Abstract

The effects of black rice powder on the quality of sausage were investigated. Samples were prepared with 0% (control), 1%, 3%, and 5% black rice powder. With increasing black rice powder content, the moisture and ash content of sausage increased, while protein content was significantly less than that observed for the control (p<0.05). The fat content in samples containing 5% black rice powder was significantly less than that observed for other samples (p<0.05). With increasing black rice powder content, the pH of uncooked and cooked samples increased. In addition, lightness, redness, and yellowness decreased. With increasing content of black rice powder, emulsion stability decreased. On the other hand, with increasing black rice powder content, cooking yield increased. As compared to the other samples, those containing high content of black rice powder exhibited higher viscosity. With increasing black rice powder content, the hardness of samples decreased, while the gumminess and chewiness of samples containing black rice powder were less than those observed for the control (p<0.05). Moreover, with increasing black rice powder content, the flavor, juiciness, and overall acceptability of samples increased. In addition, the tenderness of samples containing 3% and 5% black rice powder was significantly greater than that observed for the control and sample containing 1% black rice powder (p<0.05). In addition to the economic benefits, black rice powder can be used to improve quality characteristics.

Keywords: black rice, quality characteristics, sausage, meat product

Introduction

The increase of the gross domestic product (GDP) and highly westernized food culture has resulted in an upsurge in the consumption of meat and meat products. When consumers purchase food, they consider various factors, such as appearance, taste, convenience, and nutrition (Issanchou, 1996). Typically, consumers are concerned about the use of diverse additives, such as preservatives, in processed products (Han and Ahn, 1998), which is reflected in the actual consumption of these foods (Kim and Kim, 2005). Such a consumption trend is presumed to negatively affect consumers while purchasing meat products.

On the other hand, rice has been a staple food for ages; however, its consumption has been significantly reduced because of the Westernization of food culture, making it a side dish more than a main dish. Moreover, growing interest in functional foods (Grunert, 2006) have led to the development of specialty rice, the consumption of which is steadily increasing (Hwang and Kim, 2000). Black rice, a type of specialty rice, is milled as brown rice, where only the hull is removed; as compared to white rice, black rice contains high amounts of nutrients, such as fiber, vitamins, minerals, vitamin B complex, and unsaturated fatty acid (Ha et al., 2006). Furthermore, it contains diverse bioactive substances, which exert antioxidative effects on the body (Fardet et al., 2008). Anthocyanins contained in rice pericarp have been reported to exhibit various functional effects, such as antioxidative effects (Park et al., 2016), as well as the inhibition of DNA damage (Choi et al., 2016). As a result, black rice is predicted to be very useful for the manufacturing and development of food.

On the other hand, common meat products include sausage, ham, pressed ham, and bacon (Moon et al., 2007), with ham and sausage being particularly popular in lunch boxes or as a side dish for dinner (Yoon et al., 2001). Sausage, which is the most common processed meat product, is produced by the addition of various seasonings and spices to mixed and emulsified meat, which is cut and ground, followed by the filling and heating of the casing (Moon et al., 2007). For establishing the utility of black rice as a functional additive, research should be conducted for examining the manner in which the addition of black rice to the processed meat products affects the quality characteristics of the products.

Hence, in this study, quality characteristics of sausage with the addition of black rice powder were investigated.

Materials and Methods

Materials and preparation of emulsion-type sausage

Pork ham (Hongju Meat Co., Korea) refrigerated for 24 h after slaughter was used for making sausage for the tests. First, pork hams (meat) and back fat were individually ground using a grinder (PA-82, Mainca, Spain) with plates of 3 mm. Second, meat (60%), back fat (20%), and ice (20%) were cut using a bowl cutter (K-30, Talsa, Spain), and nitrite pickling salt (NPS) (1.2%), sugar (1%), mixed spices (0.6%), and black rice powder (pH: 6.68, CIE L*: 35.6, a*: 8.4, b*: -3.7, Garunara, Korea) were added in proportion to the total weight to produce a sausage emulsion; third, this emulsion was filled in a natural pork intestine casing using a filler (EM-12, Mainca, Spain). Next, this filled emulsion was thermally processed in an 80℃ chamber (10.10ESI/SK, Alto Shaam Co., USA) for 30 min, followed by cooling at 10℃ for 30 min. No black rice powder was added to the control group (Control: 0%), while 1%, 3%, or 5% of black rice powder, in addition to the initial mix ratio, was added to the treatment groups (Table 1). The manufactured sausages were stored at 4℃ during the experiment.

