Abstract

Regenerative medicine holds the promise of engineering functional tissues or organs to heal or replace abnormal and necrotic tissues/organs, offering hope for filling the gap between organ shortage and transplantation needs. Three-dimensional (3D) bioprinting is evolving into an unparalleled bio-manufacturing technology due to its high-integration potential for patient-specific designs, precise and rapid manufacturing capabilities with high resolution, and unprecedented versatility. It enables precise control over multiple compositions, spatial distributions, and architectural accuracy/complexity, therefore achieving effective recapitulation of microstructure, architecture, mechanical properties, and biological functions of target tissues and organs. Here we provide an overview of recent advances in 3D bioprinting technology, as well as design concepts of bioinks suitable for the bioprinting process. We focus on the applications of this technology for engineering living organs, focusing more specifically on vasculature, neural networks, the heart and liver. We conclude with current challenges and the technical perspective for further development of 3D organ bioprinting.

1. Introduction

Human organs are highly complex structures formed by the combined, functional organization of multiple tissue types. The cells in these organs are highly specialized and group together to perform distinctive functions.[1] Organ dysfunction or failure is drastically increasing due to traumatic injury and disease.[2] Often, clinical treatments are limited by a paucity of available donors and immune rejection of donated tissue.[3] In the search for alternatives to conventional treatment strategies for the repair or replacement of missing or malfunctioning human tissues and organs, tissue engineering approaches are being explored as a promising solution.[2–4]

Presently, tissue engineering approaches have been widely studied in cartilage, bone, skin, vascular tissue and nerve regeneration, among others.[4–7] When designing a tissue engineered scaffold, the combination of material, biological and engineering requirements must be considered in an application-specific manner.[8–11] Biomimetic design of the scaffolds, including 3D structural characteristics and physical properties, can substantially enhance the physiological performance through appropriate cell–cell and cell–matrix interactions, further enhancing biological functions.[10,12,13] However, most 3D scaffolds currently fabricated with traditional techniques lack these qualities.[14] Although significant successes have been achieved in engineered tissues, both in research and clinical applications, it is obvious that complex 3D organs require more precise multicellular structures with vascular and neural network integration. These requirements cannot be fulfilled using traditional methods.[15–17]

3D printing is a rapid prototyping and additive manufacturing technique used to fabricate complex architecture with high precision through a layer-by-layer building process.[18] This automated, additive process facilitates the manufacturing of 3D products having precisely controlled architecture (external shape, internal pore geometry, and interconnectivity) with highly reproducibility and repeatability.[9,19] Therefore, in the regeneration field, it can provide an excellent alternative for biomimetic scaffold fabrication by accurately positioning multiple cell types and biofactors simultaneously into complex multi-scale architectures that better represent the structural and biochemical complexity of living tissues or organs.[18,20,21] In the past three decades, 3D bioprinting has been widely developed to directly or indirectly fabricate 3D cell scaffolds or medical implants for the field of regenerative medicine. It offers very precise spatiotemporal control on placement of cells, proteins, DNA, drugs, growth factors, and other bioactive substances to better guide tissue formation for patient-specific therapy.[20,22,23] 3D printing of bioactive scaffolds contains two types of scaffold fabrication: acellular functional scaffolds which incorporate biological components, and cell-laden constructs aiming to replicate native analogues.[21,24] Both of them aim to produce biocompatible, implantable constructs for tissue/organ regeneration, thus we refer to 3D printing in the context of bioactive scaffold fabrication as “bioprinting”. In this regard, the term bioprinting does not indicate whether cells are directly printed or involved at any stage of the fabrication process.

An essential requirement for reproducing the complex, heterogeneous architecture of functional tissues or organs is a comprehensive understanding of the composition and organization of their components.[10,11] Therefore, medical imaging technology is an indispensable tool to provide information on 3D structure and function at the cellular, tissue, organ and organism levels, aiding the design of a patient-specific construct.[20,25] It commonly offers noninvasive imaging modality, including computed tomography (CT) and magnetic resonance imaging (MRI). Computer-aided design (CAD) and computer-aided manufacturing (CAM) tools and mathematical modeling are also used to collect and digitize the complex tomographic and architectural information for tissues.[25] The 3D imaged tissue or organ model is divided into 2D horizontal slices that are imported into a 3D bioprinter system for the layer-by-layer deposition. Considering the available 3D bioprinting techniques, the cell types (differentiated or undifferentiated), biomaterials (synthetic or natural), and supporting biochemical factors are then selected, and the configuration of these printing components drives the construction of the 3D tissues and organs. This integrated technique (imaging-design-fabrication) can recreate more complex 3D organ level structures and incorporate mechanical as well as biochemical cues that are crucial elements of the whole organ architecture.[20,26] In addition, this technique has the capacity to build a 3D tissue-or organ-specific microenvironment by mimicking the natural, highly dynamic yet variable 3D structures, mechanical properties, and biochemical microenvironments.[27] In this manner, 3D bioprinting for organ regeneration involves additional strategies for printing multiple living cells, including vasculature and neural network integration, and eventually developing the specific functions of 3D bioprinted organ analogues.

Charles W. Hull, in 1986 received a patent for the liquid, photopolymer-based manufacturing technology of stereolithography; this proved to be the pioneering work for future 3D printing techniques.[28] In 2003, a cellular bioprinting technique based on traditional 2D inkjet technology was proposed.[29] In 2009, Organovo and Invetech created one of the first commercial 3D bioprinters.[30,31] Finally in 2016, the Food and Drug Administration (FDA) issued draft guidance, titled “Technical Considerations for Additive Manufactured Devices”, which provided guidance for 3D printing techniques and products.[32] Currently, with the increasing global interest and need, more and more businesses have been established in the expanding bioprinting market, such as 3D Systems (Rock Hill, SC, USA), Hewlett-Packard (Palo Alto, CA, USA), Novogen MMX Bio-printer (Organovo, Inc., San Diego, CA, USA), 3D Bioplotter (EnvisionTEC, Gladbeck, Germany), Oxford Performance Materials (South Windsor, CT, USA), and Commercial Blood Vessel Bioprinter (Revotek, Sichuan, China) among others.[31] By 2022, the global 3D bioprinting market is expected to reach $1.82 billion and will include products and materials for dental, medical, analytical, and food applications.[31] Although still in its infancy considering the complexity and functionality, this technology appears to show great promise for advancing tissue engineering toward organ fabrication, ultimately mitigating organ shortage and saving lives.

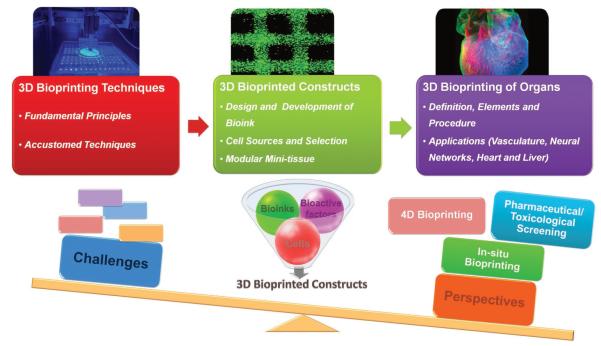

In this review, we focus on general principles, techniques, and other essential elements pertaining to the application of 3D bioprinting technologies for generating 3D tissues and organs. We propose a stepwise process of regenerating a complex tissue/organ, and also present recent advances in 3D bio-printing for organ regeneration. Furthermore, we discuss current challenges and exciting opportunities of 3D bioprinting technologies toward creating realistic organs that further fundamental research and translational medicine (Figure 1).

Figure 1.

Schematic diagram outlining information covered in this review. Reproduced with permission.[139] Copyright 2015, the American Association for the Advancement of Science.

2. 3D Tissue/Organ Bioprinting and Related Manufacturing Strategies

2.1. Fundamental Principles

3D bioprinting is basically a rapid prototyping and additive manufacturing technique used to fabricate artificial implants or complex tissue constructs through a layer-by-layer building process for patient-specific therapy. 3D bioprinting shares three basic concepts with ordinary 2D printing – desktop printer (3D printer), print file (3D model file), ink (bioink consisting of biomaterials, bioactive components and cells), and paper (print platform). Unlike 2D printing, 3D bioprinting is a comprehensive process requiring various design considerations, including imaging, modeling, printer choice, bioink selection, culture condition, and 3D construct development among others. Generally, the manufacturing activities can be divided into three steps: pre-bioprinting (modeling), bioprinting, and post-bioprinitng.

