interior.

The heat produced by metabolic activity increases as the level of activity increases. Several standard values can be found for the heat produced by human metabolism (Williams, 2009; Bauer and Kohler, 2009). According to Bauer and Kohler, for examining RA heat and humidity, a representative metabolic heat input of 117 W (399 Btu/hr) per person is adequate. The physical testing and thermal simulation model discussed in this paper use this value as the representative input heat rate of miners in an RA.

Heat transfer to and from the human body occurs from conduction, convection, radiation, respiration and evaporation. Because miners in a tent-type RA will sit or lie directly on the floor, heat loss through conduction can be significant. The differential between skin and core temperatures results in heat transfer from the body’s core to the skin, where it can be lost through conduction, convection, radiation and perspiration. Sweating occurs when conduction, convection, radiation, respiration and evaporation of sweat become insufficient to dissipate the accumulation of heat from metabolic and environmental sources. Because evaporation of sweat absorbs significant amounts of heat from the skin, it allows the body to lose heat rapidly. As the ambient temperature approaches or exceeds skin temperature, sweating becomes the body’s primary mechanism of heat loss. However, the rate of sweat evaporation is limited by the relative humidity of the surrounding air. As the relative humidity increases, the rate of sweat evaporation slows, reducing the body’s ability to cool itself. Evaporation of sweat becomes very slight at high relative humidity. For example, the Zunis Foundation (2009) found that the maximum sweat evaporation rate drops from ~2.5 L/h (84.5 oz/h) at relative humidty of 50 percent to ~1.3 L/h at relative humidity of 80 percent at an air temperature of 35 °C (95 °F). Therefore, high humidity will reduce the effectiveness of the body’s most effective heat loss mechanism.

In-mine experiments

Tests were conducted underground in the Experimental Mine at the NIOSH research laboratory in Pittsburgh, PA. A tent-type RA with a 1.7-m-high (5.5-ft-high) tent, an internal volume of roughly 55.3 m3 (1,881 ft3) and a floor surface area of about 31.8 m2 (342 ft2) was used for these tests (Fig. 1). This RA meets the unrestricted surface area requirement of 1.4 m2 (15 ft2) per miner specified in 30 CFR 7.505 for up to 23 people, and it meets the unrestricted volume criteria of 1.7 m3 (60 ft3) per miner for seam heights up to 1.37 m (4.5 ft), as mandated by the U.S. Mine Safety and Health Administration (MSHA) for RA manufacturers to comply with by 2018 (U.S. Government Publishing Office, 2016). Tent-type RAs, such as the tested RA, use a metal box to store their tent prior to its deployment, to store the compressed air cylinders that are used to inflate the tent, and to store compressed oxygen cylinders that are used to provide occupants with oxygen. The metal box for the tested RA was 1.98 m (6.5 ft) wide and 4.72 m (15.5 ft) long.

Figure 1.

A 23-person tent-type RA: (a) during deployment, (b) after deployment and (c) showing an interior view with simulated miners and heated water tanks.

Because using actual miners for 96-hour heat and humidity tests is not practical, simulated miners were developed to input the metabolic heat that is representative of real miners. Because tent-type RAs are not provided with benches, cots or pads, miners in a tent-type RA will sit or lie directly on the floor of the RA. Therefore, the simulated miners should approximate the heat transfer area of a seated or lying miner. For this reason, each simulated miner’s surface area should be approximately 75 percent of the 1.8-m2 (19.4-ft2) surface area of the typical human body (Bernard, 2012). These simulated miners (Fig. 2) were developed using commonly available 0.11-m3 (30-gal) steel drums, thin-walled aluminum pipes, two aquarium air pumps, an aquarium water pump and two silicone-encapsulated electrical resistance heaters, each with a nominal power rating of 120 W (409.5 Btu/hr) at 120 V to represent human metabolic heat (Yantek, 2014). Each simulated miner had a surface area of 1.35 m2 (14.5 ft2), which is exactly 75 percent of 1.8 m2 (19.4 ft2). More details on the design of the simulated miners can be found in Yantek (2014).

