Abstract

Background:

Low back pain caused by work, ranked the second after cardiovascular diseases, are among the most common reasons of patients’ referral to the physicians in Iran. This study aimed to determine the changes in back compressive force when measuring maximum acceptable weight of lift in Iranian male students.

Methods:

This experimental study was conducted in 2015 on 15 young male students were recruited from Tehran University of Medical Science. Each participant performed 18 different lifting tasks involving three lifting frequencies, with three lifting heights, and two box sizes. Each set of experiments was conducted during the 20 min work period using free-style lifting technique. The back compressive force evaluated with hand-calculation back compressive force method. Finally, Pearson correlation test, analysis of variance (ANOVA) and t-test were used for data analysis.

Results:

The mean of back compressive force (BCF) for the small and large boxes at a frequency of 1lift/min at heights of F - K height, were 1001.02 (±86.74), 1210.57 (±93.77) Ib, respectively. There was a significant difference between mean BCF in terms of frequencies of lifts (P=0.02). The result revealed significant difference between frequencies of 1 lift/min and 6.67 lift/min (P=0.01). There was a significant difference between mean BCF in terms of the sizes of the two boxes (P=0.001). There was a significant relationship between the BCF and maximum acceptable weight of lift in all test conditions (P=0.001).

Conclusion:

BCF is affected by box size, lifting frequency and weight of load.

Keywords: Back compressive force, Maximum acceptable weight of lift, Psychophysical methodology

Introduction

There are several harmful factors at work environment that causes fatigue, burnout, and early exhaustion of individuals, and lead to the waste of time and money. Some of the occupational factors are responsible for the incidence of musculoskeletal problems. Manual Material Handling (MMH) tasks are one of the common occupational factors (1). In most industries, and even in non-occupational settings, manual handling and lifting of weights happens very frequently; each of these tasks have their own specific requirements, and such tasks are one of the important reasons for the incidence of low back pain (2). Low back pain and other musculoskeletal disorders caused by work, ranked the second after cardiovascular diseases, are among the most important and common diseases and cause of patients’ referral to the physicians in Iran (3). Moreover, 85% of the population would suffer from back pain at some points in their life time. On the other hand, 25% of days off from the work are due to back pain (4).

In recent years, low back pain related to the job or career has become a major concern. In many studies conducted so far on different jobs and employees (such as posts staff, doctors, soldiers, construction workers and other groups) the prevalence of low back pain has been reported from 15% to 84% (5). Low back pain can reduce the functional performance and lead to absenteeism around the world and it imposes a huge economic burden on the individual, family, community, industry, and government. Until 10 years ago it was thought that the problem is limited to Western countries, however, since then the increased number of researches has found that low back pain is also a big problem in low and middle income countries as well (6). Low back pain can be caused by mechanical, ergonomic, personal, and social factors. Among the ergonomic and mechanical factors, we can note the followings: lack of adequate rest between the work shifts, doing work with hurry and top speed, improper body postures, high frequency and repetitive movements, and lifting or moving heavy objects. In addition, obesity, gender, age and other factors can be also introduced as the causes of low back pain (7). Based on the mentioned facts, back injuries associated with MMH tasks have been a rigid problem for both the person and the national economy. There are several different main types of the MMH tasks, such as lifting, holding, carrying, pushing, and pulling. Nearly 50% of back injuries occur when lifting objects, whereas only 9% occur when holding, throwing, or carrying objects. Therefore, as the most common MMH task associated with the prevalence of low back injuries is lifting tasks (8).

