Abstract

The direct grafting of poly(N-isopropylacrylamide) to the basal plane of graphene oxide has been achieved in a single step: cleavage of the terminal thiocarbonylthio group on RAFT grown poly(N-isopropylacrylamide) reveals a reactive thiol that attacks the epoxides present across the surface of graphene oxide. The new composite material was characterised by a combination of SSNMR, FTIR, Raman, EDX, XPS, TGA and contact angle measurement; it shows enhanced thermal stability and solubility in water.

Introduction

There is currently much interest in exploiting graphene1 for a variety of applications given its many superlative physical properties: it is exceptionally electrically2 and thermally3 conductive, transparent,4 elastic,5 highly impermeable,6 extremely strong5b and yet is the thinnest6a 2D material ever obtained. However, rather than using pure graphene, which is only available in small quantities via mechanical exfoliation or chemical vapour deposition (CVD) growth, graphene oxide (GO) has become the graphene-like material of choice. Though not as strong or as conductive as graphene, GO is arguably more commercially applicable owing to its cheaper synthesis and potential for routine, large-scale production; it can be manipulated chemically7 and it is possible to reduce graphene oxide back to a more graphene-like material by thermal8 or chemical9 means. Moreover, the versatility of GO may be extended by combination with other species as part of a composite material. Considering this, polymers provide an obvious partner given the plethora of interesting properties (solubility, switchable characteristics, stimuli responsiveness,10 or impacting ‘stealth’ properties for in vivo application11) they can possess and which have been applied to controlling the interfacial properties of nanoparticles. Most previous attempts at combining GO with polymers have focussed on a simple mixing procedure,12 though this approach can be hampered by phase separation and aggregation issues.

An alternative approach is to covalently functionalise a graphene-like structure with polymer chains following a traditional “grafting-from” or “grafting-to” like methodology13 as has been used for the functionalization of solid substrates and particles. Controlled-radical polymerisation technologies now enable the routine formation of materials with increasing levels of control over the molecular weights and structures.14 However, to apply the likes of Nitroxide-Mediated Polymerisation (NMP),15 copper-mediated polymerisations16 or Reversible Addition–Fragmentation Chain Transfer (RAFT)17 polymerisation using the grafting-from approach would require the functionalisation of the GO sheet with initiating or chain-transfer type species, which prevents characterization of the polymer chains and introduces batch-batch variability. A simpler alternative, which we demonstrate in this work, is therefore to covalently add pre-formed polymer chains of controlled sizes to the GO surface. Previous approaches to this grafting-to methodology have relied on multi-step synthetic routes that typically target the carboxyl groups found at the edges of the GO flakes.18

Recently, we have demonstrated a way of functionalising GO with thiol functional groups. This was achieved by ring-opening the epoxides present on the surface of GO with nucleophilic thioacetate anions followed by a simple hydrolysis procedure.19 Here, we extend this concept to directly attach a thiol-terminated polymer to GO in one reaction step. This is achieved by exploiting the thiocarbonylthio moiety at the ω-terminus of a RAFT-derived polymer chain which can be readily converted to a thiol group upon the addition of a nucleophile such as a primary amine. We demonstrate not only the successful attachment of polymer chains to a GO surface in this fashion, but also its value as a tool with which to significantly change the properties of the system.