Table 1. Formulation of various sausage formulated with different amounts of black rice powder.

| Ingredients (%) | Black rice powder (%) | ||||

|---|---|---|---|---|---|

| 0 (control) | 1 | 3 | 5 | ||

| Main | Meat | 60 | 60 | 60 | 60 |

| Back Fat | 20 | 20 | 20 | 20 | |

| Ice | 20 | 20 | 20 | 20 | |

| Additive | NPS1) | 1.2 | 1.2 | 1.2 | 1.2 |

| Sugar | 1 | 1 | 1 | 1 | |

| Mixed spice | 0.6 | 0.6 | 0.6 | 0.6 | |

| Black rice powder | - | 1 | 3 | 5 | |

1)NPS: Nitrite pickling salt.

Proximate analysis

In compliance with the AOAC method (AOAC, 2000), crude protein content was measured by the Kjeldahl method, crude fat content was measured by the Soxhlet method, moisture content was measured by the drying oven method at 105℃, and crude ash content was measured the dry ashing method at 550℃.

pH measurement

For measuring pH, 4 g of a sample was mixed with 16 mL of distilled water in an Ultra-Turrax homogenizer (HMZ-20DN, Pooglim Tech., Korea) at 8,000-9,000 rpm for 1 min. The pH was recorded using a pH meter (Model S220, Mettler-Toledo, Switzerland).

Colorimetry measurement (CIE color)

The inner surface of the specimen before and after heating was tested using a colorimeter (CR-10, Minolta, Japan) for measuring CIE L* (lightness), CIE a* (redness), and CIE b* (yellowness). A white standard plate with a CIE L* of +97.83, CIE a* of −0.43, and CIE b* of +1.98 was used as reference.

Viscosity measurement

The viscosity of the sausage emulsion was measured using a rotational viscometer (Merlin VR, Rheosys, USA). The sample was placed on a parallel plate of 30 mm with a gap of 2.0 mm, and measurement was conducted in 60 s at 20℃ with a head speed of 20 rpm.

Emulsion stability

Triplicate samples of meat batter from each treatment were analyzed for emulsion stability using the modified method of Kim et al. (2010). A 15 mesh sieve (50 mm diameter) was placed in the middle of a graduated glass tube. Approximately 30 g of the meat batter was weighed on the sieve in glass tubes, which were then covered. Triplicate samples from each treatment were cooked at 75, 80, and 100±1℃ for 30 min. After cooling to approximately 4±1℃ to facilitate fat and water layer separation. The water and fat, which separated in the bottom of graduated glass tube, were measured in milliliters and calculated as a percentage of the original weight of batter. The mean value of the six tubes was taken for each treatment.

Watere loss (%) = [the water layer (mL) / raw meat batter weight (g)] × 100

Fat loss (%) = [the fat layer (mL) / raw meat batter weight (g)] × 100

Cooking yield measurement

Cooking yield was calculated using pre- and post-cooking weights.

Texture profile analysis (TPA)

The texture of the sample was measured using a texture analyzer (TA 1, Lloyd, USA). A ϕ2.5 cm × 2 cm heated sample was prepared and measured at room temperature, with the following settings: a cylinder probe of 100 mm with a pre-test speed of 2.0 mm/s, a post-test speed of 5.0 mm/s, a maximum load of 2 kg, a head speed of 2.0 mm/s, a distance of 8.0 mm, and a force of 5 g. Hardness (kg), springiness, and cohesiveness were measured and recorded, which were utilized for calculating gumminess (kg) and chewiness (kg).

Sensory evaluation

Twelve panelists were selected from a group of 15 potential panelists using basic taste identification tests. Each chicken nugget was evaluated in terms of color, flavor, juiciness, tenderness, and overall acceptability. The samples were served to 12 experienced panel members. The panelists were presented with randomly coded samples. The color, flavor, tenderness, juiciness, and overall acceptability (1 = extremely undesirable, 10 = extremely desirable) of the samples were evaluated using a 10-point descriptive scale. The panelists were also required to cleanse their palates with water between tasting the samples (Keeton, 1983).