During lifting and bending forward, the trunk is placed in front of the lumbar spine and it leads to shear and compressive forces to be imposed on the disk. On the other hand, each person's tolerance of the load on the spine depends on different factors such as body posture, gender, age, the weight of the imposed load, and the individual anatomical changes (9). Many studies have examined the lifting task through using a biomechanical approach, which estimated the stresses incurred in the body while lifting materials. The Focus of these studies is primarily on the lower back, especially the L5/ S1 disc (10, 11). Accordance of the statistical data, between 85% and 95% of all disc herniations with a repeat equal proportion occur at the L4/L5 and L5/S1 levels, respectively (12). In all the methods designed for the assessment of the risk related to the lifting, the biomechanical factors are of great importance. Biomechanical factors in the work place, such as the workload, distance, and location of the workstations are effective in the prevalence of musculoskeletal disorders. Based on the previously conducted studies, the severity of the effects of each of these factors is quite variable and depends on the range of changes in the shear and compressive forces imposed on the lumbar discs and the incidence and prevalence of low back pain (13). Manual lifting tasks can be evaluated for back injury risk via the analysis of the back compressive force (BCF) (14). There are several methods used to estimate the compressive force in the lower back, among which we can note the followings: direct measurement method, simulation models, finite element method, NIOSH Lifting Equation, 3D Static Strength Prediction Program (3DSSPP), Hand Calculated BCF Model (HCBCF), and Surface EMG-based models.

In this study, we used HCBCF method to evaluate back compressive force. The HCBCF is a simple hand-calculation method for BCF based on the original Utah BCF Calculation model.

In a study by Elfeituri and Taboun, the same method was used to estimate the biomechanical force. The maximum force imposed on the low back was estimated to be 3685 Newton. Of all the subjects, 54% of the workers were suffering from a force on their low back, which was more than the permissible limit (3400 Newton). Moreover, in this study, the researchers concluded that the workers lifted a weight that was proportional to their capacity (15). The peak BCF for dynamic model on the lumbosacral joint was 33% to 60% higher than that in the static model at four different lifting techniques (16). NIOSH work practices guide for Manual Lifting indicated, biomechanical BCF on the L5/S1 disc in most workers are not tolerable over 650 kg (1430 lb) and a 350 kg (770 Ib) BCF can be tolerated by most young, healthy workers. These criteria from cadaver spine failure and cross-sectional epidemiologic studies of job loads associated with back injuries were established (17).

This study was aimed to determining the changes in back compressive force when measuring maximum acceptable weight of lift in Iranian male students.

Materials and Methods

Participants

This experimental study was conducted in 2015. Fifteen young male students (20–30 yr old) were recruited from the total population of students at Tehran University. The sample size was consistent with those of previous studies (18–21). The mean (SD) demographic data of the subjects were as follows: age 22.2 (±2.1) yr, body weight 67.5 (±7.4) kg and height 177.7 (±5.3) cm. We were looking at after that examined to ensure they had no considerable cardiovascular and musculoskeletal problems and no previous history of significant regarding lower back pain. They participated in training sessions and familiarized using the experimental processes before collecting your experimental data. The reason for selecting students as the subjects was the availability in terms of schedule flexibility and experimental duration. Prior to commencing the study, smoking habits, alcohol and carbonated liquids consumption, eating habits, physical activity, and normal sleep duration of students were considered. All participants signed a consent form before the test, and they were paid to them. The summary of data on the subjects' age, height, and weight are presented in Table 1.

Table 1:

Demographic description of the subjects (n=15)

| Variable | Mean | SD | Range |

|---|---|---|---|

| Age (yr) | 22.20 | 2.10 | 20–26 |

| Weight (kg) | 67.50 | 7.40 | 54.0–77.0 |

| Height (cm) | 177.70 | 5.30 | 169.0–187.0 |

Equipment

A height adjustable set up, shown in Fig. 1, similar to the device used by Snook, was used to simulate the 18 different lifting conditions considered in this study. The stopwatch was used to measure the time and instructing the subjects. Digital accurate scale was used for weighing body weight and determined maximum weight of lifting. Two plastic boxes with external handles (4.2 cm thick and 17.8 cm long) were used. Each box represents a special industrial tote box. The small box has the width, length, and depth of 33.4 cm, 56.2 cm, and 16.0 cm, respectively. The large box has the width, length, and depth of 76.1 cm, 56.5 cm, and 22.0 cm, respectively. The width of the box represents the horizontal distance between hands and the central axis of the body. The length of the box represents the distance between two handles. Box dimensions and handles were the same as those used in the Snook and Ciriello MMH lifting tables (22). These boxes were rectangular (Fig. 1).

