Abstract

In this study, interactions between resistant corn starch (RS) (5% w/w) and locust bean gum (LBG) (0, 0.125, 0.25, 0.50 and 1.0% w/v) on the viscoelastic, pasting and morphological characteristics of aqueous dispersions were evaluated. Results showed that the storage modulus (G′), loss modulus (G′′), and apparent viscosity values of starch/gum (RS/LBG) mixtures were enhanced with the addition of LBG, and the rheograms demonstrated a biphasic behavior. RS/LBG samples were predominantly either solid like (G′ > G′′) or viscous (G′′ > G′), depending on the added concentration level of LBG. Gum addition also caused higher peak viscosity, breakdown and total set back of RS/LBG mixtures. A strong correlation between rheological and structural properties was found. Confocal laser scanning microscopy (CLSM) images confirmed the transition of starch particles from a scattered angular shape to clustered structures cross-linked by dense aggregate junction zones justifying the observed changes in rheological properties.

Keywords: Corn starch, Rheology, Locust bean gum, Pasting properties, Confocal laser scanning microscopy

Introduction

Starch/hydrocolloid mixtures are often used in food industry to improve the quality and stability of developed formulations. Although, the reason for using their combinations depends on the type of product; the main reason appears to be the fact that native starches, when used alone, do not generally exhibit ideal functional properties for the preparation of food products (Blibech et al. 2015). Moreover, native starches are often chemically modified to improve their resistance to various physical changes during processing (heat, shear, and acidic medium), retrogradation and breakdown, to impart better textures of pastes and gels, and to enhance cold storage and freeze–thaw stability (BeMiller 2011). Some limitations of native starch can be overcome by addition of a suitable hydrocolloid, without chemical modification, and thus improve product texture and rheology (Singh et al. 2016, Qiu et al. 2015), moisture retention and syneresis (Yamazaki et al. 2013) and other attributes desired by food processors.

Locust bean gum (LBG), also known as Carob gum is a natural hydrocolloid, which has been used in numerous industrial applications (food, cosmetic, textile, pharmaceutical, paint, milling and construction industries), because of its ability to enhance viscosity at relatively low concentrations (≤0.02%), to stabilize emulsions and as a fat replacement (Barak and Mudgil 2014). In food industry, LBG alone or in combination with other hydrocolloids (e.g. carrageenan, xanthan gum, guar gum) is widely used in beverages (Dogan et al. 2011), bakery products (Kohajdová et al. 2009), noodles (Pan et al. 2016), dairy products (Cropper et al. 2013) and as edible coatings (Martins et al. 2012).

Corn starch is also used in many food formulations for its desirable rheological properties (Amini et al. 2015). Further, different starches and their derivatives can be classified on the basis of their digestibility as “rapidly digesting starch” (RDS), “slowly digesting starch” (SDS) and “resistant starch” (RS) (Englyst and Macfarlane 1986). RS is classified into five groups on the basis of its structure and properties: RS 1: physically inaccessible starch; RS II: native granular starch; RS III: retrograded starch; RS IV: chemically—modified starch and RS V: amylose—lipid complex (Vamadevan and Bertoft 2015). RS has been primarily used as a functional ingredient to improve the quality and dietary fiber content of low-moisture foods such as bakery products (bread and muffins), pasta products, and in breakfast cereals and snacks (Fuentes-Zaragoza et al. 2010). Additionally, being a dietary fiber, RS plays several physiological functions against colonic carcinogenesis and reducing the risk of diabetes, obesity, high cholesterol and other chronic diseases (Choi et al. 2010).

Several studies have reported that the effect of hydrocolloids (cellulose derivatives, alginates, carrageenan, xanthan gum, guar gum, locust bean gum) on corn starch is dependent on the structure and concentration of the hydrocolloid (Ptaszek 2013; Qiu et al. 2015). The interaction between starch and hydrocolloid is also reported to be dependent on the starch source, differences in granule size (Amini et al. 2015) and crystalline microstructure (Techawipharat et al. 2008). In general, all hydrocolloids and specifically starch/LBG interactions have modified the pasting behavior (Kaur et al. 2015) and viscoelastic properties of the native starch (Dogan et al. 2011). In order to take advantage of starch/gum interactions and enhance their applications in food formulations, it is important to assess their functional and physicochemical properties (Lee et al. 2012).

In a recent review covering over 50 studies (BeMiller 2011), it is noted that a few have focused on the effect of LBG on different starches but none have included RS. As resistant starches have high nutritional and nutraceutical importance and, locust bean gum could favorably influence many functional properties. The majority of previous reports have mostly focussed on the nutritional, functional, and digestibility characteristics of resistant starches, while the use of resistant starches in food formulations often involve a noticeable amount of other hydrocolloids (gums). Data on understanding the contributions and interactions of these combinations (starch—locust bean gum) obviously should be of considerable interest.

With this background, the aim of this study was to evaluate the influence of LBG gum on the rheological and structural properties of starch–LBG mixtures. From an industrial point of view, this research is significant because of the dearth of basic data on the dynamics of interactions between LBG and RS in connection to develop resistant—starch mixtures based food products.

