Abstract

Amorphous solids are ubiquitous among natural and man-made materials. Often used as structural materials for their attractive mechanical properties, their utility depends critically on their response to applied stresses. Processes underlying such mechanical response, and in particular the yielding behaviour of amorphous solids, are not satisfactorily understood. Although studied extensively, observed yielding behaviour can be gradual and depend significantly on conditions of study, making it difficult to convincingly validate existing theoretical descriptions of a sharp yielding transition. Here we employ oscillatory deformation as a reliable probe of the yielding transition. Through extensive computer simulations for a wide range of system sizes, we demonstrate that cyclically deformed model glasses exhibit a sharply defined yielding transition with characteristics that are independent of preparation history. In contrast to prevailing expectations, the statistics of avalanches reveals no signature of the impending transition, but exhibit dramatic, qualitative, changes in character across the transition.

The onset of yielding can be difficult to define unambiguously for amorphous materials. Here the authors undertake computer simulations of model glasses of varying system sizes and show that, under oscillatory shear, they exhibit a sharp transition independent of preparation history.

The mechanical response to applied stresses or deformation is a basic material characteristic of solids, both crystalline and amorphous. Whereas the response to small perturbations are described by elastic moduli, the plastic, irreversible, response to large deformation1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16 is often more important to characterize, as it determines many material parameters such as strength and ductility, and is also of relevance to thermomechanical processing of metallic glasses17. Amorphous solids lack the translational symmetry of crystals, and thus no obvious analogs to dislocation defects in terms of which plasticity in crystals has been sought to be understood. Based on work over the last decades, it is appreciated that plasticity arises in amorphous solids through spatially localized reorganizations1,2,18, termed shear transformation zones, and that such localized zones interact with each other through long ranged elastic strains they induce19. While many details of the nature of these localized regions of non-affine displacements remain to be worked out, they form the basis of analyses and models of elasto-plasticity and yielding7,15,19,20,21. In addition to extensive experimental and theoretical investigations, computer simulations of atomistic models of glasses have also been employed, to eludictate key features of plastic response1,2,4 on atomic scales. While several studies have been conducted at finite shear rates (for example,13,15), many studies have focussed on behaviour in the athermal, quasi-static (AQS)4,6,7,16,22 limit, wherein the model glasses studied remain in zero temperature, local energy minimum, configurations as they are sheared quasi-statically. The AQS protocol represents a limit in which the deformation behaviour of the solids does not depend crucially on thermally induced processes, and relaxation processes are expected to occur on time scales much faster than the shear rate. Thus, results from AQS may be expected to be useful in understanding the behaviour of glasses sufficiently below the glass transition, and for small shear rates. Both these conditions may be expected to be satisfied in the context of understanding the mechanical failure of glasses. Such deformation induces discontinuous drops in energy and stress with corresponding nonaffine displacements that are highly spatially correlated, and exhibit power law distributions in size. In analogy with similar avalanches that arise in diverse context of intermittent response in disordered systems, from earthquakes, crackling noise in magnetic systems, depinning of interfaces in a disorded medium and so on23, a theoretical description of mechanical failure in amorphous solids5, predicts the mean avalanche size to diverge as a critical stress is approached from below, leading to a power law distribution with a diverging mean size at and above the transition. Indeed, it has been observed that (for example,6,15,22) system spanning avalanches are present in the steady state beyond yield, whose sizes scale with system size. The character of avalanches upon approaching the yielding transition, however, has not received much attention, as also the differences between pre- and post-yield avalanches. Among the reasons is the sample to sample variability of behaviour below yield, in contrast with the universal behaviour seen in the post-yield regime.

Here we show that oscillatory deformation offers a robust approach to systematically probe behaviour above and below a sharply defined point of mechanical failure, which we associate with yielding. As our results pertain to oscillatory deformation in the limit of vanishing shear rate, we caution that comparisons with uniform shear at finite rates must be made with due care. Oscillatory deformation is a widely used experimental technique12,24,25,26,27,28,29 as well as a common protocol in materials testing. However, it has not been employed widely in computational investigations, barring some recent work14,30,31,32, to probe yielding in amorphous solids. In the present work, we perform an extensive computational study of plastic response in a model glass former, over a wide range of system sizes, and amplitudes of deformation that straddle the yielding strain.

Results

Simulations

We study the Kob-Andersen 80:20 binary mixture Lennard-Jones glasses for a range of system sizes (see Methods for details). The glasses studied are prepared by performing a local energy minimization of equilibrated liquid configurations, at a reduced temperatures T=1 and T=0.466. The inherent structures so obtained represent poorly annealed (T=1) and well annealed (T=0.466) glasses. These glasses, referred to by the corresponding liquid temperature in what follows, are subjected to volume preserving shear deformation through the AQS protocol, wherein the strain γxz is incremented in small steps, with each step being followed by energy minimization. The strain is incremented in the same direction in the case of uniform strain, whereas for oscillatory strain for a given maximum amplitude γmax, a cycle of strain 0→γmax→0→−γmax→0 is applied repeatedly over many cycles, until a steady state is reached. Results presented below, except Fig. 1d are from analysing steady state configurations. Further details concerning the simulations and analysis are presented in Methods and Supplementary Figs 1–11.

