SUMMARY

Object

The aim of this paper is to present a clinical case in which the CAD-CAM procedure was applied for a prosthetic rehabilitation on implants.

Materials

Digital CAD-CAM production by laboratory of the final restoration.

Results

CAD-CAM production offers the opportunity to easily collaborate with laboratory. This prosthetic production gives better and demonstrated clinical results for the patient.

Conclusion

CAD-CAM production is a very important instrument for prosthetic team. This work-flow compared with traditional methods is faster, precise and predictable.

Keywords: implant, CSD-CAM, complete rehabilitation

Introduction

The CAD-CAM technology is a computerized technique that allows to obtain a three-dimensional object from a vector drawing performed on the computer. Both CAD and CAM are acronyms, respectively, for Computer Aided Design and Computer Aided Manufacturing. Born in the 60s of last century, this technology is now used in industry for the production of an infinite number of objects also in the dental field. In the 80s the first systems in the dental industry, Cerec and Procera, have been commercialized.

The evolution of techniques and of implant components is making the implant-prosthetic rehabilitation increasingly complete and reliable. The increased demands of rehabilitation can be processed more serenely by operators in the industry. In this regard a valuable aid for the prosthodontist comes from a rapidly expanding sector which is that of the CAD-CAM applications in dentistry.

The aim of this paper is to present a clinical case in which the CAD-CAM procedure was applied for a prosthetic rehabilitation on implants.

Case report

A 60-year-old female patient in good general health (ASA 1) presents itself to observation with residual elements borne arch upper and lower jaws suffering from advanced periodontal disease, and old prosthetic rehabilitation in both arches (1) (Figure 1).

Figure 1.

Pre-operative case. Vestibular view.

After a careful evaluation of the case and the execution of diagnostic radiographic examinations (OPT, Dentascan) (Figure 2) we decide for total implant prosthetic rehabilitation of the upper jaw and partial of the lower (2). Brånemark fixture in the upper maxilla (3) and Bonefit - ITI in the lower, followed by the relative prosthetic rehabilitation (4, 5). The patient also needed to use a temporary prosthesis throughout the treatment period for professional reasons (6, 7).

Figure 2.

Pre-operative Rx O.P.T.

By means of computed tomography, we evaluated the amount of bone remaining after the extraction of the compromises elements and we have planned two surgical templates (Figure 3) in order to mark implant sites, in excess and in areas with sufficient bone quantity and suitable for prosthetic rehabilitation choice for the patient.

Figure 3.

Surgical guides. Upper and lower.

After recording the vertical dimension of occlusion (DVO) and mounting in articulator by means of face bow and its calibration, two mobile prostheses have been prepared, a total for the upper arch and a partial for the lower arch (8). These prostheses in order to recover the masticatory function and aesthetics after the extractions, and throughout the healing period after the implant surgery.

Two temporary dentures, after extractions and implant surgery in both arches, have been adapted and rebased with HydroCast® Tissue Treatment (9) (a soft acrylic resin clinically proven to stay soft and functionally flexible for weeks) throughout the healing period and after the placement of the healing screws (3 months) (Figure 4) (10, 11).

Figure 4.

Upper and lower maxilla after implant surgery. Implants with healing screws.

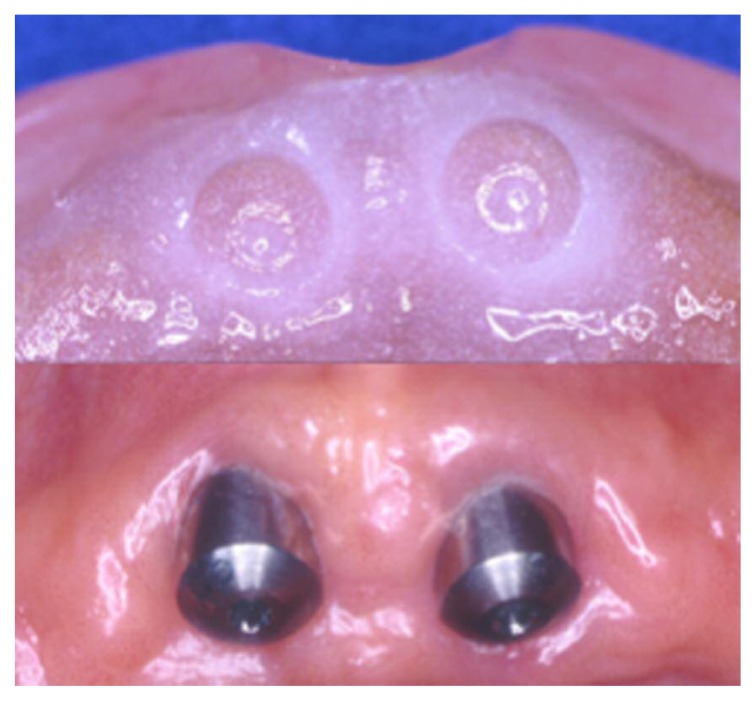

The peri-implant tissue management has been entrusted only to the conditioning of the healing abutment associated to HydroCast® (Figure 5). After three months the healing screws were removed, have been verified transmucosal tissues and two final polyether impressions have been taken through conventional impression methods (Figures 6, 7).