Materials and methods

Materials

Commercial grade chemically modified resistant starch with average particle size 10–15 µm (Hi-Maize 260 corn starch termed as RS) (National Starch and Chemical Co., NJ, USA) was used in the study. The proximate composition of the starch was: moisture content, 10.8 ± 0.1%; ash content, <0.4%; fat content, <0.8%; and protein content, 0.8% (all on dry basis), as provided by the manufacturer. In order to verify moisture content of the starch sample, RS samples were dried (in duplicate) in an oven at 130 °C to constant weight. The evaluated moisture content was within 1% of the supplier data. Laboratory food-grade LBG (galactomannan polysaccharide 100 K0220) was from Sigma Chemicals (St. Louis, USA).

Preparation of starch and starch/LBG dispersions

Aqueous 5% dispersion of RS was prepared by dispersing 5 g of starch to 95 g deionized water at room temperature. LBG powder was dispersed in deionized water at 0.25, 0.50 and 1% (w/w). Both dispersions were prepared with constant stirring overnight on a magnetic stirrer (400 rpm) to achieve complete hydration. Starch/gum dispersion mixtures were prepared by gradually adding 5% (w/w) RS powder into fully-hydrated gum solutions to achieve samples with the required concentrations of starch/LBG dispersions. The final dispersions were stirred for 2 h and immediately used for tests.

Rheology

Dynamic tests

Oscillatory rheology measurements of starch/LBG dispersions were made using a controlled-stress rheometer (AR 2000, TA Instruments, New Castle, DE, USA). A cone-plate geometry was used with a diameter of 60 mm and a cone angle of 2°. The gap between the base plate and geometry was set at 64 µm. The sample temperature (25 °C) was controlled by a Peltier system and monitored by platinum resistance thermometer sensors (accuracy ± 0.1 °C), which were positioned both in the upper and lower plates. The sample perimeter was covered with a thin layer of high-temperature-resistant silicone oil to prevent sample dehydration. Small-amplitude oscillatory strain sweep experiments (0.001–10%) were carried out, and elastic (G′) and viscous (G′′) shear moduli, at a constant frequency of 0.1 Hz were measured to determine the limit of the linear viscoelastic region (LVR) (Ahmed et al. 2014). The LVR analyses was carried out for the entire range (2–5 Pa depending on gel stiffness), and measurements were carried out accordingly. Frequency sweep tests (0.01–25 Hz) were carried out in the linear regime, at constant strain (0.05%) at 25 °C (Ahmed et al. 2014). All the rheological measurements were carried out in triplicate and rheological parameters (G′, G″) were obtained directly from the manufacturer supplied computer software (Rheology Advantage software, TA Instruments, New Castle, DE, USA).

Steady flow tests

Steady flow measurements (shear stress, shear rate, apparent viscosity) were made over a shear rate ranging from 0.1 to 100 s−1 at 25 °C in triplicate. Flow curves of RS/LBG dispersions at 25 °C was modeled using Rheology Advantage software, TA Instruments, New Castle, DE, USA. The Power Law model, represented by the following equation, was used to describe the pseudoplastic behavior of test samples (Marcotte et al. 2001).

| 1 |

where τ is the shear stress (N/m2), is the shear rate (s−1), K (Pa.sn) is the consistency coefficient and n is the flow behavior index (for Newtonian fluids, n is equal to 1 while it is below 1 for pseudoplastic fluids).

Pasting properties

The pasting properties were studied using a starch pasting cell (SPC) attached to a controlled-stress rheometer (AR 2000, TA Instruments, New Castle, DE, USA) in duplicate. The SPC consists of an impeller and a cylindrical cup (3.6 cm wide and 6.4 cm high). The upper part of mixing element shaft is progressively extended to offer a non-contact, solvent evaporation is protected by a conically-shaped cover. Heating and cooling of the SPC are controlled through electrical elements and water recirculation unit respectively. The cooling control unit located upstream of cup regulates cooling water flow. A 25 ml of starch/LBG dispersion sample was placed in the cylindrical cup of the SPC. The sample was first stirred strongly (100 s−1) for 10 s at 30 °C, then the shear rate was held at 30 s−1 until the end of the test. The sample was heated from 30 to 90 °C at 15 °C/min and the temperature was held at 90 °C for 5 min. Following this, the sample was cooled to 30 °C at 15 C/min and held at 30 °C for 5 min. To compare the pasting behaviors of starch/LBG dispersions, following parameters were calculated from the viscograms with the TA data analysis software provided by the instrument’s manufacturer; pasting temperature (PT): the temperature at which viscosity starts to rise; peak viscosity (PV): the highest viscosity recorded throughout heating; hot paste viscosity (HPV): the viscosity value at the end of the isothermal period at 90 °C; and cold paste viscosity (CPV): the viscosity value at the end of the isothermal period at 30 °C (Martínez-Cervera et al. 2014).

