Abstract

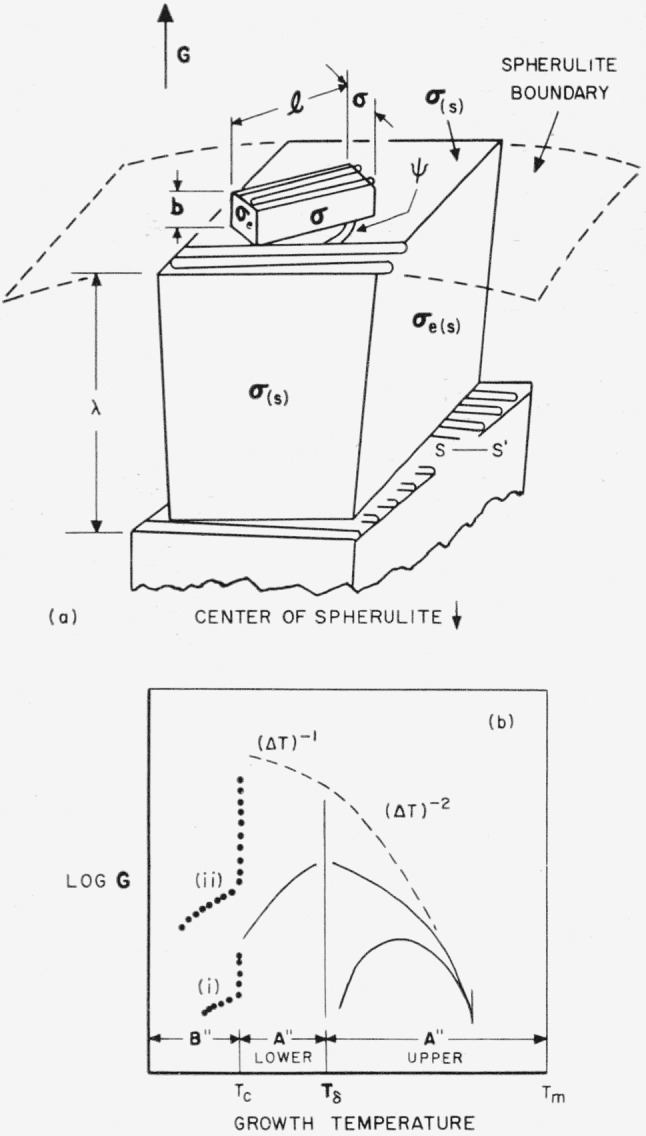

A systematic study of the problem of spherulitic growth in linear polymers in bulk has been carried out. A calculation of the radial growth of polymer spherulites is given for four models. These concern growth where the surface nuclei that control the rate are (1) bundlelike and coherent, (2) chain folded and coherent, (3) chain folded and noncoherent, and (4) bundlelike and noncoherent. The required modifications of nucleation theory are given. Then the radial growth rate laws are derived for each model, and the type of “spherulite” that would be formed discussed.

The model with chain folded and coherent growth nuclei leads to a typical lamellar spherulite. The properties of the individual chain folded lamellae that form the spherulite are predicted, including the change of step height with growth temperature, melting behavior, and the behavior on recrystallization. (Chain folded lamellae may also occur in specimens that are not obviously spherulitic.) Under certain conditions, the noncoherent model with chain folds can lead to a modified lamellar spherulite. None of the bundlelike models will lead to a typical lamellar spherulite, though a spherical microcrystalline object might be formed. It is concluded that lamellar spherulites consist largely of chain folded structures.

The factors that could cause chain folded crystals to appear in profusion in bulk polymers are discussed. The case of homogeneous initiation is considered first. Homogeneous initiation of chain folded nuclei in bulk will prevail if the end surface free energy of the bundlelike nucleus exceeds that of the folded. It is shown that the end surface free energy of the bundlelike nucleus, as calculated with a density gradient model, will be larger than had been supposed previously. It is therefore considered to be theoretically possible that the end surface free energy of the bundlelike nucleus may in some cases exceed that of the folded nucleus. Attention is given to the possibility that folded structures appear in large numbers because cumulative strain or large chain ends prevent the growth of bundlelike nuclei to large size, even when the latter type of nucleus is energetically favored when small. Heterogeneous initiation of folded structures is then considered.

Other topics mentioned include: (1) Conditions that might lead to nonlamellar or nonspherulitic crystallization in bulk, (2) the origin of the twist that is frequently exhibited by the lamellae in spherulites, (3) the transitions that may sometimes occur in the radial growth rate law, and (4) interlamellar links.

★1. Introduction1

In recent years there has been much interest in the growth of spherulites in bulk polymers. These objects are the principal site of the crystallization in a number of highly crystallizable linear polymers, at least under certain conditions. Further, the mechanical, optical, and dielectric properties of such polymers are known to be affected by the presence of spherulitic crystallinity. Hence the rate of spherulitic growth, and the type of crystals existing in the spherulites, are of prime importance in connection with any attempt to understand the physical properties of these systems. Except where specifically noted otherwise, this paper is confined to crystallization from the unoriented melt. Attention is directed mainly to polymers that may be represented as systems of flexible linear chains which can in time achieve a high degree of crystallinity.

In introducing the subject of the nature of the crystals in polymer spherulites, it is essential to first mention the important studies of Keller and coworkers [1, 2]2 on the nature of the platelike single crystals of linear polymers that may be deposited from supercooled dilute solutions. Polymer crystals formed in this manner consist of regularly shaped platelets that have a thinness or “step height” of roughly 50 to 250 A, depending on the degree of supercooling. (The step height is larger the lower the supercooling.) By electron diffraction experiments, Keller demonstrated that the long axes of the polymer molecules in such crystals are approximately perpendicular to the large and flat upper and lower surfaces. Since the polymer molecules were known to be much longer than the step height, the startling but nevertheless definite conclusion was reached that the upper and lower surfaces consist of chain folds. Stacks of thin platelets resembling a terraced pyramid are frequently formed in dilute solution preparations, often around what appears to be a spiral dislocation. In such cases, each terrace step corresponds to the thickness or step height of a single crystal. A theory describing the formation of single polymer crystals from dilute solution has been given by Lauritzen and Hoffman [3].

Spherulites in bulk polymers grow outward from a nucleation center that is frequently of a heterogeneous character. The radial growth of a spherulite is commonly the result of the formation of stacks of bladelike lamellae that grow outward from the nucleation center. As shown in electron micrographs of surface replicas of spherulites, these lamellae possess a thickness or “step height,” corresponding to the thin dimensions of the blade, that is commonly between 50 and 250 A. The resemblance between the system of steps seen in a bulk polymer and the steps seen in the stacks of chain folded platelets in a dilute solution preparation of the same polymer is most striking. It is well known from optical studies that the polymer chains in the crystalline matter in spherulites are approximately normal to the spherulite radius. Since the lamellae lie mostly parallel to the radius of the spherulite, it is therefore reasonable to assume that the polymer chains are more or less normal to the large flat surfaces of the lamellae. (Evidence interpretable as proof that the chain axes are nearly normal to the flat lamellar surfaces in polyethylene has been obtained by microcamera X-ray diffraction studies by Fujiwara [42]. Other investigators [4] have shown by optical methods that a similar condition probably applies in certain other cases.) The lamellae often twist as they grow outward, so that a given sector of a spherulite somewhat resembles a stack of propeller blades (twisted lamellae) radiating from a central point. We refer to an object fitting this general description as a lamellar spherulite.3

In view of the above, it is certainly reasonable to give strong consideration to the possibility that a lamellar spherulite formed in bulk consists of chain folded crystals of the same general type known to arise in dilute solution, and to consider spherulite growth mechanisms based on the chain folded pattern. At the same time, one must attempt to construct a lamellar spherulite on the customary bundlelike pattern. By carrying out calculations on both models, it is possible to arrive at certain conclusions concerning the existence of chain folded crystals in bulk polymers. In the course of such an attack on the problem, it is natural to see if any of the models are capable of predicting the existence of a nonlamellar spherulite.

While no attempt will be made in this paper to effect a detailed comparison of theory and experiment, or to give a complete survey of the experimental situation with respect to the nature of spherulitic crystallization in bulk polymers, it is of interest to mention some of the studies on which the above remarks on spherulitic structure in bulk are based. Much of what is known about lamellae in spherulites has been learned from studying electron micrographs. An outstanding example of this approach is to be found in the recent work of Geil [5] on polyoxymethylene, where clear evidence of the lamellar structure of bulk crystallized material is presented. Geil, Symons, and Scott [6] have shown that chain folded crystals with a rather similar step height are formed from dilute solution by polyoxymethylene; the resemblance between the terraces formed by stacks of chain folded crystals in dilute solution and the terraces seen in material crystallized in bulk is especially striking in this polymer. Eppe, Fischer, and Stuart have presented clear evidence of lamellar structure in bulk polychlorotrifluoroethylene [40]. This and other examples that could be cited render it clear that lamellar structures are common in linear polymers crystallized in bulk. Information on the orientation of the lamellae and polymer chains in spherulites, and the twist of the lamellae, has been obtained by optical microscopy together with a detailed theory of the extinction patterns of such objects due to Keller [7], Keith and Padden [8, 9], and Price [10]. The beautiful rings seen in spherulites in a polarizing microscope are a result of the twist of the lamellae.

The body of the paper begins with a discussion of homogeneous initiation of bundle and loop type structures in bulk. It is concluded that if homogeneous nucleation is the cause of the prevalence of folded structures in bulk, the end surface free energy of the bundlelike nucleus, σe, must exceed that of the end surface free energy of the nucleus with chain folds, σe. (A simple bundlelike nucleus model that explicitly involves the density gradient at the bundle end is used to bring out certain factors that may contribute to σe.) Then the possibility that large chain ends or strain may tend to subdue growth of bundlelike nuclei to large size is considered. Finally, since it is by no means certain that spherulites are generally of homogeneous origin, heterogeneous initiation of chain folded lamellar structures is discussed.

With this background, attention is then directed toward the problem of calculating the isothermal rate of radial growth of spherulites as a function of temperature in supercooled bulk polymers. This property has been singled out for special emphasis because it can often be determined experimentally as a function of temperature, and does not depend on whether the spherulites are of heterogeneous or homogeneous origin.

