Abstract

Objectives

Mechanical wear and corrosion at the head-stem junction of total hip arthroplasties (THAs) (trunnionosis) have been implicated in their early revision, most commonly in metal-on-metal (MOM) hips. We can isolate the role of the head-stem junction as the predominant source of metal release by investigating non-MOM hips; this can help to identify clinically significant volumes of material loss and corrosion from these surfaces.

Methods

In this study we examined a series of 94 retrieved metal-on-polyethylene (MOP) hips for evidence of corrosion and material loss at the taper junction using a well published visual grading method and an established roundness-measuring machine protocol. Hips were retrieved from 74 male and 20 female patients with a median age of 57 years (30 to 76) and a median time to revision of 215 months (2 to 324). The reasons for revision were loosening of both the acetabular component and the stem (n = 29), loosening of the acetabular component (n = 58) and infection (n = 7). No adverse tissue reactions were reported by the revision surgeons.

Results

Evidence of corrosion was observed in 55% of hips. The median Goldberg taper corrosion score was 2 (1 to 4) and the annual rate of material loss at the taper was 0.084 mm3/year (0 to 0.239). The median trunnion corrosion score was 1 (1 to 3).

Conclusions

We have reported a level of trunnionosis for MOP hips with large-diameter heads that were revised for reasons other than trunnionosis, and therefore may be clinically insignificant.

Cite this article: H. S. Hothi, D. Kendoff, C. Lausmann, J. Henckel, T. Gehrke, J. Skinner, A. Hart. Clinically insignificant trunnionosis in large-diameter metal-on-polyethylene total hip arthroplasty. Bone Joint Res 2017;6:52–56. DOI: 10.1302/2046-3758.61.BJR-2016-0150.R2.

Keywords: Taper, Corrosion, Wear, Hip, Metal-on-polyethylene

Article focus

It is currently unclear how much material loss and corrosion must occur at the taper junction of total hip arthroplasties (THAs) to be of clinical significance.

We examined tapers of retrieved metal-on-polyethylene hips that had been revised for reasons other than adverse tissue reactions, suggesting that metal release was clinically insignificant.

We aimed to quantify the volume of material loss and severity of corrosion to develop an understanding of ‘acceptable’ levels of metal release.

Key messages

We measured median rates of taper material loss of 0.084 mm3/year (0 to 0.239) and median corrosion scores for the taper and trunnion were 2 and 1, respectively (scale 1 to 4).

Our data help define levels of metal release from the taper junction of THAs revised for reasons other than trunnionosis and therefore may be clinically insignificant.

Strengths and limitations

A strength of this study is the large sample size (94).

It is acknowledged that a single cobalt-chromium (CoCr) alloy head-stem combination is not as prevalent as titamium-CoCr junctions.

Introduction

The term ‘trunnionosis’ describes the mechanisms of material loss at the taper junction that may involve corrosion, mechanical wear or a combination of the two. Incidences of clinically significant trunnionosis in large-diameter (> 36 mm) metal-on-metal (LD-MOM) total hip arthroplasties (THAs) have been widely reported;1-11 metal ions released from this junction have been implicated in soft-tissue reactions and early failure.12-14

The pairing of a metal femoral head with a polyethylene acetabular component (MOP) is commonly selected by orthopaedic surgeons.15 Previous studies have reported evidence of corrosion damage at the taper junction of MOP hips16,17 which has been linked to adverse tissue reactions in some patients.18,19 A recent clinical study described a consecutive series of 17 patients with MOP hips who were all found to have solid, cystic or mixed soft-tissue lesions intra-operatively, with evidence of corrosion in all cases.20 It is not known, however, how much material was lost from the head-stem interface in these cases and a clinically significant level of material loss has not been defined. Retrieval studies comparing the severity of trunnionosis in MOP hips with clinical data can help us understand the size of the clinical impact of taper damage in these implants.

This study examined a consecutive series of 94 retrieved MOP hips of a single design. There were no symptomatic reactions to metal debris reported in any of the cases, suggesting that the level of trunnionosis in these hips was clinically insignificant. The purpose of this study was to quantify this level by 1) grading the severity of corrosion at the head-stem junction, and 2) measuring the volume of material lost at the taper surface.

