Abstract

Khoa is a heat desiccated milk product which serves as base material for traditional dairy based Indian sweets. Sensory, textural and microstructural changes in khoa were studied to assess the effect of developed acidity and neutralization of milk. Noticeable changes were observed in sensory, textural and micro structural quality of khoa as affected by quality of milk. Lower hardness, springiness, cohesiveness and accordingly, gumminess and chewiness were observed in khoa manufactured using neutralized milk due to higher moisture retention as compared to control and acidic milk khoa. It was also evident from the Scanning Electron Microscopy that higher moisture retention in neutralized milk khoa resulted in elongation of native microstructure of khoa by suppressing the grain formation leading to smooth and plain surface while, developed acidity in milk resulted in greater granule formation in the resulting khoa causing shrinkage of native microstructure and acidic flavour in khoa. Similarly, acidification and subsequent neutralization of milk adversely affected sensory attributes of resulting khoa.

Keywords: Khoa, Acidification, Neutralization, Texture profile, Microstructure

Introduction

The textural characteristics of a dairy product is always influenced by its composition, type and quality of raw materials used and manufacturing practices/parameters followed during preparation. There is an interrelationship among the texture, composition and microstructure. Hardness, gumminess and chewiness are negatively correlated with moisture and fat content, but positively with protein, lactose, added carbohydrates, ash and calcium content (Adhikari et al. 1994). The composition of cow and buffalo milks is different with respect to total solids, proteins, lactose and fat. Therefore, the use of these milks as such or their combination produces milk products with different textural properties. Depending on its characteristics, milk is eminently suitable for certain types of region specific indigenous traditional milk products and Khoa is one of the most important heat desiccated product in India, Nepal, Bangladesh and Pakistan (Choudhary et al. 2015). Approximately 5.5% of total milk produced in India is utilized for production of khoa. Khoa production is the easiest way of preserving rurally produced milk by its conversion into semi-solid form i.e. khoa which can be utilized for the production of traditional products (Kumar 2013). Milk with more than 0.17% acidity produces khoa with grainy texture. The size and hardness of grains increased with the increase in acidity. As a result of complex interactions occurring among the individual milk components like casein, whey protein, lactose and fat globules in addition to additives such as acidulants, enzymes, and thickening agents added during the production of milk products results in changes in microstructure. These changes in microstructure can be observed using scanning electron microscopy (SEM). The heat treatment employed during khoa-making considerably changed the physical state of the milk proteins, fat globules, and lactose (De 2004). These changes include coagulation of the proteins, fat globule coalescence leading to large lumps of fat and super saturation of lactose in the milk serum (Patil et al. 1992). Adhikari (1993) reported protein agglomerates joined together by thick protein bridges in khoa and compaction of protein agglomerates with reduction in void spaces and fat globule interspersed in between. Adhikari et al. (1993) also reported coalesced, compact casein micelles with associated fat globules in chhana and numerous small voids interspersed throughout the matrix. Rapid development of natural acidity in milk at ambient temperature is a common problem in India. Historically, such type of milk with developed acidity is not suitable for sweets preparation, as heating of milk with developed acidity resulted in coagulation of milk proteins. Therefore, addition of neutralizer to such milk is a common and ancient practice. Manufacture of traditional dairy products adds value to milk as it preserves milk solids for longer time at room temperature and hence increases the shelf life of milk solids. Existing reports on khoa are focused on standardization of manufacturing methods, chemical composition, sensory evaluation, preservation and improvement in keeping quality (De and Ray 1952; Kumar and Srinivasan 1982; Patil et al. 1990; Rehman and Salariya 2006; Kulkarni and Hembade 2012; Kumari et al. 2012; Sivakumar et al. 2014). Rajorhia et al. (1990) studied the effect of quality of buffalo milk on khoa but the work was limited to chemical, sensory and rheological properties of buffalo milk khoa only. However, Patil et al. (1992) studied the texture and microstructure of khoa which was limited to buffalo milk khoa only. There is hardly any information on the microstructural and textural changes as affected by quality of milk. This was essential, since it largely determines the material and rheological behavior of the product. Therefore, an attempt has been made to determine the effect of developed acidity and subsequent neutralization of milk to recognize the interrelation among sensory, texture and microstructure changes of khoa.

Materials and methods

Materials

Ethanol was procured from Jiangsu Huaxi International Trade Co. Ltd., China. Sodium bicarbonate was procured from HiMedia Laboratories Pvt. Ltd., Mumbai, India. Glutaraldehyde (25%), cacodylate buffer, osmium tetraoxide, from Sigma Aldrich, St. Louis, Missouri, USA.

Methods

Collection and preparation of samples

Good quality pooled cow and buffalo milk was obtained from the experimental dairy of the ICAR-National Dairy Research Institute, Karnal. Fresh milk samples were incubated at 30 °C in an incubator (Narang Scientific Works Pvt. Limited, Delhi, India) for rapid development of acidity up to 0.18% lactic acid (LA). Acidity of milk was evaluated hourly until it reaches up to 0.18% LA. Developed acidity was neutralized with the addition of calculated amount of neutralizer (sodium bicarbonate) at required rate to adjust the acidity to 0.14% LA (~acidity of fresh milk). The fresh, acidic and neutralized cow and buffalo milk samples were used to prepare khoa.

