Abstract

Controlling float coal dust in underground coal mines before dispersal into the general airstream can reduce the risk of mine explosions while potentially achieving a more effective and efficient use of rock dust. A prototype flooded-bed scrubber was evaluated for float coal dust control in the return of a continuous miner section. The scrubber was installed inline between the face ventilation tubing and an exhausting auxiliary fan. Airborne and deposited dust mass measurements were collected over three days at set distances from the fan exhaust to assess changes in float coal dust levels in the return due to operation of the scrubber. Mass-based measurements were collected on a per-cut basis and normalized on the basis of per ton mined by the continuous miner. The results show that average float coal dust levels measured under baseline conditions were reduced by more than 90 percent when operating the scrubber.

Introduction

Airborne coal dust is a byproduct of coal production, and engineering controls exist to deal with both the respirable dust health hazard as well as the float dust explosion safety hazard. Float coal dust, smaller than 75 µm (0.003 in.) in size, can deposit throughout mine entries and propagate explosions that had been initially fueled by methane gas. The inertization of float coal dust with rock dust helps prevent a potential secondary float coal dust explosion, but a preferable course of action is to significantly reduce the hazard by removing float coal dust from the airstream before it has the opportunity to deposit on the mine’s surfaces.

Since 1970, disasters due to explosions in underground coal mines have caused 201 deaths in the U.S. mining industry, including 29 deaths in a single mine explosion in 2010 (Wade, 2010; U.S. Mine Safety and Health Administration, 2015). The U.S. National Institute for Occupational Safety and Health (NIOSH) had initiated a five-year research project that aims to investigate methods and technologies to reduce the potential for secondary coal dust explosions by the purposeful capture and/or suppression of float coal dust prior to its deposition on the mine roof, rib and floor (NIOSH, 2013). The project aims to evaluate the efficiency of methods to reduce longwall and belt airway float dust in the general airstream as well as methods to capture it at or near the source. Prioritization is given to longwall sections given the amount of coal produced relative to continuous miner sections, but the research is open to technologies that may be adapted from one method of mining to another.

While coal dust behavior, suppression and capture have been under investigation for many years at NIOSH (Colinet et al., 2010), the bulk of the investigation has been focused on particles in the respirable range, sized smaller than 10 µm. It is quite possible that those technologies that are effective at reducing airborne respirable dust are good candidates for float dust reduction, but differences in the transport properties of large particles, sized 10 to 70 µm, can affect removal efficiency. Removal efficiency differences for respirable and large dust have been reported for air-and-water spraying systems (Prostanski, 2013) and foam de-dusting agents (Chen et al., 2015). Given constant flow and atmospheric conditions, the stopping distance, or inertial range, of a particle is largely a function of its diameter, and for particles between 1 and 100 µm, that distance could change by a factor of more than 3,500 (Hinds, 1999). Larger particles are more prone to impact on surfaces and less likely to follow airflow streamlines. A recent computational fluid dynamic and experimental study of a water mist control system suggests that water droplet diameter should be similar to dust diameter to increase the frequency of dust impaction (Ren, Wang and Cooper, 2014).

The removal of additional coal dust from the airways would have the obvious benefit of improving the inertization of deposited dust by increasing the total incombustible content, or TIC, ratio. Studies have shown that inertization of flammable coal dust with limestone dust does not begin to occur in earnest until the mixtures contain between 70 and 80 percent rock dust, and this curve is sharp, meaning that even at a nearly indistinguishable 65 percent inerting ratio, the mixture is still potentially explosive (Cashdollar, 2000).

Recently, Spendrup Fan Co. (Grand Junction, CO) partnered with CFT GmbH (Gladbeck, Germany) under the direction of Irwin Car and Equipment (Irwin, PA) to demonstrate a flooded-bed scrubber mounted inline with an auxiliary fan ventilating a continuous miner face. NIOSH testing on similar scrubber technology used on continuous mining machines had shown greater than 90 percent reductions in respirable dust levels (Colinet and Jankowski, 1998). Recent testing of a prototype dry, mobile section scrubber also showed greater than 95 percent reductions in respirable dust levels in a laboratory test setting with mean air concentrations of 17.8 mg/m3 (Kendall and Organiscak, 2015). The current paper discusses the mine, scrubber and methods used to reduce float coal dust in a production environment.

