Abstract

Pastırma is a dry-cured meat product, produced from whole beef or water buffalo muscles. This study was carried out to investigate the effect of production stages (raw meat, after curing, after 2nd drying and pastırma) on the total lipid, neutral lipid, phospholipid and fatty acid composition of phospholipid fraction of pastırma produced from beef M. Longissimus dorsi muscles. The pH and colour (L*, a* and b*) analyses were also performed in raw meat and pastırma. It was found that pastırma production stages had significant effects (p<0.01) on the total amounts of lipid, neutral lipid and phospholipid, and the highest amounts of lipid, neutral lipid and phospholipid were detected in pastırma. In pastırma, neutral lipid ratio was determined as 79.33±2.06% and phospholipid ratio as 20.67±2.06%. Phospholipids was proportionately lower in pastırma than raw meat. Pastırma production stages affected pentadecanoic acid (15:1) (p<0.01), linoleic acid (18:2n-6) (p<0.05), γ-linoleic acid (18:3n-6) (p<0.05), erucic acid (22:1n-9) (p<0.05), docosapentaenoic acid (22:5n-6) (p<0.05), total unsaturated fatty acid (ΣUSFA) (p<0.05) and total saturated fatty acid (ΣSFA) (p<0.05) ratios of phospholipid fraction and also the moisture content (p<0.01). Pastırma process also affected pH and colour (L*, a* and b*) values (p<0.01), and these values were higher in pastırma than raw meat.

Keywords: Pastırma, phospholipid fraction, fatty acid composition, PUFA n-6/n-3, ΣPUFA/ΣSFA, moisture, pH, colour

Introduction

Pastırma is a traditional meat product produced from beef or water buffalo meat. In pastırma production stages, whole muscles obtained from carcasses are cured/salted, dried, pressed, redried, repressed and redried with cemen paste is added by special methods (Aksu et al., 2005a; Aksu and Erdemir, 2014; Ceylan and Aksu, 2011).

Several factors affect the quality of pastırma. These include the quality of raw meat, curing methods and temperature, drying, pressing, the quality and addition of cemen, and the physical, chemical and microbiological changes in the meat during production. Rich in chemical compound, pastırma also affects the quality with protein, fat and moisture values and the changes in their composition. The highest component in pastırma is protein, other than water, which is followed by fats. Fat content of the pastırma changes between 1.14% and 53.14% (Tekinşen and Doğruer, 2000) or between 1.41 and 24.67% (Çakıcı et al., 2015). Amount of intramuscular fat is higher in pastırma with low fat content than that of with high fat content. Therefore, phospholipid amount may be higher in pastırma with low fat.

Phospholipids are dominant lipids in the cell membrane and they constitute 80% of the lipids in sarcoplasmic reticulum. Alcohols and fatty acid compositions bound to R1 and R2 positions in phospholipid structure differ. Saturated fatty acids (SFA) are bound to R1 position, while oleic, linoleic, linolenic and arachidonic fatty acids are bound to R2 position (Aurand et al., 1987; Muriel et al., 2005). Due to these characteristics, phospholipids have a great importance for meat technology. Muscle type is important in terms of phospholipid content and composition of the meat. Oxidative muscles contain more phospholipids than glycolytic muscles. Moreover, oxidative muscles contain higher ratios of cardiolipin and phosphatidylethanolamine (PE) than glycolytic muscles (Alasnier et al., 1996; Leseigneur-Meynier and Gandemer, 1991). On the other hand, monounsaturated fatty acids are dominant in the phospholipid structure of white muscles and polyunsaturated fatty acids are dominant in the phospholipid structure of dark muscles. Depending on the muscle type, the amount of unsaturated fatty acid is higher in phospholipid fractions of beef (Habeanu et al., 2014). Moreover, the number of double bonds in the structure of unsaturated fatty acid is higher in the phospholipid fraction. While only 0.1% of the triglycerides in beef have four or more double bonds, 19% of the unsaturated fatty acids in the phospholipid structure have four or more double bonds (Hornstein et al. 1961). Therefore, phospholipids are more sensitive to oxidation and they oxidise more quickly in both fresh and processed meat (Alasnier and Gandemer, 1997).

Type, amount and fraction of phospholipids in meat are effect from the race, age and sex of the animal (Malau-Aduli et al., 1998). Various technological processes such as fermentation, cooking, drying and salting/curing also affect the phospholipid fraction of processed meat. In fermented products, phospholipid amount decreases as a result of the changes or deformation in the lipid structures depending on the fermentation conditions (such as temperature, moisture and O2 etc.) (Visessanguan et al., 2006). With cooking, phospholipid amount decreases and neutral lipid amount increases depending on the oxidation of polyunsaturated fatty acids in the phospholipid fraction (Legako et al., 2015). At the maturation stages of the meat during curing, drying and processing with various products, the amount of free fatty acid increases and phospholipid amount decreases depending on the oxidation of intramuscular fats, lipolytic enzymes and especially lipoxygenase (LOX) enzyme (Jin et al., 2010).

During pastırma production, important physical, chemical and microbiological changes occur; production stages and durations affects various quality criteria such as moisture, aw, pH, salt, nitrite, nitrate, non-protein nitrogen, myofibriller fragmentasyon index, protein amount and structure, free amino acid composition, colour, firmness, fatty acid composition and volatile compounds. Moreover, lipid oxidation is observed at important levels during production and thiobarbutiric acid reactive substances (TBARS) values also increase. As a result of these lipolytic changes, the amount of free fatty acid increases and important changes occur in the fatty acid composition. As known, polyunsaturated fatty acids in the intramuscular fats, which are more prone to oxidation, are generally observed in the structures of phospholipids. Therefore, it is thought that substantial changes may occur in the fatty acid composition of phospholipids during pastırma production. Until today, changes in the fatty acid composition of phospholipids in pastırma or during pastırma production have not been studied. This research aims to determine the amount or ratio of phospholipid fraction during pastırma production and the changes in the fatty acid composition of phospholipids. For this purpose, pastırma was produced from M. Longissimus dorsi muscle of beef; moisture, pH, colour (L*, a*, b*) analyses and the neutral lipid amount, phospholipid amount or ratio and the fatty acid composition of phospholipid fraction were determined in the raw meat, after curing, after 2nd drying and in the final product (pastırma).

Material and Method

Material

In this study, beef M. Longissimus dorsi muscles was used from a local slaughterhouse, Et ve Süt Kurumu A.Ş, in Erzurum, Turkey.