Patients and Methods

This was a retrieval study involving 94 Endo-Model Mark III (Link, Hamburg, Germany) MOP total hip arthroplasties that had been revised at a single institution and subsequently received at our centre (Table I). All hips consisted of a 38 mm cobalt-chromium (CoCr) femoral head that had been paired with a CoCr femoral stem (29 stems were retrieved). All implants had a 14/16 stem trunnion. The implants had been retrieved from 74 male and 20 female patients with a median age of 57 years (30 to 76) and a median time to revision of 215 months (2 to 324). Pre-revision radiographs were obtained for each hip in order to measure the position of the implants; the median acetabular inclination was 52° (17° to 76°). The reasons for revision, as reported by the revising surgeons, were loosening of both the acetabular component and stem (n = 29), loosening of the acetabular component (n = 58), and infection (n = 7). No adverse tissue reactions were reported.

Table I.

Implant and patient demographic data for the MOP hips. Median and range (where applicable) values presented.

| Characteristics | |

|---|---|

| Gender (M:F) | 74:20 |

| Age at primary surgery (yrs) | 57 (30 to 76) |

| Time to revision (mths) | 215 (2 to 324) |

| Head size (mm) | 38 |

| Trunnion design | 14/16 |

| Inclination (°) | 52 (17 to 76) |

| Reason for revision | Loosening of the acetabular component and stem (n = 29); loosening of the acetabular component (n = 58); infection (n = 7) |

Visual assessment of corrosion

We performed both macroscopic inspection and microscopic analysis (Leica M50, Leica Microsystems, Wetzlar, Germany) of the female head taper and male stem trunnion surfaces to determine the presence and severity of corrosion. A widely published semi-quantitative scoring method21 was used to grade each surface with a score between 1 (no corrosion) and 4 (severe corrosion). This method grades the increasing severity of corrosion based on visual evidence of black deposits, pitting or other obvious surface damage. It has previously been demonstrated to be both repeatable and reproducible.6 All corrosion assessments were completed by a single examiner experienced in retrieval analysis.

Measurement of head taper material loss

We used a Talyrond 365 (Taylor Hobson Ltd, Leicester, United Kingdom) roundness-measuring machine to measure the volume of material lost from the taper surface of each femoral head. Methods for this measurement have previously been published6 and use a 5 μm diamond stylus to capture data from 180 vertical traces taken along the axis of the taper. The annual rate of material loss (mm3/year) was calculated by dividing the total measured volume by the duration of implantation.

Statistical analysis

Non-parametric Mann-Whitney U tests were performed to determine the significance of differences in the rates of corrosion and material loss at the taper surfaces between men and women.

We then performed linear regression analysis to determine the relationship between the rate of material loss (mm3/year) at each MOP head taper and potential explanatory variables of time to revision, age, acetabular component inclination, and gender.

We confirm that all investigations were conducted in conformity with ethical principles of research, that informed consent for participation in the study was obtained and that institutional approval of the human protocol for this investigation was obtained.

Results

Corrosion assessment

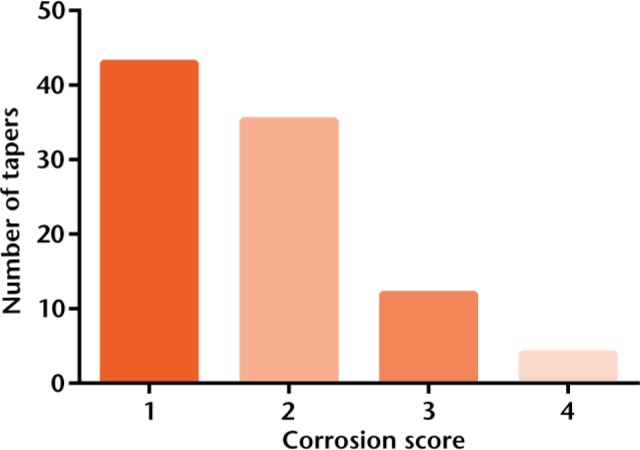

We found that approximately 45% of the MOP head tapers had no evidence of corrosion (score 1), 38% were mildly corroded (score 2), 13% were moderately corroded (score 3) and 4% were severely corroded (score 4) (Fig. 1). The four tapers with signs of severe corrosion all had evidence of black surface deposits. The median (range) corrosion score of the head tapers was 2 (1 to 4). There appeared to be minimal surface damage (corrosion score 1 or 2) in 93% of stem trunnions with a median corrosion score of 1 (1 to 3). Comparison of corrosion scores between taper and trunnion, in the 29 cases where both components were retrieved, revealed that there was no significant difference between the two component surfaces (p = 0.282).

