Abstract

Background

Modularity in total hip arthroplasty has been used for decades with great success, but new findings regarding corrosion artifacts have caused a resurgence in tapered junction research. Mechanically assisted crevice corrosion (MACC) is thought to be the mechanism by which corrosive attack occurs. Myriad multi-factorial variables are known to influence the susceptibility of a modular taper junction to MACC. Some of these variables are design and manufacture related and others can be controlled by the surgeon.

Questions/Purposes

This study was performed to assess a 22-year retrieval database to determine if correlations exist between severity of corrosion artifacts and head size, time in vivo, head offset, or head material. Secondarily, the agreement of visual and semi-quantitative scoring methods was assessed using the retrieved components.

Methods

A total of 210 femoral head tapers were scored and heads receiving high scores were measured to quantify material loss due to MACC.

Results

Increased head size and increased time in vivo did not correlate to higher corrosion scores. Contrarily, there were differences in corrosion scores based on femoral head offset and material. Deviations away from a neutral offset (where neutral is defined as the alignment of femoral head center and stem taper gage point) resulted in higher scores. Cobalt-chromium-molybdenum heads were associated with higher corrosion scores and higher material loss as compared to oxidized zirconium heads.

Conclusion

Reducing the moment arm at the head-neck junction and choosing a more inert material appears to provide greater resistance to corrosion.

Electronic supplementary material

The online version of this article (doi:10.1007/s11420-016-9517-5) contains supplementary material, which is available to authorized users.

Keywords: mechanically assisted crevice corrosion, taper, total hip arthroplasty, retrievals

Introduction

The use of tapered junctions in total hip arthroplasty (THA) has excellent long-term results spanning decades of use. The modularity in THA provided by mechanically locked tapers allows for appropriate component sizing to ensure satisfactory patient outcomes. Corrections for leg length discrepancies, reduction of dislocation potential, the ability to optimize wear performance, and mitigating future complications during revision THA through component selection are important during pre- and intra-operative assessment. However, recent findings regarding corrosion artifacts at tapered surfaces have spurred growing interest. First hypothesized in the 1990s, mechanically assisted crevice corrosion (MACC) has become the predominant mechanism by which modular junctions are thought to undergo corrosive attack [4, 11].

It is now known that a myriad of factors influence THA susceptibility to MACC. Firstly, as the name implies, MACC is dependent upon the mechanical integrity of the taper lock. Micromotion at the head-neck taper junction occurs when the femoral head undergoes loading. The magnitude of this micromotion can be attributed to both device-related and surgeon-related factors. Design- and manufacturing-related factors such as taper size, straightness, roughness, roundness, rigidity, angular mismatch (whether through design or as a result of manufacturing tolerances), and location of taper lock (proximal versus distal) are known to influence micromotion [2, 25, 33]. Surgeon-related factors include magnitude and orientation of the impact blow when seating the femoral head, cleanliness of tapers prior to locking, and selection of component sizes to reduce the resultant moment arm at the head-neck junction [30, 32].

Secondly, MACC occurrence requires a conducting medium. Crevice corrosion occurs when metal surfaces are partially shielded from the environment. It can occur to metals that would typically be resistant to pitting or other types of corrosion and is generally seen to occur in threaded types of junctions [8]. In modular THA connections, narrow crevices where fluid penetration can occur exist. During loading, the passive oxide film of the metal is ruptured, leading to dissolution of metal ions in the crevice fluid. The exposed metal surface reacts with oxygen in the fluid to form passive oxide and depletes the solution of oxygen. As the fluid is entrapped in a crevice, it has no access to fresh fluid to increase oxygen concentration. As the process of rupturing of the passive oxide and reformation of the passive oxide continues, the crevice gets depleted of oxygen and gets rich in metal ions. The metal ions react with chloride ions in the fluid to form metal chlorides. Metal chloride reacts with water to form metal hydroxide and hydrochloric acid, which reduces pH of the fluid.

This reduction in pH can chemically reduce the passive oxide and thus leads to etching and pitting of the surfaces as has been observed clinically for some retrievals [11]. This particular model does not require that the mating surfaces be dissimilar for galvanic interaction. In MACC, disruption of the surface oxide due to repeated micromotion and restricted transport of oxygen in the crevice leads to significantly lower pH, which can result in active attack of the metals. Acidic environments with a pH below 3.0 have been observed during THA revision [23, 37] and are known to be a contributing factor in MACC. The oxide of cobalt-chromium-molybdenum (CoCrMo), a material used extensively in femoral heads and in some THA stems, is known to be thermodynamically unstable at a pH below 3.5 [11]. However, certain metals or alloys may perform better than the others based on the pH of the crevice. For example, in a simulated fatigue test with an acidic pH of 3.5, a stainless steel head on a stainless steel trunnion showed much higher corrosion than a CoCrMo head on a titanium-6aluminum-4vanadium (Ti-6Al-4V) trunnion and oxidized zirconiuim-2.5niobium (OxZr) head on Ti6Al4V trunnion [31]. Material selection is one of the primary means by which to combat corrosive attack. Choosing materials that are more inert may lessen the likelihood of corrosive interactions.

