Abstract

Due to their unique characteristics such as multifold change of volume in response to minute change in the environment, resemblance of soft biological tissues, ability to operate in wet environments, and chemical tailorability, stimuli responsive gels represent a versatile and very promising class of materials for sensors, muscle-type actuators, biomedical applications, and autonomous intelligent structures. Success of these materials in practical applications largely depends on their ability to fulfill application-specific mechanical requirements. This article provides an overview of recent application-driven development of covalent polymer gels with special emphasis on the relevant mechanical factors and properties. A short account of mechanisms of gel swelling and mechanical characteristics of importance to stimuli-responsive gels is presented. The review highlights major barriers for wider application of these materials and discusses latest advances and potential future directions toward overcoming these barriers, including interpenetrating networks, homogeneous networks, nanocomposites, and nanofilamentary gels.

Keywords: hydrogels, stimuli-responsive gels, mechanical properties, swelling, sensors, actuators

Graphical Abstract

1. Introduction

Covalent polymer gels are crosslinked polymer networks swollen by a solvent. They consist mostly of liquid, but behave like a solid due to three-dimensional crosslinked macromolecular network. Their properties can be varied in a broad range because a wide variety of polymers can form 3D gel networks, while density and structure of the cross-links allow additional degree of control. Large inner volume of gels, accessible for storage, is used in many applications such as superabsorbents, drug delivery carriers, and batteries. The gels are particularly attractive for biomedical applications, such as tissue engineering, owing to their resemblance of soft biological tissues and their operation in wet environments. In fundamental research, gels proved to be useful for understanding polymer thermodynamics and rubber elasticity.

Gels are known to change their volume in response to alteration of the environmental parameters. The change in volume results from the absorption or release of the fluid and may reach hundreds and even thousands percent. Often it is accompanied by considerable swelling force. Gels that demonstrate substantial (and often abrupt) volume change in response to small environmental change and gels that are selective to a specific stimulus are called stimuli-responsive or responsive gels (SRGs).

One of the first experimental observations of reversible and profound volume change in gels was reported by Kuhn and Katchalsky who also noted the resemblance of such gels to muscles [1–3]. Almost at the same time, Flory and Rehner developed a theory of swelling of polymer networks [4–6] that was found to be capable of explaining gel response to stimuli.

The development of responsive gels accelerated in the last quarter of the twentieth century. Tanaka demonstrated abrupt gel volume change caused by small change of environmental conditions, which was named volume phase transition [7]. He created gels responsive to different stimuli, such as solvent composition [7], temperature [7], metal ions [8], electric field [9], and light [10]. Tanaka also advanced the theory of equilibrium swelling of responsive gels and developed a theory of gel swelling kinetics [11–14]. By the end of the twentieth century, responsive gels became an important class of functional materials. The number of applications of SRGs, as well as the amount of research in this field, is continually increasing. Several applications have already been commercialized.

To ensure further success of SRGs in a broad range of practical application, it is becoming critical to better understand and control their mechanical properties. This report describes the current state in the assessment and control of properties of gels relevant to their mechanical behavior, discusses challenges and their proposed or potential solutions, and identifies and reviews new directions.

The scope of this report is limited to covalent stimuli-responsive polymer gels. Other relevant materials, including self-assembled gels and stimuli-responsive and shape-memory materials that are not gel-based are not covered. Nevertheless, it still would be impossible to include every important result and publication in a single review. The preference was given to recent publications. Additional information can be found in the relevant previously published reviews [15–25] as well as in a significant number of more specialized papers and reviews that are referenced below in the following sections.

2. Underlying Mechanisms of Gel Swelling (Classification and Theoretical Fundamentals)

Gel properties, including gel volume, are mostly influenced by interaction of macromolecules that constitute the gel network with mobile molecules in the solution (although other interaction may also be present). According to Flory-Rehner model [4,5,26], the free energy of the gel can be considered to be a sum of contributions from mixing of the polymer network with the solvent, elasticity of the network, and interactions between mobile charges and charges immobilized on the network electrical charges (Fig. 1). The gel reaches its equilibrium volume when a balance of the forces is reached, i.e. the osmotic pressure inside and outside the gel equilibrates. Osmotic pressure of the solvent in the gel is a derivative of the free energy and therefore also includes three components:. Πtotal = Πmix + Πelast + Πcharge

Fig. 1.

Schematic representation of the thermodynamics of gel equilibrium. The total free energy of the gel (Gtotal) is considered to be a sum of the energy of mixing (Gmixing), the elasticity energy of network (Gelasticity), and the energy associated with electrical charges (Gcharge). The mixing can be described by Flory-Huggins theory. The elasticity can be described by a model of rubber elasticity. The contribution of the electrical charges arises from electrostatic repulsion and attraction and osmotic pressure produced by Donnan equilibrium.

Changes in the environment disturb the balance and cause mass transfer until a new equilibrium is reached. Often, the response of the gel is caused by the stimuli-induced change in the miscibility of the polymer network and the solvent. The most studied example of such gels are the hydrogels composed of poly(N-isopropylacrylamide) (PNIPAM). This polymer has low critical solution temperature (LCST) around 33°C in water. Above that temperature, PNIPAM-based network’s miscibility with water rapidly decreases and hydrogel shrinks loosing almost all of its water [27,28].

The elasticity of the gel arises from the forces generated by thermal motion of the network chains constrained by the crosslinks. According to classical theories of polymer network elasticity [29], the elastic forces are proportional to the number of effective chains per unit volume and therefore proportional to the crosslinking density. Stimuli that cause dissociation of the crosslinks reduce the elastic component of the gel osmotic pressure and increase the swelling of gels. Other stimuli may cause formation of additional cross-links, for example, as a result of formation of complexes involving two functional groups attached to the polymer network, and therefore trigger gel shrinkage.

Ionic and polyelectrolyte gels contain charged groups immobilized on the polymer network. The network of such gel is usually not electrically neutral by itself. As a result, mobile ions must distribute unequally between the gel interior and the outside solution to maintain electroneutrality [30]. The unequal distribution of the mobile ions, which is called Donnan equilibrium [31], produces osmotic pressure that must be counterbalanced by other forces. Donnan equilibrium results in additional swelling that augments the swelling of the neutral network. This additional swelling is most pronounced in solutions with low ionic strength. Change of the solution ionic strength or change of the network charge cause substantial change of the gel volume. The most studied gels of this class are polyacrylic acid-based pH-sensitive hydrogels. Electrical charges can also contribute to the swelling through their electrostatic repulsion or attraction. However, the electrical charges are often effectively screened by mobile ions or the solvent, and therefore the contribution of electrostatic repulsion/attraction between the charges may be negligible even when the Donnan osmotic pressure is quite high. Nevertheless, in highly charged polyelectrolytes, electrostatic interactions are significant and accompanied by other phenomena such as counterion condensation and chain stiffening [30].

SRGs can be classified by the mechanisms of response i.e. by the part of their osmotic pressure that is most affected by stimuli. Thus, SRGs may be divided in three groups: gels responsive in consequence of change of free energy of mixing, gels responsive due to change of the network elasticity, and gels responsive through ion interactions. It is important to remember, however, that the division of the free energy of gels into these three parts is somewhat artificial. Many molecular interactions can be included in one part or another. For example, effects of hydrogen bonding are usually associated with the mixing part although they can be considered as crosslinks and thus included into the elastic part. The electrostatic repulsion of polyelectrolyte segments often thought to be a part of the charge interactions, even though for linear polyelectrolytes, the electrostatic repulsion is normally included in the free energy of mixing. Also, many stimuli affect more than one part. For example, dissociation of acid groups gives rise to the “charge interactions” part, but it also may increase the hydrophilicity of the gel network, i.e. alter the “mixing” part.

The transition of the gel from a state that is no longer in equilibrium with the environment to a new equilibrium state, i.e. the kinetics of swelling, can be described by Tanaka-Fillmore theory [11]. According to the theory, which is based on the linear model of elasticity of the gel network, the characteristic time of the transition for spherical gel is directly proportional to the square of the dimension of the gel and inversely proportional to the collective diffusion coefficient D, which is defined as a ratio of the longitudinal bulk modulus of the network to the “coefficient of friction” between the network and the solvent f:

where r(t) is the current radius of gel, r0 is the initial radius, req is the equilibrium radius, τ is the characteristic time, and K and μ are bulk and shear moduli of the gel network.

The prediction of the Tanaka-Fillmore theory that the response time is proportional to the square of the gel’s smallest spatial dimension has been extended to other gel shapes and confirmed experimentally [32]. Yet many aspects of swelling kinetics remain poorly understood. The swelling kinetics of SRGs is often complicated by concurrent diffusion of several types of mobile solutes coupled with chemical reactions. These processes occur simultaneously with the swelling, proceed with different rates, and influence each other. Therefore, in some cases the gel may approach the equilibrium very slowly [33,34], or “overshoot” the balance point [35,36], as shown in Fig. 2.