Preparation of khoa

Khoa samples were prepared using the method of De (2004). The concentration of milk was carried out in batches of 5 L each in an open double jacketed stainless steel kettle at a steam pressure of 2 kg/cm2. Stirring and scrapping with the help of a flat iron ladle was continued to avoid burning of milk solids during boiling. This process was continued until the entire mass reached a pasty consistency and the steam pressure was reduced to 1 kg/cm2. Vigorous stirring was pursued with the help of an iron ladle with simultaneous scraping of the pan bottom sides, more so at the last stage. As soon as the milk solids started leaving the sides of the kettle, steam was closed and vigorous stirring-cum-scrapping was continued till the viscous mass reached a semi-solid/pasty consistency. The pasty mass was then worked up and down to form a pat of single compact mass i.e. khoa. The proximate composition of khoa in terms of fat, lactose, ash, total solids pH and acidity of khoa was determined by the method described in Indian Standard (IS: SP: 18 part XI 1981). Moisture and protein content was determined by Indian Standard (IS: 16072 2012; AOAC 1970, respectively). The gross composition of three types of khoa prepared from buffalo and cow milk is presented in Table 1a, b.

Table 1.

Gross composition and physico chemical characteristics of fresh, acidic and neutralized (a) buffalo milk khoa, (b) cow milk khoa (Choudhary et al. 2016)

| Parameters→ Sample↓ |

Fat | Protein | Lactose | Moisture | Ash | Total solids | pH | Acidity (% LA) | |

|---|---|---|---|---|---|---|---|---|---|

| (a) | |||||||||

| Buffalo | FBMK | 35.13 ± 1.06A | 17.56 ± 0.17A | 20.59 ± 0.78B | 23.94 ± 0.41B | 2.74 ± 0.025B | 76.06 ± 0.41B | 6.48 ± 0.003B | 0.57 ± 0.003B |

| Milk | ABMK | 35.50 ± 1.53A | 17.70 ± 0.14A | 17.66 ± 1.02A | 22.43 ± 0.55A | 2.64 ± 0.034A | 77.57 ± 0.55C | 6.38 ± 0.005A | 0.62 ± 0.002C |

| khoa | NBMK | 35.41 ± 1.35A | 17.76 ± 0.29A | 17.03 ± 1.32A | 25.44 ± 0.70C | 2.85 ± 0.040C | 74.56 ± 0.70A | 6.68 ± 0.005C | 0.55 ± 0.005A |

| (b) | |||||||||

| Cow | FCMK | 26.46 ± 0.50A | 18.30 ± 0.12A | 24.87 ± 0.18B | 29.65 ± 0.62B | 3.24 ± 0.017B | 70.35 ± 0.62B | 6.40 ± 0.005B | 0.63 ± 0.002B |

| Milk | ACMK | 26.13 ± 1.08A | 18.43 ± 0.29A | 21.53 ± 0.44A | 27.07 ± 0.37A | 3.17 ± 0.012A | 72.92 ± 0.37C | 6.22 ± 0.005A | 0.68 ± 0.006C |

| khoa | NCMK | 25.19 ± 0.80A | 19.03 ± 0.04A | 20.80 ± 0.50A | 30.75 ± 0.30C | 3.46 ± 0.019C | 69.25 ± 0.30A | 6.51 ± 0.003C | 0.58 ± 0.006A |

Data are presented as mean ± Standard Error Mean (n = 3)

ABMK acidic buffalo milk Khoa, FBMK fresh buffalo milk Khoa, NBMK neutralized buffalo milk Khoa, ACMK acidic cow milk Khoa, FCMK fresh cow milk Khoa, NCMK neutralized cow milk Khoa

A–CMeans within column with different upper case superscript are significantly different (p < 0.05) from each other

Sensory evaluation

Sensory evaluation of fresh, acidic and neutralized cow and buffalo milk khoa samples was carried out using a score card developed for khoa by Gupta and Pal (1985). This was used for measuring any variation in the sensory attributes due to developed acidity and neutralization of milk by a sensory panel. A sensory panel consisting of 15 selected panelists was drawn from the faculty of Dairy processing departments of ICAR-National Dairy Research Institute, Karnal. The panelists for the present study were dairy professionals having adequate knowledge regarding the sensory evaluation methods and products attributes. All the samples were evaluated for sensory attributes such as flavour (50), body and texture (35), colour and appearance (15) and total score on the basis of 100-point composite score card. This method does not, of course, reflect actual consumer perception, but it does strongly indicate attributes which a good quality product should possess.

Texture profile analysis

The texture profile of khoa samples were determined using texture analyzer fitted with 25 kg load cell using cylindrical P25 probe of 25 mm diameter. Cylindrical khoa samples (1 × 1 mm) were cut with the help of knife and kept in immersion chamber maintained at 25 °C before texture analysis. The samples were subjected to mono-axial compression of 20 mm distance on the texture analyzer by the pre-test and post-test speed of 2 mm/s and test speed of 1 mm/s with compression of 50% of distance with single TPA (texture profile analysis) i.e. single time penetration. From the resulting force–time graph, obtained with force experienced by probe on Y-axis and time on X-axis various textural characteristics such as hardness, cohesiveness, adhesiveness, springiness, gumminess and chewiness were calculated using the Texture Expert Exceed software (v 2.55) supplied by the manufacturer along with the instrument. The firmness of khoa sample was estimated as the height of positive peak force up to rupture point. A minimum of three replicates per sample was run.

