Abstract

In this study, the effect of heating on the oil yield and fatty acid composition of eggs cooked in drying oven, microwave oven, pan and boiled were determined, and compared. The highest oil content (15.22%) was observed for egg cooked in drying oven, while the lowest oil (5.195%) in egg cooked in pan. The cooking in microwave oven caused a decrease in oleic acid content (46.201%) and an increase in the amount of palmitic acid content (26.862%). In addition, the maximum oleic acid (65.837%) and minimum palmitic acid (14.015%) contents were observed in egg oil cooked in pan. Results showed that fatty acids were significantly affected by cooking method. This study confirms that the cooking processing influences the fatty acid composition of egg oils.

Keywords: Egg, Heating, Cooking, Boiling, Oven, Microwave, Fatty acid, GC

Introduction

Egg is a good source of high quality lipids which contained polyunsaturated fatty acids (PUFAs) for the human diet (Mazalli et al. 2004). Meat, milk and egg play an important role in human nutrition (Newman et al. 2002; Basmacıoğlu et al. 2003). Consumers are increasingly interested in functional foods that can prevent or ameliorate disease (Patterson et al. 2001). Chicken eggs are popular foods due to their high nutritional value. Edible part of egg (100 g) contains approximately 11.2 g of fat (Decker and Cantor 1992). Fatty acid composition of egg can changed depending on the diet of laying hens. Heating is one of the main operations applied nuts, that can lead to various physico-chemical changes (Alatas and Citil 2013; Ciemniewska-Zytkiewicz et al. 2014). Applied microwave treatment can be alternative to conventional process due to be faster and reduce energy costs (Giese 1992). Moreover, microwave treatment to hazelnuts decreases contamination of the aflatoxin (Basaran and Akhan 2010). Microwave energy and conventional heating are currently being used for cooking, drying, baking and pasteurization (Rosenberg and Bogl 1987; Megahed 2001). When compared to conventional heat processes, microwave process can offer several advantages such as speed of operation, energy savings, precise process control, faster start up and shut-down times (Megahed 2001). The objective of this study was to assess the effect of heating on oil yields and fatty acid composition of hen eggs cooked in microwave, oven, pan and hot water.

Materials and methods

Materials

Eggs were obtained from a local market in Konya, Turkey. All reagents and solvents were of analytical grade and purchased from Sigma-Aldrich Co.

Methods

Eggs were cracked in a bowl and whipped immediately. Scrambled eggs were put in petri dishes at equal amounts and cooked separately in microwave oven at 540 W, drying oven at 120 °C and pan without using oil until reach up to solid state. A microwave (Arçelik ARMD 580, Turkey) oven capable of generating 900 W power at 2450 MHz was used for the heating experiments. The dimensions of the microwave cavity were 34.5 × 34.0 × 22.5 cm. Also, as another processing, eggs were also boiled for six min after boiling water.

Oil extraction

After eggs were extracted by petroleum benzine in soxhlet apparatus for 5 h, the solvent was removed with a rotary evaporator at 50 °C. Oil contents of samples were determined according to AOAC (1990) method.

Fatty acid composition

After the egg oil (50–100 mg) was converted to their fatty acid methyl esters (FAME), it (1 µl) was analyzed by gas chromatography (Shimadzu GC-2010) equipped with flame-ionization detector (FID) and capillary column (Tecnocroma TR-CN100, 60 m × 0.25 mm, film thickness: 0.20 µm). The temperature of injection block and detector was 260 °C. Carrier gas was nitrogen with 1.51 ml/min flow rate. Split rate was also 1/40. Column temperature was programmed 120 °C for 5 min, and increased to 240 °C at 4 °C/min and held 25 min at 240 °C. Fatty acid methyl ester mixture (Sigma Chemical Co.) was used as standard to determine sample peaks. (AOAC 1990).

Statistical analysis

Analysis of variance (ANOVA) was performed by using JMP version 9.0 (SAS Inst. Inc., Cary, N.C.U.S.A). The results are mean ± standard deviation (MSTAT C) of 25 independent egg samples (Püskülcü and İkiz 1989).