Fig. 2.

Complexity of gel response kinetics is demonstrated by this example of gel response overshoot. In response to addition of 1 mM glucose, a poly(acrylamide) gel functionalized with fluorophenylboronic acid groups shrinks past the equilibrium point and then re-swells. In the subsequent test (Exp 2) the gel reaches the equilibrium faster and demonstrates smaller overshoot that in the initial test (Exp 1). The gel volume change is monitored by the shift of the diffraction of a photonic crystal embedded in the gel. Reprinted with permission from Ref. [35]. Copyright 2009 American Chemical Society.

3. Mechanical Factors of Importance to Stimuli-Responsive Gels

The thermodynamical forces mentioned above are directly related to mechanical properties important for applications of gels. Among the main mechanical parameters of regular gels, we consider swelling ratio, swelling time (or swelling rate), and mechanical robustness. SRGs are additionally characterized by such mechanical parameters as amplitude of response to stimuli, response time, and the amount of work that the gel is able to produce during its response to stimuli.

The swelling ratio, which represents the amount of fluid that the gel is able to hold, is the most characteristic property of gels. Most often the swelling ratio is reported for free swelling, i.e. when the gel is immersed in the fluid and not constrained in any way. Fig. 3 shows examples of dry and swollen gels [37]. The swelling ratio Q is usually measured as the mass of absorbed fluid mfluid per unit mass of dry gel network mdry:

although other definitions exist in the literature. For example, the swelling ratio may also be reported as volume percent of fluid in the gel. Notably, a constrained gel or a gel under load is not able to hold as much fluid as a free gel. Therefore it is critical to take into account any forces or constrains that are applied to the gel during characterization of its swelling ratio. It is also important to consider forces and constraints that may be applied to gels in applications.

Fig. 3.

(A) Dried and (B) swollen in tetrahydrofuran lipophilic polyelectrolyte gel demonstrates a typical magnitude of swelling ratio in polymer gels. Reprinted from Ref. [37] by permission from Macmillan Publishers Ltd, copyright 2007.

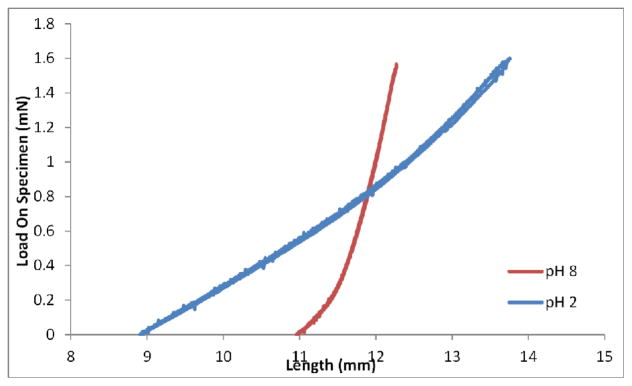

Amplitude of response is a parameter specific to stimuli-responsive behavior of the gel. It is most often reported as the ratio of the volumes of the gel with and without the stimulus. The amplitude of response can be deducted from swelling ratios of gels with and without the stimulus, but not from the single swelling ratio in the presence of the stimulus, because the gel also swells in the absence of the stimuli. Quite often in applications, the response of the gel is important in one dimension only. Moreover, the gel may be constrained or may swell anisotropically. In such cases it is more appropriate to measure the amplitude of response separately for specific dimensions. A constrained gel, being unable to change a dimension, will respond to stimuli by generating force. In this case, the amplitude of response can be measured as stress in the constrained direction or pressure generated by the gel [38].

The amount of mechanical work that the gel is able to produce is important for applications where the gel is employed as an actuator. The work is proportional to both generated force and displacement, and therefore may be also regarded as a measure of the amplitude of response.

Obviously, mechanical robustness is required for many applications. The gel must be strong enough so that its functioning is not compromised and that it is not damaged during processing, handling, service, or storage. It is important to keep in mind that during mechanical deformation a gel may behave either as a “closed system,” for which the volume fraction of solvent remains constant during deformation, or, if immersed in fluid, as a semi-open system that may absorb or give out the fluid [39]. Even in air, a highly swollen gel may expel the fluid in response to a deformation. Depending on these conditions, the results of mechanical testing require different interpretation.

Gels ability to resist deformation is typically characterized by two moduli. Bulk modulus determines the ability of the gel to maintain its volume against external pressure, while shear modulus quantifies the ability of the gel to maintain its shape. The ability to withstand the mechanical load without failure is characterized by the ultimate stress at break, and is usually determined in both compression and tensile tests. Also the maximum strain achievable without gel breakage is important for some applications.

The major structural factor contributing to all those parameters is the number of polymer chains per unit volume, which is proportional to the number of cross-links per volume. It is well known that gel robustness decreases when the gel swells because the numbers of polymer chains per volume decreases. In a recent work, Johnson et al. [40] demonstrated reduction in ultimate tensile strength from 300 to 60 kPa, accompanied by reduction in elongation at break from 150% to 30%, between swollen and unswollen states of a hydrogel. Therefore, the gels need to be characterized in dry state and/or at one or several degrees of swelling, depending on the application.

The moduli and the stress at break usually increase with the increase of crosslinking degree (Fig. 5). Five-fold increase of the crosslinking density may result in an increase in Young’s modulus by an order of magnitude [40]. At the same time, the swelling ratio and the amplitude of volume response typically decrease with the increase of crosslinking degree. This demonstrates that a compromise between the swelling ratio or response amplitude and the mechanical properties may have to be achieved depending on the application requirements.

Fig. 5.

Tensile stress vs strain dependence of Ca2+-cross-linked alginate hydrogels at Ca2+ concentration 0.24 M (1), 0.30 M (2), and 0.60 M (3). Both moduli and stress at break increase with the increase of crosslinking degree. Reprinted with permission from Ref. [41]. Copyright 2003 American Chemical Society.

Some other mechanical parameters can be important for applications. In addition to the already mentioned factors, cyclic repeatability and fatigue durability are essential, because the useful lifetime of many gel-based devices depends on the reversibility of the gel volume change.

The most important parameter for many applications is the speed with which the gel changes its volume. It is a crucial limiting factor for gels, because their volume response is a diffusion process. The volume change of the gel is accompanied by movement of the fluid through the polymer network, as well as diffusion-limited equilibration of chemical potentials of all mobile species present in the fluid. The time needed for dry gel to reach its swelling ratio after immersion in a fluid is called swelling time. Similarly, the time required to reach equilibrium after a change in environment is called response time.

Because one of the main aims of the development of responsive gels is the improvement of the speed of response, it is very important to use a standardized characteristic of this parameter that would allow comparison of gels with various structures. In spite of this, there is currently no well-defined measurement for the response time or swelling time that would suit multiple applications. In superabsorbent polymers industry, Vortex method and Voigt-based model are widely used [42], which appears to be the only examples of standardized measurement of gel swelling speed. Those methods, however, are hardly applicable for other applications, other responsive gel systems, and fundamental research.

Ideally, one would define swelling time as the time needed to reach equilibrium swelling. But gel equilibrium is reached asymptotically and thus would require an infinite time. Often, the response time is considered to be the time after which no additional change of the gel state can be observed during arbitrary long enough time interval by the method used to monitor swelling. Such method is obviously controversial. More reproducible results may be attained if the response time defined as the time needed to reach a certain degree of transition. In general however, the profile of swelling vs. time may differ significantly from one gel system to another thus requiring analysis of the complete time profile of swelling in order to compare the speed of response of the gel systems.

Because the speed of response strongly depends on the gel shape and dimensions, it is important to consider these factors when comparing results obtained on different systems. It is also important to keep in mind that the response time may depend on environmental parameters. For example, characteristic time of swelling of collagen-based materials is pH-dependent [34]. Ionic strength affects the response time of many pH responsive gels [43], while temperature affects the kinetics of almost every process including response of SRG-based sensors [35,44].

4. Overview of Gel-Based Materials by Application

The research in the field of responsive gels is often driven by specific applications. Responsive gels are finding applications in very diverse areas with different requirements. Some applications utilize gels unique ability to hold large amount of fluid, others employ them as actuators or sensors, and some use both their sensing and actuating capabilities at the same time. Different applications require gels to possess different combination of mechanical properties. This section overviews recent application-driven developments of gels and discusses relevant application-specific mechanical factors and needs.