Thirdly, patient-related factors influencing MACC may be more difficult to predict. While correct sizing is appropriate, larger head diameters are increasing in popularity due to the ability to achieve greater stability and avoid dislocation [1, 18]. Anatomical constraints may necessitate head offsets away from neutral, such that the femoral head center is not aligned with the stem gage point. Patient compliance varies, as does the orientation and magnitude of loading vectors due to patient BMI and activity levels. Expected time in vivo can vary greatly from one patient to another. The purpose of this study was to assess an on-going 22-year retrieval database to determine if correlations exist between severity of corrosion artifacts and head size, time in vivo, head offset, or head material.

Materials and Methods

Retrieved THA femoral heads revised from 1997 to 2014 were investigated for corrosion artifacts in this study. Exclusion criteria included less than 1 week in vivo and monolithic ceramic heads. Tapers with such short in vivo durations were not expected to be associated with corrosion. Monolithic ceramic heads in the database were primarily revised due to fracture, making analysis difficult, and were therefore excluded. Investigation included a semi-quantitative scoring method, scanning electron microscopy (SEM) analyses, and vertical straightness profile (VSP) measurements. As a validation measure, the agreement of visual and semi-quantitative scoring methods was assessed using the retrieved components.

Head tapers were scored independently by a panel according to Goldberg et al. for assessment of corrosion [12]. Tapers were manually cleaned with a mild detergent (CitriSurf, Stellar Solutions, McHenry, IL USA) and cotton-tipped applicator for removal of biological contaminants prior to characterization. A score of 1 (none), 2 (mild), 3 (moderate), or 4 (severe) was given to a taper surface depending on the level of discoloration, fretting, and corrosion evidence. Tapers from metal-on-polyethylene hips exhibiting worst-case fretting and corrosion features (Goldberg Score [GS] ≥ 3) were further analyzed using electron microscopy, energy-dispersive x-ray spectroscopy (EDAX), and profilometry. Vertical straightness profile (VSP) measurements were taken on this subset of heads as an additional measure to quantify corrosion within the taper contact region by measuring linear depth of material loss. VSP analyses of the tapers were measured using a Taylor Hobson TR290 roundness machine (Leicester, UK) with a 1-mm ruby-tipped probe using the straightness measurement function of the machine. Measurements started at 0.5 mm from the proximal end through the whole taper length to the distal rim at a scanning speed of 1 mm/s. Using the profile within the non-contact region as a reference, the depth of material loss (or build-up) in the contact region was measured from the VSP profile using Taylor Hobson Ultra 2.0 software, as has been previously documented [24]. For each measured taper, eight VSPs were taken in line with the long axis of the taper at 45° intervals around the circumference. Since most heads were returned either without a stem or disassociated from a returned stem, the orientation of each head was unknown. In an effort to standardize the scans, a 0° start point was designated as a reference by marking each head at the same location near the company logo. Deviations from straight were used to represent depth of linear material loss. Profile mapping around the circumference of each head at the 45° intervals was acquired by reporting the maximum depth of linear material loss from each of the eight scans.

Data was reported as average ± standard deviation. Where applicable, Pearson correlation coefficients (r) or adjusted correlation coefficients (r adj) were determined with regression analyses. Fisher’s f tests for variance and two-tailed Students’ t tests for differences between means were conducted at α = 0.05.

Results

There were 210 retrieved femoral heads that met the inclusion criteria. All femoral heads were coupled with either CoCrMo or Ti-6Al-4 V stems. The majority of the head tapers were 12/14 in size (n = 136, 65%). Head sizes ranged from 22 to 56 mm diameter, and there were n = 111 heads (53%) that were 36 mm or greater in diameter. Both metal-on-polyethylene (MoP, n = 145, 69%) and metal-on-metal (MoM, n = 65, 31%) bearings were scored. The top three reported reasons for revision were stem fracture (n = 48, 23%), unexplained pain (n = 42, 20%), and dislocation (n = 38, 18%). Corrosion or metallosis was reported as primary reason for revision in n = 18 (9%) cases and positive identification of pseudotumor in n = 3 (1%) MoM devices.

The aggregate Goldberg Score (GS) for the retrieved femoral heads was 2.4 ± 0.9, indicating that on average mild corrosion evidence was found on the examined devices. There was not a strong positive correlation between increasing head size and increasing corrosion score (r adj = 0.42, p > 0.05) when both MoP and MoM heads were analyzed together. Given that MoM heads are associated with larger head sizes and tapers of large diameter MoM total hips have been the source of metallosis issues reported in the literature [35], these datasets were also analyzed separately. Within each subset, the correlation between increasing head size and increasing GS was reduced even further (MoP r adj = 0.07, p > 0.05; MoM r adj = 0.19, p > 0.05), indicating the inclusion of MoM within the analyses may have contributed to the correlation. However, there was no statistically significant difference between the GS of MoP versus MoM heads (2.2 ± 0.9 versus 2.8 ± 1.0, respectively; p > 0.05).