Confocal laser scanning microscopy (CLSM)

Morphological characteristics of starch/LBG dispersions were observed using confocal scanning microscope (Nikon Instruments, Nikon Eclipse TE 800-E, Radiance 2100, BIO-RAD, Japan). A few drops of the starch dispersions with or without LBG were transferred to a 2 cavity slide (Electron Microscopy Sciences, Hatfield, PA, USA), sealed with nail enamel and observed within 15 min. A laser with an excitation wavelength of 488 nm and a 40× air immersion objective was used. Only transmission detectors were used. Digital image files were acquired at 1024 × 1024-pixel resolution using 1 × 3 zoom factors. At least 4 images were obtained per sample for each replicate, and representative micrographs were selected.

Statistical analysis

All experiments were carried out in triplicate and the results were reported as mean. Data were analyzed by Minitab 16 analysis software (Minitab Inc. USA). Statistically, significant effects were further analyzed, and the means were compared using spearmen’s multiple range test. Statistical significance was determined at p < 0.05.

Results and discussion

Dynamic rheology

Starch and gum: individually tested

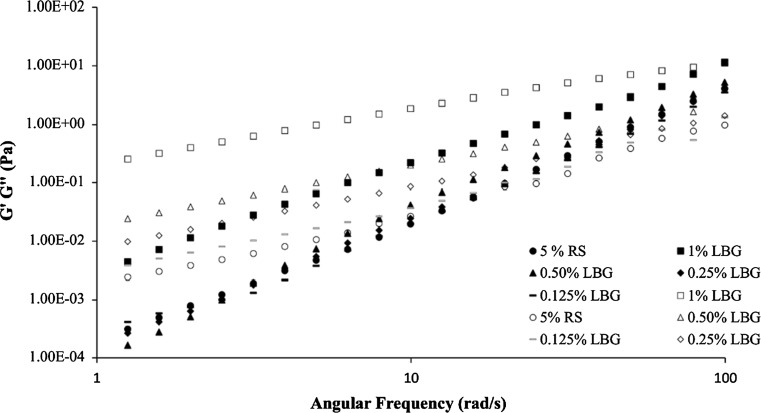

Figure 1 shows changes in dynamic mechanical spectra (G′ and G″) for 5% RS and different LBG concentrations (0.125, 0.25, 0.50 and 1%) as a function of oscillation frequency (ω) and some representative values are reported in Table 1. For RS, G″ values predominated over G′ values at lower frequencies (0.1–10 rad/s), while G′ exceeded G″ at high frequencies (20–100 rad/s). The frequency dependent variations in the oscillatory parameters of resistant starch (modified starch) have been recognized to be linked to the source and concentrations (Lee et al. 2012; Ahmed et al. 2014).

Fig. 1.

Rheological properties: dynamic mechanical spectra (closed symbols, storage modulus, G′; open symbols, loss modulus, G′′) measured at 0.001–10% strain of 5% RS (w/w) and different concentrations (0.125,0.25,0.50 and 1%) of Locust bean (RS and LBG stands for resistant corn starch and locust bean gum respectively). All measurements were made at 25 °C

Table 1.

Storage modulus (G′), loss modulus (G″) at lower (10 rad/s) and higher (50 rad/s) frequencies and apparent viscosity (10 s−1), consistency index (Pa.sn), flow behavior index for starch (RS), Locust bean gum (LBG) and RS-LBG dispersions with different concentration at 25 °C

| Samples | G′ at 10 rad/s | G″ at 10 rad/s | G′ at 50 rad/s | G″ at 50 rad/s | η (Pa.s) at 10 s−1 | K (Pa.sn) | n (−) | R2 |

|---|---|---|---|---|---|---|---|---|

| 5% RS | 0.02 | 0.02 | 0.90 | 0.38 | 0.004 | 4.12 | 0.72 | 0.99 |

| 0.125% LBG | 0.02 | 0.03 | 0.69 | 0.48 | 0.003 | 28.4 | 0.69 | 0.94 |

| 0.25% LBG | 0.02 | 0.08 | 0.82 | 0.66 | 0.008 | 30.2 | 0.64 | 0.99 |

| 0.50% LBG | 0.04 | 0.20 | 1.20 | 0.80 | 0.021 | 34.8 | 0.58 | 0.97 |

| 1% LBG | 0.32 | 1.88 | 4.39 | 7.06 | 0.211 | 36.5 | 0.57 | 0.97 |

| 5% RS/0.125% LBG | 0.04 | 0.04 | 1.28 | 0.44 | 0.006 | 24.6 | 0.65 | 0.95 |

| 5% RS/0.25% LBG | 0.04 | 0.08 | 1.13 | 0.64 | 0.019 | 26.9 | 0.67 | 0.98 |

| 5% RS/0.50% LBG | 2.74 | 5.24 | 11.22 | 14.83 | 0.058 | 22.4 | 0.66 | 0.99 |

| 5% RS/1% LBG | 4.15 | 6.41 | 15.22 | 17.05 | 0.441 | 25.1 | 0.66 | 0.99 |

Values are average of three determinations (n = 3); k = consistency index (Pa.sn), n = flow behavior index (dimensionless). R2 values are for k and n