Results and discussion

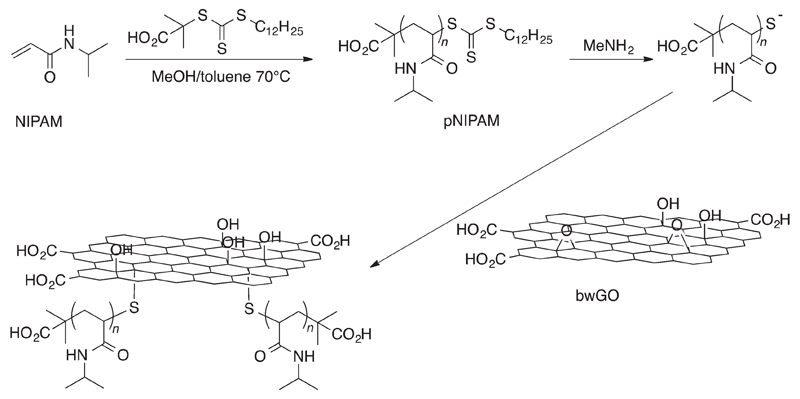

A series of well-defined water-soluble poly(N-isopropylacrylamide), pNIPAM, polymers with differing chain lengths (i.e. 30, 200 and 440 repeat units) was prepared using the RAFT methodology, giving a thiocarbonylthio moiety at the ω-chain-end (Scheme 1 and ESI, Table S1†). Each polymer was then treated with methyl amine to cleave the thiocarbonylthio group and added directly to a suspension of base-washed GO (bwGO) – used here to avoid any issues relating to reactions with oxidative debris.20 The resulting thiol-terminated polymer chains reacted in situ with the bwGO via an epoxide ring-opening reaction, which can proceed by both direct attack at the epoxide (an SN2 reaction) or by an attack on the double bond adjacent to the epoxide (an SN2′ reaction) to produce final products with polymer chains grafted randomly across both faces of the graphene-like sheet (Scheme 1).

Scheme 1.

Synthetic route used to the GO-pNIPAMn samples.

For each polymer sample, a single graphene containing material, free of unbound polymer was isolated following extensive washing with a variety of solvents. Five spectroscopic techniques (ssNMR, FTIR, EDX, XPS and Raman) were then used to confirm the presence of the polymer chains on the bwGO, whilst TGA and WCA measurements indicated changes in property following the chemical modification.

Sample characterisation

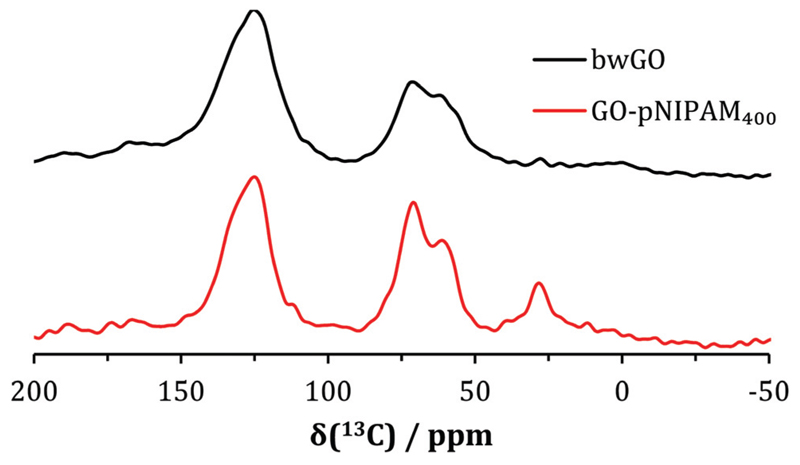

The solid-state 13C NMR spectra of the polymer/GO hybrids clearly show the expected peaks for the GO (broad peak at around 126 ppm for the sp2 areas of the GO sheets and the epoxide and hydroxide functionlised carbons at 61 and 72 ppm, respectively) and for those of the polymer side groups (sp3 aliphatic carbons at 30 and 35 ppm and the amide carbon at around 172 ppm) and the main polymer chain (shoulder at 40 ppm). Fig. 1 shows the spectrum for the GO-pNIPAM440 material, but other samples showed similar spectra. Alongside the new peaks in the spectrum, there is a decrease in the intensity of the epoxide carbon in the GO, consistent with reaction taking place at this site. An approximate integral shows that the total area represented by the polymer peaks corresponds to around 20% of the total signal area.

Fig. 1.

The direct excitation 13C MAS ssNMR spectra of bwGO and GO-pNIPAM440.

