We’re awash in plastics, many of which are hard to recycle. Could innovations, girded by the right incentives, finally whittle down the piles of plastic waste?

The waste that arrives at MBA Polymers’ big blue factory in Worksop, in England’s industrial heartland, is a dirty, smelly mess. Fresh from a metals recycler that has extracted hunks of steel from the crushed remains of cars and other trash, it contains many types of plastic jumbled in with carpeting, rubber, glues, bits of metal and glass, and even the occasional dead animal. Inside the cacophonous facility, powerful magnets and other technologies strip out everything but the plastic, which is ground into small 6–8 millimeter particles.

Companies are finding better ways to recycle multiple types of plastic, but costs often remain a barrier. Image courtesy of Shutterstock/Warut Chinsai.

These flakes are then washed, sorted, melted, filtered, and extruded. The final result: small pellets of pure plastic that can be melted down and then reshaped into anything from printers to vacuum cleaners, thus replacing virgin polymers made from fossil fuel feedstocks. “We take some of the ugliest waste streams and produce high-value products,” says MBA Polymers Inc. director Mike Biddle, who founded the company in his garage in California.

Such transformations aren’t confined to MBA Polymers. There’s been a “quiet revolution” in the technology of mechanically sorting waste plastic, says Edward Kosior, managing director of international recycling consultant Nextek. Near-infrared scanners, centrifuges, and other high-tech tools can now sort plastic flakes as small as 2 millimeters from mixed trash. That means recycling companies can produce high-quality plastic not just from the contents of carefully sorted curbside recycle bins, but also from general municipal solid waste.

And the advances aren’t limited to sorting. Researchers are using clever chemistry to break apart the polymer molecules in plastic waste, and to recombine them to produce materials of equal or even higher value. “We now have the technology to really make a difference and clean up the world,” says Tonnis Hooghoudt, CEO and cofounder of Ioniqa Technologies in The Netherlands.

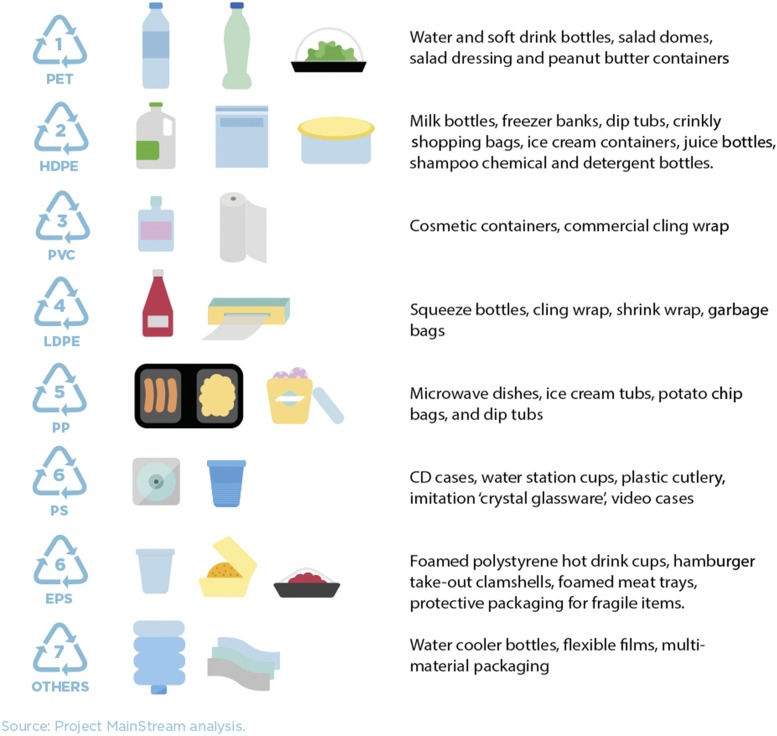

These innovations can’t solve all recycling problems. Whereas the vast majority of plastics are thermoplastics, which typically can be recycled, a small portion are thermosetting plastics, whose chemical cross-links among polymer strands make them more difficult to melt and reshape. Even among thermoplastics, some types face barriers. For example, expanded polystyrene—commonly known as Styrofoam—has such a low density that it’s difficult to collect sufficient quantities of coffee cups, clamshell food packaging, and other products made from expanded polystyrene to recycle the material economically. Meanwhile, the recycling of other plastics still faces daunting economic, policy, and cultural barriers.