Results and discussion

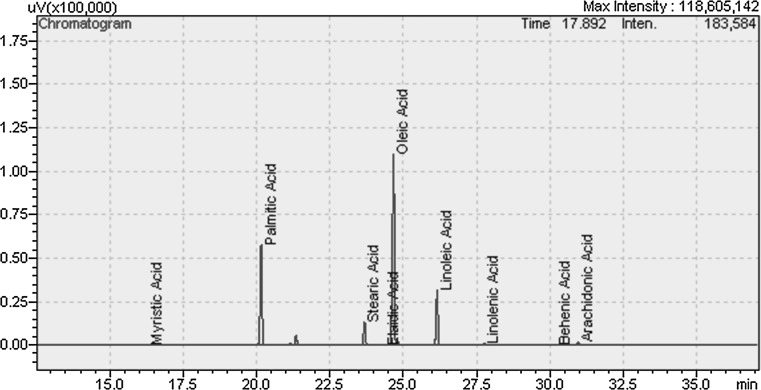

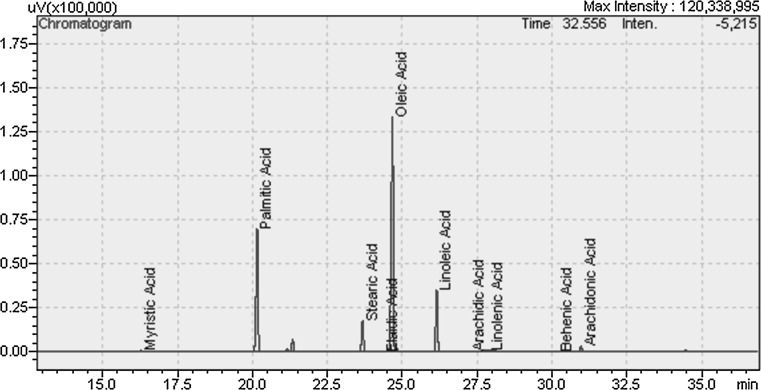

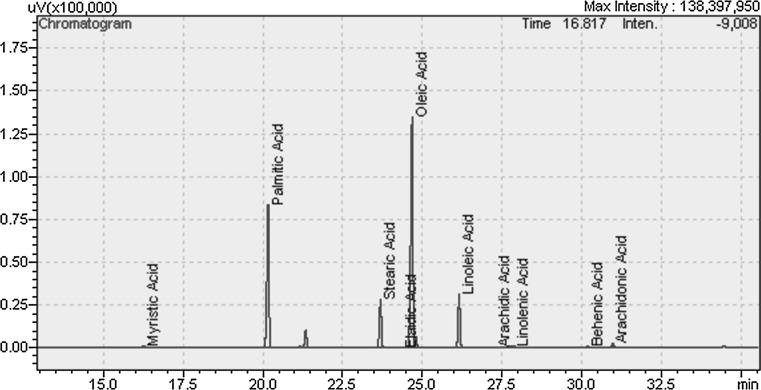

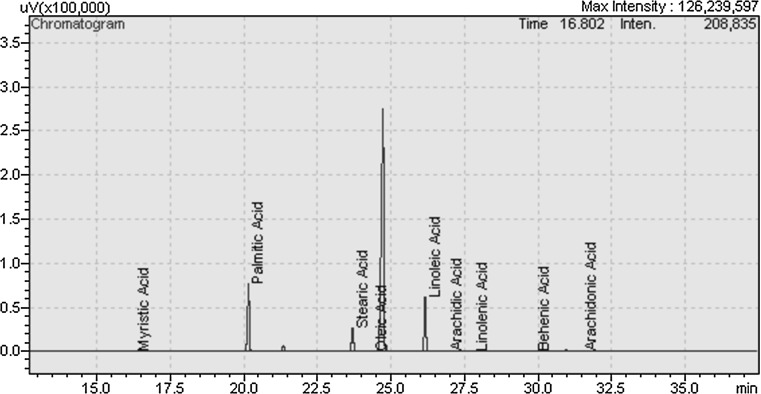

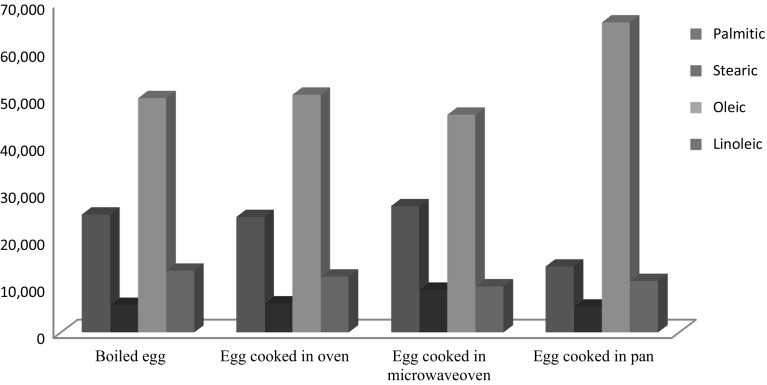

Oil contents and fatty acid compositions of eggs which boiled, cooked in drying oven, microwave and pan are given in Table 1 and Figs. 1, 2, 3 and 4. Oil content of egg samples ranged from 5.19 to 15.22% (p < 0.05). Cooking methods had significant effect on oil contents. The highest oil (15.223%) was observed for egg cooked in drying oven, followed by boiled egg (7.72%), while the lowest oil content was found in egg cooked in pan (5.19%). In previous study, oil contents of several eggs changed between 10.3 and 10.8% (Beynen 2004). The oil in eggs cooked with different methods showed nine fatty acids (Table 1). There were significant differences among the heating processing regarding oil content and fatty acid compositions of egg oils. Both oil content and fatty acid compositions were significantly influenced by different cooking processing.