Statistical analysis

Experimental results were assessed after a minimum of three repeated trials. Statistical analyses were performed using SAS (version 9.3 for window, SAS Institute Inc., USA), and the results were indicated as means and standard deviation. ANOVA and Duncan’s multiple range test were performed for verifying the significance of differences in each characteristic.

Results and Discussion

Proximate composition

Table 2 shows the proximate analysis for the black-rice-powder-added sausage. With increasing content of black rice powder, moisture content tended to increase, while protein content in the both 3% and 5% black rice powder groups was significantly less than that observed for the control group (p<0.05). Moreover, with increasing content of black rice powder, fat content in the 5% black rice powder was significantly less than that observed for the control and other treatment groups, while ash content tended to increase. However, Serdaroglu and Değırmencioğlu (2004) have examined the addition of corn powder in meatballs and reported an increase in the protein content, with no significant changes in the fat and ash content, which is in contrast to the results obtained herein. On the other hand, other studies have reported that wild-rice-added patty exhibits increased moisture content, with reduced fat and protein (Minerich et al., 1991), and for frankfurter with the addition of lupin seed powder, which is a type of bean, increased moisture and ash content is observed, albeit with reduced fat content, corresponding to results similar to those reported in our previous study (Alamanou, 1996). Grain powder is used as an emulsifier in meat products, attributed to its moisture-absorbing property (Lee et al., 2003), which is presumed to have improved the moisture-holding capacity of sausage, thereby increasing moisture content. Furthermore, with the addition of black rice powder while maintaining the initial mix ratio (control group), ash content increased, which subsequently resulted in relatively lower protein and fat content.

Table 2. Proximate composition of various sausage formulated with different amounts of black rice powder.

| Traits (%) | Black rice powder (%) | |||

|---|---|---|---|---|

| 0 (control) | 1 | 3 | 5 | |

| Moisture | 50.98±0.77bc | 49.99±1.04c | 53.80±1.91ab | 56.51±0.78a |

| Protein | 14.82±0.29a | 13.94±0.47ab | 12.89±0.06b | 13.59±0.12b |

| Fat | 36.85±0.81a | 37.07±0.07a | 34.59±1.08a | 28.94±1.39b |

| Ash | 1.32±0.01c | 1.40±0.15bc | 1.44±0.10b | 1.62±0.03a |

All values are mean ± standard deviation.

a-cMean in the same row with different numbers are significantly different (p<0.05).

pH and color

As shown in Table 3, the pH and color of the sausages increased with the black rice powder content. With increasing content of black rice powder, pre- and post-heating pH tended to increase; particularly, post-heating pH significantly increased (p<0.05). This observation is in agreement with results previously reported by Jang et al. (2004), where black-rice-added sausage exhibits pH greater than that observed for cereal-added sausage. The results from another study indicated pH increase with the addition of lupin seed powder to frankfurter (Alamanou et al., 1996); this observation is believed to be attributed to the fact that the pH of samples added black rice powder is greater (pH 6.68) than that of the control group both before and after heating. Pre-heating lightness and yellowness significantly increased depending on the content of black rice powder (p<0.05). All treatment groups with the addition of black rice powder exhibited significantly lower redness as compared with that observed for the control group (p<0.05), with no significant differences among the treatment groups. Post-heating lightness and yellowness significantly increased in accordance with the black rice powder content (p<0.05). Redness was significantly higher in the control group (p<0.05), and the least redness was observed for the 1% black rice powder group, indicating significant increase with the black rice powder content (p<0.05). Similar results have been reported for bean-protein-added meatballs, where increased lightness, with no significant changes in redness and yellowness (Serdaroglu et al., 2005), has been observed, and black-rice-powder-added sausage, as compared to other cereal-added sausages, exhibits markedly lower lightness and redness (Jang et al., 2004). The color of the black rice powder (L*: 35.6, a*: 8.4, b*: −3.7) is presumed to have affected such color changes in sausages.