Pre-bioprinting, also known as modeling, mainly includes 3D imaging acquisition, digital 3D design and bioink/biomaterial selection based on the type of 3D bioprinting model.[20] Several imaging technologies, such as 3D scanner, CT, MRI and others, are applied to collect and digitize the complex tomographic and architectural information of tissues. Giesel et al. described and discussed the various methods of 3D imaging technology for 3D printing applications in detail.[25] The desired structure of digital 3D models is precisely created using CAD software and stored as a stereolithography (stl) files. Bioink or biomaterial selection depends on the specific bioprinter type and the product properties required.

The 3D structure with patient-specific design is then printed in layer-by-layer deposition modeling process in the bio-printing phase. According to the program design of different printers, the 3D design files can be directly loaded into the printer, or must first be passed through a slicing program for further modification before being imported into the printer. The slicing program can parse the solid object into a stack of thin, axial cross sections; each respective 2D cross section is reproduced integrating various infill patterns, as programmed. In this step, the printer reads the stl file and deposits successive layers of liquid, powder, or several other materials to build the 3D model from a series of 2D cross-sections. Several 3D printing techniques are capable of using multiple nozzles (multiple materials), adjustable angles, and even multiple printing combinations.

3D bioprinting for tissue engineering applications can be divided into two forms, with and without incorporated living cells printed directly into the constructs. Cellular bioprinting techniques can directly deposit bioinks with viable cells to form a 3D living structure. Based on the working strategies, they can primarily be classified into three categories, droplet-based, extrusion-based and laser-assisted bioprinting.[20,33] Variations in the available bioprinting technologies also affect the characteristics of living tissue/organ constructs. Comparatively, acellular bioprinting techniques provide more extensive choices for tissue regeneration applications.[18] Without the consideration of cell viability or bioactive components, several 3D printing techniques with higher temperatures, chemicals and other harsh environments can be utilized to manufacture implants.[34] Considering the specific requirements of the targeted tissues/organs properties, the design must take into account the capabilities and properties of the bioprinting systems (both bioinks and bioprinters), which we discuss next in detail.

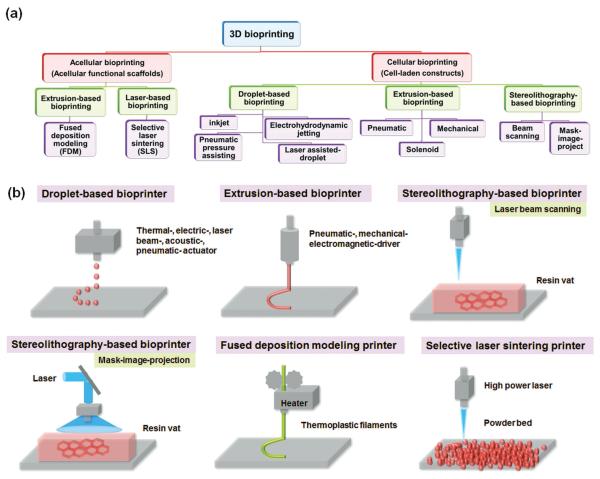

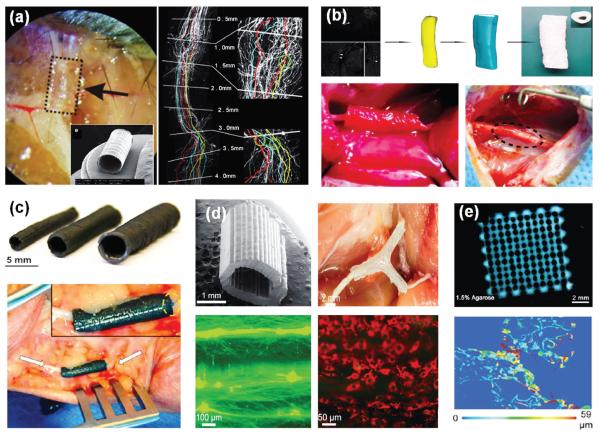

Finally, post-bioprinting, which involves the development of biomimetic structures, mechanical supports and biological functionality, is an essential step to develop mature tissues/organs for living applications.[35,36] Several additional manufacturing techniques, including substrate supports and sacrificial templates, among others, are potentially required to create higher mechanical elasticity/strengths, more precise structures, more complex structures or multiple biological functions due to current printing technique limitation.[16] More importantly, in vitro culture (preference in a bioreactor), in vivo implantation, or even in situ bioprinting will be performed to induce and enhance construct maturation thereby transforming constructs into functional tissues/organs.[26] Figure 2 shows a tree-diagram of the various 3D bioprinting techniques with simplified illustrations of typical 3D bioprinting techniques.

Figure 2.

(a) A tree-diagram of the various 3D bioprinting techniques and (b) Simplified illustrations of typical 3D bioprinting techniques for tissue/organ regeneration.

2.2. Accustomed Bioprinting Techniques

Typically, ASTM (F2792) standard terminology for 3D printing technologies consists of several parts including vat photopolymerization, material jetting, material extrusion, powder bed fusion, binder jetting, sheet lamination, and directed energy deposition.[37] To some extent, the terminology of bioprinting techniques more specifically refers to both the bioink formulations and printing modality. Acellular bioprinting is divided into two forms, direct implantation and cell post-seeding. The acellular implant serves as a nonliving implant device or artificial graft substitute, while the cellular implant often requires an extra step depositing cells onto the constructs after acellular bioprinting. In contrast, the direct cellular bioprinting is a one-step process of generating a rapid prototyped tissue by accomplishing both the construct fabrication and cellularization jointly.

2.2.1. Cellular Bioprinting

Cellular 3D bioprinting directly employs living cells in the construct fabrication process together with the inherent advantages of 3D printing-based rapid prototyping. Diverse techniques have been developed to create 3D living tissue/organ analogues, and each of them has different features (strengths and limitations) in terms of the available conditions such as biological materials, resolution, printing speed and cell viability. Depending on the printing modality (bioink deposition mechanism), the representative techniques of cellular bioprinting can be categorized into three types: droplet-based, extrusion-based, and stereolithography.[14,20,22,38]

Droplet-based bioprinting relies on various energy sources (thermal-, electric-, laser beam-, acoustic- or pneumatic- mechanisms) to pattern the bioink micro-droplets of living cells and other biologicals in a high-throughput manner. It offers greater advantages due to its simplicity and agility with precise control on deposition of biologicals including cells, growth factors, and genes for tissue/organ regeneration. It has also been the most common for pharmaceutical use due to its simplicity, versatility, and high-through put capability.

Extrusion-based (dispensing, or direct writing) bioprinting which originates from fused deposition modeling (FDM) printing uses pneumatic-, mechanical- or electromagnetic-driven systems to deposit cells based on a “needle-syringe” type. During bioprinting, bioink dispensed by a deposition system precisely prints cell-laden filaments forming desired 3D structures.

Stereolithography-based (vat-photopolymrization) bioprinting mainly utilizes laser energy to deposit cell-laden bioink in a reservoir via beam scanning or image projection modeling, allowing the molding of the high-precision patterns. It offers greater advantages due to the precise control on deposition of biologicals and high resolution.

2.2.1.1. Droplet-Based Cellular Bioprinting (DCB)

The key feature of droplet-based bioprinting is that the droplets of cell-laden bioink (hydrogels or slurries) are generated and deposited to pre-defined locations on the substrate. As a noncontact bio-printing technique, it provides a high-throughput method for depositing multiple cells or biologicals in small droplets onto a targeted spatial position. Droplet techniques can be classified into four categories: inkjet, electrohydrodynamic jetting, pneumatic pressure assisted-, and laser assisted- droplet bioprinting.[39–42]