Scanning electron microscopy of khoa

Microstructure of buffalo and cow milk khoa prepared using fresh, acidic and neutralized milk was examined using scanning electron microscope (EV018, 18th special edition, Zeiss, Tokyo, Japan by the method of Tomar and Prasad (1989) with slight modification (Instead of one primary fixative, an additional secondary fixative agent was also used). Primary (2% glutaraldehyde) and secondary (1% osmium tetraoxide) fixative agents were prepared in 0.1 M cacodylate buffer (pH 7.2). Small pieces of 1 cm3 khoa samples were fixed using primary and secondary fixatives and examined by SEM at an acceleration voltage of 15 kV under high vacuum (9.0 × 10−5 Torr) and micrographs were recorded at 500 and 1.00 KX (1000X).

Statistical analysis

Means and standard error mean (SEM) were calculated using Microsoft excel, 2007 (Microsoft Corp., Redmond, WA). Significant difference between values was verified by one way or two way analysis of variance and comparison between means was made by critical difference value (Snedecor and Cochran 1994).

Result and discussion

Sensory evaluation

Various sensory score attributes viz. flavour, body and texture, colour and appearance and total score of buffalo and cow milk khoa prepared using fresh, acidic and neutralized milk are presented in Table 2a, b. Quality of khoa was better when prepared from buffalo milk in comparison to khoa prepared from cow milk due to its moist surface, sticky and sandy texture which is not considered suitable for the preparation of sweetmeats (De and Ray 1952). Cow milk gave a product with sticky body leading to lower sensory scores than khoa prepared from buffalo milk. Stickiness in khoa from cow milk was attributed to insufficient release of free fat (Vogra and Rajorhia 1983). Significant difference (p < 0.05) was observed between the flavour, body and texture and total scores of khoa from fresh, acidic and neutralized milk (both buffalo and cow milk). Khoa prepared from fresh milk possessed the characteristic flavour and secured significantly higher (p < 0.05) average scores while, khoa samples prepared from acidic milk carried slight acidic smell. In case of khoa prepared from neutralized milk, salty taste resulted in lowest flavour scores. Khoa prepared from neutralized cow milk exhibited pronounced salty flavour as compared to khoa manufactured from neutralized buffalo milk due to higher chloride content in cow milk than buffalo milk. Due to inherent compositional make up of buffalo milk, fresh buffalo milk khoa was slightly grainy in texture which is desirable. However, in case of khoa prepared from acidic milk, the increase in acidity of milk resulted in increase in size and hardness of grains which resulted in hard body and loose texture hence lower body and texture scores in acidic khoa samples (Rajorhia et al. 1990). The abrupt coagulation of casein due to change in pH and acidity of milk made the product grainy which is not desirable for some dairy based sweetmeats such as peda. Neutralization of sour milk suppressed the grain formation thereby producing khoa with smooth and homogenous texture. The colour and appearance scores of fresh and acidic khoa samples prepared from buffalo and cow milk, exhibited non-significant (p > 0.05) difference however, neutralized samples had significantly higher (p < 0.05) scores. Khoa prepared from fresh buffalo milk was white in colour with greenish tint, whereas in case of fresh cow milk khoa it was pale yellow in colour due to the presence of carotenoids in cow milk (Fox and Mcsweeney 1998) which imparted yellow colour to khoa. Khoa prepared from neutralized milk was brownish yellow in colour due to the presence of neutralizers. These neutralizers shifted the pH towards alkaline value, leading to increase in maillard browning (Sakac et al. 2012) and thus resulting in more pronounced colour in khoa prepared from neutralized milk (Rajorhia et al. 1990). Significant difference (p < 0.05) was observed in total sensory scores of khoa prepared from fresh, acidic and neutralized milk (buffalo and cow samples). Total scores were highest in fresh samples. However, total sensory scores of buffalo milk khoa samples were comparatively higher than cow milk khoa samples.

Table 2.

Sensory score of fresh, acidic and neutralized buffalo milk khoa and, cow milk khoa

| Sensory → parameters Sample↓ |

Flavour | Body and texture | Colour and appearance | Total scores | |

|---|---|---|---|---|---|

| Buffalo | FBMK | 48.00 ± 0.41C | 34.25 ± 0.25C | 13.00 ± 0.57A | 95.25 ± 0.25C |

| Milk | ABMK | 47.50 ± 0.29B | 32.75 ± 0.25A | 12.65 ± 0.33A | 92.90 ± 0.25B |

| Khoa | NBMK | 44.50 ± 0.29A | 33.50 ± 0.25B | 14.00 ± 0.34B | 92.00 ± 0.89A |

| Cow | FCMK | 44.75 ± 0.25C | 33.25 ± 0.25C | 12.75 ± 0.25A | 90.75 ± 0.48C |

| Milk | ACMK | 44.25 ± 0.25B | 30.75 ± 0.25A | 12.50 ± 0.29A | 87.50 ± 0.28B |

| Khoa | NCMK | 41.00 ± 0.41A | 31.50 ± 0.28B | 13.50 ± 0.28B | 86.00 ± 0.71A |

Data are presented as mean ± Standard Error Mean (n = 15)

ABMK acidic buffalo milk khoa, FBMK fresh buffalo milk khoa, NBMK neutralized buffalo milk khoa, ACMK acidic cow milk Khoa, FCMK fresh cow milk khoa, NCMK neutralized cow milk khoa