An aqueous solution of LBG also depicted a typical behavior of macromolecular biopolymer with dominating G″ over G′ in the lower frequency range (0.1–40 rad/s) whereas G′ dominated over G″ (except 1% LBG) in high-frequency ranges (40–100 rad/s). It means that locust bean gum solutions (0.125–1.0%) show a liquid-like behavior at lower frequencies (G″ > G′) and a rigid solid like behavior at higher frequencies (G′ > G″) (Table 1). The results for frequency sweep of LBG dispersions are well supported by Wu et al. (2009) who investigated rheological properties of four commercial galactomannans (Fenugreek gum, guar gum, Tara gum and Locust bean gum) at 0.5–2.0% concentration, with different mannose to galactose ratios (M/G). They reported both liquid-like (at lower frequencies) and solid like (at higher frequencies) behaviors for these gums, which was analogous to their molecular weight. Hence, the overall comparison of individual polymers showed a typical weak gel behavior with highest magnitude of G′ and G″ for 1% LBG > 0.50% LBG > 0.25% LBG > 0.125% LBG > 5% RS.

Starch–gum mixtures

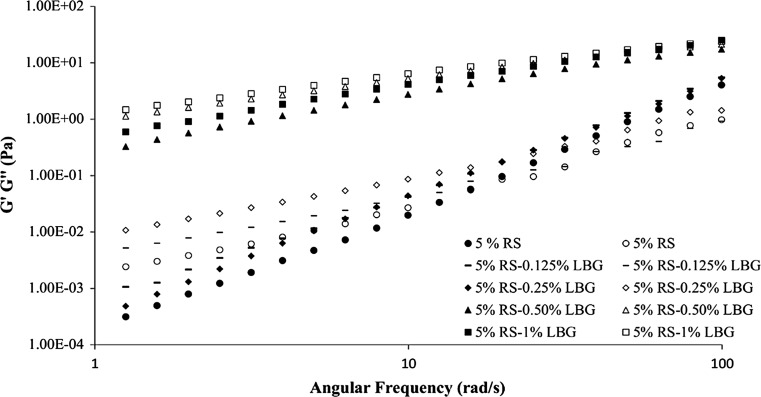

Figure 2 shows that the viscoelastic properties of RS were modified with the addition of LBG at concentration levels tested (0.125–1%). Two distinctive behaviors were observed based on LBG concentration. In addition, starch–gum mixtures at a lower concentration of LBG (0.125, 0.25%) led to low values of G′ and G″ (Table 1). For example, RS/LBG mixture with the lowest concentration of LBG (0.125%) showed a liquid-like behavior (G″ > G′) at lower oscillatory frequencies (0.1–10 rad/s) and a solid-like behavior (G′ > G″) at higher frequencies (15–100 rad/s).

Fig. 2.

Rheological properties: dynamic mechanical spectra (closed symbols, storage modulus, G′; open symbols, loss modulus, G′′) measured at 0.001–10% strain of 5% RS (w/w) and RS–LBG dispersions (5% RS with 0.125, 0.25, 0.50 and 1% LBG) (RS and LBG stands for resistant corn starch and locust bean gum respectively). All measurements were made at 25 °C

However, at higher concentration of LBG (0.50–1%), the loss modulus completely dominated over the elastic modulus (G″ > G′) and the G′ and G″ values of the mixtures were much higher than those of RS alone and/or with 0.125 and 0.25% LBG and, the mechanical spectral behavior for these moduli were almost parallel (Fig. 1). The increase in the values for the dynamic moduli (G′ and G″) can be attributed to the dominant viscoelastic properties of added LBG, which is concentrated within the continuous phase in RS/LBG mixtures as also confirmed by Alloncle and Doublier (1991). The addition of LBG seems to have a synergistic effect on the rheological properties of RS/LBG mixtures. Generally, this overall shift of starch/gum gel network from an elastic to a more viscous nature can be attributed to two mechanisms, including phase separation (Closs et al. 1999) and thermodynamic incompatibility between like and unlike polysaccharides (BeMiller 2011). Similar findings have been reported with waxy starch–xanthan gum (Achayuthakan and Suphantharika 2008) and maize starch–corn fiber gum blends (Qiu et al. 2015), indicating that starch-gum network shifted from an elastic to more viscous nature.

Steady shear flow behavior of starch-gum mixtures

The steady shear flow behavior of RS and RS/LBG mixtures are presented as apparent viscosity determined at the shear rate of 10 s−1, and the flow behavior index (n) and consistency index (k) data are included in Table 1 and as flow curves showing flow behavior under shear rates (Fig. 3). The shear stress (τ) versus shear rate () data at 25 °C were well fitted with power law model (Eq. 1) with high determination coefficients (R2 = 0.94–0.99) as shown in Table 1. The flow behavior index (n) which indicates the extent of shear—thinning behavior or pseudo-plasticity as it deviates from 1, was in the range of 0.57—0.72 (Table 1). The n values did not change much with the inclusion of LBG in the concentration range, 0.25–1%, indicating the low effect of LBG on the flow behavior of starch.

Fig. 3.