FTIR spectra of the polymer-functionalised GO (Fig. ESI.2†) reveal peaks at 2880 and 2900 cm−1 due to C–H stretches from the alkyl component of the polymer, and a reduction in the intensity of peaks from epoxy groups at 1240 cm−1.21 The expected C=O stretch of an amide to falls between 1630 and 1670 cm−1, but in practice it cannot be distinguished from the overlapping carboxyl C=O and C=C bands found in GO itself.

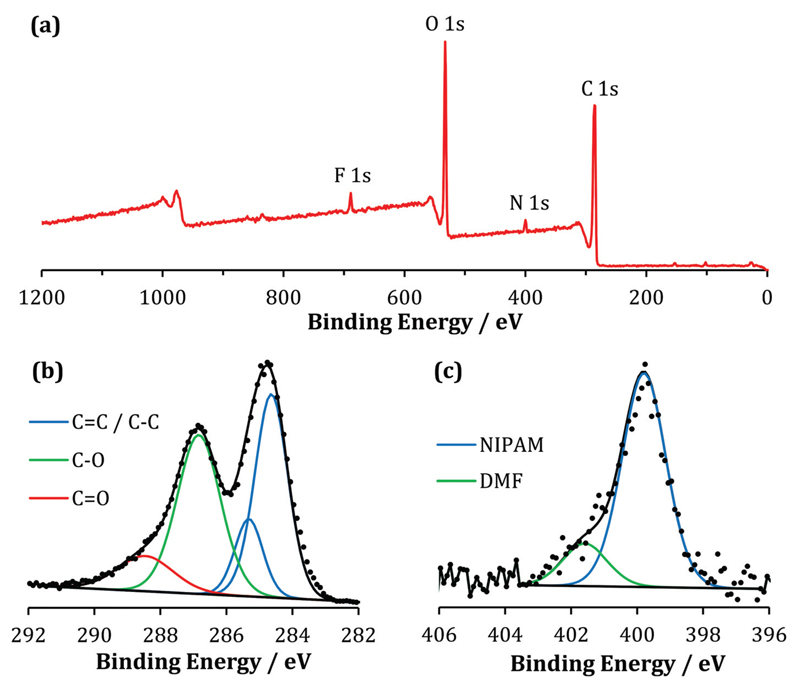

EDX (ESI Table 2†) shows nitrogen incorporation (approximately 2.7 ± 0.4 atomic% for GO-pNIPAM440) consistent with amide functionalities being introduced, but cannot be used to distinguish the chemical environments of the nitrogen. XPS measurements give a similar level of N incorporation (2.9 ± 0.4 atomic% nitrogen) and Fig. 2a shows the survey scan of GO-pNIPAM440 which gives the incorporation level. The XPS core level spectra were used to determine the chemical environment of the both the carbon and the nitrogen. The C 1s core level spectrum (Fig. 2b) shows the environments expected for a GO-based material with little apparent change upon polymer incorporation. However, since the polymer chain consists of a simple alkyl chain with amide functionality, it is not possible to identify peaks from the alkyl chain, as they will be obscured by the C–C bonded carbons in GO; likewise the amide carbons, which are expected to have a binding energy of 287.9–288.3 eV,22 will be obscured by the C–O (hydroxy and epoxy) and C=O (keto, carboxy) peaks of GO itself. The N 1s core level spectrum (Fig. 2c) is much more illuminating and shows nitrogen in two different chemical environments. The principal contribution has a measured binding energy of 400 eV, consistent with amide functionalities;22 by area, this peak corresponds to 80% of the nitrogen present in GO-pNIPAM440. The smaller peak at 401.5 eV can be assigned to residual DMF solvent in this particular sample.

Fig. 2.

XPS analysis of GO-NIPAM400, complete with survey scan (a), and core level spectra C 1s (b) and N 1s (c). The experimental data is shown as points with the underlying lines showing the fitted peaks (assignments as labelled).