A–CMeans within column with different upper case superscript are significantly different (p < 0.05) from each other

Texture parameters

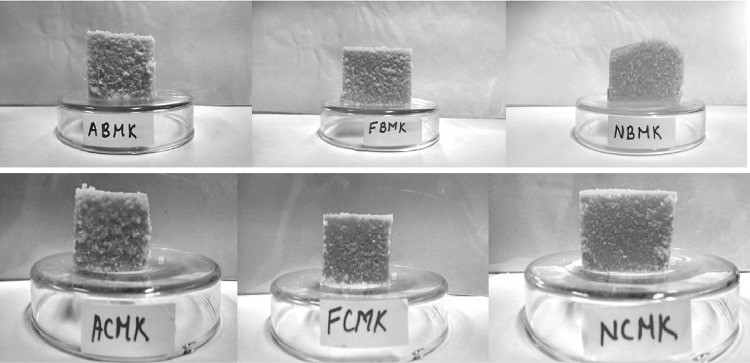

Texture is an important attribute in khoa and khoa based sweets as it decides the ultimate acceptability of a product by the consumers. The changes in the textural attributes (hardness, springiness, cohesiveness, chewiness, gumminess) of cow and buffalo milk khoa as affected by the development of acidity and neutralization of milk were also determined. Changes in these textural attributes directly affected the quality of khoa e.g. higher hardness in khoa will result in brittle texture of khoa and khoa based sweet. Similarly, higher gumminess and springiness will result in elastic and gummy texture of khoa which is not desirable in khoa based sweets. In present study, texture changes were also visible in chopped diced samples of khoa (Fig. 1) as the khoa prepared from acidic milk was granular as compared to fresh cow and buffalo milk khoa while, in case of neutralized sample khoa prepared was smooth and plain surfaced when compared with fresh milk khoa samples.

Fig. 1.

Chopped diced sample of khoa ABMK- acidic buffalo milk khoa, FBMK- fresh buffalo milk khoa, NBMKneutralized buffalo milk khoa ACMKacidic cow milk khoa, FCMK- fresh cow milk khoa, NCMK- neutralized cow milk khoa

Hardness

Significant difference (p < 0.05) was observed in the hardness of khoa prepared using fresh, acidic and neutralized milk from both buffalo and cow. Hardness of khoa prepared from acidic milk was significantly higher (p < 0.05) than khoa from fresh and neutralized milk. This might be due to the higher amount of total solids mainly contributed by low moisture content in acidic samples, as a decrease in pH resulted in lower moisture retention (Choudhary et al. 2016). Sachdeva and Singh (1988) reported that with a fall in pH, moisture retention and yield of buffalo milk paneer decreased. Adhikari et al. (1994) also reported negative correlation between moisture and instron hardness of khoa. Our results were also supported by Rajorhia et al. (1990) who reported higher hardness values in khoa prepared from acidic buffalo milk. Patel et al. (1990) reported that moisture content of peda (a khoa based sweet) had a direct relationship with hardness. Our findings were in accordance with the reports of Gupta et al. (1990) and Suresh and Jha (1994) who reported that the increased hardness of khoa correlated highly with the total solids and by increasing the total solids, hardness also increased.

Cohesiveness

Cohesiveness expresses the strength of internal structure of food and can be calculated as area of work during the second deformation divided by the area of work during the first deformation. Cohesiveness values were significantly higher (p < 0.05) in khoa prepared from acidic milk and lowest in khoa prepared from neutralized milk as compared to khoa from fresh milk which might be due to difference in moisture and total solids of respective khoa samples (Choudhary et al. 2016). Adhikari et al. (1994) and Garg et al. (1989) also reported negative correlation between cohesiveness and moisture content in khoa. Gupta et al. (1990) reported that cohesiveness of khoa tended to decline with increasing total solids. Puranik et al. (1998) reported cohesiveness value of 0.260 in cow milk khoa. Rajorhia et al. (1990) also reported that cohesiveness was highest in khoa prepared from acidic milk and lowest from neutralized milk.

Gumminess

The gumminess expresses the force needed to disintegrate a semi solid food to a state ready for swallowing. It is the product of hardness and cohesiveness. Gumminess of acidic samples was significantly higher (p < 0.05) than khoa prepared using fresh and neutralized cow and buffalo milk. Since gumminess is a secondary parameter derived from hardness and cohesiveness, hence a slight change in these two textural parameters also affected it. Gupta et al. (1990) also reported an increase in total solids, which resulted in increase in instron gumminess in khoa. Adhikari et al. (1994) also reported negative correlation between moisture and instron gumminess of khoa. Similar results were also reported by Rajorhia et al. (1990) that the gumminess of khoa from acidic buffalo milk was higher than khoa from fresh and neutralized buffalo milk.

Springiness

Springiness expresses the rate at which the deformed food material returns to its original condition after removal of force. Significant difference (p < 0.05) was observed in springiness values of khoa prepared from fresh, acidic and neutralized buffalo and cow milk samples. Springiness values of khoa from acidic milk was significantly higher (p < 0.05) than khoa prepared using fresh and neutralized milk. It may be due to the better defined granular texture in acidic samples as compared khoa from fresh and neutralized milk samples owing to their moisture difference (Choudhary et al. 2016). Jha et al. (2014) reported that lower springiness value in lalpeda was due to the porous texture of lalpeda. Results were in accordance with Rajorhia et al. (1990) who reported higher springiness value in khoa from acidic buffalo milk followed by khoa from fresh and neutralized milk.