Production of Pastirma

In this study, pastırma production, in two replicates, was performed in reference to the methods by and Aksu et al. (2005b) as following:

Preparation of the meat: The M. Longissimus dorsi muscles obtained from two different beef carcasses were used as the raw material for pastırma production. Right and left M. Longissimus dorsi muscles from beef carcass were divided into two pieces, and, in this way, meat for the production of four pastırma was obtained from the same carcass (total n=8). Then, excess fat, tendon and connective tissues on the muscles were removed. The prepared meats for the pastırma process were then cut at a 45-degree angle from one surface to the muscle fibres at a depth of smaller than the 2/3 of the meat thickness.

Curing: During this process, dry curing was applied, and 50 g salt was used per 1 kg meat. Salted meats were stored at 6°C for 30 h with the cuts facing up, then they were turned over with the cuts facing down and they were stored at 6°C for 18 h.

1st Drying: After dry curing, cured meats for pastırma were dried at 15°C for 4 d in an environment of 80-85% relative humidity.

1st Pressing: After the 1st drying process, cured and dried meat was subjected to the 1st pressing process. Pressing was applied at 7-10°C for 17 h.

2nd Drying: After the 1st pressing process, meats were redried for 3-4 d in an environment of 20°C with 70% relative humidity.

2nd Pressing: After the 2nd drying, 2nd pressing was applied. 2nd pressing was performed at 25°C for 7 h.

Addition of Cemen Paste: In the production of cemen paste, 500 g fenugreek seed flour, 350 g freshly crushed garlic, 150 g red pepper (75 g powdered hot red pepper + 75 grams powdered paprika) and 1200 mL tap water mixture were used (Aksu et al., 2006). After drying and pressing processes was completed, meats were waited in cemen paste for 4.5 d (at 7°C), then the excess cemen around the meat was removed leaving behind a thin layer of 2-3 mm and the addition of cemen paste was completed

Final Drying: After the addition of cemen paste, meats were subjected to the final drying in an environment of 15°C with 70% relative humidity for 2 d, in an environment of 18°C with 65% relative humidity for 2 d and then in an environment of 20°C with 60% relative humidity for 4-5 d.

Analyses

Analyses of moisture and fatty acid composition of phospholipid fraction were performed for raw meat, after curing, after 2nd drying and pastırma. pH and colour (L*, a* and b*) analyses were only performed for raw meat and pastırma.

pH analysis

For pH analysis, 10 g samples were taken from each pastırma type in parallel, 10 mL distilled water was added to each sample and then they were homogenised in Ultra Turrax for 1 min. Afterwards, pH values of these homogenates were measured with a pH meter. Before measurement, pH meter was calibrated with 4.00 and 7.00 buffer solutions.

Measurement of colour values

Colour intensities (L*, a* and b*) of the samples were determined with a Minolta (CR-400, Minolta Co., Japan) calorimeter. For colour intensities, criteria of the International Commission on Illumination CIELAB (Commision Internationele de I’e Clairage) based on three-dimensional colour measurement was taken as reference.

Moisture analysis

Moisture content of the samples were performed according to the drying method. The 10 g of grounded meat or pastırma samples were put into drying plates in parallel and they were dried in a drying oven at 102°C until a constant weight was provided. Then, dried samples cooled in a desiccator and weighed. Moisture amounts of the samples were determined taking the weight loss into consideration.

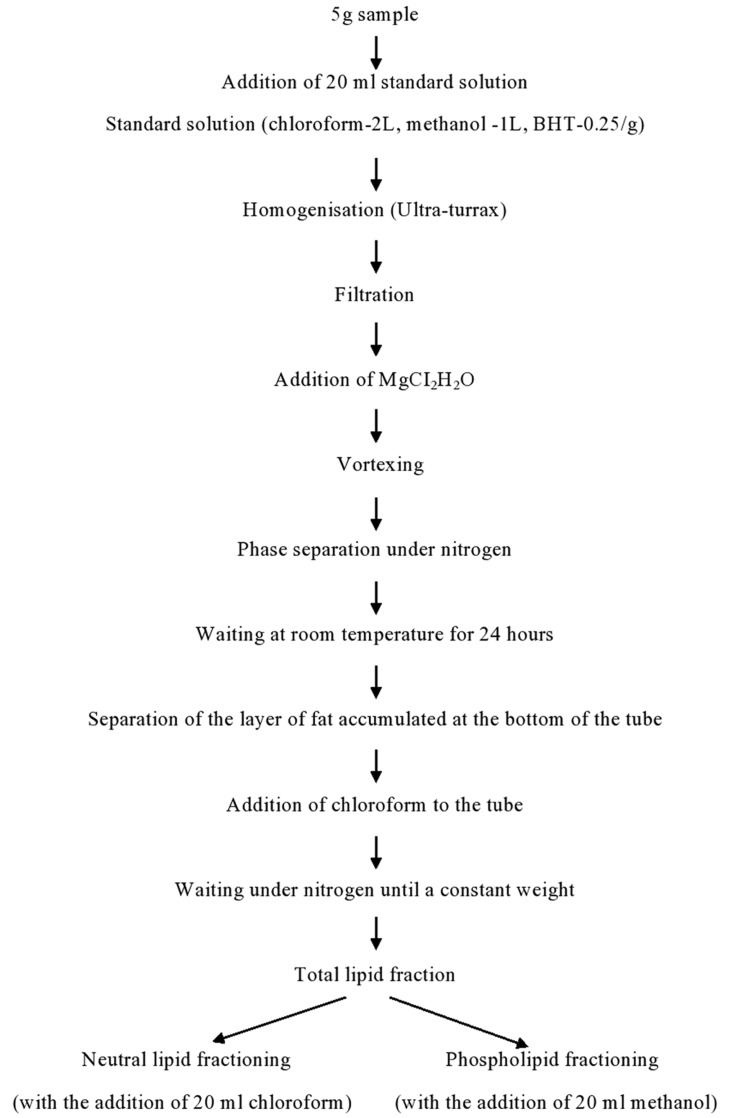

Extraction of fat from the samples and separation of phospholipid fraction

For the extraction of fats from the samples, Folch extraction method shown in Fig. 1 was used (Folch et al., 1957). Fats taken by this method were subjected to various pre-treatments and they were separated into neutral lipid and phospholipid fractions.