4.1. Superabsorbents

Many applications of gels are built on their unique swelling properties. Superabsorbents, i.e. materials capable to spontaneously take in fluid in the amount of 20 times and more of their dry weight while retaining the shape, are the most straightforward example of such applications. In fact, it is the first successful application of hydrogel swelling capacity. Commercial production of hydrogel-based superabsorbents began in 1978 [42]. Hydrogels in the role of superabsorbent materials are currently widely employed in hygienic products. They also find applications in agriculture for enhancing water retention, improving soil properties, increasing fertilizer and pesticide efficiency, and mitigating contamination of the environment [45,46]. In civil engineering they are used for water blocking in optical cables [47] and for improving properties of cement-based materials [48]. The recent development in superabsorbent materials was reviewed by Zohuriaan-Mehr [42].

Swelling ratio and swelling time are the most important parameters of superabsorbents. Nevertheless, the practical use of hydrogels as superabsorbent revealed the importance of other mechanical properties of gels. Even in hygienic applications, the hydrogel particle must have sufficient integrity to retain its shape and resist the flow and fusion with the neighboring items [42]. Weak superabsorbent materials release moisture upon compression or get squeezed through seams or textile pores. Given that modulus of elasticity and strength of the superabsorbent gels in swollen state is typically low [39], special attention is required to ensure that the mechanical properties of superabsorbent materials meet the application requirements. When the importance of the mechanical properties was recognized, the priorities in diaper manufacturing, a characteristic application of superabsorbents, shifted from maximizing free swelling ratio of superabsorbents to optimizing absorbency under load (ability to absorb fluid while under static load) [49] and to improving gel stability and ability to maintain the absorption capacity against shearing. Additionally, modern superabsorbent materials are required to possess desired rate of absorption, minimal soluble content, and sufficient durability and stability in swelling environments and during storage [42].

Higher absorbency under load and better robustness are typically achieved by increasing crosslinking density, at the expense of free swelling capacity and the speed of absorption. Although the speed of absorption can be increased by creating smaller superabsorbent particles, it usually makes handling them more difficult and does not recover the loss in swelling capacity. Therefore, research of alternative approaches to improve mechanical properties of superabsorbents without compromising their swelling speed and capacity continues. For example, particles with higher crosslinking degree on surface that in the middle showed faster swelling rate and better mechanical properties than the uniformly crosslinked particles with same swelling ratio from the same materials [50]. Further improvement is expected from reinforced superabsorbents described in Section 5.1.

Superabsorbents are commonly based on polyelectrolytes. The global market of superabsorbents is currently dominated by copolymers of acrylic acid. As alternatives, systems based on hydrolyzed polyacrylonitrile, poly(isobutylene-co-disodium maleate), neutral polymers such as poly(acrylamide) (PAAm) and poly(ethylene glycol) (PEG), and natural polymers such as polysaccharides (cellulose and starch) and polypeptides (fish and soy proteins, collagen) are considered.

Although swelling in response to contact with moisture may be to some extent considered as stimuli-responsive behavior, regular superabsorbents are not usually classified as stimuli-responsive hydrogels; nevertheless they are very relevant. Materials used as superabsorbents often constitute a base of systems employed in other gels applications with stimuli-responsive capabilities. Use of gels as superabsorbents demonstrated the demands for mechanical properties that are likely to arise in other applications of gels. Meanwhile, stimuli-responsive materials were recently proposed as recyclable, multiple-use superabsorbents. As an example, Mudiyanselage and Neckers prepared azobenzene-based photochromic superabsorbent polymeric system that expel 80% of absorbed water upon irradiation at 350 nm [51].

4.2. Oil absorbents

By analogy with aqueous superabsorbents, gels can also be used as oil sorbents [52]. Oil sorbents are utilized to control oil spills on water surface and on the ground. Conventionally, polypropylene fiber or non-woven fabrics, polyurethane foam sheets, and melt blown polyesters are employed for this purpose [53,54]. However, gel-forming systems are now considered as promising high-performance oil absorbents and several examples of such systems have been reported. Thus, crosslinked cinnamoyloxyethyl methacrylate/isooctyl acrylate copolymers demonstrated 12 g/g toluene absorbency and 6 g/g crude oil absorbency with swelling time 3–5 h [55]. Docosanyl acrylate/cinnamoyloxy ethyl methacrylate demonstrate 35 g/g oil absorbency after 10 h swelling time [56]. Crosslinking polymerization of 4-tert-butylstyrene/ethylene–propylene–diene terpolymer/styrene–butadiene blend produced absorbent capable of 60 g/g oil absorbency upon ~ 5 days swelling time [57]. Graft terpolymer 4-tert-butylstyrene/ethylene–propylene–diene terpolymer/divynilbenzene attained, depending on synthesis routine, either 84 g/g maximum oil absorbency with reaching 60% of this value in 20 h, or 56 g/g maximum oil absorbency reaching 60% of this value in 10 min [58]. Regular copolymer poly(octadecene-alt-maleic anhydride) crosslinked by ethylene glycol reached 60 g/g oil absorbency within 30 min swelling time [59]. Atta and Arndt performed a detailed parametric study of copolymers of 1-octene and isodecyl acrylate and obtained an absorbent with both high oil absorbency 60 g/g and high Young modulus in the swollen state (0.4 MPa), although with a long swelling time (4–50 h) [60].

Similarly to the aqueous superabsorbent, the applications of gels as oil sorbents require optimization of swelling ratio, swelling time, and mechanical strength. Among unresolved issues remains the question of the most appropriate form/shape/format of the oil sorbents. Bulk form results in slow absorption while particulate form is harder to collect. Systems with open pores may combine faster absorption with ease of collecting provided such systems have mechanical strength in the swollen state sufficient for handling.

The most critical weaknesses of current oil sorbents are their bulkiness, high material cost, and environmental and economic problems with their disposal, as the used absorbent needs to be incinerated or buried after single use [61]. Multiple-use oil absorbents based on SRGs would alleviate these shortcomings. Additionally, stimuli-responsive oil absorbents may offer a way for oil recovery. Development of stimuli-responsive oil absorbents has been recently initiated. For instance, Kulawardana and Neckers synthesized light-sensitive oil sorbent comprising isodecyl acrylate, lauryl acrylate, tert-butylstyrene, and photoresponsive azobenzene groups. Absorbency of gasoline diluted with toluene was 12 g/g within 50 min swelling time. Upon irradiation with 350 nm light, 94% of absorbed diluted gasoline was expelled in 60 min while the nonirradiated gels needed more than 1 day to desorb the oil [62].

In summary, gels and SRGs are still in the early stages of development for oil absorption applications. They demonstrated high oil absorbency but, as in the case of superabsorbents, in order to be successful in this application, their other properties need to be investigated and improved, most notably absorbency rate and mechanical strength.

4.3. Catalysts support media

Several factors make gels very attractive as catalyst supports. First, the catalysts are easier to recycle if they are immobilized in hydrogel. Second, reactions that commonly do not proceed well enough in aqueous media may be possible in a hydrogel environment because reactants can be activated through interactions with the hydrogel. Finally, reactants can be concentrated within the hydrogel because of affinity between the reactants and the hydrogel network [63]. Approaches for entrapping man-made catalysts and enzymes in a gel have been investigated and developed since the early Bernfeld and Wan report [64] on physical immobilization of enzymes into a cross-linked synthetic acrylamide gel.

SRGs possess several advantages over regular gels as catalyst support and reaction media [65]. Responsive behavior of hydrogels simplifies recycling of the catalyst. Reversible deswelling allows further concentrating of the reactants. Control of catalyst activity and availability opens perspectives of intelligent regulation of the reaction rate. Future development in this field may lead, for example, to an antioxidant medicine, where catalytic efficiency can be controlled according to the need of the human body.

The current development of SRGs as catalyst support media has been recently reviewed by Diaz Diaz and co-authors [66]. Here we summarize just a few achievements. A thermoresponsive hydrogel of poly(glycidyl methacrylate-co-NIPAM) with gold nanoparticles was shown to act as a recyclable catalyst [67]. At a temperature below the LCST, it was a homogeneous and efficient catalyst, whereas at a temperature above the LCST, it became heterogeneous and its catalytic activity greatly decreased. A thermally recyclable (via swelling/deswelling) catalyst was attained by immobilizing the enzyme thermolysin on copolymer of NIPAM and N-acryloxysuccinimide [68]. A thermoresponsive and pH-responsive, chelating, and superabsorbent hydrogel of poly(NIPAM)-co-poly[2-methacrylic acid 3-(bis-carboxymethylamino)-2-hydroxypropyl ester] was synthesized and proposed as both a reaction medium and a recyclable Pd catalyst support for Suzuki, Heck, and other organic reactions [69]. Same polymer system with gold nanoparticles was demonstrated also to concentrate reactants within the hydrogel matrix through the reversible deswelling [70].

For applications as a catalyst support media, the gel must possess the adequate characteristics as a reaction media, i.e. required hydrophilicity and lipophilicity and activation of reactants. These applications also require that the gel efficiently immobilizes the catalyst and provides adequate mechanical robustness for handling, while allowing an easy access of reactive compounds to the catalyst.