Radial growth where the rate determining step is the formation of a two-dimensional coherent surface nucleus is treated first. (By the term “coherent” we mean to imply that the crystal structure and molecular orientation in the surface nucleus and in its polymer substrate are essentially the same.) Both bundlelike coherent surface nuclei and coherent surface nuclei with chain folds are considered.

Treatments of radial spherulitic growth by two-dimensional coherent surface nucleation have been given by Burnett and McDevit [11], Kahle and Stuart [12], Takayanagi [13], and Hirai [14]. We must now indicate why we shall add yet another.

First, it is considered desirable to give a detailed analysis of spherulitic growth for coherent nuclei with chain folds. Second, it is instructive to reexamine the theory of the radial growth rate for coherent bundlelike nuclei. It is evident that some problems connected with this model have not been emphasized previously, nor its full range of behavior elucidated. Third, it is necessary to treat the general problem of growth by monomolecular accretion, taking into account the fact that the activated state is in some instances reached in one step. This leads to an important revision of the nucleation and growth rate expressions, especially in the chain fold case. Fourth, it is important to consider the role of chain ends on the formation of polymer crystals. Finally, it is considered to be of special interest to examine closely the connection between a given model for the growth rate, and the physical structure and orientation of the crystalline bodies that this model actually implies in a spherulite. It will emerge that some of the models frequently cited in the literature and used for the analysis of radial growth rate data on spherulites will not lead to typical spherulitic structures.

It will be demonstrated that radial growth through the agency of coherent nucleation with chain folds can lead to a three-dimensional object recognizable as a lamellar spherulite. The existence of the lamellae, the orientation of these lamellae and the molecules in them with respect to the spherulite radius, the dependence of the step height on growth temperature, recrystallization behavior, and the twist exhibited by the lamellae, can be predicted. It is adduced that the coherent bundlelike model cannot lead to a lamellar spherulite.

The theory given here for the rate of radial spherulitic growth in bulk as controlled by coherent surface nuclei with chain folds is based mostly on an analysis by Lauritzen and Hoffman [3] on the appearance of polymer crystals with chain folds from dilute solution. Price [15] has independently treated some aspects of this problem.

The problem of calculating the rate of radial growth of a spherulite where the rate determining step is the formation of a three-dimensional noncoherent surface nucleus is treated next. (By the term “noncoherent” we mean to indicate that the orientation of the molecules in the surface nucleus is different from that in the polymer crystal to which it is attached, so that a definite interface exists between the substrate polymer crystal and the surface nucleus.) As before, bundlelike noncoherent surface nuclei, and noncoherent surface nuclei with chain folds, are treated. The concept of noncoherent surface nucleation in spherulites treated here is based largely on an interesting suggestion due to Price [16]. The radial growth rate laws are given, and the nature of the resultant physical structures is predicted.

The results obtained for the bundlelike noncoherent growth model resemble in general form those given previously by Flory and McIntyre [17], who proposed that the free energy of formation of the three-dimensional bundlelike surface nucleus is in some manner lowered in the vicinity of the growing boundary compared to the free energy of formation of the corresponding three-dimensional homogeneous nucleus. The present treatment is more explicit concerning the possible cause of the lowering of the free energy of formation of the surface nucleus. The noncoherent bundlelike model might possibly lead to a spherical and microcrystalline but non- lamellar object. The noncoherent chain folded model leads to a somewhat modified lamellar spherulite.

In all the calculations of the radial growth rate, an effort has been made not only to derive the rate laws near and somewhat below the melting point, but also to determine the type of behavior that might obtain at strong supercooling. Rather abrupt changes in the radial growth rate, and even the mode of crystallization, may occur with sufficient supercooling.

Toward the end of the paper, the radial growth rate equations are summarized in tabular form, and a discussion presented on various aspects of the initiation and growth of spherulites, and lamellar and nonlamellar crystallization in polymers.

★2. Rate of Homogeneous Initiation in Bulk for Bundlelike and Chain Folded Nuclei

2.1. Homogeneous Nucleation Theory

Turnbull and Fisher [18] give for the steady state rate of homogeneous nucleation in a condensed system the expression

| (1) |

Here T is the absolute temperature, h Planck’s constant, k Boltzmann’s constant, ΔH* the heat of activation of the elementary jump rate process at the supercooled liquid—nucleus interface, ΔS* the corresponding entropy of activation, and Δϕ* the free energy of formation of a nucleus of critical size, i.e., a nucleus at the saddle point in the appropriate free energy surface. The constant K has a numerical value within several orders of magnitude of unity for most nucleation problems of interest, and may be ignored for the present.4 Equation (1) was derived on the basis that the nucleus contains a large number of segments or atoms, and is built up in a stepwise manner. The net nucleation rate was obtained by summation over all forward and backward reactions. The pre-exponential factor (NkT/h) exp (ΔS*/k) nuclei sec−1 mole−1 may be converted to exp (ΔS*/k) nuclei sec−1 cm−3, where m0 is the molecular weight of the length of polymer segment that enters the nucleus in an elementary process, and the specific volume of the supercooled liquid.

The main problem is the calculation of Δϕ* in terms of the surface free energies and other parameters associated with the model under consideration.

2.2. Primary Bundlelike Nuclei: The End Surface Free Energy Problem

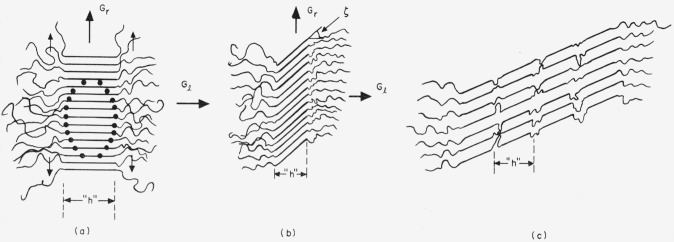

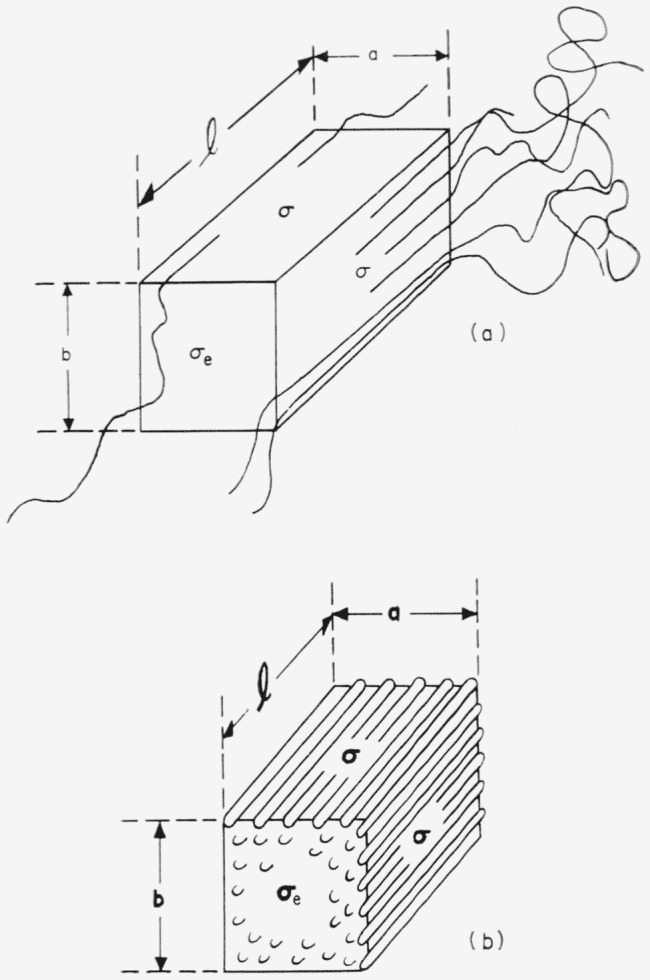

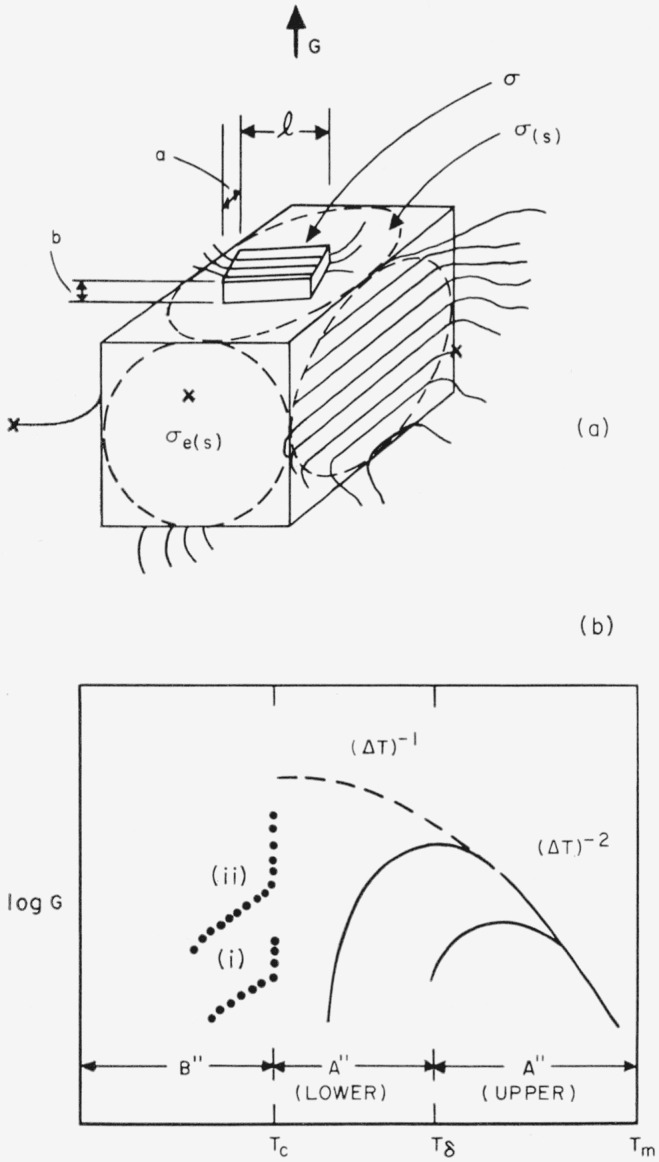

We employ a bundlelike primary nucleus that is a rectangular parallelepiped as shown in figure 1a. The quantity σ is the lateral surface free energy, and σe is the end surface free energy. The surface free energies are defined as the work that is needed to isothermally form 1 cm2 of the appropriate type of surface from the required number of segments in the normal (interior) crystalline phase.