Fig. 1.

Taper corrosion scores for the metal-on-polyethylene hips.

Material loss measurement

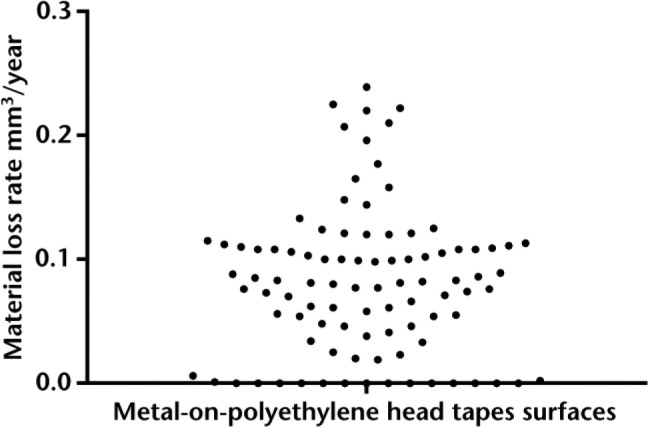

The median volume of total material loss measured at the MOP head taper surfaces was 1.45 mm3 (0 to 4.53). The median rate of material loss annually was 0.084 mm3/year (0 to 0.239) (Fig. 2).

Fig. 2.

Dot plot of the annual rate of material loss for the metal-on-polyethylene hips from each head taper in this study.

Statistical analysis of influencing MOP variables

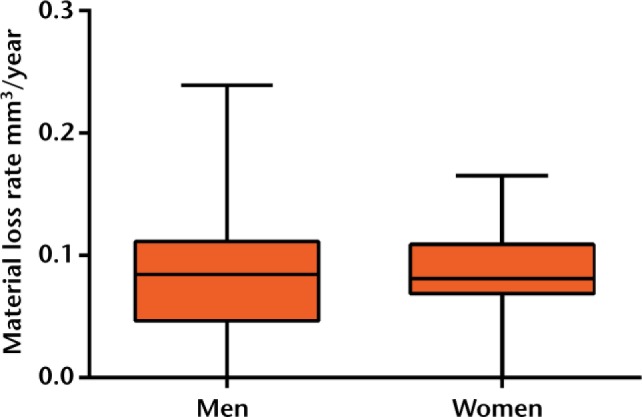

The median rate of material loss at the MOP head taper was 0.081 mm3/year (0 to 0.239) in men and 0.0845 mm3/year (0 to 0.165) in women. This difference was not statistically significant (p = 0.89) (Fig. 3).

Fig. 3.

Box plot presenting the annual rate of material loss for male and female patients. The plots present the median values, upper and lower quartiles and the maximum and minimum values of material loss rate.

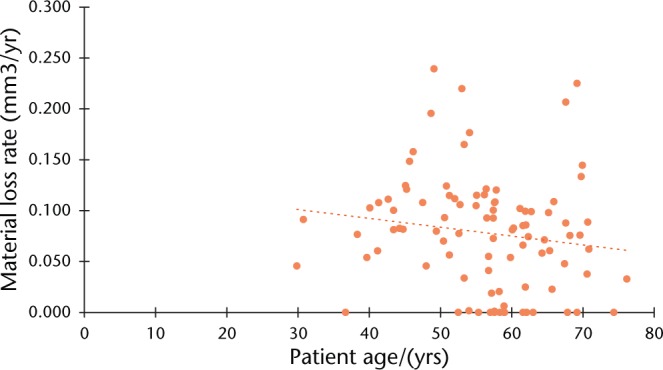

We found a weak negative correlation between patient age at the time of the original arthroplasty procedure and rate of taper material loss (r = -0.2307; p = 0.033) (Fig. 4). There was no correlation between the time to revision and rate of material loss (r = 0.0075; p = 0.9452). Similarly, we did not find any significant correlation between acetabular component inclination and rate of material loss (r = -0.0834, p = 0.5263).