Time in vivo was known for n = 138 (66%) of the femoral heads investigated. The average time in vivo was 2.9 ± 2.7 years and ranged from 1 week to 15 years. A weak positive correlation existed between increasing time in vivo and increasing corrosion score (r adj = 0.28, p < 0.05). As the most frequent reason for revision in this database was stem fracture, which by inference may indicate a shorter time in vivo, these datasets were analyzed separately. Heads with known in vivo times and coupled with fractured stems (n = 17) averaged 1.7 ± 1.3 years in the body, while heads revised for other reasons (n = 121) averaged 3.0 ± 2.8 years (p < 0.05). However, there was no difference between the GS for those femoral heads associated with stem fracture as compared to other reasons for revision (2.4 ± 0.8 versus 2.4 ± 0.9, respectively; p > 0.05).

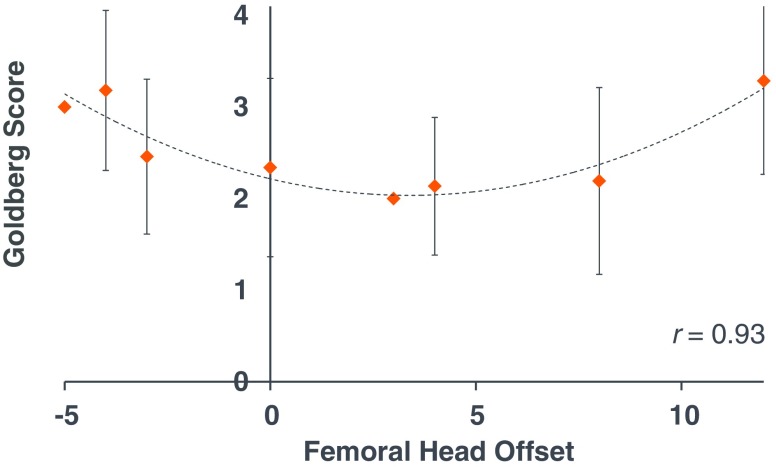

Eight femoral head offsets were included in this study ranging from −3 to +12. There was a very strong parabolic correlation between head offset and average corrosion score (r = 0.93), with more neutral offsets trending toward lower scores. Higher scores were observed with the progression away from neutral head offsets (Fig. 1).

Fig. 1.

Average (±SD) GS for each femoral head offset analyzed showing a parabolic correlation (dashed line, r = 0.93) with offsets away from neutral indicating higher scores.