Figure 1. Bundlelike and chain folded primary nuclei.

(a) Bundlelike nucleus: ordinary symbols are used to denote the dimensions a, b, and l, and the lateral and end surface free energies σ and σe. A density gradient of considerable extent in the l direction will exist at the end surface.

(b) Nucleus with chain folds: bold face symbols are used for the dimensions a, b, and l, and the lateral and end surface free energies σ and σe. Well defined surfaces exist on all faces.

The rectangular parallelepiped model is not proposed with the intention of conveying the meaning that the cross section of a nucleus or crystal is necessarily rectangular. The cross section could have other shapes, e.g., a parallelogram, hexagon, or other polygon. The lateral faces of the crystal will correspond to some single preferred crystallographic plane, and the lateral surface free energy σ will correspond to the work required to form 1 cm2 of this surface. The particular geometrical model chosen is just the simplest that is sufficiently illustrative of the phenomena we wish to discuss. The slight modifications necessary to deal with other cross-sectional shapes have been outlined elsewhere [3].

Lateral Surface Free Energy (Bundles)

The lateral surface free energy σ refers to a definite and well defined surface, and a reasonably good estimate of its numerical value can be obtained. We should expect σ to be fairly close to that for a typical molecular crystal of approximately the same chemical composition as the polymer, since the molecules on the lateral faces are not “connected” through covalent bonds to the surrounding supercooled liquid. Rough estimates of σ may be surmised from the results of Thomas and Stavely [19] on homogeneous crystallization in fogs of supercooled droplets of simple nonchain organic compounds. From this work we would anticipate that the lateral surface free energy σ would frequently be in the range of 5 to 25 erg cm−2.

It is useful to indicate a method of estimating the lateral surface free energy for a polymer that should generally give a value that is more accurate than would be guessed simply by perusing the results on nonchain type molecular crystals quoted by Thomas and Stavely. Several authors [19, 20] have suggested that for a specific class of compounds the ratio of the work required to form a certain amount of surface phase to the heat of fusion of the same amount of bulk phase is approximately a constant. This ratio may be written as

| (2) |

where (Δhf) is the heat of fusion in erg cm−3, d the lattice spacing in cm, and σ the surface free energy in erg cm−2. The constant α is about 0.5 for many metals [20], and about 0.3 for simple (non-chainlike) molecular crystals [19]. Using the values of σ obtained from carefully conducted homogeneous nucleation experiments with pure chain hydrocarbons dispersed in water recently quoted by Turnbull [21]5, we estimate that α is about 0.1 for the paraffin chain system. This value of α should hold quite well for the calculation of the lateral surface free energy σ of polyethylene (σ ~ 10 erg cm−2). It is to be expected that a fairly similar value of α will hold for the estimation of the lateral surface free energies of other linear polymers. Turnbull’s technique could be used to obtain more precise values of α appropriate to other types of chain structure.

End Surface Free Energy (Bundles)

The value of σe appropriate to the bundlelike nucleus is difficult to assess. No reliable experimental values seem to be available. Flory [22] has treated the configurational contribution to the end surface free energy for a bundlelike crystal as a function of concentration. In this formulation, the end surface free energy at v2=1 (bulk phase) is proportional to RT ln D, where D is a parameter. No theoretical method of evaluating D was given. Also, Flory’s treatment does not deal explicitly with the density gradient region at the bundle ends, where important contributions to σe will arise.

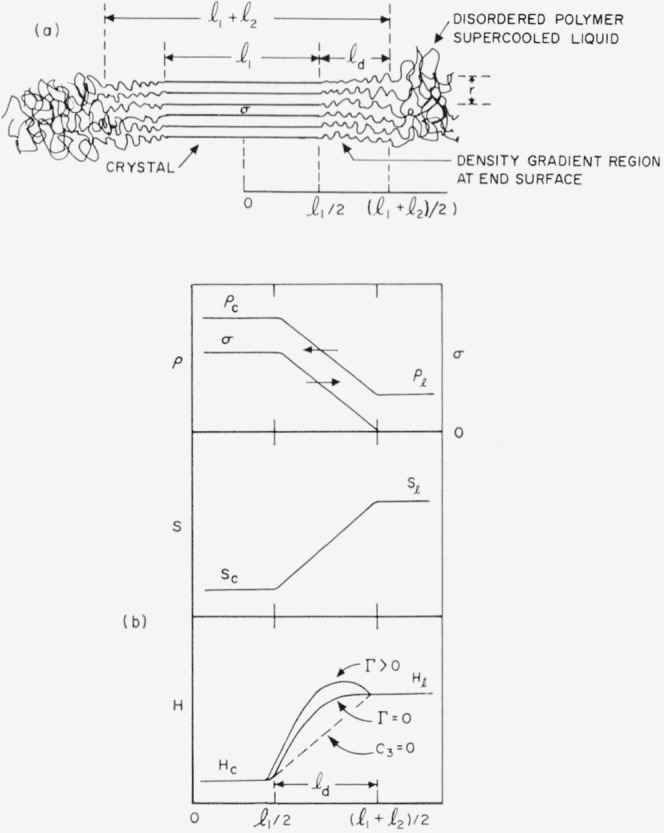

Insight into some of the factors that will contribute to the work required to build the end of a bundlelike nucleus with a flat end may be gained by noting the calculations in the appendix, section 10, for a cylindrical bundlelike nucleus with a density gradient at the bundle ends. This simplified treatment shows to the approximations indicated (see eq (A-20) of the appendix) that

| (3) |

Here ld is the length of one of the diffuse bundle ends in cm, (Δhf) the heat of fusion in erg cm−3, ρc and ρl the density in g cm−3 of the crystal and supercooled liquid, respectively, (Δρ) = ρc−ρl, ρo= (ρc+ρl)/2, and Γ a constant in erg cm−3 that may reasonably be expected to exceed zero. The magnitude of Γ is related to the height of the maximum that will exist in the free energy somewhere in the bundle ends. This maximum must exist in order to cause phase separation, and may result from either repulsion or abnormal separation of the segments in the partly disordered region of the bundle ends. The derivation of eq (3) is valid only when the cross section of the nucleus contains a fairly large number of polymer molecules.

Equation (3) with Γ=0 may be used to obtain a reasonable lower limit on the value of σe for a bundlelike nucleus with a flat end, which we call σe(min). The minimum value of σe implied by eq (3) is surprisingly large. For example, with (Δhf)=3×109 erg cm−3, ρc/ρl=1.15, parameters that apply approximately to polyethylene,6 when taken together with the assumption that ld=10×10−8 cm = 10 A, lead to σe(min)≅60 erg cm−2. Reflected in this result is the fact that a fairly large amount of work will be required to construct an interface between two phases that are connected together by chains containing covalent bonds.

The true value of σe for polyethylene is probably in excess of this, since Γ may be greater than zero. Also, certain cumulative strain contributions are neglected in the derivation of eq (3), and these would further increase σe. From the above we draw the conclusion that it is not necessary to consider the effect of small σe values, i.e., those substantially smaller than the lateral surface free energy σ, in calculating the properties of bundlelike nuclei.7 It is entirely possible that σe for bundlelike nuclei may be at least several hundred erg cm−2 in some instances.

An analysis of the particular model used to arrive at eq (3) does not suggest a marked dependence of σe on temperature. Nevertheless, even the simplified treatment outlined in the appendix indicates that, under certain circumstances, σe could depend on temperature to a noticeable extent. In view of the above, we must emphasize that the calculations to follow with σe treated as a constant are approximate. Nevertheless, they are believed to be sufficient for the purpose of dealing with the question of how nuclei with chain folds might come to prevail over bundlelike nuclei in bulk. The symbol σe in the expressions to be derived for the bundlelike nucleus may be thought of as representing an effective value containing contributions analogous to those shown in eq (3).

2.3. Rate of Homogeneous Nucleation for Bundlelike Nuclei

Region A (steady state nucleation)

In the temperature region near and somewhat below the melting point, which we designate region A, the primary nuclei are much larger than the unit cell, and the free energy of formation of a bundlelike crystal or embryo of the type shown in figure 1a may be written

| (4) |

where a, b, and l are treated as variables. (Δf) is the bulk free energy of fusion per unit volume of crystal. Both σ and σe are regarded as constants. The problem is to calculate Δϕ* by finding the saddle point in the free energy surface described by eq (4).

The saddle point in the free energy surface described by eq (4) is found by setting ∂Δϕ/∂a)bl, ∂Δϕ/∂b)al and ∂Δϕ/∂l)ab equal to zero to get a*= 4σ/(Δf), b*=4σ/(Δf), and l*=4σe/Δf. As plotted on the orthogonal coordinates Δϕ, l, (ab)1/2, the saddle point is at l*=4σe/Δf, and (a*b*)1/2=4σ/(Δf). Inserting these values into eq (4) the value of the free energy of formation at the saddle point is found to be

| (5) |

which may be compared with the value 8πσ2σe/(Δf)2 for a bundlelike nucleus with a circular cross section. Then with eq (1), the steady-state nucleation rate is

| (6) |

where we have set

| (7) |

Here Δhf is the heat of fusion per unit volume of crystal at the equilibrium melting temperature, Tm, and (ΔT) the degree of supercooling, Tm–T, where T is the crystallization temperature. It has been shown in a previous study [23] that eq (7) is a good approximation in a glass-forming system.8

Region B (nonsteady state nucleation)

Observe from the foregoing that a*=b*=4σ/(Δf). From this expression and eq (7) it is clear that at some high degree of supercooling (large ΔT), the a and b dimensions of a nucleus of critical size will approach their minimal values, amin and bmin. This will occur at a temperature Tc corresponding to a degree of supercooling of approximately

| (8) |

As a rough approximation the product (aminbmin) may be taken as the area corresponding to a nucleus with a cross section containing roughly 5 to 7 polymer segments, i.e., a body with at least one central molecule in an ordered environment. This is the smallest object that may be considered as a typical nucleus. (Note that amin will be somewhat larger than the corresponding dimensions of the unit cell.)