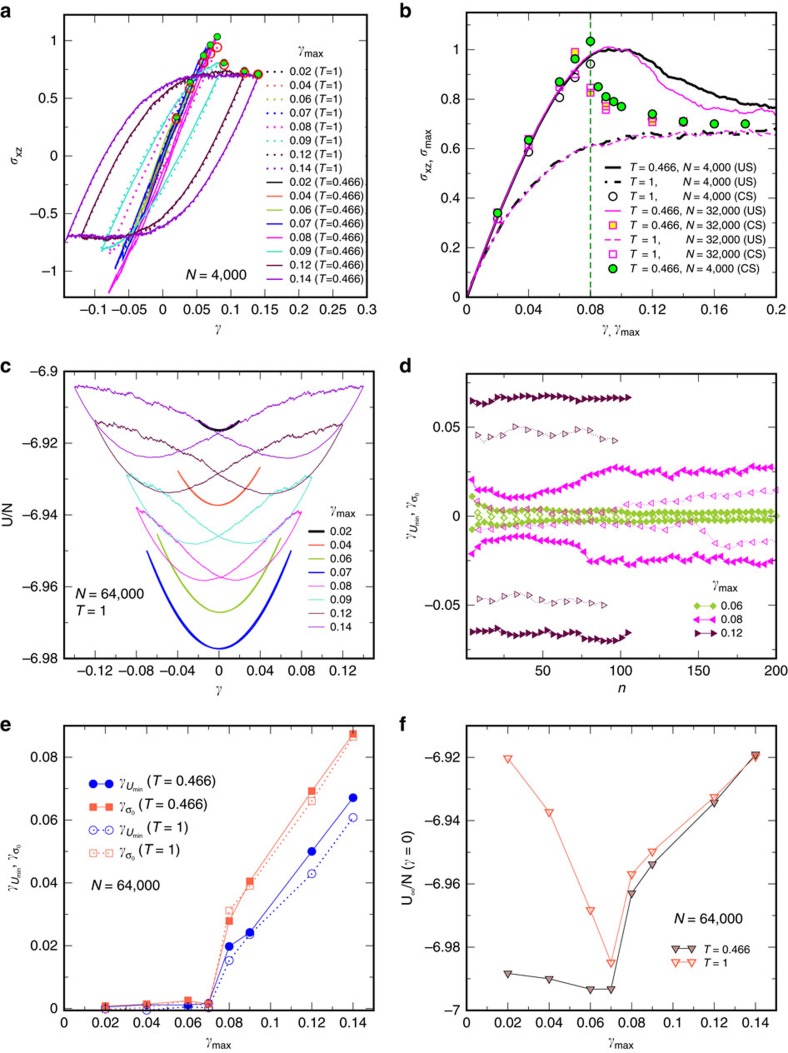

Figure 1. Stress and energy across the yielding transition.

(a) Stress–strain plots of the two differently annealed glasses for various strain amplitudes in the steady states of oscillatory shear deformation. Maximum stress in the cycle for each amplitude is marked by filled and open circles for T=0.466 and T=1, respectively. (b) Averaged stress–strain curves for uniform strain (US) are shown as lines—thick (black) for N=4,000 and thin (magenta) for N=32,000 while solid and dashed lines represent T=0.466 and T=1, respectively. Maximum stress σmax versus γmax are shown for cyclic strain (CS) (circle and square denote N=4,000 and 32,000, respectively, with filled and open symbols corresponding to glasses from T=0.466 and T=1). The vertical line at γmax=0.08 indicates the sharp yielding transition seen. (c) Energy versus strain in the steady states, displaying a bifurcation in the strain corresponding to minima in energy at the yielding transition between γmax=0.07 and 0.08. (d) Strain values corresponding to energy minima (γUmin) and and zero stress  are shown as open and filled symbols respectively, versus the number of cycles for different γmax. For γmax=0.08 an initial relaxation towards zero is reversed as the system evolves to a yielded steady state with finite γUmin and

are shown as open and filled symbols respectively, versus the number of cycles for different γmax. For γmax=0.08 an initial relaxation towards zero is reversed as the system evolves to a yielded steady state with finite γUmin and  . (e) γUmin and

. (e) γUmin and  as functions of strain amplitude γmax, displaying a transition beyond γmax=0.07. (f) Asymptotic energy per particle at γ=0 versus strain amplitude γmax. Energies decrease with γmax until the yield strain is reached, after which they increase with γmax.

as functions of strain amplitude γmax, displaying a transition beyond γmax=0.07. (f) Asymptotic energy per particle at γ=0 versus strain amplitude γmax. Energies decrease with γmax until the yield strain is reached, after which they increase with γmax.

Yielding transition

Previous work30 has shown that as the amplitude of strain γmax approaches a critical value γy from either side, the number of cycles needed to reach the steady state becomes increasingly large, with an apparent divergence at γy (Supplementary Fig. 1). We identify γy (∼0.07) as the yield strain, as justified below. In Fig. 1a we show the averaged stress–strain curves for N=4,000. For each γmax, we obtain a maximum stress σmax reached at γ=γmax, which are plotted in Fig. 1b for T=1, 0.466, for N=4,000, 32,000. Figure 1b also shows the stress–strain curves for the same cases obtained with uniform strain. Whereas stresses vary smoothly for uniform strain, with no sharp signature of the onset of yielding, and differ significantly for T=1 and T=0.466, they display a sharp, discontinuous, drop above γmax=0.07 (0.08 for N=4,000) for oscillatory strain. Interestingly, below γy, the maximum stress increases as a result of oscillatory deformation, indicative of hardening, consistently with previous results33. Above γy, repeated oscillatory deformation leads to a stress drop relative to values just below γy, indicating yielding.