The inkjet bioprinting, which is granted with the earliest cellular printing patent, is originated from commercial 2D inkjet printing.[29] The necessary equipment is easily remolded from 2D inkjet desktop printers making this technology widely available and relatively inexpensive. In this technique, the bioink solution including biomaterial, bioactive factors, and cells is stored in a cartridge or reservoir, and then transferred to the ink chamber for droplet ejection. The droplets can be generated by two mechanisms, thermal or piezoelectric actuation, which can be ejected from the inkjet-head nozzle to the print surface.[43] They operate similar to the traditional “drop-on-demand” 2D inkjet printers. The thermal actuation is based on a heating element, which can superheat the bioink to create vapor bubbles for ejecting the droplets. Although the temperature reaches 200~300 °C, the process only persists for a few microseconds (~2 μs) resulting in an overall temperature rise of ~10 °C in the printer head. Many results have demonstrated that this increase in temperature causes minimal damage to the viability of both printed cells and other integrated biologicals. The piezoelectric technique employs a voltage to induce a rapid shape change of the piezoelectric material, which generates a pressure pulse in the fluid forcing a droplet of ink from the nozzle. Droplet shape and size can be adjusted by tuning the applied voltage to the piezoelectric material. It allows a wider variety of inks than thermal inkjets as there is no requirement for a volatile component, and no issue with coagulation. The acoustic radiation force associated with the ultrasound field is also utilized to eject the droplets from an air-liquid interface on the piezoelectric printer.[44] Ultrasound parameters, including pulse, duration and amplitude, can be adjusted to control the size of droplets and the rate of ejection. The acoustic radiation is capable of generating and controlling uniform droplet size and ejection directionality. However, the acoustic frequencies used in these printers have the potential to induce damage of the cell membrane and cell lysis. Additionally, several modified inkjet techniques with multi-jets have been developed to build complex tissue and organ prototypes by arranging multiple cell types and other tissue components.[45] Overall, the inkjet bioprinting technique ensures rapid fabrication with highly repeatable patterns; additionally, small volume droplets enable high printing resolution (lower to 50 μm). Moreover, inkjet bioprinting typically exhibits over 80% cell viability after cellular bioprinting.[20] Inkjet bioprinters do, however, still have limitations on material viscosity, cell density and mechanical strength. Devices are typically compatible with low solution viscosities (below 0.01 Pa•s) and low cell concentrations (fewer than 10 million cells/mL), avoiding high shear stress and nozzle clogging.[20]

The electrohydrodynamic jetting (electrospraying or electrospinning) applies an electric potential difference between a positively charged needle and a grounded electrode to generate repulsive Coulombic force. Droplet ejection occurs, in the micrometer to nanometer size range, when the charged medium exiting the needle enters the high-intensity electric field.[39,46,47] The size and distribution of these droplets can be controlled through the applied potential difference, the flow rate to the needle, the distance of electrodes and the liquid solution properties.[48] Inkjet bioprinting dimensions are currently limited by the diameter of the jetting needle. Typically, droplet diameter is approximately two times the size of the needle diameter; as such, this technology has limitations in the size range of tens of nanometers. In contrast to inkjet technology, electrohydrodynamic jetting does not suffer from these limitations and can be used to process concentrated suspensions from needles that are a few hundred micrometers in size yet are capable of generating droplet deposits a few micrometers in size and smaller. Furthermore, no adverse effects on cell viability have been observed when jetting the cell-laden bioinks.[49]

The pneumatic pressure technique uses a set of electromechanical micro-valves where the droplets are produced by opening the micro-valve under constant pneumatic pressure.[42] This technique uses various types of liquid biomaterials with viscosities of up to 200 Pa•s, and controls the droplet volume by adjusting the pressure to the fluidic pathway and valve gating time. Although a higher liquid viscosity can be applied, there remain several concerns regarding droplet controls and cell viability. In order to obtain a favorable printing structure, the effect of the printing conditions must be fully considered to include substrate stiffness, material preparation, droplet size, printing speed, surfactant usage, and agitation among others.[22]

However, for the inkjet and pneumatic pressure assisted bioprinting, the viscosity of the available bioinks is too low to facilitate the rapid generation and sustainment of 3D structures. Therefore, additional cross-linking methods are applied to address this limitation, including UV/Vis light, pH, temperature or chemical reagents. The photocurable materials can be independently used, associated as the droplet bioinks, or deposited as supporting materials to assist in 3D molding. Additionally, multi-jet bioprinting strategies can be used to co-print the bioinks and the cross-linkers in turn, allowing the generation of a solid, stable 3D structure. The crosslinking procedure may slow down the printing process, and several crosslinking methods may result in excessive damage of cell viability and biological functionality; these risks must be considered and managed carefully during fabrication.

In addition to the high resolution, simple processing, and low cost benefits of these bioprinting techniques, another advantage is the potential to introduce concentration gradients of cells, materials or growth factors throughout the 3D structure by altering droplet densities or sizes. Recent developments of this technique have reported controlling droplet sizes and deposition rates ranging from 1 pL to 300 pL in volume with up to 10 000 droplets/s. Droplet bioprinting also shows great promise for “scaffold-free” bioprinting by depositing layers of cells into a sacrificial mold.

Besides the three aforementioned droplet techniques, laser-assisted droplet systems have also been developed.[40] Differing from several other reviews that listed it as a laser-assisted bio-printing technique individually, we combine it into droplet bioprinting because of some similarities. Laser-assisted droplet bioprinting (also known as laser-induced forward transfer or LIFT), consists of a pulsed laser source, a donor layer (this includes a laser-energy-absorbing layer, such as gold or titanium, and a bioink layer) and a receiving substrate. It utilizes a focused laser to pulse on the absorbing layer generating a high-pressure bubble that propels cell-laden droplets onto the substrate. The absorbing layer is used to transfer heat for bioink droplet production; this prevents from direct laser. The droplet volume can be controlled from 10 to 7000 pL by adjusting the viscosity and thickness of the bioink layer contributing to a higher printing resolution. The resolution is also influenced by many additional factors, including the laser fluence, the surface tension, the wettability of the substrate, the air gap between the donor layer and the substrate, and the thickness and viscosity of the bioink layer. Moreover, this technique is capable of employing a high cell densities (up to 108 cells/mL) and as well as high bioink viscosity (1~300 mPa•s) because of its nozzle-free droplet model. Despite these advantages, a relatively low efficiency, high cost and limited availability of bioinks for this technique are still major concerns.

2.2.1.2. Extrusion-Based Cellular Bioprinting (ECB)

Extrusion-based (or dispensing, direct writing) bioprinting is an integrated technique consisting of a fluid-dispensing system for extrusion control and an automated robotic system for bioprinting.[20,22] The bioink is extruded into the manner of cell-laden cylindrical filaments or discrete volumes of bioinks that can be precisely deposited into the desired 3D structures. Continuous deposition provides better structural integrity during rapid fabrication. Dispensing systems can be classified into three types: pneumatic-, mechanical- (piston or screw), and solenoid-based microextrusion.[50]

Pneumatic-based systems utilize pressurized air to extrude filaments using a valve-free or a valve-based configuration. Compared to the valve-free configuration, the valve-based configuration possesses a higher precision due to a controlled pressure and pulse frequency.[42] Mechanical micro-extrusion (or direct writing) provides a simpler and more direct method of controlling the bioink printing.[51–53] The piston system commonly composed of syringes and needles is suitable to a fluid with low viscosity, whereas the screw system is capable of generating a larger pressure for dispensing the bioinks with higher viscosities.[50] However, a large shearing force along the nozzle in mechanical micro-extrusion can potentially harm the laden cells. Solenoid (or electromagnetic driven) microextrusion applies electrical pulses to open a valve by canceling the magnetic pull force generated between a floating ferro-magnetic plunger and a ferro-magnetic ring magnet.[42] Mechanical dispensing systems might provide more direct control over the material flow, because of the delay of the compressed gas volume in pneumatic systems and the high complexity of electromagnetic driven systems. Materials with viscosities ranging from 30 to >6 × 107 mPa•s have been shown to be compatible with microextrusion bioprinters, with higher-viscosity materials often providing structural support for the printed construct and lower-viscosity materials providing a suitable environment for maintaining cell viability and function.[52]

In addition to dispensing systems, the extrusion printers include a stage and one or more cartridges (i.e., syringes or pens) that can be loaded with cell-laden bioinks or other biologicals for printing. The materials inside the cartridges may be dispensed using a microextrusion system. The printing process can be controlled by the dispensing procedure, speed, nozzle size, the displacement of the cartridge, and/or the stage motion in x, y, and z axes. Moreover, several advanced techniques have been developed for the cartridges and the stages such as: temperature-controlled cartridge (nozzle) or stage systems, multiple independently controlled nozzles or chambers, multiple direction-controlled nozzle or stage systems, and coaxial nozzle systems, among others.[20,50,54]