Effect of LBG concentration on the apparent viscosities of 5% RS-LBG (0.125, 0.25, 0.50 and 1%) mixtures at 25 °C (RS and LBG stand for resistant corn starch and locust bean gum respectively)

The low degree of pseudo-plasticity of LBG can be explained in terms of its structure. It is stated elsewhere that LBG consists of a mannan backbone which tends to coil with the formation of intramolecular hydrogen bonds (Sajjan and Rao 1987). Therefore, interacts less with linear amylose molecules, due to the lower number of hydroxyl groups available to form intermolecular hydrogen bonding, and hence pseudo-plasticity decreases. Contrarily, the k, which represents the consistency of the sample, a measure sample viscosity and resistance to flow, increased with an increasing concentration of LBG. These results are in good agreement with those found in acorn starch-LBG mixtures (Kim and Yoo 2011).

Rheograms of RS/LBG mixtures with different LBG concentrations (0, 0.125, 0.25, 0.50 and 1%) at 25 °C as a function of shear rate (1–100 s−1) indicated the intensification non-Newtonian (pseudoplastic) nature of the mixture (Fig. 3). The apparent viscosity and consistency coefficient of RS/LBG mixtures increased with the incorporation of the LBG, a fact attributed to synergism (Alloncle et al. 1989).

Among all analyzed samples, RS/LBG mixtures at the maximum LBG concentration (1% LBG) have the highest apparent viscosity and shear thinning behavior (Table 1). The low viscosity of RS compared to other native starches (corn, rice, potato, wheat, and tapioca) may be due to its modified structure that is more shear resistant as compared to native starches. Wu et al. (2009) determined the rheological properties of LBG and reported a non-Newtonian flow behavior (shear thinning) at high shear rates, but exhibits Newtonian behavior at lower shear rates. The thickening capacity of LBG is influenced by many factors such as; shear rate, solubilisation methods, particle size, polymer concentration, molecular weight distribution and impurities (Barak and Mudgil 2014).

As reported by Alloncle et al. (1989), starch dispersions may be considered as composite materials comprising of swollen granules (amylopectin) dispersed in a continuous biopolymer matrix (amylose). They further stated that, in galactomannan (e.g. locust bean gum) and corn starch mixture systems, gums are located within the continuous phase. Subsequently, the volume of this phase is reduced, and concentration of gum within the continuous phase is increased, thereby resulting in a very high viscosity. Similar observations were reported by (Qiu et al. 2015) and (Mandala and Bayas 2004) for corn fiber gum-maize starch and xanthan-wheat starch dispersions respectively. Hence, our results showed that flow properties of RS-LBG dispersions were apparently influenced by the addition of gum and appears to be dependent on its concentration.

Pasting properties starch–gum mixtures

Changes in pasting properties of 5% RS as influenced LBG (0, 0.125–1%) are listed in Table 2. In order to evaluate the characteristics of RS-LBG mix systems, the pasting temperature (PT), peak viscosity (PV), hot paste viscosity (HPV) and cold paste viscosities (CPV) values were obtained from viscograms, the relative break down (PV–HPV/PV) and relative total set back (CPV–HPV)/CPV) were calculated as reported by (Martínez-Cervera et al. 2014). Data presented in Table 2 show that resistant corn starch exhibited very low pasting parameters as compared to the values reported for native type in the literature (Alamri et al. 2013). Since resistance starches are chemically modified so the granular structure is more stabilized as compared to native one, consequently offering more resistance against swelling (Lee et al. 2012) whereas, native waxy starches swell quickly when heated above the gelatinization temperature (Heyman, et al. 2013).

Table 2.

Amylograph pasting properties of starches and starch/LBG mixture

| Samples | Pasting Temp (°C) | Peak Viscosity (cP) | HPV (cP) | CPV (cP) | Breakdown (cP) | Total setback (cP) |

|---|---|---|---|---|---|---|

| 5% RS | 89.3 | 12.73 | 12.24 | 15.65 | 0.49 | 3.41 |

| 5% RS/0.125% LBG | 86.3 | 23.63 | 23.18 | 40.74 | 0.45 | 17.56 |

| 5% RS/0.25% LBG | 86.8 | 24.19 | 23.37 | 36.15 | 0.82 | 12.78 |

| 5% RS/0.50% LBG | 76.6 | 42.56 | 42.08 | 83.99 | 0.48 | 41.91 |

| 5% RS/1% LBG | 68.8 | 115.6 | 114.9 | 335.8 | 0.70 | 220.90 |

Values are average of three determinations (n = 3)

The pasting temperatures (onset of viscosity increase) were slightly shifted to lower values by the addition of LBG. A remarkable rise in paste viscosity of the starch pastes was also found by the addition of LBG, which agreed with previous studies on starch-hydrocolloids interactions (Alamri et al. 2013; Funami et al. 2005). For example, PV of 5% RS dispersions in the presence of LBG increased from 23 to 115 cP (5 times) with an increase in LBG level. These observations show that effect of hydrocolloid on the starch peak viscosity was a function of both the starch used and concentration of the hydrocolloid (Kaur et al. 2008). Furthermore, it has been shown in previous studies that there are many factors including amylose leaching, friction between swollen granules, amount of free water and amylose–lipid complex formation among many others which can affect peak viscosity (Ahmadi-Abhari et al. 2013; Qiu et al. 2015). When samples were heated from 30 to 95 °C, there was a small dip in the viscosity which was followed by constant but slight increase throughout the heating period. This variation in the viscosity was probably due to the resistance of sample during heating. On the other hand, the viscosity was found to be increasing upon cooling, which means that cold paste viscosity was relatively very high in comparison to hot paste.