Figure 1c displays the potential energies obtained over a full cycle in the steady state (Supplementary Fig. 2). For γmax<γy, the energies display a single minimum close to γ=0, but above, bifurcate into two minima, indicating the emergence of plasticity. The stress–strain curves show a corresponding emergence of loops (Fig. 1a) with finite area. Strain values at the minima for energy, γUmin and σxz=0,  (see Supplementary Fig. 3), are shown in Fig. 1d as a function of the number of cycles for different γmax. We note that γmax=0.08 displays interesting non-monotonic behaviour, with an initial decrease in these strain values, similar to smaller γmax, but an eventual increase to larger strains, similar to the case γmax=0.12, in the yielded regime. Figure 1e shows γUmin and

(see Supplementary Fig. 3), are shown in Fig. 1d as a function of the number of cycles for different γmax. We note that γmax=0.08 displays interesting non-monotonic behaviour, with an initial decrease in these strain values, similar to smaller γmax, but an eventual increase to larger strains, similar to the case γmax=0.12, in the yielded regime. Figure 1e shows γUmin and  versus γmax, which show an apparently continuous departure from nearly zero, signalling a transition at

versus γmax, which show an apparently continuous departure from nearly zero, signalling a transition at  . Figure 1f shows that the minimum energies in the steady state versus γmax decrease with increasing γmax below γy, but increase above, reaching the same values for T=1 and T=0.466. These data demonstrate the presence of a sharp transition between a low strain regime where oscillatory shear produces better annealed, hardened, glasses to a yielded regime displaying stress relaxation and rejuvenation.

. Figure 1f shows that the minimum energies in the steady state versus γmax decrease with increasing γmax below γy, but increase above, reaching the same values for T=1 and T=0.466. These data demonstrate the presence of a sharp transition between a low strain regime where oscillatory shear produces better annealed, hardened, glasses to a yielded regime displaying stress relaxation and rejuvenation.

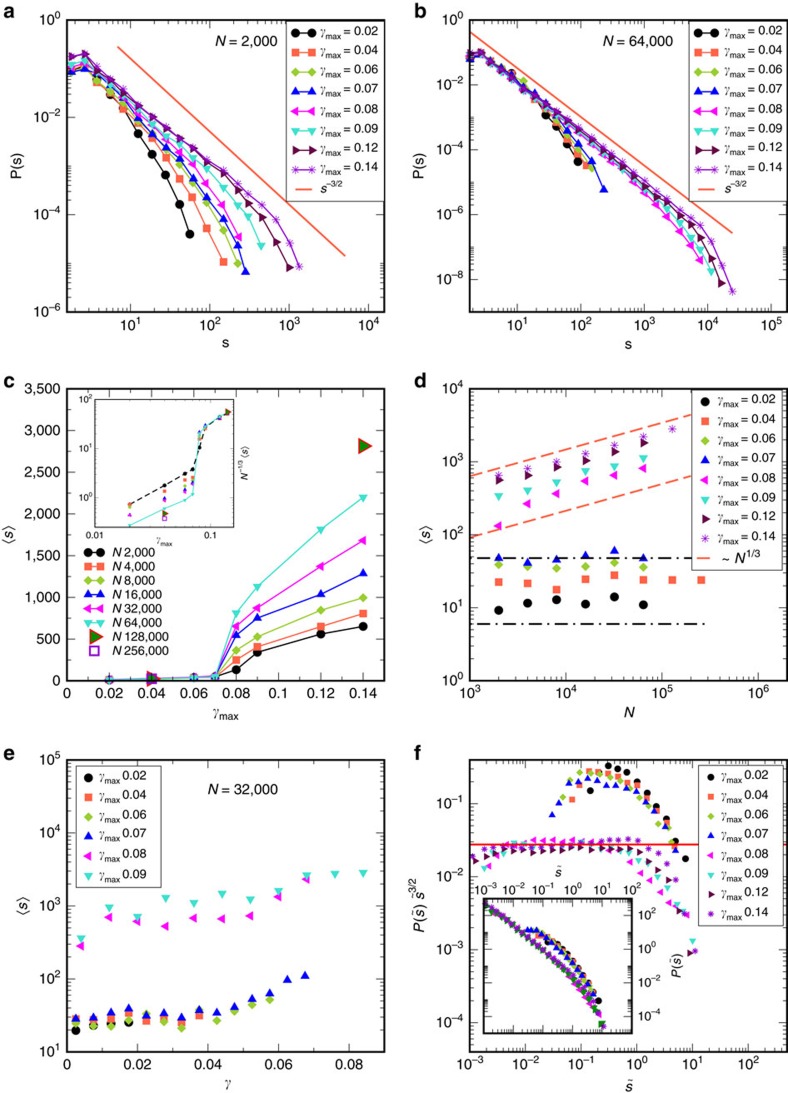

Statistics of avalanche sizes

We next study (i) distribution of avalanche sizes, which we compute as the size of clusters of particles that undergo plastic rearrangements (see Methods for how they are identified), and (ii) distributions of the size of energy drops. In Fig. 2a we show the distributions P(s) of avalanche sizes s for N=2,000, which display a characteristic power law decay with a cutoff. Although the cutoffs move to larger values as γmax increases, we see no indication of a transition. To assess the role of system sizes, we compute the avalanche sizes for a variety of system sizes. Figure 2b shows the avalanche size distribution for N=64,000. The distributions fall into two clear sets, corresponding to γmax above and below γy. We compute and display in Fig. 2c the mean avalanche size  as a function of γmax, for all studied system sizes. The striking observation is that below γy,

as a function of γmax, for all studied system sizes. The striking observation is that below γy,  displays no system size dependence, and only a very mild dependence on γmax, and no indication of the approach to γy. Above γy, a clear system size dependence is seen. Figure 2d shows the same data versus system size, revealing a roughly N1/3 (or

displays no system size dependence, and only a very mild dependence on γmax, and no indication of the approach to γy. Above γy, a clear system size dependence is seen. Figure 2d shows the same data versus system size, revealing a roughly N1/3 (or  ) dependence above γy, and minimal N dependence below. The N1/3 dependence is consistent with previous results6,34 for mean energy drops, but the absence of system size dependence below, to our knowledge, has not been demonstrated before. We next ask whether the mean size of avalanches, for a given γmax depend on the strain γ at which they appear, and conversely, for a given γ what the dependence on γmax is. As shown in Fig. 2e (N=32,000, T=1), for a given γmax the γ dependence is weak and is the same for γmax<γy (and γmax>γy), but the data fall into distinct groups for γmax<γy and γmax>γy. The same pattern is seen for the full distributions (Supplementary Fig. 5). For a given γmax, the avalanche distributions can be collapsed on to a master curve by scaling s by