Fig. 1:

Height-adjustable shelves and boxes for handling lifts

Experimental design

The experiments, designed to study the effects of independent variables on the back compressive force (Table 2). Factorial randomized complete block design was used to collect data. Three different task variables including frequency and height of lifting and box size were used in this study.

Table 2:

MMH task Parameters at Different Levels

| No | Symbol | Factors | Level | Units | ||

|---|---|---|---|---|---|---|

| Level-1 | Level-2 | Level-3 | ||||

| 1 | A | Freq. of lift | 1 | 4.3 | 6.67 | lifts/min |

| 2 | B | Box size | Small | Large | - | cm3 |

| 3 | C | Height of lift | Floor to knuckle height | Knuckle to shoulder height | Shoulder to arm reach | cm |

These Three variables are the important descriptors of manual lifting tasks. Three levels of lifting frequency (1 lift/min, 4.3 lift/min, 6.67 lift/min) were applied. Three different lifting heights (floor to knuckle (F-K), knuckle to shoulder (K-S), and shoulder to arm reach (S-A) were fixed. Two different box sizes were used (small and large). The levels of these three variables (frequency of lift /height of lift /box size), thus, provided 18 combinations of similar basic manual lifting tasks. The participants were randomly performed the task of lifting for all 18 combinations tasks. Each subject determined the maximum acceptable weight of lift and randomly, started with either a very light or a heavy weight (According to 10% ile and 90% ile male as per the Snook Tables and were allowed to adjust it to arrive at the maximum acceptable weight of lift (26). The adjustment took approximately 20 min. The room temperature was kept in the range of 22–24 °C and the relative humidity was 45–55%.

Study procedure

The psychophysical methodology (18, 22, 23) was used in this experiment. The maximum amount of weight or force could handle for 8 h without symptoms of fatigue or muscle weakness were determined by subjects. The students wore the normal clothes and flat-soled sport shoes. Prior to commencing the experiments, the participants rested for 10 min in prone lying position. The procedure of experiments and the purpose of the research were explained to the students. Before the start of each series of tests, subjects performed 5 min of light warm-up exercises. Following this, the box-handling tasks were done in the specific experimental conditions. Next, the participant performed one of the eighteen possible experimental conditions (three lifting frequencies, three lifting heights, and two box sizes). Each person participating in the test was asked to lifting the box using a free-style posture. To the control the frequency of lifting a periodic sound that was broadcast by the mobile phone was used. Once the participants heard the sound, they lifted the box and then waited for the next sound. The Participants were allowed to added or subtracted inside the weight from the box between the lift trials. During the lifting, the subjects changed the weight of boxes by adding and subtracting the sand bags. Subjects were aware of the sand bags but never knew their weights. The weights of bags were randomly varied. During 20 min, the weight of the boxes was set in accordance with procedures. The Final weight at the end of each course as it was intended as the maximum acceptable weight (MAWL) for that particular frequency. The condition of the experiments was run twice for each subject (one replication). For a given lifting task condition, if the participant’s MAWL for the second adjustment was within 15% of the first adjustment, the average of the two adjustments was considered as the final MAWL for that lifting condition. Otherwise, the results were discarded and the relevant data were collected at the next time.

The back compressive force evaluated with HCBCF method.