Chewiness

Chewiness expresses the work needed to masticate a solid food to a state ready for swallowing. Chewiness (N mm) values were higher in cow milk khoa as compared to buffalo milk khoa which might be due to higher protein and ash content as compared to buffalo milk khoa. Wasnik et al. (2015) reported positive correlation between chewiness and protein content of santraburfi. Acidic samples had significantly higher (p < 0.05) values for chewiness as compared to khoa samples from fresh and neutralized milk which might be due to higher total solids and granular texture of acidic khoa samples as compared to fresh and neutralized samples (Choudhary et al. 2016). Since chewiness is a secondary parameter derived from hardness, cohesiveness and springiness, hence a slight change in these textural parameters also affected it. Gupta et al. (1990) also reported that the increase in total solids resulted in increase of instron chewiness in khoa. Adhikari et al. (1994) also reported negative correlation between moisture and instron chewiness of khoa. Rajorhia et al. (1990) observed similar findings and reported that chewiness was highest in acidic buffalo milk khoa followed by khoa samples prepared from fresh and neutralized buffalo milk. Puranik et al. (1998) reported chewiness values up to 1.60 in cow milk khoa.

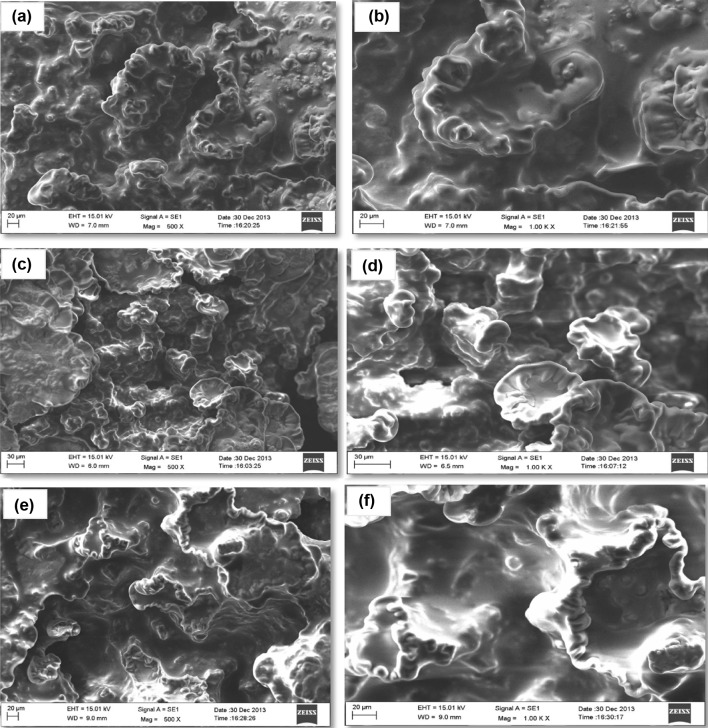

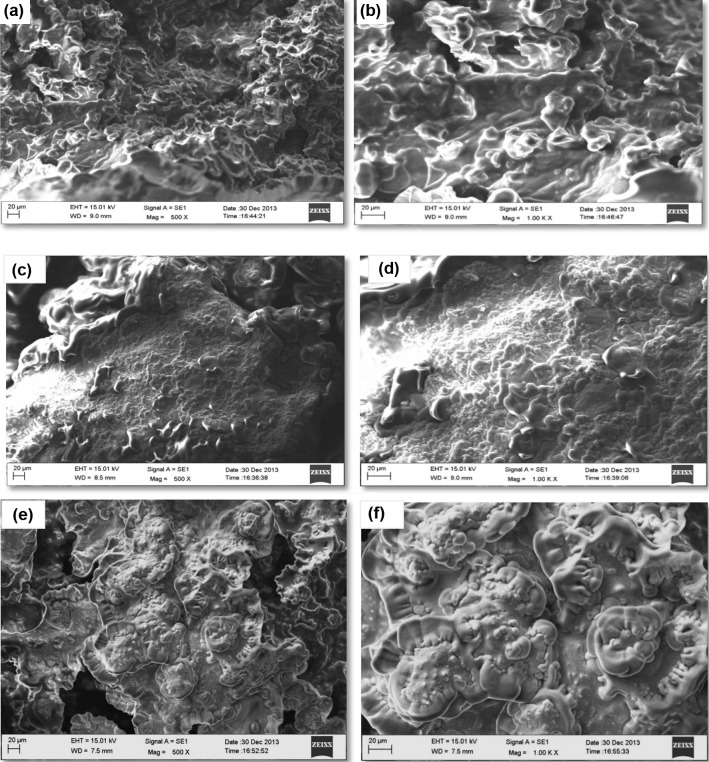

Effect of acidity and neutralization on microstructure of cow and buffalo milk khoa

Scanning electron microscopy is an important tool in the study of surface topography as it produces a 3-D impression of the rough surface. This technique is especially useful in the study of various microstructural changes taking place during the various stages of processing of a product. Casein, organized in micellar form in fluid milk, in conjugation with other milk components is capable of forming structures widely ranging in density depending on the manufacturing conditions. During the preparation of sample for SEM, they were chemically dehydrated by passing through a graded series of alcohol-water mixture which resulted in removal of fat. The void spaces as evident from the photographs might have developed as a result of the fat extraction during sample preparation for electron microscopy. Microstructure of khoa revealed an agglomerated, dense, threaded protein bodies forming a ragged surface. The gritty, loose matrix of coagulated milk protein vanished completely during patting stage.