) dependence above γy, and minimal N dependence below. The N1/3 dependence is consistent with previous results6,34 for mean energy drops, but the absence of system size dependence below, to our knowledge, has not been demonstrated before. We next ask whether the mean size of avalanches, for a given γmax depend on the strain γ at which they appear, and conversely, for a given γ what the dependence on γmax is. As shown in Fig. 2e (N=32,000, T=1), for a given γmax the γ dependence is weak and is the same for γmax<γy (and γmax>γy), but the data fall into distinct groups for γmax<γy and γmax>γy. The same pattern is seen for the full distributions (Supplementary Fig. 5). For a given γmax, the avalanche distributions can be collapsed on to a master curve by scaling s by  (data not shown). The distributions of scaled sizes

(data not shown). The distributions of scaled sizes  , averaged over system size are shown in the inset of Fig. 2f. The same data are shown, multiplied by

, averaged over system size are shown in the inset of Fig. 2f. The same data are shown, multiplied by  in the main panel, and demonstrate that the character of the distributions are different above and below yield: whereas above γy one finds a range of sizes over which the power law form

in the main panel, and demonstrate that the character of the distributions are different above and below yield: whereas above γy one finds a range of sizes over which the power law form  is clearly valid (and thus the cutoff arises purely because of system size), below γy this is not the case, and the qualitative shape of the distributions is different (with a cutoff function multiplying the power law)5,8,14,35.

is clearly valid (and thus the cutoff arises purely because of system size), below γy this is not the case, and the qualitative shape of the distributions is different (with a cutoff function multiplying the power law)5,8,14,35.

Figure 2. Statistics of avalanches as a function of strain amplitude γmax and system size N.

(a) Cluster size distributions for N=2,000 displaying a power law with a cutoff that grows with γmax but does not indicate sharp changes at yielding. (b) Cluster size distribution for N=64,000 displaying a sharp increase in the cutoff size across the yielding transition. The line in both panels corresponds to a power law with exponent −3/2. (c) Mean cluster size versus γmax showing a qualitative change across the yielding transition, with strong system size dependence above γy. The inset shows the mean cluster size scaled with N1/3, which describes well the size dependence above γy. (d) Mean cluster size versus system size N shows no significant size dependence for γmax<γy but a clear N1/3 dependence above. A crossover in behaviour is seen for γmax=0.08. Lines, with N0 (constant) and N1/3 dependence, are guides to the eye. (e) Mean cluster sizes for bins in strain γ for different γmax for N=32,000. Mean cluster size does not depend on γmax, and depends only mildly on strain γ, for two distinct sets, below and above yield strain γy. (f) Scaled cluster size  distributions exhibit data collapse separately for γmax<γy and γmax>γy (inset). Distributions for γmax<γy do not display a power law regime, whereas γmax>γy do, over about two decades in

distributions exhibit data collapse separately for γmax<γy and γmax>γy (inset). Distributions for γmax<γy do not display a power law regime, whereas γmax>γy do, over about two decades in  , as highlighted in a plot of

, as highlighted in a plot of  versus

versus  . Data shown are for T=1, and averages are over the full cycle, except for (e) which are averaged over the first quadrant.

. Data shown are for T=1, and averages are over the full cycle, except for (e) which are averaged over the first quadrant.