Compared to droplet-based bioprinting, extrusion-based bio-printing enables rapid printing, easy operation and a wide selection of bioinks, including cell aggregates, cell-laden hydrogels, micro-carriers, decellularized matrices and synthetic polymer fibers. Synthetic polymers that have relatively high mechanical strength are often employed to reinforce printed 3D tissue/organ analogues. There are two main types of bioinks used in microextusion systems.[50] The first is high-viscosity, cell-laden solutions or low-modulus cell-laden hydrogels, which need be rapidly solidified into a 3D construct after extrusion. However, the printing conditions of the cell-laden hydrogel are somewhat limited by high shear force management. Another type involves using spherical and cylindrical multicellular systems with or without supportive biomaterials as a bioink; cell spheroids and cell-laden microcarriers are two examples of this type of bioink. After printing, the multicellular systems fuse together to replicate the 3D tissue structure. This technique directly prints solid cellular units enabling scaffold-free bioprinting, or printing free of exogenous biomaterials. In order to obtain appropriate mechanical integrity of a 3D configuration, the molding process and the properties of bioinks, as well as their interactions, are very important considerations for extrusion printing and must be addressed in the experimental design.[50] The typical molding processes include: (1) self-assembly (i.e., shear-thinning materials, self-healing materials), (2) crosslinking agent integration (i.e., pre-crosslinked bioink, bioplotting, coaxial crosslinking, aerosol crosslinking or spraying crosslinking system), (3) UV/Vis photocuring and (4) environmentally sensitive deposition (pH, temperature, and others). In extrusion based bioprinting, bioplotting refers to syringe dispensing system requiring a curing process involving additional solidification over time.[50,55] Therefore, we do not separately introduce it as a bioprinting technique. In the bioplotting approach, cell-laden bioinks are directly extruded into a plotting medium (crosslinking pool) to complete the curing process. It requires the use of relatively viscous bioinks printed into plotting medium that can support the extruded structures temporarily until crosslinking is complete.[56]

Overall, extrusion-based techniques are capable of greater deposition and printing speed and have more tolerance for heterogeneous formulations, allowing physiologically relevant cell densities, which facilitate scalability in a relatively short period of time. Despite its versatility and great benefits, extrusion-based bioprinting still has several challenges mainly involving lower resolutions, higher shear stresses, and limited material selection among others. The minimum feature size of the technology is generally over 100 μm; nonbiological microextrusion printers are capable of 5 μm resolution.[20,50] Bioinks should possess shear thinning ability to overcome surface tension to extrude in filament form. The resulting high shear stress at the nozzle may decrease the cell viability. Cell viability after microextrusion bioprinting is typically lower than that with inkjet-based bio-printing; cell survival rates are in the range of 40~86%, controllable by changing extrusion speed and nozzle gauge.[50]

2.2.1.3. Sterelithography-Based Cellular Bioprinting (SCB)

Sterelithography appearance (SLA) offers an additive manufacturing technique with very high resolution and accuracy.[20,22,57] The Sterelithography-based bioprinting technique (vat photopolymerization) utilizes the spatially controlled irradiation of light or laser to solidify a geometrically 2D pattern layered through selective photopolymerization in the bioink reservoir. The 3D structure can be consecutively built on 2D patterned layers in a “layer-by-layer” fashion, and the uncured bioink can be easily removed from the final product. The photo-polymerization of 2D patterned layers is the most crucial step in SLA-based bio-printing. Traditional SLA-based bioprinting techniques have two types: beaming-scanning and mask-image-projection.[22,24,58]

The beam-scanning technique, or laser direct writing (LDW), uses a laser beam to scan photocurable bioinks for solidification of a 2D patterned layer.[59] The resolution is dependent on irradiant exposure conditions (laser spot size, wavelength, power, exposure time/velocity and the occurrence of absorption or scattering of the laser beam), and the selection of photo-initiator or any UV absorbers.[60,61] The types and concentration of bioinks, scanning speed and laser power contribute to the overall mechanical properties of the bioprinted structure. Additionally, when printing multiple layers, early layers may be repeatedly exposed to the laser, causing uneven mechanical strength or undesired 3D structures/patterns. With the development of micro-stereolithography (μSLA) techniques, a resolution of about 5 μm in the x/y plane and 10 μm in the z axis can be achieved.[62,63]

The mask-image-projection printing system dynamically generates a defined mask image that is projected onto the surface of the photocurable bioinks using a digital light procession technique (DLP), which can solidify an entire 2D patterned layer simultaneously.[22,37,57,58] The DLP system uses a digital micromirror device (DMD) to project a set of 2D images from the horizontally sliced 3D structure. Compared to the beam-scanning technique, mask-image-projection printing can be much faster due to its ability to simultaneously form the shape of an entire layer.

There is a limited choice of photopolymerizable bioinks, however polymer modification can technically enable more options.[58] The commonly photocurable bioinks include polyethylene glycol acrylate/methacrylate and its derivatives, methacrylated/acrylated natural biomaterials (gelatin, hyaluronic acid, dextran, and others), and methacrylated/acrylated capped among other synthetic polymers. Overall, the main advantages of sterelithography-based bioprinting techniques are their ability to simply fabricate complex designs with high resolution and rapidly print constructs without support material. Most commercial systems prepare structures with low to 50 μm features; μSLA systems are capable of preparing structures with <5 μm features.[57] However, the photopolymerization is driven by a radically induced chemical reaction, and the free radicals can damage the cell membrane, proteins, and nucleic acids. This technique can achieve up to 40~80% cell viability depending on the laser wavelength, power, exposure time and toxicity of photo-intiator.[22,57] Therefore, it is important to apply a cytocompatible photo-initiator. Additionally, the limited availability of photocurable biomaterials and high equipment costs are major concerns with this technology.

2.2.2. Acellular Bioprinting

Compared to cellular bioprinting techniques, acellular 3D bio-printing provides more extensive choices for material selection and manufacturing method. The aforementioned cellular bio-printing techniques can also employ acellular bioinks to fabricate tissue engineered scaffolds. An additional cell seeding technique can be employed to create artificial 3D cell-laden scaffolds for tissue/organ regeneration after printing. Here, a universal cell seeding procedure can be used in a post-seeding process, or perfusable cell seeding can be obtained using a bioreactor device. Also 3D printed grafts without cells can be directly implanted into injured patients for functional replacement or structural support during healing. The representative techniques of acellular bioprinting fall into two categories: extrusions-based acellular bioprinting (EAB) or laser-based acellular bioprinting (LAB).

2.2.2.1. Extrusion-Based Acellular Bioprinting (EAB)

Unlike the previously presented extrusion systems focusing on cellular bioprinting, acellular extrusion (or acellular direct writing) can utilize volatile or easily displaced organic solvents to dissolve polymers, followed by conversion from a highly viscous solution to solid 3D structures.[51,64] After removing the organic solvent thoroughly, the cells can be seeded and grown on the scaffold’s surface for tissue/organ regeneration.

Fused deposition modeling (FDM) or fused filament fabrication (FFF) was developed in the early 1990s and is a major acellular, extrusion-based system.[18,21,34,37] It is the most widely used and generally well-explored 3D printing strategy because it is low-cost and relatively fast. This technique employs thermoplastic filaments that are heated to their melting point or to a semimolten state, passed through an extrusion nozzle and allowed it to solidify on the printing stage without any additional crosslinking requirment.[18,65] This method is analogous to conventional extrusion or injection molding except molds are not used. Multiple print heads can be accommodated to permit co-printing of temporary support material for complex overhanging structures or multiple material integration with different properties within a single structure for complicated construct fabrication. The printer is composed of heating blocks with temperature controllers, an extrusion block and motors.[58] The extrusion force is driven pneumatically or mechanically with a lead screw. These models result in an overall resolution of >50 μm in layer height and an accuracy of >100 μm.[18] The main advantages of the FDM method in tissue engineering applications are its simple employment, rapid printing capability, diverse synthetic biomaterial availability, and favorable mechanical properties make it suitable for hard tissue regeneration applications. This technique also eliminates the need for solvent submersion and has the ability to fabricate large-format objects positively impacting scalability. Several synthetic biomaterials such as poly(caprolactone) (PCL), poly(lactic acid) (PLA), polyurethane, and their derivatives have demonstrated adequate thermoplastic performance and biocompatibility.[58] Any biomaterials that can be melted and then re-solidified or thermally cross-linked are suitable for FDM printing.[66] Exploiting low-temperature thermoplastic biomaterials is preferable in that biologicals can be added though more mild processes after bio-printing, preserving their functionality. Moreover, in order to offer a higher and more uniform strength between each layer, a conversion from thermoplastic material to thermoset material can be conducted via an additional crosslinking reaction using ionizing radiation or novel material design.[67] The disadvantages are the limited material selection related to thermoplastic polymers and it is not suitable for printing with cells due to the high manufacturing temperature. Therefore, an extra step is required after the FDM printing to seed cells on constructs for tissue/organ regeneration.