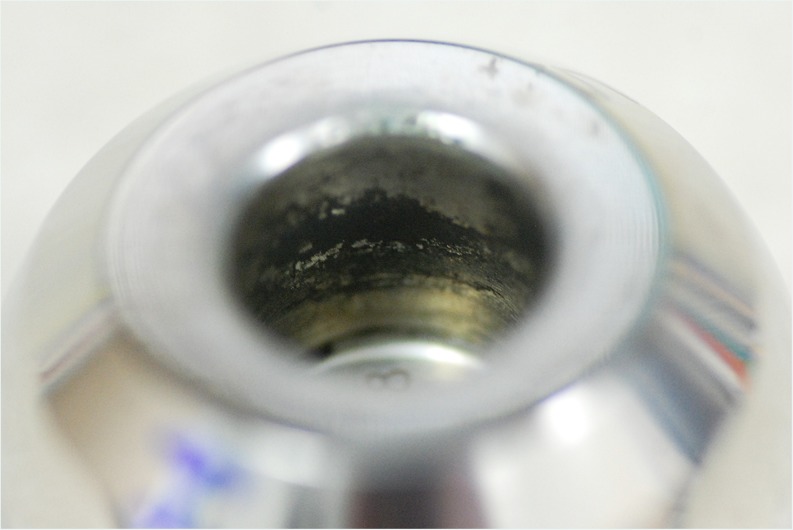

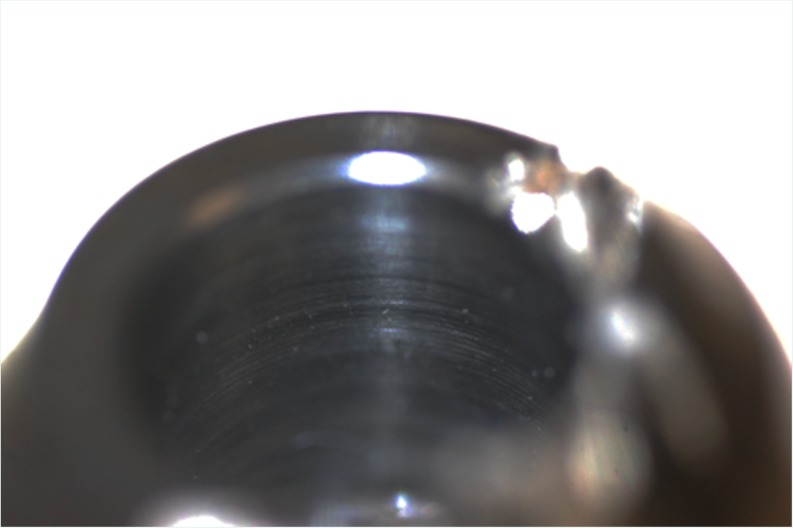

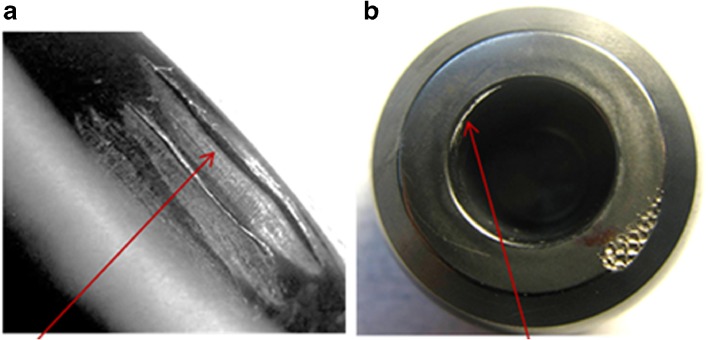

Two head materials were found in the database: CoCrMo and OxZr. There were n = 165 (79%) CoCrMo and n = 45 (21%) OxZr heads. CoCrMo heads exhibited higher scores as compared to OxZr heads (2.5 ± 1.0 versus 1.9 ± 0.7, respectively, p < 0.05). When MoM bearings were removed from this comparison, CoCrMo heads still exhibited higher scores as compared to OxZr heads (2.3 ± 0.9 versus 1.9 ± 0.7, respectively, p < 0.05). There were n = 22 (76%) CoCrMo heads and n = 7 (24%) OxZr heads that received a score of 3. There were n = 8 (89%) CoCrMo heads and n = 1 (11%) OxZr head that received a score of 4. Large areas of black discoloration were observed on CoCrMo femoral head tapers receiving a score of 3 or 4 (Fig. 2). Observations were largely limited to mechanical surface disruptions on the OxZr head tapers scoring a 3 or 4 (Fig. 3). The one OxZr head scoring a 4 was in vivo only 1 month and exhibited signs of dislocation. Its surface damage was shown to be mechanical deformation localized to the mouth outside the taper contact region (Fig. 4).

Fig. 2.

CoCrMo head which received a GS of 4 due to visual signs of severe corrosion as characterized by large areas of black discoloration and multiple bands of fretting scars spanning adjacent machine lines.

Fig. 3.

OxZr head which received a GS of 3 due to visual signs of mechanical surface disruptions on the taper surface.

Fig. 4.

The OxZr head receiving a GS of 4 showed a localized deformation (arrows) primarily b at the taper mouth due to dislocation.

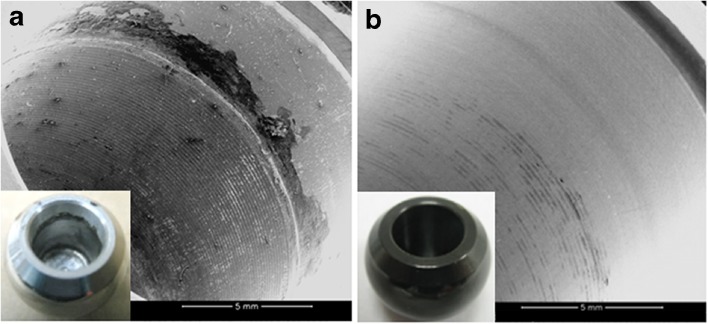

Distinct regions of contact and non-contact were observed on CoCrMo head tapers (Fig. 5a). Fretting scars spanning multiple adjacent machine lines were also observed. SEM analyses showed corrosion evidence primary localized to the distal contact taper regions. Mechanical deformation was greatest at the gage point regions, and evidence of stem imprinting was visible on CoCrMo femoral head tapers. These features were not observed on OxZr heads (Fig. 5b). Metal transferred from the stem was found within femoral head tapers paired with Ti-6Al-4V stems as confirmed by EDAX spectra in these regions, which showed peaks consistent with Ti-6Al-4V. Chromium-rich precipitate build-up was observed near the contact/non-contact demarcation zones. Higher chromium versus cobalt peaks and high oxygen content indicated these build-up regions were likely chromium oxide.

Fig. 5.

a Worst-case CoCrMo head (GS: 4) showed evidence of MACC and b worst-case OxZr head (GS: 3) which showed no MACC evidence.

