Dear Sir,

3D printing is now well versed in the hospital environment for producing useful pre and intraoperative surgical models. These have become common place among medical professionals from a range of different disciples across the globe. However, recently this technology has taken a turn which accelerates its development as a process for directly improving the lives of many thousands of patients. Nylon 645 polymer is specifically engineered to allow for the fabrication of biologically inert implants using standard fused deposition manufacturing 3D Printers. One such use of this material is in producing custom implants for rebuilding the damaged cartilage of the knee. 645 Nylon Co-Polymer consists of the purest form of a delta transition of Nylon 6/9, Nylon 6 and Nylon 6T with crystallinity optimisation for ensuring maximum bonding during a 3D Printing thermal transition process. This process allows for the fabrication of an accurate patient specific structure which is biological compatible.

One of the most exciting and closely watched uses of this material is for producing patient specific 3D printed implants, such as for cartilage joint replacement. These are often more difficult than bone replacements as the part must accurately conform to an existing internal bone structure, be pliable enough to conform to unusual mounting methods during the operative procedure. The implant must be inherently strong to keep the joint from becoming misaligned by stress during walking or even running. Further to this, the polymer provides a long term slippery surface for thirty years or more to the biological mating surface.

Although Nylon polymer implants are not new to the operating theatre. The significant feature of 3D printing is its ability to produce a part that is difficult or impossible to make with traditional industry-based CNC machinery. This implant can feature a number of intricate chambers for attachment to a bone and without 3D printing technology then these would otherwise be impossible to make. But in less than two hours an implant can be produced complete to ±25 μm degree of precision. The newly printed and pliable implants do split, break or tear, can be autoclaved and subsequently transplanted.

Recently, surgeons and doctors at the Hague University have determined Nylon 645 exceed the requirements to support several possible uses inside and outside of the human body. Hospitals and clinics can now design and subsequently print on-demand patient specific support components under the direct control of the surgeon.

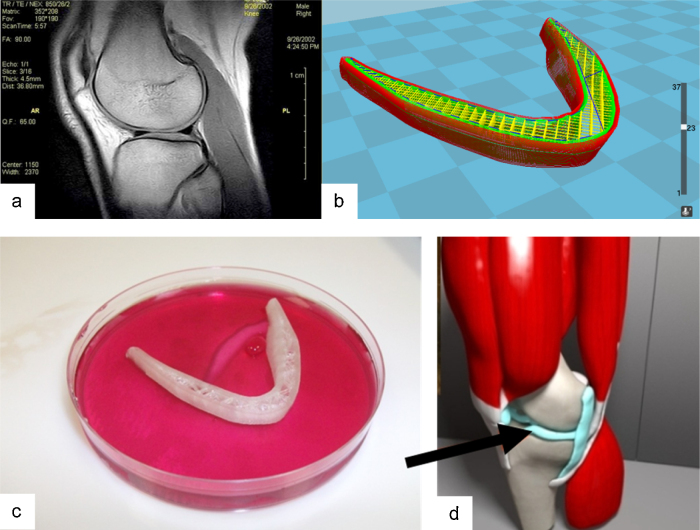

In the past, a specialised implant could be designed specifically for a patient shape, weight and structure which required iterations of models and try-outs. With the combination of 3D computer modelling and on-demand 3D printing, a patient can now leave the hospital with a pliable implant specifically made to size (Fig. 1).

Fig. 1.

(a) Computerised tomography scan of an adult male knee (b) design and rebuild of the open meniscus disc (c) replacement implant 3D printed from Nylon 645 and (d) computer model showing patient specific fit up before a procedure is carried out.

As the Fig. 1 shows we start off with a scan of a patient knee, and then using Mimics software the 2D computerised tomography images are reconstructed in the form of a 3D printing file. The unique feature of 3D Printing is that it offers a means to produce custom implants on demand at low cost. This disruptive approach towards engineering implants could allow for them to be produced at the hospital days before a procedure is carried out.

This exciting technology is an interesting paradigm to the research scholar as it is to enterprising surgeon. 3D printing technology offers significance towards instigating a medical innovation to manufacture a range of useful personalised patient specific implants and improve patient morbidity to a range of complex joint conditions of the lower limbs.

Acknowledgements

The author would like to thank the support of the University of Florida College of Medicine during the pursuit of writing this letter to the Editor.