2.2.2.2. Laser-Based Acellular Bioprinting (LAB)

Sterelithography techniques can also be applied for fabrication of acellular scaffolds. In these cases, however, more photocuring resins and crosslinking conditions are available since acellular constructs eliminate the concern of cell damage during the printing process. The increase in material selection is beneficial in that it allows for more diverse scaffold properties. Selective laser sintering (SLS) is another laser based printing technique that uses a high power laser for powder sintering, forming solid 3D structures on the surface of a powder bed.[21,31,68] The technique relies on two energy sources, a bed-heater and a high-power laser. First, the particles are preheated between their melting transition and the temperature necessary for recrystallization during the cooling cycle. Localized thermal sintering of the particles is achieved by the controlled additional energy input of the a high-power laser, which traces the 2D layer design fusing exposed particles together within the layer as well as connecting it to the previously scanned underlying layer.[37,68] This process may be printed using several material types such as ceramics, metals, polymers and their composites.[68] Printing parameters, such as energy source, particle size, particle shape, free packing density, and thermodynamic variations of materials play critical roles in the fabrication process. The resolution of the different SLS machines usually ranges from 20 to 100 μm; this is achieved and manipulated through a careful balance between therefore we need to consider a balance between obtaining fine resolution and allowing for adequate powder dispensability.[68] The un-sintered powder serves as the physical support during 3D manufacturing, and unused powders may be removed or recycled after bioprinting. For polymer powder sintering, the laser parameters of power, beam size, scanning speed and spacing needs to be carefully controlled to avoid polymer degradation by overheating.[68]

Selective laser sintering is applied to rapid scaffold prototyping in much the same fashion as in the industrial fabrication of metal or plastic components. The main advantages of this process for tissue engineering applications are the wide range of available biomaterials. Specifically, ceramics and metals are suitable to the fabrication of hard bone replacements or structural-supporting materials.[68] Moreover, the powders used in this technique are more readily available than FDM materials, which are limited by filament prefabrication. Compared to other 3D printing techniques, the SLS is more expensive, cumbersome, and provides low resolutions for tough, stiff grafts. Additionally, material oxidation, thermal degradation, material shrinkage, and crystallinity change are concerns about material properties affected by the heating process that must be considered in fabrication.[69] Additionally, a range of fillers can also be incorporated into the powder to further modify the appearance and properties of the printed parts. Being analogous to the SLS approach, a technology known as selective heat sintering (SHS) utilizes a thermal print head rather than a laser to fuse the surface of powdered thermoplastic materials into patterned, layered structures.[31]

2.2.3. Recent Developments in Bioprinting Techniques

A recent development in SLA-based 3D printing involves continuous liquid interface production (CLIP), which is facilitated through a well-controlled oxygen inhibited dead-zone (persistent liquid interface) preventing the resin from attaching to the UV window.[21,58,70] Traditional SLA techniques use the bottom-up building approach and therefore require slow solidification to inhibit the adhesion process. CLIP, on the other hand, employs an oxygen-permeable curing window (a thin, amorphous Teflon film) below the UV image projection plane to create an oxygen-containing zone between the solid part and the liquid precursor where solidification cannot occur.[58] The rate of resin replenishment in this dead-zone, the initiation efficiency, and the resin reactivity all combine to determine the rate at which the part can be formed in a continuous, rather than layer-by-layer, fashion. This approach allows 3D constructs production in minutes instead of the hours required with traditional SLA, and generates structures tens of centimeters in size that could contain features with resolutions below 100 μm. The choice of photocuring resins is fairly broad in CLIP; the viscosity and reactivity of the monomers, however, are more critical since they affect the oxygen diffusion within the resin affecting the permeable curing window.[70]

3D powder printing is a powder-based 3D bioprinting technique that has been developed based on the principles of SLS.[31,71–73] This technology uses a binder solution, such as water, citric acid or phosphoric acid, among others, to selectively bind the loose powdered biomaterial together in the designed geometry. Available biomaterials for binder integration include starch, dextran, gelatin, calcium phosphates, and hydroxyapatite among others.[31,71,74] This process is reasonably inexpensive compared with other modalities, and provides more options for tissue engineering and drug-delivery because it avoids the damage of incorporated bioactive components. A major limitation of this system is the difficulty in removing unbound powder from desired hollow spaces. In addition, the usage of aqueous binding agents exhibits limited mechanical strength and resolution, and requires further post-processing. This technique is also difficult for direct depositing or patterning living cells. Several researchers are also using the inkjet printer to eject the binder droplet. This concept is closer to the traditional 2D inkjet technique where the powder bed acts like the paper.[31]

A nano-stereolithography technique, also called two-photon polymerization printing (TPP), is used to photocure the liquid polymers by simultaneous two-photon absorption.[75,76] Unlike the single photon polymerization process in SLA, two-photon polymerization allows electron transitions over excited energy levels; the polymerization process occurs when an atom absorbs two photons simultaneously. More specifically, a specific photoinitiator that reacts at low wavelengths simultaneously absorbs two photons with high wavelengths, their energies combine to achieve the energy of one photon with low wavelength and thus initiate the polymerization process.[76] The photopolymerization that is triggered by nonlinear excitation happens at the focal point, but other regions are not affected by the laser energy. So it has the potential to print precise 3D structure with very high resolution, and even enable 3D construct printing inside the photocuring material solution without affecting other regions. This technique can achieve spatial solidification with a resolution of up to 100 nm.[22] By exploiting the high resolution of this technique, many researchers have focused on the realization of 3D environments for cell adhesion and proliferation. Two-photon polymerization printing is an improvement, but the process and cost of materials often limits products to a small scale.

3. Material/Cells in 3D Bioprinting: From Bioink to Modular Building Blocks

3.1. Design and Selection Principles of Bioink

In addition to the bioprinting techniques chosen for the targeted tissue requirements, appropriate bioink selection, including cells, biomaterials and biochemical signals, is necessary for the successful construct fabrication. As printing and fabrication depend on the solidifying kinetics of the biomaterials and the native, chemically, or environmentally induced material properties, specific concerns arise based on the deposition mechanism and printing modality as discussed above.[77] The bioink material is crucial because it should provide the spectrum of biochemical (i.e., chemokines, growth factors, adhesion factors, or signaling proteins) and physical (i.e., inter-stitial flow, mechanical and structural properties of extracellular matrix) cues which promote a favorable environment for cell survival, motility, and differentiation.[10] Strategies for bioink selection can be divided into two categories: functional scaffold bioprinting (biomaterials with/without cells as the printing ink) or scaffold-free bioprinting (only use cells as the printing ink).[20] In this section, we focus on the design strategies of bio-materials for functional scaffold bioprinting; scaffold-free bio-printing will be introduced in detail in section 3.5.

Generally, biomaterials range from cell supportive soft hydrogels, to stiff metal or ceramic implants and from nanoparticles and quantum dots for drug delivery and imaging, to complex functioning medical devices.[16,50,78–80] In tissue engi neering, the scaffolds fabricated by biomaterials serve as extra-cellular matrix (ECM) biomimetic structures that organize the tissue regeneration, temporary substitutes for tissue functions, and guides for regenerating tissue ingrowth or integration within a host tissue. Some basic elements including porosity, interconnectivity, pore dimensions, internal geometry, biodegradation kinetics, mechanical properties, and biocompatibility are also taken into account in the scaffold manufacturing process. Therefore, material science and/or engineering play crucial roles in programming an active and effective building block for tissue formation.