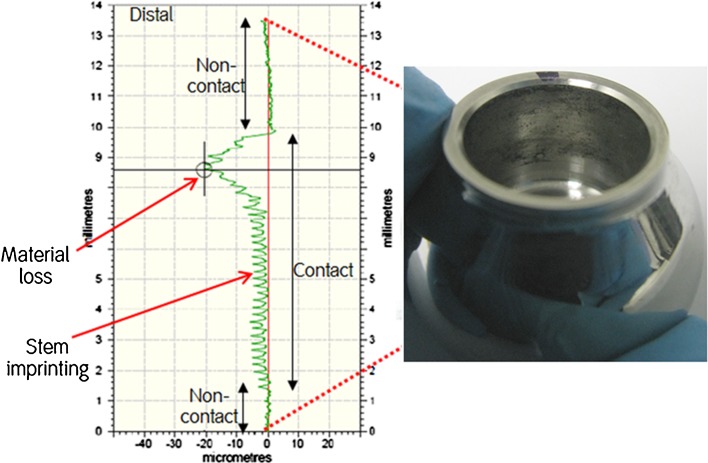

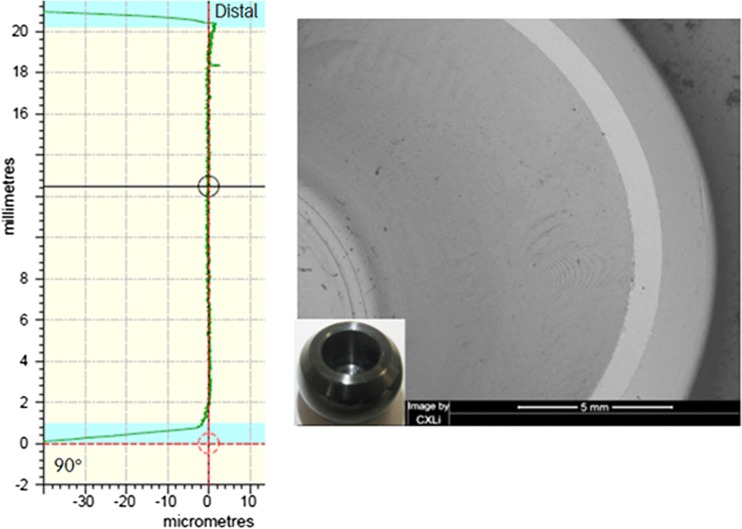

VSP measurements were taken on all MoP heads that received a score of 3 (n = 29) or 4 (n = 9). Measureable material loss was found on 17 CoCrMo heads (Fig. 6). No measureable material loss was found on any OxZr heads (Fig. 7). The dislocated OxZr head showed mechanical deformation, which was at the taper mouth and not attributable to MACC. The maximum depth of linear material loss for MoP CoCrMo heads ranged from 1 to 103 μm. All CoCrMo heads with measureable material loss showed macro- and microscopic features of MACC, such as surface discoloration, stem imprinting marks, and deposits of chromium-rich debris.

Fig. 6.

One (of 8) VSP scans taken from a CoCrMo head showing distinct contact and non-contact regions within the taper, stem imprinting, and maximum linear material loss.

Fig. 7.

One (of 8) VSP scans taken from an OxZr head showing no evidence of MACC features.

Tapers scoring a 4 had higher average maximum depth of linear material loss values as compared to tapers scoring a 3 (35 ± 42 versus 2 ± 5 μm, respectively, p = 0.05). Thus, there was positive corroboration between the semi-quantitative Goldberg scoring and quantitative VSP methods.

Discussion

Modularity in THA devices remains a beneficial surgical tool that provides options tailored to patient needs. For the majority of patients, mechanical taper locking provides an excellent junction between the stem neck and femoral head. In some cases however, the potential exists for complications due to increased modularity. One such complication has been explained to arise via the MACC pathway, which leads to oxide depletion and an increase in acidity in the local taper environment. The understanding of MACC prevalence in THA is growing. Although MACC can be attributed as the cause for only a small percentage of THA revisions, the percentage is not negligible. Retrospective postulations that diagnoses for unexplained pain may be MACC certainly call for greater research into variables affecting corrosion [16]. Visual and quantitative scoring methods have been used to assess these variables [12, 29], which were employed with adequate agreement in this study. While correlation does not imply causation, in this study, femoral head size, time in vivo, head offset, and head material were evaluated as potential contributors to MACC based on a 22-year retrieval database.

Increasing the femoral head size theoretically increases the resultant moment arm at the THA head-neck junction. It has been shown that this influences the amount of torque generated at this junction [9, 15]. Based on these principles, larger head diameters (i.e., 36 mm and greater) are thought to be more susceptible to fretting and corrosion due to the potential for generating higher torques. However, this finding has not been universally supported for MoP bearings [20, 28]. And based on the retrieval findings in this study, no correlation was found between increasing head size and increased corrosion evidence as measured by two established analysis methods. It is important to note, however, that this study investigated femoral head tapers from a single manufacturer, which merits caution when extrapolating to other taper designs.