Results

The mean and standard deviation of BCF for the small box at a frequency of one lift/min at different heights of F - K height, K - S height and S-A height, were 1001.02 (± 86.74), 875.26 (± 86.81), and 833.57 (± 72.64) Ib. The obtained values for the same box at frequencies of 4.3 and 6.67 lift/min at the mentioned heights are presented in Table 2. In addition, the mean and standard deviation of the BCF for the large box at a frequency of one lift/min at different heights of F - K height, K - S height and S-A height, were 1210.57 (± 93.77), 1166.57 (± 72.31), and 1092.42 (± 84.69) Ib. The obtained values for the same box at frequencies of 4.3 and 6.67 lift/min at the mentioned heights are presented in Table 3.

Table 3:

Mean of back compressive force (Ib) for lifting various boxes at different heights and frequencies

| Frequency of lift | Floor to knuckle height (F-K) | Knuckle to shoulder height (K-S) | Shoulder to arm reach | |||

|---|---|---|---|---|---|---|

| Small | Large | Small | Large | Small | Large | |

| 1 lift/min | 1001.02 (86.74) | 1210.57 (93.77) | 875.26 (86.81) | 1166.57 (72.31) | 833.57 (72.64) | 1092.42 (84.69) |

| 4.3 lift/min | 904.07 (64.92) | 1097.08 (89.53) | 798.32 (58.87) | 1064.62 (73.04) | 788.40 (68.57) | 1004.41 (85.19) |

| 6.67 lift/min | 817.05 (52.71) | 1027.58 (104.96) | 761.97 (59.07) | 1002.09 (61.36) | 741.04 (69.83) | 934.24 (119.16) |

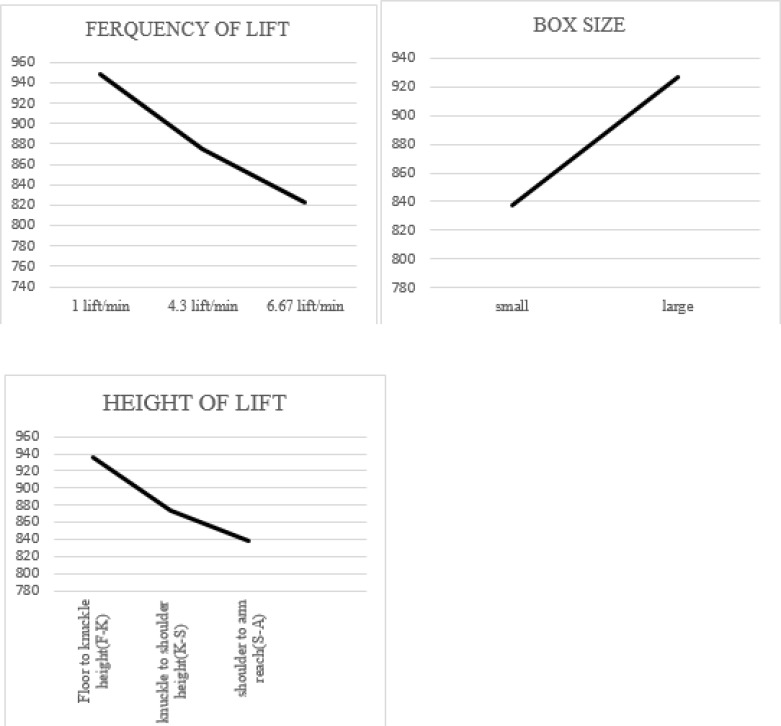

The results of the ANOVA showed that there was a significant difference between mean BCF in terms of frequencies of lifts (P=0.02). Turkey's post hoc test showed that the mean BCF did not show a significant difference between the frequencies of 1 lift/min and 4.3 lift/min (P>0.05); however, there was a statistically significant difference between the frequencies of 1 lift/min and 6.67 lift/min (P=0.01). There was no significant difference between the frequencies of 4.3 lift/min and 6.67 lift/min (P>0.05). As the frequency increased from 1 lift/min to 4.3 lift/min, the mean BCF declined by nearly 8.00%, from approximately 948.65 Ib to 875.74 Ib. A further decline of 6.20% from 875.74 Ib to 822.16 Ib was observed when the lifting frequency increased to 6.67 lift/min.