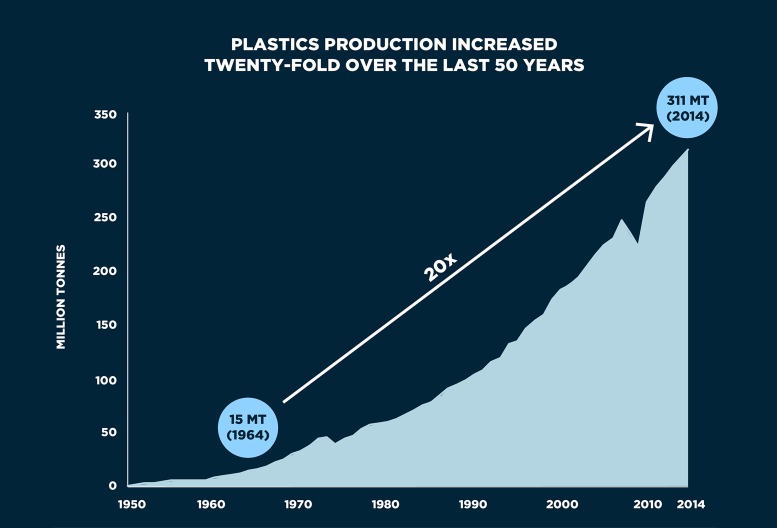

The problem is immense. More than 90% of the plastic in our cars, phones, and myriad other products is virgin, consuming about 6% of the oil and gas used each year (1). Only about 14% of plastic packaging is even collected for recycling, and much of that is “down-cycled” into cheaper plastics used for garbage bags or plastic benches. Their low value makes it hard for recyclers to make money, especially after the plunge in the price of oil, and the products are typically discarded after just one use. So it’s no surprise that most of the estimated 300 million tons of plastic that the world discards every year ends up in landfills, incinerators, or the oceans. A team of United States scientists recently calculated that 4.8–12.7 million tons flowed out to sea in 2010 alone (2), contributing to massive garbage patches in the oceans (3). We are “poisoning the planet with plastic,” says Kosior.

But the future doesn’t have to be so grim. Biodegradable plastics have made strides (see Sidebar). And along with new processing technologies and polymer science, environmental policies could reduce the amount of hazardous additives in plastics that make recycling more difficult and less safe. Improving waste collection infrastructure could slow the flood of waste to low-cost recyclers in the developing world. Plus, consumer demand and government incentives or regulations could convince manufacturers to buy more recycled plastic. “We have to get over the old stigma of recycled plastics not being as good,” says Biddle.

Designing Out Waste

Already, technological innovations are making it possible to produce high-purity, high-value recycled plastic that can compete with virgin materials, rather than being limited to low-value applications. This recycled plastic’s higher quality makes it possible to convert discarded bottles and washing machines into new bottles and appliances in what is called a “circular economy.” Closing the loop in this way turns waste into a resource, and much of the innovation is coming from the commercial sector.

The steel recycling industry took decades to shift from producing cheap rebar to supplying high-quality steel. The plastics recycling industry is now beginning a similar journey to high-quality materials—and higher profits. “I’m very, very optimistic for the future,” says Huub Meessen, CEO of QCP (Quality Circular Polymers) in The Netherlands. “I think, in the end, we can supply more than 100 million tonnes of recycled plastic to industry—really big numbers.”

The path to a circular economy in plastics starts with better product design. A few years ago, Kosior analyzed a simple plastic spray bottle made from polyethylene terephthalate (PET) and found it to be “a nightmare to recycle,” he says. Magnets would struggle to extract the stainless steel spring on the trigger. A polymer in the piston gave off potentially explosive formaldehyde gas when melted with PET. And a small glass part would be ground up into tiny pieces during processing, contaminating the PET with bits of glass that couldn’t be removed.

Recently, however, Kosior has seen major improvements: the glass and stainless steel in some spray bottles had been replaced with recyclable plastics. “You can design recycling in or design it out,” he says.

Materials science is also helping to solve these design challenges (4). That includes creating plastics with fewer toxic additives, and not mixing PET with polyvinyl chloride (PVC), which makes recycled PET brittle. The chemicals used to strengthen high-density polyethylene (HDPE) might be replaced with alternatives that are easier to remove or that give the recycled material other beneficial properties. And the labels on plastic bottles can be tweaked so that they are lighter than water, making them simpler to separate from denser PET.

Even color is an issue. Black plastics are typically colored with carbon-black pigments that confound the spectroscopic scanners used to sort the material. Alternatives from Nextek and others use engineered ceramic or metal-oxide pigments that reflect the near infrared light from the detectors while still absorbing visible light. That would make black plastics easier to identify and separate. And although recycled plastic pellets are often gray or darker, which limits the palette of new products made from the material, companies can choose to turn this to their advantage. When Electrolux launched its first vacuum cleaners made largely with recycled plastics, for example, it offered them only in black, pitching “black as the new green” (5).