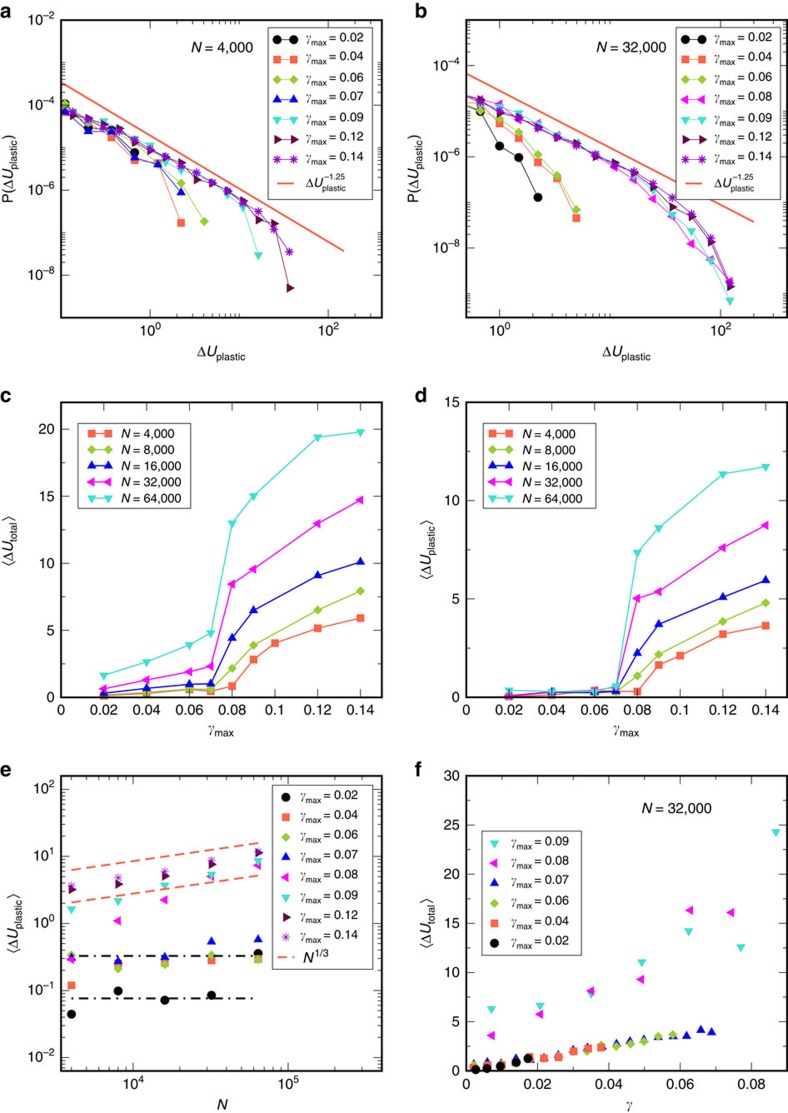

We now discuss the distributions of energy drops. Shown for N=4,000 and 32,000 in Fig. 3a,b, these distributions show the same features as the avalanche sizes, but with a different power law exponent of ∼1.25 (as found in ref. 15). Thus, the exponent depends on the quantity employed, and the avalanche size based on particle displacements is in closer agreement with mean field predictions. In Fig. 3c, we show the γmax dependence of the mean energy drop, for different system sizes, which reveal the same pattern as the avalanche sizes, albeit with a stronger apparent size dependence below yield. However, the total energy drops for the whole system include also an elastic component, in addition to the plastic component. The component of the energy drop corresponding to the plastic regions alone, which are plotted in Fig. 3d, to demonstrate that the plastic component has no system size dependence below yield. Figure 3e shows the system size dependence of the mean energy drop (plastic component), and Fig. 3f shows the mean energy drop versus γ for different γmax (N=64,000, T=1), revealing the same separation below and above yield as the avalanche sizes. This is in contrast with the case of uniform shear, wherein both energy drops and avalanche sizes show a gradual, and strongly sample dependent, variation with strain (Supplementary Figs 6–9).

Figure 3. Statistics of energy drops as a function of strain amplitude γmax and system size N.

Distributions of energy drops (a) for N=4,000 show no clear separation of γmax<γy and γmax>γy, whereas (b) for N=32,000 a clear separation is visible. In both cases, a power law regime is apparent, with exponent ∼1.25. (c) Mean energy drops versus γmax, indicating a sharp change at γy. (d) Mean energy drops considering only plastic regions show no system size dependence below γy. (e) Mean energy drop (plastic component) versus system size N shows no significant size dependence for γmax<γy but a clear N1/3 dependence above. A crossover in behaviour is seen for γmax=0.08. Lines, with N0 (constant) and N1/3 dependence, are guides to the eye. (f) Mean energy drops (total) for bins in strain γ for different γmax for N=32,000, T=1 showing no dependence on γmax, and only a mild dependence on strain γ, for two distinct sets, below and above yield strain γy. Data shown are for T=1, and averages are over the first quadrant.

Spatial structure of avalanches

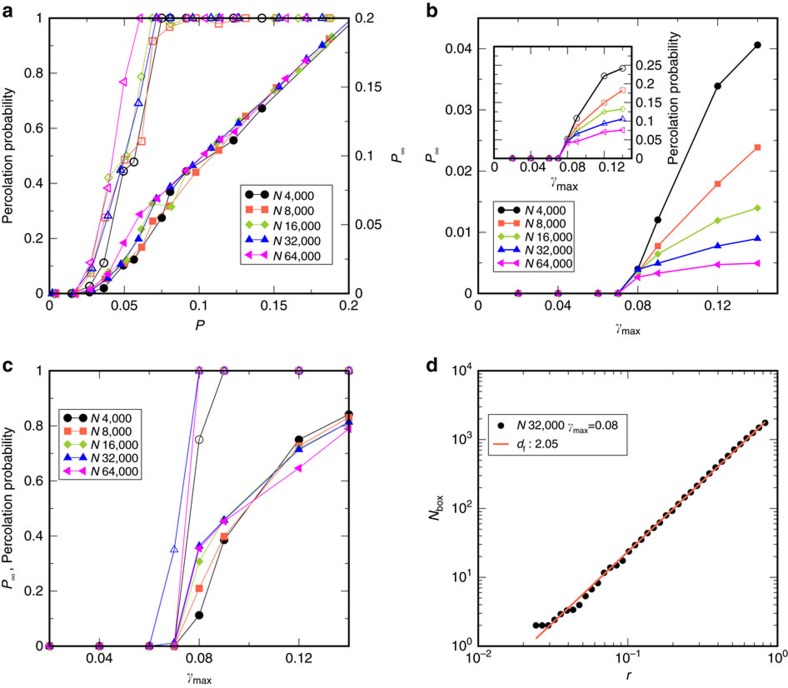

Finally, we analyse the spatial structure of the avalanches briefly, by studying (i) the percolation, and (ii) fractal dimension, of the avalanches. Below γy, none of the avalanches percolate, whereas above, a finite fraction does so. Figure 4a shows the weight of the spanning cluster P∞, and percolation probability PP averaged over bins in ‘probability' P, obtained from the fraction of displaced particles, (see Methods) for different system sizes for γmax=0.08, indicating a percolation transition at  . However, the threshold is system size dependent, and thus merits further investigation. In Fig. 4b, P∞ and PP averaged over all considered events are shown as a function of γmax. The percolation probability does not become 1, a result of considering all the drop events. To address this artefact we analyse the cumulative set of all particles displaced in any of the events. The P∞ and PP values shown in Fig. 4c indicate that above γy, this cumulative set always percolates and the weight P∞ is comparable for different system sizes. However, P∞ at the smallest γmax above γy appears to increase with system size, suggesting a discontinuous change across γy. The variation of P with γmax in either method also shows an apparently discontinuous behaviour across γy (Supplementary Fig. 10).

. However, the threshold is system size dependent, and thus merits further investigation. In Fig. 4b, P∞ and PP averaged over all considered events are shown as a function of γmax. The percolation probability does not become 1, a result of considering all the drop events. To address this artefact we analyse the cumulative set of all particles displaced in any of the events. The P∞ and PP values shown in Fig. 4c indicate that above γy, this cumulative set always percolates and the weight P∞ is comparable for different system sizes. However, P∞ at the smallest γmax above γy appears to increase with system size, suggesting a discontinuous change across γy. The variation of P with γmax in either method also shows an apparently discontinuous behaviour across γy (Supplementary Fig. 10).