The Raman spectrum of the GO-pNIPAM samples (Fig. SI.6†) is as expected; showing strong D, G and G′ bands, consistent with a disordered monolayer structure. The D/G ratio is calculated to be 1.3, indicating that the addition of the polymer chain has caused no significant change (e.g. reduction) to the sheet structure of GO.

Using our elemental analysis data, it is possible to approximate the relative grafting density for each of the different polymers. Increasing the chain length from pNIPAM30 to pNIPAM200 gave a increase in nitrogen from 1.3 to 2.9%, consistent with a doubling of the mass of polymer being in-corporated. However, this must be normalised by the relative length of the polymer chains, and therefore actually corresponds to a 3 fold decrease in grafting density (Table 2 ESI†). This is consistent with observations on flat surfaces (and RAFTed polymers onto gold particles) as the increased steric crowding of longer polymers lower the grafting density, even though more ‘mass’ is absorbed.23 pNIPAM440 had a similar nitrogen level to pNIPAM200, indicating another corresponding decrease in grafting density. A more detailed analysis of the EDX data showed that there was approximately 1 polymer chain per 1100 carbon atoms for pNIPAM30 (roughly equal to 1 chain per 150 nm2, which is a circle with radius 6.9 nm). As polymers can normally graft at densities up to 2 × Rg (radius of gyration), we can conclude that for small polymers, the grafting density was limited by the availability of the reactive sites (as we would expect an Rg < 1 nm), but as the chain length increases, sterics dominate as the longer polymers would be expected to have a radius of gyration >5 nm.24 Thus the composition (and any subsequent applications) of these nano-composites must take into account the balance between the grafted chain length and the achieved grafting densities. Any polymer derived from RAFT/Xanthate polymerization will have this terminal thiol group making this a versatile approach. However, it must be noted that issues such as steric hindrance from both the monomer class (acrylamide verses methacrylamide) and the monomer side chains will play a role in the final grafting efficiency, as would monomers with competing nucleophiles (e.g. thiols). Such considerations have previously been reviewed in detail in the context of RAFT end-group modification.13a,25

Properties

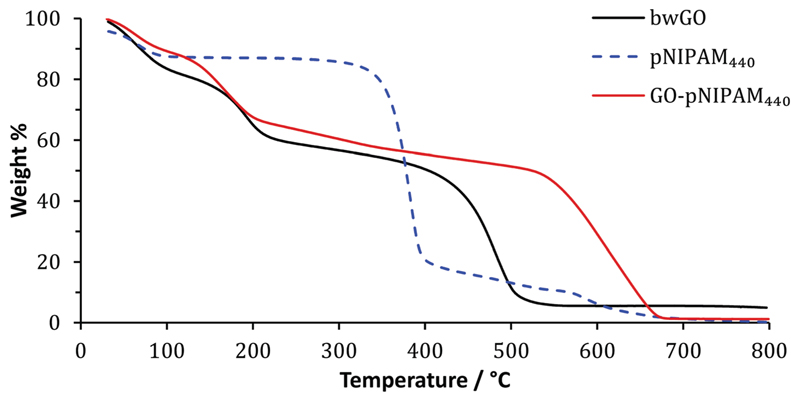

The new hybrid material has properties that reflect its composition: TGA measurements show a major decomposition temperature of the new material, at 550–600 °C, higher than that of both the isolated polymer, which decomposes sharply at around 380 °C (Fig. 3), and of that of the bwGO which loses the majority of its mass at around 460 °C. The decomposition temperature of the new material is comparable with that of other functionalised GO samples, where we see a stabilisation of the GO sheets which is attributable to the capping of the reactive surface functionalities which are believed to be the sites of initial decomposition.8,21,26

Fig. 3.

TGA profile of bwGO, pNIPAM440 and GO-pNIPAM440.