Because ΔTc depends on the well-defined lateral surface free energy σ, for which numerical values can be estimated with reasonable accuracy, a fairly reliable conception of its magnitude can be obtained. Taking σ=5 erg cm−2, amin=bmin=10×10−8 cm, Tm=400 °K, and (Δhf) = 109 erg cm−3, ΔTc calculated from eq (12) comes to 80 °C. ΔTc should rarely be less than 30 or 40 °C, and in many cases it may be so large that it falls near or below the glass transition, which would render it inherently unobservable.

It is clear that the nucleation rate will change its character near and below Tc. Attention is now directed to the interesting question of the nature of the nucleation process in the temperature region near and below Tc, region B.

At and below Tc, the free energy of formation may be written

| (9) |

The coefficient of l is zero at Tc, but becomes negative at lower temperatures. Thus, it is seen that the nucleus is formed by “increasing” its length l to its minimum possible dimension, which we call lmin. Hence, in effect, we are calculating the steady-state nucleation rate for a nucleus of fixed dimensions amin, bmin, lmin. The modification of classical continuum free energy surface theory necessary to deal with this type of problem is mentioned in section 3.1. The appropriate free energy of formation is given by eq (9) with l=lmin The steady state nucleation rate in region B is

| (10) |

[(ΔT)+1 law; will not be directly observable]

where the constant term 2bmin(aminσe+lminσ) is denoted as ΔH**. (Ordinarily, ΔH** will not exceed several kcal mole−1.) This (ΔT)+1 steady state nucleation rate expression appears to be new in nucleation and growth theory. It must immediately be pointed out, however, that it is very unlikely that such a rate law would be observed over any substantial range of temperature because of the effect of nonsteady-state nucleation near and below Tc. In the case of such small nuclei forming by steady state nucleation in a strongly supercooled polymer, the additional effect of pre-existing embryos of minimal size must be taken into account.9

At any temperature T1 above the melting point of the polymer, the free energy of formation of an embryo always increases as its size increases. This is in contrast to the case of embryos in the supercooled liquid state, where the free energy of formation goes through a maximum at a saddle point so that embryos can become nuclei, and eventually stable crystallites. Nevertheless, numerous small embryos will exist in the normal liquid above Tm, and the population of such embryos can be estimated by straightforward methods. (In the expression for Δϕ, ΔT simply changes sign above Tm.) Now when a polymer specimen is rapidly cooled from a temperature T1 that is above Tm to a temperature T2 in the strongly supercooled state, a number of these pre-existing embryos will be found to be of the critical size relevant to T2. The number of such pre-existing embryos that correspond to nuclei of critical size will be negligible if the stable nuclei arc large, as will be the case at low or moderate supercooling, but near and below Tc, where the nuclei are of the minimal dimensions amin, bmin, lmin, the number of pre-existing embryos that correspond to nuclei of critical size will be high. Thus, near and below Tc, this transport of bundlelike embryos from the normal melt to the strongly supercooled state will greatly increase the rate of injection of nuclei above that predicted by eq (10), or eq (6) as extrapolated into region B. Calculations show that this effect might become so pronounced somewhat below Tc as to cause a very rapid and fine-grained crystallization to occur that might aptly be described as a “nucleative collapse” of the supercooled liquid state. (This effect may deter glass formation as noted in section 8.2.)

At sufficiently low temperatures, the rate of injection will eventually fall because of the increasing importance of the interfacial jump rate term, exp (−ΔH*/kT). Depending on the values of ΔH* and the various surface free energies involved, this could happen in regions A or B.

Summary

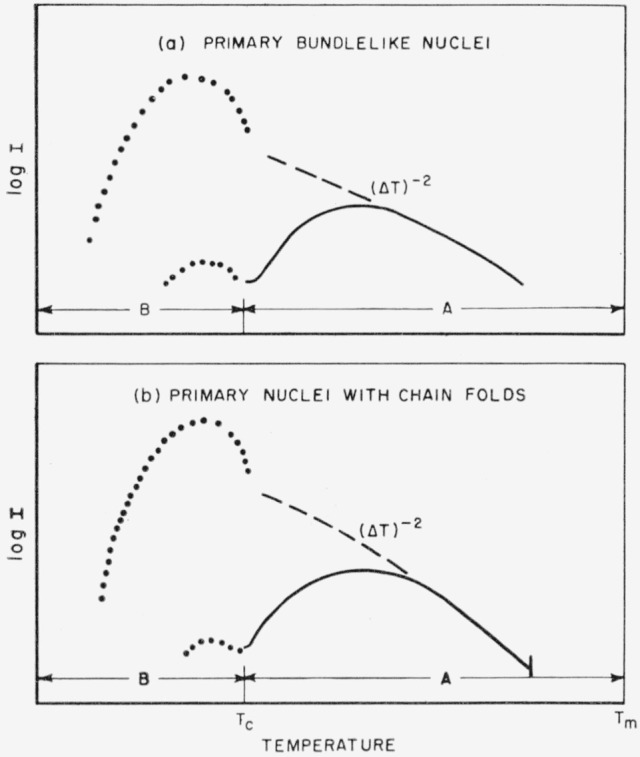

The overall picture of the homogeneous nucleation rate for bundlelike nuclei is shown in figure 2a. The interfacial jump rate term, exp (−ΔH*/kT), with its positive temperature coefficient, will commonly overcome the strongly negative temperature coefficient of the nucleation term, exp , and cause a maximum to appear in the steady state nucleation rate in region A (see solid line). If the nucleation rate is still observable at all at and below Tc, the excess nucleation rate characteristic of nonsteady state nucleation in region B may be seen.

Figure 2. Rate of injection of homogeneous nuclei as a function of temperature.

I is the homogeneous nucleation rate in nuclei per second per unit volume. — — — — behavior of steady state value of log I if effect of jump rate is small; ▬▬customary behavior where jump rate lowers log I;….. shows nucleation in excess of steady state value of log I in region B resulting from transport of nuclei of minimal size from above Tm.

2.4. Primary Nuclei With Chain Folds

Quantities that are closely related or specific to chain folds are denoted by bold face symbols. Note especially that

The corresponding quantities for bundlelike systems are

The specific type of folded nucleus to be discussed is shown in figure 1b.

Lateral Surface Free Energy (Folded Crystals)

The lateral surface free energy σ for the folded nucleus refers to an abrupt phase boundary, since no polymer molecules pass through this surface and connect the supercooled liquid and crystalline phases. The quantity σ is thus similar in general character to the quantity σ for the bundlelike system, i.e., σ≅σ, and eq (2) applies to its estimation. Thus, σ will usually fall between 5 and 25 erg cm−2.

End Surface Free Energy (Folded Crystals)

The end of the chain folded nucleus, unlike the end of the bundlelike nucleus, has a well defined phase boundary. Hence, the folded nucleus has abrupt phase boundaries on all its faces. As a consequence, the treatment of chain folded nuclei can be approached with more certainty than can bundlelike nuclei under like circumstances. Both σ and σe may to a good approximation be assumed to be independent of temperature and other variables.

The value of the surface free energy σe for a folded nucleus is related to the work required to form a fold [3]:

| (11) |

Here q is the work required to form a fold, and A0 is the area of the cross section of the polymer molecule. An important contribution to q will arise from the internal rotational potential of atoms or groups of the loop itself, i.e., from the stiffness of the polymer chain. Then values of q in the range of roughly 1 to 10 kcal per mole of loops are to be expected. For molecules with the cross-sectional area ordinarily encountered, say 20×10−16 cm2, this means that q/2A0 might be expected to run from roughly 15 to 150 erg cm−2. (1 kcal/mole of folds=6.95×10−14 ergs/fold.) The quantity σe0 is the contribution of σe due to factors other than folding, and is probably not in excess of σ. Thus we might expect σe to be somewhere from 15 to 40 erg cm−2 to roughly 150 to 175 erg cm−2 for chains of normal flexibility and cross section. It is to be expected that σe will generally be larger than σ in any specific case.

2.5. Rate of Homogeneous Nucleation With Chain Folds

Region A

By simply replacing σe and σ in eq (4) with σe and σ, and proceeding as before, we get

| (12) |

for the steady state rate of injection of loop type nuclei in bulk.

The auxiliary equation

| (13) |

which defines the length or “step height” of the primary nucleus, is obtained in the derivation of eq (12). A numerical calculation using the estimated values of σe, and reasonable values of the other parameters in eq (13), reveals that the step height of the primary nucleus should frequently lie between 100 and 500 A for a degree of supercooling of 20° C. (As will be noted subsequently, the step height of chain folded lamellae growing by monomolecular accretion may initially be substantially less than that given by eq (13).) Observe from eq (13) that the step height of the primary nucleus increases as the degree of supercooling decreases.

The derivation of eqs (12) and (13) is based on the idea that the primary nucleus is large, i.e., the critical size is reached after many successive steps. Therefore, the free energy surface may be treated as a continuum. As will be seen in section 5.1, this assumption cannot be used for monomolecular growth with chain folds. For the latter, a different theory of the rate of nucleation and step height will be given.

Important restrictions exist on the path of nucleation on the free energy surface for loop type nuclei that are not evident in the simplified derivation indicated above. In particular, the step height of the primary nucleus, , may be regarded as essentially invariant as the nucleus is built up. The theory for the constancy of the step height of loop type primary nuclei has been given in detail elsewhere [3]. The step height of one primary nucleus as compared with another is restricted to a narrow range of values centering about because of the steepness of the sides of the saddle point in the free energy surface, and the fact that the chain folds prevent (or seriously deter) an increase of length after a loop is laid down.10 This type of restriction does not apply to bundlelike nuclei.