4.4. Sensors

Gel ability to change volume in response to a specific stimulus is utilized in many sensing designs that are currently under development. A variety of gels with various chemical structures have been proposed, which can collectively achieve response to a broad range of stimuli (Table 1).

Table 1.

Characteristics of some SRG-based sensor prototypes

| Detecte d signal |

material | Sensing mechanism | shape | Respon se time |

Signal transducing technology |

Notes | Ref. |

|---|---|---|---|---|---|---|---|

| Ionic strength | Poly(AAm-co-APTAC-co-AMPS) | Mobile ions interrupt interactions between hydrogel-bound ions, reducing effective cross-linking | Film 10 μm | 30 s | Hologram | Response to ionic strength is near independent of pH | [71] |

| pH | P4VP | Donnan equilibrium (protonation of pyridyl groups) | Film ~100 nm | QCM | [72] | ||

| pH | Poly(MAAc-co-poly(ethylene glycol) dimethacrylate) | Donnan equilibrium (ionization of MAAc) | Film 2.2 μm | 10–15 min | Microcantilever | Sensitivity up to 5×10−5 pH unit | [73,74] |

| pH | Poly(AAm-co-DMAEM) | Donnan equilibrium (ionization of DMAEM) | Film 15 μm | ~ 15 min | Microcantilever | [75] | |

| pH | Poly(AAm-co-DMAEM) | Donnan equilibrium (ionization of DMAEM) | Film 400 μm | 10–30 min | Pressure sensor | Pressure up to 180 kPa | [76] |

| pH | Poly(AAm-co-DMAEM) | Donnan equilibrium (ionization of DMAEM) | Film 10 μm | 10–30 min | Pressure sensor | Pressure up to 200 kPa | [77] |

| pH | PVA/PAAc mixture | Donnan equilibrium (ionization of AAc) | Film 0.4–1 μm | 500–800 ms | QCM | [78] | |

| pH | Poly(iOA-co-AAc) | Donnan equilibrium (ionization of AAc) | Film 1–4 μm | 14–27 min | Magnetoelastic sensors | [79] | |

| pH | PVA/PAAc mixture | Donnan equilibrium (ionization of AAc) | Film 250 μm | 15–200 min | Bending plate | Response time depended on pH | [80] |

| pH | Copolymers of HEMA with MAAc, TFMPA, DMAEM, or VI | Donnan equilibrium | Film 10 μm | 250–2000 s | Hologram | Response time depended on buffer concentration | [43] |

| pH and ionic strength | Poly(AAm-co-DMAPAAm) | Donnan equilibrium (ionization of DMAPAAm) | half-sphere 60 μm radius | 8 s for ionic strength and 90–130 s for pH | Optical fiber interferometric technique | [81] | |

| pH, Ca2+, and Cu2+ | Polyvinylbenzyl chloride with dicarboxylate groups | Dissociation of dicarboxylate groups or formation of complexes between dicarboxylate groups and metal ions | Gel micro particles in gel support film | 12–30 min | Optical transmittance | pH range: 5–8; Ca2+:0–0.01 M; Cu2+: 0–0.001 M | [82] |

| K+ | Poly(HEMA) with pendant 18-crown-6 groups | Donnan equilibrium (charged complex with 18-crown-6) | Film 10 μm | 30 s | Hologram | Selective to K+ over Na+ | [83] |

| Pb2+ | Poly(AAm-co-4-acrylamidobenzo-18-crown-6) | Donnan equilibrium (charged complex with benzo-18- crown-6) | Film | PCCA | Also sensitive to K+ | [84,85] | |

| Pb2+ | Poly(AAm-co-4-acrylamidobenzo-18-crown-6) | Donnan equilibrium (charged complex with benzo-18- crown-6) | Film 15 μm | Microcantilever | [86] | ||

| Metal ions | PAAm with pendant 8-hydroxyquinoline groups | Complexation-induced additional cross-links | Film | PCCA | Sensitive to Cu2+, Co2+, Ni2+, Zn2+ | [87] | |

| Metal ions | Poly(HEMA-co-carboxymethyl-(2-methyl- acryloyl)-amino acetic acid) | Network ionization and crosslinking due to complexation between ions and chelating groups | Film 10 μm | 30 s | Hologram | Sensitive to Ni2+, Zn2+, Co2+, Ca2+, Mg2+; also sensitive to pH and ionic strength | [88] |

| CrO42− | Poly(AAm-co-APTAC) | Neutralization of network due to complex between trimethylammonium group and CrO42−. Also possible cause is exchange of a highly hydrated anion(Cl−), for a less hydrated CrO4−2 | Film 15 μm | Microcantilever | In addition to proposed mechanism, volume change may be caused by shrinkage due to additional cross-links | [89] | |

| CO2 | PMAAc grafted with DETA | Donnan equilibrium (ionization MAAc (anion) and DETA (cation)) | Micro particles | 50 min | Pressure sensor | Sensitivity over wide pH range; 400 kPa can be generated | [38] |

| urea | Poly(HEMA-co-DMAEM) with immobilized urease | Urease hydrolyses urea to ammonium bicarbonate; pH change shifts Donnan equilibrium | Film | 50–500 s | Hologram | Cross-sensitivity to pH | [90] |

| Organo phosphorus compounds | PAAm with pendant organophosphorus hydrolase and 3-aminophenol | Hydrolysis of organophosphorus compounds leads to pH change detected by pH sensitive gel | Film | PCCA | Cross-sensitivity to pH | [91,92] | |

| Organo phosphorus compounds | Poly(HEMA-co-MAAc) with immobilized organophosphorus hydrolase | Hydrolysis of organophosphorus compounds leads to pH change detected by pH sensitive gel | Film | 10–30 min | Magnetoelastic sensor | Detection limit as low as 10−7 M; cross-sensitivity to pH | [93] |

| Glucose | Hydrolyzed PAAm with immobilized GOx | GOx hydrolyzes glucose; pH change shifts Donnan equilibrium | film | PCCA | AAc is produced by hydrolysis | [84] | |

| Glucose | Poly(iOA-co-AAc) for pH sensing and GOx and catalase for glucose hydrolysis | GOx hydrolyzes glucose; pH change shifts Donnan equilibrium; catalase removes H2O2 and recovers oxygen | Two-layered film | 20–100 min | Magnetoelastic sensors | Cross-sensitivity to pH and ionic strength | [94] |

| Glucose | Poly(glucosyloxyethylmethacrylate) with pendant concanavalin A (ConA) | Free glucose breaks complex between immobilized glucose groups and ConA reducing the number of cross-links | Bulk 1 mm thick | Few hours | [95] | ||

| Glucose | PAAm with pendant phenylboronic or fluorophenylboronic acid groups | Donnan equilibrium (complexation-induced network ionization) | Film 10 μm | Hologram | Selectivity to glucose over lactose was investigated | [96] | |

| Glucose | PAAm with pendant phenylboronic acid and dimethylaminopropyl groups | Complexation-induced additional cross-links | Film 10 μm | Hologram | Selectivity to glucose over lactose, galactose, fructose, etc. | [97] | |

| Glucose | Copolymer of 2-acrylamidophenylboronic acid with PEG, APTAC, and [2-(acryloyloxy)ethyl]trimethyl ammonium chloride | Complexation-induced additional cross-links | Film | 10 min (50%) | Hologram | Little pH dependence; little sensitivity to lactose | [98] |

| Glucose | PAAm with pendant phenylboronic acid groups | Glucose binding shifts pKa of boronic acid groups and changes network ionization | Film | PCCA | [99] | ||

| Glucose | PAAm and poly(AAm-co-n- hexyl acrylate) with pendant fluorophenylboronic acid groups | Complexation-induced additional cross-links | Film | 10–60 min | PCCA | Demonstrated dependence of response speed on temperature | [35,44] |

| Glucose | 3-aminophenylboronic acid-functionalized poly(NIPAm-co-AAc) | Glucose binding shifts pKa of boronic acid groups and changes network ionization | Film 0.2–15 μm | 30–120 min | Fabry–Pérot interferometer | [100] | |

| Glucose | PMMA modified with diethylenetriamine, butylamine, and 3-aminophenylboronic acid | Complex of glucose with pendant groups acts as additional cross-links | Bulk ~8×7×1 mm | 40 min | High glucose selectivity over fructose and galactose. | [101] | |

| Glucose | Imprinted copolymer of HEMA and MAAc | Imprinted sites | Film ~1mm | 60 min | [102] | ||

| Penicillin G | Poly(HEMA-co-MAAc) with immobilized penicillinase | Penicillinase hydrolyses penicillin to penicilloic acid resulting in shrinking of pH sensitive gel | Film | 50–500 s | Hologram | [90] | |