Table 1.

Oil contents and fatty acid compositions of egg samples (%)

| Fatty acids | Boiled egg | Egg cooked in oven | Egg cooked in microwave oven | Egg cooked in pan | ||||

|---|---|---|---|---|---|---|---|---|

| Myristic | 0.312 | ±0.002*a | 0.270 | ±0.005b | 0.434 | ±0.018a | 0.175 | ±0.001c |

| Palmitic | 25.075 | ±0.035b** | 24.558 | ±0.088c | 26.862 | ±0.388a | 14.015 | ±0.054d |

| Stearic | 5.882 | ±0.014bb | 6.206 | ±0.026b | 9.079 | ±0.001a | 5.504 | ±0.015 |

| Elaidic | 0.157 | ±0.002b | 0.199 | ±0.001a | 0.176 | ±0.021a | 0.095 | ±0.002c |

| Oleic | 49.735 | ±0.166b | 50.482 | ±0.187b | 46.201 | ±0.389c | 65.837 | ±0.084a |

| Linoleic | 13.170 | ±0.133a | 11.877 | ±0.245b | 9.822 | ±0.116c | 10.947 | ±0.002c |

| Linolenic | 0.397 | ±0.007a | 0.240 | ±0.002a | 0.113 | ±0.059b | 0.172 | ±0.032b |

| Behenic | 0.113 | ±0.004c | 0.145 | ±0.002b | 0.159 | ±0.002a | 0.050 | ±0.001d |

| Arachidonic | 0.649 | ±0.012b | 1.121 | ±0.011a | 0.880 | ±0.070b | 0.048 | ±0.002c |

| Oilcontent | 7.723 | ±0.594b | 15.223 | ±1.650a | 6.667 | ±0.196c | 5.195 | ±0.050c |

* mean ± standard deviation

** values within each column followed by different letters are significantly different (p < 0.05)

Fig. 1.

Boiled egg

Fig. 2.

Cooked egg in oven

Fig. 3.

Cooked egg in microwave

Fig. 4.

Cooked egg in pann

Oleic acid was predominant fatty acid in all eggs cooked by different methods. The two major unsaturated fatty acids determined were oleic and linoleic acid, which varied from 46.20 to 65.83% and 9.82 to 13.17%, respectively (p < 0.05). Palmitic acid was found to be predominant saturated fatty acid with a range of 14.01–26.86%, followed by stearic acid with a range of 5.50–9.07%. Linolenic acid was present in a low proportion, observed between 0.113 and 0.397%. Other fatty acids, e.g., myristic, elaidic, behenic and arachidonic acids, were present at a lower levels. Results showed that fatty acids were significantly affected by cooking method. On the other hand, cooking in pan caused an increase in oleic acid and a significant decrease in palmitic acid compared to other cooking methods. The high oleic and low palmitic acid content contributed the oil better health properties. The highest level of palmitic acid (26.862%) and the lowest of oleic acid (46.201%) were observed in oil of egg cooked in microwave oven (p < 0.05; Fig. 5). Additionally, the maximum stearic acid content (9.079%) and the minimum linoleic acid (9.822%) and linolenic acid (0.113%) levels were found in this oil of egg. Palmitic, stearic, palmitoleic, oleic, linoleic, arachidonic, docosahexaenoic, total oil contents of hen egg were determined as 26.1, 8.9, 3.2, 42.6, 16.2, 2.0, 0.7 and 25.1% (Cherian et al. 2002). In a previous study, Alatas and Citil (2013) reported that white egg oil purchased from market contained 23.75% palmitic, 7.09% stearic, 2.58% palmitoleic, 37.38% oleic, 22.63% linoleic acids. Table eggs oil contained myristic (0.28), palmitic (21.67%), palmitoleic (3.58%), stearic (9.80%), oleic (43.86%), linoleic (14.92%), C20:4(n-6) (2.60), C22:6(n-3) (1.34%) (Stibilj et al. 1999). In the experiment of Sehu et al. (2012), oleic acid was the key fatty acid of egg yolk. The amount of all fatty acids of eggs is different. The results of this work showed that cooking significantly effected oil contents and fatty acid composition of eggs. Compared with the cooking methods used in the study, oil from eggs cooked in pan has the largest oleic acid content (65.837%). In addition, linoleic acid content was at the low levels. Linoleic acid content in oils from eggs cooked in microwave oven and pan was lower than the other cooking processing. In addition, palmitic and stearic acids were significantly affected by pan cooking method. But, fatty acid composition of egg oils treated were affected by pan cooking. In view of these results, it would be highly recommendable to increase oleic acid contents and decreased oil content. This study confirmed that the heat processing influenced the oil contents and fatty acid composition of egg.