Effect of Molecular Weight on Nucleation in Upper Part of Region A

The critical volume of the primary folded nucleus, v*, is . For the parameters σ=5 erg cm−2, σe=25 erg cm−2, Tm=400 °K, and (Δhf) =109 erg cm−3, this comes to 2.6×10−16/(ΔT)3 cm3. At relatively low supercooling, e.g., (ΔT) = 10 °C, this would give v*=2.6×10−19 cm3. If it is now assumed that the average length of the polymer molecules, lm, is 5000 A, and that the cross-sectional area is 20×10−16 cm, the mean volume per molecule is calculated to be 10−19 cm3 molecule−1. In this case, the nucleus would have to be formed from more than one polymer molecule. If the polymer molecule has large chain ends that are excluded from the crystal, it follows that the folded nucleus will occasionally possess a chain that emanates bundle-fashion from the plane of the chain folds. This leads to no serious limitation on the theory of nucleation as presented above. At ΔT≥14 °C, the primary nucleus could form from one molecule.

If the chain ends are so large as to be practically completely excluded from the crystal, a serious limitation on the ability of the polymer to form a primary nucleus with chain folds will occur as the step height approaches one half the length of the molecule. For the parameters cited above, and lm=5000 A. Then when ΔT≤1.6 °C, chain folded primary nuclei cannot form if chain ends are excluded from the crystal. For materials with higher σe values or lower molecular weight, this limitation will appear further below Tm. For example, with σe=50 erg cm−2 and lm = 2000 A, this limitation would appear at ΔT≤8 °C. This means that simple homogeneous nucleation with chain folds will not be possible very near the melting point if chain ends are strictly excluded from the crystal. (The same is of course true for bundlelike nucleation at some low supercooling if chain ends are excluded from the crystals.) For polymers of high molecular weight, this limitation on folding is not apt to be encountered in the region where the rate is commonly observed.

It will be possible to tolerate a certain concentration of small chain ends as defects in a polymer crystal. In this case, the degree of supercooling at which chain folds would have difficulty in forming because of chain end effects would be substantially smaller than indicated above. Also, a number of short chains may be included bundle fashion in the nucleus.

Region B

The expression given for IA will hold from temperatures near Tm on down to considerably lower temperatures. Then there will be an increase in the rate of injection of loop type nuclei at a degree of supercooling ΔTc=4σTm/(Δhf)amin resulting from the transport of pre-existing loop type embryos, resembling ∪ shaped kinks, from the melt to the supercooled state. The argument for the existence of this nonsteady state nucleation effect is similar to that given previously for bundlelike nuclei, and need not be repeated here.

Note that the expressions for ΔTc for the bundlelike nucleus and the loop type nucleus are similar, and involve only the lateral surface free energy. The type of nucleus of minimal dimensions that will actually be deposited near and below Tc will be the one that has the lowest free energy of formation, and this will depend largely on which has the lowest end surface free energy. The same symbol is used to denote the transition temperature for both types of nuclei, since it is generally clear which kind is meant.

Summary

A schematic diagram of the rate of homogeneous injection of folded nuclei as a function of temperature is shown in figure 2b. The solid line indicates the manner in which the interfacial jump rate term exp (−ΔH*/kT) will generally lower the nucleation rate at some degree of supercooling, causing a maximum to appear in IA. (This maximum would ordinarily appear between 0.8 to 0.9 Tm.) It is probable that the A→B transition will frequently be unobservable because the jump rate term lowers the nucleation rate so much that Tc falls near or below the glass transition. The pip mark just below Tm represents the temperature above which the molecular length is too small to accommodate chain folding if large chain ends are excluded from the crystal.

2.6. Bundlelike Versus Folded Nuclei in Bulk

As will be brought out subsequently, there are substantial reasons for believing that lamellar spherulites formed in bulk are composed of crystals with chain folds, each individual lamella having a thickness corresponding to the step height associated with the chain folds. The intriguing question of how folded structures could nucleate and then propagate in linear polymers crystallized in bulk will now be discussed in the light of what may be said about homogeneous nucleation in the bundlelike and folded patterns, the possibility that heterogeneous nucleation may be involved in the initiation act, and the fact that under certain conditions chain ends or strain may interfere with the formation of large bundle like objects, even under conditions where small bundlelike nuclei are formed easily.

Consider first the problem of how folded nuclei might predominate in bulk crystallization on the assumption that the folded structures that are observed are of homogeneous origin. (This assumption is by no means proved in any case of bulk crystallization known to the author, but serves as a convenient starting point for the discussion.) We will deal only with crystallization near the melting point.

There is no difficulty in explaining why crystals with chain folds are deposited from a sufficiently dilute solution of a linear polymer. Lauritzen and Hoffman [3] have discussed this in terms of the rate of injection of bundle and loop type nuclei in solution which are11

| (14) |

| (15) |

Equation (14) has been recast to accord with the particular notation and geometry used in the present paper. (The parameters σ, σe, I0, ΔH*, and (Δf) might have somewhat different values in dilute solution than in the bulk phase.) The quantity v2 is the volume fraction of polymer. The lateral surface free energy for the bundlelike nucleus in solution will be essentially the same as the lateral surface free energy of the loop type nucleus in solution, i.e., σ≅σ. The end surface free energies σe and σe will differ to a significant extent.

The important point to note in comparing these two expressions is that, independent of the values of σe and σe that are chosen, Iloop will always exceed Ibundle if v2 is taken to be sufficiently small, since the exponent in eg (14) containing loge v2 will be a large negative number under these conditions. Numerical estimates given in an earlier paper indicate that even if σe is taken to be considerably smaller than σe, folded nuclei will predominate at concentrations of less than about 1 to 10 percent. The term in eq (14) involving loge v2 results from the fact that a number of different polymer molecules must be gathered together to form a bundlelike nucleus, whereas only a few polymer molecules (and often a single one) can form a loop type primary nucleus. Therefore, there is a large configurational entropy contribution to the formation of a bundlelike nucleus in dilute solution that does not arise in the case of the loop nucleus.12 In the case where σe is larger than σe, folded nuclei will predominate across the entire concentration range (see below).

For this same basic reason, a folded crystal is more stable in sufficiently dilute solution than a bundlelike one of the same size and shape even if σe is smaller than σe. Specifically, it can be shown [3] that the total end surface free energy per unit area for the two types of crystal may be written as 12

| (16) |

and

| (17) |

The term in eq (16) containing loge v2 arises from the configurational entropy effect mentioned earlier. Thus, even for the case σe<σe, σend bundle (tot.) will exceed σend loop (tot.) at some low concentration of polymer, and the folded crystal will be the most stable type in dilute solution because it has less total surface free energy. In the event σe>σe, the folded crystal would be the most stable type across the entire concentration range when compared with a bundlelike crystal of the same size and shape.

We are thus led to a discussion of the relative homogeneous injection rates for bundle and loop type nuclei in bulk polymers. The appropriate comparison is given by eq (15) in the case of loop nuclei, and by eq (14) with v2→1 for bundlelike nuclei (cf. eqs (6) and (12)):

| (18) |

| (19) |

Anywhere near the melting point, the exponents involving the surface free energies in these two expressions are by far the largest and most temperature dependent. Recall also that σ is essentially the same as σ for the two types of nuclei. It follows that if homogeneous nucleation of folded nuclei is to prevail over any sensible temperature range in the bulk phase, the condition σe>σe must exist.

While the condition σe>σe for homogeneous nuclei would lead to the dominance of folded nuclei (and the resultant chain folded lamellar structures) in bulk polymers, this is not necessarily the only condition that can lead to a significant number of such structures in bulk. Other factors must be taken into account. For example, chain ends may in some instances prevent the formation of large bundlelike objects, as Flory’s theory [22] suggests. (Cumulative strain may have a similar effect.) Also, heterogeneous initiation, which is certainly a very common source of spherulite initiation, must be considered. However, before discussing these points it is worth commenting on the important case σe>σe.

Conditions giving σe>σe (chain folding the basic mode of nucleation and growth in bulk)

It has been shown for a bundlelike nucleus with a flat end and noncumulative strain that the minimum value of σe is given by ld(Δhf)ρc/6ρl, where ld is the length of the part of the bundle end where the density falls from the crystal to the supercooled liquid value (see eq (A-20) in the appendix). Further, it was estimated in section 2.2 for the particular case of polyethylene that σe (min) was in the vicinity of 60 erg cm−2 on the basis of the assumption ld=10 A. An analysis of σe for folded polyethylene crystals based on data on single crystals formed in dilute solution due to Keller and O’Connor [1] suggests that σe is probably between 30 and 75 erg cm−2 [3]. More recently, a value in the vicinity of 100 erg cm−2 has been suggested [41]. (Although these figures apply to folded crystals formed in dilute solution, the σe value relevant to folded crystals formed in bulk should not differ greatly from that appropriate to dilute solution.) Thus, while it is not altogether certain that σe(min) is larger than σe, it is clear for the particular model used that σe for the bundlelike nucleus can readily exceed σe(min) = 60 erg cm−2, since Γ will generally exceed zero. With this considered, σe could easily be as high as several hundred erg cm−2. Therefore, the possibility that σe>σe for polyethylene would appear to exist.

Before drawing any conclusions from the above, several points must be made clear: (1) The value of σe (min) = 60 erg cm−2 is admittedly based, on the assumption ld=10 A. However, it is believed that this is if anything an underestimate, so σe(min) for the flat bundle end model without cumulative strain is probably even larger than the value cited. (2) The expression σe(min)=ld(Δhf)ρc/6ρl depends on the assumptions used in the simplified model for the heat content and entropy as a function of density in the bundle ends. For example, a narrower maximum in ΔH(ρ) would lead to a lower value of σe(min). Nevertheless, the estimate given for σe(min) is probably not significantly high on this account, and may be too low. (3) Cumulative strain at the flat bundle ends resulting from the density difference between the “connected” liquid and crystalline phases has been omitted from the calculations. However, this will in general lead σe to be underestimated. As will be seen subsequently in the discussion of the hypothetical bundlelike “lamellar” structure, cumulative strain will occur at flat bundle ends of large extent, especially in the case where the chain axes are perpendicular to the plane of the bundle ends. Crudely, one can think of such strain as greatly increasing Γ in eq (3), causing σe to attain values far in excess of σe(min). We regard that it is quite certain that σe>σe for large nuclei with polymer chains that are perpendicular to flat end surfaces on account of cumulative strain alone. (4) The cumulative strain in the flat bundle end model may be reduced by allowing the chains in the (still flat) surface phase to subtend a certain angle ζ with respect to those in the crystal itself (see section 4.3). (This is related to the fact that the end surface of a bundlelike crystal will tend to be curved in order to minimize the surface energy, as pointed out by Matsuoka and Maxwell [25], and Frank [26].) Estimates obtained using appropriate variations of the model treated in the appendix suggest that σe will be fairly large for the “tilted,” model even if the cumulative strain is completely removed. The bending of the chains at a nontetrahedral angle, and the abnormal separation of the chains at the boundary nearest the crystal, produce the required contributions to the heat content in the surface phase.