The results of ANOVA showed that there was no significant difference between mean BCF in terms of lifting heights (P>0.05). The results of t-test showed that there was a significant difference between mean BCF in terms of the sizes of the two boxes (P=0.001). When the box size increased from the small size to the large one, the mean BCF increased by approximately 10% from 837.47 Ib to 926.98 Ib.

The main effect of various lifting parameters for back compressive force is shown in Fig. 2.

Fig. 2:

Effect of main lifting parameters on back compressive force (BCF)

The results of Pearson correlation test showed that there was a significant relationship between the BCF and maximum acceptable weight of lift in all test conditions (P=0.001). Thus, with an increase in the maximum acceptable weight of lift, BCF also increased.

The mean BCF had no significant difference in terms of the combined variables of lifting frequency, lifting height, and the size of the box (P>0.05), except for the simultaneous effects of frequency of lifts and height of lifts (P=0.02).

Discussion

This study applied a HCBCF method to determine BCF. The purpose of this study was to estimate changes BCF when subjects determined maximum acceptable weight of lifts during a 20 min lifting of the loads. Lifting studies alternatively focus on L5/SI moments rather than L5/SI compressive forces. Chen, to estimate the peak BCF at level of the L5/S1 disc and reported that for the subjects with an average mass of 67 kg, a mean value of 3300±370 N was generated when lifting a 5-kg load, a mean value of 4490±520 N while lifting a 15-kg load, and a mean value of 5050±500 N while lifting a 20-kg load.

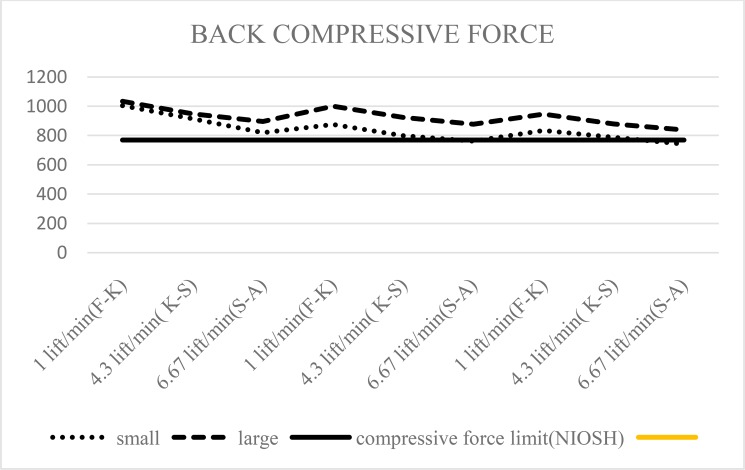

The mean of the BCF at L5/SI ranged from 3272 to 5877 N and average subject's mass of 67.5 kg, which is comparable as observed in Chen study (24). In this study, subjects significantly increased peak BCF at L5/S1 disc when they had to lift the heavy loads. This result supports previous studies (24, 25), where lifting the heavy loads led to significantly increase peak BCF at L5/S1 disc. Budihardjo et al. in a study conducted to assess the effects of magnitude and knowledge of loads on the L5/S1 compressive force during lifting the loads, showed that during lifting of light load whereas subject no knowledge of weight the load, subjects overestimated the load, and significantly the peak BCF at L5/S1 increased. Knowledge of the mass did not significantly change the peak BCF while lifting a heavy load (25). In addition, the results of this study were compared with the safety limit of BCF proposed by the NIOSH organization. The results showed that in all cases of lifting the big box the mean rate of BCF was higher than the safety limit. With reference to the small box, at a frequency of 6.67 lift/min at the heights of the K-S height and the S-A height mean rate BCF was lower than the safety limit while in other cases it was higher (Fig. 3).