Figure 5.

The peri-implant tissue management has been entrusted only to the conditioning of the healing abutment associated to HydroCast®.

Figure 6.

Upper maxilla impression.

Figure 7.

Lower maxilla impression.

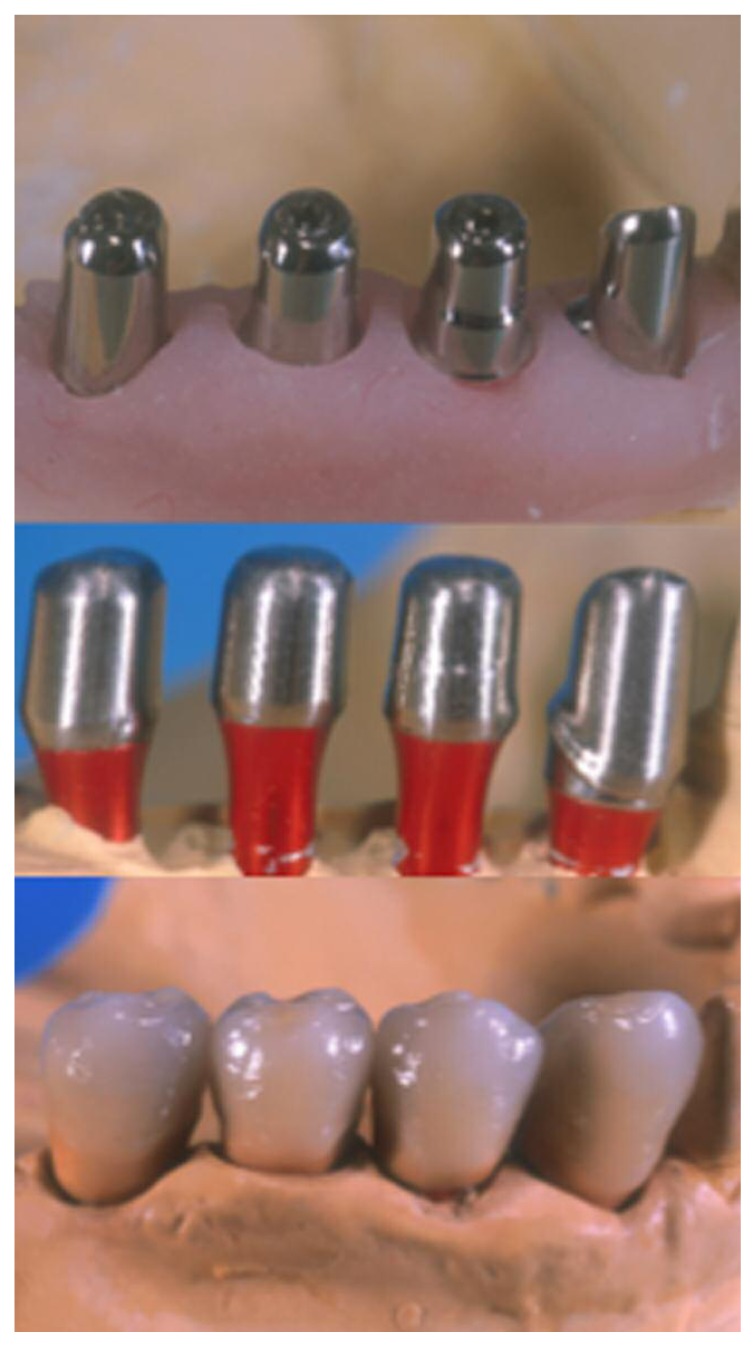

The laboratory after the development of master models, of the wax models and of the wax abutments, has scanned the mesostructures with systematic PROCERA (Phase CAD) (12–14). The thus obtained data are processed are sent to a milling machine connected to the network that develops the final abutments by means of the milling of a titanium cylinder (15mm × 15mm) (Step CAM) (15). The laboratory produces the abutments and a resin guide for the correct oral positioning in the studio, and to check the frameworks before ceramization (Figure 8) (16–18). The abutments are verified by the clinician in the oral cavity with resin guide (Figure 9). Then frameworks are waxed on the mesostructures and so scanned and milled following the same procedure of the abutments (19–21).