Scrubber under test

Among the various types of scrubbers developed and used in underground coal mining operations, by far the most prevalent are flooded-bed scrubbers on continuous mining machines. Although these scrubbers are much smaller than the inline scrubber in the current study, both in throughput and dimensionally, they operate in much the same way by pulling dust-laden air from the face through the machine’s ducts and through a wetted filter panel where dust scavenged by water droplets is removed from the airstream by a demister. Continuous miner scrubbers had been shown to be effective at reducing downwind dust levels by as much as 91 percent in operating sections (Colinet, Reed and Potts, 2014). Due to the collection efficiency potential offered by this inline scrubber along with its higher air handling capacity, it was believed that significant reductions in float coal dust could be achieved.

The scrubber assembly consists of the scrubber and recirculation tank as two separate units, both mounted on steel skids to allow for repositioning as the face advances (Fig. 1a). The overall scrubber was 3.1 m (10 ft) long, 1.3 m (4.3 ft) wide and 1.6 m (5.2 ft) high. Fitted inside it, from inlet to outlet, were (1) spray nozzles, consisting of four spray bars with three nozzles each, (2) a filter panel, measuring 1.3 m (4.3 ft) by 1.1 m (3.6 m), and (3) a mist eliminator. Figure 1b shows the filter panel partially slid out from the scrubber and two of the spray bars. The inlet and outlet connections were approximately 786 mm (2.6 ft) in diameter. Air flow of about 8 m3/s (17,000 cfm) was induced by the connection to the auxiliary fan. Water used in the spray nozzles was recirculated by means of an external pump through a 1.2-m3 (1.6-cu yd) recirculation tank. The recirculation tank was separated into three chambers to allow for cascading settling. The pressure loss induced by the connection of the scrubber was on the order of 11 percent.

Figure 1.

(a) Overall view of the inline scrubber (right) and recirculation tank (left). (b) Filter panel shown partially removed with spray bars and nozzles visible to the right of the filter panel.

A wet scrubber’s function occurs through the primary means of diffusion, interception and impaction. Diffusion is the major mechanism for small particles, smaller than 0.05 µm, while interception works well when water droplet sizes are much greater than the dust size. Impaction is most effective on larger particles, larger than 5 µm (Kim et al., 2004).

Scrubber performance is a function of the operating parameters, including the filter panel efficiency and capture efficiency. Capture efficiency is the percentage of dust-laden air that is drawn into the scrubber from the total quantity of air ventilating the face. The airflow rate of the scrubber significantly affects capture efficiency and can change quite drastically when the filter panel becomes clogged. NIOSH research had shown that scrubber airflow at a continuous miner may be reduced by as much as 32 percent after taking only one cut (Colinet, Reed and Potts, 2014).

Sampling plan and methods

Mine information

In collaboration with a participating U.S. underground coal mine, NIOSH performed a short-duration case study of the flooded-bed scrubber’s effectiveness. This study focused on the ability of the inline scrubber to remove float coal dust from the return air from the continuous miner face, with the goal of reducing float coal dust in the section return entry. The continuous miner development section operated as a four-entry super section, with one miner and twin-boom roof bolter on each side of the super section. Roof support pillars were maintained at approximately 15 × 46 m (50 × 150 ft) for the yields and 53 × 137 m (175 × 450 ft) for the permanent supports. Typical cuts ranged from 4.6 to 7.6 m (15 to 25 ft) deep, depending on the condition of the roof strata. The face was ventilated using a combination of exhaust tubing, approximately 45.7 m (150 ft) long, and curtain, with the auxiliary exhaust fan providing about 481 m3/min (17,000 cfm) of airflow through the 508 mm (20 in.)-diameter exhaust tubing. A rock duster was located at the fan discharge and was operated continuously. However, in order to isolate coal from rock dust, it was necessary to suspend rock dusting while sampling in the return entry. The mine proposed to place a trickle duster outby the last NIOSH dust sampling station and operate this duster on a continuous basis. The duster at the fan discharge would not be operated when the miner was cutting and NIOSH was sampling. At the completion of the cut and sampling, the duster was turned on to rock dust the portion of the return between the fan discharge and the trickle duster before starting the next cut. This temporary plan was submitted to and approved by the local Mine Safety and Health Administration (MSHA) district office.