Figure 2.

Inside view of a simulated miner.

During testing, 23 simulated miners were used to deliver 117 W (399.2 Btu/hr) of heat each to the interior of the RA. To simulate the latent heat transfer from actual miners due to sweating, each simulated miner was used to input a nominal 1.3 L/d of water vapor into the RA. For each simulated miner, an additional 27.5 W (93.8 Btu/hr) of heat was input to represent the heat generated by a lithium hydroxide CO2 scrubbing system (Yantek, 2014). The heat to represent that of the scrubbing system was generated using four heated water tanks. These tanks provided make-up water for the moisture generation system of the simulated miners. For the tests conducted with 23 simulated miners, the total heat input was nominally 3,323.5 W (11,340.3 Btu/hr).

Test setup

The RA was positioned in the Experimental Mine with the center of the tent located at the center of the entry so that the sides of the RA were equidistant from the ribs. To prevent bulk airflow into the test area, the RA was isolated from the mine ventilation system using polystyrene walls. This represents a worst-case scenario – a loss of the mine ventilation fans. The encapsulated test area was approximately 44.2 m (145.0 ft) long and 1.8 m (5.9 ft) high. The 23 simulated miners and four heated water tanks were arranged to distribute the heat as evenly as possible within the deployed tent.

Numerous transducers were used to measure various parameters with three Data Translation DT9874 data acquisition systems. During the test, all data were acquired at a rate of 1 sample every 20 seconds with 24-bit resolution. For all testing, the actual heat input was measured using two Flex-Core PC5-019CX5 watt transducers, one for the group of 11 simulated miners along the left side of the tent, and one for the group of 12 simulated miners along the right side of the tent.

Sensors were used inside and outside the tent to record the internal and external air temperatures, relative humidities, airflows, condensations and RA surface temperatures. Figure 3a shows the sensors positioned inside the RA, and Fig. 3b shows the locations for surface-mount temperature sensors on the exterior surfaces of the RA. For ease of reference, the tent was divided into three sections: Tent 1, Tent 2 and Tent 3. To determine the mine airflow speed near the RA, three omnidirectional airflow sensors were positioned near the tent. These particular airflow sensors were chosen because they can accurately measure flow speeds as low as 0.05 m/s (10.0 ft/min) and are not sensitive to flow direction. Measuring the airflow is important because any heat transfer simulation requires the specification of the convection coefficient that is directly related to the air velocity.

Figure 3.

Sensor locations: (a) interior and (b) exterior.

The mine air and mine strata temperatures were measured using resistance temperature detectors (RTDs). The mine air temperatures near the RA were measured using eight 182.9-cm-long (72-in.-long) averaging RTDs, which are not shown in Fig. 3. The average mine air temperature near the RA was calculated by averaging the readings of these eight sensors. The mine roof, rib and floor strata temperatures were measured at multiple locations. To measure the mine strata temperatures at different depths, polyvinyl chloride rods with four attached RTDs at depths of 0, 15.2, 61.0 and 121.9 cm (0, 6, 24 and 48 in.) were installed in the mine roof, rib and floor. To install the RTD-instrumented rod, a hole with diameter of 2.54 cm (1.0 in.) was drilled into the mine strata and the instrumented rod was pushed into the hole. In the floor strata, the rods were installed beneath the centers of the metal box, Tent 1, Tent 2 and Tent 3. An additional instrumented rod was installed in the mine floor beneath Tent 2 to monitor floor strata temperatures between the two simulated miners BP #11 and BP #13. To measure the average temperature along the mine floor strata-tent interface, three 1.8-m-long (6.0-ft-long) averaging RTDs were installed in shallow slots cut into the mine floor under Tent 1, Tent 2 and Tent 3. To measure rib strata temperatures, three RTD-instrumented rods were installed: one aligned with the center of the metal box, one aligned with the center of Tent 2 and one aligned with the center of Tent 3. To measure roof strata temperatures, two RTD-instrumented rods were installed: one above the center of Tent 1 and one above the center of Tent 2. Above the center of the metal box and Tent 3, the temperature with depth was not measured due to concerns of water being released from the roof strata when drilling holes to install the RTD-instrumented rods. At these two locations, the roof strata surface temperatures were measured using RTDs attached to the roof surface.