With the above remarks in mind, it seems reasonable to suppose that it is entirely possible that σe>σe for polyethylene for the important case of flat end surfaces. This would lead in a natural way to a predominance chain folded nuclei in bulk in this polymer, as opposed to bundlelike nuclei with flat ends. From this illustrative example, we consider that it is at least not nonsense to propose that σe may exceed σe in some linear polymers.

The free energy of formation of a bundlelike nucleus with curved ends (“ellipsoidal” model) has not been explicitly considered here. This would probably require the use of considerations akin to those proposed by Cahn and Hilliard [27] for homogeneous nucleation in systems with density gradients. This model is not considered revelant to the problem of the nucleation and growth of bundlelike “lamellae” with large flat end surfaces. Thus, while it seems reasonable on the basis of our calculations to suppose that in some cases σe>σe for nuclei with flat ends, no such simple calculations will provide as much information on whether or not the free energy of formation in bulk of a folded nucleus (which of course has flat ends) is less than that of an ellipsoidal bundlelike nucleus under similar conditions. Nevertheless, our surmise would be that the necessity of having the chain molecules go through a density gradient in the ellipsoidal bundlelike case might well be able to increase its free energy of formation to the point that folded primary nuclei are still the favored type in the bulk phase. This is not certain, however, and the possibility therefore exists that ellipsoidal bundlelike nuclei may form more readily at a specified supercooling than folded nuclei, even when folded nuclei are preferred to bundlelike nuclei with flat end faces. However, if strain or chain ends limited bundlelike growth, the macroscopically observable crystals would still be of the folded type even though coexisting with a number of bundlelike microcrystals or embryos (see below).

Possibility of chain folds in case σe<σe

We now mention certain conditions that might lead to the appearance of a considerable amount of chain folded material in a bulk polymer even in the case where σe<σe for primary nuclei.

Consider the effect of chain ends on the formation of the two types of nuclei (or crystals) under discussion, namely the bundlelike and the folded. We deal principally with the case where the chain ends are assumed to be sufficiently large so that the majority cannot enter the crystal.

It is reasonable to ignore the effect of even large chain ends in constructing the expression for the free energy of formation of relatively small bundlelike nuclei of a polymer of high molecular weight. However, this is not the case for bundlelike crystallites where large chain ends are excluded. Flory has clearly indicated for this case that there are restrictions of an equilibrium character on the size of the bundlelike polymer crystals [22]. The restriction discussed explicitly in Flory’s paper refers to a limitation on the mean length of the crystallites. Flory’s theory of bundlelike crystallization also implies a limitation on the mean radius of the crystallites. The net result is that a large number of bundlelike microcrystals of varying sizes is predicted to exist in a polymer with a distribution of molecular weight. The restriction on the ultimate (equilibrium) size of bundlelike crystallites must be given consideration in dealing with the formation of large nuclei, and the growth of crystallites, in the bundlelike pattern. The description of bundlelike microcrystallinity just mentioned does not appear to suggest the existence of large numbers of lamellae of uniform thickness and extended “radial” dimensions of the type seen in lamellar spherulites.

Even the assumption that chain ends are totally excluded from the crystal will not cause folded nuclei or thin folded crystals to fail to grow to large dimensions in the “radial” direction, i.e., in the direction normal to the polymer chain axes. (Once formed, a folded crystal will grow slowly, if at all, in the chain axis direction because of the existence of the folds, and the slowness of the requisite internal “lengthwise” diffusion mechanism.) A chain end can readily be “denucleated” the short distance to the plane of the chain folds when it finds itself on the lateral (growing) surface, thus being rapidly and efficiently excluded from the interior of the folded crystal. Such chain ends would protrude outward from the fold plane on a short section of polymer chain.

Thus, thin chain folded crystals, once nucleated, should be able to grow to large “radial” dimensions, corresponding to a certain fraction or even the entire radius of a spherulite. The main limitation would arise with low molecular weight material where the molecular length was less than twice the step height, but all molecules that were significantly longer than this would be potentially crystallizable in a basically chain folded manner. Some of the chains (including rather short ones) may be included bundle fashion in the otherwise folded crystal.

The concept that chain ends are excluded from polymer crystals must not be pressed too far, especially in the case of small chain ends. A substantial number of sufficiently small chain ends may enter chain type crystals. (This evidently applies in the case of the —CH3 end groups in the solid solutions formed by the n-paraffins of different lengths.) In the case where a certain number per unit volume of such ends can be assimilated by the polymer crystal, the restrictions noted in Flory’s theory on the size of bundlelike crystals would be relaxed, i.e., larger crystallites would form. Similarly, any restrictions on the ultimate size of the step height due to finite molecular length would be minimized, as noted earlier in section 2.5.

The radial growth of bundlelike nuclei may be significantly reduced or even stopped by cumulative strain at the bundle ends resulting from the density difference of the liquid and crystalline phases. As mentioned earlier, this will certainly be the case for bundlelike nuclei with flat ends where the chain axes are perpendicular to the end face. This may possibly even occur for ellipsoidal bundlelike nuclei, or bundlelike nuclei with flat ends where the chain axes are inclined at an angle to the end surface. In such situations, the condition σe<σe might exist for small nuclei or very small crystals, while cumulative strain leads to σe>σe for large nuclei or crystals. Homogeneous nucleation of tiny bundlelike nuclei would then prevail over the folded type, but the crystals apparent on a large scale in the system would be formed on a basically chain folded pattern.

Even in the case where σe<σe for small nuclei, and σe>σe for large nuclei, the rate of homogeneous nucleation of lamellar spherulites with chain folds will be given approximately by eq (19), especially at moderate to low supercooling where the nuclei will be rather large. The nucleus, though starting on the bundlelike pattern, would begin folding as it grew and exhibit the overall energetics characteristic of a folded nucleus. At high supercooling, stable bundlelike nuclei would appear in profusion, though folding would occur as these grew to large size. In this region, the apparent homogeneous injection rate of folded objects would increase above that given by eq (19). This effect may strongly resemble the onset of region B.

The above remarks form the basis of the conception that even if σe<σe for small nuclei, chain folded structures may under certain circumstances be the most prevalent and physically obvious form of bulk crystallization in linear polymers. Specifically, cumulative strain or sufficiently large chain ends may poison the coherent growth of bundlelike crystals to large dimensions, causing any strictly bundlelike crystals that were initiated to be of limited size: then any folded structures that were introduced into the system through the agency of either homogeneous or heterogeneous nucleation might be able to grow to very large size in the two dimensions normal to the chain axes in the same general sense that folded single crystals do in dilute solution. In this case, it is important to distinguish between the prevalence and ease of observation of a certain type of crystal on the one hand, and the rate of homogeneous initiation of small nuclei of limited growth potential on the other. For the case where σe>σe for nuclei, the formation of folded structures will dominate the bulk crystallization process.

The remaining point concerning the origin of nuclei deals with the possibility of heterogeneous nucleation. In real polymer systems, the initiation of spherulites is for the most part of pseudohomogeneous or heterogeneous origin. (Pseudohomogeneous initiation, which refers to the essentially sporadic initiation events that may take place on the flat surfaces of weakly wettable heterogeneities, can imitate the truly sporadic initiation characteristic of homogeneous initiation.) As a result of special interactions, heterogeneities might conceivably have a strong predilection for producing structures containing loops on their surfaces, even if σe<σe for the homogeneous process. This might cause chain folded structures to be prevalent in linear polymers crystallized in bulk. In the case where σe>σe, chain folded structures of heterogeneous or pseudohomogeneous origin would arise in numbers far in excess of that characteristic of homogeneous nucleation if suitable heterogeneities were present, and these structures would certainly be the dominant form present. Certain questions relating to homogeneous, pseudohomogeneous, and heterogeneous nucleation will be discussed subsequently in section 8.

Summary

The following conclusions may be drawn. If folded nuclei are to predominate in the supercooled bulk phase of a polymer on a homogeneous basis over any important range of temperature, the end surface free energy of the bundlelike nucleus must for some reason exceed that of a folded nucleus (σe>σe). (This statement refers specifically to nuclei with flat end surfaces.) Because of a certain flexibility in the parameters that define σe and σe, it is not possible to say a priori that homogeneous formation of folded nuclei should dominate the bulk nucleation mechanism. However, a plausible case can be made for supposing that σe might well exceed σe under certain circumstances. In any event, the quantity σe is evidently considerably larger than has been assumed in the past. (A compelling theoretical case can be made for the dominance of folded nuclei of homogeneous origin in sufficiently dilute solution.) In the case of heterogeneous nucleation under the condition σe>σe folded structures are to be expected. It is probably not absolutely necessary that σe always be greater than σe to have a significant amount of folded structures appear in bulk. Sufficiently large chain ends may poison the formation of large bundlelike crystallites, but at the same time not seriously affect the formation of large chain folded objects. Similarly, cumulative strain may abort the growth of bundlelike crystals; this corresponds to σe<σe for small bundlelike nuclei, and σe>σe for large bundlelike nuclei or crystals. Further, heterogeneities, a common source of spherulite initiation, might induce folded surface nuclei by specialized interactions.

Attention is now directed to the main problem of the rate of radial growth of spherulites, and the connection between the proposed mechanisms and spherulite structure.

★3. Rate of Radial Growth of Spherulites: Preliminary Considerations

3.1. The Two Types of Nucleation Problem in Spherulitic Growth

We will repeatedly encounter two types of nucleation problem in connection with the rate of radial growth of a spherulite. The first of these is quite similar to that already treated for primary nuclei in the previous sections, in that it deals with a nucleus that is built up, step by step, until a critical size is finally reached. Nucleation of this type has already been treated by Turnbull and Fisher [18], and is readily adapted to deal with surface nuclei that are gradually built up to critical size in a stepwise manner. The second type of nucleation problem commonly encountered is that where the maximum in the free energy barrier is reached in a single step, rather than in a large number of steps. This problem often arises when nucleation of a monomolecular layer is considered. The problem of monomolecular layer growth has been considered by Lauritzen and Hoffman [3].