| Penicillin G | Poly(iOA-co-AAc) with immobilized penicillinase | Penicillinase hydrolyses penicillin to penicilloic acid resulting in shrinking of pH sensitive gel | Film | 40 min | Magnetoelastic sensor | Cross-sensitivity to pH and ionic strength | [103] |

| L-lactate | Poly(AAm-co-4-acrylamidophenyl boronate) | Ionization of network as a result of complexation between boronic acid and L-lactate | Film | 200–500 s | Hologram | [104] | |

| Nucleotides (ATP/AMP) | Poly(APTAC-co-3-(acrylamido)phenylboronic acid) | Complexation that results in change in network ionization | Film | QCM | [105] | ||

| Nucleotides (AMP/GMP/CMP/UMP)) and saccharides | Imprinted poly(AAm-co-3-(acrylamido)phenylboronic acid) | Imprinted sites | Film | 300 s | QCM; ion-sensitive field-effect transistors | Imprinting enhances selectivity and sensitivity | [106] |

| herbicides | Herbicide-imprinted poly(AAm-co-MAAc) | Imprinted sites; unexplained water uptake due to complex formation | Film 10 μm | 120 s | QCM; ion-sensitive field-effect transistors | [107] | |

| Molecular weight of polyelectrolytes | Charged PNIPAm-based gel film coated with gold layer of various thickness | Thickness and average pore size of gold layer determine what polyelectrolytes can penetrate into microgel | Film | Array of Fabry–Pérot interferometers | [108] | ||

| AFP (tumor-specific marker) | Interpenetrating network of AFP-imprinted lectin (ConA) and polyclonal AFP-antibody grafted AAm gel | Reversible cross-link formation through lectin–glycoprotein–antibody complexes | Bulk | Designed to detect human hepatocellular carcinoma | [109] |

Temperature sensors are in high demand for industrial applications and to identify sites of infection, inflammation, or other pathology in health care. Many polymer systems were therefore investigated for applications in gel-based temperature sensors. Most of these systems contain polymers that exhibit LCST, i.e. shrink when heated, or upper critical solution temperature (UCST), i.e. swell when heated. Among the polymers with LCST, in addition to classical poly(NIPAM)-based hydrogels, several polymers such as N,N-Diethylacrylamide, proline methyl ester, and poly(N-vinylcaprolactam) were used in sensing devices. PAAc/PAAm blends and PAAc/PEG blends are examples of systems that exhibit UCST.

Several hydrogel-based sensors were designed to measure pH, an important parameter of aqueous solutions. Usually, such sensors utilize the pH dependence of the ionization degree of weak polyelectrolytes. The ionization degree determines the charge of the network and therefore the amount of the contribution of charge interactions to the osmotic pressure of the hydrogel. Hydrogels based on negatively charged groups, such as AAc, etc. increase their volume in response to increase of pH. Hydrogels that swell in response to decrease of pH are based on polycations, such as DMAEM. SRG-based sensors have been developed for detection of other cations, such as K+, Na+, Pb2+, and anions such as CrO42−.

Several sensing motifs have been proposed for detecting the concentration of glucose, a measurement important for controlling blood glucose level in the care of diabetes mellitus. The most common approach utilizes glucose oxidase (GOx). In this approach, glucose inside the gel is enzymatically converted to gluconic acid which lowers local pH and in turn triggers volume change of a pH-sensitive gel [110]. One shortcoming of this approach is that enzymatic reaction consumes oxygen and produces hydrogen peroxide, which inhibits the GOx activity. This shortcoming can be partially overcome by incorporation of catalase in addition to GOx. Catalase recovers a fraction of consumed oxygen and removes hydrogen peroxide [94,111]. Another shortcoming is the sensor cross-sensitivity to pH and usually also to the solution ionic strength. An alternative approach, with low sensitivity to pH or the ionic strength, is based on complexation of glucose and concanavalin A (ConA). In this approach, the portion of SRG cross-links is made by complexation between glucose groups and ConA that both are covalently attached to the gel network. In the presence of free glucose, some complexes between immobilized glucose and ConA break in favor of formation of complexes between free glucose and ConA, thus reducing the number of cross-links and causing the gel to swell [95,112,113].

Fully synthetic glucose sensors are more attractive for commercial use. The majority of such sensors are currently based on phenylboronic acid. In these sensors, glucose binds to phenylboronic acid leading to change in the dissociation constant of the acid. Thus, at pH close to pKa of the phenylboronic acid groups, the charge of a gel network with pendent phenylboronic acid groups will depend on the concentration of glucose. Unfortunately, pKa of phenylboronic acids is usually outside of the physiologically relevant pH range. Additionally, SRGs that are built on the charge interactions are sensitive to ionic strength and may lose their sensitivity at physiological ionic strength [99]. Therefore, significant effort was devoted to the development of better glucose sensors based on boronic acid. The most noticeable advancement was achieved in gels that utilize the mechanism of reversible cross-links, which can be independent of the ionic strength [35,44,96–98,114]. In such gels, a molecule of glucose forms a complex with two phenylboronic acid groups, causing gel shrinkage. pKa of phenylboronic acid groups can be lowered by using fluorinated derivatives of the acid [35,44,114] or the pH dependence of the complex formation can be eliminated by adding an acrylamide group to the ortho position of the phenylboronic acid group [98]. Another completely synthetic glucose-sensitive gel was obtained from PMMA modified with diethylenetriamine, butylamine, and 3-aminophenylboronic acid. The gel showed high selectivity to glucose over fructose and galactose [101].

Hydrogel-based sensors for other biologically relevant compounds are also being developed. The approach based on immobilization of enzymes was utilized in sensors detecting urea and penicillin [90,103]. Phenylboronic acid binding was used in sensors to nucleotides, saccharides, and L-lactate [104,105]. Several sensing motifs utilize approach of reversible crosslinking, where free analyte compete with pendent groups for binding positions within protein sites. When free analyte replaces pendent groups in complexes, the network loses effective crosslinks. When the analyte decreases in concentration within the bulk phase, the protein binds again with the pendent groups closing the network structure. Similarly, systems have been designed that have a specific antigen and corresponding antibody grafted to a semi-interpenetrating network, which swells in response to binding of the antigen due to a loss of effective crosslinks (Fig. 6) [115,116].

Fig. 6.

Scheme of response mechanism of an antigen-sensitive hydrogel. Free antigen (analyte) replaces immobilized antigen in antigen-antibody complex, reducing the number of cross-links in the gel and thus causing gel swelling. Reproduced with permission from Ref. [116]. Copyright 1999 American Chemical Society

Recently, molecular imprinting, a promising technique of artificially generated molecular recognition, has been extended to stimuli-responsive hydrogels. Molecular imprinting involves forming complexes between the template molecules and functional monomers, oligomers, or polymers prior the polymerization or crosslinking. The polymerization and crosslinking occurs in the presence of the complex. The template is then removed after the synthesis, producing a matrix with specific recognition elements for the template molecules (Fig. 7) [117]. The potential of molecular imprinted sensing hydrogels was demonstrated by Miyata et al. in a tumor marker-responsive hydrogel that can be used to detect human hepatocellular carcinoma [109]. Molecular imprinting was also used to create hydrogels sensitive to glucose [102,118,119], various nucleotides [106], herbicides [107], proteins [120], etc. More detailed account of the evolving field of molecular imprinting can be found in several recent reviews [102,117,121–127].

Fig. 7.

Scheme of the imprinting process of atrazine in a hydrogel film. The polymerization and crosslinking occurs in the presence of atrazine. After the synthesis, atrazine is removed, producing a matrix with specific recognition elements for the imprinted molecules. Reproduced from Ref. [107] with permission of The Royal Society of Chemistry.

Several methods are used to convert the stimuli-responsive changes in hydrogels to evaluable output signals. One group of methods works on optical principles. These methods monitor optical transparency [82,128], refractive index [128,129], or fluorescence intensity [130]. Other optical methods measure directly the volume of miniature hydrogels. A simple device may consist of an optical fiber coated on the end with a drop of SRG (Fig. 8A) [81,131,132]. Alternatively, the SRG can be coupled to a reflector so that the reflector is moved in response to the change of the hydrogel volume. The position of the reflector can be determined from light interference (Fig. 8B) [22,100,133,134] or from the intensity of light in a system of two optical fibers (Fig. 8C) [135].

Figure 8.

Reflective optical methods for detecting gel volume change in sensors. (A) Drop of gel at the end of optical fiber; gel volume change alters interference of reflected light in the optical fiber. (B) Gel film attached to reflective surface and covered with reflective metal islands; change in thickness of the film is determined from light interference. (C) Gel moving reflector; position of the reflector determines the amount of light delivered from one optical fiber to another. 1 – gel; 2 – optical fiber; 3 – reflector; 4 – flexible diaphragm.