Test procedure

Unlike a human miner, who is at body temperature when he or she enters an RA, a simulated miner is “cold” when it is first powered, and it may take up to a day for it to reach its steady-state temperature. As a simulated miner is allowed to heat up to its operating temperature, the surroundings in the test area also heat up, effectively preheating the RA and the test area. In this case, the final air temperature measured inside the RA at the end of the 96-hour time period would be higher than it would have been if the simulated miners were at their operating temperatures at the start of the 96-hour period.

To address this, the following approach was used to decrease the time for the simulated miners to reach their operating temperatures and to minimize heating of the RA and surroundings: Prior to the beginning of each test, all of the simulated miners were wrapped in quilted, 2.54-cm-thick (1.0-in.-thick) fiberglass insulating blankets, with R-value of ~3.14, and the top of each was covered with a 2.54-cm-thick (1.0-in.-thick) Styrofoam disk. By insulating the simulated miners, the heat lost to the RA can be minimized so that the temperatures of the simulated miners increase relatively quickly. As an additional step to reduce the time required for the simulated miners to reach their operating temperatures, the simulated miners were designed to use two heaters: a steady-state heater and a preheater, each with a rating of 120 W (410 Btu/hr) at 120 V. At the beginning of the tests, both the steady-state heater and the preheater for each simulated miner were turned on and the surface temperatures at the mid-height of two of the simulated miners were monitored. The preheaters were turned off and the insulation was removed when the monitored temperatures were in the range of 29 to 35 °C (85 to 95 °F), roughly the expected steady-state temperature of the simulated miners and the skin temperature of the human body. The simulated miners approached their steady-state temperatures within three to four hours. At this time, most of the heat generated by the simulated miners was transferred to the RA air and mine floor strata, with the remaining heat acting to increase the simulated miner temperatures.

Experimental results

Because the measured temperatures were observed to change very slowly – less than 0.6 °C (1.0 °F) over the final 24-hour time period – the sample rate at which the raw test data were acquired was found to be much higher than necessary, and reducing the data set would not affect the characteristics of the data. The sample rate was therefore reduced from 1 sample per 20 seconds to 1 sample per 5 minutes.

The RA internal air temperatures are the temperatures of the most interest because they are used to determine the apparent temperatures within the RA. The air temperatures within the tent rose relatively quickly during the first day before leveling off with a slow, steady rise for the remainder of the test (Fig. 4). The temperatures at the mid-heights of Tent 1, Tent 2 and Tent 3 – labeled X28-I-Tnt1-AT-MH, X33-I-Tnt2-AT-MH and X36-I-Tnt3-AT-MH, respectively – were within about 0.83 °C (1.5 °F) of each other throughout the test. The average measured air temperature within the tent at mid-height, calculated using the temperatures at the centers of Tent 1, Tent 2 and Tent 3, increased by 9.4 °C (17 °F) during the tests. At the metal box end of the RA – labeled X26-I-MB-AT-MH – the data show that the interior air temperatures at the mid-height of the metal box were about 5.6 °C (10 °F) lower than the temperatures within the tent.

Figure 4.

RA internal air temperatures at various locations.

The mine ambient temperature rose steadily throughout the test. Eight 182.9-cm-long (72-in.-long) averaging RTDs were positioned near the RA – both along the tent side and over the tent. The temperatures along the sides of the RA at mid-height were a bit lower than the overhead temperatures (Fig. 5). This air temperature gradient was caused by warm air rising due to buoyancy effects both inside and outside the RA.

Figure 5.