Likewise, time in vivo was not a major contributor to higher corrosion evidence. There was a weak correlation between increased time and increased corrosion (r adj = 0.28, p < 0.05), and MACC is expected to be a time-dependent mechanism through which some threshold must exist before corrosion onset occurs, but other extenuating circumstances seem to have a greater effect. With much fewer retrievals analyzed, some authors have found more conclusive evidence time in vivo is a significant contributor to presence of corrosion [11, 17], while still others show little effect of time [5]. We chose to include retrievals with in vivo times less than a month but did not expect nor find significant corrosion evidence on these tapers. However, there were tapers with relatively low in vivo times (less than 1 year) that received scores of 4 and had measureable material loss. Contradistinctively, there were also tapers with in vivo times greater than 5 years that received scores of 1. Time in vivo may be a confounding factor but does not appear to be the primary driver of MACC.

Similar to head size, femoral head offset also contributes to the resultant moment arm at the THA head-neck junction. Eight head offsets were evaluated in this study. A −3 head offset is characterized by the head center being distal to the gage point, and a +12 head offset is characterized by the head center being proximal to the gage point. A neutral offset occurs when the head center and gage point are aligned. These distances vary based on taper design, and a +0 offset does not necessarily mean exact alignment. But head offset was shown to be a major contributor to corrosion evidence in this study. The combination of options for stem neck offsets (standard, high, varus, valgus) and femoral head offsets add to the complexity of taper engagement and subsequent in vivo loading induced micromotion. The purpose of this study did not include investigation of stem offsets or the varying load conditions that exist in vivo on these tapered surfaces, and these variables may also play a role.

The use of CoCrMo as a THA material has been reported to be linked with presentation of adverse local tissue reactions associated with ion release from MoP devices [6], indicating this phenomenon is not constrained to MoM alone. This follows MACC theory, which suggests that the chromium oxide layer of CoCrMo alloy is thermodynamically unstable at low pH [11]. Chromium-rich precipitates and other artifacts were found on the femoral head tapers associated with high corrosion scores and deviations from vertical straightness in this study. These features were absent from OxZr femoral head tapers, which displayed lower scores and no measureable material loss. OxZr femoral heads have a transformed ceramized metal substrate that provides a greater degree of inertness [7, 27] and may not be as susceptible to the issues with mixed alloy combinations others have reported [5, 12]. As femoral head material is one of the few parameters under surgeon control for any given taper design, a ceramic taper is a viable option. Indeed, recent findings of corrosion of metallic heads have propagated the use of ceramics as an alternative bearing material. While complications with ceramics in primary THA are uncommon, revising to a monolithic ceramic head requires the use of an additional titanium sleeved junction which may corrode, opens up the possibility for phase transformation while in vivo [3, 10, 14], and may cause further susceptibility to fracture or third body wear [13, 19, 21, 22, 36]. This fracture risk is eliminated when OxZr heads are used [34]. Additionally, as the oxide layer of any implant helps protect it in an acidic environment, improving its depth and hardness reduces corrosion susceptibility. The oxide layer of OxZr has been shown to be orders of magnitude thicker and twice as hard as that of CoCrMo [26]. Thus, a greater magnitude of micromotion is required for surface disruption to occur.

MACC can be mitigated through design-related and surgeon-related factors. Reducing micromotion through manufacture and design and improving outcomes through surgical technique, material, and size selections are important. CoCrMo heads have years of clinical success, but as shown in this retrieval assessment are still associated with MACC, with quantifiable material loss and evidence of corrosion artifacts. Two analysis techniques were employed in agreement to this finding, which is further validated through a purview of the current orthopedic literature. Though many confounding variables contribute to MACC, in this study, a strong correlation was not observed for head size or time in vivo and corrosion score. However, significant correlations existed between head offset and head material. More neutral offsets and OxZr heads are associated with decreased corrosion damage. Reducing the moment arm at the THA head-neck junction and choosing a more inert material provide greater resistance to corrosion.

Electronic supplementary material

Below is the link to the electronic supplementary material.

(PDF 1224 kb)

(PDF 1224 kb)

(PDF 1224 kb)

(PDF 1224 kb)

Compliance with Ethical Standards

Conflict of Interest

Jacob Cartner, MS, reports other from Smith & Nephew, during the conduct of the study; other from Smith & Nephew, outside the work. Patrick Aldinger, BS, reports other from Smith & Nephew, during the conduct of the study; other from Smith & Nephew, outside the work. Chenxi Li, PhD, reports other from Smith &Nephew, during the conduct of the study; other from Smith & Nephew, outside the work. David Collins, MS, reports other from Smith & Nephew, during the conduct of the study; other from Smith & Nephew, outside the work.

Human/Animal Rights

This article does not contain any studies with human or animal subjects performed by the any of the authors.

Informed Consent

N/A

Required Author Forms

Disclosure forms provided by the authors are available with the online version of this article.