Figure 4. Percolation of avalanches and fractal dimension of percolating clusters.

(a) Percolation probability and weight of the spanning cluster P∞ shown as open and filled symbols, respectively, against the occupation number P for different system sizes, considering all events, for γmax=0.08. A percolation transition takes place for P≃0.05 although the threshold is system size dependent. (b) Percolation probability (inset) and P∞ averaged over all events, versus γmax. (c) Percolation probability and P∞ for the cumulative set of particles rearranging over a cycle, shown as open and filled symbols respectively versus γmax, indicating a percolation transition at the yielding strain γy. P∞ just above the transition increases with system size. (d) Fractal dimension estimation from box counting. A log-log plot of the number of occupied boxes (Nbox) is shown versus the magnification r. The slope results in an estimated fractal dimension df=2.05. Data shown are for T=1, and averages are over the first quadrant.

We compute the fractal dimension of the spanning clusters using the box counting method (see Methods). Figure 4d shows a log-log plot of the occupied boxes versus magnification r (the largest r corresponds to the smallest box size, of 1.1σAA) for γmax=0.08, N=32,000. We find a fractal dimension of df=2.05, close to 2, which appears consistent with the possibility that yield events are quasi-two dimensional. We find a fractal dimension of df=2.05, close to 2, which is in consistent with the appearance of shear bands above the transition which are quasi-two dimensional (Supplementary Fig. 11). However, based on the system size dependence of the mean cluster size, the fractal dimension deduced is df∼1 (ref. 15), which is at odds with the result here, and requires further investigation for it to be properly understood.

Discussion

The results that we have discussed demonstrate that a sharp yielding transition is revealed through oscillatory deformation of model glasses. The character of the avalanches is qualitatively different across the transition, being localized below the transition, and becoming extended above. Contrary to theoretical expectations for uniform deformation, the mean size of the avalanches does not diverge upon approaching the yielding transition, and prompts theoretical investigation, including development of suitable elasto-plastic models, of yielding under oscillatory deformation36. A signature of yielding is instead revealed by the progressive sluggishness of annealing behaviour as the transition is approached. Both the avalanche statistics and percolation characteristics suggest a discontinuous yielding transition, which may be consistent with the suggestion that yielding is a first order transition12,16,37, but a comprehensive characterization of the nature of the transition requires further investigation. Finally, our results reveal systematic, non-trivial annealing behaviour of the glasses near the yielding transition, which we believe are of relevance to thermomechanical processing of metallic glasses. In particular, processing near the yielding transition, both above and below, may lead to significant change of properties, which may be utilized according to specific design goals.

Methods

Model

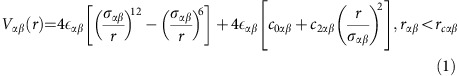

The model system we study is the Kob-Andersen binary (80:20) mixtures of Lennard Jones particles. The interaction potential is truncated at a cutoff distance of rcαβ=2.5σαβ such that both the potential and the force smoothly go to zero as given by

|

where α, β∈{A, B} and the parameters  ,

,  , σAB/σAA=0.80, σBB/σAA=0.88. Energy and length are in the units of

, σAB/σAA=0.80, σBB/σAA=0.88. Energy and length are in the units of  and σAA, respectively, and likewise, reduced units are used for other quantities. The correction terms c0αβ, c2αβ are evaluated with the conditions that the potential and its derivative at rcαβ must vanish at the cutoff.

and σAA, respectively, and likewise, reduced units are used for other quantities. The correction terms c0αβ, c2αβ are evaluated with the conditions that the potential and its derivative at rcαβ must vanish at the cutoff.

Initial glass configurations

The initial liquid samples are equilibrated at two temperatures, T=0.466 and T=1 using the Nosé Hoover thermostat, at reduced density ρ=1.2. Independent samples are generated for each temperature and system size by further evolving the equilibrated liquid configurations by performing the molecular dynamics simulations of constant energy, which are separated by the structural relaxation time (τα) obtained from the self intermediate scattering function (Fs(k, t)). For the uniform shearing data, we have atleast 100 samples for all the system sizes. The avalanche data shown for cyclic shearing are for at least 20 samples for N≤32,000, and 10 samples for larger systems. All the simulations are carried out using LAMMPS38.

Simulation details

Shear deformation of the model amorphous solids is done employing athermal-quasi static (AQS) simulations which consist of two steps. An affine transformation of coordinates x′=x+dγ × z; y′=y; z′=z is imposed, subsequently followed by an energy minimization using the conjugate-gradient method with Lees-Edwards periodic boundary conditions. Strain steps of dγ=2 × 10−4 are used throughout, except for N=256,000 for which dγ=5 × 10−4. Initial configurations are the inherent structures (local energy minima) of equilibrated liquid samples. Potential energy and mean square displacements are computed at γ=0 as functions of cycles to ascertain that steady states are reached, wherein the coordinates of particles, and properties such as the potential energy U and shear stress σxz remain (below yield strain) unchanged at the end of each cycle, or (above yield strain) become statistically unchanged upon straining further, and exhibit diffusive motion as a function of the number of cycles. Steady states for strain amplitudes of γmax=0.02, 0.04, 0.06, 0.07, 0.08 0.09, 0.12, 0.14 are studied for system sizes N=2,000, 4,000, 8,000, 16,000, 32,000 and 64,000. To further probe finite size effects, we have consider amplitude below the yield transition at γmax=0.04 for N=128,000 and 256,000 and γmax=0.14 for N=128,000.