Mine air temperature along the sides of the RA at mid-height and over the tent.

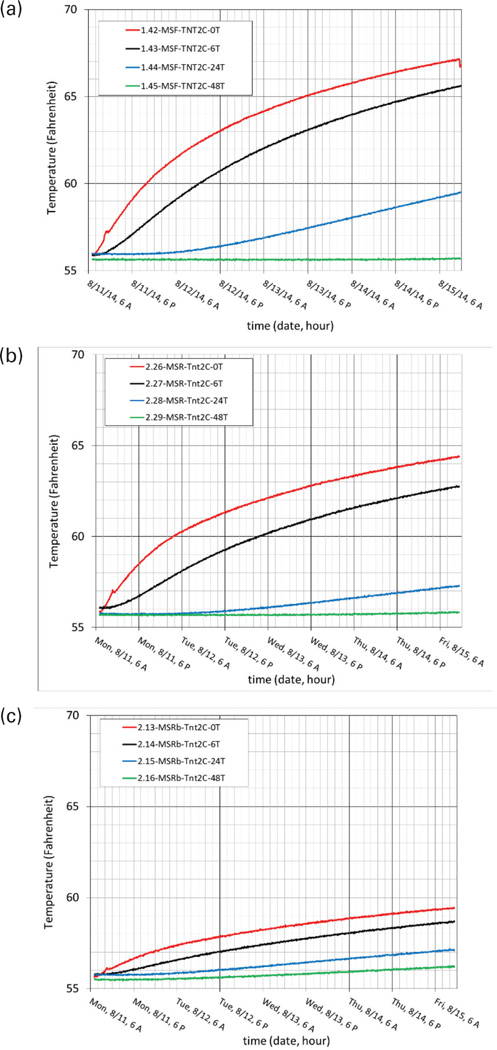

Strata temperatures were also monitored. The temperatures on the mine roof, rib and floor surfaces increased almost immediately after beginning the test. Figure 6 shows the measurements from the probes overhead, beside and underneath the center of Tent 2. As depth into the strata increased, the temperatures increased less and at lower rates. The temperatures measured between the tent and mine floor increased by about 3.1 °C (5.5 °F) in the first 24 hours. By the end of four days, the temperatures between the tent and the surface of the mine floor increased by 6.1 °C (11.0 °F), the temperature at 15.2 cm (6 in.) deep increased by 5.3 °C (9.5 °F), the temperature at 61.0 cm (24 in.) deep increased by 1.9 °C (3.5 °F), and the temperature at 122 cm (48 in.) deep remained constant. The roof strata temperatures behaved similarly except that the final temperature reached was about 1.1 to 1.7 °C (2 to 3 °F) below that of the floor strata at the end of the 96-hour test. The rib strata temperatures increased more slowly compared with the roof and floor strata temperatures. The rib strata temperatures also had less gradient with depth compared with the roof and floor strata temperatures.

Figure 6.

Mine strata temperatures for: (a) floor under the center of Tent 2, (b) roof above the center of Tent 2 and (c) rib at the center of Tent 2, as measured during the 96-hour test.

The temperatures of the mine floor strata beneath the tent showed the largest increases because the simulated miners were in direct contact with the tent floor. The in-mine test data showed that the strata temperatures at a depth of 1.2 m (4.0 ft) remained nearly constant throughout the tests. Therefore, because the strata temperatures up to a depth of 1.2 m change within 96 hours, thermal simulation models of an RA in an underground coal mine should include at least a 1.2-m-thick (4.0-ft-thick) layer of mine strata. The temperatures at a depth of 1.2 m (4.0 ft) can then be assumed to remain constant at the temperatures corresponding to the mine that the model is to represent (Yantek, 2014).