References

- 1.Allen CL, Hooper GJ, Frampton CM. Do larger femoral heads improve the functional outcome in total hip arthroplasty? J Arthroplast. 2014;29(2):401–4. doi: 10.1016/j.arth.2013.06.017. [DOI] [PubMed] [Google Scholar]

- 2.Barrack R, Cook S, Lavernia C, Jani S, Tozakoglou E. The modular Morse taper junction in total hip replacement, Scientific Exhibit at AAOS Meeting, San Francisco; 1997.

- 3.Clarke IC, Manaka M, Green DD, et al. Current status of zirconia used in total hip implants. JSJBS-Am. 2003;85-A(supp 4):73–84. doi: 10.2106/00004623-200300004-00009. [DOI] [PubMed] [Google Scholar]

- 4.Collier JP, Surprenant VA, Jenson RE, et al. Corrosion at the interface of cobalt-alloy heads on titanium-alloy stems. CORR. 1991;271:305–12. [PubMed] [Google Scholar]

- 5.Cook SD, Barrack RL, Baffes GC, et al. Wear and corrosion of modular interfaces in total hip replacements. CORR. 1994;298:80–88. [PubMed] [Google Scholar]

- 6.Cooper JH, Della Valle CJ, Berger RA, et al. Corrosion at the head-neck taper as a cause for adverse local tissue reactions after total hip arthroplasty. JCJS-Am. 2012;94(18):1655–61. doi: 10.2106/JBJS.K.01352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Dalal A, Pawar V, McAllister K, et al. Orthopedic implant cobalt-alloy particles produce greater toxicity and inflammatory cytokines than titanium alloy and zirconium alloy-based particles in vitro, in human osteoblasts, fibroblasts, and macrophages. JBMR-A. 2012;100A(8):2147–58. doi: 10.1002/jbm.a.34122. [DOI] [PubMed] [Google Scholar]

- 8.Davis JR editor. Handbook of materials for medical devices. ASM International; 2003.

- 9.Dyrkacz RMR, Brandt JM, Ojo OA, et al. The influence of head size on corrosion and fretting behavior at the head-neck interface of artificial hip joints. J Arthroplast. 2013;28(6):1036–40. doi: 10.1016/j.arth.2012.10.017. [DOI] [PubMed] [Google Scholar]

- 10.Elpers M, Nam D, Boydston-White S, et al. Zirconia phase transformation, metal transfer, and surface roughness in retrieved ceramic composite femoral heads in total hip arthroplasty. J Arthroplast. 2014;29(11):2219–23. doi: 10.1016/j.arth.2014.08.011. [DOI] [PubMed] [Google Scholar]

- 11.Gilbert JL, Buckley CA, Jacobs JJ. In vivo corrosion of modular hip prosthesis components in mixed and similar metal combinations: the effect of crevice, stress, motion, and alloy coupling. JBMR. 1993;27:1533–44. doi: 10.1002/jbm.820271210. [DOI] [PubMed] [Google Scholar]

- 12.Goldberg JR, Gilbert JL, Jacobs JJ, et al. A multicenter retrieval study of the taper interfaces of modular hip prostheses. CORR. 2002;401:149–61. doi: 10.1097/00003086-200208000-00018. [DOI] [PubMed] [Google Scholar]

- 13.Guhrs J, Krull A, Witt F, et al. The influence of stem taper re-use upon the failure load of ceramic heads. Med Eng Phys. 2015;37:545–52. doi: 10.1016/j.medengphy.2015.03.010. [DOI] [PubMed] [Google Scholar]

- 14.Haraguchi K, Sugano N, Nishii R, et al. Phase transformation of a zirconia ceramic head after total hip arthroplasty. JBJS-Br. 2001;83-B(7):996–1000. doi: 10.1302/0301-620X.83B7.12122. [DOI] [PubMed] [Google Scholar]

- 15.Higgs GB, Hanzlik JA, MacDonald DW, et al. Is increased modularity associated with increased fretting and corrosion damage in metal-on-metal total hip arthroplasty devices? A retrieval study. J Arthroplast. 2013;28(8 sup):2–6. doi: 10.1016/j.arth.2013.05.040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Jacobs JJ, Cooper HJ, Urban RM, et al. What do we know about taper corrosion in total hip arthroplasty? J Arthroplast. 2014;29(4):668–9. doi: 10.1016/j.arth.2014.02.014. [DOI] [PubMed] [Google Scholar]

- 17.Kop AM, Swarts E. Corrosion of a hip stem with a modular neck taper junction: a retrieval study of 16 cases. J Arthroplast. 2009;24(7):1019–23. doi: 10.1016/j.arth.2008.09.009. [DOI] [PubMed] [Google Scholar]