Uniform rounded shaped protein complexes (Fig. 2c) were observed in buffalo milk khoa. Surface of buffalo milk khoa was slightly granular and smooth as compared to cow milk khoa (Fig. 3c) which had rough and dry native surface presumably due to lower initial fat content. In addition to this, smaller rounded protein aggregates and an irregular surface pattern were observed in cow milk khoa. The microstructure of buffalo milk khoa was characterized with loose matrix, uneven surfaces and thick protein complexes joined together. Acidification of milk up to 0.18% lactic acid brought about shrinkage of native microstructure. Native protein aggregates in khoa samples prepared from acidic buffalo milk consisted of compact agglomerated irregular protein complex (Fig. 2a, b) as compared to control buffalo milk khoa. Similarly in case of khoa prepared from acidic cow milk (Fig. 3a, b) very dense, compact and relatively uniform pattern of agglomerated protein mass was observed. Shrinkage of microstructure can be explained by the fact that acidic milk has tendency to form granular khoa and has comparatively higher hardness, chewiness and springiness as compared to fresh milk khoa. The microstructure appeared to be hard and compact as compared to fresh khoa samples which might be due to higher TS in acidic khoa samples as compared to fresh khoa samples. The coarse structure of khoa increased with increase in the acidity of milk, also the in size and hardness of grain leads to poor body and texture of khoa (Rajorhia et al. 1990). Khoa from neutralized milk had comparatively higher moisture, smooth surface and pasty consistency which resulted in slightly elongated loose matrix. Khoa prepared from neutralized buffalo milk (Fig. 2e, f) indicated elastic and loose round shaped protein agglomerates and granules which were comparatively smooth surfaced as compared to khoa prepared using neutralized cow milk.

Fig. 2.

Khoa prepared from fresh, acidic and neutralized buffalo milk. a Acidic buffalo milk khoa at 500X. b Acidic buffalo milk khoa at 1.00KX. c Fresh buffalo milk khoa at 500X. d Fresh buffalo milk khoa at 1.00KX. e Neutralized buffalo milk khoa at 500X. f Neutralized buffalo milk khoa at 1.00KX

Fig. 3.

Khoa prepared from fresh, acidic and neutralized cow milk. a Acidic cow milk khoa at 500X. b Acidic cow milk khoa at 1.00KX. c Fresh cow milk khoa at 500X. d Fresh cow milk khoa at 1.00KX. e Neutralized cow milk khoa at 500X. f Neutralized cow milk khoa at 1.00KX

Khoa prepared from neutralized cow milk (Fig. 3e, f) possessed uniform, plain and smooth surface as compared to control cow milk khoa (Fig. 3c, d). Besides, large rounded granules with inner microvilli were observed which were frequently found spread over the whole surface. The microstructure appeared to be open or loosely held which can be ascribed to the greater moisture retention and lower hardness in neutralized samples (Pal 2006) resulting in smooth texture as compared to fresh khoa samples. Microstructural changes correlated with textural attributes as loose networks in neutralized samples can be explained by the low hardness, cohesiveness and accordingly lower gumminess and chewiness in khoa samples from neutralized milk and shrinkage of microstructure in acidic samples might be due to greater hardness, cohesiveness and accordingly lower gumminess and chewiness values in khoa samples from acidic milk (Tables 3a, b). Adhikari et al. (1994) also reported that moisture was negatively correlated with hardness, cohesiveness, gumminess and chewiness and the observed values for these parameters were the lowest in khoa samples from neutralized milk. Rajorhia et al. (1990) also reported lower cohesiveness, gumminess and chewiness values in khoa samples prepared using neutralized buffalo milk as compared to khoa samples from fresh and acidic milk. Tunick et al. (1993) also reported that higher moisture level resulted in lower hardness in low fat mozzarella cheese.

Table 3.

Effect of acidity and neutralization on textural properties of buffalo milk khoa and cow milk khoa

| Parameters Sample↓ |

Textural attributes | |||||

|---|---|---|---|---|---|---|

| Hardness (N) | Cohesiveness | Gumminess | Chewiness (N mm) | Springiness | ||

| Buffalo Milk | FBMK | 9.60 ± 0.67B | 0.352 ± 0.001B | 2.62 ± 0.01B | 0.96 ± 0.003B | 0.351 ± 0.003B |

| ABMK | 13.53 ± 0.76C | 0.412 ± 0.002C | 3.36 ± 0.31C | 1.25 ± 0.091C | 0.369 ± 0.002C | |

| NBMK | 7.96 ± 0.34A | 0.299 ± 0.005A | 1.75 ± 0.14A | 0.62 ± 0.005A | 0.310 ± 0.002A | |

| Cow milk | FCMK | 18.34 ± 0.61B | 0.178 ± 0.001B | 3.25 ± 0.021B | 1.41 ± 0.033B | 0.290 ± 0.004B |

| ACMK | 23.06 ± 0.26C | 0.195 ± 0.002C | 3.88 ± 0.292C | 1.94 ± 0.045C | 0.320 ± 0.005C | |

| NCMK | 15.75 ± 0.70A | 0.158 ± 0.003A | 2.71 ± 0.084A | 0.91 ± 0.035A | 0.261 ± 0.006A | |

Data are presented as mean ± Standard Error Mean (n = 3)