Table 3. pH and color of sausage formulated with different amounts of black rice powder.

| Traits | Black rice powder (%) | |||||

|---|---|---|---|---|---|---|

| 0 (control) | 1 | 3 | 5 | |||

| pH | Raw | 5.95±0.01c | 5.95±0.01c | 6.12±0.01b | 6.19±0.01a | |

| Cooked | 6.12±0.01d | 6.19±0.01c | 6.20±0.01b | 6.27±0.01a | ||

| Color | Raw | CIE L* | 71.9±0.51a | 69.7±0.74b | 61.53±0.33c | 56.50±0.91d |

| CIE a* | 8.58±0.08a | 7.85±0.23b | 8.15±0.15b | 7.73±0.20b | ||

| CIE b* | 19.7±0.12a | 14.35±0.25b | 8.88±0.13b | 5.75±0.38b | ||

| Cooked | CIE L* | 72.73±0.30a | 69.58±0.18b | 63.03±0.30c | 57.33±0.08d | |

| CIE a* | 7.23±0.08a | 5.58±0.04d | 5.88±0.04c | 6.58±0.04b | ||

| CIE b* | 16.78±0.13a | 12.58±0.11b | 7.30±0.19c | 5.13±0.08d | ||

All values are mean ± standard deviation.

a-dMean in the same row with different numbers are significantly different (p<0.05).

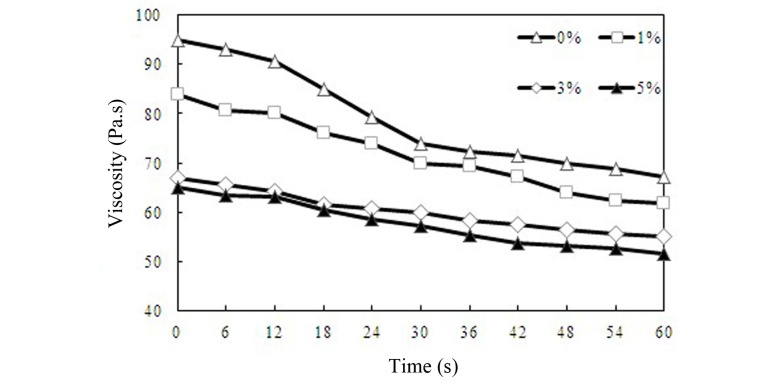

Viscosity

Fig. 3 shows the results obtained by the viscosity measurements conducted for 1 min using sausage emulsions. Meat emulsions exhibit characteristic non-Newtonian flow behavior (Kim et al., 2010). Frankfurter emulsions exhibited the same flow behavior. The control group without black rice powder and 1% added black rice powder exhibited high viscosity values of 61.84-67.23 Pa·s, and the viscosities of 3% and 5% black rice powder groups were 55.04 Pa·s and 51.58 Pa·s, respectively, suggesting that viscosity decreases with increasing black rice powder content. On the other hand, Rivero De Padua (1983) has reported different results of increased viscosity with the addition of sesame powder to ground meat products, attributed to the fact that changes in viscosity are closely associated with the emulsion stability of meat emulsions (Kim et al., 2010); hence, it is believed that the increased moisture content in sausage emulsions, caused by increased emulsion stability, results in low viscosity

Fig. 3. Viscosity of various sausage batters formulated with different amounts of black rice powder.