Thermal simulation model description

There are several thermal models used to simulate and predict the temperature and humidity within an occupied RA. In one study, the temperature inside an RA was simulated using ANSYS Fluent software to investigate the effects of chamber structure, size and mine air temperature (Collingwood, 2012). In another, a thermodynamic heat transfer model was developed with some assumptions specified to produce a simple model given some RA design parameters (Gillies, 2012). Another heat dissipation mathematical model was developed and used to calculate RA interior temperature (Brune, 2012). The results agreed well with the test data, provided the equation parameters were chosen appropriately. All of these models treated the mine strata surface temperature and the mine air temperature as constant.

We developed a TAITherm model of the Experimental Mine test to account for the RA and mine geometry, the RA and mine strata thermal properties, and the heat generated by the simulated miners and the heated water tanks that were used to represent the CO2 scrubber heat. In this model, the mine strata surface temperature and the mine air temperature were not treated as constant. TAITherm is a validated heat transfer prediction software tool that applies a multiphysics approach to solve for thermal conduction, radiation, convection and moisture transport under both steady-state and transient conditions. The thermal model was created from the three-dimensional, computer-aided-design geometry of the tested 1.7-m-tall (5.5-ft-tall) tent-style RA. The geometry was modified so that a finite element shell mesh could be applied. In TAITherm, a shell element mesh was used to model the mine strata up to a depth of 1.8 m in twenty-four 7.62-cm-thick (3.0-in.-thick) layers. Twenty-three simulated miners and four heated water tanks were positioned within the model at the same positions as during testing. Due to a limitation of TAITherm, a single bulk air temperature was modeled in the tent. In addition, a single air temperature was modeled for the mine.

The model predicts the transient thermal responses of the simulated miners, RA surfaces, RA interior air, mine strata and mine air. In addition, it accounts for moisture input and condensation on the RA interior surfaces. Inputs to the model are the simulated miner heat rates, the CO2 scrubber system heat rate, and the moisture input rate. The initial RA air temperature, RA structure temperature, mine air temperature and mine strata temperatures are used as initial conditions for the model. During simulations, the measured heat rates and initial temperatures from the test data were used as inputs into the model.

The thermal properties of the RA and simulated miners were estimated based on information provided by the RA manufacturer and from commonly available material property information. The thickness of the concrete layer of the mine floor was estimated using ground penetrating radar. Core samples were taken of the mine rib, roof and floor. These samples were used to perform material thermal property analysis.

Model validation

To validate the accuracy of the model, the transient thermal response predicted by the model was compared with the experimentally collected physical measurements. From the test data, the temperature averaged over the entire RA interior volume was used for a comparison with the model’s results. The model calculates a single average air temperature for the entire tent interior. A plot comparing the transient temperatures predicted by the model with the experimental data is shown in Fig. 7. The figure shows comparisons for the temperature at the top of the BP #13 simulated miner, the RA interior air temperature, and the temperature at the tent floor at the junction of Tent 2 and Tent 3. For the mine floor temperature, from the simulation results, an average of predicted element temperatures over a 1.8-m (6.0-ft) distance was used to compare the model results with the 1.8-m-long (6.0-ft-long) averaging RTDs used in the physical test. Figure 8 shows a comparison of the measured and calculated relative humidities inside the tent. The final relative humidity for the model was 92.5 percent, and the averaged measured final relative humidity was 93.9 percent.

Figure 7.

Simulated (solid line) versus measured (dotted line) temperature results for the top of the BP #13 simulated miner; the interior air at mid-height; the floor strata, underneath the intersection of Tent 2 and Tent 3, of the tested RA; and the mine floor under BP #10.

Figure 8.

Modeled (solid line) versus measured (dotted line) interior relative humidities.

Comparisons were made between the measured and predicted temperatures at numerous locations on the RA surfaces. Figure 9 shows examples of elements that were selected for comparison with measured data (see numbered callouts). TAITherm calculates temperatures at the centroid of each surface mesh element.

Figure 9.

Three-dimensional view of the simulated RA model at the end of the 96-hour test.