Figure 8.

The upper abutment produced with CAD-CAM systematic PROCERA.

Figure 9.

The abutments are verified by the clinician in the oral cavity with resin guide.

After verification of the superstructures in the oral cavity is performed their ceramization according to traditional technique (Figures 10, 11). Finally, before delivery, a final test is performed to verify the correct vertical dimension and eccentric movements (Figures 12, 13, 14).

Figure 10.

After checking frameworks in the oral cavity is performed their ceramization according to traditional technique.

Figure 11.

Implant prosthetic rehabilitation in lower maxilla. CAD-CAM production step by step.

Figure 12.

The implant prosthetic rehabilitation in oral cavity.

Figure 13.

Final Rx O.P.T.

Figure 14.

The implant prosthetic rehabilitation and its integration with perioral tissues and smile.

Results and conclusions

The evidence of our clinical practice suggests that CAD-CAM applications in dentistry offer a valuable aid for the prosthodontist, these techniques give the opportunity to easily collaborate with laboratory, and their prosthetic production gives better clinical results for the patient. CAD-CAM production is a very important instrument for prosthetic team. NobelProcera has set new standards with cutting edge scanner and software. With optical scanning methods, and ground-breaking intuitive 3D design software version expands the capabilities of dental clinicians and labs for producing individualized prosthetics with excellent precision of fit, production accuracy <10 μm and internal fit < 40 μm (Nobel Biocare internal measurements. Data on file). Simultaneously, these new tools increase efficiency and reduce in-house costs. This work-flow compared with traditional methods has shown many positive aspects that make easier, faster, less expensive and predictable the prosthetic workflow. However improvements in materials and technologies are needed in order to improve and perfect the systematic.

Footnotes

Conflict of interest

The Authors declare no conflict of interest.

References

- 1.Clementini M, Ottria L, Pandolfi C, Bollero P. A Novel Technique to Close Large Perforation of Sinus Membrane. ORAL and Implantology. 2013;6(1):11–14. [PMC free article] [PubMed] [Google Scholar]

- 2.Leung CK, Pow EH, Li TK, Lo EC, Chow TW. Accuracy of radiographic measurements for implant planning using cone-beam and helical computer tomography. J Investig Clin Dent. 2016 Jul 31; doi: 10.1111/jicd.12232. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 3.Diamanti MV, Del Curto B, Barlattani A, Bollero P, Ottria L, Pedeferri M. Mechanical characterization of an innovative dental implant system. Journal of Applied Biomaterials and Biomechanics. 2009;7(1):23–28. [PubMed] [Google Scholar]

- 4.Tatullo M, Marrelli M, Falisi G, Rastelli C, Palmieri F, Gargari M, Zavan B, Paduano F, Benagiano V. Mechanical influence of tissue culture plates and extra-cellular matrix on mesenchymal stem cell behavior: A topical review. International Journal of Immuno pathology and Pharmacology. 2016;29(1):3–8. doi: 10.1177/0394632015617951. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Baggi L, Di Girolamo M, Mirisola C, Calcaterra R. Microbiological evaluation of bacterial and mycotic seal in implant systems with different implant-abutment interfaces and closing torque values. Implant Dent. 2013;22(4):344–50. doi: 10.1097/ID.0b013e3182943062. [DOI] [PubMed] [Google Scholar]

- 6.Spinelli D, Ottria L, De Vico GD, Bollero R, Barlattani A, Jr, Bollero P. Full rehabilitation with nobel clinician ® and procera implant bridge®: Case report. ORAL and Implantology. 2013;6(2):25–36. [PMC free article] [PubMed] [Google Scholar]

- 7.Meleo D, Baggi L, Di Girolamo M, Di Carlo F, Pecci R, Bedini R. Fixture-abutment connection surface and micro-gap measurements by 3D micro-tomographic technique analysis. Ann Ist Super Sanità. 2012;48(1):53–8. doi: 10.4415/ANN_12_01_09. [DOI] [PubMed] [Google Scholar]

- 8.Stamoulis K, Hatzikyriakos AE. A technique to obtain stable centric occlusion records using impression plaster. J Prosthodont. 2007;16(5):406–8. doi: 10.1111/j.1532-849X.2007.00215.x. Epub 2007 Jun 9. [DOI] [PubMed] [Google Scholar]