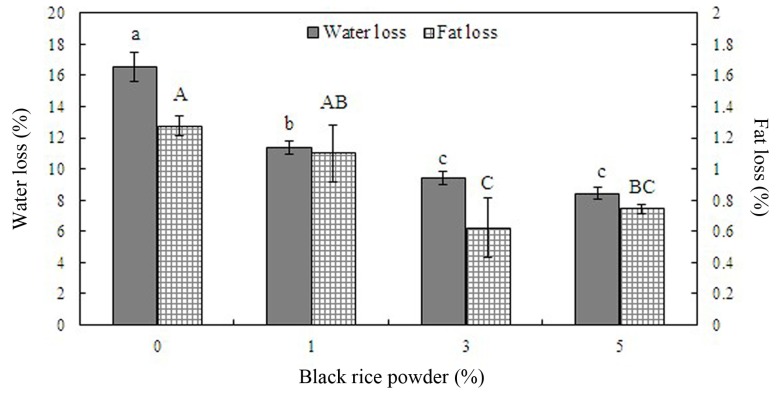

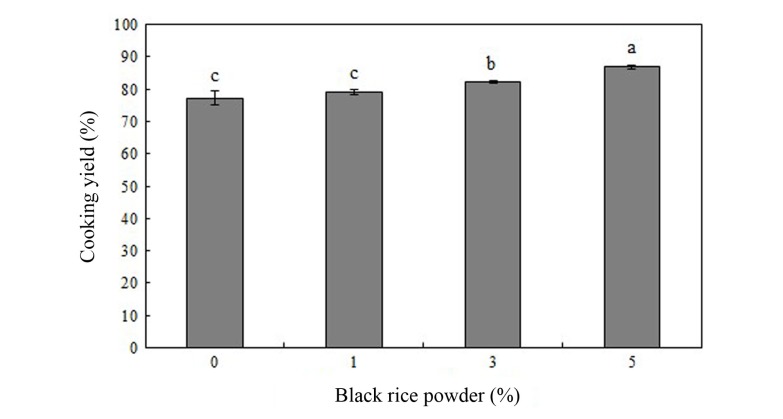

Emulsion stability and cooking yield

As shown in Figs. 1 and 2, the emulsion stability and cooking yields of the sausage were in accordance with the added black rice powder content. Cooking yield was correlated with moisture and fat retention, where increased cooking yield also increased moisture and fat retention. Fat is well known to be retained for improving sensory properties (Serdaroglu and Değırmencioğlu, 2004). In terms of emulsion stability, with increasing content of black rice powder, water loss tended to decrease, where the 3% and 5% black rice powder groups exhibited the lowest water loss (p<0.05). With increasing content of black rice powder, fat loss also tended to decrease. Gnanasambandam and Zayas (1992) have reported similar results, where meat products with the addition of wheat, corn germs, and bean proteins exhibit increased moisture retention and emulsion stability, and meatballs with the addition of bean proteins exhibit superior moisture and fat retention rates (Alamanou et al., 1996). Furthermore, fat retention and cooking yields have been reported to be improved with the addition of corn powder (Serdaroglu and Değırmencioğlu, 2004). The addition of a powder prevents a certain degree of water loss, and grain powders particularly improve water-holding capacity (Lee et al., 2003), which in turn helps in forming a stable emulsion; this stable emulsion results in low water and fat reduction, ultimately reducing cooking loss.

Fig. 1. Emulsion stability of various sausage formulated with different amounts of black rice powder. a-c, A-CMeans on bars with different alphabets are significantly different (p<0.05).

Fig. 2. Cooking yield of various sausage formulated with different amounts of black rice powder. a-cMeans on bars with different alphabets are significantly different (p<0.05).

Textural properties

As shown in Table 4, the textural characteristics of sausages were found to be in accordance with the added black rice powder content. Textural characteristics directly affect tenderness, which is the most important sensory property of meat products (Rhodes et al., 1955). With increasing content of black rice powder, hardness tended to decrease, albeit springiness and cohesiveness were not significantly changed in accordance with the black rice powder content (p>0.05). Moreover, in all black rice powder treatment groups, gumminess and chewiness were significantly less than that observed for the control group (p<0.05), with no significant differences among the treatment groups. Verma et al. (1984) have reported that sausages with the addition of garbanzo beans are more tender, and Alamanou et al. (1996) have reported that lupin-seed-powder-added frankfurters exhibit reduced hardness, gumminess, and chewiness in accordance with the lupin seed powder content, the results of which are similar to those observed herein. Nevertheless, another study has reported that for the typical main ingredients of sausage (meat, fat, and ice) partially substituted with grains, substituted sausage exhibits higher hardness (Jang et al., 2004), which is in contrast to our results. Such a difference is believed to have occurred because of the addition of black rice powder without the reduction in the content of other main or minor ingredients, which resulted in a relatively higher moisture content in the treatment groups as compared with observed for the control group; the higher moisture content results in the overall reduction of material property.

Table 4. Texture properties of sausage formulated with different amounts of black rice powder.

| Traits | Black rice powder (%) | |||

|---|---|---|---|---|

| 0 (control) | 1 | 3 | 5 | |

| Hardness (kg) | 2.35±0.15a | 1.93±0.23b | 1.74±0.10c | 1.87±0.12bc |

| Springiness | 0.92±0.01 | 0.90±0.05 | 0.91±0.03 | 0.91±0.02 |

| Cohesiveness | 0.34±0.06 | 0.34±0.06 | 0.33±0.04 | 0.32±0.03 |

| Gumminess (kg) | 0.79±0.14a | 0.64±0.10b | 0.57±0.07b | 0.59±0.05bc |

| Chewiness (kg) | 0.73±0.13a | 0.58±0.10b | 0.52±0.07b | 0.54±0.06b |

All values are mean ± standard deviation.

a-cMeans in the same row with different numbers are significantly different (p<0.05).