Photonic crystals are another approach in optical detection of hydrogel volume. Asher et al. incorporated colloidal crystalline arrays into various SRGs [84]. Such arrays diffract the light giving rise to an intense color. Volume change of the gel modifies the lattice spacing of the colloidal array and shifts the wavelength of the maximum intensity of the diffracted light (Fig. 9). Same effect can be attained by means of inverse opal structures, which are produced by dissolving the material of the colloidal crystalline array after the fabrication of the hydrogel [136–138]. Alternatively, a hologram fabricated inside the hydrogel can be utilized to monitor the volume of the SRG by the diffraction wavelength or color [43,71,88,90,96,104]. Plasmon resonance techniques were also shown to be a feasible, although somewhat complicated, method to measure the thickness of nanosized films [139].

Fig. 9.

Detection of gel volume by diffraction maximum of embedded photonic crystal (colloidal crystalline array). When illuminated by white light, (A) shrunken gel diffracts light with shorter wavelength than (B) swollen gel. (C) Diffraction maximum is detected by spectrometer. Swelling of the gel causes red-shift of the diffraction maximum while shrinking causes blue-shift. Reproduced from Ref. [91] with permission of Springer.

Change of electric conductivity [140–142] and capacity [143] associated with the volume change of hydrogels was also used in sensing devices. Other sensors employed quartz crystal microbalance technique (Fig. 10) [78]. These sensors were built on the ability to measure very precisely the resonance frequency of piezoelectric quartz crystal resonator. The resonance frequency depends on the elastic properties and the mass of the vibrating body; these parameters in turn depend on the swelling state. Similarly, detection of mechanical resonance frequency was used in magnetoelastic sensors with remote query capabilities [79,103,144]. Finally, several approaches were developed that measure force or deformation of an elastic body generated by the constrained hydrogel. Such devices utilize, among other approaches, bending plates and other pressure sensors [38,76,77,80,143,145,145,146] or microcantilevers [73–75,89,147] (Fig. 11).

Fig. 10.

(A) Scheme of quartz crystal microbalance sensor. (B) Frequency response of poly(4-vinylpyridine)-coated quartz crystals to pH change. (B) is reprinted with permission from Ref. [72] Copyright 2005 American Chemical Society

Fig. 11.

Sensing devices based on force or deformation of an elastic body generated by SRG. (A) Pressure sensing approach: stimuli-dependent force generate by confined gel is registered by pressure sensor [38], (B) Capacitive transducer approach: stimuli-triggered expansion of gel changes distance between capacitor plates that is being captured by measuring the capacitance. Reproduced from Ref. [143] with permission of Springer. (C) Microcantilever approach: expansion of a gel layer causes deflection of cantilever that is determined by deflection of laser beam. Reproduced from Ref. [74] with permission of Springer.

Sensing applications impose specific requirement on SRG. A list of important sensor specifications includes such characteristics as sensitivity, stability, accuracy, speed of response, hysteresis, stimulus range, resolution, and selectivity [148]. Although not always obvious, these characteristics in most gel-based sensors are, in fact, determined by gel mechanical properties. The response of the gel usually consists of generation of force, change of volume or shape, or other mechanical processes.

The time of response is one of the critical parameters of gel-based sensors. Most sensors are currently comparatively slow. The time of response depends, among other factors, on the dimensions of the gel. Therefore, the sensing devices based on gels have a tendency for miniaturization. Those devices utilize either a thin film of hydrogel or small particles. Miniaturization, however, complicates the reading of the response. Additionally, small particles are hard to immobilize and the film-based sensors often suffer from delamination from the surface [149]. Future improvement of the response time is expected with the methods presented in Section 5.2.

Stimulus range, sensitivity, and resolution are other major characteristics that attract significant attention in the research on gel-based sensors. Those parameters have a direct relation to the response ratio of gels which is influenced by the structure of SRG. Other characteristics, such as accuracy, hysteresis, and stability of gel sensors are also beginning to receive attention. A very important parameter which is often overlooked by researchers is selectivity. This parameter defines the ability of the sensor to respond primarily to one stimulus in the presence of other stimuli. For SRG, selectivity issue is especially critical because the volume of the gel usually depends on several environmental parameters. For instance, many temperature sensitive hydrogel systems are also sensitive to pH; response of pH-sensitive hydrogels often depends on ionic strength; and PAAc-based and other pH sensors may also be responsive to metal ions.

Several recent scientific reports addressed this issue and demonstrated the extent of the selectivity problem, as well as methods for improving sensitivity. González et al. investigated selectivity and cross-sensitivity of poly(HEMA-co-carboxymethyl-(2-methyl-acryloyl)-amino acetic acid) hydrogel to various metal ions, pH, and ionic strength [88]. Selectivity of other metal sensors has also been investigated [83,84,87]. A significant effort was devoted to understand the requirements for selectivity of glucose sensors and to improve the existing designs [35,94,96–99,101]. Temperature, pH, ionic strength, other carbohydrates, and lactose were identified as the parameters that can cause interference in detecting glucose. Glucose itself, on the other hand, was found to be the major possible interference for detection of L-lactate in blood with the holographic sensor based on phenylboronic acid. In the last case, reducing the concentration of the ligand in the hydrogel, although decreased the sensitivity toward L-lactate, eliminated the interference from glucose [104]. Analyte specificity and responsiveness can be achieved with molecular imprinting strategies [117,150,151]. Molecular imprinting was shown to improve selectivity for glucose in one sensor design [118,119] and selectivity to metal ions in another [152]. Watanabe et al. [153] produced norephedrine- and adrenaline-imprinted stimuli-responsive gel with molecular recognition achieved by molecular imprinting. Both gels were sensitive to the analyte used for imprinting and insensitive to the other. Arnold et al. proposed another technique to improve selectivity. Their hydrogel glucose sensor was encapsulated within a bipolar ion exchange membrane impermeable for ions, but freely permeable for glucose [141]. This way the hydrogel response to glucose can be measured without the interference of ions. Finally, an array of sensors, each with selectivity to a particular parameter, can be employed to determine simultaneously the parameter of interest and all interfering factors [154].

In conclusion, SRGs are a versatile platform for development of sensors for a broad range of analytes. SRG-based sensors are especially attractive for medical applications and for development of inexpensive sensors. To avoid slow response time, gels with small dimensions can be utilized. Most often the gels are used in a form of thin films. Reading of the volumetric changes of such gels is a significant undertaking; several approaches were proposed. The majority of these approaches employ optical methods. Additional research is needed to establish and optimize SRG sensor selectivity, accuracy, and stability. Further development of theory of gel swelling and understanding of their response mechanisms is required to gain wide acceptance and utilization of this sensing platform.

4.5. Actuators

Application of gels as actuators was historically considered promising because gel properties resemble properties of muscles. Thanks to this resemblance, such systems became known as “artificial muscles”. They are particularly attractive for making biologically inspired devices and robots that mimic the movements of humans, animals, and insects. Several gel actuators systems were proposed (see Table 2) and a number of proof-of-concept devices that utilize gel actuators have been reported. Thus, Kurauchi et al. reported a robotic hand and a “swimming” device, both based on PVA-PAAc hydrogel actuated by electric field [155]. Osada and Gong fabricated similar “swimming” device based on poly[2-(acrylamido)-2-methylpropanesulfonic acid] hydrogel. The device showed eel-like motion in a surfactant solution at the 10 V alternating voltage [156]. An actuator based on poly(acrylonitrile) (PAN) gel fibers build by students from Virginia Tech participated in the first arm-wrestling match between an EAP actuated robotic arm and a human (AMERAH) organized by Bar-Cohen [157]. In the second AMERAH, the modified version of the actuator was the strongest artificial arm [158].

Table 2.