Viscosity enhancement in RS/LBG mixtures was supposed to arise from starch –hydrocolloids interactions in continuous phase as well as a modification in granule swelling and deformability during gelatinization. This result can be explained presupposing that the RS/LBG system was biphasic with LBG located in the continuous phase. The effective concentration of LBG remarkably increases in the continuous phase because starch granules swell during pasting by soaking up water at high temperatures. The swelling of starch granules results into a decrease in the volume available to hydrocolloid and a spectacular rise in the viscosity of continuous phase which explains thickening ability of LBG compared to leached amylose (Achayuthakan and Suphantharika 2008; Alloncle et al. 1989). Therefore, the addition of gum caused an increase in viscosity reflecting an easy starch swelling process leading to higher viscosity factor.

Similarly, there was an increase in the relative breakdown (RB) which shows that heating caused more structural damage during continuous heating and mechanical shearing, thus reducing the frictions between starch granules which are the main cause of viscosity breakdown. RB values for each RS/LBG blends were significantly (p ≤ 0.05) larger than that for control. There was an increase in setback values with an increasing LBG concentration suggesting an increased tendency aggregate in the continuous phase. This result indicated that the addition of LBG affected the retrogradation of starch by a significant factor during the cooling process (at 50 °C), which can be related to the extent of the increase in viscosity. Some researchers have reported similar results based on a possible association between hydrocolloid molecules in the continuous phase and swollen starch granules (Funami et al. 2008).

Morphological characteristics of starch-gum mixtures

Figure 4 shows the photomicrographic images of resistant corn starch (5% w/w) with and without LBG (0.25–1%), obtained from the confocal scanning microscope. The starch granules alone (without gum addition) appears to be in continuous phase, well separated, angular shaped and fully swollen due to complete hydration based on their respective concentrations (A). Also, swollen starches granules were observed to be larger than those in the RS/LBG mixtures. With the addition of LBG at a critical concentration of 0.25% (w/v), these individual starch particles tend to become closer, forming a weak gel-like network (B). In some sense, at higher concentration of LBG (0.50–1.0%), there is an indication of clumpy structures cross-linked by dense aggregates junction zones, in addition to small evenly dispersed granules (C, D). These RS–LBG blends seemed to be much more compact and to have smaller and fewer pores embedded in a strong and close network compared to control (A). Though, shape, and structure of these clumps seem to be denser and coarser than of those at a lower concentration of gum and/or control but their individual size is reduced. It is well documented that mixing of two polymers (e.g. starch and gum) could result in phase separation and development of two liquid phases; each phase being enriched with one of the two polymers (Flory 1976).

Fig. 4.

CLSM images of RS alone (a) and RS–LBG mixtures containing 0.25% (b), 0.50% (c) and (d) 1% LBG (w/v)

In the present work, as mixing of resistant starch (not gelatinized) into hydrated gum solution was carried out at room temperature (cold mixing) so one should not expect any chemical reactions taking place rather than intermolecular interactions. Recently, Qiu et al. (2015) reported that micrographs of 5% maize starch gels undergo a transition from a fibrillar network of spongy structure to more compact network in the presence of corn fiber gum (0.1–1% w/v). Thus, several factors such as; a possible phase separation and thermodynamic incompatibility of two polymers, high water binding ability of LBG, and possible exclusion and immobilization of water molecules by hydrocolloid could have resulted in the formation of “dense entanglements” of RS/LBG dispersions, which are dependent on LBG concentration.

Conclusion

It is concluded that characteristics of resistant corn starch/LBG mixtures at a various concentration of LBG were highly correlated with most of their rheological and structural properties. Steady-flow and dynamic rheological parameters were strongly influenced by the addition of gum showing a synergistic effect. The varying concentration of LBG promoted the extent of the variations of pasting properties of starch, by the modification in granule swelling and deformability during gelatinization process. Overall, the addition of LBG contributed extensively to the stability of starch-gum mixtures and their physical and structural properties based on added concentration. The results suggested the potential for enlarging the use LBG to modify specifically the structure and texture of processed formulated resistant starch based products (e.g. dough used for baking, sauces, beverages and meat industry). Further investigation should be done in order to understand better locust bean gum role in these systems. It is assumed, that in order to simplify the interpretations for molecular mechanisms, it would be useful to focus on specific factors e.g. locust bean gum concentration (between 0.25 and 0.50%) and preparation methods at certain heating time and temperature. This will be done in a future study by coupling high-pressure treatment, Fourier transfer infrared (FTIR) and particle size analyzer.

Acknowledgements

The authors are gratefully indebted to Natural Sciences and Engineering Research Council of (NSERC) for the fellowship of the first author. The authors also wish to thank Dr. Pramod Pandey and Dr. Maria Briceno for helpful discussions to improve the quality of this paper.