Sampling plan

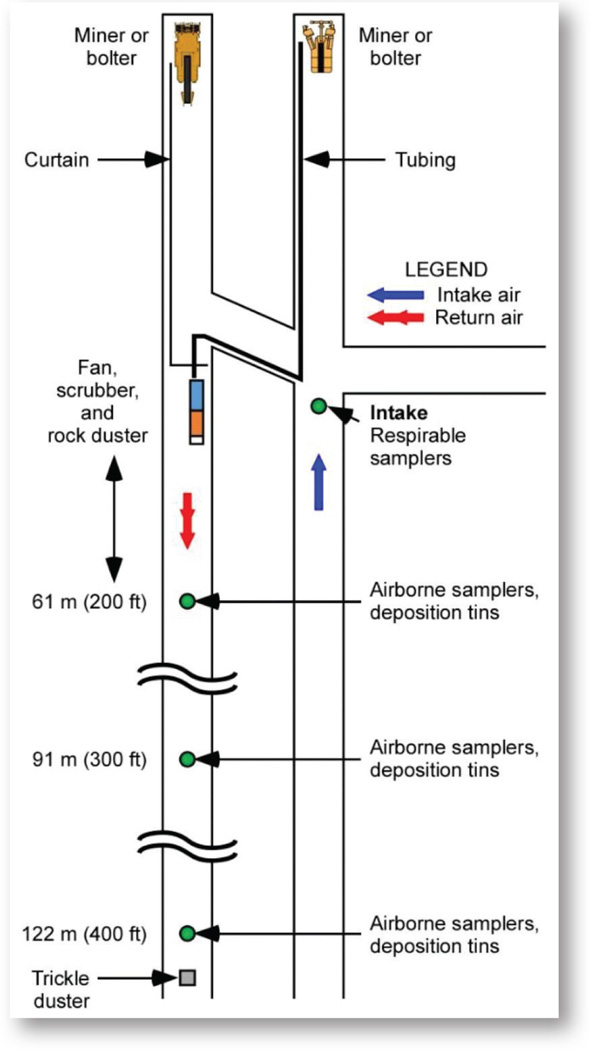

Three sampling stations were chosen outby the exhaust fan/scrubber location, and one was placed in the intake to quantify the background dust levels. The outby sampling stations were located in the center of the return entry at fixed distances of 61, 91 and 122 m (200, 300 and 400 ft) from the auxiliary fan exhaust (Fig. 2). To ensure that the float dust scrubber was being used as it would be in normal operations, the testing was scheduled after the mine had experienced using the unit for about two months. Sampling was conducted during the day shift just before and after the introduction of the scrubber to minimize any possible influence of different cutting techniques, amount of roof rock cut, and atmospheric changes.

Figure 2.

Diagram of sampling instrument placement with respect to the section’s exhaust fan.

Sampling instruments

Each return entry sampling station had two major components: (1) a roof-suspended sampling rack with both total and respirable airborne sampling instruments (Fig. 3), and (2) a deposition table with pre-weighed metal tins for collecting deposited dust.

Figure 3.

Airborne dust sampling rack containing three total dust samplers, two gravimetric respirable samplers and one real-time light-scattering respirable dust monitor.