Fig. 4.

Plot showing the association between patient age (years) and the annual rate of material loss (mm3/year). A line of correlation is fitted with r = 0.

Discussion

This study is one of the first retrieval studies to quantify the volume of material loss from the taper junction of a large number of retrieved MOP hips of a single design. We found that the annual rate of taper material loss was considerably less than 1 mm3/year and a large percentage (84%) of head tapers presented evidence of little to no corrosive damage. Similarly, we observed minimal levels of corrosion on the corresponding stem trunnions that were retrieved.

Corrosion or other surface damage will result from the exposure of metal components to the environment of the human body. It is important therefore to distinguish between levels of material loss that result in changes to patient outcome and levels that are not of clinical consequence. No adverse tissue reactions were reported for the cases in this study, suggesting that the level of trunnionosis quantified was clinically insignificant. It is difficult to define a specific volume of metal that may be released from the taper junction before a clinical effect is detected; indeed, individual patient response is likely to play a considerable role in defining clinical relevance. Our study contributes to this discussion by helping improve the understanding of what may be acceptable levels of material loss and corrosion.

MOP THAs have been used worldwide for several decades, however, reports of trunnionosis in these implants have only become prevalent in recent years.16-19 It may be argued that this problem has always existed but improvements in imaging techniques and knowledge gained from LD-MOM implants have made detection of this phenomenon easier. Indeed, it was suggested by Whitehouse et al20 that the clinical presentation of taper damage in MOP hips is at risk of being misdiagnosed as infection.

Another explanation is that the increase in reported problems may be due to design changes introduced at the head-stem junction in contemporary hip implants. The implants investigated in the current study were introduced in 1986; these were found to have low corrosion damage scores and median rates of material loss (0.084 mm3/year) at the taper junction with no evidence of adverse tissue reactions after approximately 20 years of use. In contrast, Whitehouse et al20 presented a consecutive series of 17 contemporary MOP implants that were all revised within a median of 47 months due to adverse local tissue reactions resulting from corrosion at the taper junction.

The lower severity of taper damage of the MOP hips in the current study in comparison with the previous study reporting clinically significant trunnionosis20 may be explained by considering the design differences between the two groups: the 14/16 trunnions in the current study were thicker than the 12/14 stem trunnions in the previous study; the engaging length of the trunnion was longer in the current study (14 mm versus 10 mm); the trunnion surface in the current study is macroscopically smoother than the surface of the contemporary stems; and the implants in the current study employed a single CoCr alloy at the taper junction, rather than a titanium (Ti) stem with CoCr head.

It has previously been reported that mixing of alloys at the head-stem junction, most often with Ti/CoCr combinations, leads to a process of galvanic corrosion whereby one surface is preferentially corroded over the other.22 In these cases, retrieval evidence has shown that the CoCr head is corroded by the Ti stem with chromium-rich black deposits found on the head taper surface and signs of imprinting of the trunnion-threaded surface. We therefore speculate that the use of a single CoCr alloy for both the stem and head in the current MOP hips is likely to have minimised the corrosion that may otherwise have occurred. It is acknowledged that the majority of surgeons in the United States will utilise a Ti-alloy stem with a CoCr head and that the CoCr-CoCr head-stem junction is less common. However, the results of this study help add to the discussion of the influencing factors behind clinically significant levels of trunnionosis seen in MOP hips;18,19 the material and design combination used at the head-stem junction may be key to controlling corrosion and material loss.22

It has also been shown previously that shorter, rougher trunnions increase the risk of taper damage.1,23,24 The design of the comparatively longer, smoother trunnion surfaces in the current study may therefore help explain some of the low volumes of material loss observed, due to a distribution of contact stresses over a larger surface area.