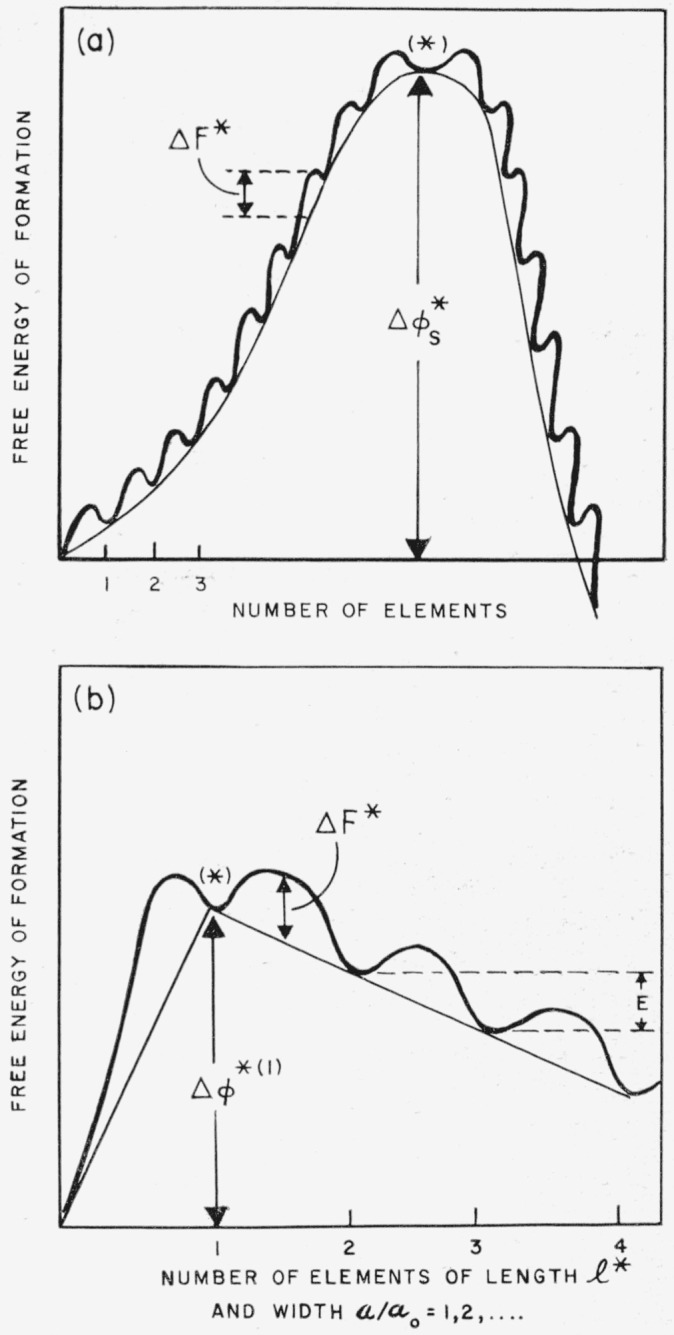

If the surface nucleus is built up by successive addition of a large number of elements until a nucleus of critical size is reached, the free energy of formation may be represented as in figure 3a. Each elementary forward reaction has a reaction rate of the form (kT/h) exp (−wf/kT), and each backward reaction a rate of the form (kT/h) exp (−wb/kT). Then by summing over all the forward and backward reactions in the manner described by Turnbull and Fisher, it is found that the overall rate of nucleation per unit area of substrate is

| (20) |

where ΔF* is the free energy of activation of the interfacial jump rate, the work required to build a nucleus of critical size, and Is(0) a factor that does not depend strongly on temperature. As before, the term in ΔF* may be broken up to give ΔH*–TΔS*. The quantity is, in general, calculated in a manner similar to that used previously for primary nuclei, i.e., the free energy surface is treated as a continuum. Each nucleus then rapidly grows across the substrate crystal and produces a new layer, or substantial fraction thereof. A new surface nucleus will then form on this new layer. Accordingly, the rate of growth on this crystal face depends on the rate of nucleation on the face. When the crystal face in question corresponds to that leading to radial growth of the spherulite the steady state rate of radial growth may be written

| (21) |

(large surface nuclei built up step by step; calculated from continuum model of free energy surface)

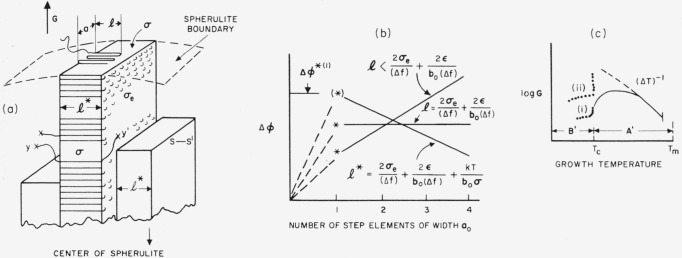

Figure 3. The two types of nucleation problem encountered in calculating the rate of radial growth of polymer spherulites.

(a) Activated state (*) reached by successive addition of a large number of ele ments (Turnbull and Fisher, continuum free energy surface model).

(b) Activated state (*) reached in single step, i.e., by the accretion of one element of length l*, as in certain cases of monomolecular layer growth (Lauritzen and Hoffman, discrete free energy surface model).

Here G0 is a constant with the dimensions lt−1, r the radius of the spherulite at time t. The quantity G0 contains the factor exp (ΔS*/k), and certain relatively unimportant geometrical factors. The principal problem connected with calculating the radial growth rate for a model is the evaluation of . As in the case of homogeneous nucleation, is the free energy at the saddle point described by the appropriate free energy function.

At low to moderate supercooling, the main temperature dependence in eq (21) is due to the term, the term in ΔH* being next in importance. The temperature dependence of G0 is negligible in comparison.13 For steady state surface nucleation, the term in always has a negative temperature coefficient. The term in ΔH* has the usual positive temperature coefficient.

The problem takes on a somewhat different character in cases where the activated state is reached in one step (fig. 3b). Although from a formal standpoint the free energy surface in question may have a saddle point, it is not correct to treat the free energy of formation Δϕ as a continuous function of the width a of the nucleus when the activated state is reached at a=a0. Then Δϕ is defined only for discrete values of a. The net rate is maximized when the length of the step element has a critical length l*, the nucleus being formed by passage over part of the barrier ridge which is not necessarily at the saddle point in the free energy surface treated as a continuum. For this problem, a summing of all the forward and backward reactions leads to a nucleation rate per unit area of surface of the form [3]:

| (22) |

Here is the free energy function Δϕs evaluated for the case v=1, where v is the number of elements (i.e., the number of chains of critical length l*) laid side by side on the crystal substrate, and E the incremental increase of stability on adding each new element (see fig. 3b).

In the case under consideration, the activated state is reached when one such element of length l* attaches to the surface. This is what is meant by the statement that the activated state is reached in “one step”; the term “one step” does not refer here to the elementary process where a single polymer segment is laid down during the process of building up the length l*. The value of ΔF* and ΔH* relevant to the interfacial jump rate characteristic of the laying down of an entire step element of length l* may be larger than and , which refer to the jump rate at the interface for the elementary segmental processes. The principal contribution to ΔF* and ΔH* probably comes from jump rate processes at the end of the nucleus, especially in the case of folded systems.

In most cases of practical interest, the term in brackets involving sinh (E/2kT) will be sufficiently independent of temperature to be taken into the pre-exponential. Then by applying the same arguments used earlier, Is may be transformed into an expression for the radial growth rate of a spherulite:

| (23) |

(small surface nuclei where activated state is reached in single step; Δϕ*(1) calculated from discrete free energy surface model)

It is emphasized that eq (23) frequently applies in the important case of growth by addition of monomolecular layers. If eq (21) is inadvertently applied in such instances, misleading or even erroneous results may be obtained; it is important not to confuse (continuum model) with (discrete model) in calculating the work required to form the nucleus of critical size.

The calculations of the radial growth rate of spherulites to be given in this paper refers to experiments where an unoriented polymer is first heated well above Tm and then rapidly cooled to the growth temperature. The less readily interpretable experiments where specimens are first quenched from the melt and then rewarmed to the growth temperature are discussed briefly in section 8.2.

3.2. The Jump Rate Term in Supercooled Liquids

Another point of interest is that the interfacial jump rate term may require modification, particularly if it depends strongly on segmental motions in the supercooled liquid polymer. If such motions dominate the interfacial jump rate process, it can be shown that the term exp [−ΔH*/kT] in the various equations that have been given may be replaced by the empirical expression based on the work of Williams, Landel, and Ferry [28]

| (24) |

that is valid between Tg and Tg+100°. Here Tg is the glass transformation temperature. This is equivalent to the statement that ΔH* depends on temperature, and has the value 4.12 × 103T2/(51.6 + T−Tg)2. For the sake of simplicity, and for the reason that crystallization temperatures of interest often lie above Tg+100°, we have not employed this empirical expression in the body of the paper. Near the melting point, the constant value ΔH*=20,000 cal mole−1 may be employed for trial purposes.