Table 1 summarizes the results of the model validation at the end of the 96-hour test. For comparing the RA internal air temperature predicted by the model to the measured RA internal air temperature, a volume-weighted average RA internal air temperature was calculated from the test data. The predicted air temperature within the RA tent is very close to the average measured air temperature inside the tent, with only a 0.06 °C (0.1 °F) overprediction. The temperatures of the simulated miners, BP #10 and BP #13, and tent side also match closely. The largest error was 1.9 °C (3.4 °F) for a point on the bottom of BP #13. A similar error was not seen on the bottom of BP #10. As shown in Table 1, the mine strata temperature predictions may differ from the measured data by 1.1 to 1.6 °C (2.0 to 3.0 °F). The discrepancies are most likely due to uncertainties in strata properties such as the rock types, thicknesses and specific thermal properties, and the lack of inclusion of air stratification in the model.

Table 1.

Model error summary at 96 hours (positive value means overprediction by model, negative means underprediction).

| Sensor location | Sensor no. | Prediction error (°C) |

|---|---|---|

| Tent air | x-26, x-28, x-33, x-36 |

0.06 |

| Mine air | 2–31 to 2–40 | −0.3 |

| BP10 bottom | x-8 | 0.5 |

| BP10 side | x-9 | 0.2 |

| BP10 top | x-10 | −1.3 |

| BP13 bottom | x-11 | −1.9 |

| BP13 side | x-12 | 1.0 |

| BP13 top | x-13 | −0.5 |

| Tent side 1 | 1–18 | −0.1 |

| Tent side 2 | 1–24 | 0.1 |

| Tent side 3 | 1–28 | −0.6 |

| Tent top 1 (middle) | 1–20 | −0.7 |

| Tent top 2 (middle) | 1–26 | −1.0 |

| Tent top 3 (middle) | 1–30 | −0.6 |

| Tent floor 1–2 | 1–5 | 1.0 |

| Tent floor 2–3 | 1–11 | 0.0 |

| Mine walls (rib) 2 | 2–13 | 0.9 |

| Mine walls (rib) 3 | 2–17 | 0.9 |

| Mine roof over tent | 2–26 | −0.3 |

| Mine roof over case | 2–21 | 0.3 |

| Mine floor under Tent 1 - under simulated miners |

1–41 | 1.4 |

| Mine floor under Tent 2 -middle |

2–4 | 1.0 |

Conclusions and remarks

Test results were used to validate a thermal simulation model. In the 96-hour in-mine tests, the average measured air temperature within the RA increased by 9.4 °C (17 °F). The mine air and mine strata temperatures increased over the tests. The mine strata temperatures at a depth of 1.2 m (4 ft) remained nearly constant throughout the tests, while the strata surface temperatures increased at almost the same rates as the air temperatures. When the transient thermal response predicted by the TAITherm model was compared with physical measurements collected during the test, it was found that the model predicted the average tent interior air temperatures after 96 hours to within 0.06 °C (0.1 °F) of the measured temperatures.

Uncertainties in the rock types and their thermal properties are likely the largest source of error in the model, even with taking core samples and performing thermal conductivity and specific heat measurements. The RA may perform differently in mines that have different strata with different thermal conductivity properties. Hence, the validation of the thermal simulation model of a particular RA may need to provide a baseline strata model against which the RA’s performance can be compared.

Although not discussed in this paper, the validated model has been used to extend the analysis to include TAITherm models of humans instead of simulated miners. The human thermal model could be used to predict the transient core temperature response of RA occupants. Further studies could use the core temperature response to determine safety limits based on the mine ambient temperature and number of RA occupants (Van der Linde et al., 1992; Webber et al. 2003). It is worth mentioning that the mine ambient air temperature around the chamber may increase during a mine fire. This could affect the results, and the possibility should also be investigated.

Finally, the benchmarked model can be used to develop derating tables for occupied tent-type RAs at hot mines to provide the miners with more comfortable thermal environments and ensure that the interior apparent temperatures do not exceed the 95 °F specified by MSHA regulations.