Characteristics of some SRG applications in actuators and microfluidics.

| Material | Type of control | Shape | Application | Notes | Ref. |

|---|---|---|---|---|---|

| PEDOT, PSS, PAAm, PAAc | Electroactive | Bulk | Macroscopic actuator | Compressive fracture stress of 1.2 MPa and a fracture strain of 90%. | [178] |

| Layers of PAAm and PAAc gels | Electroactive | Multilayered | Macroscopic actuator | When AAc layer expels water, AAm layer takes water, and vice versa. Thickness changes by 10–15% in response to 3 V. | [165] |

| Poly(AAc-co-vinylsulfonic acid) | Electroactive | Bulk | Macroscopic actuator | Contraction by 15–40% in response to 4.5 V in ~60 min. | [179] |

| P(Aac-co-Aam) blended with conductive polypyrrole/carbon black composite | Electroactive | 400×400×2500 μm | Bending actuator | Bending up to 30 degree. 5 s response time. | [171] |

| Saponified PAN | Electroactive | Yarns of roughly 2000 fibrils of 7 μm diameter | Artificial muscle | Response time: 10–15 min. Linear response ratio: 2 times. Contracted: 1 MPa modulus, 5 MPa strength, 2.4 elongation. Elongated: 4 MPa modulus, 1.5 MPa strength, 0.4 elongation. | [180] |

| PNIPAM | Temperature | Microparticles (~500 μm) and photopatterned microactuator (250×250×50 μm) | Control valve for microfluidics | Explored optimal particle size and optimal particles volume/chamber volume ratio. 0.3–10 s response time. Up to 840 kPa pressure resistance. | [181] |

| PNIPAM | Temperature | Photopatterned microactuator (2000×200×100 μm) | Control valve for microfluidics | 3–5 s response time. 1400 kPa pressure resistance in closed state. 300 kPa back pressure in open state at flow velocity 5 cm/s. | [182] |

| PNIPAM | Temperature | Photopatterned microactuator | Control valve for microfluidics | Applied in polymerase chain reaction device. 5 s response time. Pressure resistance 200 kPa. | [174] |

| P(NIPAM-co-NEAAm) | Temperature | Photopatterned microactuator (5000×100×40 μm) | Control valve for microfluidics | Copolymers with NEAAm enabled higher switch temperature than PNIPAM along. 1–4 s response time. Pressure resistance more than 15 MPa in closed state. | [183] |

| P(NIPAM-co-sodium acrylate) | Temperature | Microactuator | Control valve for microfluidics | 5–10 min response time. | [184] |

| PNIPAAm | Temperature | Photopatterned microactuator (5000×100×100 μm) | Control valve for microfluidics | 4–6 s response time. 9 MPa pressure resistance. | [185] |

| PNIPAAm | Temperature | Microgels | Control valve for microfluidics | Pressure resistance up to 9 MPa; opening time as low as 0.3 s; 2 s closing time. | [186] |

| PNIPAAm | Temperature and alcohol concentration | Microgels | Electronically adjustable automatic control of concentration of alcohols | Pressure resistance up to 600 kPa. Flow rate changes more than 30 times. | [187] |

| PNIPAAm | Temperature | Microactuator | Control valve for microchannel concentrator | 50–240 s valve switching time. | [188] |

| PNIPAAm | Temperature | Photopatterned microactuator | Diffusion micropump | 0.54 μl/min in peristaltic mode and 2.8 μl/min in pulsating mode at 0.43 kPa pumping pressure. 1.28 kPa maximum pumping pressure. | [189] |

| PNIPAAm | Temperature | Packed microgels | Displacement micropump | Higher performance can be achieved by increasing actuator thickness and pump chamber volume. 4.5 μl/min at 0.5 kPa and 0.2 μl/min at 7.5 kPa. | [189] |

| Composite of poly(NIPAAm-co-AAm) and light absorbing particles | Light | Microvalves | Microfluidic control of flow by light of specific wavelength | Gold colloid nanocomposite collapses in response to green light. Gold nanoshells composite collapses in response to near-IR light | [190] |

| PNIPAM functionalized with spirobenzopyran | Light | Microvalves | Microfluidic control of flow by light | 18–30 s to open; more than 1 h to close. | [191] |

| PAN | pH and electroactive | Fibers | Macroscopic actuator | 2.2 times change in length. 0.1 MPa contraction stress. | [192] |

| Poly(HEMA-co-AAc) | pH | Microvalve ~200 μm | “Self-regulated” pH control valve in microfluidic | Several minutes response time. | [193] |

| Poly(HEMA-co-AAc) or poly(HEMA-co-DMAEM) | pH | Microvalves | Switching between channels | 8–12 s response time. More than 300 kPa differential pressure. | [194,195] |

| poly(4-hydroxybutylacrylate–co-AAc) | pH | Microsphere | Microfluidic valve | Flow rate changes 10 times. Valve opens/closes in 4–8 min. | [196] |

| Poly(HEMA-co-AAc) | pH | Cylindrical microactuators | Microvalve and micropump | 35 kPa pressure of micropump. 1.5 MPa pressure resistance of microvalve. 2 μl/min flow rate by the pump along. For a fast bolus release the micropump is used in combination with the valve. The valve is opened after full swelling of the pump actuator, releasing the content of the pump chamber within a few seconds at an average flow rate of 540 μl/min. | [197] |

| Poly (AAm-co-3-methacrylamidophenylboronic acid) | Glucose | 70 μm thick film | Microfluidics; artificial pancreas. | More than 5.4 kPa pressure resistance. 17–18 min response time. 1.5 linear response ratio for 0–100 mM glucose shift. | [198] |

| Poly(NIPAM-co-AMPS-co-Ru(bpy)3) | Cyclic BZ reaction | 0.5 mm thick film | Self-oscilating | Self-waking on ratchet surface. ~100 s per cycle. Walking speed 170 μm/min. | [199] |

| Poly(NIPAM-co-AMPS-co-Ru(bpy)3) | Cyclic BZ reaction | 0.5 mm thick free-standing membrane | Self-oscilating | Cyclic pendulum motion. ~300 s per cycle. | [200] |

| Poly(NIPAM-co-AMPS-co-Ru(bpy)3) | Cyclic BZ reaction | Film | Transport of particles on surface | 1–4 mm/min particle speed. | [201] |

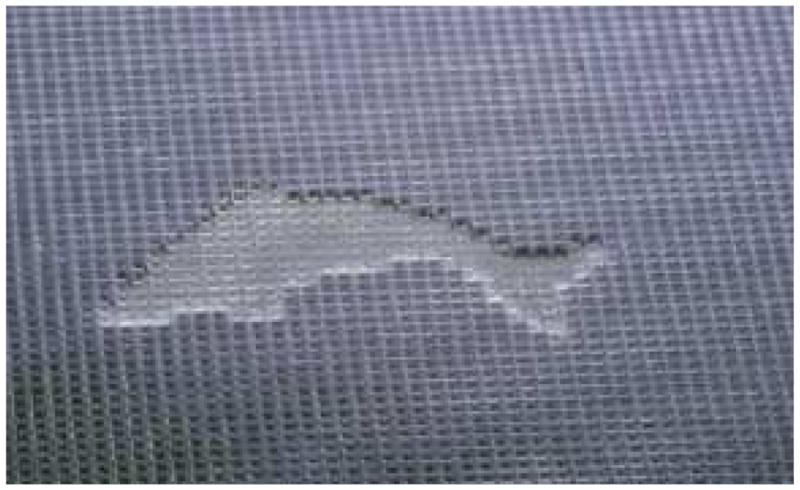

More recently, Lee et al. demonstrated pH-sensitive hydrogels mimicking the shape and motion of octopus and sperm [159]. Richter and Paschew fabricated a tactile display consisting of 4,225 PNIPAM actuators at a pitch of 580 um (Fig. 12) [160]. Each actuator was individually controlled by light-induced temperature field. Within several seconds, the display generated palpable information based on various height and softness of the actuators. Such display would allow advanced virtual reality devices and improved communication for visually impaired persons with electronic media. Additional examples of gel actuators can be found in several specialized reviews [161–164].

Fig. 12.

Image of a dolphin displayed by SRG-based tactile display. The length of the image from mouth to tail is 14.5 mm. Reproduced with permission from [160]. Copyright 2009 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

However, several well developed actuator technologies already exist. In order to be compatible with other actuation technologies, gels need to match or outperform other platforms in a combination of parameters. One set of important factors is related to the “amount” of actuation that an actuator can produce. These factors include actuation strain, actuation stress, and work that the gel can produce in a single stroke. Gels perform quite well in regard to some of these factors (Fig. 13), offering one of the highest actuation strains among all devices and above average work per stroke; actuation stress, however, is relatively low. Other gel advantages include high resilience and ability to handle fragile objects. Some of the properties of gels, however, are rather unconventional for current common designs of machines and devices. The gels are wet and, on fundamental level, controlled chemically. For many applications, the requirement of keeping the gel wet represents a hurdle. It makes gels, however, a natural candidate for applications in aquatic environment or biological fluids. Solutions are being developed to circumvent the gel need to stay immersed in liquid. Liu and Calvert, for instance, suggested a “sandwiched” structure that contains a responsive gel layer and another gel layer used to store the fluid (Fig. 14) [165].

Fig. 13.

Actuation stress versus actuation strain for various actuators. Performance of SRGs usually falls into the shaded box. SRGs produce high actuating strain but improvement of actuating stress is needed. Data for non-gel-based actuators is taken from Ref. [166].

Fig. 14.