References

- Achayuthakan P, Suphantharika M. Pasting and rheological properties of waxy corn starch as affected by guar gum and xanthan gum. Carbohydr Polym. 2008;71:9–17. doi: 10.1016/j.carbpol.2007.05.006. [DOI] [Google Scholar]

- Ahmadi-Abhari S, Woortman AJJ, Hamer RJ, Loos K. Assessment of the influence of amylose-LPC complexation on the extent of wheat starch digestibility by size-exclusion chromatography. Food Chem. 2013;141:4318–4323. doi: 10.1016/j.foodchem.2013.06.088. [DOI] [PubMed] [Google Scholar]

- Ahmed J, Singh A, Ramaswamy HS, Pandey PK, Raghavan GSV. Effect of high-pressure on calorimetric, rheological and dielectric properties of selected starch dispersions. Carbohydr Polym. 2014;103:12–21. doi: 10.1016/j.carbpol.2013.12.014. [DOI] [PubMed] [Google Scholar]

- Alamri MS, Mohamed AA, Hussain S. Effects of alkaline-soluble okra gum on rheological and thermal properties of systems with wheat or corn starch. Food Hydrocoll. 2013;30:541–551. doi: 10.1016/j.foodhyd.2012.07.003. [DOI] [Google Scholar]

- Alloncle M, Doublier JL. Viscoelastic properties of maize starch/hydrocolloid pastes and gels. Food Hydrocoll. 1991;5:455–467. doi: 10.1016/S0268-005X(09)80104-5. [DOI] [Google Scholar]

- Alloncle M, Lefebvre J, Llamas G, Doublier J. A rheological characterization of cereal starch-galactomannan mixtures. Cereal chem (USA) 1989;66:90–93. [Google Scholar]

- Amini AM, Razavi SMA, Mortazavi SA. Morphological, physicochemical, and viscoelastic properties of sonicated corn starch. Carbohydr Polym. 2015;122:282–292. doi: 10.1016/j.carbpol.2015.01.020. [DOI] [PubMed] [Google Scholar]

- Barak S, Mudgil D. Locust bean gum: processing, properties and food applications-A review. Int J Biol Macromol. 2014;66:74–80. doi: 10.1016/j.ijbiomac.2014.02.017. [DOI] [PubMed] [Google Scholar]

- BeMiller JN. Pasting, paste, and gel properties of starch-hydrocolloid combinations. Carbohydr Polym. 2011;86:386–423. doi: 10.1016/j.carbpol.2011.05.064. [DOI] [Google Scholar]

- Blibech M, Maktouf S, Chaari F, Zouari S, Neifar M, Besbes S, Ellouze-Ghorbel R. Functionality of galactomannan extracted from Tunisian carob seed in bread dough. J Food Sci Technol. 2015;52:423–429. doi: 10.1007/s13197-013-0966-2. [DOI] [Google Scholar]

- Choi HJ, Lee CJ, Cho EJ, Choi SJ, Moon TW. Preparation, digestibility, and glucose response in mice of rice coated with resistant starch type 4 using locust bean gum and agar. Int J Food Sci Technol. 2010;45:2612–2621. doi: 10.1111/j.1365-2621.2010.02434.x. [DOI] [Google Scholar]

- Closs CB, Conde-Petit B, Roberts ID, Tolstoguzov VB, Escher F. Phase separation and rheology of aqueous starch/galactomannan systems. Carbohydr Polym. 1999;39:67–77. doi: 10.1016/S0144-8617(98)00048-4. [DOI] [Google Scholar]

- Cropper SL, Kocaoglu-Vurma NA, Tharp BW, Harper WJ. Effects of locust bean gum and mono-and diglyceride concentrations on particle size and melting rates of ice cream. J Food Sci. 2013;78:811–816. doi: 10.1111/1750-3841.12073. [DOI] [PubMed] [Google Scholar]

- Dogan M, Toker OS, Goksel M. Rheological behavior of instant hot chocolate beverage: Part 1. Optimization of the effect of different starches and gums. Food Biophy. 2011;6:512–518. doi: 10.1007/s11483-011-9233-0. [DOI] [Google Scholar]

- Englyst HN, Macfarlane GT. Breakdown of resistant and readily digestible starch by human gut bacteria. J Sci Food Agric. 1986;37:699–706. doi: 10.1002/jsfa.2740370717. [DOI] [Google Scholar]

- Flory PJ. Spatial configuration of macromolecular chains. Br Polym J. 1976;8:1–10. doi: 10.1002/pi.4980080102. [DOI] [PubMed] [Google Scholar]

- Fuentes-Zaragoza E, Riquelme-Navarrete MJ, Sánchez-Zapata E, Pérez-Álvarez JA. Resistant starch as functional ingredient: a review. Food Res Int. 2010;43:931–942. doi: 10.1016/j.foodres.2010.02.004. [DOI] [Google Scholar]

- Funami T, Kataoka Y, Omoto T, Goto Y, Asai I, Nishinari K. Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll. 2005;19:1–13. doi: 10.1016/j.foodhyd.2004.04.024. [DOI] [Google Scholar]

- Funami T, Kataoka Y, Noda S, Hiroe M, Ishihara S, Asai I, Takahashi R, Inouchi N, Nishinari K. Functions of fenugreek gum with various molecular weights on the gelatinization and retrogradation behaviors of corn starch-2: characterizations of starch and investigations of corn starch/fenugreek gum composite system at a relatively low starch concentration; 5 w/v% Food Hydrocoll. 2008;22:777–787. doi: 10.1016/j.foodhyd.2007.03.004. [DOI] [Google Scholar]