Footnotes

Disclaimer

Mention of a company name or product does not constitute an endorsement by NIOSH. The findings and conclusions in this report are those of the authors and do not necessarily represent the views of NIOSH. This article is not subject to U.S. copyright law.

Contributor Information

L. Yan, Email: LYan1@cdc.gov, National Institute for Occupational Safety and Health (NIOSH), Pittsburgh Mining Research Division, Pittsburgh, PA, USA.

D. Yantek, National Institute for Occupational Safety and Health (NIOSH), Pittsburgh Mining Research Division, Pittsburgh, PA, USA.

M. Klein, ThermoAnalytics Inc., Calumet, MI, USA.

P. Bissert, National Institute for Occupational Safety and Health (NIOSH), Pittsburgh Mining Research Division, Pittsburgh, PA, USA.

R. Matetic, National Institute for Occupational Safety and Health (NIOSH), Pittsburgh Mining Research Division, Pittsburgh, PA, USA.

References

- Bauer ER, Kohler JL. Update on Refuge Alternatives: Research, Recommendations, and Underground Deployment. SME Annual Conference & Expo; Denver, CO. Englewood, CO: Society for Mining, Metallurgy & Exploration; 2009. [Google Scholar]

- Bernard T. Physiological analysis of human generated heat. Tampa, FL: University of South Florida; 2012. [Google Scholar]

- Brune J. Dissipating the Heat Inside Mine Refuge Chambers. SME Annual Conference & Expo/14th U.S./North American Mine Ventilation Symposium; 2012; Salt Lake City, UT. Englewood, CO: Society for Mining, Metallurgy & Exploration; 2012. [Google Scholar]

- Collingwood W. Analysis of Underground Coal Miner Heat Exposure in a Refuge Chamber. Englewood, CO: Society for Mining, Metallurgy & Exploration; 2012. [Google Scholar]

- Gillies S. Design Aspects of Underground Rescue Chambers. SME Annual Conference & Expo, Society for Mining, Metallurgy & Exploration; Englewood, CO. 2012. [Google Scholar]

- Johnson D. Assessment of Thermal Environment of Mine Refuge Chamber. Carrollton, TX: Industrial Hygiene and Safety Technology, Inc; 2008. [Google Scholar]

- Macpherson MJ. Subsurface Ventilation and Environmental Engineering. Springer; 1993. Physiological reactions to climatic conditions; pp. 1–42. [Google Scholar]

- Williams WJ. personal communication. 2009 [Google Scholar]

- U.S. National Institute for Occupational Safety and Health. Research Report on Refuge Alternatives for Underground Coal Mines. Office of Mine Safety and Health, NIOSH, Centers for Disease Control and Prevention, Department of Health and Human Services; 2007. Dec, p. 16. 2007. [Google Scholar]

- U.S. Government Publishing Office. 30 CFR, Part 75.1506. 2016 http://www.ecfr.gov/cgi-bin/text-idx?node=se30.1.75_11506&rgn=div8.

- Van der Linde A, Klelblock AJ, Rex DA, Terblanche SE. Diagnostic and prognostic criteria for heat stroke with special reference to plasma enzyme and isoenzyme release patterns. International Journal of Biochemistry. 1992;24(3):477–485. doi: 10.1016/0020-711x(92)90042-y. http://dx.doi.org/10.1016/0020-711x(92)90042-y. [DOI] [PubMed] [Google Scholar]

- Webber RCW, Franz RM, Marx WM, Schutte PC. A review of local and international heat stress indices, standards and limits with reference to ultra-deep mining. Journal-South African Institute of Mining and Metallurgy. 2003;103(5):313–324. http://dx.doi.org/10.17159/2411-9717/2015/v115n2a6. [Google Scholar]

- Yantek D. Investigation of Temperature Rise in Mobile Refuge Alternatives. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Office of Mine Safety and Health Research; 2014. [Google Scholar]

- Zunis Foundation. 2009 http://www.zunis.org/Sweat_page_4.htm. [Google Scholar]