Fig. 1. Fat extraction stages.

Determination of the fatty acid composition of the phospholipid fraction

Tubes containing phospholipid fraction were waited under nitrogen until a constant weight was provided. 200 microliters of the standard solution (methynonadecanonte 8 mg for 1 mL) was added to the samples at a constant weight again, they were waited under nitrogen for the second time. 2 mL BF3-methanol (25% of Borontrifluoride methanol) was added to the samples and they were waited in the drying chamber at 80°C for 30 min. Then, tubes were cooled down to room temperature. 1 mL hexane was added to the tubes and then they were vortexed. 1 mL ultra-distilled water was added to the tubes and then they were vortexed again. Afterwards, these tubes were centrifuged at 3,000 rpm for 5 min. After centrifuge, the top phase was taken, put into another tube containing sodium sulphate and 1 mL hexane was added. Then, it was vortexed and the top phase was removed to another vial. Fatty acid compositions of these samples were determined by gas chromatography (Name of the device: Agilent 6980 Gas Chromatography (GC), Detector used in the Gas Chromatography: FID, Colon: DB-23 (60 m × 0.25 mm × 0.25 μm), Detector Temperature: 200°C, Column Temperature: waited at 165°C for 15 min. Then reach to 200°C by 5°C increases per min., Flow Rate: 1/50 (nitrogen/dry air), Air Pressure: 350 mL/min).

Statistical analyses

The study was conducted according to completely randomised experimental design in two replicates. Data were analysed with SPSS in variance analysis (SPSS, 22.0), means of the main significant variance sources were compared with Duncan’s Multiple Range Test. The results of the statistical analysis are presented with the standard deviations.

Results and Discussion

Moisture content

Moisture content of the raw meat, after curing, after 2nd drying and final product (pastırma), and means of the pH and colour (L*, a* and b*) values for raw meat and pastırma and the results of the Duncan’s Multiple Range Test are presented in Table 1. Moisture content of pastırma production stages was determined between 74.54-75.23%, 65.38-68.83%, 44.25-48.46% and 35.79-41.48% respectively. It was found that production stages significant (p<0.01) affected the moisture content (Table 1). Moisture content decreased during production (p<0.05). Moisture content was determined as 74.38±0.52% in the raw meat used for pastırma production, and it decreased to 38.88±1.78% in pastırma. In their research, Aksu and Kaya (2002a) determined the decreasing moisture content as 75.13% in raw meat, as 55.82% after 2nd drying and as 45.02% in pastırma. Yilmaz and Gecgel (2009) determined that moisture content of pastırma was between 37.71% and 45.56%. Similarly, Aksu and Kaya (2002b) found that the moisture content decreased during pastırma production. According to Turkish Food Codex Meat and Meat Products Notification (Anonymous, 2012), moisture content should be maximum 45% in pastırma without cemen paste.

Table 1. The results of Duncan's multiple range test for the mean values of moisture, pH and colour values in the raw meat, after curing, after 2nd drying and in the final product (p<0.05).

| Properties | Production Stage |

p | |||

|---|---|---|---|---|---|

| Raw Material | End of curing | End of second drying | Pastırma | ||

| Moisture (%) | 74.38±0.52a | 66.88±1.11b | 45.26±1.62c | 38.88±1.78d | ** |

| pH | 5.53±0.05b | - | - | 5.71±0.05a | ** |

| L* values | 35.77±2.59b | - | - | 38.86±2.04a | ** |

| a* values | 26.05±4.69b | - | - | 39.14±0.43a | ** |

| b* values | 9.26±2.67b | - | - | 20.62±1.80a | ** |

a-dAny means in the same column with the same letters are not significantly different at p<0.05, ±: Standard deviation, **p<0.01.

pH values

pH value was determined between 5.47-5.58 in raw meats used in pastırma production and between 5.65-5.76 in pastırma. Production stages were determined to significant effects (p<0.01) on the pH value. The pH value was determined as 5.53±0.05 in raw meat and it increased to 5.71±0.05 in pastırma. Proteolytic changes during pastırma production process (Erdemir and Aksu, 2016), drying, fermentation and the quality of the raw meat affected pH value. The mean value determined in the final product pastırma was below the upper limit of 6.0 determined by Turkish Food Codex Meat and Meat Products Notification (Anonymous, 2012). In various studies, changes in the pH values are in parallel with our findings and they all increase during production process (Aksu and Kaya, 2001a; Aksu and Kaya, 2002a; Aksu and Kaya, 2002c; Aksu et al., 2016).

Colour values

Significant effects of the production stages were found on the L* value (p<0.01). L* value was determined as 35.77±2.59 in raw meat and it increased to 38.86±2.04 in pastırma (Table 1). Aksu and Kaya (2001b) found the L* value in their control group pastırma as 41.22 in average. Aksu and Kaya (2005) determined that the L* value is 38.08±0.07 in raw meat and it increased to 47.38±1.59 in pastırma. Aksu et al. (2016) also found the L* value as 38.40±5.44 in raw meat, it increased during production process and determined as 41.91±3.64 in the final product.

Colour is a significant quality criterion for pastırma. The a* value is especially important in terms of consumer choices. The a* value was determined between 20.94-32.50 in the raw meat used in the pastırma production, and between 38.57-40.06 in pastırma. It was found that production stages affected significant (p<0.01) on the a* value. The mean a* value determined as 26.05±4.69 in raw meat increased to 39.14±0.43 in pastırma (Table 1). Aksu and Kaya (2005) specified a* value in pastırma as 36.38±1.15. The quality of raw meat, production conditions and duration, production methods, packaging, storage time and conditions may affect the colour properties of pastırma, especially a* value (Aksu and Kaya, 2002a; Aksu and Kaya, 2005). Therefore, in the market researches, important variations have been determined in a* values of sliced pastırma. In this context, Aksu and Kaya (2001a) found that the a* value between 13.66-36.63 in pastırma samples, Çakıcı et al. (2015) found it changing between 21.45-30.22 in the pastırma.

While b* value changed between 5.96-13.86 in raw meat used for pastırma, it was determined between 17.50-23.71 in pastırma. Significant effects of the production stages were determined on the b* value (p<0.01), and the b* value was as 9.26±2.67 in the raw meat and it increased to 20.62±1.80 in pastırma. In various researches, b* value was determined as 16.67-19.54 (Aksu and Kaya, 2001a), 19.23±0.75 (Aksu and Kaya, 2005) and 21.75±3.5 (Aksu et al., 2005a) in the sliced pastırma samples produced from L. dorsi muscle. Same researchers stated that b* value increased during pastırma production.