4. Polymer Crystal Growth by Coherent Bundlelike Surface Nucleation

4.1. Model

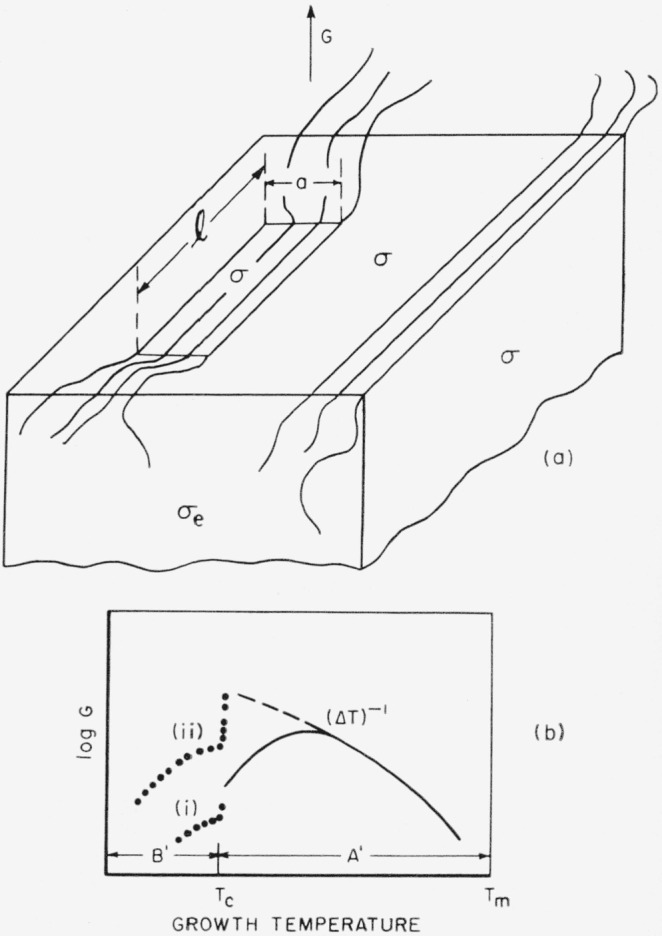

The model used is shown in figure 4a. The polymer molecules in the nucleus are colinear with those in the substrate, i.e., the surface nucleus is of the coherent type. The thickness of the surface nucleus is b0, corresponding to one molecular layer.14 Once formed, this nucleus, which has a length l and width a, leads to the rapid completion of a layer of thickness b0 on some large area of the growing face. Note that the molecules are oriented at a right angle to the direction of growth, which is marked “G”. The lateral surface free energy is σ, and the end surface free energy is σe.

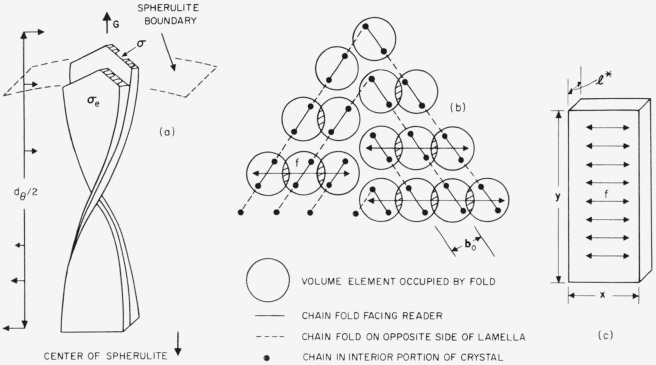

Figure 4. The coherent bundlelike surface nucleus model and its crystal growth rate behavior.

(a) Coherent nucleus of length l, width a, and monomolecular layer thickness b0 on substrate crystal. Heavy arrow marked G indicates direction of crystal growth.

(b) The logarithm of growth rate versus temperature, — — — — log G versus T if effect of jump rate is small; ▬▬ behavior where jump rate lowers log G causing maximum to appear in log G versus T;…. possible effect of interference with growth by excess nucleation in surrounding medium (cf. fig. 1(a)).

The coherent bundlelike surface nucleus model (or one of several simple modifications of it) has been presented at various places in the literature as a pattern for typical spherulitic growth. However, calculations on this model should be approached with full recognition of the fact that it is very improbable that it will lead to a typical lamellar spherulite. The relationship of this model to the structure of spherulites will be discussed shortly. Meanwhile, we shall treat the model as if it did produce a large crystal for which one could define a radial growth rate G.

4.2. Growth Rate for Bundlelike Coherent Nucleus Model

A prime will be used to distinguish the quantities connected with coherent surface nuclei from those belonging to primary nuclei. Later, a double prime will be used to denote quantities related to noncoherent nuclei.

Region A′

In region A′, i.e., from temperatures near Tm on down to those corresponding to rather high supercooling, a and l may be regarded as not having reached their minimal values, and the free energy of formation may be written as

| (25) |

Notice that no term involving al appears in this expression: for a strictly coherent nucleus, only the work required to build the sides enters. By setting (∂Δϕ/∂a)l and (∂Δϕ/∂l)a equal to zero, it is determined that a* = 2σ/(Δf) and l* = 2σe(Δf). Then it is found that

| (26) |

Since a and l are variables, so that the surface nucleus is not formed in one step, G is to be calculated with eq (21):

| (27) |

Region B′

The question must now be raised as to what behavior must be expected of the radial growth rate at high degrees of supercooling, provided that the jump rate term has not already caused G to fall to a low value.

Suppose that the crystals whose radial growth rate we have discussed were of heterogeneous origin, so that in region A' they were born near t = 0. Then at the Tc transition in the supercooled bulk phase, a vast number of tiny bundlelike nuclei would be injected by the nonsteady state nucleation mechanism described in section 2.3 into the matrix in which the crystal was attempting to grow. Thus, at or near the Tc transition characteristic of the pure bulk phase, which will take place at ΔTc ≅ 4σTm/(Δhf)amin, the radial growth of the older and larger crystals would be rather abruptly slowed down because of depletion of crystallizable material, and impingements.

If it is assumed that the crystallites are of entirely homogeneous origin, a rather similar phenomenon can take place. Here IA, as calculated for a bundlelike nucleus in section 2 may be regarded as being proportional to the rate of injection. Barring interference from the jump rate term, the injection rate would rather abruptly attain a value considerably in excess of the extrapolated value of IA. Such a high injection rate at and below Tc due to nonsteady state nucleation would lead to a massive number of impingements. Any crystallites formed in these circumstances would tend to be small, and have a significantly reduced growth rate.

Summary

A schematic diagram of the variation with temperature of the radial growth rate of a body that is governed by a coherent bundlelike surface nucleus is shown in figure 4b. Curves (i) and (ii) in region B′ are intended to represent different degrees of interference with the growth resulting from the incursion of a vast number of competing microcrystals resulting from nonsteady state nucleation. The solid line in region A′, which exhibits a maximum in G because of the effect of the jump rate term, shows the type of behavior that is most probable if the model is valid.

It is considered that the treatment of the secondary (coherent) bundlelike surface nucleus outlined in section 4.2 is more fully illustrative than that given previously using the customary pillbox surface nucleus (cf. reference [11]). The pillbox nucleus requires only a single surface free energy that corresponds to our σ, and leads to a nucleation term involving σ2. For a surface nucleus consisting of chain molecules lying on a flat surface, it seems better to distinguish between the lateral surfaces, and the end surface, giving a nucleation term involving the product σσe. If the growth nucleus were assumed to form on the end of the bundle, so that the direction of growth was parallel to the polymer chains, then the pillbox nucleus with its single lateral surface free energy would be justified. However, this model would not lead to a “spherulite” where the polymer chains were normal to the radius.

4.3. Coherent Bundlelike Growth and Spherulite Structure

Though much attention has been given here and elsewhere to various coherent bundlelike growth nucleus models, it remains to be seen whether or not such a growth mechanism would lead to a roughly spherical object that would be recognized as a spherulite. When this is done, it will emerge that one must have strong reservations about the ability of the model to reproduce anything resembling a typical lamellar spherulite.

Suppose that we attempt to construct a single “lamella” on the strictly bundlelike pattern of the type shown in figure 5(a) where the polymer chain axes are perpendicular to the σe plane. It is simply not possible to create a large flat surface of the type commonly seen in lamellar spherulites in this manner because of the density difference between the supercooled liquid and crystalline phases, and the fact that polymer molecules with covalent bonds connect these two phases in the bundlelike system of crystallization. Growth in the “radial” direction, Gr, for such a hypothetical “lamella” would clearly result in cumulative strain at the bundle ends. As pointed out by Matsuoka and Maxwell [25], and Frank [26], the crystal would actually tend to become ellipsoidal (see dotted lines in figure 5(a)) in order to minimize the total surface free energy. If the bundle end were assumed to remain flat, the effective value of σe would increase enormously as the crystal grew in the Gr direction, thus aborting its growth.

Figure 5. Hypothetical structure of bundlelike lamellae.

(a) Isolated lamella with chains perpendicular to flat bundle ends. Light arrows show site of cumulative strain, “h” represents hypothetical step height. Dotted lines illustrate how crystal would round off end to reduce strain and total surface free energy.

(b) Isolated lamella with chains tilted with respect to flat bundle end. Cumulative strain is reduced, but “lamella” will grow in both Gl and Gr directions.

(c) Stacks of interconnected bundlelike “lamellae” with tilted chains.

This effect should become distinctly apparent for nuclei where the radius corresponds to a mismatch between the supercooled liquid and crystal of one molecular diameter. A conservative estimate would place this radius at less than 50 A under normal circumstances. The coherent bundlelike growth model where the polymer chains in the crystal are perpendicular to the hypothetical σe plane is clearly defective in its ability to predict anything resembling a typical lamella.

It might be suggested that the cumulative strain problem discussed above for the perpendicular case can be minimized by allowing the chains on the faces of a flat bundlelike lamella to exit from the crystal at an angle ζ. In such a “lamella”, the chain axes would thus be tilted with respect to the presumably flat surface of the end, as shown schematically in figure 5(b). The idea is that the chains in the surface region open up to spacings a0+Δa0 and b0+Δb0 that closely corresponds to the mean molecular spacing in the supercooled liquid polymer. It is not entirely clear that this would relieve the cumulative strain of the type that exists in the perpendicular case if the σe surface must be kept flat. It must be remembered that the “lamella” will be three dimensional, i.e., both the a and b spacings in the surface phase must be larger than a0 and b0. It seems likely that the end surface would tend to become curved. Even ignoring these effects, it is clear that the work required to bend the polymer bonds at the required angle, and to increase the spacings in the surface phase, will lead to at least a fairly large σe value from noncumulative strain as noted in section 2.6. As will be demonstrated below, a lamella with a sensible end surface free energy that is not subject to cumulative strain will not maintain its “step height” or “lamellar” thickness.

Consider now the relative growth rates in the radial (r) and lengthwise (l) directions for a bundlelike crystal of the type illustrated in figures 5(a) and 5(b) on the assumption that cumulative strain is absent. The growth in the radial direction has already been calculated:

| (28) |

The corresponding growth rate on the σe faces of the “lamella” is

| (29) |