Our analysis of taper retrieval findings with clinical data found that patient age at the time of primary arthroplasty was a significant negative predictor of trunnionosis severity; younger patients appeared to have more material lost from the taper surface. These findings may be explained by considering younger patients as being more physically active, thereby transferring greater stresses to the junction, however, there are many other confounding variables, such as body mass index, which may influence this and should be explored in future work.

We acknowledge the limitations of this study. Only one implant was investigated with a taper junction material combination that is not widely used, however, our findings may inform future designs. Additionally, imaging protocols similar to MOM hips may have detected some form of adverse reaction, although all were asymptomatic.

In conclusion, we have reported our findings of trunnionosis in a series of 94 retrieved large-diameter MOP hips. We found that trunnionosis does occur in these hips but the annual rate of material loss was notably less than that of previously reported MOM taper junctions. No adverse tissue reactions were reported by the revising surgeons, suggesting that the level of trunnionosis in this study may be clinically insignificant.

We speculate that the lower severity of trunnionosis may be due to the use of a single CoCr alloy at the taper junction, and a trunnion design that has a long engaging length, a smooth surface topography and a larger diameter compared with contemporary 12/14 trunnions.

Footnotes

Author Contribution: H. S. Hothi: Data collection, Study design, Data interpretation, Writing the paper.

D. Kendoff: Study design, Data interpretation, Writing the paper.

C. Lausmann: Study design, Data interpretation, Writing the paper.

J. Henckel: Study design, Data interpretation, Manuscript writing.

T. Gehrke: Study design, Data interpretation, Writing the paper.

J. Skinner: Study design, Data interpretation, Writing the paper.

A. Hart: Study design, Data interpretation, Manuscript writing.

ICMJE Conflicts of Intrest: None declared

Funding Statement

We are grateful for the technical assistance of R. Whittaker and J. Meswania and the support of G. Lloyd and E. Ellis for their coordination of the retrieval centre.

Two authors (A. Hart and J. Skinner) have received funding unrelated to this study from the British Orthopaedic Association through an industry consortium of nine manufacturers: DePuy International Ltd, Zimmer GmbH, Smith & Nephew UK Ltd, Biomet UK Ltd, JRI Ltd, Finsbury Orthopaedics Ltd, Corin Group PLC, Mathys Orthopaedics Ltd, and Stryker UK Ltd.

References

- 1. Hothi HS, Whittaker RK, Meswania JM, et al. Influence of stem type on material loss at the metal-on-metal pinnacle taper junction. Proc Inst Mech Eng H 2015;229:91-97. [DOI] [PubMed] [Google Scholar]

- 2. Kop AM, Swarts E. Corrosion of a hip stem with a modular neck taper junction: a retrieval study of 16 cases. J Arthroplasty 2009;24:1019-1023. [DOI] [PubMed] [Google Scholar]

- 3. Goldberg JR, Gilbert JL, Jacobs JJ, et al. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res 2002;401:149-161. [DOI] [PubMed] [Google Scholar]

- 4. Matthies AK, Cro S, Bills P, et al. Which factors determine the volume of material lost from the taper junction of metal-on-metal hip replacements? [abstract]. Annual Meeting of the American Academy of Orthopaedic Surgeons, 2014. [Google Scholar]

- 5. Hothi HS, Matthies AK, Berber R, et al. The reliability of a scoring system for corrosion and fretting, and its relationship to material loss of tapered, modular junctions of retrieved hip implants. J Arthroplasty 2014;29:1313-1317. [DOI] [PubMed] [Google Scholar]

- 6. Matthies AK, Racasan R, Bills P, et al. Material loss at the taper junction of retrieved large head metal-on-metal total hip replacements. J Orthop Res 2013;31:1677-1685. [DOI] [PubMed] [Google Scholar]

- 7. Cross MB, Esposito C, Sokolova A, et al. Fretting and corrosion changes in modular total hip arthroplasty. Bone Joint J 2013;95-B(Suppl 15):127.23307686 [Google Scholar]

- 8. Higgs G, Kurtz S, Hanzlik J, et al. Retrieval analysis of metal-on-metal total hip prostheses: characterizing fretting and corrosion at modular interfaces. Bone Joint J 2013;95-B(Suppl 15):108. [Google Scholar]