- 9.Murata H, Kawamura M, Hamada T, Saleh S, Kresnoadi U, Toki K. Dimensional stability and weight changes of tissue conditioners. J Oral Rehabil. 2001;28(10):918–23. doi: 10.1046/j.1365-2842.2001.00736.x. [DOI] [PubMed] [Google Scholar]

- 10.Marrelli M, Falisi G, Apicella A, Apicella D, Amantea M, Cielo A, Bonanome L, Palmieri F, Santacroce L, Giannini S, Di Fabrizio E, Rastelli C, Gargari M, Cuda G, Paduano F, Tatullo M. Behaviour of dental pulp stem cells on different types of innovative mesoporous and nanoporous silicon scaffolds with different functionalizations of the surfaces. Journal of biological regulators and homeostatic agents. 2015;29(4):991–997. [PubMed] [Google Scholar]

- 11.Gargari M, Prete V, Pujia M, Ceruso FM. Development of patient-based questionnaire about aesthetic and functional differences between overdentures implant-supported and overdentures tooth-supported. Study of 43 patients with a follow up of 1 year. ORAL and Implantology. 2012;5(4):86–91. [PMC free article] [PubMed] [Google Scholar]

- 12.de Morais Alves da Cunha T, de Araújo RP, da Rocha PV, Amoedo RM. Comparison of fit accuracy between Procera® custom abutments and three implant systems. Clin Implant Dent Relat Res. 2012;14(6):890–5. doi: 10.1111/j.1708-8208.2010.00323.x. Epub 2010 Dec 22. [DOI] [PubMed] [Google Scholar]

- 13.Scherg S, Karl M. Screw Joint Stability in Conventional and Abutment-Free Implant-Supported Fixed Restorations. Int J Prosthodont. 2016;29(2):142–6. doi: 10.11607/ijp.4458. [DOI] [PubMed] [Google Scholar]

- 14.Winter W, Karl M. Screw loading and gap formation in implant supported fixed restorations: Procera implant bridge vs. conventionally cast screw-retained restorations. Quintessence Int. 2013;44(3):263–6. doi: 10.3290/j.qi.a29051. [DOI] [PubMed] [Google Scholar]

- 15.Souza RO, Özcan M, Pavanelli CA, Buso L, Lombardo GH, Michida SM, Mesquita AM, Bottino MA. Marginal and internal discrepancies related to margin design of ceramic crowns fabricated by a CAD/CAM system. J Prosthodont. 2012;21(2):94–100. doi: 10.1111/j.1532-849X.2011.00793.x. Epub 2011 Nov 2. [DOI] [PubMed] [Google Scholar]

- 16.Ottria L, Zavattini A, Ceruso FM, Gargari M. Maxillofacial prosthesis (P.M.F): In a case of oral-nasal communication post-surgery and post-radiotherapy. ORAL and Implantology. 2014;7(2):46–50. [PMC free article] [PubMed] [Google Scholar]

- 17.Cho SY, Huh YH, Park CJ, Cho LR. Three-Dimensional Finite Element Analysis of the Stress Distribution at the Internal Implant-Abutment Connection. Int J Periodontics Restorative Dent. 2016;36(3):e49–58. doi: 10.11607/prd.2351. [DOI] [PubMed] [Google Scholar]

- 18.Peñarrocha-Oltra D, Rossetti PH, Covani U, Galluccio F, Canullo L. Microbial Leakage at the Implant-Abutment Connection Due to Implant Insertion Maneuvers: Cross-Sectional Study 5 Years Postloading in Healthy Patients. J Oral Implantol. 2015;41(6):e292–6. doi: 10.1563/aaid-joi-D-14-00235. Epub 2014 Dec 23. [DOI] [PubMed] [Google Scholar]

- 19.Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001;85(3):268–75. doi: 10.1067/mpr.2001.114266. [DOI] [PubMed] [Google Scholar]

- 20.Abdel-Azim T, Zandinejad A, Elathamna E, Lin W, Morton D. The influence of digital fabrication options on the accuracy of dental implant-based single units and complete-arch frameworks. Int J Oral Maxillofac Implants. 2014;29(6):1281–8. doi: 10.11607/jomi.3577. Epub 2014 Sep 26. [DOI] [PubMed] [Google Scholar]

- 21.Gargari M, Ottria L, Morelli V, Benli M, Ceruso FM. Conservative zirconia-ceramic bridge in front teeth. Case report. ORAL and Implantology. 2015;7(4):93–98. [Google Scholar]