This increase in thermal stability does not come at the cost of reduced solubility. Indeed, the GO–polymer composites show smaller contact angles (34°) than bwGO, suggesting an increase in hydrophilicity due to the hydrophilicity of the polymer chains (Fig. ESI.13†), and it could be dispersed in water. pNIPAM has a strong concentration (and co-operative) dependence on its LCST27 (cloud point) but the grafting densities employed here are low enough to prevent this transition at the temperatures employed, thus rendering this essentially a permanently hydrophilic polymer.

Conclusions

Here we have demonstrated a simple ‘grafting-to’ methodology and obtained graphene oxide/polymer hybrid materials. RAFT polymerization was used to generate well-defined polymers with a masked thiol at the chain end, and this was then exploited to conjugate the polymers directly to graphene oxide via the epoxide groups that are present across the entire basal plane. As all RAFT-derived polymers have this masked thiol present, this demonstrates a versatile, yet facile, route to polymer/GO composites. Here, hydrophilic poly(N-isopropyl acrylamide) was grafted onto the GO to give water-dispersible composites, but the methodology could equally well be used to graft hydrophobic polystyrene or bioactive polymers such as glycopolymers to the surface. Grafting was confirmed by high resolution TEM, XPS, TGA and solid state NMR. These revealed that, for shorter polymers, the grafting density was limited by the number of reactive sites, but for longer polymers by steric hindrance. This new and accessible synthetic route is highly scalable, using GO in place of graphene and a 1-step conjugation method and offers opportunities to precisely control the interfacial properties of GO in a wide range of applications.

Supplementary Material

†Electronic supplementary information (ESI) available: Experimental data. See DOI: 10.1039/c5py01358e

Acknowledgements

We thank EPSRC for a studentship award to HRT and the University of Warwick for a Scholarship to DJP. The TGA, XPS and some of the TEM equipment used in this research were purchased with support from Advantage West Midlands (part funded by the European Regional Development Fund). We thank Marc Walker for assistance with XPS measurements. Solid-state NMR spectra were obtained at the EPSRC UK National Solid-state NMR Service at Durham. MIG acknowledges the European Research Council for a Starter Grant (638661 CRYOMAT).

References

- 1.Novoselov KS. Angew Chem, Int Ed. 2011;50:6986–7002. doi: 10.1002/anie.201101502. [DOI] [PubMed] [Google Scholar]

- 2.Meric I, Han MY, Young AF, Ozyilmaz B, Kim P, Shepard KL. Nat Nanotechnol. 2008;3:654–659. doi: 10.1038/nnano.2008.268. [DOI] [PubMed] [Google Scholar]

- 3.Ghosh S, Nika DL, Pokatilov EP, Balandin AA. New J Phys. 2009;11 [Google Scholar]

- 4.Loh KP, Bao Q, Eda G, Chhowalla M. Nat Chem. 2010;2:1015–1024. doi: 10.1038/nchem.907. [DOI] [PubMed] [Google Scholar]

- 5.(a) Sakhaee-Pour A. Solid State Commun. 2009;149:91–95. [Google Scholar]; (b) Lee C, Wei XD, Kysar JW, Hone J. Science. 2008;321:385–388. doi: 10.1126/science.1157996. [DOI] [PubMed] [Google Scholar]

- 6.(a) Berry V. Carbon. 2013;62:1–10. [Google Scholar]; (b) Bunch JS, Verbridge SS, Alden JS, van der Zande AM, Parpia JM, Craighead HG, McEuen PL. Nano Lett. 2008;8:2458–2462. doi: 10.1021/nl801457b. [DOI] [PubMed] [Google Scholar]

- 7.Dreyer DR, Todd AD, Bielawski CW. Chem Soc Rev. 2014;43:5288–5301. doi: 10.1039/c4cs00060a. [DOI] [PubMed] [Google Scholar]

- 8.Larciprete R, Fabris S, Sun T, Lacovig P, Baraldi A, Lizzit S. J Am Chem Soc. 2011;133:17315–17321. doi: 10.1021/ja205168x. [DOI] [PubMed] [Google Scholar]