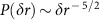

Identifying avalanches

In the steady state, we compute the potential energy per particle and stress for each strain step. Plastic events result in discontinuous energy and stress drops. A parameter κ= (ref. 34) exceeding a value of 100 is used to identify plastic events, where δU is the change in energy during minimization after a strain step. Avalanche sizes based on the magnitude of energy drops and the cluster sizes of ‘active' particles (that undergo plastic displacements) are both computed. Particles are considered active if they are displaced by more than 0.1σAA. The choice of this cutoff is based on considering the distribution of single particle displacements δr, which are expected to vary as a power law

(ref. 34) exceeding a value of 100 is used to identify plastic events, where δU is the change in energy during minimization after a strain step. Avalanche sizes based on the magnitude of energy drops and the cluster sizes of ‘active' particles (that undergo plastic displacements) are both computed. Particles are considered active if they are displaced by more than 0.1σAA. The choice of this cutoff is based on considering the distribution of single particle displacements δr, which are expected to vary as a power law  for elastic displacements around a plastic core, but display an exponential tail corresponding to plastic rearrangements (see, for example, ref. 30). The separation is clear cut only for small γmax, and we choose the smallest cutoff value (observed for γmax=0.02) so that plastic rearrangements at all γmax are considered. In performing cluster analysis, two active particles are considered to belong to the same cluster if they are separated by <1.4σAA (first coordination shell). The normalized histogram of cluster sizes P(s) is obtained from statistics for all the events. The mean cluster size is computed from the distributions as

for elastic displacements around a plastic core, but display an exponential tail corresponding to plastic rearrangements (see, for example, ref. 30). The separation is clear cut only for small γmax, and we choose the smallest cutoff value (observed for γmax=0.02) so that plastic rearrangements at all γmax are considered. In performing cluster analysis, two active particles are considered to belong to the same cluster if they are separated by <1.4σAA (first coordination shell). The normalized histogram of cluster sizes P(s) is obtained from statistics for all the events. The mean cluster size is computed from the distributions as  (Supplementary Fig. 4).

(Supplementary Fig. 4).

Percolation analysis

For the percolation analysis, we consider all the plastic events in the first quadrant of the cycle (γ from 0 to γmax), and compute the ‘probability' P from the fraction of particles that undergo plastic displacement, and the weight of the spanning cluster P∞, from the fraction of particles that belong to the spanning cluster (P∞=0 if there is no spanning cluster). The percolation probability PP=1 if a spanning cluster is present and 0 otherwise.

Fractal dimension

To obtain the fractal dimension of percolating clusters, we employ the method of box counting. The simulation volume is divided into boxes of a specified mesh size, and the number of boxes that contain a part of the cluster, Nbox, is counted. This is repeated for a series of mesh sizes, and the fractal dimension is obtained as the slope  where r is the inverse of mesh size.

where r is the inverse of mesh size.

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

Additional information

How to cite this article: Leishangthem, P. et al. The yielding transition in amorphous solids under oscillatory shear deformation. Nat. Commun. 8, 14653 doi: 10.1038/ncomms14653 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Material

Supplementary Figures and Supplementary References

Acknowledgments

We wish to thank J.L. Barrat, P. Chaudhuri, M. Falk, G. Foffi, A.L. Greer, J. Horbach, I. Procaccia, M. Robbins, A. Rosso and M. Wyart for useful discussions. We wish to specially thank H.A. Vinutha for discussions and help regarding computations reported here. We gratefully acknowledge TUE-CMS and SSL, JNCASR, Bengaluru for computational resources and support.

Footnotes

The authors declare no competing financial interests.

Author contributions S.S. conceived the project and supervised the research. P.L. and A.D.S.P. performed the simulations and data analysis. P.L., A.D.S.P. and S.S. analysed and interpreted the results, and wrote the paper.

References

- Falk M. L. & Langer J. Deformation and failure of amorphous, solidlike materials. Annu. Rev. Condens. Matter Phys. 2, 353–373 (2011). [Google Scholar]

- Barrat J. L. & Lemaître A. in Dynamical heterogeneities in Glasses, Colloids, and Granular Media (eds Berthier L., Biroli G., Bouchaud J. P., Cipelletti L., Saarloos W. V. ) Ch. 8 264–297Oxford Science Publications (2011). [Google Scholar]

- Hébraud P. & Lequeux F. Mode-coupling theory for the pasty rheology of soft glassy materials. Phys. Rev. Lett. 81, 2934–2937 (1998). [Google Scholar]

- Maloney C. E. & Lemaître A. Amorphous systems in athermal, quasistatic shear. Phys. Rev. E 74, 016118 (2006). [DOI] [PubMed] [Google Scholar]

- Dahmen K. A., Ben-Zion Y. & Uhl J. T. Micromechanical model for deformation in solids with universal predictions for stress-strain curves and slip avalanches. Phys. Rev. Lett. 102, 175501 (2009). [DOI] [PubMed] [Google Scholar]

- Karmakar S., Lerner E. & Procaccia I. Statistical physics of the yielding transition in amorphous solids. Phys. Rev. E 82, 055103 (2010). [DOI] [PubMed] [Google Scholar]

- Dasgupta R., Hentschel H. G. E. & Procaccia I. Microscopic mechanism of shear bands in amorphous solids. Phys. Rev. Lett. 109, 255502 (2012). [DOI] [PubMed] [Google Scholar]

- Lin J., Lerner E., Rosso A. & Wyart M. Scaling description of the yielding transition in soft amorphous solids at zero temperature. Proc. Natl Acad. Sci. USA 111, 14382–14387 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Keim N. C. & Arratia P. E. Yielding and microstructure in a 2d jammed material under shear deformation. Soft Matter 9, 6222–6225 (2013). [Google Scholar]

- Knowlton E. D., Pine D. J. & Cipelletti L. A microscopic view of the yielding transition in concentrated emulsions. Soft Matter 10, 6931–6940 (2014). [DOI] [PubMed] [Google Scholar]