Fig. 3:

compare mean of the back compressive force for all experimental conditions (small and large boxes) and for the compressive force limit (NIOSH)

In a study, the force on the back (back compressive force) was more than the admissible rate. However, as the result of correction of the angle of load lift, the estimated biomechanical force was set back in the permissible range (26). Compressive and shear forces exerted on the disc L5/S1, respectively, in 17.5% and 10.8% of the studied workers were higher than permissible rate (27).

This study was only conduced on students aged 20 to 30 yr, as they were easily available, therefore, it is recommended to conduct similar studies on workers with a wider age range, so that to achieve more accurate standards for the BCF and to reduce the risks of handling weights.

Conclusion

There was a significant difference between mean BCF in terms of frequencies of lifts and size of the boxes, but the difference was not significant in terms of lifting height. With increasing the maximum acceptable weight of lift, BCF also increased significantly. Besides, in 100% of cases of lifting the large box, BCF was larger than the safety limit while it 77.87% of cases it was true for the small box. BCF is affected by box size, lifting frequency and weight of load.

Ethical considerations

Ethical issues (Including plagiarism, informed consent, misconduct, data fabrication and/or falsification, double publication and/or submission, redundancy, etc.) have been completely observed by the authors.

Acknowledgments

This paper was extracted from a doctoral thesis on Occupational Health conducted in Tehran University of Medical Sciences. Hereby, we would like to thank Tehran University of Medical Sciences for their scientific helps and financial supports. The authors declare that there is no conflict of interest.

References

- 1.Gnaidy AM, Waly SM, Khalil TM, Hidalgo J. (1993). Spinal compression tolerance limits for the design of manual material handling operations in the workplace. Ergonomics, 36(4): 415–34. [DOI] [PubMed] [Google Scholar]

- 2.Industrial Accident Prevention Association (2008). A Health and Safety Guideline for Your Workplace for manual material handling, Toll-free: 1-800-406-IAPA (4272). Available from: www.iapa.ca

- 3.Ghaffari M, Alipour A, Farshad AA, Yensen I, Vingard E. (2006). Incidence and recurrence of disabling low back pain and neck-shoulder pain. Spine, 31(21):2500–6. [DOI] [PubMed] [Google Scholar]

- 4.Abdoli-Eramaki M, Stevenson JM, Reid SA, Bryant TJ. (2007). Mathematical and empirical proof of principle for an on-body personal lift augmentation device. J Biomech, 40(8): 1694–1700. [DOI] [PubMed] [Google Scholar]

- 5.Li JY, Wang S, He LH, Wu SS, Yang L, Yu SF, et al. (2012). Risk Factors of Low Back Pain among the Chinese Occupational Population: A Case-control Study. Biomed Environ Sci, 25(4): 421–9. [DOI] [PubMed] [Google Scholar]

- 6.Hoy D, Brooks P, Blyth F, Buchbinder R. (2010). The epidemiology of low back pain. Best Pract Res Clin Rheumatol, 24(6): 769–81. [DOI] [PubMed] [Google Scholar]

- 7.Mehrparvar AH, Ranjbar S, Mostaghaci M, Salehi M. (2011). Risk assessment of musculoskeletal disorders by QEC method in a food production factory. J Occup Med, 3(2): 54–60. [Google Scholar]

- 8.Klein BP, Jensen RC, Sanderson LM. (1984). Assessment of workers’ compensation claims for back sprain/strains. J Occup Med, 26(6): 443–448. [DOI] [PubMed] [Google Scholar]

- 9.Graham RB, Agnew MJ, Stevenson JM. (2009). Effectiveness of an on-body lifting aid at reducing low back physical demands during an automotive assembly task: Assessment of EMG response and user acceptability. Appl Ergon, 40(5): 936–942. [DOI] [PubMed] [Google Scholar]

- 10.Bush-Joseph C, Schipplein O, Andersson GB, Andriacchi TP. (1988). Influence of dynamic factors on the lumbar spine moment in lifting. Ergonomics, 31 (2): 211–216. [DOI] [PubMed] [Google Scholar]