- 9.Cui P, Lee J, Hwang E, Lee H. Chem Commun. 2011;47:12370–12372. doi: 10.1039/c1cc15569e. [DOI] [PubMed] [Google Scholar]

- 10.Phillips DJ, Gibson MI. Polym Chem. 2015;6:1033–1043. doi: 10.1039/C5PY01358E. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Pasut G, Veronese FM. Prog Polym Sci. 2007;32:933–961. [Google Scholar]

- 12.Vallés C, Kinloch IA, Young RJ, Wilson NR, Rourke JP. Compos Sci Technol. 2013;88:158–164. [Google Scholar]

- 13.(a) Barbey R, Lavanant L, Paripovic D, Schüwer N, Sugnaux C, Tugulu S, Klok H-A. Chem Rev. 2009;109:5437–5527. doi: 10.1021/cr900045a. [DOI] [PubMed] [Google Scholar]; (b) Salavagione HJ, Martinez G, Ellis G. Macromol Rapid Commun. 2011;32:1771–1789. doi: 10.1002/marc.201100527. [DOI] [PubMed] [Google Scholar]

- 14.Matyjaszewski K, Spanswick J. Mater Today. 2005;8:26–33. [Google Scholar]

- 15.Hawker CJ, Bosman AW, Harth E. Chem Rev. 2001;101:3661–3668. doi: 10.1021/cr990119u. [DOI] [PubMed] [Google Scholar]

- 16.Matyjaszewski K. Macromolecules. 2012;45:4015–4039. [Google Scholar]

- 17.Moad G, Rizzardo E, Thang SH. Aust J Chem. 2009;62:1402–1472. [Google Scholar]

- 18.(a) Tan Y, Fang L, Xiao J, Song Y, Zheng Q. Polym Chem. 2013;4:2939–2944. [Google Scholar]; (b) Cao Y, Lai Z, Feng J, Wu P. J Mater Chem. 2011;21:9271–9278. [Google Scholar]

- 19.Thomas HR, Marsden AJ, Walker M, Wilson NR, Rourke JP. Angew Chem, Int Ed. 2014;53:7613–7618. doi: 10.1002/anie.201404002. [DOI] [PubMed] [Google Scholar]

- 20.(a) Rourke JP, Pandey PA, Moore JJ, Bates M, Kinloch IA, Young RJ, Wilson NR. Angew Chem, Int Ed. 2011;50:3173–3177. doi: 10.1002/anie.201007520. [DOI] [PubMed] [Google Scholar]; (b) Thomas HR, Day SP, Woodruff WE, Vallés C, Young RJ, Kinloch IA, Morley GW, Hanna JV, Wilson NR, Rourke JP. Chem Mater. 2013;25:3580–3588. [Google Scholar]

- 21.Bagri A, Mattevi C, Acik M, Chabal YJ, Chhowalla M, Shenoy VB. Nat Chem. 2010;2:581–587. doi: 10.1038/nchem.686. [DOI] [PubMed] [Google Scholar]

- 22.Jagst E. Surface Functional Group Characterization Using Chemical Derivatization X-ray Photoelectron Spectroscopy (CD-XPS) BAM; 2010. [Google Scholar]

- 23.Gibson MI, Paripovic D, Klok HA. Adv Mater. 2010;22:4721–4725. doi: 10.1002/adma.201001382. [DOI] [PubMed] [Google Scholar]

- 24.Hiemenz PC, Lodge TP. Polymer Chemistry. 2nd edn. CRC Press; 2007. [Google Scholar]

- 25.Willcock H, O’Reilly RK. Polym Chem. 2010;1:149–157. [Google Scholar]

- 26.Gao W, Alemany LB, Ci LJ, Ajayan PM. Nat Chem. 2009;1:403–408. doi: 10.1038/nchem.281. [DOI] [PubMed] [Google Scholar]

- 27.Phillips DJ, Gibson MI. Chem Commun. 2012;48:1054–1056. doi: 10.1039/c1cc16323j. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.