Total fat, neutral lipid and phospholipid ratio or amounts

Total fat, neutral lipid and phospholipid ratios or amounts of the phospholipid fraction in raw meat, after curing, after 2nd drying and in the final product, and their percentages, are presented in Table 2. Total lipid amount was determined as 1.16-1.57 g/100 g, in raw meat, as 0.77-1.40 g/100 g after curing and as 1.19-1.97 g/100 g after 2nd drying. It reached the maximum level in pastırma due to reduction of water during processing and it was determined between 2.14-2.96 g/100 g. During production, neutral lipid was specified between 0.77-1.18 g/100 g in raw meat, between 0.58-1.00 g/100 g after curing, between 0.80-1.57 g/100 g after 2nd drying and between 1.75-2.37 g/100 g in pastırma. The ratio of neutral lipid was 66.38-75.16% in raw meat, 71.42-78.79, 2% after curing, 66.39-79.29% after 2nd drying and 76.98-81.78% in pastırma. Phospholipid amount was found between 0.39-0.40 g/100 g in raw meat and between 039-0.60 g/100 g in pastırma. Phospholipid ratio was 24.84-33.61% in raw meat and 18.22-23.02% in pastırma.

Table 2. The results of Duncan's multiple range test for the mean values of total fat, neutral lipid and phospholipid amounts in the phospholipid fraction in raw meat, after curing, after 2nd drying and in the pastırma, and their percentages (p<0.05).

| Fat or fractions | Amounts or ratio (%) | Production Stage |

p | |||

|---|---|---|---|---|---|---|

| Raw Material | End of curing | End of second drying | Pastırma | |||

| Total Lipids | g/100g | 1.37±0.23b | 1.10±0.27b | 1.48±0.34ab | 2.60±0.36a | ** |

| Neutral Lipid | g/100g | 0.98±0.23b | 0.81±0.18b | 1.08±0.34b | 2.06±0.27a | ** |

| % | 70.77±5.07b | 75.03±3.03ab | 72.11±5.33b | 79.33±2.06a | ** | |

| Phospholipid | g/100g | 0.39±0.01b | 0.27±0.10c | 0.40±0.00b | 0.54±0.10a | ** |

| % | 29.23±5.07a | 25.22±3.03ab | 27.89±5.33a | 20.67±2.06b | ** | |

a-eAny means in the same column with the same letters are not significantly different at p<0.05, ±: Standard deviation, **p<0.01.

Significant effects of the pastırma production stages were determined on the lipid amount (p<0.01), and the highest total lipid amount was determined as 2.60±0.36 g/100 g in pastırma (Table 2). During production, there was not any statistical difference (p>0.05) among the values in raw meat, after curing and 2nd drying in terms of lipid amount. Pastırma production stages also significant (p<0.01) affected the total neutral lipid amount and its percentage, and in total lipid amount, neutral lipids were determined to be dominant with 79.33±2.06%. It was determined that pastırma production stages affected (p<0.01) the phospholipid amount and percentage in total lipid amount, the lowest amounts were detected after curing and the highest were detected in pastırma (Table 2). In various researches, parallel to our findings, neutral lipid amount was determined to be higher than the phospholipid amount in intramuscular fats. Yang et al. (2005) researched the changes in intramuscular lipid fractions during the production of traditional Xuanwei jambon, and they found that the neutral lipid ratio was 73.2±2.33% in raw meat and it increased to 80.2±3.02% in final dried product, while the phospholipid ratio decreased from 25.3±1.31% to 5.8±0.41%. Similarly, He et al. (2012) reported that the neutral lipid amount was 76.72±0.99% and the phospholipid amount was 20.54±1.06 in the intramuscular lipid content of beef M. Longissimus muscle. Jin et al. (2010) found the neutral lipid amount as 67.8±2.6% in raw meat, as 71.1±2.5% after curing, as 73.0±1.2% in the final product, while determined the phospholipid as 22.4±0.7% in raw meat, as 16.1±0.3% after curing and as 10.3±0.3% in the final product. Additionally, several researches pointed out that phospholipid amount decreased during the processing of various meat types from different animals (Huang et al., 2014; Muriel et al., 2005).

Saturated fatty acid composition of phospholipid fraction

Palmitic (16:0) and stearic (18:0) acids were determined to be the dominant saturated fatty acid in phospholipid fractions during all production stages. However, production stages did not affect these fatty acids (p>0.05; Table 3). Similarly, pastırma production stages did not have any effects on the amounts of myristic (p>0.05), pentadecanoic (p>0.05), margaric (p>0.05) and arachidonic acid (p>0.05). On the other hand, pastırma production stages significant (p<0.05) affected the total saturated fatty acid of phospholipid fraction (Table 3). The lowest amount of saturated fatty acid was determined as 34.27±0.47% in raw meat and the highest as 36.09±0.41% after curing. In the produced pastırma, saturated fatty acid amount of phospholipid fraction was determined as 34.56±0.44%, which was very close to the value determined in raw meat. Indurain et al. (2006) determined the highest amount of palmitic acid (C16:0) as 26.49±3.19% and stearic acid (C18:0) as 19.98±5.42% among the saturated fatty acids in the intramuscular fatty acid composition of male beef. Huang et al. (2014), in the fatty acid composition of phospholipid fraction during the production of Chinese traditional smoke-cured bacon, found that the amounts of palmitic (19.52±0.51%) and stearic (12.68±0.28%) acids were higher than other fatty acids among saturated fatty acids.

Table 3. The results of Duncan's multiple range test for the mean values of saturated fatty acid compositions in raw meat, after curing, after 2nd drying and in the pastırma (p<0.05) (%).

| Fatty acids | Raw Material | End of curing | End of second drying | Pastırma | p |

|---|---|---|---|---|---|

| Myristic (14:0) | 0.93±0.20 | 1.51±0.88 | 1.44±0.55 | 1.01±0.61 | NS |

| Pentadecanoic (15:0) | 0.62±0.05 | 0.61±0.03 | 0.54±0.05 | 0.57±0.09 | NS |

| Palmitic (16:0) | 20.16±0.50 | 20.67±0.39 | 20.62±1.09 | 20.27±0.21 | NS |

| Margaric (17:0) | 0.96±0.08 | 1.05±0.08 | 1.00±0.05 | 0.97±0.02 | NS |

| Stearic (18:0) | 11.54±0.17 | 12.17±0.82 | 12.12±0.48 | 11.65±0.36 | NS |

| Arachidonic (20:0) | 0.080.03 | 0.08±0.01 | 0.07±0.00 | 0.09±0.03 | NS |

| ΣSFA | 34.27±0.47c | 36.09±0.41a | 35.82±1.15ab | 34.56±0.44bc | * |

a-eAny means in the same column with the same letters are not significantly different at p<0.05, ±: Standard deviation, *p<0.05. NS: Not significant (p>0.05).