Sensory properties

Table 5 shows the results obtained from the sensory properties of sausages with the addition of black rice powder. The 3% and 5% black rice powder groups exhibited scores significantly higher than those observed for the control group for all characteristics from sensory evaluation (p<0.05). With increasing content of black rice powder, flavor, juiciness, and overall acceptability tended to increase. The 1% black rice powder group and control group did not exhibit a significant difference in tenderness, and tenderness was significantly different starting from the 3% addition group, indicating that a specific content of black rice powder must be added to increase tenderness. Minerich et al. (1991) have reported that wild-rice-added beef patty afforded sensory evaluation results superior to those observed for the control group, and black-rice-powder-added sausages, as compared to other cereal-added sausages, exhibit the best flavor, taste, and acceptability (Jang et al., 2004). The addition of grain powder, such as wheat, corn, and beans, to the meat products has been reported to enhance the material and sensory properties of meat (Gnanasambandam and Zayas, 1992). Similarly, the results obtained herein verified that the addition of black rice powder results in the enhancement of the sensory properties of sausage.

Table 5. Sensory properties of sausage formulated with different amounts of black rice powder.

| Traits | Black rice powder (%) | |||

|---|---|---|---|---|

| 0 (control) | 1 | 3 | 5 | |

| Color | 8.07±0.47b | 8.39±0.49ab | 8.66±0.59a | 8.43±0.51ab |

| Flavor | 8.00±0.50c | 8.97±0.37b | 9.29±0.56b | 9.74±0.44a |

| Tenderness | 8.06±0.75b | 8.47±0.62ab | 8.82±0.64a | 8.61±0.61a |

| Juiciness | 8.18±0.81c | 8.79±0.69b | 9.29±0.47a | 9.35±0.49a |

| Overall acceptability | 8.09±0.51c | 8.71±0.44b | 9.32±0.47a | 9.24±0.81a |

All values are mean ± standard deviation.

a-cMeans in the same row with different numbers are significantly different (p<0.05).

Conclusions

Black rice powder, as functional additives, was added to sausage for investigating the effects of black rice powder on the quality characteristics of meat products. Different amounts of black rice powder (0%, 1%, 3%, and 5%) was added to sausages. Based on the results, the addition of specific black rice powder content (3% and 5%) to pork sausage resulted in a characteristic color, improved emulsion stability and cooking yield, and enhanced sensory properties, suggesting that the functional effects of black rice powder improve the overall quality of sausage.

References

- 1.Alamanou S., Bloukas J. G., Paneras E. D., Doxastakis G. Influence of protein isolate from lupin seeds (Lupinus albus ssp. Graecus) on processing and quality characteristics of frankfurters. Meat Sci. 1996;42:79–93. doi: 10.1016/0309-1740(95)00013-5. [DOI] [PubMed] [Google Scholar]

- 2.AOAC. Official methods of analysis of AOAC international. (17th ed.) Association of Official Analytical Chemistry; Maryalnd, USA: 2000. [Google Scholar]

- 3.Choi H. C., Oh S. K. Diversity and function of pigments in colored rice. Korean J. Crop Sci. 1996;41:1–9. [Google Scholar]

- 4.Fardet A., Rock E., Remesy C. Is the in vitro antioxidant potential of whole-grain cereals and cereal products well reflected in vivo? J. Cereal Sci. 2008;48:258–276. doi: 10.1016/j.jcs.2008.01.002. [DOI] [Google Scholar]

- 5.Gnanasambandam R., Zayas J. F. Functionality of wheat germ protein in comminuted meat products as compared with corn germ and soy proteins. J. Food Sci. 1992;57:820–833. [Google Scholar]

- 6.Grunert K. G. Future trends and consumer lifestyles with regard to meat consumption. Meat Sci. 2006;74:149–160. doi: 10.1016/j.meatsci.2006.04.016. [DOI] [PubMed] [Google Scholar]

- 7.Ha T. Y., Park S. H., Lee C. H., Lee S. H. Chemical composition of pigmented rice varieties. Korean J. Food Sci. Technol. 1999;31:336–341. [Google Scholar]