Different plastics compounds present different recycling challenges. Image courtesy of the Ellen MacArthur Foundation (www.ellenmacarthurfoundation.org).

Get Sorted

Good design is only part of the solution, however. Recyclers have long relied on relatively pure feedstocks of waste plastic that have already been sorted in a curbside recycling bin system or by standard waste sorting plants. The input for QCP’s new facility in Chemelot in The Netherlands, for example, is largely HDPE detergent and shampoo bottles and polypropylene (PP) pots and trays. After processing, flakes of plastic from the bottles are separated by density and color, and put through extruders where additives are mixed in to meet customer requirements. The company expects to increase production to 100,000 tons a year, and has gotten approval for the recycled plastic to be used in new bottles and paint pails, among other products.

It is much more difficult to deal with dirtier trash, such as the shredded cars and electrical equipment that MBA Polymers takes in, or the municipal solid waste with which German manufacturer of optical sorting technologies, TOMRA Sorting GmbH, has been experimenting. But tackling this trash will be vital to creating a circular economy in plastics: if major manufacturers embrace recycled plastics to make new products, their demand would far outstrip the amount of plastic now being collected separately in recycling bins.

MBA Polymers is tight-lipped about the details of its processes, although they include sorting by density, magnetic properties, plastic type, and color to produce pure grades of acrylonitrile-butadiene-styrene (ABS), polystyrene (PS), PP, and HDPE. Recently, the company added the ability to separate out a high-strength blend of polycarbonate (PC) and ABS used in computer monitors and cell phones. Although it makes up only 5–6% of the discarded plastic, the PC/ABS—because it’s particularly strong and heat-resistant, yet flexible—is worth up to twice as much as other plastics, offering greater rewards for successful recyclers. “The majority of innovation now is going after that next wave of material like PC/ABS,” says Biddle.

Teasing out another highly sought-after plastic is among the aims of TOMRA. “In Germany, we found three times more polypropylene packaging material in the mixed waste than in the yellow [recycling] bin where it should be, and it’s even worse in other countries, such as America,” says Jürgen Priesters, TOMRA’s Business Development Director Recycling. So TOMRA conducted an experiment. It ran batches of regular municipal solid waste through its full separation system; and then followed that with presorted plastic from Germany’s “Green Dot” recycling system. When it sent the recycled PP pellets to outside laboratories for testing, the results showed that both waste sources produced pellets that were indistinguishable from each other and very similar to virgin plastic.

TOMRA now plans to outfit two plants using the technology on a large scale to recycle plastic from regular municipal waste. If those plants succeed, “a whole universe of an untapped treasure would open up,” says Priesters. Ordinary trash bins would become sources of raw material, making plastics recycling even more economically attractive. “If we can get polypropylene from mixed waste, that would change the world,” says Priesters.

As plastics use skyrockets, will new recycling methods help keep more plastics out of landfills? Image courtesy of the Ellen MacArthur Foundation (www.ellenmacarthurfoundation.org).

Chemical Recycling

Even with sophisticated sorting technology, a growing amount of packaging contains multiple layers of different plastics that are difficult to separate by mechanical flaking. One possible solution being developed by APK in Germany is chemical recycling. The start-up company takes waste from packaging producers, dissolves just the polyethylene with a reusable solvent under high temperature and pressure, and then turns the polyethylene into pellets. “We can use an input stream—waste multilayer packaging—no one else wants, and the output is very high purity,” says Florian Riedl, APK’s head of sales and marketing. In 2017, the company plans to start producing more than 10,000 tons a year.

Another tack is to break down waste plastic into its component monomer molecules, such as ethylene (C2H4) in the case of polyethylene, and repolymerize those building blocks into the desired material. That would also make it easier to strip out potentially hazardous additives, like flame-retardants. The problem is that depolymerization and reformulation is typically expensive and energy intensive, wiping out the economic and greenhouse gas emission reduction benefits of reusing plastic.

Ioniqa believes it has found a cheaper and easier way. In the early 2000s, Carlos Guerrero-Sanchez and colleagues at the Eindhoven University of Technology and Dutch Polymer Institute developed smart fluids made up of iron nanoparticles in an ionic liquid (6). Casting about for possible applications, Guerrero-Sanchez and Hooghoudt discovered that they could equip the nanoparticles with catalysts that depolymerize PET into its monomers, individual ethylene terephthalate molecules (which, in turn are a combination of ethylene glycol and terephthalic acid). The colorants and other impurities adsorb onto the nanoparticles, which then can be removed with magnets, leaving behind the pure PET monomers.