Details of total dust sampler

While the Dorr-Oliver cyclone with Zefon cassette gravimetric sampler (Zefon International, Ocala, FL) and pDR-1000 personal DataRAM real-time light-scattering sampler (Thermo Fisher Scientific, Waltham, MA) are frequently used for respirable dust sampling in coal mines, a new instrument was needed for collecting airborne float dust samples. Float coal dust refers to dust smaller than 75 µm for which a dedicated sampler is not available. Therefore, the sampler chosen to sample airborne float dust is technically collecting a “total” dust sample. This total dust sampler consisted of a stainless steel version of the commercially available Institute of Occupational Medicine (IOM) sampler, which is an inhalable dust lapel sampler, along with a custom-designed and machined interchangeable inlet configuration to allow for isokinetic sampling (Fig. 4). A series of stainless steel isokinetic nozzles were machined with inner diameters of 3.05, 3.86, 5.31 and 9.40 mm (0.12, 0.15, 0.21 and 0.37 in.) for use in airflow rates of 4.57, 2.85, 1.51 and 0.48 m/s (15, 9.4, 4.9 and 1.6 ft/sec) when attached to a 2.0 L/min (0.04 cfm) sampling pump. Each nozzle had a length of at least 5.6 times its diameter, from inlet tip to filter media, and a 30-degree tapered knife edge was cut onto the end of each nozzle to optimize sample collection. The interior of the custom 3D-printed adapter was flared so that the dust was directed toward the filter. As the mine airflow downwind of the scrubber was about 2.8 m/s (550 ft/min), the 3.86-mm (0.15-in.) inner-diameter nozzles were used exclusively for field sampling.

Figure 4.

Exploded detail of the total dust sampler, consisting of a commercially available stainless steel IOM sampler with a custom-printed inlet adapter (black) allowing inlet nozzles (blue) of different sizes to be used.

Despite a temporary, approved ventilation plan that permitted the suspension of rock dusting during sampling periods, significant airborne rock dust was still present due to the sheer amount used by the mine. It was not uncommon to have at least 127 mm (5 in.) of loose rock dust on the floor, and the high airspeed induced in the return by the auxiliary fan created a challenge to collecting only coal dust. The stainless steel filter capsule within the IOM sampler could be removed and heated by the low-temperature ashing method (Barone et al., 2016) so that coal and inerting rock dust fractions could be determined. A Type R-100 quartz filter (SKC Inc., Eighty Four, PA) with 1.2-µm nominal pore size was used in the IOM sampler.

Deposition samples

In addition to the total airborne dust measurements, deposition information was also desirable, as this material ultimately acts as a fuel source in secondary coal dust explosions if not inerted with enough incombustible material. Various deposition collection methods had been used (Li and Bhaskar, 1994; Courtney, Kost and Colinet, 1982), typically involving a flat tray mounted in a horizontal, flat position, including using hanging trays, thin filter papers on the floor or trays lined with plastic food wrap, vacuum methods, and brushing into jars. In all of these methods it can be extremely difficult to accurately quantify the amount of coal dust deposited, given that the samples need to be collected and transferred out of the mine without losing any material. To meet this need, we used coated steel tins with fitted lids (Fig. 5) with dry weight of about 58 g (0.13 lb) each. An Ohaus AP310S high-capacity scientific balance (Ohaus Corp., Parsippany, NJ) with 310-g (0.68-lb) capacity and 0.2-mg precision was used to quantify dust deposition on these tins. The tins were arranged outby on wooden tables located just behind each airborne sampling rack, in the middle of the entry. Keeping the tins off the floor minimized the possibility of dust being kicked up and confounding the measurement. After transport back to the NIOSH weighing laboratory, the exteriors of the tins were cleaned with an alcohol wipe, allowed to sit for environmental acclimation and then weighed, and the mass gains were calculated. For simplicity only, the total mass gain results are presented here as coal + rock dust.

Figure 5.

Steel tins used for deposition measurements. Not shown are the matching fitted lids.