- 8.Han M. Y., Ahn M. S. A study on the purchase action of processed foods and the recognition for food additives of urban housewives. Korean J. Dietary Culture. 1998;13:119–126. [Google Scholar]

- 9.Hwang Y. K., Kim T. Y. Characteristics of colored rice bread using the extruded Heugjinju rice. Korean J. Soc. Food Sci. 2000;16:167–172. [Google Scholar]

- 10.Issanchou S. Consumer expectations and perceptions of meat and meat product quality. Meat Sci. 1996;43:S5–S19. doi: 10.1016/0309-1740(96)00051-4. [DOI] [PubMed] [Google Scholar]

- 11.Jang S. M., Lim J. S., Cho E. J. The effect of various cereal flours on quality and storage characteristics of sausage. J. East Asian Soc. Dietary Life. 2004;14:265–274. [Google Scholar]

- 12.Keeton J. T. Effect of fat and NaCl/phosphate levels on the chemical and sensory properties of pork patties. J. Food Sci. 1983;48:878–881. doi: 10.1111/j.1365-2621.1983.tb14921.x. [DOI] [Google Scholar]

- 13.Kim H. C., Kim M. R. Consumer attitudes towards food additives. J. East Asian Soc. Dietary Life. 2005;15:126–135. [Google Scholar]

- 14.Kim H. Y., Lee E. S., Jeong J. Y., Choi J. H., Choi Y. S., Han D. J., Lee M. A., Kim S. Y., Kim C. J. Effect of bamboo salt on the physicochemical properties of meat emulsion systems. Meat Sci. 2010;86:960–965. doi: 10.1016/j.meatsci.2010.08.001. [DOI] [PubMed] [Google Scholar]

- 15.Lee Y. C., Song D. S., Yoon S. K. Effects of ISP adding methods and freezing rate on quality of pork patties and cutlets. Korean J. Food Sci. Technol. 2003;35:182–187. [Google Scholar]

- 16.Minerich P. L., Addis P. B., Epley R. J., Bingham C. Properties of wild rice/ground beef mixtures. J. Food Sci. 1991;56:1154–1157. doi: 10.1111/j.1365-2621.1991.tb04722.x. [DOI] [Google Scholar]

- 17.Moon B. K., Kim E. A., Park M. S., Lee D. K., Lee M. S., Choi B. R. Quality characteristics of cookies with black rice powder. J. Hum. Ecol. 2007;26:21–28. [Google Scholar]

- 18.Park S. Y., Kim G. W., Kim H. Y. Study on physicochemical properties of emulsion-type sausage added pork skin gelatin. J. Korean Soc. Food Sci. Nutr. 2016;45:209–214. doi: 10.3746/jkfn.2016.45.2.209. [DOI] [Google Scholar]

- 19.Rhodes V. J., Kiechi F. R., Brady D. E. Visual references for grades of retail beef cuts. College of agriculture. Res. Bull. 1955:583. [Google Scholar]

- 20.Rivero De Padua M. Some functional and utilization characteristics of sesame flour and proteins. J. Food Sci. 1983;48:1145–1147. doi: 10.1111/j.1365-2621.1983.tb09178.x. [DOI] [Google Scholar]

- 21.Serdaroglu M., Değırmencioğlu O. Effects of fat level (5%, 10%, 20%) and corn flour (0%, 2%, 4%) on some properties of Turkish type meatballs (koefte) Meat Sci. 2004;68:291–296. doi: 10.1016/j.meatsci.2004.03.010. [DOI] [PubMed] [Google Scholar]

- 22.Serdaroglu M., Yildiz-Turp G., Abrodimar K. Quality of low-fat meatballs containing legume flours as extenders. Meat Sci. 2005;70:99–105. doi: 10.1016/j.meatsci.2004.12.015. [DOI] [PubMed] [Google Scholar]

- 23.Verma M. M., Kedward D. A., Lawrie R. A. Utilization of chickpea flour in sausages. Meat Sci. 1984;11:109–121. doi: 10.1016/0309-1740(84)90009-3. [DOI] [PubMed] [Google Scholar]

- 24.Yoon M. H., Chang K. M., Choe I. S. Consumption pattern of meat products in Korea. Korean J. Food Sci. An. 2001;21:18–23. [Google Scholar]