ABMK acidic buffalo milk khoa, FBMK fresh buffalo milk khoa, NBMK neutralized buffalo milk khoa, ACMK acidic cow milk khoa, FCMK fresh cow milk khoa, NCMK neutralized cow milk khoa

A–CMeans within column with different upper case superscript are significantly different (p < 0.05) from each other

Such changes were also visible in chopped diced samples of khoa as the khoa prepared from acidic milk (Fig. 1) was granular as compared to fresh cow and buffalo milk khoa. Khoa from neutralized milk possessed a smooth and plain surface as compared to fresh khoa samples. Arora et al. (2007) also reported that the loose network in microstructure in burfi could be due to lower hardness, cohesiveness and accordingly, gumminess and chewiness. Adhikari (1993) reported that constant boiling of milk during khoa manufacture led to the formation of casein-whey protein complexes, which coalesced gradually with the progress of boiling, forming a fuzzy-agglomerated mass and finally precipitating as heat-induced milk gels, joined together by thick protein bridges. Further heat desiccation of this gel resulted in the compaction of the protein agglomerates with reduction in void spaces and fat globules interspersed in between (i.e. khoa). Adhikari (1992) reported that structure of khoa from cow milk showed agglomerated protein complexes interlinked together with thick bridging material with minimal void spaces. However, buffalo milk khoa showed comparatively loose matrix with thick protein bodies joined together forming more uneven surfaces and more voids in between.

Summary and conclusion

The results of the present investigation have established that the type and quality of milk used for preparation of khoa produced noticeable changes in sensory, textural and microstructural changes in the product. Development of acidity in milk resulted in bigger granules, shrinkage of native microstructure due to lower acidity of milk with slight acidic flavor of resulting khoa. Neutralization of milk resulted in khoa with plain and smooth texture, elongation of native structure and comparatively higher moisture retention and salty taste and yellowish tint. Textural attributes such as hardness, cohesiveness, springiness, chewiness and gumminess were significantly affected by development of acidity and neutralization of milk, indicating lower values for hardness, cohesiveness, springiness, chewiness and gumminess in khoa manufactured using neutralized milk and higher values in khoa manufactured using acidic milk.

Contributor Information

Sonika Choudhary, Phone: +91-8950125767, Email: sonikachoudhary15@gmail.com.

Sumit Arora, Phone: 0184-2259156, Email: sumitak123@gmail.com.

Anuradha Kumari, Phone: +91-9729287234, Email: anu.ndri@gmail.com.

Vikrant Narwal, Phone: +91-9812777545, Email: vikrantnarwal7@gmail.com.

S. K. Tomar, Phone: +91-9896431072, Email: sudhirndri@gmail.com

A. K. Singh, Phone: +91-9416292406, Email: aksndri@gmail.com

References

- Adhikari AK (1992) Status and role of major minerals and trace elements on physico-chemical properties of selected Indian milk products (khoa, gulabjamun and rasogolla).Ph.D. thesis, ICAR-National Dairy Research Institute (Deemed University), Karnal, p 517

- Adhikari AK. Microstructure and Texture of khoa and gulabjamun made from cows’ milk, heat-induced changes during processing and frying. J Sci Food Agric. 1993;61:7–15. doi: 10.1002/jsfa.2740610103. [DOI] [Google Scholar]

- Adhikari AK, Mathur ON, Patil GR. Texture and microstructure of channa and rasogolla made from buffalo milk. Aust J Dairy Technol. 1993;48:52–58. [Google Scholar]

- Adhikari AK, Mathur ON, Patil GR. Interrelationships among instron textural parameters, composition and microstructure of khoa and gulabjamun made from buffalo milk. J Food Sci Technol. 1994;31:279–284. [Google Scholar]

- AOAC . Official method of analysis of AOAC international. 11. Washington: Association of Official Analytical Chemist; 1970. [Google Scholar]

- Arora S, Singh VP, Yarrakula S, Gawande H, Narendra K, Sharma V, Wadhwa BK, Tomer SK, Sharma GS. Textural and microstructural properties of burfi made with various sweeteners. J Texture Stud. 2007;38:684–697. doi: 10.1111/j.1745-4603.2007.00120.x. [DOI] [Google Scholar]

- Choudhary S, Kumari A, Arora S. Factors affecting heat induced changes in khoa, a review. Indian J Dairy Sci. 2015;68:415–424. [Google Scholar]

- Choudhary S, Arora S, Kumari A, Narwal V, Sharma V (2016) Impact of developed acidity in milk and subsequent neutralization on changes in physico-chemical properties and oxidative stability of khoa. Indian J Dairy Sci 69(6):665–675

- De S. Outlines of dairy technology. 19. New Delhi: Oxford publishing Company; 2004. [Google Scholar]

- De S, Ray SC. The studies on the indigenous method of khoa making. Part-1. The influence of the conditions of dehydration and the type of milk on the production of khoa. Indian J Dairy Sci. 1952;5:47–60. [Google Scholar]