- Heyman B, De Hertogh D, Van Der Meeren P, Depypere F, Dewettinck K. Influence of xanthan transition on the rheological properties of waxy starches. Carbohydr Polym. 2013;96:568–577. doi: 10.1016/j.carbpol.2012.10.077. [DOI] [PubMed] [Google Scholar]

- Kaur L, Singh J, Singh H, McCarthy OJ. Starch–cassia gum interactions: a microstructure—Rheology study. Food Chem. 2008;111:1–10. doi: 10.1016/j.foodchem.2008.03.027. [DOI] [Google Scholar]

- Kaur A, Shevkani K, Singh N, Sharma P, Kaur S. Effect of guar gum and xanthan gum on pasting and noodle-making properties of potato, corn and mung bean starches. J Food Sci Technol. 2015;52:8113–8121. doi: 10.1007/s13197-015-1954-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim WW, Yoo B. Rheological and thermal effects of galactomannan addition to acorn starch paste. LWT Food Sci Technol. 2011;44:759–764. doi: 10.1016/j.lwt.2010.11.009. [DOI] [Google Scholar]

- Kohajdová Z, Karovičová J, Schmidt Š. Significance of emulsifiers and hydrocolloids in bakery industry. Acta Chim Slovaca. 2009;2:46–61. [Google Scholar]

- Lee KY, Yao H, Bae IY, Lee S, Lee HG. Effect of hydrocolloids on the pasting and rheological characteristics of resistant starch (type 4) Food Sci Biotech. 2012;21:769–774. doi: 10.1007/s10068-012-0100-7. [DOI] [Google Scholar]

- Mandala IG, Bayas E. Xanthan effect on swelling, solubility and viscosity of wheat starch dispersions. Food Hydrocoll. 2004;18:191–201. doi: 10.1016/S0268-005X(03)00064-X. [DOI] [Google Scholar]

- Marcotte M, Hoshahili ART, Ramaswamy HS. Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Res Int. 2001;34:695–703. doi: 10.1016/S0963-9969(01)00091-6. [DOI] [Google Scholar]

- Martínez-Cervera S, Salvador A, Sanz T. Comparison of different polyols as total sucrose replacers in muffins: thermal, rheological, texture and acceptability properties. Food Hydrocoll. 2014;35:1–8. doi: 10.1016/j.foodhyd.2013.07.016. [DOI] [Google Scholar]

- Martins JT, Cerqueira MA, Bourbon AI, Pinheiro AC, Souza BWS, Vicente AA. Synergistic effects between κ-carrageenan and locust bean gum on physicochemical properties of edible films made thereof. Food Hydrocoll. 2012;29:280–289. doi: 10.1016/j.foodhyd.2012.03.004. [DOI] [Google Scholar]

- Pan ZL, Ai ZL, Wang T, WangYH Zhang XL. Effect of hydrocolloids on the energy consumption and quality of frozen noodles. J Food Sci Technol. 2016 doi: 10.1007/s13197-016-2217-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ptaszek P. Influence of xanthan gum on viscoelastic retardation processes in starch pastes. Starch/Staerke. 2013;65:483–489. doi: 10.1002/star.201200131. [DOI] [Google Scholar]

- Qiu S, Yadav MP, Chen H, Liu Y, Tatsumi E, Yin L. Effects of corn fiber gum (CFG) on the pasting and thermal behaviors of maize starch. Carbohydr Polym. 2015;115:246–252. doi: 10.1016/j.carbpol.2014.08.071. [DOI] [PubMed] [Google Scholar]

- Sajjan SU, Rao MRR. Effect of hydrocolloids on the rheological properties of wheat starch. Carbohydr Polym. 1987;7:395–402. doi: 10.1016/0144-8617(87)90005-1. [DOI] [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53:1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Techawipharat J, Suphantharika M, BeMiller JN. Effects of cellulose derivatives and carrageenans on the pasting, paste, and gel properties of rice starches. Carbohydr Polym. 2008;73:417–426. doi: 10.1016/j.carbpol.2007.12.019. [DOI] [Google Scholar]

- Vamadevan V, Bertoft E. Structure-function relationships of starch components. Starch/Staerke. 2015;67:55–68. doi: 10.1002/star.201400188. [DOI] [Google Scholar]

- Wu Y, Cui W, Eskin NAM, Goff HD. An investigation of four commercial galactomannans on their emulsion and rheological properties. Food Res Int. 2009;42:1141–1146. doi: 10.1016/j.foodres.2009.05.015. [DOI] [Google Scholar]

- Yamazaki E, Sago T, Kasubuchi Y, Imamura K, Matsuoka T, Kurita O, Nambu H, Matsumura Y. Improvement on the freeze-thaw stability of corn starch gel by the polysaccharide from leaves of Corchorus olitorius L. Carbohydr Polym. 2013;94:555–560. doi: 10.1016/j.carbpol.2013.01.079. [DOI] [PubMed] [Google Scholar]