The ability to remove colorants is a “game-changer” in the marketplace for recycled PET, says Hooghoudt. The catalyst is inexpensive and reusable, the yield is high, and the process works at a relatively low temperature of 180 °C. The company is now building a demonstration facility to test the process at larger scale.

Depolymerization may even make it possible to turn one type of plastic into another that is more valuable. Chemist Jeannette García at IBM’s Almaden Research Center in San Jose, California knew that polycarbonates could be broken up into their individual monomers with a base, such as carbonate salts, and that a base also helped synthesize a high-value specialty plastic, polyether sulfone (PSU), used in medical devices. García wondered if the whole process could be done in one step with the same base.

It could, as she and others reported in PNAS this year (7). “The surprise was that it worked even better than expected,” says her coauthor, Gavin Jones at IBM, which now hopes to find a partner to commercialize the process.

Other researchers are enlisting microbes to perform a similar up-cycling feat. PET can be pyrolized at high temperatures to produce solid terephthalic acid (TA), and a team led by microbiologist Kevin O’Connor at University College Dublin has discovered several strains of bacteria that can use TA as a source of energy and carbon to make a high-value biodegradable plastic called polyhydroxyalkanoate (PHA). A type of polyester currently produced by microbial fermentation of sugars or lipids, PHA is used for sutures and other medical applications.

The microbes in O’Connor’s study (8), which the scientists isolated from soil exposed to PET granules, use the TA, composed of carbon, hydrogen, and oxygen, to string together monomers of 3-hydroxydecanoic acid into PHA. That technology has been spun out into a company called Bioplastech Ltd., in Dublin, which has taken on the major challenges of scaling up the technology and making it economically competitive.

Complex Caveats

All of this progress is encouraging. But these efforts still face three big hurdles. One is the recent decline in oil prices, which reduces the price of virgin plastics and makes it harder for recyclers to compete.

The second is boosting demand for recycled plastics. Currently, global manufacturers worry about inconsistent quality of recycled materials, or about the presence of additives and potentially hazardous impurities above regulatory limits. And they often find it easier and safer to design products using virgin plastics with the right strength and properties for a specific application, rather than trying to shoehorn in an available recycled material. Electrolux, for example, has aggressive sustainability goals (9) and is increasing its use of recycled plastic by 60% per year. But that still only amounts to only 3% of the total.

The final hurdle is to collect the vast amounts of plastics thrown out every year. Far too much of it, especially old computers and other electronic waste, ends up being picked apart under terrible conditions in developing countries. Groups like the Basel Action Network, based in Seattle and named after the 1989 United Nations convention that restricted the trade of hazardous waste, have documented that large amounts of plastic-containing electronic waste are exported to countries like China, India, and Vietnam, where the materials are separated by hand or by melting, leading to serious health and environmental consequences. (10) “We care about how our stuff is made, but we have yet to care as much about how it is unmade,” says Biddle.

So much electronic waste flows out of the United States, in fact, that MBA Polymers couldn’t secure a big enough supply to justify building a recycling plant in the United States. However, the US Congress has so far failed to limit the exports or require manufacturers to take more responsibility for what happens when their products are thrown out. “The US is one of the last countries still standing that doesn’t have a national e-waste policy,” laments Biddle.

And so the nascent plastics recycling industry finds itself at a crossroads. Recent innovations have made it possible to seriously whittle down the mountains of plastic waste now going into landfills, incinerators, and the oceans. But oil prices, demand for recycled plastics, and lack of regulation are holding them back. “We’ve been able to demonstrate the technology and show that the economics work,” says MBA Polymers CEO Richard McCombs. “Now, when does the tipping point occur? No one knows.”

Bioplastics Blossom, but Face Financial Headwinds

Recycling is not the only way to reduce plastic’s impact on the planet. Most plastics are made of petrochemicals derived from fossil fuels, but a new breed of bioplastics relies instead on feedstocks from renewable biomass sources, making them potentially more sustainable.

Case in point: In 2015, the Coca-Cola Company updated its PlantBottle, first launched in 2009, to create a 100% bio-PET version (11). It includes sustainably sourced versions of its ingredients: ethylene glycol and terephthalic acid. The company says it aims to switch entirely to bio-based plastics by 2020.