Sample handling and post-processing

All samplers were set up in the return at the start of each shift. The packages were protected against contamination by keeping the sampler inlets and tins capped, and plastic sheeting was used to cover the racks and tables. Immediately prior to the mining of each cut, proceeding from inby to outby, the coverings and caps were removed and the sampling pumps started. The deposition tin lids were removed and stored in clean bags. At the conclusion of the cut sequence, NIOSH researchers entered the entry from the outby side and proceeded inby, stopping the pumps, capping the samples and removing the filters. Special attention was given to the total samples, which had to be transported in an upright position because they were later to be separated for the ashing process. For this, a modified metal transport case was fitted with a machined liner that held the samplers in a stable position.

After transportation to the laboratory, all samples were allowed to equilibrate in the climate-controlled weighing room for 24 hours. All samples were weighed, including the control cassettes used for environmental and handling correction. The total samplers were further processed with a low-temperature ashing technique, whereby they were heated in a muffle furnace for 2.5 hours at 515 °C (959 °F) to leave only the noncombustible portion. Samples of mined coal and rock dust, taken from the working section of the mine during testing, were hand-collected and analyzed to determine their percent combustible content. Using these pre- and post-combustion weights, as well as the combustible fraction information, two simultaneous equations were solved to determine the coal dust mass present on the total airborne dust samples:

| (1) |

| (2) |

where RDmass is the mass of rock dust in the sample, RDcomb is the fraction of rock dust that is combustible, RDincomb is the mass of incombustible portion of rock dust in the sample, CDmass is the coal dust mass in the sample, CDcomb is the fraction of coal dust that is combustible, CDincomb is the mass of incombustible portion of the coal dust in the sample, Mtotal is the total mass of collected sample, Mincomb is the total mass that is incombustible, Mpre is the pre-weight of clean sampler assembly, Mdry is the mass of sample after drying at 105 °C (221 °F) for two hours and Mpostburn is the mass of sample after combustion at 515 °C (959 °F) for 2.5 hours.

After the data were tabulated, it was normalized for the production rate. In this case, we chose to represent the coal dust in terms of milligram per metric ton of production. The mine typically estimates 12.8 metric tons per meter (4.3 short tons per foot) of face advance. Of the six cut sequences measured (Table 1), that of cut #3 on day 2 had to be omitted because of intermittent power issues with the recirculation tank on the scrubber.

Table 1.

Summary of measured sample quantities.

| Cut | Day | Scrubber | Tons | Depth (m) | Total samplers | Respirable samplers | Deposition samplers |

|---|---|---|---|---|---|---|---|

| 1 | 1 | No | 62.4 | 4.9 | 9 | 6 | 12 |

| 2 | 1 | No | 66.3 | 5.2 | 9 | 6 | 12 |

| 3 | 2 | Yes | Scrubber power interruption. | ||||

| 4 | 2 | Yes | 70.2 | 5.5 | 9 | 6 | 12 |

| 5 | 3 | Yes | 78.0 | 6.1 | 9 | 6 | 12 |

| 6 | 3 | Yes | 78.0 | 6.1 | 9 | 6 | 12 |

Survey results

All three dust sampling methods showed reductions in dust levels that were statistically significant with nonover-lapping 95 percent confidence intervals when running the scrubber. Table 2 shows reductions of 92.5, 85.5 and 84.2 percent for the total, respirable and deposited samples, respectively. When averaged across the sampling locations, the coefficients of variation for the baseline case are 15.6, 14.7 and 31.5 for the total, respirable and deposition samples, respectively. With the addition of the scrubber, measured masses dropped significantly and the coefficients of variation increased to 46.8, 25.8 and 81.9 percent for the total, respirable and deposited data, respectively.

Table 2.