3.1.1. Design Principles

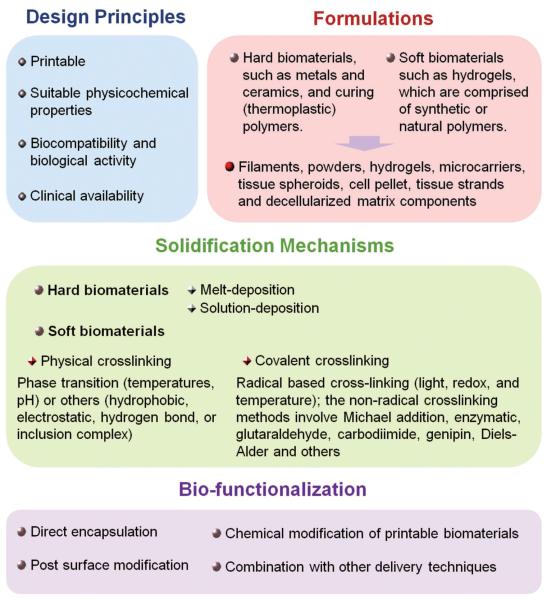

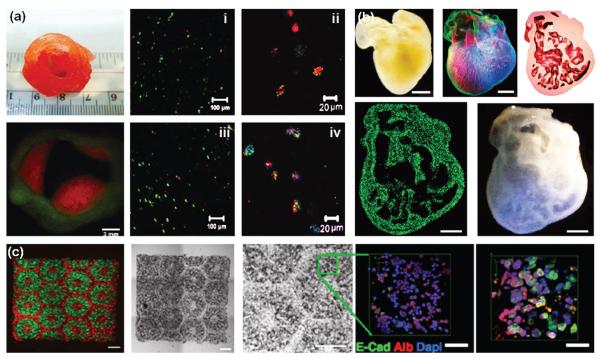

The design principles can be combined into four major considerations for selection (Figure 3):[22,38,50,52,75,81] (1) Biomaterials must have suitable properties to meet specific bioprinter deposition requirements (printability). Printability refers to the capability of the material to support manufacturing and rapid solidification, the printability and interrelation of bioinks in various bioprinters and on associated substrates must be evaluated carefully to produce accurate, high-quality patterns. (2) Biomaterials must possess suitable physicochemical properties, including wetting/swelling, internal and external structure characteristics range from nano- to macro-scale, degradation kinetics, mechanical strength and structural stability. (3) Biocompatibility and biological activity are necessary for tissue development and remodeling over long-term in vivo implantation. The bioink material should facilitate engraftment with the endogenous tissue without generating an immune response and provide a spectrum of biochemical cues (i.e., chemokines, growth factors, adhesion factors, or signaling proteins) that promote an environment for cell survival, motility, and differentiation. (4) The materials should be affordable, abundant, and commercially available with appropriate regulations for clinical use.

Figure 3.

Design of bioinks for 3D bioprinting, including design principles, formulations, solidification mechanisms and bio-functionalization.

3.1.2. Bioink Formulations

Acellular 3D bioprinting technologies, including the deposition of metals, ceramics and thermoplastic polymers, generally involve the use of organic solvents, high temperatures, crosslinking agents or other severe process conditions. As such, an extra post-process step such as purification, sterilization, or other modification is necessary for further biomedical application.[21,78] In contrast, cellular bioprinting requires biocompatible fabrication processes and biomaterials during printing, ensuring cell viability and development throughout. Therefore, Food and Drug Administration (FDA)-approved biomaterials are preferred in these applications; the biocompatibility evaluation for newly developed materials and their degradation byproducts needs to be performed in vitro or/and in vivo before gaining approval.

In general, the printable biomaterials are divided into two categories:[22,38,50] (1) Hard biomaterials, such as metals, ceramics, and curing (thermoplastic) polymers. They can fabricate mechanically robust and durable constructs. These materials typically require high temperatures or toxic solvents to facilitate printing, so that they are not appropriate for printing together with cells. Therefore, cells are usually seeded onto the printed constructs after fabrication, avoiding conditions harmful to the cells. A dynamic cell seeding method is often utilized to improve scaffold coverage. The interconnectivity of pores allows for uniform cell distribution. (2) Soft biomaterials such as hydrogels, comprised of synthetic or natural polymers, possess biomimetic characteristics, providing a favorable environment for cells. The cellular bioprinting technologies currently available are only capable of dispensing liquid materials or hydrogels (they should be in liquid or paste-like form during printing). In order to better mimic the properties of natural ECMs, many biomaterial combinations have been designed for cell printing mimicking the mechanical properties and bioactivity of native tissue. Moreover, the more specific and complex printable materials are steadily being developed to match desirable traits for a variety of biomedical application.

In addition to the components of bioink, the resultant formation is also an important factor. For example, extrusion-based and SLA-based bioprinting are very versatile in depositing a wide array of bioink types, including hydrogels, microcarriers, tissue spheroids, cell pellet, tissue strands and decellularized matrix components. Extrusion-based bioprinting also is capable of depositing small building blocks in a fugitive liquid delivery medium, remains flexible in nozzle tip design, and has the ability to extrude bioink in near solid state, due to larger nozzle diameter ranges.[50]

3.1.3. Solidification Mechanisms

Some general types of curing approaches are described in Figure 2.[38,50,52,81] The curing methods of hard biomaterials can be easily understood. (1) The melt-deposition is based on phase transition of associated materials around their melting point. (2) The solution-deposition is mainly used in curable polymers. The proper organic solvents (volatile or exchangeable) need be chosen to dissolve the different polymers. For soft biomaterials, cell-laden hydrogel solutions are the most typical or universal bioinks. Various key properties such as concentration, molecular weight, viscosity, gelation kinetics, and stiffness are important determinants. The solidification (or gelation) mechanisms include physical crosslinking and covalent crosslinking. As one of the typical physical crosslinking methods, a phase transition from sol to gel state can be controlled by the printing environment change (various external stimuli) such as temperatures, pH, or others. The ionically cross-linked network is formed via multivalent counterions, however, these ions could be leached out or exchanged by other ionic molecules in long term culture, compromising the control over the construct properties. Other physical interactions such as hydrophobic, electrostatic, hydrogen bond, or inclusion complex can employ the solidification of 3D structures, however, their weak mechanical strength limits their application. Therefore, covalent network formation is preferred in order to enhance the mechanical stability. In general, the radical based cross-linking can be induced by light, redox, and temperature; the non-radical crosslinking methods involve Michael addition, enzymatic, glutaraldehyde, carbodiimide, and genipin among others, so the toxicity of the crosslinking agents should be considered. In the light-induced deposition or solidification strategies, the photoinitiators or photosensitizers are commonly applied to initiate the radical crosslinking reaction of monomers and/or pre-polymer solutions, such as D-p-chromophore (known for its high sensitivity in 2PP processes), Irgacure 2959 (I2959; high biocompatible initiator and UV working range), lithium acylphosphinate salt (LAP, biocompatible initiator and visible light working range), VA-086 (high biocompatible initiator and visible light working range), and camphorquinone (CQ; an initiator with many dental applications and visible light working range) among others. Some chemical crosslinking reactions are too slow to support 3D structures during rapid printing, thus multiple-step crosslinking offers a better choice. Normally, the printing temperatures of cells encapsulated in the hydrogels should be around the physiological temperature in order to avoid ice nucleation or overheating, which are harmful to cells. In vivo stabilities, permeability, compatibilities, and degradation rates of polymer hydro-gels should be seriously considered before the 3D constructs can be implanted, particularly for soft tissues or organs. In addition, the swelling and contraction characteristics of the bio-inks have to be considered so that deformation of the final construct can be prevented via the proper selection of bio-ink type.

3.1.4. Bio-Functionalization

An ideal scaffold should possess excellent bioactivity for regulating cell events. Directly encapsulating growth factors or cytokines into bioinks is a simple way of regulating cellular behaviors through diffuse release after bioprinting.[82] Several conventional approaches can also be used to modify the printable biomaterials such as incorporation with bioactive factors, enzymatic recognition sites, and adhesion factors among others.[12,83] The bulk modification before or during the printing process may affect the physicochemical properties of the resultant scaffolds, while post-processing surface modification on printed scaffolds only changes the interactions between cell/tissue and material surface.[66,84–86] Based on the 3D printed biomimetic spatial structure, incorporating bioactive components into constructs provides the proper spatial distribution of biochemical cues for guiding tissue formation and remodeling.[82,87] Herein, the surface modification involving physical adsorption or chemical conjunction has been widely utilized to increase cell attachment, proliferation and regulate cell differentiation by means of interacting with cellular surface ligands and/or modulating the signaling pathways.[6,86,88] Moreover, the presence of nanoscale features also affects cell adhesion, cell orientation, cell motility, and cytoskeletal assembly.[8,11] Other techniques such as microspheres or hydrogels can be combined into 3D bioprinted scaffolds to achieve efficiently sustained release of various bioactive factors.[89] The strategies to engineer biomaterials with specific physiological functions requires a comprehensive understanding of the complex biological mechanisms of the regeneration process, involving the natural tissue-specific composition, the localization of bioactive components in ECM, and the complex cascade of signaling pathways in normal physiological events.