Unsaturated fatty acid composition of phospholipid fraction

The values of unsaturated fatty acid composition in phospholipid fractions of the samples at the stages of raw meat, after curing, after 2nd drying and pastırma are presented in Table 4. In the unsaturated fatty acid compositions of the phospholipid fraction, the dominant fatty acids were oleic (18:1n-9) and linoleic (18:2n-6) acids, followed by arachidonic (20:4n-6), palmitoleic (16:1n-7), α-linolenic (18:3n-3), eicosapentaenoic (20:5n-3) and vaccenic (18:1n-7) acids.

Table 4. The results of Duncan's multiple range test for the mean values of unsaturated fatty acid compositions in the phospholipid fraction in raw meat, after curing, after 2nd drying and in the pastırma (p<0.05) (%).

| Fatty acids | Raw material | End of curing | End of second drying | Pastırma | p |

|---|---|---|---|---|---|

| Myristioleic (14:1) | 0.38±0.05 | 0.52±0.28 | 0.47±0.16 | 0.44±0.20 | NS |

| Pentadecanoic (15:1) | 0.92±0.21b | 1.53±0.26a | 1.54±0.25a | 0.99±0.13b | ** |

| Palmitoleic (16:1n-7) | 1.89±0.19 | 1.77±0.03 | 1.81±0.04 | 1.85±0.11 | NS |

| Heptadecanoic (17:1) | 1.02±0.11 | 1.07±0.08 | 1.05±0.04 | 1.03±0.04 | NS |

| Vaccenic (18:1n-7) | 1.13±0.07 | 1.28±0.10 | 1.22±0.05 | 1.24±0.09 | NS |

| Oleic (18:1n-9) | 20.34±1.69 | 19.60±1.24 | 20.28±0.57 | 20.40±0.21 | NS |

| Linoleic (18:2n-6) | 18.91±0.62a | 17.66±0.49b | 17.73±0.69b | 18.53±0.20ab | * |

| α-linolenic (18:3n-3) | 2.26±0.17 | 2.13±0.10 | 2.09±0.03 | 2.19±0.06 | NS |

| γ-linolenic (18:3n-6) | 0.15±0.02ab | 0.17±0.05a | 0.13±0.01b | 0.13±0.02b | * |

| Stearidenoic (18:4n-3) | 0.14±0.01 | 0.15±0.00 | 0.13±0.04 | 0.14±0.02 | NS |

| Eicosoenoic ( 20:1n-9) | 0.05±0.02 | 0.06±0.03 | 0.04±0.00 | 0.04±0.01 | NS |

| Gadoleic (20:1n-11) | 0.10±0.02 | 0.10±0.01 | 0.10±0.01 | 0.10±0.01 | NS |

| Eicosadienoic (20:2n-6) | 0.47±0.04 | 0.47±0.02 | 0.48±0.01 | 0.51±0.01 | NS |

| Eicosatrienoic (20:3n-3) | 0.30±0.02 | 0.30±0.03 | 0.30±0.01 | 0.30±0.01 | NS |

| Dihomo γ-linolenic (20:3n-6) | 1.60±0.19 | 1.54±0.10 | 1.52±0.05 | 1.62±0.06 | NS |

| Eicosatetraenoic (20:4n-3) | 0.08±0.02 | 0.10±0.04 | 0.10±0.02 | 0.10±0.08 | NS |

| Arachidonic (20:4n-6) | 9.89±1.58 | 9.50±0.84 | 9.40±0.53 | 9.80±0.43 | NS |

| Eicosapentaenoic (20:5n-3) | 1.27±0.21 | 1.23±0.15 | 1.24±0.10 | 1.26±0.08 | NS |

| Erucic (22:1n-9) | 0.18±0.10a | 0.19±0.11a | 0.04±0.00b | 0.05±0.02b | * |

| Ketoleic (22:1n-11) | 0.05±0.01 | 0.07±0.05 | 0.07±0.04 | 0.06±0.04 | NS |

| Docosadienoic (22:2n-6) | 0.99±0.05 | 0.95±0.01 | 0.96±0.02 | 1.01±0.04 | NS |

| Docosatetraenoic (22:4n-6) | 0.16±0.02 | 0.17±0.03 | 0.16±0.02 | 0.17±0.01 | NS |

| Docosapentaenoic (22:5n-3) | 0.11±0.01b | 0.19±0.07a | 0.19±0.03a | 0.19±0.05a | * |

| Docosahexaenoic (22:6n-3) | 3.08±0.41 | 2.92±0.26 | 2.93±0.15 | 3.04±0.15 | NS |

| Nervonic (24:1n-9) | 0.28±0.05 | 0.25±0.04 | 0.25±0.02 | 0.26±0.03 | NS |

| ΣUSFA | 65.73±0.46a | 63.92±0.41b | 64.18±1.15b | 65.44±0.43a | * |

| ΣMUFA | 26.32±1.79 | 26.55±0.81 | 26.86±0.59 | 26.48±0.40 | NS |

| ΣPUFA | 39.36±1.98 | 37.36±1.13 | 37.32±1.39 | 38.98±0.76 | NS |

a,bAny means in the same column with the same letters are not significantly different at p<0.05, ±: Standard deviation, *p<0.05, **p<0.01. NS: Not significant (p>0.05).