Overall reductions in airborne and deposited dust (µg/t).

| Sampler type |

No. of samples (n) | Mean | Standard deviation | Confidence interval | |||||

|---|---|---|---|---|---|---|---|---|---|

| Baseline | Scrubber | Baseline | Scrubber | Change (%) | Baseline | Scrubber | Baseline | Scrubber | |

| Total, airborne. |

18 | 27 | 45.0 | 3.4 | 92.5 | 7.1 | 1.6 | 5.8 | 1.0 |

| Respirable, airborne. |

12 | 18 | 6.4 | 0.9 | 85.5 | 0.9 | 0.2 | 1.1 | 0.2 |

| Total, deposited. |

24 | 36 | 607.2 | 96.0 | 84.2 | 194.8 | 77.2 | 130.5 | 40.0 |

The total airborne coal dust measurements demonstrate that the scrubber is able to effectively remove airborne coal dust, with reductions of 93.4, 92.1 and 91.7 percent for the 61-m, 91-m and 122-m (200-ft, 300-ft and 400-ft) sampling stations (Fig. 6). Between the 61-m and 122-m (200-ft and 400-ft) sampling stations without the scrubber, 11 µg/t, or 22 percent, of the dust had dropped out of the return airstream with a worst-case confidence interval of 7.6 µg/t.

Figure 6.

Coal dust fraction of airborne total dust collected with and without the scrubber in operation.

For the deposited dust samples, reductions of 80.3, 86.1 and 88.5 percent were measured during scrubber operation for the 61-m, 91-m and 122-m (200-ft, 300-ft and 400-ft) sampling stations, respectively (Fig. 7). Although the deposition samples exhibited substantially higher coefficients of variation compared with the other samples, the dust reductions due to the scrubber easily maintain statistical significance.

Figure 7.

Deposited dust collected with and without the scrubber in operation.

The total airborne results represent only the combustible fraction of coal dust as determined with the low-temperature ashing method. The respirable and deposition samples contain all dust, regardless of dust composition. Respirable dust levels did not vary significantly with distance as confidence intervals overlap the means. With the scrubber running, reductions of 85.3, 85.4 and 86.0 percent were measured between the 61-m, 91-m and 122-m (200-ft, 300-ft and 400-ft) stations (Fig. 8).

Figure 8.

Respirable dust collected with and without the scrubber in operation.

Conclusions

A flooded-bed scrubber, attached inline to an auxiliary fan on a continuous miner development section, was able to reduce the total airborne coal dust, airborne respirable dust and deposited coal dust from the return by 92.5, 85.5 and 84.2 percent, respectively. The unit was tested during actual mining operations at an active, producing coal mine. The scrubber limited the amount of potentially explosive coal dust distributed downstream in the return of a continuous miner section. Also, the amount of rock dust necessary to inert the deposited float coal dust to compliance levels would be reduced. While scrubber technology is not new, implementation for the purpose of controlling float coal dust is uncommon in the U.S. mining industry, and it is hoped that these positive results will encourage other mines to investigate return-scrubbing options. Following the NIOSH testing, the prototype scrubber has remained in use for over a year and has been purchased by the cooperating mine, which is additionally considering a larger unit capable of de-dusting air quantities from multiple entries. Due to the nature of this limited-scope field study, a more comprehensive evaluation of the scrubber’s performance as a function of water flow rates, pressure and filter panel loading was not possible.

Footnotes

Disclaimer

The findings and conclusions in this manuscript are those of the authors and do not necessarily represent the views of NIOSH. Mention of company names or products does not constitute endorsement by NIOSH.

Contributor Information

J.R. Patts, U.S. National Institute for Occupational Safety and Health, Pittsburgh Mining Research Division (NIOSH/PMRD), Pittsburgh, PA, USA.

J.F. Colinet, U.S. National Institute for Occupational Safety and Health, Pittsburgh Mining Research Division (NIOSH/PMRD), Pittsburgh, PA, USA.

S.J. Janisko, Sheetz Inc., Altoona, PA, USA, formerly of NIOSH/PMRD..

T.L. Barone, U.S. National Institute for Occupational Safety and Health, Pittsburgh Mining Research Division (NIOSH/PMRD), Pittsburgh, PA, USA.

L.D. Patts, U.S. National Institute for Occupational Safety and Health, Pittsburgh Mining Research Division (NIOSH/PMRD), Pittsburgh, PA, USA.