To date, the exploration of new biomaterials for tissue/organ bioprinting is still underway. Emphasis should be given to those printed scaffolds that play a significant role in cell survival, proliferation, migration and differentiation during and after bioprinting processes. They also must possess the principal means of mechanical support and biochemical signals for the long term tissue regeneration. Due to the limitations of material properties relative to specific printing techniques, 3D constructs with complex structures and characteristics were difficult to realize.[7,20,65] Therefore, multiple printing techniques or material systems can be integrated into a 3D construct by choosing the proper printer and materials with appropriate printability. Combining 3D bioprinting platforms and techniques has been proven to be an effective alternative, especially for complex organ manufacturing.[87]

The inherent characteristics of these different printing materials, including solubility, viscosities, melting points, mechanical properties, and available chemistries for crosslinking and functionalization are responsible for the overall success of the design. More importantly, the customized approaches described above will provide potential strategies for creating versatile materials to support successful bioprinting.

3.2. Common Bioinks and Recent Developments

Currently, most research focuses on the development of new printing techniques, the update of printing parameters (resolution, speed or others) or the bio-application of printed constructs instead of exploring new printable materials and their functionalization. Therefore, the lack of variety in ideal, printable biomaterials remains a major challenge. The different printing techniques have specific requirements for the properties of bioinks as we discussed above. In this section, we will briefly cover the traditional and universal biomaterials used in bioprinting, and will further discuss the development of new printable biomaterials.

3.2.1. Hard Biomaterials (Metals, Ceramics, and Thermoplastic Polymers)

In the field of tissue engineering, hard biomaterials are derived either from natural or synthesized materials, containing in metallic components, polymers, ceramics or composites.[21,31,78]

Metals have been used clinically for bone replacement or repair in the biomedical community because of their high mechanical strength and in vivo safety.[21] Common metals such as stainless steel, titanium, and certain alloys have been studied in 3D printing as well, and some have progressed to clinical trials.[68,69] However, limited 3D metal printing techniques, metal corrosion and ageing, and potential toxicity of metal ions are serious considerations being further evaluated for long term implantation. Biodegradable implants are preferred for tissue regeneration, thus a “biodegradable metal” concept has been proposed.[90] Some magnesium-based, iron-based, zinc-based, or other biodegradable metal-based composites, which consist of the pure metals themselves, alloys, or metal matrix composites have been reported.[90] The favorable biocompatibility, suitable degradation rates, and completed metabolism can be observed in studies either in vitro, or in vivo. As the availability of biodegradable metals increase, more comprehensive research is needed before further clinical applications can progress.

Ceramics and glasses are widely used as biocompatible materials for dental, joint and bone implantation due to their mineralization abilities.[72,91] Therefore, bioceramics containing both metallic and nonmetallic elements are applied in the 3D bioprinting field ranging from ceramic oxides (inert in the body) to resorbable materials (eventually replaced by regenerated tissue).[92] Hydroxyapatite (HA) is a primary component in human teeth and bones. It, along with its analogues tri-calcium phosphate (TCP) and calcium phosphate (CaP), has been printed into bone scaffolds with biomimetic structures, adequate mechanical strength, and the ability to promote osteogenesis.[93]

The physicochemical and mechanical properties of synthetic polymers can be easily modified for enhancing tissue engineering outcomes, and these materials can be produced at low cost without immunogenicity. Some FDA-approved degradable polymers and their copolymers are extensively used in FDM and SLS bioprinting.[22,31,81] Polycaprolactone (PCL) and poly lactide (PLA) are the most widely used biocompatible and biodegradable polymers used with FDM because of their proper melting temperatures and good solubility allowing easy printing and processing.[78,79] In addition to being used for fabricating tissue engineering scaffolds, they can also be used as a 3D structural support for cell-laden soft materials in the printed constructs. PCL, however, exhibits very slow degradation, due to its semicrystalline structure, hydrophobicity, and low water absorption capacity. Poly(lacticco-glycolide) (PLGA) is another material that is ideal for extrusion bioprinting; degradation can be controlled by adjusting the polymerization ratio between the lactide and glycolide groups, another favorable feature of this material. Poly(3-hydroxybutyrate) (PHB) is a natural thermoplastic polyester produced by microorganisms that has also attracted attention for 3D bio-printing applications. Acrylonitrile-Butadiene-Styrene copolymer (ABS) is not widely used in medical devices in comparison to biomaterials such as PCL and PLA which offer greater native biocompatibility. Although surface modification has been applied to engineer hydrophilicity and enable biocompatibility, it shows limited promise for biomedical application. Variations in the copolymer structure and polymer concentration enable the tailoring of mechanical properties for the scaffolds.

3.2.2. Soft Biomaterials (Hydrogels)

With the exception of the stiffest tissue types such as bone and teeth, hydrogels can recapitulate a range of elastic modulus values through manipulation of chemistry, crosslinking density, and polymer concentration, thus mimicking the elastic moduli of most soft tissues in the body.[14,50,94] Soft biomaterials mainly used in the cellular bioprinting techniques are predominantly based on either naturally occurring polymers and their derivatives (including alginate, gelatin, collagen, chitosan, fibrin and hyaluronic acid, often isolated from animal or human tissue) or synthetic materials (polyethylene glycol (PEG), Pluronic F127 and their derivate copolymers, includes polyesters, polypeptides or others).[21,65,79,81] The advantages of natural polymers are their similarity to human ECM, and their inherent bioactivity, however, they are limited by immunogenicity, weak mechanical strengths and a lack of control in composition/molecular weight. The advantage of synthetic polymers is that they can be tailored with specific physical properties in terms of tissue response such as specific molecular weight, chemical structure, composition and functional group chemistry as well as bioactive anchored sites (i.e., adhesion motif or enzyme degradation sites) to suit particular applications.[50]

As the synthetic polymers, both polyethylene glycol PEG and Pluronic F127, are water-soluble polymers, they are intensively used as a representative sacrificial material for fabricating complex 3D constructs.[50] Pluronic F127 is of particular interest because it possesses the characteristic of thermo-reversible gelation dependent on the solution concentration. Pluronic F127 can transform from a liquid under 4 °C to a gel at over 16 °C when above 20% w/w concentration. Both PEG and Pluronic F127 should be chemically modified prior to forming physical or chemical networks when using as tissue engineered scaffolds.[95] The typical method for achieving gel formation is acrylation or methacrylation, where the chemically modified PEG or Pluronic F127 is generally crosslinked under UV exposure. Additionally, their derivative copolymers including polyesters and polypeptides, among others, have been widely synthesized as physical or chemical hydrogels and used for cell encapsulation, which can also be applied in 3D cellular printing and manufacturing.

Natural polymers and their chemical modifications are the most widely used as printable biomaterials and encapsulating living cells due to the similarity of their components to the native tissue microenvironment.[20,50,81] They can also provide tissue-specific biochemical and physical stimuli to guide cellular behaviors including migration, proliferation, differentiation, and maturation. For use in bioprinting, natural polymers have been employed in several ways, to include the use of the temperature sensitivity or ionic interaction characteristics to facilitate extrusion, and the use of covalent addition of functional groups to induce chemical crosslinking approaches.