- 11.Buseck M, Schipplein OD, Andersson GB, Andriacchi TP. (1988). Influence of dynamic factors and external loads on the moment at the lumbar spine in lifting. Spine, 13 (8): 918–921. [DOI] [PubMed] [Google Scholar]

- 12.Gracovetsky S. (1990). Musculoskeletal Function of the Spine. In: Multiple Muscle Systems. Ed, Winters JM, Woo SL. Springer-Verlag, New York, PP. 410–437. [Google Scholar]

- 13.Marras WS. (2005). The future of research in understanding and controlling work-related low back disorders. Ergonomics, 48(5): 464–77. [DOI] [PubMed] [Google Scholar]

- 14.Bloswick DS, Villnave T. (2000). Ergonomics. In: Patty’s Industrial Hygiene. Ed, Harris RL. New York, John Wiley and Sons, PP. 2531–2638. [Google Scholar]

- 15.Elfeituri FE, Taboun SM. (2002). An Evaluation of the NIOSH Lifting Equation: A Psychophysical and Biomechanical Investigation. Int J Occup Saf Ergon, 8(2): 243–258. [DOI] [PubMed] [Google Scholar]

- 16.Leskinen TP. (1985). Comparison of static and dynamic biomechanical models. Ergonomics, 28 (1): 285–291. [DOI] [PubMed] [Google Scholar]

- 17.Gary S., Nelson Henry Wickes, Jason T. (1981). NIOSH Work Practices Guide for Manual Lifting. N. DI-II-IS, Washington, DC: US Government Printin Officepublication no. 81-122; Available from: http://www.hazardcontrol.com/factsheets/pdfs/NIOSH-1981.pdf [Google Scholar]

- 18.Ciriello VM, Snook SH. (1983). A study of size distance height, and frequency effects on manual handling tasks. Hum Factors, 25 (5): 473–83. [DOI] [PubMed] [Google Scholar]

- 19.Ciriello VM, Snook SH, Hashemi L, Cotnam J. (1999). Distributions of manual materials handling task parameters. Int J Ind Ergon, 24(4): 379–88. [Google Scholar]

- 20.Karwowski W, Yates JW. (1986). Reliability of the Psychophysical Approach to Manual Lifting of Licjuids by Females. Ergonomics, 29(2): 237–248. [DOI] [PubMed] [Google Scholar]

- 21.Snook SH, Vaillancourt DR, Ciriello VM, Webster BS. (1995). Psychophysical studies of repetitive wrist fexion and extension. Ergonomics, 38(7): 1488–507. [DOI] [PubMed] [Google Scholar]

- 22.Snook SH, Ciriello VM. (1991). The design of manual tasks: revised tables of maximum acceptable weights and forces. Ergonomics, 34(9): 1197–213. [DOI] [PubMed] [Google Scholar]

- 23.Ciriello VM, Snook SH, Hughes GJ. (1993). Further studies of psychophysically determined maximum acceptable weights and forces. Hum Factors, 35 (1): 175–186. [DOI] [PubMed] [Google Scholar]

- 24.Chen YL. (2000). Changes in lifting dynamics after localized arm fatigue. Int J Ind Ergon, 25: 611–619. [Google Scholar]

- 25.Budihardjo Iwan. Studies of compressive forces on L5/S1 during dynamic manual lifting [PhD thesis]. School of Industrial Engineering, Iowa State University, United States; 2002. [Google Scholar]

- 26.Panjali Z, Mazloumi A, Ahsani H, Rezaee E. (2014). Evaluation of the risks factors for manual material handling in a metal casting industry in Iran. Iran Occupational Health, 11(1):13–22. [Google Scholar]

- 27.Asadi N, Choobineh A, Keshavarzi S, Daneshmandi H. (2015). Estimation of forces exerted on the lower back in manual load lifting using 3DSSPP software. J Ergon, 2015, 2(4):25–31. [Google Scholar]