References

- Barone TL, Patts JR, Janisko SJ, Colinet JF, Patts LD, Beck TW, Mischler SE. Sampling and analysis method for measuring airborne coal dust mass in mixtures with limestone (rock) dust. Journal of Occupational and Environmental Hygiene. 2016;12(4):288–296. doi: 10.1080/15459624.2015.1116694. http://dx.doi.org/10.1080/15459624.2015.1116694. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cashdollar K. Overview of dust explosibility characteristics. Journal of Loss Prevention in the Process Industries. 2000;13:183–199. http://dx.doi.org/10.1016/s0950-4230(99)00039-x. [Google Scholar]

- Chen X, Hu H, Xu Y, Zhang Y, Yang G. Experimental investigation of foam dedusting agent in underground coal mine. Materials Research Innovations. 2015;19(S8):508–511. http://dx.doi.org/10.1179/1432891715z.0000000001736. [Google Scholar]

- Colinet JF, Listak JM, Organiscak JA, Rider JP, Wolf Al. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. Pittsburgh PA: DHHS (NIOSH), Information Circular 9517; 2010. Best Practices for Dust Control in Coal Mining. [Google Scholar]

- Colinet JF, Reed WR, Potts JD. Continuous mining dust levels in 20-foot cuts with and without a scrubber operating. SME Annual Conference & Expo; Feb. 23–26, 2014; Society for Mining, Metallurgy & Exploration; 2014. Preprint 14-033. [Google Scholar]

- Colinet J, Jankowski RA. Silica collection concerns when using floodedbed scrubbers. SME Annual Conference & Expo; March 1998; Society for Mining, Metallurgy & Exploration; 1998. pp. 1–7. [Google Scholar]

- Courtney WG, Kost J, Colinet JF. Dust Deposition in Coal Mine Airways. U.S. Bureau of Mines Technical Progress Report 116. 1982 Feb; 1982. [Google Scholar]

- Hinds W. Aerosol Technology; Properties, Behavior, and Measurement of Airborne Particles. Chapter 5. John Wiley & Sons Inc.; 1999. pp. 483pp. 111–140. [Google Scholar]

- Kendall B, Organiscak J. Final Report for Fletcher Mobile Dry Scrubber (DS) S/N 2010842. NIOSH Contract Final Report. 2015 available on request from OMSHR@cdc.gov. [Google Scholar]

- Kim HT, Jung CH, Oh SN, Lee KW. Particle removal efficiency of gravitational wet scrubber considering diffusion, interception, and impaction. Environmental Engineering Science. 2004;18(2):125–136. http://dx.doi.org/10.1089/10928750151132357. [Google Scholar]

- Li J, Bhaskar R. Some observations on turbulent deposition rates of coal dust in mine airways. Mining Engineering. 1994 Jan;:59. 1994. [Google Scholar]

- Prostanski D. Use of air-and-water spraying systems for improving dust control in mines. Journal of Sustainable Mining. 2013;12(2):29–34. http://dx.doi.org/10.7424/jsm130204. [Google Scholar]

- Ren T, Wang Z, Cooper G. CFD modelling of ventilation and dust flow behavior above an underground bin and the design of an innovative dust mitigation system. Tunneling and Underground Space Technology. 2014;41:241–254. [Google Scholar]

- U.S. Mine Safety and Health Administration. Historical data on mine disasters in the United States. 2015 http://www.msha.gov/MSHAINFO/FactSheets/MSHAFCT8.HTM.

- U.S. National Institute for Occupational Safety and Health. Mining project: float dust control in underground coal mines. 2013 http://www.cdc.gov/niosh/mining/researchprogram/projects/project/float_dust.html.

- Wade L, Kohler J, Sapko M, Morantz AS, Moore S. An Independent Panel Assessment of an Internal Review of MSHA Enforcement Actions at the Upper Big Branch Mine South. U.S. National Institute for Occupational Safety and Health. 2012 Mar 22; 2012, http://arlweb.msha.gov/PerformanceCoal/NIOSH/Independent%20Assessment%20Panel%20Report%20w_Errata.pdf. [Google Scholar]