It was determined that total unsaturated fatty acids detected in the phospholipid fractions during production stages were mostly in the structure of polyunsaturated fatty acid, and the total amounts of unsaturated fatty acid (ΣUSFA) were detected as 65.13-66.26%, 63.31-64.23%, 62.79-65.49% and 65.10-66.07%, total amounts of monounsaturated fatty acid (ΣMUFA) as 26.01-28.15%, 25.36-27.17%, 26.17-27.39% and 26.25-27.08%, total amounts of polyunsaturated fatty acid (ΣPUFA) as 36.98-41.82%, 36.14-38.87%, 36.24-39.32% and 38.00-39.82%, respectively in raw meat, after curing, after 2nd drying and in pastırma (Table 4). Corazzin et al. (2012) determined that the total amount of monosaturated fatty acid (ΣMUFA) as 20.68%, 19.94%, and the total amount of polyunsaturated fatty acid (ΣPUFA) as 36.27%, 41.55% in the fatty acid composition in the phospholipid fraction of M. Longissimus thoracis muscle of Holstein and Simmental cattle. Yang et al. (2005) determined the total amount of monosaturated fatty acid (ΣMUFA) as 21.05% and the total amount of polyunsaturated fatty acid (ΣPUFA) as 42.14% in the phospholipid fraction of the pork hams.

It was found that production stages had significant (p<0.01) effect on the amount of pentadecanoic acid (15:1) (Table 4), and the highest value was determined after curing and 2nd drying. This value is quite low in pastırma. Significant effects of the pastırma production stages were found on the dominant unsaturated fatty acid, linoleic acid, in phospholipid fraction (p<0.01) (Table 4). The amount of linoleic acid (18:2n-6) determined as 18.91±0.62% in raw meat decreased after curing and 2nd drying, and was detected as 18.53±0.20% in pastırma. The decrease in the linoleic acid during pastırma production and its increase in pastırma once again were attributed to the amount of fat in the cemen paste. In the pastırma produced with different commercial cultures, Aksu and Kaya (2002a) determined the ratio of unsaturated fatty acid as 30.77-44.71% before the addition of cemen, and this value increased to 51.07-55.48% after the addition of cemen. Küçük and Gürbüz (1999) determined that the fat ratio in cemen paste between 4.01% and 5.89%, and found the mean value as 4.92±0.64%.

γ-linolenic acid (18:3n-6), erucic acid (20:1n-9) and docosapentaenoic acid (22:5n-3) are other unsaturated fatty acids that are significant (p<0.01) affected by the production stages. While the amounts of γ-linolenic (18:3n-6) and erucic (20:1n-9) acid decreased during pastırma production (p<0.05), the lowest value was determined in pastırma. The amount of docosapentaenoic acid (22:5n-3) increased during pastırma production.

It was determined that pastırma production stages had significant (p<0.01) effect on the total amount of unsaturated fatty acid. The total amount of unsaturated fatty acid of phospholipid fraction, determined as 65.73±0.46% in raw meat, decreased after curing (63.92±0.41) and 1st drying (64.18±1.15), and increased in pastırma again (Table 4). Küçük and Gürbüz (1999) found that the fatty acids in cemen content as unsaturated such as linoleic acid (18:2n-6), linolenic (18:3n-6), oleic acid (18:1n-9), and saturated such as myristic acid (14:0). They also stated that the mean values of the fatty acids in cemen line as linoleic acid 44.64%, linolenic acid 23.12%, oleic acid 19.34% and myristic acid 10.24%. On the other hand, despite being statistically no significant (p>0.05), the amount of polyunsaturated fatty acid decreased after curing and 2nd drying compared to raw material, and then increased again after these stages. Since the change in the total amounts of unsaturated fatty acid and polyunsaturated fatty acid is parallel to each other, the increase in the total amount of unsaturated fatty acid is attributed to the increment of polyunsaturated fatty acid.

The results of Duncan's Multiple Range Test for the mean values of Σn6 PUFA, Σn3 PUFA, Σn6/Σn3 and Σn3/Σn6 ratios determined in raw meat, after curing, after 2nd drying and in the pastırma are presented in Table 5. Pastırma production stages did not affect (p>0.05) the amounts of Σn6 PUFA (p>0.05), Σn3 PUFA (p>0.05), Σn6/Σn3 (p>0.05) and Σn3/Σn6 (p>0.05).

Table 5. Mean values of Σn6 PUFA, Σn3 PUFA, Σn6/Σn3 and Σn3/Σn6 determined in the phospholipid fraction in raw meat, after curing, after 2nd drying and in the pastırma (%).

| Total n3 or n6 fatty acids | Raw Material | End of curing | End of second drying | Pastırma | p |

|---|---|---|---|---|---|

| ∑n6 PUFA | 32.17±1.59 | 30.26±0.92 | 30.36±1.14 | 31.76±0.54 | NS |

| ∑n6 PUFA | 7.24±0.47 | 7.05±0.47 | 7.02±0.45 | 7.22±0.25 | NS |

| ∑n6/∑n3 | 4.45±0.17 | 4.31±0.28 | 4.33±0.20 | 4.40±0.10 | NS |

| ∑n3/∑n6 | 0.22±0.01 | 0.23±0.02 | 0.23±0.01 | 0.23±0.01 | NS |

±: Standard deviation, NS: Not significant (p>0.05).

The dominant fatty acid in the structure of Σn6 PUFA fatty acid in pastırma was linoleic acid (18:2n-6), and in the structure of Σn3 PUFA fatty acid was α-linolenic (18:3n-3) acid. Williams (2000) stated that n-3 PUFA fatty acids were formed of α-linolenic acid (18:3) and n-6 PUFA fatty acids were formed of linoleic acid (18:2), and the amount of n-6 PUFA was higher than n-3 PUFA. Cordain et al. (2002) also reported that the amount of n-6 PUFA was higher than n-3 PUFA in beef muscle tissues.

ΣPUFA/ΣSFA and PUFA n-6/n-3 are among the specific parameters in defining the nutrition qualities of the lipid fractions of foods. It is deemed acceptable when ΣPUFA/ΣSFA ratios is >0.4, and PUFA n-6/n-3 ratio is <4. For phospholipid fraction of pastırma, these ratios are determined as 1.13 for ΣPUFA/ΣSFA and 4.40±0.10 for PUFA n-6/n-3. The PUFA n-6/n-3 ratios have been associated with cancer, coronary heart diseases and especially embolus formation, and it has been recommended that this ratio should remain below 4 (Wood et al., 2003). Similar arguments have found support from various authorities and low PUFA n-6/n-3 ratio is stated to help preventing several chronic diseases (EFSA, 2005). Moreover, Wood et al. (2003) also stated that PUFA n-6/n-3 ratio in red muscle tissues should remain below 4 for health reasons. Habeanu et al. (2014) determined that the n-6/n-3 ratios in phospholipid fatty acid compositions in Longissimus thoracis and Semitendinosus muscles as 4.31 and 3.99, respectively.