- 9. Meyer H, Mueller T, Goldau G, et al. Corrosion at the cone/taper interface leads to failure of large-diameter metal-on-metal total hip arthroplasties. Clin Orthop Relat Res 2012;470:3101-3108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10. Buente D, Huber G, Bishop N, Morlock M. Quantification of material loss from the neck piece taper junctions of a bimodular primary hip prosthesis. A retrieval study from 27 failed Rejuvenate bimodular hip arthroplasties. Bone Joint J 2015;97-B:1350-1357. [DOI] [PubMed] [Google Scholar]

- 11. Panagiotidou A, Meswania J, Osman K, et al. The effect of frictional torque and bending moment on corrosion at the taper interface : an in vitro study. Bone Joint J 2015;97-B:463-472. [DOI] [PubMed] [Google Scholar]

- 12. Chana R, Esposito C, Campbell PA, Walter WK, Walter WL. Mixing and matching causing taper wear: corrosion associated with pseudotumour formation. J Bone Joint Surg [Br] 2012;94-B:281-286. [DOI] [PubMed] [Google Scholar]

- 13. Fricka KB, Ho H, Peace WJ, Engh CA., Jr Metal-on-metal local tissue reaction is associated with corrosion of the head taper junction. J Arthroplasty 2012;27:26-31. [DOI] [PubMed] [Google Scholar]

- 14. Whitehouse MR, Endo M, Masri BA. Adverse local tissue reaction associated with a modular hip hemiarthroplasty. Clin Orthop Relat Res 2013;471:4082-4086. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.No authors listed. National Joint Registry for England, Wales, Northern Ireland the Isle of Man (NJR), 12th Annual Report, 2015. http://www.njrcentre.org.uk/njrcentre/Portals/0/Documents/England/Reports/12th%20annual%20report/NJR%20Online%20Annual%20Report%202015.pdf (date last accessed 27 October 2016).

- 16. Cook RB, Bolland BJ, Wharton JA, et al. Pseudotumour formation due to tribocorrosion at the taper interface of large diameter metal on polymer modular total hip replacements. J Arthroplasty 2013;28:1430-1436. [DOI] [PubMed] [Google Scholar]

- 17. Tan SC, Teeter MG, Del Balso C, Howard JL, Lanting BA. Effect of taper design on trunnionosis in metal on polyethylene total hip arthroplasty. J Arthroplasty 2015;30:1269-1272. [DOI] [PubMed] [Google Scholar]

- 18. Scully WF, Teeny SM. Pseudotumor associated with metal-on-polyethylene total hip arthroplasty. Orthopedics 2013;36:e666-e670. [DOI] [PubMed] [Google Scholar]

- 19. Lindgren JU, Brismar BH, Wikstrom AC. Adverse reaction to metal release from a modular metal-on-polyethylene hip prosthesis. J Bone Joint Surg [Br] 2011;93-B:1427-1430. [DOI] [PubMed] [Google Scholar]

- 20. Whitehouse MR, Endo M, Zachara S, et al. Adverse local tissue reactions in metal-on-polyethylene total hip arthroplasty due to trunnion corrosion: the risk of misdiagnosis. Bone Joint J 2015;97-B:1024-1030. [DOI] [PubMed] [Google Scholar]

- 21. Goldberg JR, Gilbert JL, Jacobs JJ, et al. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res 2002;401:149-161. [DOI] [PubMed] [Google Scholar]

- 22. Jacobs JJ, Gilbert JL, Urban RM. Corrosion of metal orthopaedic implants. J Bone Joint Surg [Am] 1998;80-A:268-282. [DOI] [PubMed] [Google Scholar]

- 23. Munir S, Walter WL, Walsh WR. Variations in the trunnion surface topography between different commercially available hip replacement stems. J Orthop Res 2015;33:98-105. [DOI] [PubMed] [Google Scholar]

- 24. Panagiotidou A, Meswania J, Hua J, et al. Enhanced wear and corrosion in modular tapers in total hip replacement is associated with the contact area and surface topography. J Orthop Res 2013;31:2032-2039. [DOI] [PubMed] [Google Scholar]