- Hima Nagamanasa K., Gokhale S., Sood A. K. & Ganapathy R. Experimental signatures of a nonequilibrium phase transition governing the yielding of a soft glass. Phys. Rev. E 89, 062308 (2014). [DOI] [PubMed] [Google Scholar]

- Denisov D. V. et al. Sharp symmetry-change marks the mechanical failure transition of glasses. Sci. Rep. 5, 14359 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shrivastav G. P., Chaudhuri P. & Horbach J. Yielding of glass under shear: a directed percolation transition precedes shear-band formation. Phys. Rev. E 94, 042605 (2016). [DOI] [PubMed] [Google Scholar]

- Regev I., Weber J., Reichhardt C., Dahmen K. A. & Lookman T. Reversibility and criticality in amorphous solids. Nat. Commun. 6, 8805 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu C., Ferrero E. E., Puosi F., Barrat J.-L. & Martens K. Driving rate dependence of avalanche statistics and shapes at the yielding transition. Phys. Rev. Lett. 116, 065501 (2016). [DOI] [PubMed] [Google Scholar]

- Jaiswal P. K., Procaccia I., Rainone C. & Singh M. Mechanical yield in amorphous solids: a first-order phase transition. Phys. Rev. Lett. 116, 085501 (2016). [DOI] [PubMed] [Google Scholar]

- Sun Y., Concustell A. & Greer A. L. Thermomechanical processing of metallic glasses: extending the range of the glassy state. Nat. Rev. Mater. 1, 16039 (2016). [Google Scholar]

- Argon A. Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 (1979). [Google Scholar]

- Picard G., Ajdari A., Lequeux F. & Bocquet L. Elastic consequences of a single plastic event: a step towards the microscopic modeling of the flow of yield stress fluids. Eur. Phys. J. E 15, 371–381 (2004). [DOI] [PubMed] [Google Scholar]

- Talamali M., Petäjä V., Vandembroucq D. & Roux S. Strain localization and anisotropic correlations in a mesoscopic model of amorphous plasticity. C. R. Mécanique 340, 275–288 (2012). [Google Scholar]

- Ganguli S., Horbach J., Sollich P., Karmakar S. & Sengupta S. Amorphization of a crystalline solid by plastic deformation. preprint at https://arxiv.org/abs/1603.05092 (2016).

- Salerno K. M. & Robbins M. O. Effect of inertia on sheared disordered solids: critical scaling of avalanches in two and three dimensions. Phys. Rev. E 88, 062206 (2013). [DOI] [PubMed] [Google Scholar]

- Sethna J. P., Dahmen K. A. & Myers C. R. Crackling noise. Nature 410, 242–250 (2001). [DOI] [PubMed] [Google Scholar]

- Rogers S. A., Erwin B. M., Vlassopoulos D. & Cloitre M. A sequence of physical processes determined and quantified in LAOS: application to a yield stress fluid. J. Rheol. 55, 435–458 (2011). [Google Scholar]

- Koumakis N., Brady J. & Petekidis G. Complex oscillatory yielding of model hard-sphere glasses. Phys. Rev. Lett. 110, 178301 (2013). [DOI] [PubMed] [Google Scholar]

- Gibaud T., Perge C., Lindström S. B., Taberlet N. & Manneville S. Multiple yielding processes in a colloidal gel under large amplitude oscillatory stress. Soft Matter 12, 1701–1712 (2016). [DOI] [PubMed] [Google Scholar]

- Jeanneret R. & Bartolo D. Geometrically protected reversibility in hydrodynamic loschmidt-echo experiments. Nat. Commun. 5, 3474 (2014). [DOI] [PubMed] [Google Scholar]

- Ali S. & Bandyopadhyay R. Effect of electrolytes on the microstructure and yielding of aqueous dispersions of colloidal clay. Soft Matter 12, 414–421 (2016). [DOI] [PubMed] [Google Scholar]

- Laurati M., Egelhaaf S. & Petekidis G. Plastic rearrangements in colloidal gels investigated by laos and ls-echo. J. Rheol. 58, 1395–1417 (2014). [Google Scholar]

- Fiocco D., Foffi G. & Sastry S. Oscillatory athermal quasistatic deformation of a model glass. Phys. Rev. E 88, 020301 (2013). [DOI] [PubMed] [Google Scholar]

- Priezjev N. V. Heterogeneous relaxation dynamics in amorphous materials under cyclic loading. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 87, 052302 (2013). [DOI] [PubMed] [Google Scholar]

- Regev I., Lookman T. & Reichhardt C. Onset of irreversibility and chaos in amorphous solids under periodic shear. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 88, 062401 (2013). [DOI] [PubMed] [Google Scholar]

- Deng C. & Schuh C. A. Atomistic mechanisms of cyclic hardening in metallic glass. Appl. Phys. Lett. 100, 251909 (2012). [Google Scholar]

- Lerner E. & Procaccia I. Locality and nonlocality in elastoplastic responses of amorphous solids. Phys. Rev. E 79, 066109 (2009). [DOI] [PubMed] [Google Scholar]

- Fiocco D., Foffi G. & Sastry S. Encoding of memory in sheared amorphous solids. Phys. Rev. Lett. 112, 025702 (2014). [DOI] [PubMed] [Google Scholar]

- Perchikov N. & Bouchbinder E. Variable-amplitude oscillatory shear response of amorphous materials. Phys. Rev. E 89, 062307 (2014). [DOI] [PubMed] [Google Scholar]

- Kawasaki T. & Berthier L. Macroscopic yielding in jammed solids is accompanied by a nonequilibrium first-order transition in particle trajectories. Phys. Rev. E 94, 022615 (2016). [DOI] [PubMed] [Google Scholar]

- Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary Figures and Supplementary References

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon request.