Conclusion

Total lipid amount increased during pastırma production and the highest value was determined in pastırma. Decreasing moisture content from raw meat to pastırma caused this increase. During pastırma production, both neutral lipid and phospholipid ratios statistically significant changed (p<0.01); while neutral lipid ratio increased (p<0.01), phospholipid ratio decreased (p<0.01). While the available total lipid fraction in raw meat was proportionately formed of neutral lipids by 70.77±5.07% and phospholipids by 29.23±5.07%, the lipid fraction in pastırma was formed of neutral lipids by 79.33±2.06% and phospholipids by 20.67±2.06%.

Palmitic and stearic acids were determined as the dominant saturated fatty acids in phospholipid fraction during pastırma production, while oleic and linoleic acids were determined as dominant fatty acids in unsaturated fatty acid compositions. On the other hand, production stages significant (p<0.01) effect on the total saturated and unsaturated fatty acid in phospholipid fractions. Polyunsaturated fatty acids have an important place among unsaturated fatty acids, and during pastırma production, ΣMUFA ratio was found quite lower than ΣPUFA ratio. Although ΣPUFA ratio decreased and ΣMUFA ratio slightly increased during pastırma production, these differences are statistically not significant (p>0.05). Based on these results, we can conclude that fatty acid composition in phospholipid fraction during pastırma production is substantially preserved. On the other hand, the mean value of Σn6/Σn3 ratio of phospholipid fraction in pastırma was determined as 4.40, which was very close to the recommended value (4.0) for meat and meat products. ΣPUFA/ΣSFA ratio of this fraction was 1.13.

Acknowledgments

Authors would like to thank the Atatürk University Research Center for financial support (BAP: 2013/390) in making this study possible.

References

- 1.Aksu M. I., Erdemir E. A survey of selected minerals in ready-to-eat pastırma types from different regions of Turkey using ICP/OES. Turk. J. Vet. Anim. Sci. 2014;38:564–571. doi: 10.3906/vet-1306-60. [DOI] [Google Scholar]

- 2.Aksu M. I., Erdemir E., Cakici N. Changes in the physico-chemical and microbial quality during the production of pastırma cured with different levels of sodium nitrite. Korean J. Food Sci. An. 2016;36:617–625. doi: 10.5851/kosfa.2016.36.5.617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Aksu M. I., Kaya M. Some microbiological, chemical and physical characteristics of pastirma marketed in Erzurum. Turk. J. Vet. Anim. Sci. 2001a;25:319–326. [Google Scholar]

- 4.Aksu M. I., Kaya M. The effect of starter culture use in pastirma production on the properties of end product. Turk. J. Vet. Anim. Sci. 2001b;25:847–854. [Google Scholar]

- 5.Aksu M. I., Kaya M. Effect of commercial starter cultures on the fatty acid composition of pastirma. J. Food Sci. 2002a;67:2342–2345. doi: 10.1111/j.1365-2621.2002.tb09551.x. [DOI] [Google Scholar]

- 6.Aksu M. I., Kaya M. Pastirma production by using different curing methods and starter culture. Turk. J. Vet. Anim. Sci. 2002b;26:909–916. [Google Scholar]

- 7.Aksu M. I., Kaya M. The possibilities for the use of commercial starter cultures in pastirma production. Turk. J. Vet. Anim Sci. 2002c;26:917–923. [Google Scholar]

- 8.Aksu M. I., Kaya M. Effect of storage temperatures and time on shelf life of sliced and modified atmosphere packaged-Pastırma, a dry meat product, produced from beef meat. J. Sci. Food Agric. 2005;85:1305–1312. doi: 10.1002/jsfa.2118. [DOI] [Google Scholar]

- 9.Aksu M. I., Kaya M., Ockerman H.W. Effect of modified atmosphere packaging and temperature on the shelf life of sliced pastirma produced from frozen/thawed meat. J. Muscle Food. 2005a;16:192–206. doi: 10.1111/j.1745-4573.2005.08404.x. [DOI] [Google Scholar]

- 10.Aksu M. I., Kaya M., Ockerman H.W. Effect of modified atmosphere packaging storage period, and storage temperature on the residual nitrate sliced pastırma, dry meat product, produced from fresh meat and frozen/thawed meat. Food Chem. 2005b;93:237–242. doi: 10.1016/j.foodchem.2004.09.018. [DOI] [Google Scholar]

- 11.Aksu M. I., Kaya M., Oz F. Inhibition of Escherichia coli O157:H7 in cemens with different garlic levels. Am. J. Food Technol. 2006;1:59–65. doi: 10.3923/ajft.2006.59.65. [DOI] [Google Scholar]

- 12.Alasnier C., Gandemer G. Fatty acid and aldehyde composition of individual phospholipid classes of rabbit skeletal muscles is related to the metabolic type of the fibre. Meat Sci. 1997;48:225–235. doi: 10.1016/s0309-1740(97)00096-x. [DOI] [PubMed] [Google Scholar]

- 13.Alasnier C., Remignon H., Gandemer G. Lipids characteristics associated with oxsidative and glycolytic fibres in rabbit muscles. Meat Sci. 1996;43:213–224. doi: 10.1016/S0309-1740(96)00015-0. [DOI] [PubMed] [Google Scholar]

- 14.Anonymous Turkish Food Codex Communique on Meat and Meat Products (28488) Gıda; Tarım ve Hayvancılık Bakanlığı, Ankara: 2012. [Google Scholar]

- 15.Aurand W. L., Woods E. A., Wells R. M. Food Composition Analysis. Van Nostrandn Reinhold Company; New York: 1987. [Google Scholar]

- 16.Ceylan S., Aksu M. I. Free amino acids profile and quantities of ‘sırt’, ‘bohça’ and ‘sekerpare’ pastırma, drycured meat products. J. Sci. Food Agric. 2011;91:956–962. doi: 10.1002/jsfa.4273. [DOI] [PubMed] [Google Scholar]

- 17.Cordain L., Watkins B. A., Florant G. L., Kehler M., Rogers L., Li Y. Fatty acid analysis of wild ruminant tissues: Evolutionary implication for reducing diet-related chronic diasease. Eur. J. Clin. Nutr. 2002;53:181–191. doi: 10.1038/sj.ejcn.1601307. [DOI] [PubMed] [Google Scholar]