Alginate (Alg) is an anionic polysaccharide derived from algae or seaweed.[96] This material is composed of two repeating monosaccharides (i.e., L-guluronic and D-mannuronic acids), therefore, the typical ionic hydrogel can be formed using multi-valent cations (i.e., Ca2+, Zn2+) instantaneously, making it attractive for 3D tissue/organ printing.[96,97] The crosslinking processes are reversible, however, so the printed structures cannot be maintained for longterm culture applications.[96] Hyaluronic acid (HA), or hyaluronan is a linear polysaccharide component of the ECM (non-sulfated glycosaminoglycans), which has been used clinically for several decades for treatments such as therapy for damaged joints and arthritis.[98] Acrylate or methacrylate modified HA can be crosslinked to form a hydrogel via light based 3D bioprinting. Thiol-modification of HA can form a hydrogel through Michael-type addition reactions with active vinyl based crosslinkers.[38] Limitations of HA as a bio-material for bioprinting are that HA hydrogels are typically too soft to form robust structures, and show significant swelling behavior. Collagen (Col) is a main structural protein of ECMs; it responds to simple crosslinking via thermosensitive gelation under physiological conditions, which can be a major advantage in 3D printing.[99,100] However, the high cost and weak mechanical strength limit its application. Gelatin (Gel) derived from partially hydrolyzed Col is inexpensive, and also possesses thermosensitive properties.[101] Both Col and Gel have abundant proteins including fibronectin, vimentin, vitronectin, and arginineglycine-aspartic acid (RGD) peptides, which promote cell adhesion. The transition temperature of Gel lies around 30 °C limiting its direct application as the cell scaffold at physiological temperature, thus it commonly serves as the sacrificial material in 3D printed structures.[50] The reversible gelation mechanism in aqueous conditions is based on the formation of an alpha helix structure below 30 °C and a random coil structure above 40 °C. Gelatin methacrylate (or gelatin methacrylamide, GelMA) has been widely used to fabricate scaffolds via the various light-based printing platforms.[102] Additionally, the aforementioned thiol-ene crosslinking method has also applied to the GelMA system when adding thiol-based materials.[94] Fibrin is comprised of fibrinogen monomers that are cleaved with thrombin by a blood coagulation crosslinking mechanism, thus fibrin plays an important role in the blood clotting and wound healing processes.[103] It is widely used as surgical glue in high concentration, or cell scaffolds in low concentration, due to its rapid gelation property. However, the fibrin hydrogel is too soft and fragile to maintain a 3D shape.[104] Decellularized extracellular matrices (dECM) from different tissues contain a variety of proteins, proteoglycans and glycoproteins of native tissue ECM components, so it has been used as bioink capable of recapitulating a tissue-specific microenvironment in printed 3D tissue/organ analogues.[100,105,106] Challenges in tissue decellularization are with ensuring the complete removal of cellular components while maintaining of the fine vascularture and other tissue structures.[107] Additionally, some toxicity has been observed when cells are grown on decellularized tissue scaffolds, potentially due to the retention of the decellularization detergent.[105] Other natural polymers such as starch, cellulose, and dextran, among others, have been developed for 3D printing scaffolds with potential use in tissue engineering or other biomedical applications.[22,38,50,65,79,80]

3.2.3. Latest Development of Bioinks

The chemical modification of biomaterials may provide a promising approach for extending 3D printable bioinks.[65,77,94] For example, the photocrosslinkable macromers or prepolymers can easily be prepared by acrylated/methacrylated multi-armed oligomers/polymers or branched polymers. Photocrosslinked networks have a high gel content, which indicates a high degree of crosslinking. However, due to the solvents used in these systems, shrinkage or swelling of scaffolds may occur after drying or soaking, resulting in changes in structural and mechanical properties. Some macromers can be heated above the melting temperature to obtain the suitable viscosity; in such cases, no solvent is needed for bioprinting and no obvious material shrinkage is observed after cooling. Additionally, other covalent crosslinking systems have been developed in the 3D printable inks. A thermally reversible dynamic covalent Diels–Alder reaction was used to synthesize a printable PLA blend for dramatically improving both strength and toughness of the scaffolds.[67]

Currently, composites of polymers and bioactive materials are being developed with the aim of increasing the mechanical scaffold stability or improving tissue interaction.[21] The composite scaffolds combining a variety of biodegradable polymers and bioactive ceramics are fabricated by 3D printing and are capable of achieving high mechanical strength and good biological activity. Generally, the stiffness of the cured composites will increase with raising the concentration of nanoparticles or other materials. Synthetic polymers can often be combined with bioactive materials, naturally derived materials or other functionalized materials to create more complex hybrid structures.

Moreover, the strongly desired characteristics of advanced tissue scaffolds involve both biomimetic properties in structure and the ability to regulate cell behavior.[7,94] Engineering techniques that mimic the critical aspects of natural healing and growth cascade are preferred to augment the proliferation and differentiation of the recruited or implanted cells; this is often achieved through the integration of growth factors and cytokines that provide suitable biochemical and physicochemical factors for tissue regeneration. Engineering these dynamic ECM mechanisms into biomaterials offers further control over cell behavior. One challenge is in developing methods to incorporate these biologically inspired materials into constructs using bioprinting technology. Material printability and degradation characteristics such as time and byproduct emission must be better understood for progression toward clinical applications. Also, it is essential that these materials have well-understood and controllable structural and functional biological effects before advancing to in vivo testing and application.

3.3. Cell Sources and Selection

The choice of cells for tissue or organ printing is crucial for functionality of the fabricated construct, especially for future clinical application.[108] Tissues and organs are comprised of multiple cell types with specific biological functions that must be recapitulated in the regenerated tissue. In addition to the primary functional cell types, most tissues contain various cell types that provide supportive, structural or other functions, or are involved in vascularization or provide an essential surrounding for functional maintenance and development of the primary cells.[20] Therefore, the options for printing cells not only involve the arrangement of primary cell types in the 3D printed construct, but also have a close relationship with other cells for contributing to complete functionality of complex tissues/organs.

3.3.1. Principles of Cell Selection

Cells used for 3D printing should take into account several elements.[16,20,81] (1) Sufficient numbers of cells can be expanded in vitro culture for bioprinting; (2) Cells must be robust enough to survive during or after the bioprinting process; (3) Appropriate cell proliferation and controllable differentiation in the 3D printed scaffolds are required for either in vitro culture or in vivo implantation; (4) Cellular functions can be maintained in vitro to closely mimic the true physiological state, and developed after implantation by stimulation with the in vivo environment, including physical forces and biological stressors; (5) Physiological specificity both structural and functional on different cell types; (6) Interaction of multiple cells for tissue development involves biological signal paths.

3.3.2. Cell Sources

In order to maintain long-term function after implantation, the bioprinted construct must be able to maintain cellular homeostasis, self-renew, respond to tissue damage or injury, and integrate with host tissue or organ.[16,20]

Host immune response may be triggered by the implantation of exogenous cells. Therefore, the autologous source of cells is the preference, autologous cells may be obtained from the patients themselves through the generation and differentiation of autologous stem cells or through reprogramming approaches, to avoid negative immune responses. However, some limitations make it difficult to apply autologous cells in bioprinted constructs for tissue regeneration. Examples of these challenges are: technique restrictions on the isolation and in vitro culture of cells, finite expansion or regeneration capacity of many primary cell types, and the effectiveness of patient-sourced cells. Pluripotent stem cells including embryonic stem cells (ES) and induced pluripotent stem cells (iPS) are promising cell types due to their ability to proliferate in an undifferentiated but multipotent state (self-renewal) and their capability to generate multiple functional tissue-specific cell phenotypes.[20,38] Especially, iPS derived directly from adult tissues requires reprogramming the cell type thus overcoming the difficulty and limitations associated with the current cell sources. Adult mesenchymal stem cells from bone marrow, fat, umbilical or other sources can differentiate into osteoblasts, chondrocytes, adipocytes, cardiac cells, endothelial cells, smooth muscle cells, hepatocytes, and neural cells and can be used in many biomedical applications. Although they have a more limited multipotent differentiation potential, they are considered safer for clinical uses and show great promise for bioprinting applications. According to previous studies, high cell viability can be obtained through optimizing the printing parameters; overall the printing processes have no adverse effects on the stem cell proliferation and differentiation abilities.[50]

The 3D printed constructs for the complex tissue or organ regeneration need to be fabricated with either functional primary cells with supporting cells or progenitors/stem cells for further differentiation.[16,23,26] In cellular printing, multiple bioinks with different cells need to be prepared to print in parallel, requiring complicated and precise control of the printing step. Additionally, acellular printing is difficult to post-seed specific cells on the desired regions of complex 3D structure. Printing stem cells with the regional bioactive factors, or post-seeding stem cells on the construct with the regional bioactive factors, may reduce the complication of the fabrication process for complex tissue/organ regeneration. Stem cells can be differentiated into target cell types by bioactive factors in the combination of location or spatial arrangement. Therefore, 3D stem cell printing can provide a simple and effective approach for regenerating complex tissue/organ.

3.4. Modular Fabrication of Mini-tissue

Regeneration of a tissue or organ including cellular and extra-cellular components, needs to reproduce specific cellular functions, thus a complete understanding of the tissue micro-environment, such as specific organization and hierarchy of various cell types, gradients and arrangement of biologicals, composition of the ECM as well as the native biomechanical stimulation in vivo.[17] Tissues or organs can be considered as an aggregate structure consisting of small structural and functional components, which can be defined as functional building blocks.[23,36,50] Modular fabrication of these building blocks can easily be assembled to complete tissues. 3D bioprinting techniques can be used to print these building blocks and guide them to assemble into 3D living structures. The process of tissue/organ development relies on cellular self-organization through direct assembly in scaffold-free conditions or aggregation along with the 3D printed scaffold degradation.[20] This spontaneous self-organization happens during development in vivo, but has also been recapitulated in numerous in vitro applications.