Schematic of a “sandwiched” structure of hydrogel actuator capable of working without external fluid [165]. Applying electric potential between electrodes produces flow of hydrogen ions from the positive electrode, which causes the polyacrylic acid layer to shrink and force water into the polyacrylamide. The shrinkage of polyacrylic acid layer (which is stiffer than PAAm layer) causes the whole stack to contract in the directions parallel to the interface between the gels.

Control of actuation with environmental stimuli such as temperature, pH, or light is also relatively uncommon in current actuator designs. For modern technologies, electrically driven actuators are usually more suitable. Electroactive ionic gels that can be controlled electrically are being currently investigated and developed [167–172].

The most important shortcoming of gel actuators, however, is their response rate, which diminishes such important characteristics as maximum frequency of strokes (Fig. 15) and power. Bulk macroscopic gels are unacceptably slow for most actuators applications. Therefore methods of improvement of response rate (discussed in Section 5.2) are highly relevant for gel actuators.

Fig. 15.

Work per unit volume in a single stroke versus maximum frequency of strokes for various actuators. Common performance of macroscopic SRGs is shown by a shaded block. While SRGs demonstrate generous work per unit volume in a single stroke, their frequency of strokes is limited by their slow response rate. Increases in response rate and frequency of stroke are critically needed. Data for non-gel-based actuators is taken from Ref. [166].

Nonetheless, gel actuators possess other unique properties, such as no power requirements, and no moving parts. Therefore, they are ideally suited for specialized applications, such as autonomous medical pumps for long-term drug release [173,174] and autonomous valves for power-free field irrigation [175–177].

4.6. Microfluidics and valves

If the response time is improved, gels offer significant benefits for many specific applications. An illustrative example is an application of gels in microfluidics. This application is being developed in the recent two decades. The application of SRGs in microfluidics has been reviewed in Refs [18,202,203].

SRG-based actuators are a good fit for the application in microfluidics. They are simple, have minimal amount of moving parts, and do not require power. Conventional microactuators (e.g. using electromagnetic, electrostatic, or thermopneumatic effects) require external power for operation and relatively complex assembly [194]. Another important aspect of SRG-based valves is their tolerance of the dust. Dust is a major source of malfunction in conventional lab-on-a-chip systems. Dust particles get caught in the actuator moving parts made from rigid materials, such as silicon or glass, compromising the actuator function. Because hydrogels are soft and resilient, the hydrogel actuator will shape itself around the dust particle. Hydrogels are also able to handle soft objects and substrates, such as cells and embryos, which would normally get damaged by the contact with rigid actuator parts.

Hydrogel actuators are an excellent option for microfluidic control valves. They can be activated by temperature, light, or flow composition (see Table 2). Although hydrogel is a soft material, hydrogel-based valves are remarkably pressure-resistant [204]; a hydrogel valve was able to operate at back pressure as high as 18 MPa [183]. Hydrogel actuators are also a viable option for micropumps [205]. Such micropumps can control lower flow rates, have lower dead volume, and are less expensive than conventional micropumps [189,206].

Importantly, microfluidic applications can benefit from using SRGs as sensor and actuator simultaneously. Same body acting as sensor and as actuator represents the smallest possible close-loop control system. Very few other materials can be used in such applications. With SRGs employed as both sensor and actuator, simple, autonomous controlling devices that require no power can be achieved. Several examples of such microfluidics devices have been reported to date. In one example [194], a self-regulated ‘flow sorter’ was demonstrated. This device (Fig. 16) consists of a ‘T’ channel in which the entrance to each branch is gated with a hydrogel structure of different chemical composition. The hydrogel for one branch expands at high pH and contracts at low pH, while the hydrogel for the other branch exhibits inverse behavior (that is, contracts at high pH and expands at low pH). The device routes the fluid down one of two paths based on the pH of the input. In a certain pH range (5.7–6.8), both hydrogel valves swell to seal the channel. Thus, hydrogels performs the sensing, actuating and regulating functions normally performed by discrete components. In another example, SRG was utilized to achieve a self-regulating chemostatic device that is able to maintain pH in output flow by mixing two input flows in a necessary proportion [193].

Fig. 16.

A device that directs (‘sorts’) a fluid stream on the basis of its pH. The hydrogel gating the right branch (circles) expands at high pH and contracts at low pH. The hydrogel gating the left branch (squares) behaves in the opposite manner (expands at low pH and contracts at high pH). At pH 7.8, the left branch is open and the right branch is closed. At a pH 4.7, the right branch is open and the left branch is closed. Both gates are closed at pH around 6.7. Scale bars are 300 um. fD is fractional change in diameter. Reprinted from [194] by permission from Macmillan Publishers Ltd., copyright 2000.

Notably, a dry gel will swell and automatically stop the flow when reached by liquid. If the gel is stimuli-responsive, the same valve can be opened later, for example, by heating. Valves based on such effect were proposed for use in point-of-care lab-on-a-chip devices for flow control, sample and reagent metering and distribution, and sealing of a reaction reactor [174]. Most recently, another peculiar phenomenon was observed during capillary filling of microtubes coated with a dry hydrogel film on their inner walls [207]. The filling velocity for water was three orders of magnitude smaller when compared to uncoated microtubes. Moreover, on macroscopic scale the filling velocity was constant throughout the filling process, whereas in uncoated microtubes the meniscus position initially changes proportionally to the square of time followed by a constant-velocity stage and finally the Lucas–Washburn behavior where the position is proportional to the square root of time [208]. On microscopic scale, the meniscus positon in hydrogel-coated microtubes undergos “stick-and-slip” motion that is caused by dynamically changing geometry and mechanical properties of the swelling hydrogel coating. Practically, this phenomenon may offer better temporal control in future lab-on-a-chip and MEMS devices.

Microfluidic applications demonstrate significant importance of mechanical properties of gels. Depending on application, such parameters as response time, amplitude of response, sensitivity, and pressure resistance can be important. However, similarly to other applications, optimization of one parameter is often attained at the expense of another. In a characteristic example, attempts to reduce closing and opening time of PNIPAM-based crosslinked network microvalves resulted in lower mechanical stability and lower leakage pressure resistance and vice versa [185].

4.7. Smart membranes, controllable lenses, and autonomous oscillators

With the help of stimuli-responsive polymers, functionality similar to control valves in microfluidic applications can be realized on macroscale in stimuli-responsive membranes and filters. Reports on responsive gel membranes date back to 1970s [209,210]. Such membranes were proposed for a range of application from externally controllable filters to functional valves in implantable drug delivery devices. The controllable filters could be adjusted by means of temperature or light. Temperature-controlled membranes for gel permeation chromatography would allow separation in a continuous way by varying the membrane swelling at appropriate time [211]. Membranes sensitive to water contaminants may be used to manage operation of water purification systems or in autonomous safety devices in water distribution system. Several examples of responsive membranes been reported recently, which can be controlled by such stimuli, as pH [163,212–214], glucose concentration [110,215], and temperature [216–218]. They have been reviewed in [211,219–222].

In another application, SRGs, due to their optical clarity, were employed as microlenses with controllable optical power [223–228].

Progress in understanding of SRGs and oscillating chemical reactions created possibility of coupling of a cyclic stimulus, which is produced by the chemical oscillator, with the response of gels [229–231]. One example of oscillating chemical reactions is the Belousov–Zhabotinsky (BZ) reaction, which generates autonomous oscillations in the redox potential. Employing this reaction, Murase et al. fabricated gels by copolymerizing N-isopropylacrylamide and 2-acrylamido-2′-methylpropanesulfonic acid (AMPS) with ruthenium tris(2,2′-bipyridine) (Ru(bpy)3) as the catalyst for the BZ reaction. The gels exhibited autonomous peristaltic motion and were used for directed particle transport [201]. Ryan et al. coupled SRG with another self-oscillation reaction, Landolt pH-oscillator, and demonstrated cyclic change of both gel size and generated force [232]. Dhanarajan et al. utilized pH-responsive hydrogel to build an autonomous chemomechanical oscillator driven by glucose [233].

Although such systems are only in initial development stages, they have shown a potential for several new applications such as a conveyer to transport soft materials, a formation process for ordered structures of micro- and/or nanomaterials, and a self-cleaning surface [199,201,231]. Further development may lead to a new design of artificial heart and other implantable devices and soft motors. Especially attractive is the possibility to realize such behavior in nanogels [234,235], which promises new concept of soft nanomotors.

4.8. Gene and drug delivery

Not only gels are able to hold fluid inside, the inner environment of swollen gel is thermodynamically different from the outside. This difference can be utilized for several purposes. Thus, gels ability to hold and slowly release various compounds is utilized in agriculture for controlled release of pesticides and nutrients [46,236]. More importantly, hydrogels are applied for sustained drug delivery. When an active compound has a short-term physiological effect, narrow therapeutic window, or low stability, sustained release system can extend exposure after a single administration thus significantly reducing the dosage and the number of times the drug must be administered.