- 18.Kostensalo I, Junnila M, Virolainen P, et al. Effect of femoral head size on risk of revision for dislocation after total hip arthroplasty: a population-based analysis of 42,379 primary procedures from the Finnish Arthroplasty Register. Acta Orthop. 2013;84(4):342–7. doi: 10.3109/17453674.2013.810518. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Kurtz SM, Kocagoz SB, Hanzlik JA, et al. Do ceramic femoral heads reduce taper fretting corrosion in hip arthroplasty? A retrieval study. CORR. 2013;471:3270–82. doi: 10.1007/s11999-013-3096-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Kurtz SM, MacDonald D, Higgs GB, et al. Are 36+ MM diameter HXLPE bearings at risk of increased wear from modular taper corrosion with ceramic and CoCr heads? JBJS-Br. 2014;96-B(sup 11):145. [Google Scholar]

- 21.Lee GC, Bistolfi A. Management of ceramic component fractures: can you ensure a safe return? Sem Arthrop. 2015;26:34–7. doi: 10.1053/j.sart.2015.04.007. [DOI] [Google Scholar]

- 22.Lee GC, Kim RH. Reliability of modern ceramic femoral heads in over 5.7 million hip implants. Las Vegas, NV: AAOS Conference Proceedings; March 2015.

- 23.Levine DL, Staehle RW. Crevice corrosion in orthopedic implant metals. JBMR-A. 1977;11(4):553–61. doi: 10.1002/jbm.820110410. [DOI] [PubMed] [Google Scholar]

- 24.Li C. Taper corrosion and measurement of a retrieved metal-on-poly total hip joint device. Proc from EORS. 2012;20:17. [Google Scholar]

- 25.Lieberman JR, Rimnac CM, Garvin KL, et al. An analysis of the head-neck taper interface in retrieved hip prostheses. CORR. 1994;300:162–7. [PubMed] [Google Scholar]

- 26.Long M, Riester L, Hunter G. Nano-hardness measurements of oxidized Zr-2.5Nb and various orthopaedic materials. San Diego, CA: Proc from Society for Biomaterials; 1998.

- 27.Marek M, Pawar V, Tsai S, Thomas R, Sprague J, Salehi A, Hunter G. Galvanic corrosion evaluation of Zr-2.5Nb coupled with orthopaedic alloys. ASM Intl, Proc from Materials and Processes for Medical Devices. Boston, MA; 2005.

- 28.Noble PC. CORR Insights: Otta Aufranc Award: large heads not increase damage at the head neck taper of metal-on-polyethylene total hip arthroplasties. CORR. 2015 doi: 10.1007/s11999-015-4468-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Panagiotidou A, Meswania J, Hua H, et al. Enhanced wear and corrosion in modular tapers in total hip replacement is associated with the contact area and surface topography. J Orthop Res. 2013;31(12):2032–9. doi: 10.1002/jor.22461. [DOI] [PubMed] [Google Scholar]

- 30.Pansard E, Fouillerona N, Dereudrea G, et al. Severe corrosion after malpositioning of a metallic head over the morse taper of a cementless hip arthroplasty. Orthop Traumatol Surg Res. 2012;98:247–50. doi: 10.1016/j.otsr.2011.05.018. [DOI] [PubMed] [Google Scholar]

- 31.Pawar V, Jones B, Sprague J, Salehi A, Hunter G. ASM Intl, Proc from Materials and Processes for Medical Devices. St. Paul, MN; 2004.

- 32.Pennock AT, Schmidt AH, Bourgeault CA. Morse-type tapers: factors that may influence taper strength during total hip arthroplasty. J Arthroplast. 2002;17(6):773–8. doi: 10.1054/arth.2002.33565. [DOI] [PubMed] [Google Scholar]

- 33.Schmidt AH, Loch DA, Bechtold JE, Kyle RF. Assessing morse taper function: the relationship between impaction force, disassembly force, and design variables. In: Marlowe DE, Parr JE, Mayor MB editors. Modularity of Orthopedic Implants, ASTM STP 1301; 1997.

- 34.Sprague J, Salehi A, Tsai S, Pawar V, Thomas R, Hunter G. Mechanical behavior of zirconia, alumina, and oxidized zirconium modular heads. San Francisco, CA: Proc from International Society for Technology in Arthroplasty; 2003.

- 35.Stryker LS, Odum SM, Fehring TK, et al. Revisions of monoblock metal-on-metal THAs have high early complication rates. CORR. 2015;473(2):469–74. doi: 10.1007/s11999-014-3791-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Varnum C, Pedersen AB, Kiaersgaard-Andersen P, et al. Comparison of the risk of revision in cementless total hip arthroplasty with ceramic-on-ceramic and metal-on-polyethylene bearings: data on 11,096 patients from the Danish Hip Arthroplasty Registry. Acta Orthop. 2015;86:1–8. doi: 10.3109/17453674.2015.1012975. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Willert HG, Broback LG, Buchhorn GH, et al. Crevice corrosion of cemented titanium alloy stems in total hip replacements. CORR. 1996;333:51–75. [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

(PDF 1224 kb)

(PDF 1224 kb)

(PDF 1224 kb)

(PDF 1224 kb)