- 18.Corrazzin M., Bovolenta S., Sepulcri A., Piasentier E. Effect of whole linseed addition on meat production and quality of Italian Simmental and Holstein young bulls. Meat Sci. 2012;90:99–105. doi: 10.1016/j.meatsci.2011.06.008. [DOI] [PubMed] [Google Scholar]

- 19.Çakici N., Aksu M. I., Erdemir E. A survey of the physico-chemical and microbiological quality of different pastırma types: A dry-cured meat product. Cyta-J. Foo. 2015;13:196–203. doi: 10.1080/19476337.2014.938123. [DOI] [Google Scholar]

- 20.EFSA. Opinion of the scientific panel on dietetic products, nutrition and allergies on a request from the commission related to nutrition claims concerning omega-3 fatty acids, monounsaturated fat, polyunsaturated fat an unsaturated fat. EFSA J. 2005;253:1–29. [Google Scholar]

- 21.Erdemir E., Aksu M. I. Changes in the composition of free amino acid during production of pastirma cured with different levels of sodium nitrite. J. Food Process Preserv. 2016 doi: 10.1111/jfpp.12801. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Folch J., Less M., Stanley G. H. S. A simple method for the isolation and purification of total lipids from animal tissue. J. Biological. Chem. 1957;226:497–509. [PubMed] [Google Scholar]

- 23.Habeanu M., Thomas A., Bispo E., Gobert M., Gruffat D. D., Bauchart D. Extruded linseed and rapeseed both influenced fatty acid composition of total lipids and their polar and neutral fractions in Longissimus thoracis and Semitendinosus muscles of finishing norm and cows. Meat Sci. 2014;96:99–107. doi: 10.1016/j.meatsci.2013.06.009. [DOI] [PubMed] [Google Scholar]

- 24.He Z., Huang Y., Li H., Qin G., Wang T., Yang J. Effect of high-pressure treatment on the fatty acid composition of intramuscular lipid in pork. Meat Sci. 2012;90:170–175. doi: 10.1016/j.meatsci.2011.06.022. [DOI] [PubMed] [Google Scholar]

- 25.Hornstein I., Growe P. F., Heingerg M. J. Fatty acid composition of meat tissue lipids. J. Food Sci. 1961;26:581. doi: 10.1111/j.1365-2621.1961.tb00799.x. [DOI] [Google Scholar]

- 26.Huang Y., Li H., Huang T., Li F., Sun J. Lipolysis and lipid oxidation during processing of Chinese traditional smoke-cured bacon. Food Chem. 2014;149:31–39. doi: 10.1016/j.foodchem.2013.10.081. [DOI] [PubMed] [Google Scholar]

- 27.Indurain G., Berian M. J., Goni M.V., Arana A., Purroy A. Composition and estimation of intramuscular and subcutaneous fatty acid composition in Spanish young bulls. Meat Sci. 2006;73:326–324. doi: 10.1016/j.meatsci.2005.12.007. [DOI] [PubMed] [Google Scholar]

- 28.Jin G., Zhang J., Yu X., Zhang Y., Lie Y., Wang J. Lipolysis and lipid oxidation in bacon during curing and drying-ripening. Food Chem. 2010;123:465–471. doi: 10.1016/j.foodchem.2010.05.031. [DOI] [Google Scholar]

- 29.Küçük M., Gürbüz B. Bazı Çemen (Trigonella foenum-graecum) Hatlarında Yağ ve Yağ Asitleri Bileşenlerinin Araştırılması. Gıda. 1999;24:99–101. [Google Scholar]

- 30.Legako J. F., Dinh T. T. N., Miller M. F., Brooks J. C. Effects of USDA beef quality grade and cooking on fatty acid composition of neutral and polar lipid fractions. Meat Sci. 2015;100:246–255. doi: 10.1016/j.meatsci.2014.10.013. [DOI] [PubMed] [Google Scholar]

- 31.Leseigneur-Meynier A., Gandemer G. Lipid composition of pork muscle in relation to the metabolic type of the fibres. Meat Sci. 1991;29:229–241. doi: 10.1016/0309-1740(91)90052-R. [DOI] [PubMed] [Google Scholar]

- 32.Malau-Aduli A. E. O., Siebert D. B., Bottema D. K., Pitchford S. W. Breed comparison of the fatty acid composition of muscle phospholipids in jersey and limousin cattle. J Anim. Sci. 1998;76:766–773. doi: 10.2527/1998.763766x. [DOI] [PubMed] [Google Scholar]

- 33.Muriel M. E., Antequera M. T., Petron M. J., Andres A. I., Ruiz J. Stereospecific analysis of fresh and dry-cured muscle phospholipids from Iberian pigs. Food Chem. 2005;90:437–443. doi: 10.1016/j.foodchem.2004.05.007. [DOI] [Google Scholar]

- 34.Tekinsen O. C., Dogruer Y. Pastrami from every aspects. Selcuk University. Press; Konya: 2000. [Google Scholar]

- 35.Visessanguan W., Benjakul S., Riebroy S., Yarchai M., Tapingkae W. Changes in lipid composition and fatty acid profile of Nham, a Thai fermented pork sausage, during fermentation. Food Chem. 2006;94:580–588. doi: 10.1016/j.foodchem.2004.11.051. [DOI] [Google Scholar]

- 36.Williams C. M. Dietary fatty acid and human health. Annal Zootechnie. 2000;49:165–180. doi: 10.1051/animres:2000116. [DOI] [Google Scholar]

- 37.Wood J. D., Richardson R. I., Nute G. R., Fisher A. V., Campo M. M., Kasapidou E., Sheard P. R., Enser M. Effects of fatty acids on meat quality: A review. Meat Sci. 2003;66:21–23. doi: 10.1016/S0309-1740(03)00022-6. [DOI] [PubMed] [Google Scholar]

- 38.Yang H., Ma C., Qiao F., Song Y., Du M. Lipolysis in intramuscular lipids during processing of traditional Xuanwei ham. Meat Sci. 2005;71:670–675. doi: 10.1016/j.meatsci.2005.05.019. [DOI] [PubMed] [Google Scholar]

- 39.Yilmaz I., Gecgel U. Determination of fatty acid composition and total trans fatty acids in meat products. Food Sci. Biotechnol. 2009;18:350–355. [Google Scholar]