- Fox PF, Mcsweeney PLH. Dairy chemistry and biochemistry. 3. New York: Blackie Academic and Professional, Chapman and Hall; 1998. [Google Scholar]

- Garg FC, Patel AA, Patil GR, Rajorhia GS, Gupta SK. Textural changes in khoa during holding. Indian J Dairy Sci. 1989;42:804–809. [Google Scholar]

- Gupta SK, Pal D. Sensory evaluation of Indian milk products. Indian Dairym. 1985;37:465–467. [Google Scholar]

- Gupta SK, Patil GR, Patel AA, Garg FC, Rajorhia GS. Instron texture profile parameters of khoa as influenced by composition. J Food Sci Technol. 1990;27:213–219. [Google Scholar]

- IS: 16072 . Determination of moisture content in milk powder and similar products. New Delhi: Bureau of Indian standards; 2012. [Google Scholar]

- IS: SP (Part XI) (1981) Indian Standard’s on Dairy Products. In: Handbook of food analysis XI dairy products. Bureau of Indian Standards, New Delhi

- Jha A, Kumar A, Jain P, Om H, Singh R, Bunkar DS. Physico-chemical and sensory changes during the storage of lal peda. J Food Sci Technol. 2014;51:1173–1178. doi: 10.1007/s13197-012-0613-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kulkarni RV, Hembade AS. Shelf life of khoa prepared in Beed district of Maharashtra state. J Dairy Food Home Sci. 2012;31:173–175. [Google Scholar]

- Kumar M. Up-gradation of khoa production and preservation technologies. A J Phys Sci Eng Tech. 2013;3:1–6. [Google Scholar]

- Kumar G, Srinivasan MR. A comparative study on chemical quality of three type of khoa. Indian J Dairy Sci. 1982;35:56–61. [Google Scholar]

- Kumari R, Shrivastva SL, Mishra HN. Optization of khoa and tikhur powder mix for preparation of khoa jalebi sweet. Sci Rep. 2012;469:1469. [Google Scholar]

- Pal D (2006) Methods of manufacture and factors affecting quality of products. In: Yadav PL, Sindhu JS, Salooja MK (ed), BPVI-015 dairy products II, Indira Gandhi National Open University School of Agriculture, Graphic Printers, Delhi, pp 18–33

- Patel AA, Patil GR, Garg FC, Rajorhia GS (1990) Texture of peda as measured by instron. In: Proceedings of XXIII international dairy congress, Brief Communication, Montreal

- Patil GR, Patel AA, Garg FC, Rajhoria GS, Gupta SK. Interrelation between sensory and instrumental data on texture of khoa. J Sci Food Technol. 1990;27:167–170. [Google Scholar]

- Patil GR, Patel AA, Allan-Wojtas P, Kalab M. Microstructure and texture of khoa. Food Struct. 1992;2:155–163. [Google Scholar]

- Puranik DB, Rao HGR, Hegde HG. Utilization of recombined milk in preparation of khoa. Karnataka J Agric Sci. 1998;11:479–482. [Google Scholar]

- Rajorhia GS, Pal D, Garg FC, Patel RS. Effect of quality of milk on chemical, sensory and rheological properties of khoa. Indian J Dairy Sci. 1990;43:220–224. [Google Scholar]

- Rehman ZU, Salariya AM. Effect of synthetic antioxidants on storage stability of khoa—a semi-solid concentrated milk product. Food Chem. 2006;96:122–125. doi: 10.1016/j.foodchem.2005.02.016. [DOI] [Google Scholar]

- Sachdeva S, Singh S. Optimisation of processing parameters in the manufacture of paneer. J Food Sci Technol. 1988;25:142–145. [Google Scholar]

- Sakac M, Gyura J, Misan A, Seres Z, Dokic L. Influence of pH and temperature on non enzymatic browning reaction between affined C sugar and amino acids. Food Feed Res. 2012;39:103–109. [Google Scholar]

- Sivakumar GM, Dhanalakshmi B, Kumar N, Pugazhenthi TR. Antioxidant activity of herbal extract on khoa. Indian J Vet Anim Sci Res. 2014;43:436–444. [Google Scholar]

- Snedecor GW, Cochran WG. Statistical methods. 8. Ames: Affiliated East-West Press, Iowa State University Press; 1994. [Google Scholar]

- Suresh I, Jha YK. Sensory, biochemical and microbiological qualities of kalakand. J Food Sci Technol. 1994;31:330–332. [Google Scholar]

- Tomar SK, Prasad DN. Microstructure of yoghurt prepared from buffalo whole milk. Buffalo J. 1989;5:25–32. [Google Scholar]

- Tunick MH, Mackey KL, Shieh JJ, Smith PW, Cooke P, Malin EL. Rheology and microstructure of low-fat mozzarella cheese. Int Dairy J. 1993;3:649–662. doi: 10.1016/0958-6946(93)90106-A. [DOI] [Google Scholar]

- Vogra VR, Rajorhia GS. Utilization of dried milk for khoa making. Asian J Dairy Res. 1983;2:113–118. [Google Scholar]

- Wasnik PG, Nikam PB, Dhotre AV, Waseem M, Khodwe NM, Meshram BD. Physico-chemical and textural properties of Santraburfi as influenced by orange pulp content. J Food Sci Technol. 2015;52:1158–1163. doi: 10.1007/s13197-013-1044-5. [DOI] [PMC free article] [PubMed] [Google Scholar]