Meanwhile, a competing plastic called PEF (polyethylene furandicarboxylate) substitutes furandicarboxylic acid for terephthalic acid. The furandicarboxylic acid is less complex and potentially cheaper to produce. Already, Avantium in The Netherlands has formed a joint venture with chemical giant BASF to make furandicarboxylic acid.

Some bioplastics are also biodegradable, eliminating the need for recycling. In the moist, warm conditions of a compost pile, polylactic acid (PLA) breaks down to form lactic acid, which hungry microbes then eat to make carbon dioxide, water, and humus. PLA is used in products from medical sutures to plates and utensils, but it is costly to make and too brittle for many uses.

Scientists are working hard to solve both problems. Using specially designed zeolite catalysts, a team led by Michiel Dusselier at the University of Leuven in Belgium converted lactic acid directly into the building blocks of PLA, thus bypassing an expensive intermediate step (12). Marc Hillmyer, director of the Center for Sustainable Polymers at the University of Minnesota, and his group have discovered that certain additives can form micelles within PLA that dissipate stress and make it more flexible.

The biggest hurdle to these efforts is cost. Bio-based plastics are up to five times the price of conventional polymers, and companies have been reluctant to make the major capital investments required to build production facilities. But economies of scale and cheaper production methods could bring costs down. The industry body European Bioplastics predicts that global bioplastic production capacity will grow from 1.7 million tons in 2014 to almost 8 million tons in 2019: promising, though still a fraction of the roughly 300 million tons of plastic produced worldwide (13). “If the economics are right,” says Hillmyer, “this is an area that could be ripe for explosive growth.”

References

- 1.World Economic Forum, Ellen MacArthur Foundation and McKinsey & Company The new plastics economy—Rethinking the future of plastics. 2016 Available at https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics. Accessed December 28, 2016.

- 2.Jambeck JR, et al. Marine pollution. Plastic waste inputs from land into the ocean. Science. 2015;347(6223):768–771. doi: 10.1126/science.1260352. [DOI] [PubMed] [Google Scholar]

- 3.Smithsonian National Museum of Natural History Ocean trash plaguing our sea. 2015 Available at ocean.si.edu/ocean-news/ocean-trash-plaguing-our-sea. Accessed December 28, 2016.

- 4.The Association of Plastic Recyclers (June 8, 2016) APR design guide for plastics recyclability. Available www.plasticsnews.com/article/20160608/news/160609811/apr-updates-recycling-guidelines. Accessed December 28, 2016.

- 5. PRWEB (2007) Black is the new green: Recycled plastic makes Electrolux UltraSilencer Green a sleek “greener“ vacuum. Available at www.prweb.com/releases/2009/08/prweb2705914.htm. Accessed December 28, 2016.

- 6.Guerrero-Sanchez C, et al. Magnetorheological fluids based on ionic liquids. Adv Mater. 2007;19(13):1740–1747. [Google Scholar]

- 7.Jones GO, Yuen A, Wojtecki RJ, Hedrick JL, García JM. Computational and experimental investigations of one-step conversion of poly(carbonate)s into value-added poly(aryl ether sulfone)s. Proc Natl Acad Sci USA. 2016;113(28):7722–7726. doi: 10.1073/pnas.1600924113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Kenny ST, et al. Up-cycling of PET (polyethylene terephthalate) to the biodegradable plastic PHA (polyhydroxyalkanoate) Environ Sci Technol. 2008;42(20):7696–7701. doi: 10.1021/es801010e. [DOI] [PubMed] [Google Scholar]

- 9. Electrolux (2016) Sustainability. Available at www.electroluxgroup.com/en/category/sustainability/. Accessed December 28, 2016.

- 10. BAN (2016) Secret tracking project finds that your old electronic waste gets exported to developing countries. Available at www.ban.org/news/2016/9/15/secret-tracking-project-finds-that-your-old-electronic-waste-gets-exported-to-developing-countries. Accessed December 28, 2016.

- 11. The Coca-Cola Company (May 31, 2015) Coca-Cola produces world's first PET bottle made entirely from plants. Available at www.coca-colacompany.com/press-center/press-releases/coca-cola-produces-worlds-first-pet-bottle-made-entirely-from-plants. Accessed November 4, 2016.

- 12.Dusselier M, Van Wouwe P, Dewaele A, Jacobs PA, Sels BF. GREEN CHEMISTRY. Shape-selective zeolite catalysis for bioplastics production. Science. 2015;349(6243):78–80. doi: 10.1126/science.aaa7169. [DOI] [PubMed] [Google Scholar]

- 13. European Bioplastics (2016) Bioplastics market data. Available at www.european-bioplastics.org/market/. Accessed November 4, 2016.