Fig. 5.

Dominant fatty acids of cooked egg samples (%)

Conclusion

The amount of all fatty acids of eggs is different, that is, it is possible to say that change fatty acid composition of the whole egg. With respect to roasting process in microwave oven, fatty acid composition of samples did not show dramatically alteration. Therefore, cooking treatment had significantly affected on fatty acid composition and oil contents of eggs.

Acknowledgements

The authors extend their appreciation to the International Scientific Partnership Program ISPP at King Saud University for funding this research work through ISPP# 0015.

References

- Alatas MS, Citil ÖB. Comparison of fatty acid composition of egg yolks obtained white and brown hens fed in the same way. Maced J Anim Sci. 2013;3:41–44. [Google Scholar]

- AOAC . Official methods of analysis. 15. Washington: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Başaran P, Akhan Ü. Microwave irradiation of hazelnuts for the control aflatoxin producing Aspergillus parasiticus. Innov Food Sci Emerg Technol. 2010;11:113–117. doi: 10.1016/j.ifset.2009.08.010. [DOI] [Google Scholar]

- Basmacıoğlu H, Çabuk M, Ünal K, Özkan K, Akkan S, Yalçın H. Effects of dietary fish oil and flax seed on cholesterol and fatty acid composition of egg yolk and blood parameters of laying hens. South Afr J Anim Sci. 2003;33:266–273. [Google Scholar]

- Beynen AC. Fatty acid composition of eggs produced by hens fed diets containing groundnut, soya bean or linseed. NJAS Wagening J Life Sci. 2004;52:3–10. doi: 10.1016/S1573-5214(04)80026-5. [DOI] [Google Scholar]

- Cherian G, Holsonbake TB, Goeger MP. Fatty acid composition and egg components of specialty eggs. Poult Sci. 2002;81:30–33. doi: 10.1093/ps/81.1.30. [DOI] [PubMed] [Google Scholar]

- Ciemniewska-Zytkiewicz H, Brys J, Brys A, Sujka K, Koczon P. Effect of roasting process on moisture content and color of Polish in shell hazelnuts. Akad Gıda. 2014;12:6–10. [Google Scholar]

- Decker EA, Cantor AH. Fatty acids in poultry and egg products. In: Chow CK, editor. Fatty acids in food and their health implications. New York: Marcel Dekker, Inc; 1992. pp. 159–160. [Google Scholar]

- Giese J. Advances in microwave food processing. Food Technol. 1992;46(9):118–123. [Google Scholar]

- Mazalli MR, Faria DE, Salvador D, Ito DT. A comparison of the feeding value of different sources of fat for laying hens: 1. Performance characteristics. J Appl Poult Res. 2004;13:274–279. doi: 10.1093/japr/13.2.274. [DOI] [Google Scholar]

- Megahed MG. Microwave roasting of peanuts: effects on oil characteristics and composition. Nahrung/Food. 2001;4:255–257. doi: 10.1002/1521-3803(20010801)45:4<255::AID-FOOD255>3.0.CO;2-F. [DOI] [PubMed] [Google Scholar]

- Newman RE, Bryden WL, Fleck E, Ashes JR, Buttemer WA, Storlien LH, Downing JA. Dietary n-3 and n-6 fatty acids alter avian metabolism: metabolism and abdominal fat deposition. Braz J Nutr. 2002;88:11–18. doi: 10.1079/BJN2002580. [DOI] [PubMed] [Google Scholar]

- Patterson PH, Koelkebeck KW, Bell DD, Carey JB, Anderson KE, Darre MJ. Egg marketing in national supermarkets: specialty eggs—part 2. Poult Sci. 2001;80:390–395. doi: 10.1093/ps/80.4.390. [DOI] [PubMed] [Google Scholar]

- Püskülcü H, İkiz F. Introduction statistic (İstatistiğe Giriş) Bornova-İzmir: Bilgehan Press; 1989. p. 333. [Google Scholar]

- Rosenberg U, Bogl W. Microwave thawing, drying and baking in the food industry. Food Technol. 1987;41:85–91. [Google Scholar]

- Sehu A, Kucukersan S, Coskun B, Koksal BH, Citil OB. Effects of dietary glycerol addition on growth performance, carcass traits and fatty acid distribution in cloacal fat in broiler chickens. Rev Méd Vét. 2012;163:194–200. [Google Scholar]

- Stibilj V, Koman Raj PM, Holcman A. Fatty acid composition of eggs enriched with omega-3 fatty acids on the market. Zbornik Bioteh Fak Univ Ljubljani Kmetijstvo Zooteh. 1999;74:27–36. [Google Scholar]